Abstract

Graphitic carbon nitride (g-C3N4) has attracted extensive research interest in pollutants remediation. However, the photocatalytic activity of g-C3N4 was significantly limited by its small specific surface area. In this work, a green, high-energy ball milling method was used to fabricate g-C3N4 nanosheets. The structure, morphology, and optical properties of the prepared g-C3N4 nanosheets were characterized. The effect of ball milling parameters on the photocatalytic performance evaluated by Rhodamine B (RhB) and tetracycline (TC) was investigated systemically. Among the tested samples, the g-C3N4 sample milled with a 4 mL isopropanol solution at a rotation speed of 420 rpm, ball-to-powder weight ratio of 10:1, and milling time of 24 h exhibited the highest RhB degradation efficiency of 91.4% and TC degradation efficiency of 70.2%. The enhanced photocatalytic activity after ball milling was ascribed to the increase in specific surface area and efficient separation of electron–hole pairs. The trapping experiment indicated that holes and superoxide radicals were the main active species in the degradation reaction. Moreover, the photocatalytic degradation mechanism of organic pollutants on g-C3N4 nanosheets was also discussed in detail.

1 Introduction

Owing to technological advancements and rapid industrialization, environmental pollution problems, especially water pollution, have increased dramatically in many countries. Organic pollutants, in particular, are harmful to human health and ecosystems due to their stable, carcinogenic, soluble, and nondegradable properties [1]. Semiconductor photocatalysis is a promising and popular technology for decomposing and mineralizing organic pollutants using renewable solar energy. In recent decades, graphitic carbon nitride (g-C3N4) has been extensively studied in the field of photocatalysis due to its moderate bandgap energy, high thermal stability, low cost, and good redox properties [2,3,4]. However, the application of g-C3N4 obtained from the traditional thermal polymerization method is greatly restricted by the insufficient active sites, small specific surface area, low quantum efficiency, and high recombination rate of the photogenerated electron–hole pairs [5]. To date, various modification strategies have been reported to enhance the catalytic properties of g-C3N4 through morphology control, surface area increase, elemental doping, and heterostructure construction [6,7,8,9]. Therefore, the structure of a photocatalyst is an important factor affecting its catalytic activity.

It is widely known that g-C3N4 nanosheets exhibit a high specific surface area, wide bandgap, and prolonged lifetime of photogenerated carriers and thus show great promise for wastewater purification [10,11,12]. Currently, thermal, chemical, and mechanical exfoliation are regarded as effective strategies to obtain g-C3N4 nanosheets. For example, Li et al. [13] reported that g-C3N4 nanosheets prepared by thermal oxidation could accelerate the separation of the photogenerated electron–hole pairs. Wu et al. [14] prepared g-C3N4 nanosheets with a large specific surface area by calcining bulk g-C3N4 at 600°C repeatedly seven times, and the obtained g-C3N4 nanosheets showed nitric oxide removal efficiency of 35.8%. Zhang et al. [15] successfully synthesized ultrathin g-C3N4 nanosheets via ultrasonic exfoliation in different liquids. Although several methods have been developed to fabricate g-C3N4 nanosheets, the low yield and complicated processing limit their applications. Ball milling with high speed can produce shear and compressive normal force, which has a broad application prospect in semiconductor modification. Ma et al. [16] prepared g-C3N4 nanosheets via a facile ball milling method at various ball milling speeds, which demonstrated that ball milling can provide more active sites and improve photocatalytic degradation. Zhu et al. [17] synthesized g-C3N4/SnO2 heterojunction using ball milling and revealed that ball milling could change the surface morphology and structure of the catalysts, thus facilitating charge transfer and prolonging the carrier lifetimes. Thereby, ball milling technology has been considered a simple and effective method to enhance the photocatalytic performance of g-C3N4. Up to now, there have been few reports on the systematic study of ball milling parameters for g-C3N4.

In this study, a green ball milling strategy was used to fabricate g-C3N4 nanosheets in different solvents. The effects of the rotation speed, ball-to-powder weight ratio, milling time, and solvent content on the photocatalytic performance were systematically investigated. The photocatalytic activity was evaluated by the degradation of Rhodamine B (RhB) and tetracycline (TC) under simulated solar illumination. In addition, the possible photocatalytic degradation mechanism was explored by determining the active species. This study provides opportunities for the design and application of g-C3N4 photocatalysts in the field of environmental remediation.

2 Experimental

2.1 Preparation of g-C3N4 nanosheets

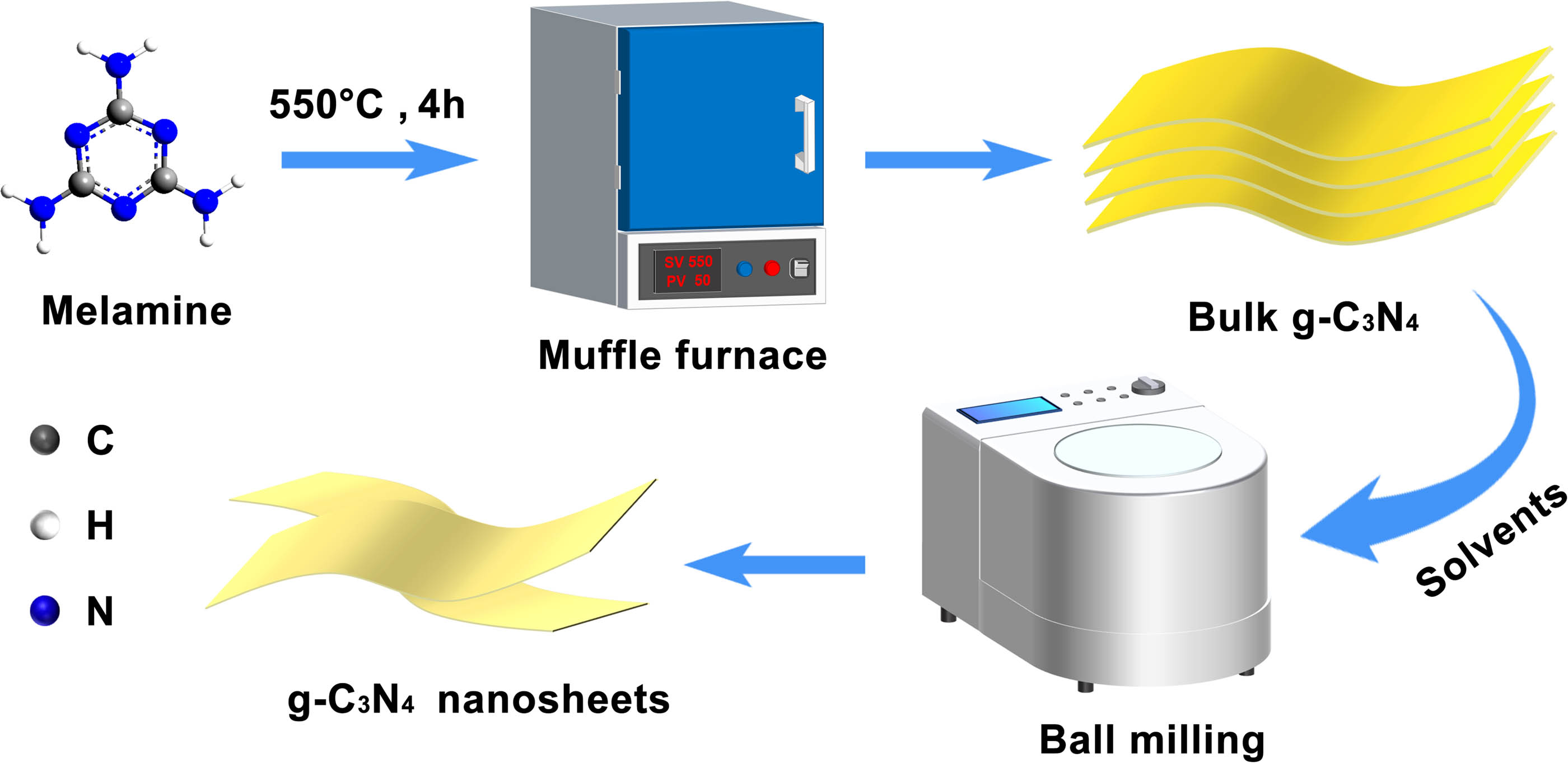

Bulk g-C3N4 (denoted as CN) was synthesized by thermal polymerization. Typically, 5 g of melamine was placed in an alumina crucible and heated at 550°C for 4 h in a muffle furnace at a rate of 5°C·min−1. After calcination, the prepared yellow powder was washed with deionized water and dried.

