Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

-

Sunardi Sunardi

, Eko Surojo

, Hammar Ilham Akbar

Abstract

The environment is a very important topic today as well as in the future. One source of air pollution that has the potential to harm health is the wear particles released by vehicle braking systems. If these wear particles come from hazardous materials, they could destroy human health and the environment. Based on these conditions, exploring more environmentally friendly materials to substitute hazardous materials as friction materials is necessary. In this study, brake linings were prepared from bamboo fiber and eggshell (ES) particles with various pre-treatment conditions. The composition of the material frictions consisted of phenolic resin, bamboo fiber, bamboo particles, ES particles, zinc, alumina, and graphite in the following: 35% phenolic resin, 10% graphite, 10% bamboo fiber, 10% alumina powder, 5% zinc powder, and 30% bamboo particles and ESs. This study focused on observing the mechanical and tribological behavior of friction materials when using ES particles as fillers. There are three stages to manufacturing friction material: a cold press, a hot press, and heat treatment. The optimization of the characteristics of ESs as organic brake linings was carried out using the Taguchi method and analyzed using data envelopment analysis-based ranking (DEAR). An interesting finding from this study was that when ES particles were calcined at 900°C for 120 min, the ES particle size was 200 mesh, and the ES volume fraction at 25% resulted in the most optimal brake lining performance. Calcination at 900°C for 120 min completely changed the CaCO3 phase to CaO. This study also shows that calcined ES particles have the potential to be developed as friction materials for environmentally friendly two-wheeled vehicles in the future. The produced brake linings exhibited hardness, a coefficient of friction, and specific wear rates of 92.82 HR, 0.32, and 4.43 × 10−6 mm3·N−1·m−1, respectively.

1 Introduction

Environmental issues are crucial today and will remain in the future. Rapid urbanization, the increasing tourism industry, and the slow adoption of vehicles with renewable energy are causing air pollution, which is harming health and the environment [1]. Transportation is one sector that contributes to the formation of vehicle pollutants, GHG emissions, and anthropogenic heat. One of the efforts to reduce the negative impact of the transportation sector is to control the number of vehicles. If vehicles continue to increase, the vehicular anthropogenic heat should increase in 50% and impact thermal comfort and urban heat island circulation [2].

Under heavy braking from 175 to 100 km·h−1, (8.4–38) × 1013 particles can be produced every 2.5–11.5000 km [3]. Using FEA simulations, Riva et al. [4] reported that rotor wears in the braking system are estimated to be relatively high. Meanwhile, PM10 emissions still show a standard deviation value of the measured emissions. Temperature and friction significantly affect the number of emissions. The particle coefficient of friction for the excellent fraction increases with increasing temperature, while the coarse and fine fractions are affected by the shear speed. The specific particle coefficient increases when the contact pressure decreases [5].

To date, asbestos continues to be a problem in the world, especially in developing countries where the prohibition of using and managing asbestos has not been employed [6]. Countries that are not serious against the use of asbestos are expected to show increased diseases due to asbestos exposure over the coming decades [7]. Several studies have shown the adverse effects of asbestos use on health and the environment [8].

Copper has begun to be limited in its use in brake linings. It is alleged to harm health and the environment. Based on Senate Bill No. 346, starting January 1, 2021, it has been stated that brake linings with a copper content of more than 5 wt% are banned in the states of America. Moreover, from January 1, 2025, the copper content in brake linings should not exceed 0.5 wt% [9]. The presence of Cu in brake linings serves to increase thermal conductivity. In the future, a copper replacement material must be sought.

Copper and asbestos are hazardous materials to human health and the environment, and yet they are still commonly found as brake lining materials. The wear debris generated from this braking system can escape into the air and be inhaled by humans, which can endanger health. For this reason, it is necessary to find alternative materials as a substitute for these two hazardous materials. Several organic materials, such as eggshell (ES) waste [10,11] and bamboo [12,13], have been found to be two environmentally friendly materials based on the literature. This research aims to reveal the potential of these two organic materials when used as friction materials.

The use of biodegradable fibers has space and the opportunity in the future to replace metal materials that are harmful to humans and the environment [14]. The presence of bamboo fiber can improve mechanical properties; therefore, it has the potential to be used as a material for brake linings in motorbikes [15]. Adding 40 vol% of bamboo fiber can increase the flexural strength by up to 4× higher compared to an oriented strand board with a value of 85.5 MPa [16]. Hybridizing bamboo fiber with date palm fiber can produce a high impact, water absorption, and low thickness expansion [17]. Bamboo has the potential to be a lightweight and sustainable final product that can reduce costs and energy consumption when compared to synthetic fibers [18]. Another advantage is the abundance of renewable, biodegradable, and low-cost bamboo fibers [19].

One of the materials used as a filler for brake linings is sawdust. Sawdust can improve brake linings with mechanical and tribological properties [20]. This research also showed that the finer the sawdust size, the larger the compressive strength and hardness as well as the water absorption and wear rate decrease. Another organic material that could be used in brake linings is bamboo leaves. A larger composition of the bamboo leaf particles tends to decrease the hardness of the composite; however, the porosity and compressive stress tend to increase. The particle size of bamboo leaves also affects the mechanical and tribological properties, with smaller particle sizes tending to decrease the wear rate but increase the compressive strength and porosity of the composite [21]. The use of organic fillers in a hybrid manner has complementary properties resulting in a better combination of composite quality.

ES particles are made of organic materials that resemble ceramics. This hardness is expected to improve the composite surface’s coefficient stability and wear rate. ES particles are widely used as a reinforcement in metal matrix composites (MMCs). Adding 5 wt% ES in MMC can improve the mechanical properties; however, the wear performance increases to 36.4 wt% at a loading below 20 N [22]. Abdullah et al. [23] also stated that adding 5 wt% ES could produce a lower wear rate on the poly methyl methacrylate composite. Increasing the content of ES nanoparticles increases water absorption and the expansion of the thickness of the composite. Saline water environments show significant thickness swelling and erosional wear [24]. Ray et al. [25] also showed that the density, voids, and wear resistance increased with the increasing ES particle content while the mechanical strength decreased. Calcination treatment on ESs can improve the wear index of epoxy composites when reinforced with ES particles and sisal fibers [26].

Bose et al. [27] compared the performance of an aluminum MMC by adding raw ES particles, carbonated ESs, and SiC + snail shell ash. The results of this study are interesting because the presence of 12.5 wt% of carbonated ESs increased the hardness, tensile strength, and fatigue strength by 80, 45.94, and 53.33%, respectively. The decrease in the corrosion rate was also significant for AMC with the addition of 12.5 wt% of ESs; however, a significant decrease occurred in the carbonized ESs. The 7.5% ES particulate (ESP) and 2.5% SiC combination in an AA2014 aluminum alloy resulted in maximum specific strength, minimum thermal expansion, and porosity.

ES particles are widely used as particulate composites [28,29]. Their compressive strength and hardness continued to increase with the addition of ES particles. However, the impact and flexural strength reached their maximum values of 20–30 wt% of ES addition in untreated and carbonized ESs [28]. The use of ES particles for developing polymer-based friction materials has not been widely used. ESs as a filler or reinforcement material for polymer composites are promising for improving composites’ mechanical, thermal, and tribological properties. However, discussion on the potential role of ES particles in brake linings is still limited.

ES particles have good characteristics as a friction material and are environmentally friendly; therefore, exposure to worn particles does not harm human health or the environment. A literature study conducted by Sunardi et al. [10] showed that ESs could be used as brake lining materials. ES particles can be hard fillers that withstand wear and tear. Using a hybrid material, ES particles, bamboo particles, and fibers can control the friction coefficient and improve mechanical properties. In practice, brake linings operate at high temperatures when friction occurs between the brake linings and the disc. Metal materials such as iron particle fillers in Timoho fiber-reinforced polyester composites can improve thermal stability and reduce flammability after adding 10% by weight of an iron filing filler [26]; however, their tensile strengths have been found to decrease [30]. ES particles can replace metal particles by increasing the thermal stability of brake linings [31].

The Taguchi method is the most established optimization technique for composite development [32]. Using the Taguchi method, factorial optimization can be obtained with a minimum number of experiments, thereby reducing experimental costs, improving optimization quality, and providing appropriate design solutions [33]. Bachchhav and Hendre [34] used the Taguchi method to estimate the specific wear rate on temperature, sliding velocity, pressure, and sliding distance parameters during the experiment. This research showed that temperature had the most significant effect, followed by other parameters. Kumar and Ghosh [35] also used the Taguchi method by modifying the hardness and friction coefficient based on the production process parameters such as compass load and the sintering temperature. In this research, the optimum friction coefficient was obtained at a load of 50 N, a speed of 400 rpm, and a pin temperature of 150°C. The Taguchi method was also used by Yilma et al. [32] to estimate the composition of the brake linings. This research showed that optimal water absorption was obtained using 22% epoxy resin, 16% graphite particles, 15% steel particles, 11% basalt particles, and 3% wheat straw fiber. The data envelopment analysis-based ranking (DEAR) method can determine the most optimum characteristics of ES particles based on the multi-responses performance index (MRPI) level ranking.