As shown in Scheme 1, the g-C3N4 nanosheets were prepared by ball milling CN powder with different solvents in a planetary ball mill (QM-3SP04). The CN powder (1.0 g) was loaded into the ball mill tank with agate balls of different mass and a specified amount of solvent (2, 4, and 6 mL) and milled for the specified time. Ball milling was performed at different ball-to-powder weight ratios (5:1, 10:1, 15:1, and 20:1), rotation speeds (240, 300, 360, and 420 rpm), and milling times (12, 24, 36, and 48 h). The obtained suspension was collected by centrifugation, washed successively with deionized water and ethanol, and dried at 70°C for 2 h. The samples milled with isopropanol (IPA), ethanol, and deionized water are denoted as ICN, ECN, and DCN, respectively. For comparison, the sample milled without the addition of solvent is denoted as MCN. When determining the effects of milling factors (except for milling time) on photocatalytic performance, samples milled for 24 h were used.

Schematic of the preparation of g-C3N4 nanosheets.

2.2 Characterization

The crystal phases of the samples were determined using X-ray diffraction (XRD) on a DX-2700B diffractometer at 40 kV and 30.0 mA using Cu Kα radiation. Scanning electron microscopy (SEM; ZEISS Gemini-300) was used to characterize the morphology of the catalysts. The microstructures of the samples were examined using field-emission transmission electron microscopy (TEM; Talos-F200S). The surface chemical states and valence band (VB) of catalysts were determined by X-ray photoelectron spectroscopy using an ESCALAB Xi+ spectrometer (Thermo Fisher). The surface area was determined using the Brunauer–Emmett–Teller (BET) method on an adsorption apparatus (V-Sorb 2800P). UV–Vis diffuse reflection spectroscopy was performed using a Persee TU-1901 spectrophotometer with BaSO4 as the reference. Photoluminescence (PL) spectra were measured using an Edinburgh Instruments FLS1000 fluorescence spectrometer with an excitation wavelength of 350 nm. Electron spin resonance (ESR) spectroscopy was performed on Bruker EMXplus using 5,5-dimethyl-1-pyrroline N-oxide (DMPO) as a radical capture reagent.

2.3 Photoelectrochemical measurements

The photocurrent measurements were carried out via an electrochemical workstation (VersaSTAT3) in a standard three-electrode system. A 0.5 M Na2SO4 aqueous solution was used as the electrolyte. A Pt net and saturated calomel electrode (SCE) were used as the counter electrode and reference electrode, respectively. The working electrode was prepared as follows: 40 mg of catalyst was mixed in 1 mL of ethylene glycol and 20 µL of Nafion 117, then ultrasonically dispersed for 30 min to obtain slurry. A 40 µL of the slurry was uniformly coated on fluorine-dope tin oxide (FTO) glasses with a fixed area of 1 cm × 1 cm and dried under 70°C. The transient photocurrent response was performed under a 500 W Xe lamp (AM 1.5, 100 mW cm−2) irradiation with 30 s on–off cycle at a voltage of 0.4 V (vs SCE). The electrochemical impedance spectroscopy (EIS) measurements were carried out at the frequency range of 10 kHz to 0.01 Hz. Mott–Schottky curves were measured at a frequency of 1,000 Hz.

2.4 Photocatalytic activity

The photocatalytic activity of the obtained catalysts was evaluated using RhB and TC decomposition under simulated sunlight irradiation (AM 1.5). A 500 W Xe lamp (CEL-S500) with a light intensity of 100 mW cm−2 was used as the light source. For the test, 0.1 g of catalyst was dispersed in 100 mL of RhB (10 mg·L−1) aqueous solution. For TC degradation, 0.04 g of catalyst was added to the 100 mL TC solution (20 mg·L−1). Prior to illumination, the mixed suspension was magnetically stirred in the dark for 30 min to achieve an adsorption–desorption equilibrium. During irradiation, 5 mL of the suspension was collected and centrifuged at intervals of 10 min for subsequent photocatalytic activity analysis using a UV–Vis spectrophotometer.

2.5 Active species trapping test

For the purpose of exploring the main active species during the photocatalytic reaction, the trapping experiment was carried out using various scavengers. Triethanolamine (TEOA) 15 mM, tert-butyl alcohol (TBA, 10 mM), and 1,4-benzoquinone (BQ, 1 mM) were used to capture holes (h+), hydroxyl radicals (˙OH), and superoxide radicals (˙O2 −) during the photocatalytic process, respectively.

3 Results and discussion

3.1 Structure and chemical composition analysis

Figure 1 shows the XRD patterns of CN and ICN milled with 4 mL IPA for 12 and 24 h. CN and ICN show similar XRD peaks at 13.4° and 27.4°, corresponding to the in-plane repeated units of tri-s-triazine (100) and the interplanar stacking peak of aromatic systems (002) (JCPDS 87-1526), respectively [18]. It is worth noting that the peak intensity of ICN is lower and the peaks are broader than those of CN, indicating that the interlayer structure of g-C3N4 was partially destroyed during ball milling. During the ball milling process, the impact force produced between grinding balls can break the weak interplanar van der Waals bonds through combined shearing and stretching [19]. With the increase in ball milling time, the crystallization of g-C3N4 in the (002) plane can be destroyed so that the sample can be effectively exfoliated [20].

XRD patterns of CN and ICN with different milling times.