Therefore, here we studied the behavior of ESs, bamboo fibers, and bamboo particles when used as a hybrid on brake linings. The ES particles used in this research were either with or without calcination treatment; therefore, the performance of the ES as a filler was known. To this date, ES particles are widely used as a reinforcement for metal matrix brake linings, while polymer matrix brake linings are still very limited. Scientific publications on organic materials such as ES particles and bamboo as brake lining materials still need to be explored. This study aims to explain the potential of these two organic materials as brake pads for two-wheeled vehicles that are environmentally friendly for the future.

2 Materials and methods

Generally, non-asbestos brake linings consist of many materials to ensure their performance requirements which usually have conflicting properties. The four main characteristics that must be present in brake pads include binder resin, reinforcing fibers, friction modifiers, and fillers [36]. In this study, the classification of materials based on their function is shown in Table 1.

Classification of brake lining’s ingredients

| Classification | Function | Ingredients |

|---|---|---|

| Binder | Binds all brake linings’ ingredients | Phenolic resin |

| Fiber | Improves the mechanical strength | Bamboo fiber |

| Friction modifier | Determines the desired friction characteristics | Al2O3, Zn, and graphite |

| Filler | Improves specific properties, reduces production costs, and acts as a space filler | Bamboo particles and ES powder |

2.1 Materials

The primary raw materials for the brake linings in this study were bamboo fibers, bamboo particles, ES particles, natural graphite, zinc powder, aluminum oxide powder, and phenolic resin. Bamboo and ESs are natural raw materials, as shown in Figure 1. ESs were collected from household waste. The type of ES used in this study was brown country chicken eggs. Bamboo in particle and fiber form was obtained from Pandeglang-Indonesia. The phenolic resin was obtained from SI Group-Shanghai Co. Ltd. Other materials, such as graphite, alumina, and Zn, were obtained from Indonesia. Sodium hydroxide (NaOH) from Merck’s and vinyltrimethoxysilane liquid (CH2═CHSi(OCH3)3) as the silane coupling agent were used in the alkali treatment in this study.

Bamboo particles (a) and ES particles (b).

The composition of the brake lining samples is shown in Table 2 and was determined based on the actual volume fraction: 35% phenolic resin, 10% bamboo fiber, 10% alumina, 5% zinc, 10% graphite, and 30% (bamboo particles/ES). The production of brake lining samples was carried out in four main stages, namely (a) the pre-treatment of bamboo and calcination of the ES particles, (b) a cold press, (c) a hot press, and (d) heat treatment.

Composition of brake lining materials

| Sample code | Phenolic resin (%) | Bamboo fiber (%) | Zinc powder (%) | Alumina powder (%) | Graphite powder (%) | ES powder (%) | Bamboo powder (%) |

|---|---|---|---|---|---|---|---|

| S1, S5, S9 | 35 | 10 | 5 | 10 | 10 | 5 | 25 |

| S2, S6, S7 | 35 | 10 | 5 | 10 | 10 | 15 | 15 |

| S3, S4, S8 | 35 | 10 | 5 | 10 | 10 | 25 | 5 |

2.2 Chemical treatment

The performance of bamboo fibers and particles can be improved by an alkali-silane treatment. The alkali treatment removes the hemicellulose content and impurities and increases the composite’s thermal stability [37]. In this study, NaOH (Merck brand) was alkali-treated at a concentration of 6% for 3 h [38]. The weight ratio of the number of particles or fibers and the NaOH solution was 1:13 [39]. After that, it was washed with distilled water until the pH was neutral.

The next treatment for the bamboo particle and bamboo fiber was the silane treatment. The silane treatment aimed to increase the interfacial bond between the bamboo particles, bamboo fibers, and phenolic resin to increase the brake linings’ hardness and decrease the specific wear rate. The silane solution used was vinyltrimethoxysilane. The silane coupling agent was pre-hydrolyzed in a mixture of ethyl alcohol and water at a composition of 80 and 20% and was stirred for 60 min to obtain complete hydrolysis [40]. The pH of the solution was maintained at 4–5 by adding acetic acid before adding silane. The particles or fibers were immersed in a 1 wt% silane solution for 1 h. The ratio between the fiber’s weight and the solution’s volume was 0.04 g·mL−1 [41].

2.3 Calcination treatment

The purpose of calcinating the ESs was to decompose calcium carbonate into calcium oxide. The calcination temperature has a crucial role in changing the structure of the ES. In this study, ESs were subjected to calcination at temperatures 100, 500, and 900°C with calcination durations of 60, 120, and 180 min.

2.4 Sample preparation

Materials in the form of powders were mixed and stirred for 2 min to obtain a homogeneous mixture. The next step was to add the fiber material and mix it for 2 min [42]. This mixture was then converted into green bodies using a press machine at a pressure of 40 MPa, which was held for 5 min. This sample was then hot pressed at 150°C with a holding time of 10 min. The equipment settings are shown in Figure 2.

Equipment setting on hot pressing.

The last process for constructing the samples was curing, which was carried out in an electric furnace at temperatures in the range of 30–140°C for 60 min, 140–180°C for 360 min, and cooled at 180–30°C for 30 min [43]. The heating and cooling rates during curing are shown in Figure 3.

The rate of heating and cooling of the sample during curing.

2.5 Experimental design

The four ES particle parameters that were selected as input parameters included the calcination temperature, calcination time, particle size, and volume fraction for the experimental process. Each parameter was determined to have three levels, as shown in Table 3. The experimental matrix was designed according to the Taguchi method with nine experiments, as shown in Table 4.

Values at the levels of input parameters

| Parameters | Symbol | Unit | Values at levels | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| A. Temperature | T | °C | 100 | 500 | 900 |

| B. Time | t | min | 60 | 120 | 180 |

| C. Particle size | PS | mesh | 80 | 140 | 200 |

| D. Volume fraction | V f | % | 5 | 15 | 25 |

Orthogonal array

| Run | A | B | C | D |

|---|---|---|---|---|

| S1 | 100 | 60 | 80 | 5 |

| S2 | 100 | 120 | 140 | 15 |

| S3 | 100 | 180 | 200 | 25 |

| S4 | 500 | 60 | 140 | 25 |

| S5 | 500 | 120 | 80 | 5 |

| S6 | 500 | 180 | 200 | 15 |

| S7 | 900 | 60 | 80 | 15 |

| S8 | 900 | 120 | 200 | 25 |

| S9 | 900 | 180 | 140 | 5 |

2.6 DEAR method

The DEAR method was used to optimize the multiple-response Taguchi experiment. In the DEAR method, the larger-the-better response weights are divided by smaller-the-better response weights. This value indicates the optimal level and can be considered an MRPI. The following are the stages of completion with the DEAR approach [44]:

Determine the weight of each response for all experiments using a weighting technique.

Transform the observed response data into weighted data by multiplying the observed data by their weight.

Divide the data with the larger-the-better weight by the smaller-the-better data.

Assume the values obtained as MRPI and obtain the solution.

The hardness (HR), coefficient of friction (CF), and specific wear rate (SWR) were the average of five experiments. HR and CF had the larger-the-better characteristics, which were calculated by dividing the single response by the total response value, as shown in Eq. (1). The SWR had the smaller-the-better characteristic, as shown in Eq. (2):

2.7 Hardness testing

Hardness measurements were based on ASTM D 785 using Rockwell hardness with Type R. The hardness test used the universal Rockwell hardness tester brand ZwickRoell. The hardness measurements were carried out 5× at different points and for different specimens. A hardness test was carried out on both sides of four different samples, including a cylindrical sample with a diameter of 10 mm and a length of 10 mm. The indenter stamping was conducted in the center of the test sample.

2.8 Friction coefficient testing

Tests for the coefficient of friction and specific wear rate were carried out using the pin-on-disc method under dry conditions and at room temperature. The pressure actuator pushed the sample clamped in the holder horizontally until it made contact with the rotating disc. The disc material was made of DIN X 153 CrMoV12 steel with a hardness of 45 RC and a surface roughness in the range of 0.43–1.37 μm. The pin-on-disc test was conducted at a contact pressure of 0.75 MPa and a shear speed of 12 m·s−1 [43]. Sukrawan et al. [15] stated that the wear rate test for the motorcycle was carried out with a load of 2.3 kg and at a speed of 180 rpm. Biokinetics and Associated Ltd state that the braking force of a motorcycle is between 45 and 89 N at a speed ranging from 48.3 to 128.8 km·h−1. In this study, the force used was 58.88 N, which was obtained based on the contact pressure on the sample contact area [45]. Before the measurement, the sample was rubbed on the disc’s surface until the sample’s surface was abraded thoroughly. Each time the next test was started, the disc surface was cleaned with a soft cloth to remove any dirt on the disc surface. The setting of the friction test equipment is shown in Figure 4.

The setting of the friction test equipment.

The recording of frictional forces that occurred between the surface of the sample and the disc’s surface used data acquisition (Advantech USB-4716). The friction test was carried out by replicating the test five times. The friction coefficient was obtained by dividing the friction force by the normal force. Mathematically, this was formulated as follows:

The SWR was measured after the sample traveled 6020.76 m for each friction test, and SWR data collection was carried out with at least five repetitions. The determination of the sliding distance in SWR testing was according to previous studies [43]. Ahmed and Mulapeer [46] used an applied load parameter of 45 N, a sliding speed of 1.34 m·s−1, and a sliding distance of 2,000 m. In their study, Demirdal and Aydın [47] used applied loads of 5, 10, and 20 N, a coating speed of 0.14 m·s−1, and a sliding distance of 200 m. Long distances were used to obtain a convincing SWR and the stability of the friction coefficient. SWR was obtained by dividing the wear volume by the contact load and the sample sliding distance, and SWR is expected to be more accurate than the volumetric wear [46]. Mathematically, the formula for measuring SWR was stated by Rajan et al. as [48]

where ΔV is the volume of the material worn (mm3), d is the sliding distance (m), and L is the contact load (N).