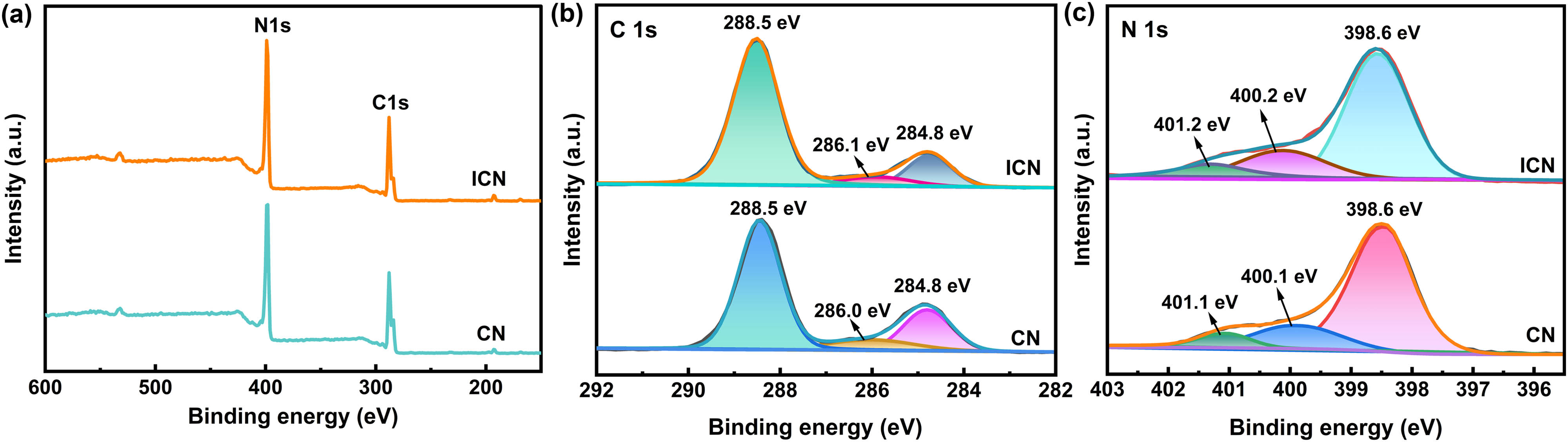

The chemical states of bulk CN and ICN were further analyzed by X-ray photoelectron spectroscopy (XPS). The survey scans the XPS spectra (Figure 2a) of the two samples to prove the existence of C and N elements. For the C 1s spectrum of the CN sample in Figure 2b, the peaks at 284.8, 286.0, and 288.4 eV are assigned to the carbon atom in the C–C bonds, sp3-bonded carbon (C–N), and sp2 N–C═N bonds, respectively [21]. In Figure 2c, the N 1s spectrum of CN can be deconvoluted into three peaks located at 398.6, 400.1, and 401.1 eV, which can be attributed to the sp2 hybridized nitrogen (C–N═C group), the bridge nitrogen (N–(C)3 group), and the N–H bond, respectively [22,23]. Compared with CN, no obvious variation in the binding energy of C 1s and N 1s can be observed after the ball milling process, which is consistent with the previous research [24].

XPS spectra of CN and ICN samples: (a) survey spectrum; (b) C 1s and (c) N 1s.

3.2 Morphology

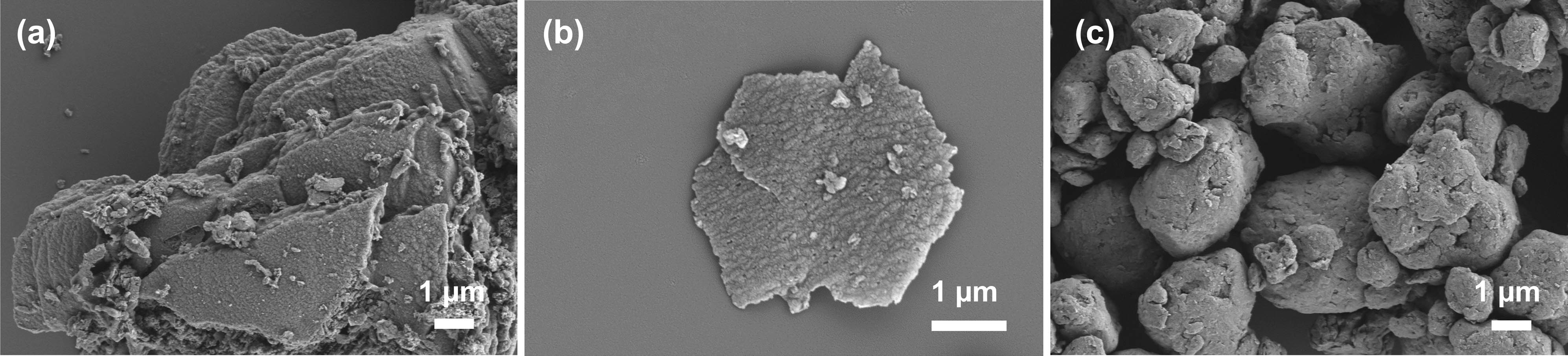

The morphology of the prepared CN, ICN, and MCN samples is shown in Figure 3. Clearly, CN (Figure 3a) exhibits an irregular layered structure with a tight stack, which is the typical structure of g-C3N4 synthesized using the polymerization method. After ball milling in 4 mL IPA with 420 rpm for 24 h, ICN (Figure 3b) displays a laminar structure with a small particle size, which demonstrates that the g-C3N4 nanosheets are successfully exfoliated from the CN. However, as shown in Figure 3(c), when the ball milling of CN was treated without solvent, the particle size of the MCN sample became larger because of severe agglomeration instead of the layer structure. Thus, dispersion of g-C3N4 powder in the liquid environment during ball milling could prevent the agglomeration of particles [16].

SEM images of the prepared samples: (a) CN, (b) ICN, and (c) MCN.

TEM technique was applied to further investigate the fine structure of CN and ICN. As observed in Figure 4, ICN displays an ultrathin 2D sheet-like structure. Compared with bulk CN, the thickness of ICN is much smaller, which confirms that CN can be exfoliated into g-C3N4 nanosheets via the ball milling method.

TEM images of (a) CN and (b) ICN.

3.3 Effect of ball milling parameters on photocatalytic performance

3.3.1 Effect of ball milling time

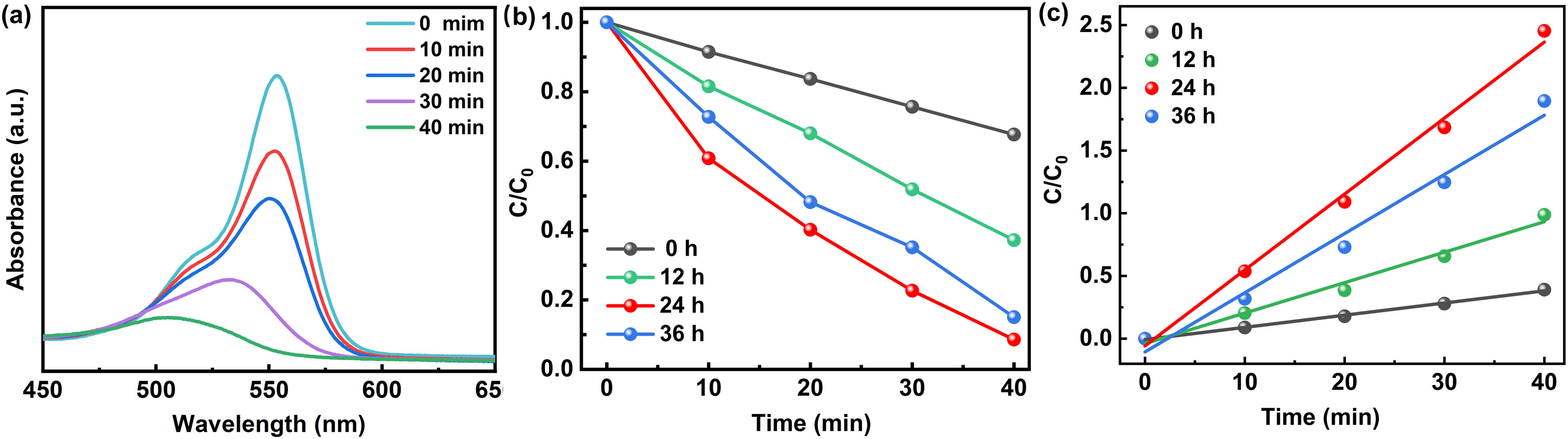

The effect of ball milling time on the photocatalytic degradation of RhB is shown in Figure 5. For the ICN photocatalyst (Figure 5a), the absorbance of RhB decreases with the increase in irradiation time, indicating the gradual degradation of the organic pollutant. Figure 5b compares the degradation efficiency of various g-C3N4 samples under the same prepared conditions except for the ball milling time. Without ball milling treatment, the degradation only reaches 30.9%. With the extension of ball milling time to 24 h, the degradation efficiency of ICN significantly increases to 91.4% after 40 min of illumination. However, with a further increase in ball milling time to 36 h, a slight decrease in removal efficiency is observed. Furthermore, the reaction rate constant for photocatalytic degradation can be calculated using the following equation [25]:

where C 0 is the initial concentration of the pollutant, C is the residual concentration of the pollutant degraded by the photocatalyst, and k is the kinetic constant. As shown in Figure 5c, the RhB degradation reaction of all samples follows pseudo-first-order kinetics model. The reaction rate constant of ICN-24 h reaches a maximum value of 0.05405 min−1, which is 5.0 times higher than that of CN (0.00901 min−1).