3 Results and discussion

3.1 Changes in the ES particle size

The ES particles that were subjected to a calcination process at 500 and 900°C changed in particle size, as shown in Table 5. The relative calcination treatment resulted in nearly the same particle size. The average particle sizes were in the range of 120.08–135.14 mm. It should be noted that the average sizes of ES particles before calcination were 200, 140, and 80 mesh, respectively, at 74.74, 96.02, and 159.57 mm.

Changes in the ES particle size after the calcination process

| Particle size | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 |

|---|---|---|---|---|---|---|---|---|---|

| Median (μm) | 63.38 | 85.6 | 144.87 | 99.3 | 139.08 | 137.44 | 127.52 | 124.39 | 104.92 |

| Mean (μm) | 74.74 | 96.02 | 159.57 | 109.68 | 144.59 | 139.32 | 134.54 | 135.14 | 120.08 |

This study shows that calcination’s temperature and time significantly affected the ES particle size changes. These results are consistent with a study conducted by Pornchai et al. [49], which stated that with a longer calcination time, there was a tendency to reduce the particle size of the ES. Increasing the calcination temperature reduced the ES particle size to 61.15% [50]. During the calcination process, ES particles vibrated with each other so that the particles were split into smaller pieces [51].

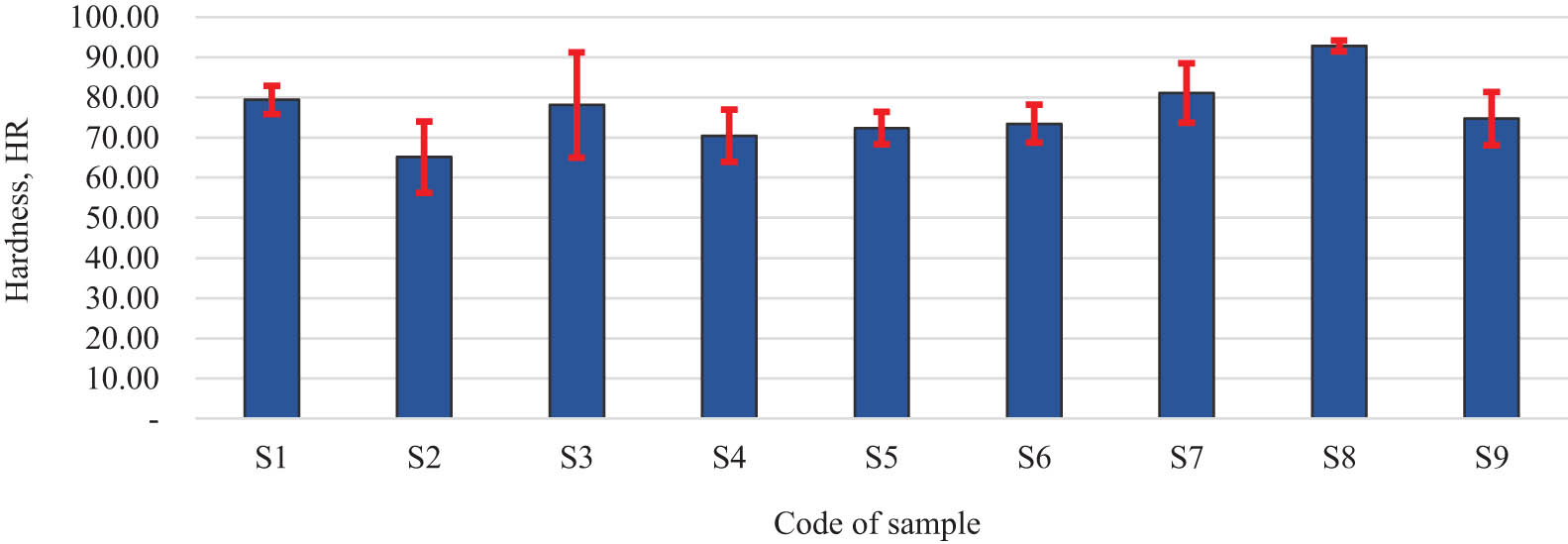

3.2 Hardness

The average hardnesses of organic brake linings developed were between 65.14 and 92.82 HR, as shown in Figure 5. The hardness of the brake linings increased only slightly on ESs without calcination. These results are linear with studies conducted by Gdabeyan et al. [52]. Using 10% calcium carbonate on a polyester composite reinforced with 20% pine fiber showed an increase in hardness. The calcium carbonate filler could withstand indentation forces against deformation and increase thermal stability [53].

Brake lining hardness based on ES waste.

However, the ESs calcined at 900°C experienced a significant increase in hardness. The composition of calcined ESs had the highest average hardness value, namely 92.82 HR. Calcined ES particles became stiffer due to the loss of moisture. This condition was the reason for the increased hardness of the composite when compared to ES particles without calcination. The study results of Iloabachie et al. [54] also showed the same phenomenon. That is, with a higher calcined ES content, the hardness of the epoxy resin/ES composite also increased. From this research, it is found that the maximum hardness occurred at 20 wt%. Even Ononiwu et al. [55] stated that using calcined ESs could increase the microhardness by up to 20%.

Several studies have shown that a calcination temperature of 500°C was not able to change the ES phase from CaCO3 to CaO; therefore, samples S-1 to S-6 show relatively the same hardness. In contrast to the 900°C calcination temperature, the ES phase wholly changed to CaO, significantly increasing the hardness. A study showed that the complete phase change from CaCO3 to CaO occurred at 900°C for 1 h [56]. Due to the unstable structure of CaO particles when exposed to air, CaO particles immediately formed Ca(OH)2.

Sample S8, with calcination treatment at 900°C for 2 h with a particle size of 200 mesh and a volume fraction of 25%, had the highest hardness value (92.82 HR). The increased hardness of S8 was due to the uniform distribution of the ESs in the brake lining samples. This study’s results align with Shah et al.’s findings that the reduction in particle size due to stearic acid treatment led to a more uniform distribution of particles [57]. In addition, a relatively fine particle size could produce a denser and stronger interface, thereby increasing the mechanical properties of the composite. The content of ES particles significantly increased the hardness of the composite. Qhazi also stated that the larger the particle size, the lower the hardness [58].

An interesting finding in this research was that ESs with calcination treatment at 900°C (S7, S8, and S9) experienced a relatively better hardness when compared to other samples. This hardness with a slight deviation indicated that the distribution of ES particles was reasonable even in the sample brake linings. Another interesting phenomenon was that the surface hardness of the brake linings increased with the addition of the ES volume fraction. This study is in line with that conducted by Panchal et al. [24], who stated that increasing the ES concentration increased the hardness of the biocomposite. This result differs from that of Oladele et al. [26], who stated that the composite with calcined ESs had a lower hardness than the untreated ES. Generally, previous research data have shown that the hardness of organic brake linings, once developed, has better hardness compared with other organic materials.

Table 6 shows that the hardness of the brake linings using ES and bamboo fillers is quite competitive compared to other organic materials. The presence of ES particles in the composite can significantly increase the hardness of the composite, especially in the S8 composite, where the distribution of ES particles occurred evenly. The surface hardness of this composite could be directly related to the coefficient of friction and the specific wear rate of the brake pads. Usually, the higher the surface hardness, the lower the friction coefficient and the wear rate.

Comparison of surface hardness of brake linings from organic and environmentally friendly materials

| No. | Binder resin | Ingredients | Average hardness | Ref. |

|---|---|---|---|---|

| 1 | Polyester | Calcium carbonate, alumina, barium sulfate, rockwool, graphite | 110.66 | [59] |

| 2 | Epoxy | MgO, bamboo fiber | 68.30–91.80 | [15] |

| 3 | Phenolic | Miscanthus, alumina, and cashew | 95.5–112.3 | [60] |

| 4 | Phenolic | Chalk, graphite, sand, aluminum powder, fly ash | 103–114 | [61] |

| 5 | Phenolic | PAN, aramid pulp, rockwool, graphite, alumina, promaxon D, potassium titanite, vermiculite, CNSL, rubber, barite, metal particle | 90.2–96.4 | [62] |

| 6 | Phenolic | Aramid pulp, PAN, rockwool, graphite, alumina, potassium titanite, rubber, friction dust, vermiculite, hydrated lime, barite, Cu | 93–98 | [63] |

| 7 | Phenolic | Aramid, glass, graphite, copper powder, alumina, calcium carbonate, friction dust, vermiculite, barite, carbon fiber | 38–56 | [42] |

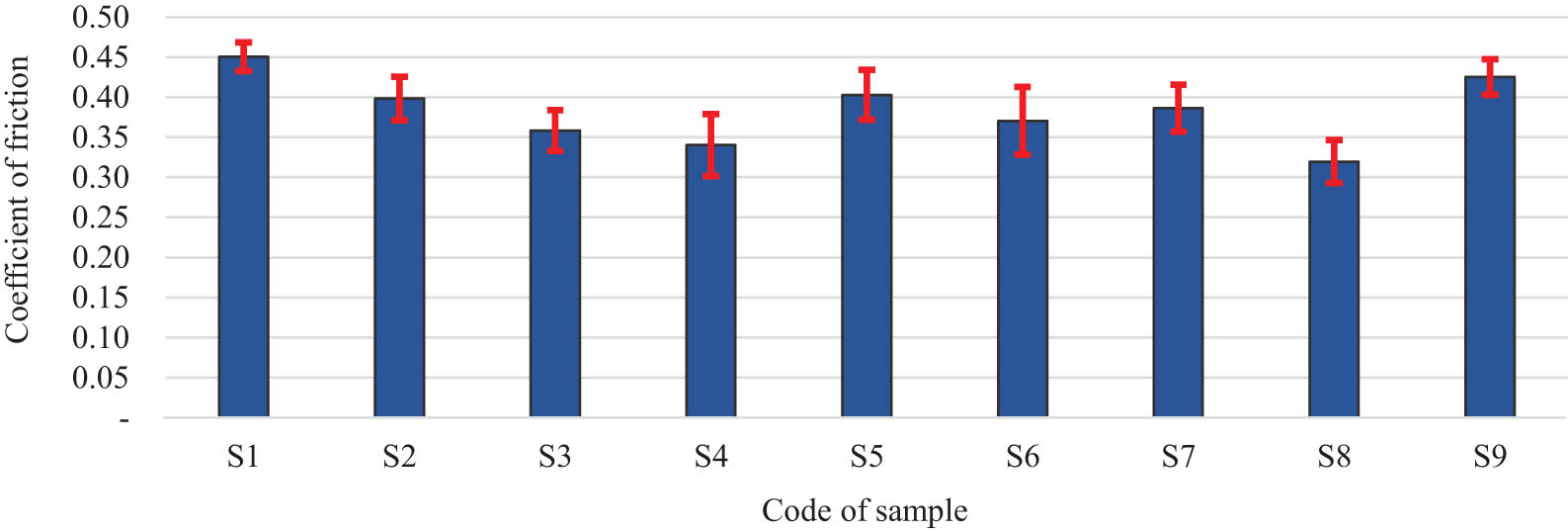

3.3 Coefficient of friction

The coefficient of friction is essential in the material’s selection and for determining material surface requirements. The value of friction coefficients was calculated using Eq. (3), and the results were shown in Figure 6. This study shows that the lower the ES particle content, the higher the surface friction coefficient. The increase in the friction coefficient is due to the bamboo particles. This statement is in agreement with a study conducted by Alajmi et al. [64], which showed that the addition of bamboo fiber to the composite could improve the stability coefficient of the friction coefficient.

The values of the friction coefficient in the sample brake linings.

From Figure 6, it can be seen that the addition of bamboo particles and ESs increased the stability and the coefficient of friction. The average coefficient of frictional stability was achieved in less than the first 35 s since the surface contact occurred between the brake lining sample and the disc, as shown in Figure 7. The stability of the friction coefficient was also strengthened by adding 10% graphite in each sample.

The stability of the friction coefficient in the brake lining samples.

This study shows that the coefficient of friction achieved the best conditions in the sample by adding 25% of the ES. The nature of the ES particles resembled ESs’ functions as a part of the brake lining and received frictional loading. The abraded ES particles, along with other materials, can then fill in the surrounding porous. This condition also contributed to the stable value of the friction coefficient. Increasing the number of ES particles in the composite tends to decrease the coefficient of thermal expansion [65]. This condition affects the stability of the friction coefficient.

An interesting phenomenon occurred in sample S9, where the contact between the surfaces had an excellent coefficient of friction. This sample contained ESs, which were calcined at 900°C for 120 min with a volume fraction of 5%. This condition is exciting because it has a similar coefficient of friction stability in the 25% ES sample, and was due to the composite’s compatibility with bamboo particles and ESs. Bamboo fiber could improve the friction performance of friction materials. Grooves or cavities that were formed after the carbonization of the bamboo fiber could also reduce noise [66].

The treatment and content of ESs have a significant influence on the friction coefficient of the brake linings. The friction coefficients obtained were in the range of 0.32–0.44. Based on the SAE J866 Standard, this friction coefficient is in Code Letter E (S4 and S8), and the others are in Code Letter F [67]. For tribological applications, it is desired that the brake linings have friction coefficients in the range of 0.30–0.70 [68]. Generally, brake linings for original equipment manufacturers have a friction in the range of 0.30–0.40 [69].

3.4 Specific wear rate

Wear is an essential property in materials, especially when there is contact between them. Several factors can affect material wear, including the normal force on the surface, the environment, and the physical and chemical properties of the material. This study used the specific wear rate to express the wear value. Figure 8 shows that a more significant volume fraction of ES particles tended to decrease the specific wear rate. The presence of ES particles caused a decrease in the wear rate. This calcined ES is a very stable structure and has the behavior of a hard-ceramic material. These ES particles resist the shear force from the disc so that the material experiences less wear and tear on the sample brake linings.

Specific wear rate in the brake lining sample.

The lowest specific wear rate for the organic brake lining samples occurred in samples treated with 900°C calcination for 2 h with a volume fraction of 25% ES particles. The presence of hard and stiff ES particles caused a decrease in the specific wear rate. The ES particles functioned to resist deformation and shear due to the contact between the canvas material and the disc. Adding ES particles reduced the effective contact between the surfaces; therefore, the wear volume also decreased. The decrease in the specific wear rate was in line with the increase in the surface hardness of the organic brake linings.

An increase in the number of ES particles also decreased the material’s tendency to stick to the disc. The impact of this was that the material did not stick to the disc; however, this worn material filled the valleys on the surface of the material and formed a secondary plateau. Several studies have shown that calcined ESs can improve wear resistance [26]. The higher the calcination temperature on the ES particles, the more the specific wear rate decreased. Ononiwu et al. [55] showed that ES particles calcined at 1,200°C for 2 h resulted in the lowest wear rate compared to temperatures of 900, 1,000, and 1,100°C.

Another interesting phenomenon is that the higher the ES particle content, the lower the wear rate of the composite. The results of this study agree with those conducted by Demirdal and Aydın [47]. The wear rate increased with the increase in the bamboo fiber content. Ma et al. [66] showed that the bamboo fiber content in the friction material was higher than 3% by weight, which could reduce its resistance to wear.

Using a bamboo and ES filler in brake linings has shown relatively good performance and has produced low specific wear rates between 4.43 × 10−6 and 1.42 × 10−5 mm3·N−1·m−1. The ES particle’s presence in the brake lining improved the composite’s specific wear rate. This study is in line with the report by Pani et al. [70], who stated that the specific wear rate increased when compared to the use of bamboo fiber without ES particles in composites with an epoxy resin, a metallic filler-based rubber resin, and brass-based organic and inorganic fibers with a specific synthetic rubber-modified resin [34]. This material’s low specific wear rate automatically reduced the wear debris that would otherwise have escaped into the air. Because the wear debris comes from environmentally friendly organic materials, this does not pose the same problems for environmental health.

The calcined ES on S8 produced the lowest wear rate; therefore, the amount of wear and tear debris during braking was also minimal. This condition further confirmed that ES is cheap, non-toxic, and environmentally friendly [71]. The SWR value in this study was lower compared to the use of polymer hybrid composites when reinforced with bamboo, hemp, and seawater glass fibers which reached 20.193 × 10−3 mm3·N−1·m−1 [70] utilizing orange peels, coconut, periwinkle, palm kernels [72], and metallic and fine brass [34]. Generally, ESs that received the calcination treatment could decrease the wear rate significantly, at around 50%, while the hardness increased by 18.8%.