(a) UV–Vis absorption spectra of RhB over ICN milled for 24 h; (b) comparison of photocatalytic activity; and (c) first-order kinetics curves.

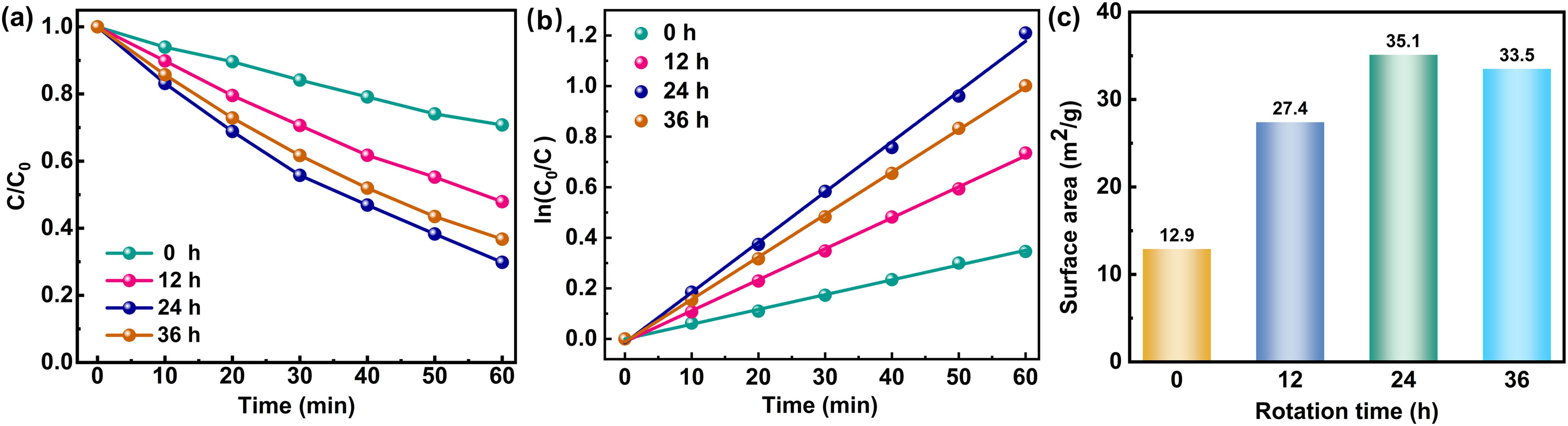

The photocatalytic performance of the prepared samples was also evaluated by degradation of TC under light irradiation. As expected in Figure 6a, ICN samples exhibit higher photocatalytic activity than CN, and the highest degradation efficiency of 70.2% is achieved when the ball milling time is 24 h. Similarly, the degradation rate of TC over all photocatalysts also follows the first-order kinetics (Figure 6b), and ICN-24 h shows the highest degradation rate constant of 0.01987 min−1, which is 2.4 times higher than that of CN (0.00585 min−1). This result is consistent with the degradation of RhB, which can be explained by the specific surface area of catalysts. As shown in Figure 6c, the specific surface areas of the samples milled for 0, 12, 24, and 36 h are 12.9, 27.4, 35.1, and 34.5 m2·g−1, respectively. As is well known, a higher specific surface area can generate more photoinduced electrons and provide more contact areas for organic pollutants, thus improving the photocatalytic activity. Ball milling is an effective way to decrease the particle size and increase the specific surface area of samples. However, when the ball milling time exceeds 24 h, small ICN particles tend to agglomerate due to the high surface energy, leading to a decrease in the specific surface area [26]. To improve milling efficiency and save energy, 24 h is selected as the optimal ball milling time.

(a) Photocatalytic degradation of TC, (b) first-order kinetics curves, and (c) specific surface area of samples milled for 0, 12, 24, and 36 h.

3.3.2 Effect of rotation speed

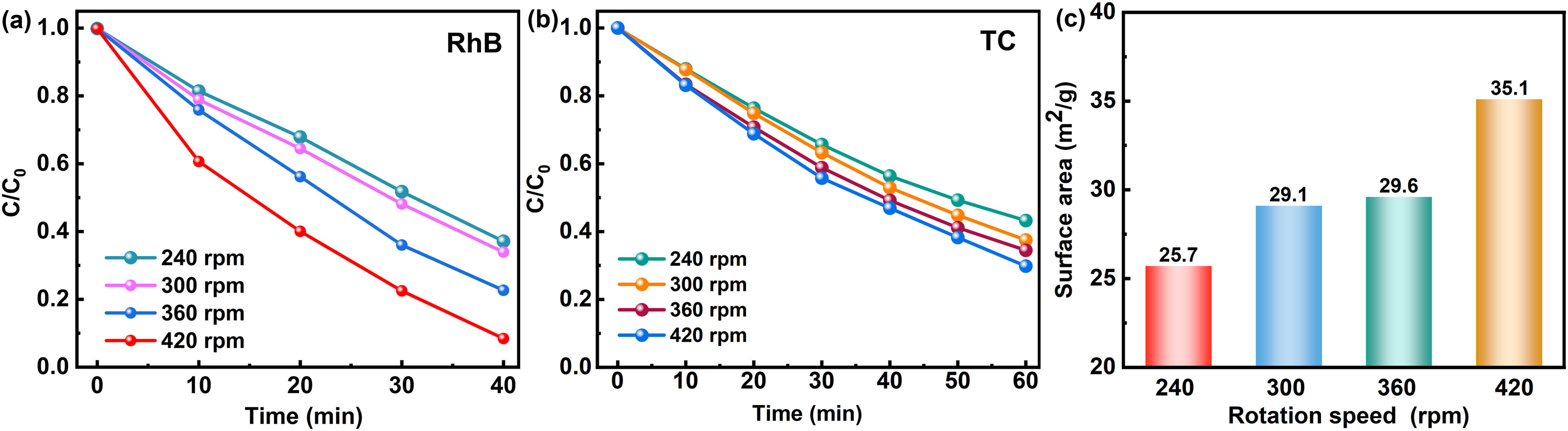

Figure 7 shows the photocatalytic activity of the samples obtained at different rotation speeds. As shown in Figure 7a, the ICN sample milled at 420 rpm exhibits the highest RhB degradation efficiency of 91.4% within 40 min. Moreover, it can also be found that the prepared samples exhibit lower photocatalytic activity in TC degradation (Figure 7b). After 60 min of irradiation, only 70.2% of TC can be degraded. Notably, both of the removal efficiencies of RhB and TC increase with increasing rotation speed from 240 to 420 rpm. Similarly, the specific surface area of the samples also increases with the ball milling speed (Figure 7c). As a result of higher rotation speed, the kinetic energy of grinding balls increases [27], and the specific surface area becomes larger, which is beneficial to the degradation of pollutants.

Photocatalytic degradation efficiency of (a) RhB and (b) TC; (c) specific surface area of samples obtained at different rotation speeds with 4 mL IPA for 24 h.