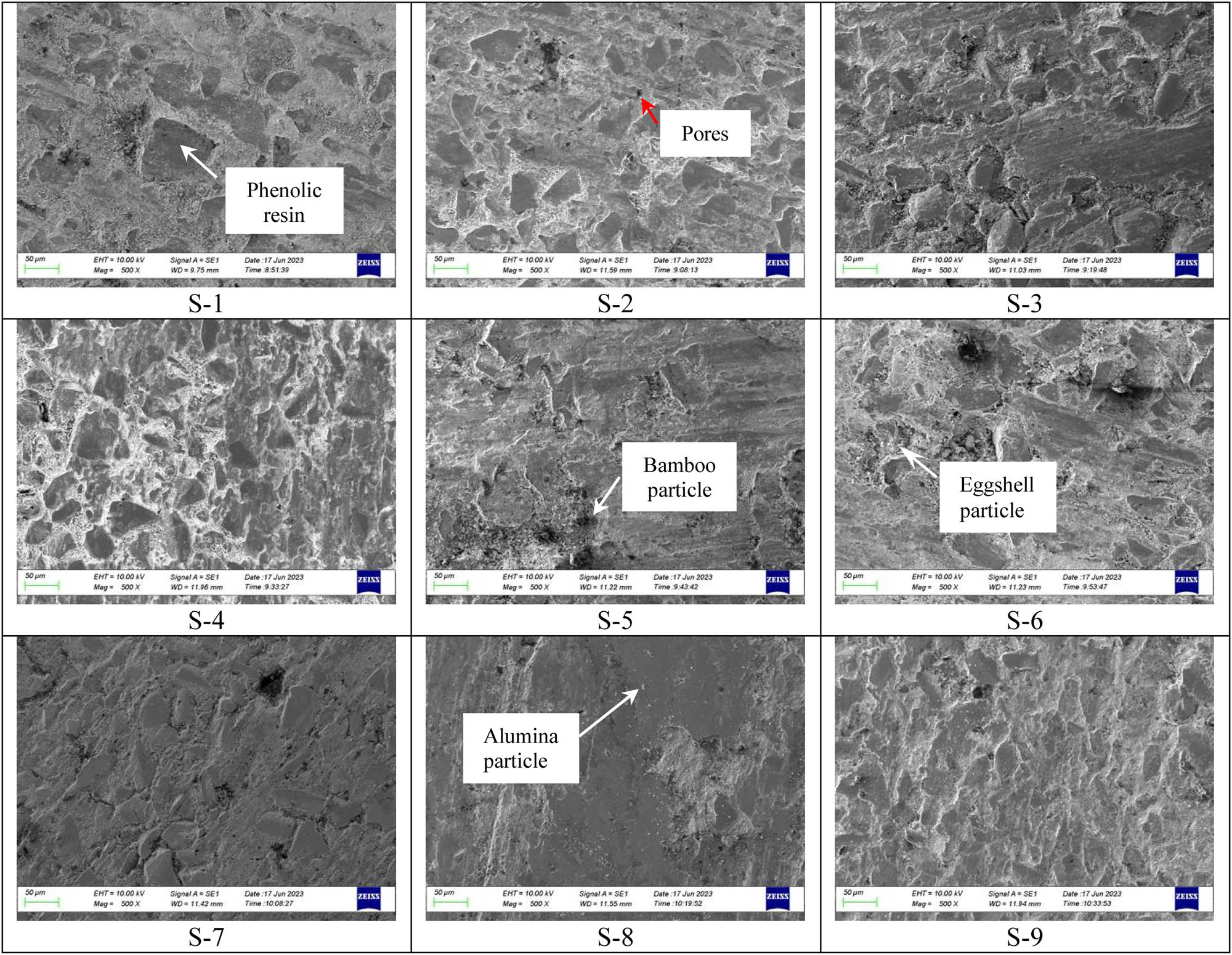

3.5 Surface morphology

Figure 9 shows the calcined and uncalcined ES particle distribution at various volume fractions. The ES particles were distributed evenly in all samples. This result is in line with the report of Oladele et al. [26]. However, 5% of ES particles (S1, S5, and S9) had a greater porosity when compared to other volume fractions. In these three composites, the content of the bamboo particles was relatively high, namely 25%. The content of these bamboo particles explains why the porosity was greater than that of composites with a lower content of bamboo particles.

Surface morphology scanning electron micrograph of phenolic composites containing ES.

Samples containing 25% of ESP produced a wider contact surface and relatively increased hardness. The increase in hardness was due to the even distribution of particles in the composite, especially ES particles with calcination treatment. Calcined ES particles were embedded more profoundly in the composite, and this acted as an indicator that there was a good interaction between the filler and matrix. This interaction was also confirmed by the composites’ increased hardness and decreased wear rate. The scanning electronic microscopy photos show how ES particles with a 200 mesh could be dispersed well and fill small cavities in the composite [73,74,75].

Sample S8 had a good distribution of ES and alumina particles on the repellent resin resulting in a wider contact surface. The resulting impact was an increase in the composite’s surface hardness, which decreased the specific wear rate and the coefficient of friction in the brake linings. Samples with a composition of 25% ES particles (S3, S4, S8) had the lowest wear rates. The increase in the hardness of this composite was due to the content of ES particles, especially S8, which produced the highest hardness of all the samples.

3.6 ES optimization

ES characteristics were optimized using the DEAR approach. For the characteristics of this response, refer to Eqs. (1) and (2). The following are the steps to obtain ES optimization, as shown in Tables 7–9. The MRPI value was obtained by dividing the number of larger-the-better (HR and CF) responses by the number of smaller-the-better responses, as shown in Table 8.

Response weight hardness, coefficient of friction, and specific wear rate values

| No. | Code of samples | HR | W HR | CF | W CF | SWR | W SWR |

|---|---|---|---|---|---|---|---|

| 1 | S1 | 79.42 | 0.1155 | 0.45 | 0.1305 | 1.42 × 10−5 | 0.0653 |

| 2 | S2 | 65.14 | 0.0947 | 0.40 | 0.1154 | 1.11 × 10−5 | 0.0836 |

| 3 | S3 | 78.12 | 0.1136 | 0.36 | 0.1038 | 8.86 × 10−6 | 0.1045 |

| 4 | S4 | 70.44 | 0.1024 | 0.34 | 0.0985 | 1.02 × 10−5 | 0.0908 |

| 5 | S5 | 72.36 | 0.1052 | 0.40 | 0.1167 | 1.33 × 10−5 | 0.0696 |

| 6 | S6 | 73.46 | 0.1068 | 0.37 | 0.1074 | 1.15 × 10−5 | 0.0803 |

| 7 | S7 | 81.10 | 0.1179 | 0.39 | 0.1119 | 7.53 × 10−6 | 0.1229 |

| 8 | S8 | 92.82 | 0.1350 | 0.32 | 0.0926 | 4.43 × 10−6 | 0.2089 |

| 9 | S9 | 74.72 | 0.1087 | 0.43 | 0.1232 | 5.31 × 10−6 | 0.1741 |

Weighted responses and MRPI calculations

| No. | Code of samples | P | Q | R | MRPI | Rank |

|---|---|---|---|---|---|---|

| HR × W HR | CF × W CF | SWR × W SWR | (P + Q)/R | |||

| 1 | S1 | 9.1735 | 0.0588 | 9.25 × 10−7 | 9.98 × 106 | 3 |

| 2 | S2 | 6.1712 | 0.0460 | 9.25 × 10−7 | 6.72 × 106 | 9 |

| 3 | S3 | 8.8757 | 0.0372 | 9.25 × 10−7 | 9.63 × 106 | 4 |

| 4 | S4 | 7.2163 | 0.0335 | 9.25 × 10−7 | 7.84 × 106 | 8 |

| 5 | S5 | 7.6151 | 0.0470 | 9.25 × 10−7 | 8.28 × 106 | 7 |

| 6 | S6 | 7.8484 | 0.0398 | 9.25 × 10−7 | 8.53 × 106 | 6 |

| 7 | S7 | 9.5657 | 0.0432 | 9.25 × 10−7 | 1.04 × 107 | 2 |

| 8 | S8 | 12.5303 | 0.0296 | 9.25 × 10−7 | 1.36 × 107 | 1 |

| 9 | S9 | 8.1199 | 0.0524 | 9.25 × 10−7 | 8.83 × 106 | 5 |

MRPI values for ES particle characteristics

| Factors | Levels | Max – min | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

| A. Calcination temperature | 2.63 × 107 | 2.46 × 107 | 3.28 × 10 7 | 8.15 × 106 |

| B. Duration of calcination | 2.82 × 107 | 2.86 × 10 7 | 2.70 × 107 | 1.58 × 106 |

| C. Particle size | 3.21 × 10 7 | 2.34 × 107 | 2.83 × 107 | 8.69 × 106 |

| D. ES volume fraction | 2.71 × 107 | 2.56 × 107 | 3.10 × 10 7 | 5.41 × 106 |

Bold writing indicates that these parameters have the most influence on the performance of friction material.

The optimal levels were identified by assuming MRPI as a single response. Table 9 shows that the optimum MRPI levels were A3, B2, C1, and D3. These results align with the research conducted by Oladele et al. [26], who stated that the wear index and hardness of the composite were higher as the number of ES particles increased. Table 9 also shows that the particle size, calcination temperature, and eggshell volume fraction are the three parameters that most influenced the performance of the brake linings.

Table 9 shows the effect of MRPI. The ES particle size, calcination temperature, volume fraction, and ES calcination time were the significant factors that affected the properties of the brake linings and were 8.69 × 106, 8.15 × 106, 5.41 × 106, and 1.58 × 106, respectively. Thus, the ES characteristics reached an optimum value in this study, namely the calcination temperature of 900°C for 120 min with an ES particle size of 200 mesh and a volume fraction of ES at 25% with hardness, coefficient of friction, and specific wear rate values of 92.82 HR, 0.32, and 4.43 × 10−6 mm3·N−1·m−1, respectively.

An ES microparticle filler was very effective for filling epoxy resin spaces with up to a 40% concentration [29]. ES particles can function more optimally if treated with stearic acid, where the toughness, particle–matrix bonding, and thermal stability can increase and the brittleness decrease [57]. When the volume fraction of ES particles was evaluated in this study, the 25% content produced the highest hardness. These results align with a study conducted by Balan et al. [76], where the higher the ES particle content, the greater the composite hardness and reduced water absorption.

This study has shown that ESs and bamboo particles as fillers in friction materials have a competitive performance compared to other organic materials, even semi-metallic materials. Based on these conditions, egg shells and bamboo could be used as alternative materials that are environmentally friendly in the future, considering that environmental sustainability is the responsibility of every human being. Compared with other potential nature-based materials, e.g., agave cantala [77,78], salacca zalacca [79,80], sea sand [81,82], hybrid metallic-based material, e.g., aluminum [83,84,85], can be considered in future to obtain performance evaluation data of the ES-based composite.

4 Conclusions

ES and bamboo particles have unique properties that complement each other regarding their mechanical and tribological performance. There are several important points that were obtained from this study, including:

Organic brake linings using ES particles and bamboo have competitive properties.

The mechanical and tribological performance of ESs has optimum values when ESs are calcined at 900°C for 2 h with a particle size of 200 mesh and a volume fraction of 25%.

The hardness and wear rate increase with the addition of ES particles, whereas, if a high coefficient of friction is needed, the bamboo composition in fiber and particle form added should be more.

Calcined ES particles have many advantages compared to untreated ESs.

Acknowledgments

The authors would like to thank the Research and Community Service Institute, Sebelas Maret University, for funding this research from the PNBP-UNS through the applied research grant scheme (PUT-UNS 2023) with contract number 228/UN27.22/PT.01.03/2023. We also thank our research colleagues from Universitas Sultan Ageng Tirtayasa and Universitas 17 August 1945, Surabaya.

-

Funding information: This research was funded by the Research and Community Service Institute, Sebelas Maret University, from the PNBP-UNS through the applied research grant scheme (PUT-UNS 2023) with contract number 228/UN27.22/PT.01.03/2023.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The authors declare that the data supporting the findings of this study are available within the article.

References

[1] Xu, X., L. Li, H. Zang, Y. Huang, and C. Feng. A compensation mechanism for air pollutants generated by tourism-related land-based transportation: An exergy-based case study from Macao. Journal of Environment Management, Vol. 331, 2023, id. 117252.10.1016/j.jenvman.2023.117252Search in Google Scholar PubMed

[2] Ribeiro, F. N. D., A. S. Umezaki, J. B. Chiquetto, I. Santos, P. G. Machado, R. M. Miranda, et al. Impact of different transportation planning scenarios on air pollutants, greenhouse gases and heat emission abatement. Science of the Total Environment, Vol. 781, 2021, id. 146708.10.1016/j.scitotenv.2021.146708Search in Google Scholar

[3] Vojtíšek-Lom, M., M. Vaculík, M. Pechout, F. Hopan, A. F. A. Raj, S. Penumarti, et al. Effects of braking conditions on nanoparticle emissions from passenger car friction brakes. Science of the Total Environment, Vol. 788, 2021, id. 147779.10.1016/j.scitotenv.2021.147779Search in Google Scholar PubMed

[4] Riva, G., G. Valota, G. Perricone, and J. Wahlström. An FEA approach to simulate disc brake wear and airborne particle emissions. Tribology International, Vol. 138, 2019, pp. 90–98.10.1016/j.triboint.2019.05.035Search in Google Scholar

[5] Alemani, M., J. Wahlström, and U. Olofssonb. On the influence of car brake system parameters on particulate matter emissions. Wear, Vol. 396–397, 2018, pp. 67–74.10.1016/j.wear.2017.11.011Search in Google Scholar

[6] Thives, L. P., E. Ghisi, J. J. T. Júnior, and A. S. Vieira. Is asbestos still a problem in the world? A current review. Journal of Environment Management, Vol. 319, 2022, id. 115716.10.1016/j.jenvman.2022.115716Search in Google Scholar PubMed

[7] Kratzke, P. and R. A. Kratzke. Asbestos-related disease. Journal of Radiology Nursing, Vol. 37, 2018, pp. 21–26.10.1016/j.jradnu.2017.12.003Search in Google Scholar

[8] Rong, Y., X. Luo, Z. Zhang, X. Cui, Y. Liu, and W. Chen. Occupational exposure to asbestos and cardiovascular related diseases: A meta-analysis. Preventive Medicine Reports., Vol. 2, 2015, pp. 920–926.10.1016/j.pmedr.2015.10.005Search in Google Scholar PubMed PubMed Central

[9] Senate Bill No. 346. Secretary of State; 2010.Search in Google Scholar

[10] Sunardi, S., D. Ariawan, E. Surojo, A. R. Prabowo, H. I. Akbar, B. Cao, et al. Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material. Journal of the Mechanical Behavior of Materials, Vol. 32, 2023, id. 20220269.10.1515/jmbm-2022-0269Search in Google Scholar

[11] Zieleniewska, M., M. K. Leszczynski, L. Szczepkowski, A. Bryskiewicz, M. Krzyzowska, K. Bien, et al. Development and applicational evaluation of the rigid polyurethane foam composites with egg shell waste. Polymer Degradation and Stability, Vol. 132, 2016, pp. 78–86.10.1016/j.polymdegradstab.2016.02.030Search in Google Scholar

[12] Silva, M. F., M. E. Menis-Henrique, M. H. Felisberto, R. Goldbeck, and M. T. Clerici. Bamboo as an eco-friendly material for food and biotechnology industries. Bamboo Food Biotechnology Industries, Vol. 33, 2020, pp. 124–130.10.1016/j.cofs.2020.02.008Search in Google Scholar

[13] Ochi, S. Mechanical properties of bamboo fiber bundle‐reinforced bamboo powder composite materials. European Journal of Wood and Wood Products, Vol. 80, 2022, pp. 263–275.10.1007/s00107-021-01757-4Search in Google Scholar

[14] Mulani, S. M., A. Kumar, H. N. E. A. Shaikh, A. Saurabh, P. K. Singh, and P. C. Verma. A review on recent development and challenges in automotive brake pad-disc system. Materials Today: Proceedings, Vol. 56, 2022, pp. 447–454.10.1016/j.matpr.2022.01.410Search in Google Scholar

[15] Sukrawan, Y., A. Hamdani, and S. Mardani. Effect of bamboo weight faction on mechanical properties in non-asbestos composite of motorcycle brake pad. Materials Physics and Mechanics, Vol. 42, 2019, pp. 367–372.Search in Google Scholar

[16] Lopes, M. D. M., M. de Souza Pádua, J. P. R. G. de Carvalho, N. T. Simonassi, F. P. D. Lopez, H. A. Colorado, et al. Natural based polyurethane matrix composites reinforced with bamboo fiber waste for use as oriented strand board. Journal of Materials Research and Technology, Vol. 12, 2021, pp. 2317–2324.10.1016/j.jmrt.2021.04.023Search in Google Scholar

[17] Supian, A., M. Jawaid, B. Rashid, H. Fouad, N. Saba, H. N. Dhakal, et al. Mechanical and physical performance of date palm/bamboo fibre reinforced epoxy hybrid composites. Journal of Materials Research and Technology, Vol. 15, 2021, pp. 1330–1341.10.1016/j.jmrt.2021.08.115Search in Google Scholar

[18] Kaur, N., S. Saxena, H. Gaur, and P. Goyal. A review on bamboo fiber composites and its applications. In 2017 International Conference on Infocom Technologies and Unmanned Systems (ICTUS'2017). 2017 Dec 18-20; Dubai-UAE.10.1109/ICTUS.2017.8286123Search in Google Scholar

[19] Javadian, A., I. F. Smith, and D. E. Hebel. Application of sustainable bamboo-based composite reinforcement in structural-concrete beams: Design and evaluation. Materials, Vol. 13, No. 3, 2020, id. 696.10.3390/ma13030696Search in Google Scholar PubMed PubMed Central

[20] Lawal, S. S., K. C. Bala, and A. T. Alegbede. Development and production of brake pad from sawdust composite. Leonardo Journal of Sciences, Vol. 30, 2017, pp. 47–56.Search in Google Scholar

[21] Adekunle, N., K. Oladejo, S. Kuye, and A. Aikulola. Development of asbestos-free brake pads using bamboo leaves. Nigerian Journal of Environ Sciences and Technology, Vol. 3, No. 2, 2019, pp. 342–351.10.36263/nijest.2019.02.0126Search in Google Scholar

[22] Turan, M. E. and F. Aydin. Wear and corrosion properties of low-cost eggshell-reinforced green AZ91 matrix composites. Canadian Journal of Metallurgical Materials Sciences, Vol. 61, No. 2, 2022, pp. 155–171.10.1080/00084433.2022.2035634Search in Google Scholar

[23] Abdullah, A. M., H. A. Jaber, and H. A. Al-Kaisy. Impact strength, flexural modulus and wear rate of PMMA composites reinforced by eggshell powders. Engineering Technology of Journal, Vol. 38, No. 07, 2020, pp. 960–966.10.30684/etj.v38i7A.384Search in Google Scholar

[24] Panchal, M., G. Raghavendra, A. R. Reddy, M. Omprakash, and S. Ojha. Experimental investigation of mechanical and erosion behavior of eggshell nanoparticulate epoxy biocomposite. Polymers and Polymer Composites, Vol. 29, No. 7, 2021, pp. 897–908.10.1177/0967391120943454Search in Google Scholar

[25] Ray, S., P. R. Pati, G. Gupta, and S. K. Nayak. Analysis and prediction of abrasion wear properties of glass–epoxy composites filled with eggshell powder. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2022, 10.1177/09544089221144188.Search in Google Scholar