3.3.3 Effect of various solvents

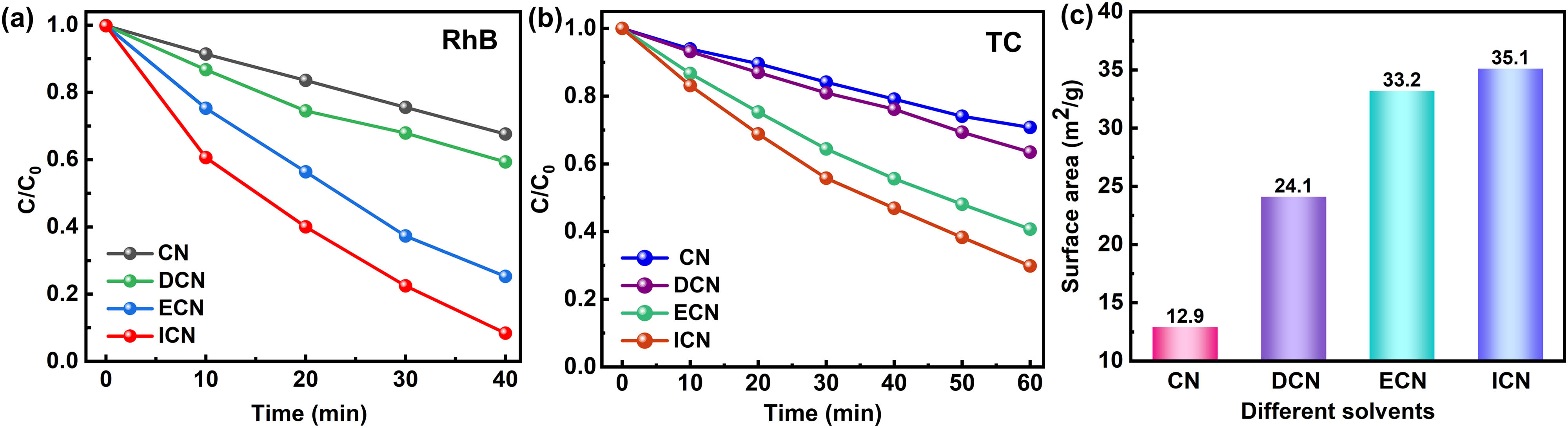

The effect of solvent during the ball milling process on the photocatalytic activity is shown in Figure 8. The RhB degradation efficiency of CN, DCN, ECN, and ICN is 30.9, 40.6, 74.6, and 91.4%, respectively. The same degradation trend occurs in the decomposition of TC (Figure 8b). It can be clearly seen that the introduction of a solvent during ball milling plays an important role in the photocatalytic reaction. The specific surface areas of DCN, ECN, and ICN (Figure 8c) are 24.1, 33.2, and 35.1 m2·g−1, respectively, and are all higher than CN. It has been found that the polarity of the solvents and surface tension are strongly correlated with the exfoliation performance [28]. Among all the solvents with different polarities and surface tension, IPA seems to be a more promising grinding aid.

Photocatalytic degradation of (a) RhB and (b) TC; (c) specific surface areas of catalysts milled with various solvents for 24 h at 420 rpm.

3.3.4 Effect of IPA volume

Figure 9a shows the degradation performance of the ball-milled samples with different amounts of IPA. For MCN sample, only 5.7% of RhB is decomposed within 40 min, while the degradation efficiency of ICN milled in 4 mL IPA reaches 91.4%. However, with a further increase in the IPA volume, the photocatalytic activity of the sample slightly decreases. A similar trend of TC degradation is found in Figure 9b. Under light irradiation for 60 min, when the volume of IPA increases from 0 to 6 mL, the removal efficiency increases first and then decreases, which is attributed to the difference in the specific surface area of catalysts (Figure 9c). Hence, an appropriate amount of solvent is conducive to restraining particle agglomeration and promoting crack propagation in large particles [29]. However, an excess of solvent in ball milling could prevent CN powder from adsorbing onto the surface of agate balls [30], resulting in a reduction in reaction activity.

Photocatalytic performance of (a) RhB and (b) TC; (c) specific surface area of the samples milled with different volumes of IPA.

3.3.5 Effect of ball-to-powder weight ratio

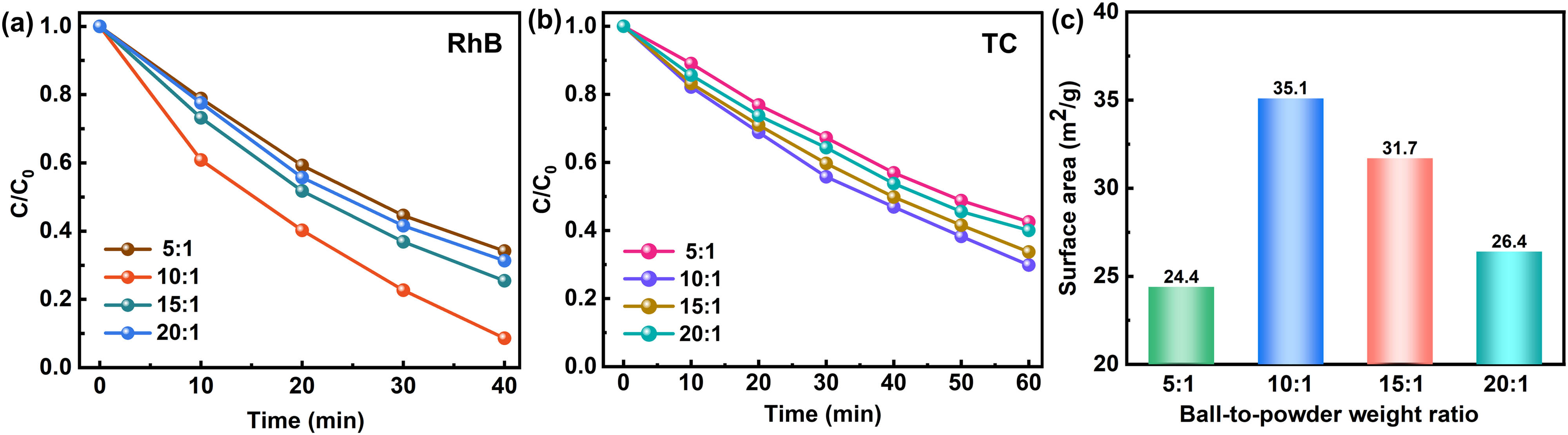

The ball-to-powder weight ratio is an important variable in ball milling. At the weight ratio of 5:1, the RhB degradation efficiency of ICN is 66.2% (Figure 10a). At the ball-to-powder weight ratio of 10:1, the sample exhibits the highest degradation capacity, with an RhB removal efficiency of 91.4%. As the ball-to-powder weight ratio increases from 15:1 to 20:1, the degradation efficiency decreases from 74.5 to 68.7%. For TC degradation, degradation curves (Figure 10b) show the same trend. The specific surface areas of the samples are measured and shown in Figure 10c. The specific surface areas of the catalysts obtained at the ball-to-powder weight ratios of 5:1, 10:1, 15:1, and 20:1 are 24.4, 35.1, 31.7, and 26.4 m2·g−1, respectively. The higher the ball-to-powder weight ratio, the more the contact chance between the powder and the grinding balls, thus increasing the number of powder collisions per unit time [31]. As the ball-to-powder weight ratio exceeds the optimum value, the high filling rate restricts the movement of the agate balls and milled material, causing a decline in the specific surface area [30].

Comparison of the degradation efficiency of (a) RhB and (b) TC; (c) specific surface area of ICN milled at different ball-to-powder weight ratios (24 h, 420 rpm, and 4 mL IPA).

3.4 Optical properties

UV–Vis diffuse reflectance spectra were obtained to examine the optical absorption properties of the CN and ICN catalysts. In Figure 11a, the maximum absorption edge of CN is observed at 463 nm, while the optical absorption edge of ICN shows a distinct blue shift to 445 nm. The bandgap energy of the samples can be calculated using the following formula:

where α, h, v, A, and E g are the absorption coefficient, Planck’s constant, light frequency, proportionality constant, and bandgap energy, respectively [32]. The bandgap values of CN and ICN are 2.57 and 2.78 eV (Figure 11b), respectively. The increased bandgap energy and blue shift can be attributed to the well-known quantum confinement effect caused by ball milling [33].

(a) UV–Vis reflectance spectra; (b) bandgap of CN and ICN; (c) XPS VB of ICN; (d) PL spectra of CN and ICN.

To further determine the band structure of the catalyst, XPS VB was used to measure the VB positions of ICN. As shown in Figure 11c, the VB value of the sample can be estimated using the following formula [34]:

where E NHE, E VL, and ϕ are the potential of the normal hydrogen electrode (NHE), the potential of the vacuum level, and the electron work function of the instrument (4.6 eV), respectively. The measured VB and conduction band (CB) potentials of ICN are +2.43 and −0.35 eV, respectively.

PL spectra can be used to evaluate the separation and recombination of photogenerated charges. Generally, a lower PL intensity indicates a more inhibited recombination of photogenerated electrons and holes, which is beneficial for photocatalytic activity. However, as shown in Figure 11d, the emission intensity of ICN is higher than that of CN, which is in agreement with the previous reports [35,36] explained by the reduction of particle size and the quantum confinement effect.

3.5 Photoelectrochemical properties

To further clarify the separation efficiency of photoexcited carriers, photocurrent response, EIS, and Mott–Schottky plots of CN and ICN were carried out. As demonstrated in Figure 12a, both CN and ICN display positive photocurrents by several on–off cycles. Noticeably, the photocurrent intensity of ICN is much stronger than that of CN, indicating a higher separation capacity of charge carriers, which is ascribed to the higher specific surface area. Figure 12b shows the EIS Nyquist plots of CN and ICN. Generally, the smaller radius means a lower electron transfer resistance. It is clear that the radius of the ICN sample is smaller than that of CN both under light illumination and in the dark, which confirms that the ball milling process can enhance the charge transfer efficiency. In addition, the Mott–Schottky tests were also carried out. As shown in Figure 12c, a positive slope of CN and ICN can be observed, which confirms that the samples are n-type semiconductors. Besides, the charge carrier density (N D) can be estimated using the following formula [37]:

where q, ε, and ε 0 are the electron charge (1.6 × 10−19 C), the dielectric constant (5.25 for g-C3N4), and vacuum permittivity (8.85 × 10−14 F·cm−1), respectively. Hence, the charge carrier density of CN and ICN can be calculated as 3.85 × 1020 and 5.34 × 1020 cm−3, respectively. It is obvious that the carrier density of ICN is larger than that of pristine CN, inferring the higher electron concentration produced by ball milling.

(a) Transient photocurrent response, (b) electrochemical impedance spectra, and (c) Mott–Schottky plots of CN and ICN.

3.6 Photocatalytic mechanism

To identify the main active species during the photocatalytic reaction, the trapping experiment was performed using various scavengers. TEOA (15 mM), TBA (10 mM), and BQ (1 mM) were used to capture holes (h+), hydroxyl radicals (˙OH), and superoxide radicals (˙O2 −), respectively. Figure 13a shows that the degradation efficiency of RhB dramatically decreases to 68.2, 3.9, and 1.9% in the presence of TBA, BQ, and TEOA, respectively. Similarly, after the addition of TBA, BQ, and TEOA, the photodegradation efficiency of TC drops to 58.1, 18.1, and 16.2% (Figure 13b), respectively. It can be concluded that h+ and ˙O2 − are the main active species, whereas ˙OH has a minor effect on the degradation reaction.

Effect of different quenchers on the degradation of (a) RhB and (b) TC over the ICN sample.

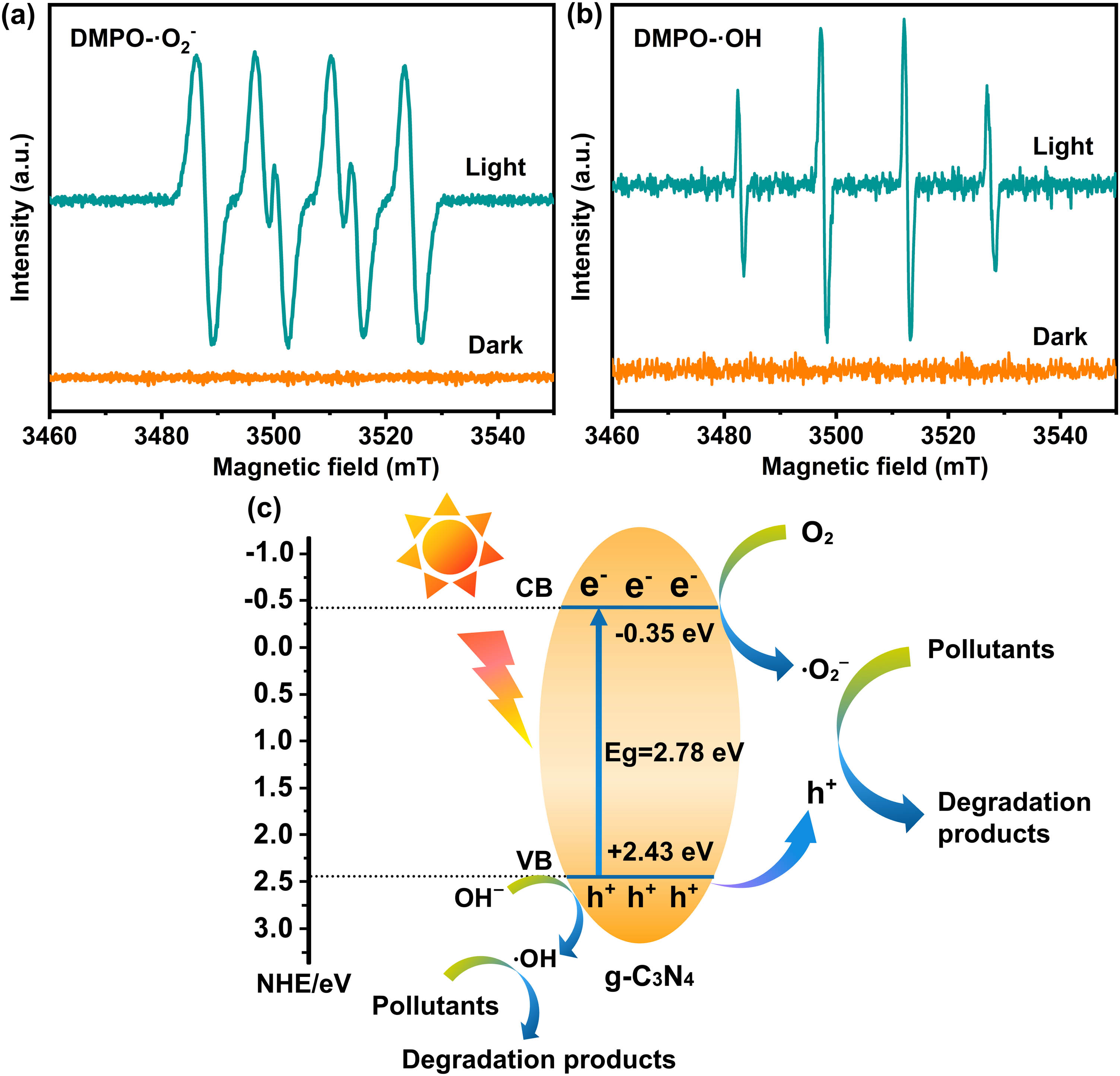

The generation of free radicals in the photocatalytic reactions can be detected by ESR using DMPO as the trapping agent. As demonstrated in Figure 14a, there is no characteristic peak of ˙

ESR spectra of (a) DMPO-˙

Based on the above considerations, a possible photocatalysis mechanism for the ICN sample is proposed in Figure 14c. Under irradiation, the photogenerated electrons excited from ICN are transferred to the CB, leaving holes in the VB. The CB potential is more negative than the standard reduction potential of O2/˙

4 Conclusion

g-C3N4 nanosheets with excellent photocatalytic activity were synthesized using the simple ball milling method. The influence of ball-milling parameters on the structure, morphology, optical properties, photoelectrochemical properties, and photocatalytic activity of g-C3N4 nanosheets was systematically analyzed. The obtained ICN sample showed higher degradation efficiency of RhB (91.4%) and TC (70.2%) than the CN sample, which was owing to its nanosheet structure that could shorten charge transfer distance to the surface and increase specific surface area, exposing more active sites. A set of optimum ball milling parameters was obtained as follows: ball-to-powder weight ratio of 10:1, milling speed of 420 rpm, milling time of 24 h, and the addition of 4 mL IPA. This study provides an alternative to traditional chemical exfoliation methods used for the preparation of thin nanosheets and yields insights into the development of advanced photocatalysts for the degradation of organic pollutants.