[26] Oladele, I., B. Makinde-Isola, A. Adediran, M. Oladejo, A. Owa, and T. Olayanju. Mechanical and wear behaviour of pulverised poultry eggshell/sisal fiber hybrid reinforced epoxy composites. Materials Research Express, Vol. 7, 2020, id. 045304.10.1088/2053-1591/ab8585Search in Google Scholar

[27] Bose, S., A. Pandey, and A. Mondal. Comparative analysis on aluminum-silicon carbide hybrid green metal matrix composite materials using waste egg shells and snail shell ash as reinforcements. Materials Today: Proceedings, Vol. 5, 2018, pp. 27757–27766.10.1016/j.matpr.2018.10.011Search in Google Scholar

[28] Hassan, S., V. Aigbodion, and S. Patrick. Development of polyester/eggshell particulate composites. Tribology in Industry, Vol. 34, No. 4, 2012, pp. 217–225.Search in Google Scholar

[29] Petrasek, S. and M. Muller. Polymeric particle composites based on filler from hen egg-shells. Engineering Rural Development, International Scientific Conference, Jelgava, 2017.10.22616/ERDev2017.16.N034Search in Google Scholar

[30] Gapsari, F., A. Purnowidodo, P. H. Setyarini, S. Suteja, Z. Abidin, S. M. Rangappa, et al. Flammability and mechanical properties of Timoho fiber-reinforced polyester composite combined with iron powder filler. Journal of Materials Research and Technology, Vol. 21, 2022, pp. 212–219.10.1016/j.jmrt.2022.09.025Search in Google Scholar

[31] Villarreal-Lucio, D., J. Rivera-Armenta, A. Martínez-Hernández, and I. Estrada-Moreno. Effect of eggshell particle size in thermal and thermomechanical properties of PP/eggshell Composites. International Journal of Engineering Sciences and Research Technology, Vol. 7, No. 4, 2018, pp. 82–88.Search in Google Scholar

[32] Yilma, W. M., B. Singh, G. Asrat, and N. Hossain. Taguchi method optimization of water absorption behavior by wheat straw-basalt hybrid brake pad composite. Journal of Composites Sciences, Vol. 7, No. 2, 2023, id. 62.10.3390/jcs7020062Search in Google Scholar

[33] Pundir, R., G. Chary, and M. Dastidar. Application of Taguchi method for optimizing the process parameters for the removal of copper and nickel by growing Aspergillus sp. Water Resources Industry, Vol. 20, 2018, pp. 83–92.10.1016/j.wri.2016.05.001Search in Google Scholar

[34] Bachchhav, B. and K. Hendre. Wear performance of asbestos-free brake pad materials. Jordan Journal of Mechanical Industrial Engineering, Vol. 16, No. 4, 2022, pp. 459–469.Search in Google Scholar

[35] Kumar, S. and S. K. Ghosh. Porosity and tribological performance analysis on new developed metal matrix composite for brake pad materials. Journal of Manufacturing Processes, Vol. 59, 2020, pp. 186–204.10.1016/j.jmapro.2020.09.053Search in Google Scholar

[36] Mahale, V., J. Bijwe, and S. Sinha. Efforts towards green friction materials. Tribology International, Vol. 136, 2019, pp. 196–206.10.1016/j.triboint.2019.03.049Search in Google Scholar

[37] Gapsari, F., A. Purnowidodo, S. Hidayatullah, and S. Suteja. Characterization of Timoho Fiber as a reinforcement in green composite. Journal of Materials Research and Technology, Vol. 13, 2021, pp. 1305–1315.10.1016/j.jmrt.2021.05.049Search in Google Scholar

[38] Manalo, A. C., E. Wani, N. A. Zukarnain, W. Karunasena, and K. T. Lau. Effects of alkali treatment and elevated temperature on the mechanical properties of bamboo fibre-polyester composites. Composites Part B, Vol. 80, 2015, pp. 73–83.10.1016/j.compositesb.2015.05.033Search in Google Scholar

[39] Sugiman, S., P. D. Setyawan, and B. Anshari. Effects of alkali treatment of bamboo fibre under various conditions on the tensile and flexural properties of bamboo fibre/polystyrene-modified unsaturated polyester composites. Jouranal of Engineering Sciences and Technology, Vol. 14, No. 1, 2019, pp. 27–47.Search in Google Scholar

[40] Liu, Y., J. Xie, N. Wu, L. Wang, Y. Ma, and J. Tong. Influence of silane treatment on the mechanical, tribological and morphological properties of corn stalk fiber reinforced polymer composites. Tribology International, Vol. 131, 2019, pp. 398–405.10.1016/j.triboint.2018.11.004Search in Google Scholar

[41] Wang, Q., Y. Zhang, W. Liang, J. Wang, and C. Youxin. Effect of silane treatment on mechanical properties and thermal behavior of bamboo fibers reinforced polypropylene composites. Journal of Engineering Fibers Fabrics, Vol. 15, 2020, id. 1558925020958195.10.1177/1558925020958195Search in Google Scholar

[42] Ahmadijokani, F., A. Shojaei, M. Arjmand, Y. Alaei, and N. Yan. Effect of short carbon fiber on thermal, mechanical and tribological behavior of phenolic-based brake friction materials. Composites Part B, Vol. 168, 2019, pp. 98–105.10.1016/j.compositesb.2018.12.038Search in Google Scholar

[43] Palmiyanto, M., E. Surojo, D. Ariawan, and F. Imaduddin. Waste glass powder as a sustainable abrasive material for composite brake block. Tribology in Industry, Vol. 43, No. 3, 2021, pp. 363–372.10.24874/ti.1061.02.21.06Search in Google Scholar

[44] Krishnaiah, K., P. Shahabudeen. Applied Design of Experiments and Taguchi Methods, PHI Learning Private Limited, New Delhi, 2012.Search in Google Scholar

[45] Biokinetics and Associates Ltd. Review of motorcycle brake standards. NHTSA, 2003.Search in Google Scholar

[46] Ahmed, D. A. and M. M. Mulapeer. Differentiation of specific wear rates of AISI 304 austenitic and AISI 2205 duplex stainless steels at room and high temperatures. Heliyon, Vol. 8, 2022, id. e11807.10.1016/j.heliyon.2022.e11807Search in Google Scholar PubMed PubMed Central

[47] Demirdal, S. and F. Aydın. The influence of low-cost eggshell on the wear and electrochemical corrosion behaviour of novel pure Mg matrix composites. Materials Chemistry and Physics, Vol. 277, 2022, id. 125520.10.1016/j.matchemphys.2021.125520Search in Google Scholar

[48] Rajan, B. S., M. S. Balaji, and A. M. A. Noorani. Tribological performance of graphene/graphite filed phenolic composite - A comparative study. Composites Communication, Vol. 15, 2019, pp. 34–39.10.1016/j.coco.2019.05.012Search in Google Scholar

[49] Pornchai, T., A. I. Putkham, and A. Putkham. Effect of calcination time on physical and chemical properties of CaO-catalyst derived from industrial-eggshell wastes. Journal of Science and Technology Mahasarakham University, Vol. 35, No. 6, 2016, pp. 693–697.Search in Google Scholar

[50] Najah, M., A. Razak, N. A. C. S. Nekmat, S. Adzila, R. Othman, and N. Nordin. Characterization of calcium carbonate extracted from eggshell waste at various calcination temperature. International Journal of Emerging Trends in Engineering Research, Vol. 8, No. 10, 2020, pp. 6725–6731.10.30534/ijeter/2020/16810202Search in Google Scholar

[51] Nuryantini, A. Y., C. D. D. Sundari, H. Halimahtussa’diah, and B. W. Nuryadin. Synthesis and characterization of calcium oxide nanoparticles from duck eggshells using ball milling methods. Jurnal Kimia Valensi, Vol. 5, No. 2, 2019, pp. 231–235.10.15408/jkv.v5i2.8779Search in Google Scholar

[52] Gbadeyan, O., S. Adali, G. Bright, B. Sithole, and O. Awogbemi. Studies on the mechanical and absorption properties of achatina fulica snail and eggshells reinforced composite materials. Composite Structures, Vol. 239, 2020, id. 112043.10.1016/j.compstruct.2020.112043Search in Google Scholar

[53] Gapsari, F., A. M. Sulaiman, T. M. Putri, H. Juliano, L. Djakfar, R. P. Handajani, et al. Influence of calcium carbonate fillers on pine fiber reinforced polyester composites. Polymer Composites, Vol. 43, No. 7, 2022, pp. 4306–4317.10.1002/pc.26692Search in Google Scholar

[54] Iloabachie, I., O. Ajina, and A. Chime. Effect of egg shell composition on the flexural and hardness properties of epoxy resin/egg shell particles composite. Journal of Engineering Research Reports, Vol. 20, No. 11, 2021, pp. 1–7.10.9734/jerr/2021/v20i1117398Search in Google Scholar

[55] Ononiwu, N. H., C. G. Ozoegwu, N. Madushele, and E. T. Akinlabi. Carbonization temperature and its effect on the mechanical properties, wear and Corrosion resistance of aluminum reinforced with eggshell. Journal of Composite Science, Vol. 5, No. 262, 2021, id. 262.10.3390/jcs5100262Search in Google Scholar

[56] Tangboriboon, N., R. Kunanuruksapong, and A. Sirivat. Preparation and properties of calcium oxide from eggshells via calcination. Materials Science-Poland, Vol. 30, No. 4, 2012, pp. 313–322.10.2478/s13536-012-0055-7Search in Google Scholar

[57] Shah, A. H., Y. Zhang, X. Xu, A. Q. Dayo, X. Li, S. Wang, et al. Reinforcement of stearic acid treated egg shell particles in epoxy thermosets: Structural, thermal, and mechanical characterization. Materials, Vol. 11, No. 10, 2018, id. 1872.10.3390/ma11101872Search in Google Scholar PubMed PubMed Central

[58] Qhazi, I. F. Study the effect of the particle size on mechanical properties of particulate natural composite materials. Al-Qadisiyah Jouranal of Engineering Sciences, Vol. 10, No. 2, 2017, pp. 120–132.Search in Google Scholar

[59] Said, E., N. Elzayady, R. El-Soeudy, and A. Omar. Manufacturing and development of low cost asbestos-free brake pad composite material. Jouranal of Egyptian Social Tribol, Vol. 16, No. 1, 2019, pp. 55–67.Search in Google Scholar

[60] Unaldi, M. and R. Kus. The effect of the brake pad components to the some physical properties of the ecological brake pad samples. IOP Conference Series: Materials Science Engineering, Vol. 191, 2017, id. 012032.10.1088/1757-899X/191/1/012032Search in Google Scholar

[61] Yilmaz, A. C. Effects of fly ash introduction on friction and wear characteristics of brake pads. International Journal of Automotive Engineering Technology, Vol. 11, No. 3, 2022, pp. 96–103.10.18245/ijaet.1108124Search in Google Scholar

[62] Kalel, N., B. Bhatt, A. Darpe, and J. Bijwe. Copper-free brake-pads: A break-through by selection of the right kind of stainless steel particles. Wear, Vol. 464–465, 2021, id. 203537.10.1016/j.wear.2020.203537Search in Google Scholar

[63] Bhatt, B., N. Kalel, S. Ameta, S. Mittal, and J. Bijwe. Fe–Al alloy for eco-friendly copper-free brake-pads. Tribology International, Vol. 163, 2021, id. 107156.10.1016/j.triboint.2021.107156Search in Google Scholar

[64] Alajmi, A. E., J. G. Alotaibi, B. F. Yousif, and U. Nirmal. Tribological studies of bamboo fibre reinforced epoxy composites using a BOD technique. Polymers, Vol. 13, No. 15, 2021, id. 2444.10.3390/polym13152444Search in Google Scholar PubMed PubMed Central

[65] Srivastava, A. K., A. Saxena, and A. R. Dixit. Investigation on the thermal behaviour of AZ31B/waste eggshell surface composites produced by friction stir processing. Composites Communications, Vol. 28, 2021, id. 100912.10.1016/j.coco.2021.100912Search in Google Scholar

[66] Ma, Y., Y. Liu, and J. Tong. Bamboo wear and its application in friction material in bamboo - current and future prospects. IntechOpen, 2018, pp. 87–104.10.5772/intechopen.69893Search in Google Scholar

[67] S. International. Friction coefficient identification and environmental marking system for brake lining. SAE International, 2019.Search in Google Scholar

[68] Calderon, J. dD., A. Rojo, C. Perez, R. Lopez, and D. Vilchis. Comparative study of friction coefficient and wear in brake pads for disc brake. Proceedings of the ASME 2010 International Mechanical Engineering Congress & Exposition, Vancouver, BC, 2010.10.1115/IMECE2010-37876Search in Google Scholar

[69] Technology, D. A. B. Brake literature. DIXCEL, 2023. https://www.dixcel.co.jp/en/literature/lid-2235/#:∼:text = In%20general%2C%20OEM%20brake%20pads,create%20a%20high%20braking%20force [Accessed 23 June 2023].Search in Google Scholar

[70] Pani, P. R., R. Nayak, B. Routara, and P. Sekhar. Flexural and specific wear rate of seawater aged bamboo, Jute and glass fiber reinforced polymer hybrid composites. Materials Today: Proceedings, Vol. 18, 2019, pp. 3409–3414.10.1016/j.matpr.2019.07.268Search in Google Scholar

[71] Waheed, M., M. Yousaf, A. Shehzad, M. Inam-Ur-Raheem, M. K. I. Khan, M. R. Khan, et al. Channelling eggshell waste to valuable and utilizable products: A comprehensive review. Trends Food Science Technology, Vol. 106, 2020, pp. 78–90.10.1016/j.tifs.2020.10.009Search in Google Scholar

[72] Ajibade, O. A., J. O. Agunsoye, and S. A. Oke. A wear rate model incorporating infationary cost of agro‐waste filled composites for brake pad applications to lower composite cost. SN Applied Sciences, Vol. 3, 2021, id. 20.10.1007/s42452-020-04016-ySearch in Google Scholar

[73] Toro, P., R. Q. Abarca, J. L. Arias, and M. Yazdani-Pedram. Mechanical and morphological studies of poly(propylene)-filled eggshell composites. Macromolecular Materials and Engineering, Vol. 292, No. 9, 2007, pp. 1027–1034.10.1002/mame.200700147Search in Google Scholar

[74] Hassan, S. and V. Aigbodian. Effects of eggshell on the microstructures and properties of Al–Cu–Mg/eggshell particulate composites. Journal King Saud University – Engineering Sciences, Vol. 27, 2015, pp. 49–56.10.1016/j.jksues.2013.03.001Search in Google Scholar

[75] Dweiri, R. Processing and characterization of surface treated chicken eggshell and calcium carbonate particles filled high-density polyethylene composites. Materials Research, Vol. 24, No. 3, 2021, id. e20210078.10.1590/1980-5373-mr-2021-0078Search in Google Scholar

[76] Balan, G. S., A. M. Krishnan, S. Saravanavel, and M. Ravichandran. Investigation on properties of bahunia racemosa fiber and egg shell powder reinforced polymer composite. Materials Today: Proceedings, Vol. 33, 2020, pp. 4084–4089.10.1016/j.matpr.2020.06.544Search in Google Scholar

[77] Sakuri, S., E. Surojo, D. Ariawan, and A. R. Prabowo. Investigation of Agave cantala-based composite fibers as prosthetic socket materials accounting for a variety of alkali and microcrystalline cellulose treatments. Theoretical and Applied Mechanics Letters, Vol. 10, No. 6, 2020, pp. 405–411.10.1016/j.taml.2020.01.052Search in Google Scholar

[78] Sakuri, S., E. Surojo, D. Ariawan, and A. R. Prabowo. Experimental investigation on mechanical characteristics of composite reinforced Cantala Fiber (CF) subjected to microcrystalline cellulose and fumigation treatments. Composites Communications, Vol. 21, 2020, id. 100419.10.1016/j.coco.2020.100419Search in Google Scholar

[79] Ariawan, D., T. S. Rivai, E. Surojo, S. Hidayatulloh, H. I. Akbar, and A. R. Prabowo. Effect of alkali treatment of Salacca Zalacca fiber (SZF) on mechanical properties of HDPE composite reinforced with SZF. Alexandria Engineering of Journal, Vol. 59, No. 5, 2020, pp. 3981–3989.10.1016/j.aej.2020.07.005Search in Google Scholar

[80] Ariawan, D., E. Surojo, J. Triyono, I. F. Purbayanto, A. F. Pamungkas, and A. R. Prabowo. Micromechanical analysis on tensile properties prediction of discontinuous randomized zalacca fibre/high-density polyethylene composites under critical fibre length. Theoretical and Applied Mechanics Letters, Vol. 10, No. 1, 2020, pp. 57–65.10.1016/j.taml.2020.01.009Search in Google Scholar

[81] Akbar, H. I., E. Surojo, D. Ariawan, A. R. Prabowo, and F. Imanullah. Fabrication of AA6061-sea sand composite and analysis of its properties. Heliyon, Vol. 7, No. 8, 2021, id. e07770.10.1016/j.heliyon.2021.e07770Search in Google Scholar PubMed PubMed Central

[82] Akbar, H. I., E. Surojo, D. Ariawan, and A. R. Prabowo. Technical investigation of sea sand reinforcement for novel al6061-sea sand composites: Identification of performance and mechanical properties. Periódico Tchê Química, Vol. 17, No. 36, 2020, pp. 47–57.10.52571/PTQ.v17.n36.2020.63_Periodico36_pgs_47_57.pdfSearch in Google Scholar

[83] Fanani, E. W. A., E. Surojo, A. R. Prabowo, and H. I. Akbar. Recent progress in hybrid aluminum composite: Manufacturing and application. Metals, Vol. 11, No. 12, 2021, id. 1919.10.3390/met11121919Search in Google Scholar

[84] Fanani, E. W. A., E. Surojo, A. R. Prabowo, D. Ariawan, and H. I. Akbar. Recent development in aluminum matrix composite forging: Effect on the mechanical and physical properties. Procedia Structural Integrity, Vol. 33, 2021, pp. 3–10.10.1016/j.prostr.2021.10.002Search in Google Scholar

[85] Akbar, H. I., E. Surojo, D. Ariawan, and A. R. Prabowo. Experimental study of quenching agents on Al6061–Al2O3 composite: Effects of quenching treatment to microstructure and hardness characteristics. Results in Engineering, Vol. 6, 2020, id. 100105.10.1016/j.rineng.2020.100105Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study