Acknowledgments

The authors are thankful for the financial support from the National Natural Science Foundation of China (No. 51702027) and the Science and Technology Planning Project of Longquanyi, Chengdu (No. LQXKJ-KJXM-2022-04). In addition, they thank the anonymous reviewers for their fruitful suggestions to improve the article.

-

Funding information: This research was supported by the National Natural Science Foundation of China (No. 51702027) and the Science and Technology Planning Project of Longquanyi, Chengdu (No. LQXKJ-KJXM-2022-04).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Ibrahim, R. K., M. Hayyan, M. A. AlSaadi, A. Hayyan, and S. Ibrahim. Environmental application of nanotechnology: Air, soil, and water. Environmental Science and Pollution Research International, Vol. 239, 2016, pp. 13754–13788.10.1007/s11356-016-6457-zSearch in Google Scholar PubMed

[2] Zhang, Y., J. Yuan, Y. Ding, B. Liu, L. Zhao, and S. Zhang. Research progress on g-C3N4-based photocatalysts for organic pollutants degradation in wastewater: From exciton and carrier perspectives. Ceramics International, Vol. 47, 2021, pp. 31005–310030.10.1016/j.ceramint.2021.08.063Search in Google Scholar

[3] Liu, X., R. Ma, L. Zhuang, B. Hu, J. Chen, X. Liu, et al. Recent developments of doped g-C3N4 photocatalysts for the degradation of organic pollutants. Critical Reviews in Environmental Science and Technology, Vol. 51, 2021, pp. 751–790.10.1080/10643389.2020.1734433Search in Google Scholar

[4] Guan, Y., Z. Ren, Y. Lang, T. Liu, Z. Gong, and Y. Lv. Preparation and photocatalytic degradation of sulfamethoxazole by g-C3N4 nanocomposite samples. Reviews on Advanced Materials Science, Vol. 62, 2023, id. 20220280.10.1515/rams-2022-0280Search in Google Scholar

[5] Inagaki, M., T. Tsumura, T. Kinumoto, and M. Toyoda. Graphitic carbon nitrides (g-C3N4) with comparative discussion to carbon materials. Carbon, Vol. 141, 2018, pp. 580–607.10.1016/j.carbon.2018.09.082Search in Google Scholar

[6] Wang, F., J. Xu, Z. Wang, Y. Lou, C. Pan, and Y. Zhu. Unprecedentedly efficient mineralization performance of photocatalysis-self-Fenton system towards organic pollutants over oxygen-doped porous g-C3N4 nanosheets. Applied Catalysis B: Environmental, Vol. 312, 2022, id. 121438.10.1016/j.apcatb.2022.121438Search in Google Scholar

[7] Thomas, A., A. Fischer, F. Goettmann, M. Antonietti, J. O. Müller, R. Schlögl, et al. Graphitic carbon nitride materials: Variation of structure and morphology and their use as metal-free catalysts. Journal of Materials Chemistry, Vol. 18, 2008, pp. 4893–4908.10.1039/b800274fSearch in Google Scholar

[8] Dong, F., L. Wu, Y. Sun, M. Fu, Z. Wu, and S. C. Lee. Efficient synthesis of polymeric g-C3N4 layered materials as novel efficient visible light driven photocatalysts. Journal of Materials Chemistry, Vol. 21, 2011, pp. 15171–15174.10.1039/c1jm12844bSearch in Google Scholar

[9] Guo, Y., J. Li, Z. Gao, X. Zhu, Y. Liu, Z. Wei, et al. A simple and effective method for fabricating novel p-n heterojunction photocatalyst g-C3N4/Bi4Ti3O12 and its photocatalytic performances. Applied Catalysis B: Environmental, Vol. 192, 2016, pp. 57–71.10.1016/j.apcatb.2016.03.054Search in Google Scholar

[10] Lin, Y., G. V. C. Dizon, K. Yamada, C. Liu, A. Venault, H. Lin, et al. Sulfur-doped g-C3N4 nanosheets for photocatalysis: Z-scheme water splitting and decreased biofouling. Journal of Colloid and Interface Science, Vol. 567, 2020, pp. 202–212.10.1016/j.jcis.2020.02.017Search in Google Scholar PubMed

[11] Wang, T., J. Zheng, J. Cai, Q. Liu, and X. Zhang. Visible-light-driven photocatalytic degradation of dye and antibiotics by activated biochar composited with K+ doped g-C3N4: Effects, mechanisms, actual wastewater treatment and disinfection. Science of the Total Environment, Vol. 839, 2022, id. 155955.10.1016/j.scitotenv.2022.155955Search in Google Scholar PubMed

[12] Yang, C., F. Zhang, X. Liu, Y. Du, D. Huang, J. Liu, et al. Long afterglow phosphor driven g-C3N4 photocatalyst for continuous water purification under light and dark conditions. Journal of Solid State Chemistry, Vol. 310, 2022, id. 123057.10.1016/j.jssc.2022.123057Search in Google Scholar

[13] Li, D., W. Huang, L. Zou, A. Pan, and G. Huang. Mesoporous g-C3N4 nanosheets, synthesis, superior adsorption capacity and photocatalytic activity. Journal of Nanoscience and Nanotechnology, Vol. 18, 2018, pp. 5502–5510.10.1166/jnn.2018.15441Search in Google Scholar PubMed

[14] Wu, X., J. Cheng, X. Li, Y. Li, and K. Lv. Enhanced visible photocatalytic oxidation of NO by repeated calcination of g-C3N4. Applied Surface Science, Vol. 465, 2019, pp. 1037–1046.10.1016/j.apsusc.2018.09.165Search in Google Scholar

[15] Zhang, X., X. Xie, H. Wang, J. Zhang, B. Pan, and Y. Xie. Enhanced photoresponsive ultrathin graphitic-phase C3N4 nanosheets for bioimaging. Journal of the American Chemical Society, Vol. 135, 2013, pp. 18–21.10.1021/ja308249kSearch in Google Scholar PubMed

[16] Ma, Z., P. Zhou, L. Zhang, Y. Zhong, X. Sui, B. Wang, et al. g-C3N4 nanosheets exfoliated by green wet ball milling process for photodegradation of organic pollutants. Chemical Physics Letters, Vol. 766, 2021, id. 138335.10.1016/j.cplett.2021.138335Search in Google Scholar

[17] Zhu, K., Y. Lv, J. Liu, W. Wang, C. Wang, S. Li, et al. Facile fabrication of g-C3N4/SnO2 composites and ball milling treatment for enhanced photocatalytic performance. Journal of Alloys and Compounds, Vol. 802, 2019, pp. 13–18.10.1016/j.jallcom.2019.06.193Search in Google Scholar

[18] Beyhaqi, A., S. M. T. Azimi, Z. Chen, C. Hu, and Q. Zeng. Exfoliated and plicated g-C3N4 nanosheets for efficient photocatalytic organic degradation and hydrogen evolution. International Journal of Hydrogen Energy, Vol. 46, 2021, pp. 20547–20559.10.1016/j.ijhydene.2021.03.174Search in Google Scholar

[19] Zhu, K., W. Wang, A. Meng, M. Zhao, J. Wang, M. Zhao, et al. Mechanically exfoliated g-C3N4 thin nanosheets by ball milling as high performance photocatalysts. RSC Advances, Vol. 5, 2015, pp. 56239–56243.10.1039/C5RA09040GSearch in Google Scholar

[20] Wei, X., X. Wang, Y. Pu, A. Liu, C. Chen, W. Zou, et al. Facile ball-milling synthesis of CeO2/g-C3N4 Z-scheme heterojunction for synergistic adsorption and photodegradation of methylene blue: Characteristics, kinetics, models, and mechanisms. Chemical Engineering Journal, Vol. 420, 2021, id. 127719.10.1016/j.cej.2020.127719Search in Google Scholar

[21] Li, X., B. Kang, F. Dong, Z. Zhang, X. Luo, L. Han, et al. Enhanced photocatalytic degradation and H2/H2O2 production performance of S-pCN/WO2.72 S-scheme heterojunction with appropriate surface oxygen vacancies. Nano Energy, Vol. 81, 2021, id. 105671.10.1016/j.nanoen.2020.105671Search in Google Scholar

[22] Zhang, W., D. Xu, F. Wang, and M. Chen. AgCl/Au/g-C3N4 ternary composites: Efficient photocatalysts for degradation of anionic dyes. Journal of Alloys and Compounds, Vol. 868, 2021, id. 159266.10.1016/j.jallcom.2021.159266Search in Google Scholar

[23] Zhu, Y., X. Zhong, X. Jia, Q. Sun, and J. Yao. Geometry-tunable sulfur-doped carbon nitride nanotubes with high crystallinity for visible light nitrogen fixation. Chemical Engineering Journal, Vol. 431, 2022, id. 133412.10.1016/j.cej.2021.133412Search in Google Scholar

[24] Mei, X., S. Chen, G. Wang, W. Chen, W. Lu, B. Zhang, et al. Metal-free carboxyl modified g-C3N4 for enhancing photocatalytic degradation activity of organic pollutants through peroxymonosulfate activation in wastewater under solar radiation. Journal of Solid State Chemistry, Vol. 310, 2022, id. 123053.10.1016/j.jssc.2022.123053Search in Google Scholar

[25] Zhao, Q., S. Liu, S. Chen, B. Ren, Y. Zhang, X. Luo, et al. Facile ball-milling synthesis of WO3/g-C3N4 heterojunction for photocatalytic degradation of Rhodamine B. Chemical Physics Letters, Vol. 805, 2022, id. 139908.10.1016/j.cplett.2022.139908Search in Google Scholar

[26] Zhu, X., Y. Wang, Y. Guo, J. Wan, Y. Yan, Y. Zhou, et al. Environmental-friendly synthesis of heterojunction photocatalysts g-C3N4/BiPO4 with enhanced photocatalytic performance. Applied Surface Science, Vol. 544, 2021, id. 148872.10.1016/j.apsusc.2020.148872Search in Google Scholar

[27] Enayati, M. H., Z. Sadeghian, M. Salehi, and A. Saidi. The effect of milling parameters on the synthesis of Ni3Al intermetallic compound by mechanical alloying. Materials Science and Engineering: A-Struct, Vol. 375, 2004, pp. 809–811.10.1016/j.msea.2003.10.060Search in Google Scholar

[28] Wang, X. L., W. Q. Fang, S. Yang, P. Liu, H. Zhao, and H. G. Yang. Structure disorder of graphitic carbon nitride induced by liquid-assisted grinding for enhanced photocatalytic conversion. RSC Advances, Vol. 4, 2014, pp. 10676–10679.10.1039/C3RA47824FSearch in Google Scholar

[29] Yin, Z., Q. Zhang, S. Li, G. Cagnetta, J. Huang, S. Deng, et al. Mechanochemical synthesis of catalysts and reagents for water decontamination: Recent advances and perspective. Science of the Total Environment, Vol. 825, 2022, id. 153992.10.1016/j.scitotenv.2022.153992Search in Google Scholar PubMed

[30] Cai, Q., J. Shen, Y. Feng, Q. Shen, and H. Yang. Template-free preparation and characterization of nanoporous g-C3N4 with enhanced visible photocatalytic activity. Journal of Alloys and Compounds, Vol. 628, 2015, pp. 372–378.10.1016/j.jallcom.2014.12.013Search in Google Scholar

[31] Patil, A. G. and S. Anandhan. Influence of planetary ball milling parameters on the mechano-chemical activation of fly ash. Powder Technology, Vol. 281, 2015, pp. 151–158.10.1016/j.powtec.2015.04.078Search in Google Scholar

[32] Zhang, Z., X. Chen, S. Chen, Q. Dong, X. Zhang, A. Jiang, et al. Synergistic interaction of Z-scheme TiO2/g-C3N4 photocatalyst and peroxymonosulfate for improving the photocatalytic efficiency of Rhodamine B. Optical Materials (Amsterdam, Netherlands), Vol. 133, 2022, id. 113081.10.1016/j.optmat.2022.113081Search in Google Scholar

[33] Kim, J. S., J. W. Oh, and S. I. Woo. Investigation for the effects of ball milling process on the physical characteristics, the behaviors of carriers and the photocatalytic activity of sulfur doped g-C3N4. International Journal of Hydrogen Energy, Vol. 42, 2017, pp. 5485–5495.10.1016/j.ijhydene.2016.08.077Search in Google Scholar

[34] Wang, T., J. Cai, J. Zheng, K. Fang, I. Hussain, and D. Z. Husein. Facile synthesis of activated biochar/BiVO4 heterojunction photocatalyst to enhance visible light efficient degradation for dye and antibiotics: Applications and mechanisms. Journal of Materials Research and Technology, Vol. 19, 2022, pp. 5017–5036.10.1016/j.jmrt.2022.06.177Search in Google Scholar

[35] Kim, J. S., J. W. Oh, and S. I. Woo. Improvement of the photocatalytic hydrogen production rate of g-C3N4 following the elimination of defects on the surface. Catalysis Today, Vol. 293, 2017, pp. 8–14.10.1016/j.cattod.2016.11.018Search in Google Scholar

[36] Dong, F., Z. Wang, Y. Sun, W. Ho, and H. Zhang. Engineering the nanoarchitecture and texture of polymeric carbon nitride semiconductor for enhanced visible light photocatalytic activity. Journal of Colloid and Interface Science, Vol. 401, 2013, pp. 70–79.10.1016/j.jcis.2013.03.034Search in Google Scholar PubMed

[37] Yang, Y., C. Zhang, D. Huang, G. Zeng, J. Huang, C. Lai, et al. Boron nitride quantum dots decorated ultrathin porous g-C3N4: Intensified exciton dissociation and charge transfer for promoting visible-light-driven molecular oxygen activation. Applied Catalysis B: Environmental, Vol. 245, 2019, pp. 87–99.10.1016/j.apcatb.2018.12.049Search in Google Scholar

[38] Lian, X., Y. Li, Y. Zou, D. An, Q. Wang, Q. Zhou, et al. High vis-light photocatalytic property of g-C3N4 on four pollutants (RhB, MB, TC-HCl and P-Nitrophenol). Current Applied Physics, Vol. 39, 2022, pp. 196–204.10.1016/j.cap.2022.04.020Search in Google Scholar

[39] Liu, W., M. Sun, Z. Ding, Q. Zeng, Y. Zheng, W. Sun, et al. Ball milling synthesis of porous g-C3N4 ultrathin nanosheets functionalized with alkynyl groups for strengthened photocatalytic activity. Separation and Purification Technology, Vol. 282, 2022, id. 120097.10.1016/j.seppur.2021.120097Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants