Abstract

The mechanical properties of large 2219 Al–Cu alloy rings need to be further improved with the diameter of the launch vehicle being more than 10 m. In this study, the effects of cold rolling (CR) and cold compression on microstructure evolution and the comprehensive mechanical properties of such rings were compared. The evolution of dislocation characteristics, grain structure, second phase, and the mechanical properties of the T8-aged samples were examined. Results show that compared with CR, because of deformation characteristics, cold compression deformation induces less increase in dislocation densities; however, the increase in dislocation densities on the core was higher than at other positions, resulting in a more uniform grain structure and elongation in the axial and radial direction. The cold compression deformation contributes to the uniform dissolution of the secondary phase, resulting in denser precipitates, and thus improved strength. Brittle fractures occur in fewer CR samples because of the longer moving distance of the Al matrix. In summary, both CR and cold compression can improve the mechanical properties. However, the cold-compressed sample exhibits more uniform microstructure and higher comprehensive mechanical properties (the radial elongation increased from 7.1 to 11.2%; the in-plane anisotropy decreased from 36.6 to 8.9%), without any brittle fractures, because of more uniform metal flow.

1 Introduction

With the development of space exploration, the diameter of the launch vehicle is more than 10 m, and the tank transition ring, which is the core component connecting the tank and the rocket body, has a higher mechanical property index [1]. Previous studies show that cold deformation is a highly effective method, which can be used to greatly change the microstructure of the 2219 Al–Cu alloy [2,3]. Based on the original manufacturing process, the additional cold deformation can lead to the formation of fine grains and crystalline phases, improving the comprehensive mechanical properties of rings. However, different cold deformation modes exhibit different deformation characteristics, and the microstructure evolution of cold deformation is complex and difficult to control [4,5].

The microstructure and mechanical properties of Al alloy can be fully changed by deformation via cold compression [6,7]. Lu et al. [8] performed multidirectional axial compression of a 2297 Al alloy sheet at 160℃ to induce different cumulative strains. The results show that the tensile strength of the sheets increases from 267 to 480 MPa due to the higher density and smaller precipitated phase of the new dislocations. Due to the destruction of the dislocated structures by the high-strain deformation mode, a large amount of precipitated phase should be located in the original dislocation, so the size of the precipitated phase is effectively reduced. The smaller precipitated phase also attenuates the local hardening during the tensile process and also yields a higher elongation (11.2%). Dong et al. [9] studied the effects of ultra-low-temperature compression on the second-phase particles of 2219 aluminum alloy. The results show that the ultra-low-temperature compression disrupts the coarse second-phase particles significantly. The crystalline phase is more soluble in the matrix, which enhances precipitation and reduces the stress concentration in the matrix, resulting in a significant improvement in the mechanical properties of the alloy.

Cold rolling (CR) is another conventional cold deformation mode [10,11]. Changela et al. [12] reported that constrained groove pressing, followed by CR, is an effective alternate route to produce Al alloy sheets with ultra-fine microstructure. The 4.7 μm fine crystal Al-6.5 Mg alloy was prepared by high strain rate hot rolling at 400℃, resulting in a combination of low ultimate strength (354 ± 1 MPa) and high elongation (34 ± 0.9%). After subsequent CR treatment, the ultimate strength was further increased to 454 ± 2 MPa, and the ductility was 9.2 ± 1.1%. The strength improvement was mainly due to the combination of strain hardening, grain refinement, and high Mg content because of additional solute during CR.

Some studies were about the comparison of deformation behaviors of cold compression and CR [13]. First, the deformation mechanisms were studied. By comparing the deformation process and crystal orientation characteristics of rolling and compression deformation, Fujita et al. [14,15] found that the metal flow for the two deformation modes was very different. Rolling was the surface material extending around unevenly, and compression was the intermediate material extending outwards. In addition, the textures formed in the uniaxially compressed rod and rolled sheet are not similar. On the other hand, the focus was on the differences in microstructures and mechanical properties caused by two such modes of deformation. The effects of cold stretching and cold compression on the microstructure evolution and strong plasticity of Al–Cu–Mg–Si alloy were compared [16]. Compared with no deformation, the sample with 4% cold compression had a finer θ′ phase, higher dislocation density, and larger contact angle of Al2Cu phases, resulting in higher strength and lower plasticity. Compared with 4% cold compression, the proportion of the θ′ phase of the cold stretching sample was higher and the contact angle of the Al2Cu phase was smaller. Therefore, the cold stretching sample of Al–Cu–Mg–Si alloy exhibits higher strength and plasticity.

Guo et al. [17,18] adopted cold compression and CR to induce the deformation of large 2219 Al–Cu alloy rings. Both cold deformation modes cause large accumulation of dislocations, contributing to grain refinement and dissolution of the Al2Cu phase, and improved strength and plasticity of the ring. However, the two deformation modes had different effects on the ring microstructure and mechanical properties. In order to further accurately control the microstructure and mechanical properties of the ring, this study compared the effects of two cold deformation modes on the microstructure evolution and comprehensive mechanical properties of the large ring, and the effects of different cold deformations on the microstructure and properties of the ring were fully explored. This study focused on the variation in dislocation density under cold deformation, the grain structure of different parts, the dissolution behavior of the second phase in the solution after cold deformation, and the subsequent aging precipitation to further analyze the mechanical behavior.

2 Experimental procedure

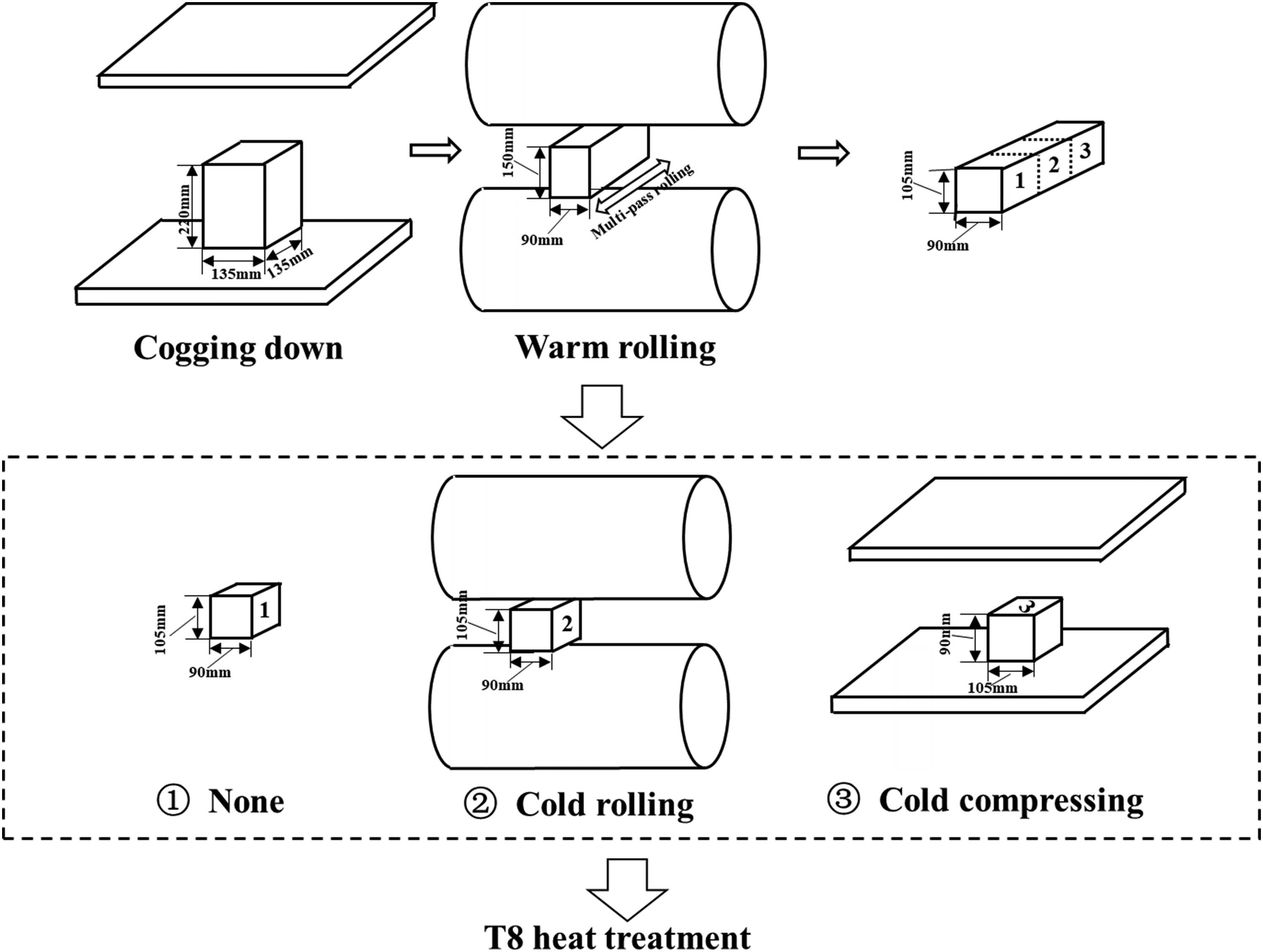

The elemental composition of the 2219 Al–Cu alloy is shown in Table 1. Figure 1 shows the process of cold deformation comparison of the 2219 Al–Cu alloy. The test method is shown in Figure 2, and the process parameters are presented in Table 2. A sample with dimensions of 135 (circumferential direction) × 220 (radial direction) × 135 (axial direction) mm was cut from the Φ1,200 mm 2219 Al alloy ingots. The samples were billeted by multi-direction forging first, followed by warm rolling at 240℃/25%. The single rolling pressure was 4.0 mm, which simulated the real ring rolling process, followed by cold deformation. According to the shape characteristics of the application object, a large ring, the selected cold deformation mode involved radial CR and axial cold compression. The three specific terms of comparison include no cold deformation, CR deformation, and cold compression deformation, with an overall deformation of 5%. The subsequent heat treatment (T8) entailed solution treatment for 4 h at 540℃, followed by water quenching and deformation via cold compression (3%). After cold deformation, they were directly transferred to the aging furnace for 30 h at 155℃.

The chemical composition of the 2219 Al alloy used in this test (wt%)

| Si | Fe | Cu | Mn | Mg | Zn | V | Ti | Zr | Al |

|---|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.3 | 6.02 | 0.40 | 0.02 | 0.1 | 0.08 | 0.08 | 0.12 | Bal |

Experimental process of the cold deformation comparison.

Experimental method of the cold deformation comparison.

Parameters of cold deformation comparison

| Rolling temperature (°C) | Rolling deformation | Single rolling reduction (mm) | Cold deformation parameters | Heat treatment | |

|---|---|---|---|---|---|

| 1 | 240 | 25% | 4.0 | None | 540℃*4 h solution |

| 2 | 5% CR | +3% compression | |||

| 3 | 5% CP | +155℃*30 h aging |

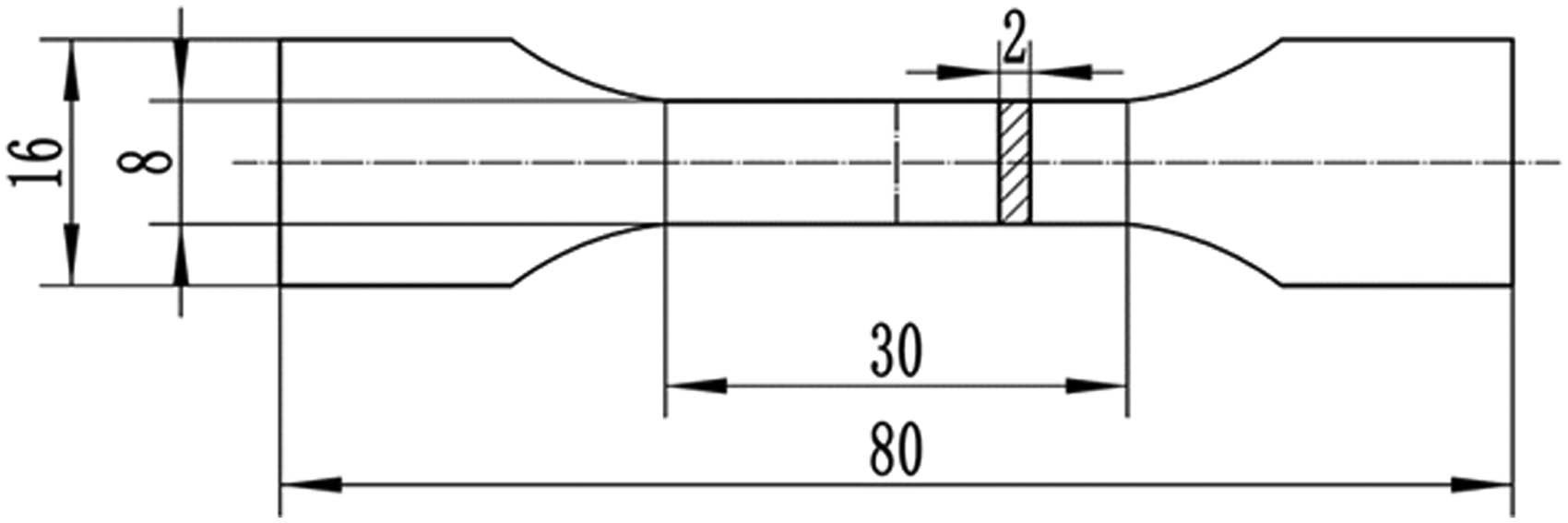

The corresponding directions and positions of each sample are shown in Figure 3. The tensile tests were conducted on the WDW-100A universal testing machine with a tensile speed of 2.0 mm·min−1. The shape of the mechanic’s performance testing sample is shown in Figure 4. Tensile tests based on the GB-T228-2002 standard were performed in the axial, radial, and circumferential directions (AD, RD, and CD), the tensile tests were conducted thrice in each direction, and the measured values were averaged. The grain structure of the 2219 Al–Cu alloy was analyzed with an OLYMPUS DSX500 metallographic microscope. The sample was polished using the Keller reagent (HF/HCl/HNO3/H2O = 2:3:5:190). The coarse second phase particles and fracture structure were observed and analyzed by scanning electron microscopy (SEM)(model: Phenom ProX desktop SEM); element composition of phases in the Al matrix or fracture surface and Cu content in the matrix were measured by SEM-energy dispersive spectrometer (EDS) analysis. In this experiment, dislocations and precipitation were observed and analyzed via Tecnai G2 F20 emission transmission electron microscopy (TEM).

Positions and directions of samples.

The shape of the mechanical property testing sample.

3 Results

3.1 Dislocation characteristics after cold deformation

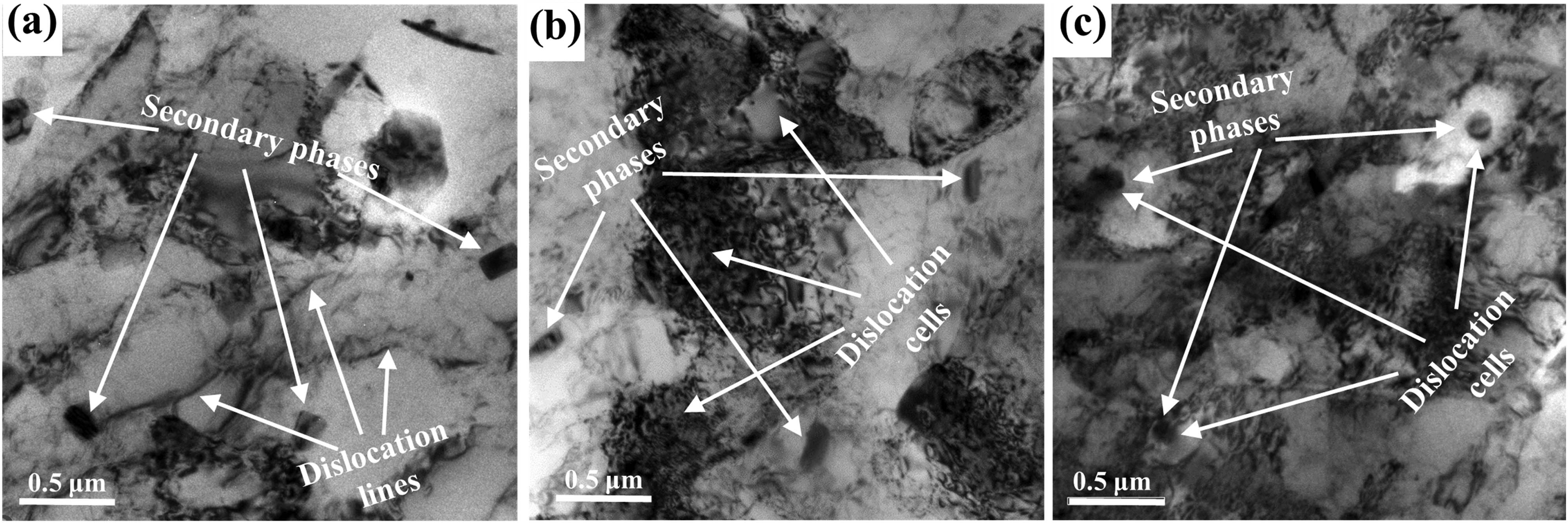

Figure 5 shows the dislocation characteristics of the Al matrix after cold deformation at the core sampling location. By scanning transmission electron microscopy-EDS analysis, the variety of secondary phases to each sample was all Al2Cu. As shown in Figure 5(a), warm rolling induced obvious dislocations in the matrix, and intertwined dislocation lines. The secondary phase was relatively dispersed without an obvious relationship with dislocation structures. As shown in Figure 5(b), after radial CR, a large number of dislocations accumulated locally in the Al matrix and spread across multiple regions through the dislocation wall. The sub-crystalline structures formed initially. Concurrently, many areas with lower dislocation densities were observed. No obvious interactions between the secondary phase and dislocation structures were found. As shown in Figure 5(c), after axial cold compression, obvious dislocation entanglements in most areas of the Al matrix indicated the flow of metal flows more evenly during cold compression than in CR, and a more uniform dispersion and accumulation of dislocations. The dislocation-free area around the secondary phase, namely the dislocation cell structure, indicates that the secondary phase, as a stress concentration location, can lead to the accumulation of a large number of dislocations during cold compression.

Dislocation structures after cold deformation. (a), (b) and (c) Cold deformation mode without deformation, 5% CR, and 5% cold compression, respectively.

With the change in the dislocation structure, the dislocation densities also change. Table 3 shows the dislocation density (obtained by XRD analysis) of samples with different cold deformations at the core in the longitudinal section. The relationship between the relevant data obtained by XRD and the dislocation densities in the sample is represented by the following equations:

Dislocation densities at each position

| Core (×1,014 m−2) | Quarter (×1,014 m−2) | Border (×1,014 m−2) | |

|---|---|---|---|

| None | 0.26 ± 0.03 | 0.30 ± 0.02 | 0.37 ± 0.02 |

| 5% CR | 0.79 ± 0.05 | 0.86 ± 0.09 | 0.93 ± 0.10 |

| 5% CP | 0.58 ± 0.05 | 0.52 ± 0.07 | 0.46 ± 0.07 |

Here, δ2θ is the half peak-width; θ

0 is the maximum position of each diffraction peak;

The dislocation density of the sample undergoing only warm rolling was 0.26 × 1014 m−2. After 5% CR deformation, the dislocation density of the sample increased greatly, reaching 0.79 × 1014 m−2. In comparison, the dislocation density increase by cold compression was less than that of CR, which was 0.58 × 1014 m−2. The results show that the dislocation density of the 2219 aluminum alloy can be significantly increased by cold deformation. The increase of CR deformation was stronger than that of cold compression. The change in the dislocation density corresponds to the change in the dislocation structure. The dislocation distribution in the matrix of the CR sample was more concentrated, and the regions of high dislocation density and free region were separated from each other. However, the dislocation distribution in the cold-compressed sample was more dispersed, and dislocations accumulated in the dispersed secondary phase. These factors contribute to the differential increase in the amplitude of dislocation densities for each sample subjected to cold deformation. In addition, the standard deviation of the dislocation density of each sample with different cold deformation modes indicate the local dislocation density uniformity of alloy after CR is lower than that of cold compression. This is related to the deformation characteristics of CR.

After radial CR and axial cold compression, the dislocation densities of the 2219 Al–Cu alloy changed significantly peripherally, and at quarter and core positions. Table 3 shows dislocation density values. In the case of the undeformed sample, the dislocation densities of the core, quarter, and edge increased successively, and the increment from the periphery to the quarter position was large, which is consistent with the distribution of flow stress during warm rolling, indicating the minor change in the deformation from the core to the quarter, and the large change from the quarter to the periphery during warm rolling. Exposure to 5% radial CR substantially increased the dislocation densities of different components, and the increase in amplitude was relatively similar, indicating uniformity of CR deformation, and the uniform increase in the dislocation density of different sample components. Exposure to 5% axial cold compression increased the dislocation densities of different parts, with a maximum increase in the core, followed by the quarter, and the periphery, indicating that the cold compression contributed to the increased core deformation. Compared with CR deformation, the deformation induced by cold compression effectively improved the dislocation densities of the core. However, the core dislocation densities were lower in the absence of cold deformation, which led to uniform dislocation densities of the cold-compressed sample.

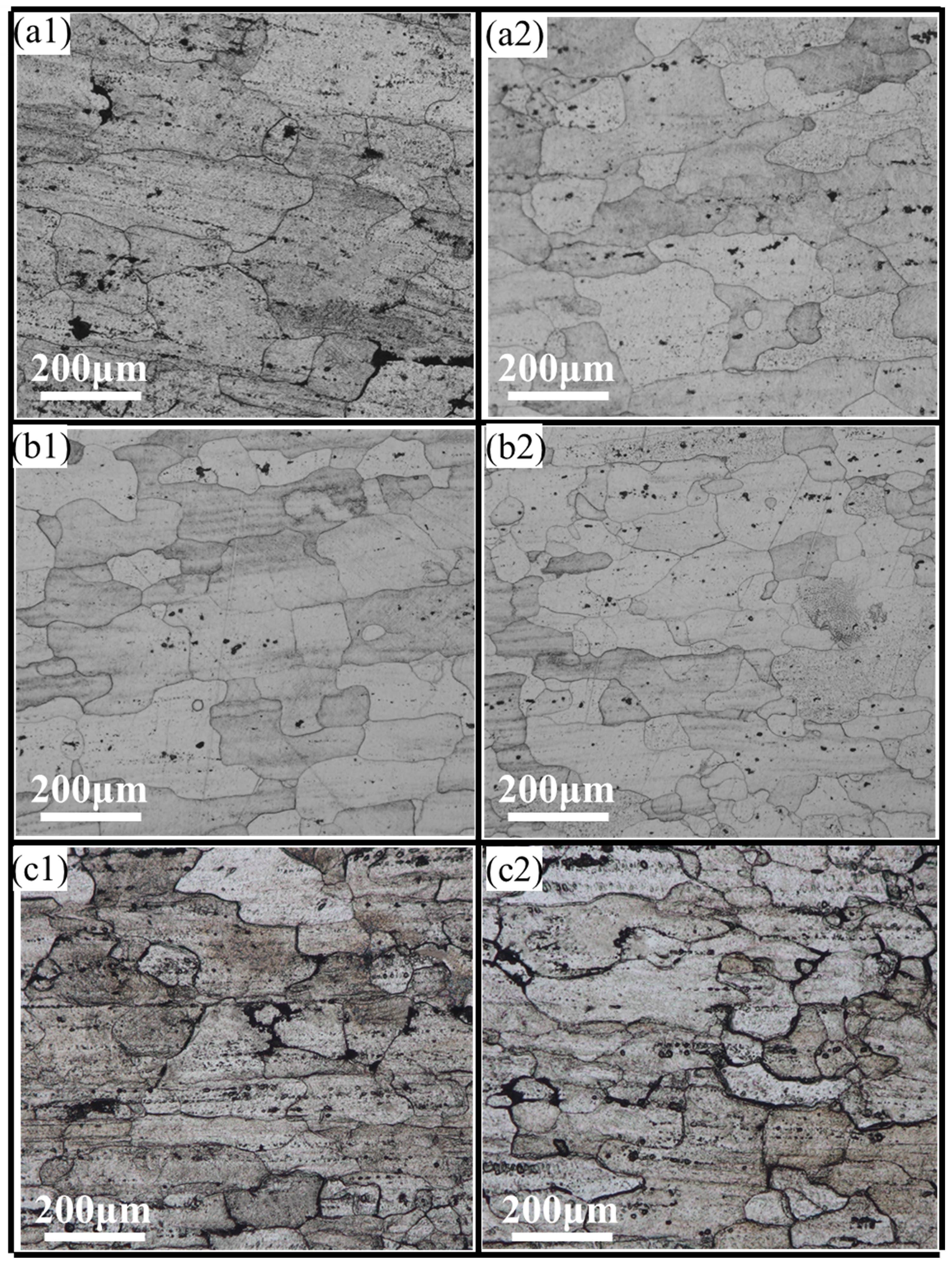

3.2 Grain structure characteristics after heat treatment

After heat treatment, each sample recrystallized completely. Figure 6 shows the grain structures of the sample periphery and core under different cold deformation modes. Table 4 presents the statistical results of the grain size. The average grain size of the sample without cold deformation was coarse (>162.0 μm). The grain size at the periphery was obviously finer than at the core, with a difference of 36.0 μm. Under 5% radial CR deformation, the average diameter of the grain at the periphery and core decreased by more than 50.0 μm. The difference in size between the periphery and the core decreased to 24.0 μm. Under 5% axial cold compression, the grain diameters at both the periphery and the core also decreased. The grain diameters of the core decreased greatly, while the grain diameters at the periphery decreased slightly. The difference in grain diameter between the border and the core was only 8.0 μm, and the grain structure uniformity greatly improved. In addition, comparing the aspect ratio of the three samples, it can be seen that after cold deformation, the equiaxial degree of grains at each position showed little change.

Grain structures of the sample under different cold deformations. (a1), (b1), and (c1) Longitudinal (core) grain structures in the absence of deformation, in the presence of CR, and cold compression, respectively. (a2), (b2), and (c2) Longitudinal (peripherally) grain structures in the absence of deformation, in the presence of CR, and cold compression, respectively.

Statistical results of the grain size

| Grain size | Aspect ratio of grains | |||||

|---|---|---|---|---|---|---|

| Core (μm) | Border (μm) | Difference (μm) | Core (μm) | Border (μm) | Difference (μm) | |

| None | 198.0 ± 25.0 | 162.0 ± 22.0 | 36.0 | 1.5 | 1.4 | 0.1 |

| 5% CR | 137.0 ± 14.0 | 113.0 ± 13.0 | 24.0 | 1.5 | 1.5 | 0 |

| 5% CP | 146.0 ± 20.0 | 138.0 ± 18.0 | 8.0 | 1.5 | 1.4 | 0.1 |

The statistical results of the grain size are basically consistent with the dislocation densities of each position, indicating the effectiveness of the method for refining grain structure of the 2219 Al–Cu alloy via cold deformation and additional dislocation. Cold compression is preferential because of the larger increase in the degree of deformation at the core, which is contrary to the effects of warm rolling. Thus, it improved the uniformity of the grain structure.

3.3 Second-phase dissolution and precipitation behavior during heat treatment

After heat treatment, the second phases of different samples undergoing cold deformation were dissolved to various degrees. Figure 7 shows the corresponding characteristics of Al2Cu phases on the core of the longitudinal section. Table 5 presents the statistical results of Cu content (SEM-EDS was used for elemental analysis); although the accuracy of this test method is not the highest, it is enough to form regular findings through obtained data from this test). In Figure 7, the Cu content in the Al matrix near the Al2Cu phase is compared. The yellow arrow points to the selected measurement point, and the two measurement points deviate from 15 μm. The Cu content in the sample matrix with 0% deformation, 5% CR, and 5% cold compression was reduced by 0.29, 0.1 and 0.21%, respectively, while the corresponding average Cu content in the matrix was 4.77, 5.03 and 4.96%, respectively. The diffusion range of Cu atoms during the dissolution was extended under cold deformation. The dissolution of the Al2Cu phase was adequate, and the Cu content in the Al matrix was increased by cold deformation. In addition, compared with cold compression, CR facilitated the increased diffusion efficiency of Cu atoms close to coarse Al2Cu phases during the dissolution process.

Al2Cu phases of the sample under different cold deformations. (a), (b) and (c) Sample with no cold deformation, 5% CR, and 5% cold compression deformation, respectively.

Cu content in the Al matrix (%), Al2Cu phase diameter (μm) and area fraction (%)

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Mean value | Standard deviation | Al2Cu phase diameter | Area fraction of Al2Cu phases | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| None | 5.15 | 4.57 | 4.6 | 5.12 | 5.01 | 5.15 | 4.39 | 4.41 | 4.48 | 4.82 | 4.77 | ±0.32 | 15.6 | 0.74 |

| 5% CR | 5.27 | 5.07 | 4.75 | 5.19 | 4.83 | 4.63 | 5.24 | 5.33 | 5.21 | 4.82 | 5.03 | ±0.25 | 13.6 | 0.62 |

| 5% CP | 4.78 | 4.82 | 4.82 | 5.12 | 5.24 | 5.07 | 4.92 | 4.79 | 4.85 | 5.16 | 4.96 | ±0.17 | 12.5 | 0.53 |

As shown in Table 5, the Al2Cu phase diameter and area fraction of Al2Cu phases in the matrix with 0% deformation, 5% CR, and 5% cold compression were in descending order. The diffusion behavior of Cu atoms indicates that the cold compression was more favorable to the fragmentation of Al2Cu particles, increasing the diffusion range of Cu atoms. By cold compression process, there are more dislocations accumulation on the coarse Al2Cu phases, and such dislocation accumulation process can make more Al2Cu phase exceed the critical load required for fragmentation, achieve more frequent fragmentation, and lower the mean diameter.

In addition, by comparing the standard deviation of the Cu content in the Al matrix of samples under different cold deformations, it can be seen that the Cu content of the Al matrix in the 5% cold-compressed sample was the most uniform. The minimal standard deviation indicates that the cold compression contributed to the uniformity of the Cu atom diffusion during the solution treatment. The cold compression increased the number of dislocation channels enormously around the secondary phase to promote atomic diffusion, while the secondary phase distribution was relatively dense.

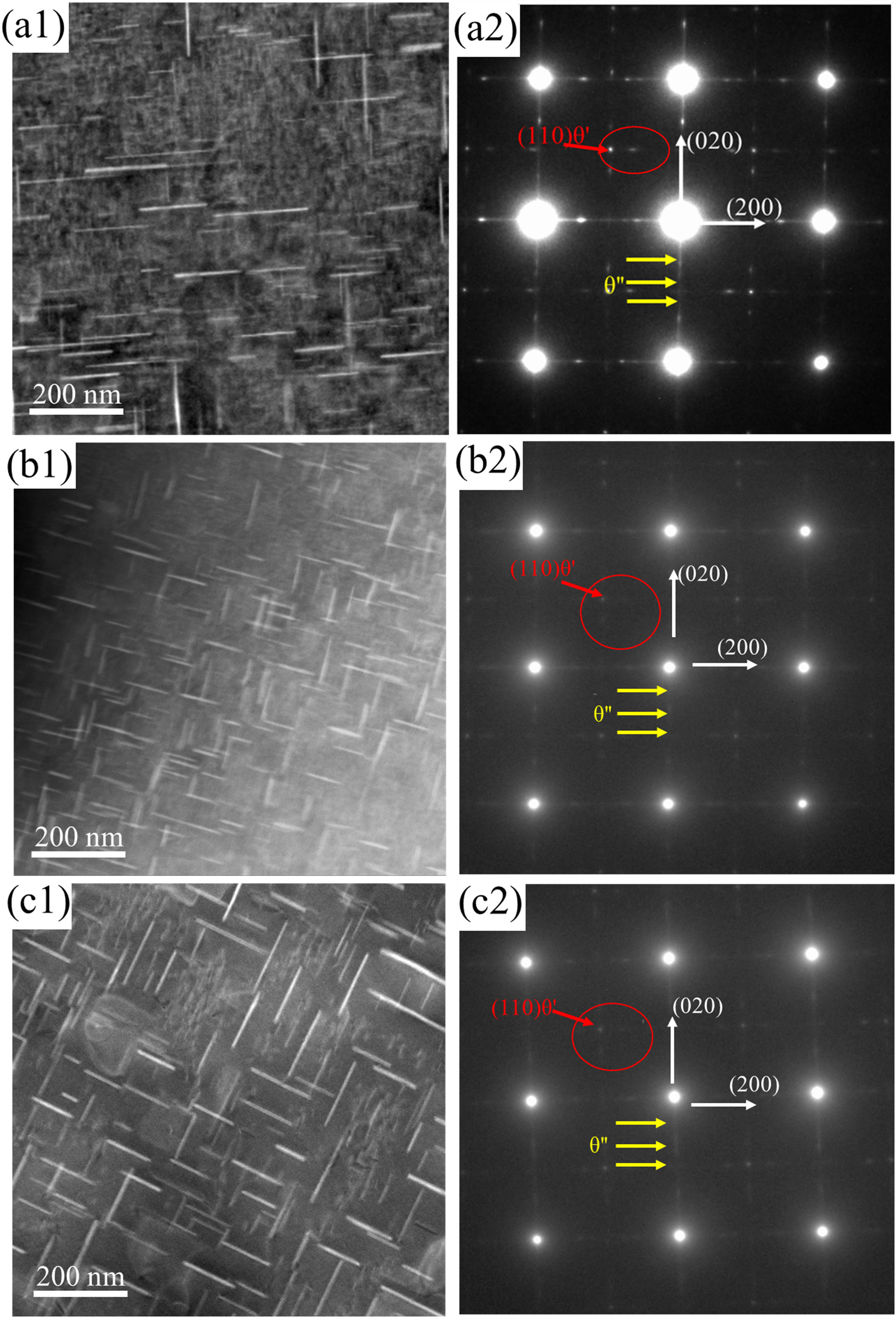

Figure 8 shows the TEM images of the sample under different cold deformations after aging. Table 6 presents the statistical results of the precipitated phase sizes. The sampling location is the core. As shown in Figure 7(a2), (b2) and (c2), the selected diffraction spots were analyzed (white arrows in SAED indicate {110} and {020} directions). Diffraction spots of θ′ and θ″ phases are observed in the selected diffraction spots of each sample. In TEM images, the coarse needle-like phase is the θ′ phase. which is also the main strengthening phase of 2219 Al–Cu alloy. (In the three-dimensional space, the θ′ phase appears as a disk shape. TEM images of only the cross section. The length of the “needle” is the diameter of the “disk,” and the width of the “needle” is the thickness of the “disk” [21,22].) When the θ′ phase is dense and uniform, the yield strength of the 2219 aluminum alloy is high. The slight, dense, and needle-like phases are represented by θ″.

Characteristics of the sample precipitate under different degrees of cold deformations. (a1), (b1), and (c1) Samples with 0% cold deformation, 5% CR, and 5% cold compression. (a2), (b2), and (c2) Corresponding diffraction spots.

θ′ phase results after T8 heat treatment

| Average volume fraction of the θ′ phase (%) | Average diameter of the θ′ phase (nm) | Average thickness of the θ′ phase (nm) | |

|---|---|---|---|

| None | 8.4 | 147.0 | 6.22 |

| 5% CR | 9.3 | 111.0 | 5.42 |

| 5% CP | 10.8 | 118.0 | 6.20 |

Figure 8(a1) shows TEM images of samples without cold deformation, the non-uniform distribution of the θ′ phase, and an obvious precipitation-free area. The diameter is 147.0 nm, the thickness is 6.22 nm and the volume fraction is 8.4%. (The volume fraction can be obtained by multiplying the average volume by the amount of the disk-shaped precipitates on the measured area, divided by the product of the area and the thickness of the measured area.) As shown in Figure 8(b1), the θ′ phase diameter of the 5% cold-rolled sample decreased to 111.0 nm and the thickness decreased to 5.42 nm. However, the θ′ phase distribution is denser and more uniform, without obvious precipitation-free region, and the volume fraction increased to 9.3%. As shown in Figure 8(c1), the θ′ phase diameter of the 5% cold-compressed sample increased to 118.0 nm, the thickness increased to 6.20 nm, and the distribution is distribution is denser and more uniform, with a volume fraction of 10.8%. The cold-compressed sample showed a greater increase in the size and a more uniform distribution of θ′ phase after heat treatment, compared to the cold-rolled sample.

Cold deformation can induce a large number of entangled dislocations around the Al2Cu phase, the dislocations act as atomic diffusion channels, can improve the dissolution of the phases, and enhance the Cu content in the Al matrix, increasing the density of the precipitated phases. Compared with CR, the dislocation structures are more inclined to wind around the secondary phases after cold compression. Because of a denser distribution of the secondary phase, and a large number of dislocations around the phases, the diffusion and range of Cu atoms in solution treatment improved greatly, enhancing Cu supersaturation in the Al matrix, and the uniform dispersion of Cu in the matrix, resulting in denser and more uniform distribution of the θ′ phase. In addition, the size of the θ′ phase also increased because of such Cu supersaturation in the Al matrix.

3.4 Mechanical properties and fracture behaviors

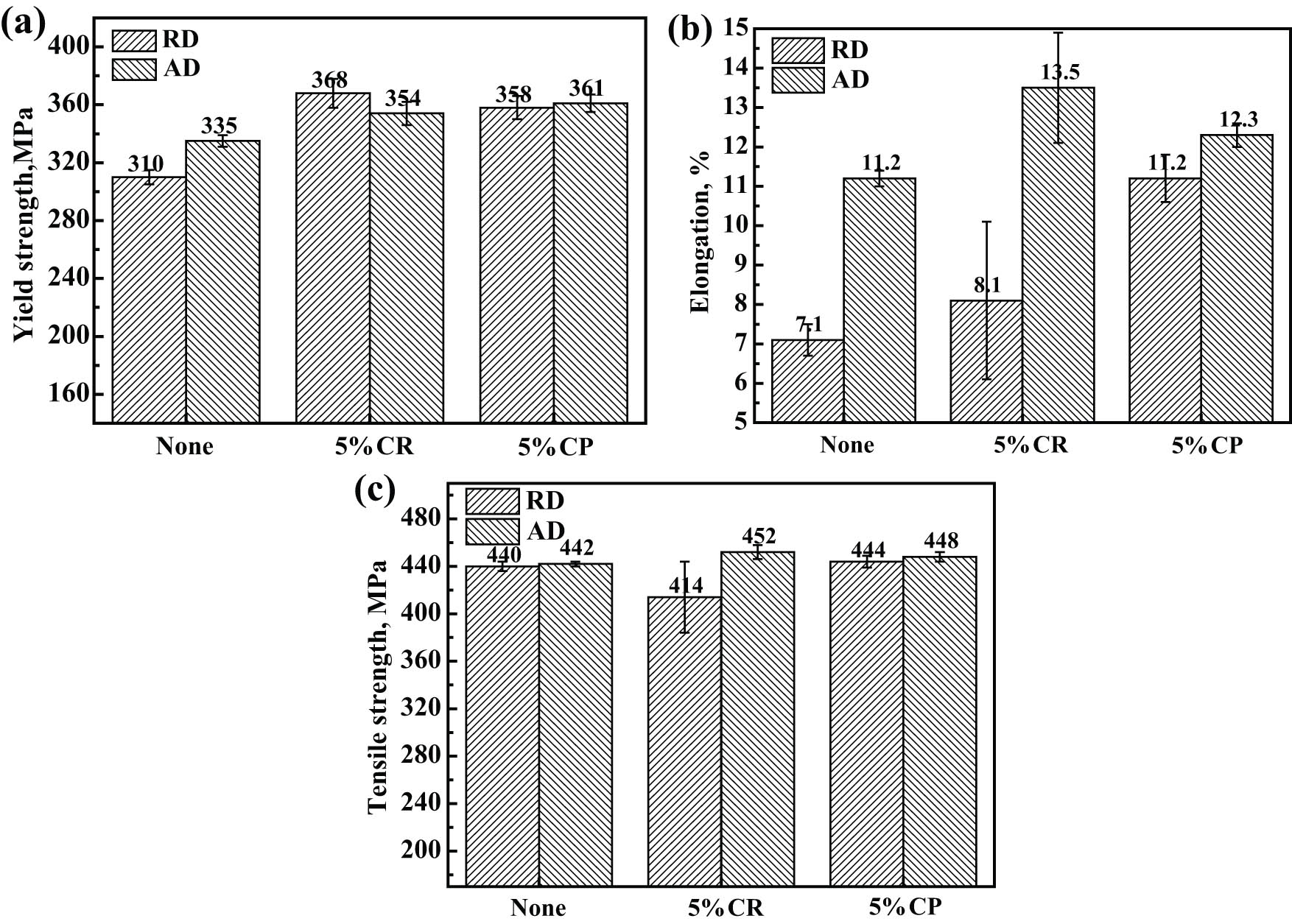

Figure 9 shows the effects of different cold deformation modes on the overall mechanical properties of large 2219 Al–Cu alloy rings. This content only reflects the axial and radial directions (with excellent circumferential performance). As shown in Figure 9(a), compared with 0% cold deformation sample, the mechanical properties were effectively improved by adding 5% cold-rolled samples. The radial yield strength increased from 310 to 368 MPa and the elongation increased from 7.1 to 8.1%. However, the tensile strength decreased significantly from 440 to 414 MPa. The axial tensile strength increased from 421 to 453 MPa; the yield strength increased from 323 to 334 MPa, while the elongation increased from 6.8 to 7.6%. Under 5% cold compression, the mechanical properties of the sample also improved significantly, with the largest increase in the yield strength and elongation of the ring. The radial yield strength increased from 310 to 358 MPa, and the elongation increased from 7.1 to 11.2%. The axial yield strength increased from 335 to 361 MPa, and the elongation increased from 11.2 to 12.3%. Both axial and radial tensile strengths improved slightly.

Mechanical properties after heat treatment: (a) yield strength, (b) elongation, and (c) tensile strength.

The mechanical properties of the samples in the current study were compared with the previous studies. Compared with the sample whose warm rolling deformation reaches 40%, the axial elongation is similar, and other mechanical property indexes have no certain advantages, indicating that the mechanical properties cannot be linearly increased by increasing the deformation amount of warm rolling [23]. Before rolling, by changing the hot forging to warm forging, severe plastic deformation is achieved; the tensile strength, yield strength, and elongation of the sample are higher than those of the current studies, especially the tensile strength and yield strength. However, due to the severe metal flow during the warm forging process, instability and cracking are likely to occur, and the warm forging needs further exploration in industry [2]. Adopting cryogenic technology to study the deformation limit and mechanical properties of the 2219 Al–Cu alloy is another exploration direction [24]. After cryogenic deformation treatment (−190℃/20%), the mechanical properties have been greatly improved compared with the normal temperature deformation, especially the tensile strength and yield strength. However, with cryogenic technology, it is difficult to realize industrial manufacturing for large components. On the contrary, the cold deformation with a small deformation amount adopted in this study is easier to realize in industrial manufacturing, having industrial application prospects. Moreover, many experiments have been carried out, including complete laboratory simulation, and selecting the samples after industrial rolling for cold deformation experiments; the evolution laws of microstructures and mechanical properties are stable [17,18].

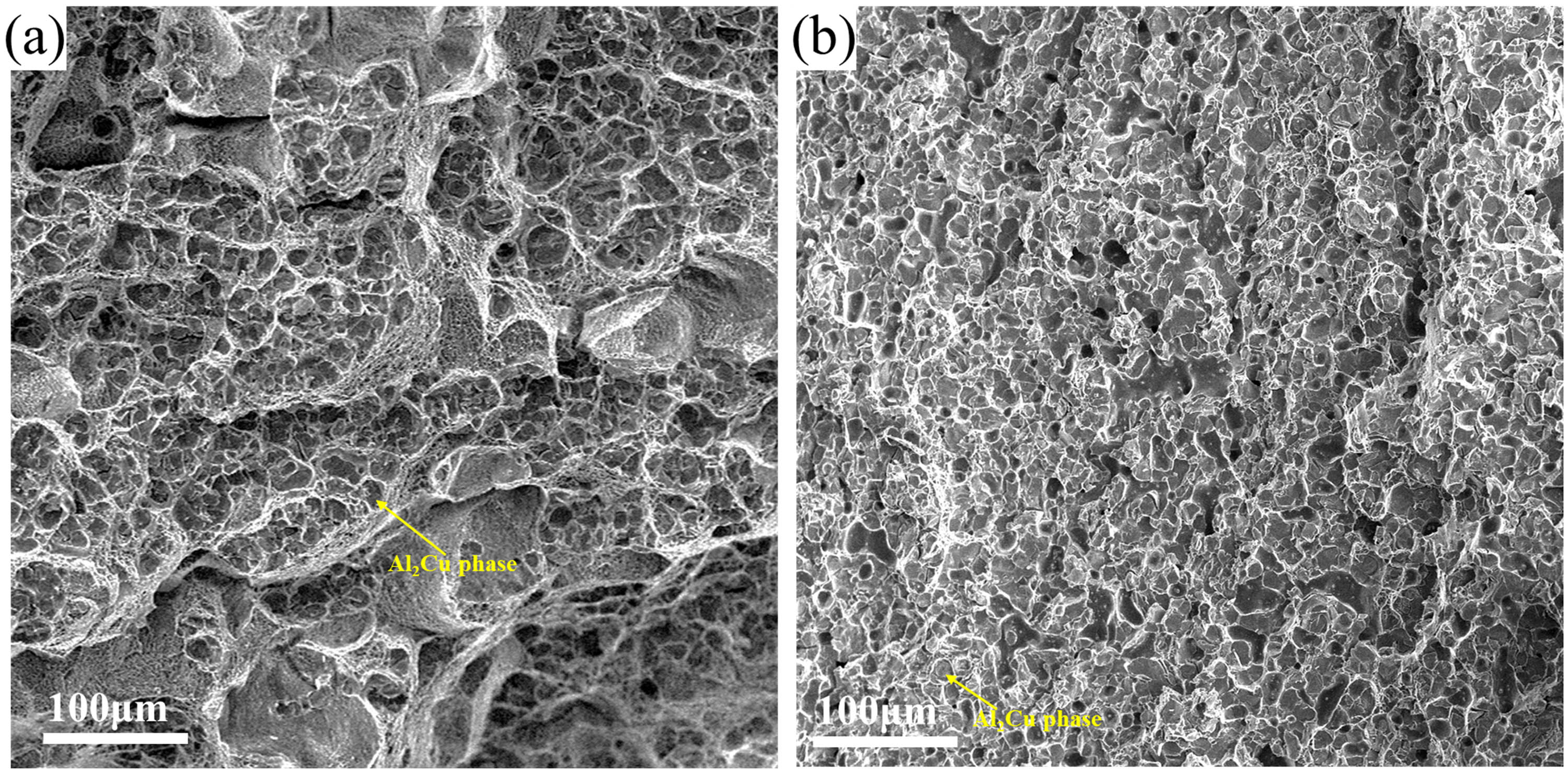

In addition, the elongation and tensile strength of the CR samples showed large amplitude. A few positions with decreased mechanical properties appeared in the CR sample, indicating that the CR process may induce material damage within a certain range of deformation [25]. As shown in Figure 10(a), the fracture surface included transcrystalline fracture (a large number of deep dimples and coarse Al2Cu phases were on the bottom of the dimple) and intergranular fracture (rough grain boundary surface) characteristics, indicating conventional ductile fracture. The transcrystalline or intergranular fracture depends on whether in this area coarse phases exist. However, unexpected brittle fractures occurred, as shown in Figure 10(b), and a large number of shallow dimples (Al2Cu phases were surrounded by shallow dimples) appeared on the fracture of a cold-rolled sample, proving the occurrence of a sort of damage [26,27].

Fracture morphologies of the tensile samples: (a) conventional ductile fracture and (b) brittle fracture.

As shown in Table 7, by comparing the in-plane anisotropy (IPA) of the samples obtained by CR and cold compression, the effect of the improved process on the ring anisotropy was determined. The IPA can be calculated as follows [28]:

Statistical results of IPA

| Yield strength (%) | Tensile strength (%) | Elongation (%) | |

|---|---|---|---|

| None | 7.5 | 0.5 | 36.6 |

| 5% CR | 3.8 | 8.4 | 40.0 |

| 5% CP | 0.8 | 0.9 | 8.9 |

Compared with the CR sample, the IPA based on the tensile strength, yield strength, and elongation of the cold-compressed sample showed a downward trend. The IPA of the original elongation was the worst. Following process improvement via cold compression, the IPA significantly decreased from 36.6 to 8.9%. The results showed that the anisotropy of the cold-compressed sample was obviously weakened.

4 Discussion

4.1 Deformation characteristics

The metal flow shows a large difference in deformation between CR and cold compression. As shown in Figure 11(a) and (b), during the rolling process, the internal particle is mainly subjected to tensile stress along the rolling direction (circumferential). However, during compression, the internal particle is subjected to both axial compression stress and tensile stress along the section perpendicular to the axial direction [13,29]. Therefore, the metal flow in CR deformation is more concentrated, while the metal flow in compression deformation is more dispersed.

Deformation and stress characteristics. (a) Reference direction; (b) and (c) cold deformation under CR and cold compression, respectively.

In addition, because the direction of the compression deformation force is perpendicular to the direction of metal flow, the direction of the rolling deformation force is parallel to the direction of metal flow. It is difficult to transfer the force to the core. Therefore, during the rolling process, the strain at the periphery is larger than at the core. The core strain is larger than at the periphery during compression deformation. Therefore, the changes in the grain size of different components under the two deformation modes differ [30,31]. The grain structure of the sample after CR deformation is still in the state of “thin border and coarse core” after heat treatment, which is consistent with the sample undergoing zero cold deformation. Under cold compression, the grain at the core is significantly reduced in size after heat treatment, resulting in more uniform changes in the state of a “thin border and coarse core” [32].

4.2 Dislocation evolution and its effects

CR and cold compression are two typical deformation behaviors; however, the metal flow during deformation differs. As described in Section 4.1, the metal flow is more concentrated during rolling and more dispersed during compression. According to the microscopic characteristics of polycrystal plasticity deformation, under low temperatures, the internal dislocations glide mainly within the grain without crossing the grain boundary into the area adjacent to the grain. Thus, the material deformation modes determine the dislocation movement. Therefore, the dislocation distribution of the CR sample is relatively concentrated, with regions of high density and dislocation-free regions separated from each other. In contrast, the dislocation distribution is more dispersed in the cold-compressed sample. This phenomenon also increases the dislocation densities after CR deformation than after cold compression [33].

As shown in Figure 12, compared with the CR deformation, the metal flow direction under cold compression is more dispersed, with a shorter metal flow distance in the single direction [34]. The Al2Cu phase (blue circle in Figure 12) represents the stress concentration [35]. A large number of dislocations do not bypass the Al2Cu phase but tangle with the Al2Cu phases, continuing to accumulate in large quantities. During the subsequent solution treatment, a large number of dislocations can be used as atomic diffusion channels to fully expand the diffusion range of Cu atoms, thus improving the density of the precipitated phase of rings during aging [36,37]. Such dislocation accumulation process can also cause partial Al2Cu phase fragmentation, also contributing to the dissolution of Al2Cu phases. However, during the CR process, the metal flows quickly and in a certain direction. The Al2Cu phase is insufficient to cause the accumulation of a large number of dislocations.

Comparison of Al2Cu phases and dislocation accumulation. (a) and (b) Cold deformation modes under CR and cold compression.

4.3 Comparison of microstructure and mechanical properties

By increasing dislocation densities via cold deformation, the degree of grain refinement can be effectively improved by the elongation of the ring because of stronger interaction between grain boundaries [21]. The more uniform grain structure induced by cold compression facilitates the extension of the alloy during the radial tensile process, resulting in better elongations [38].

In terms of tensile strength and yield strength, the range of increase under the two deformation modes is relatively similar. The yield strength mainly depends on the fine-grain strengthening and precipitation strength of the 2219 Al–Cu alloy [39]. The contribution of fine-grain strengthening to the yield strength can be expressed by the Hall-Petch relationship:

where Δσ is the yield strength, d is the average grain diameter, k and σ 0 are constants. The value of k = 0.04 MPa·m1/2 [39]. After calculation, the increase in yield strengths is calculated to be ∼1 MPa as the grain diameter decreases from 113 to 198 μm.

Precipitated phase characteristics are correlated with the material strength. θ′ phases are disk-like and non-shearable precipitate phases, and they improvise significantly towards the attainment of larger peak hardness by blocking dislocations efficiently. The size and quantity of the precipitates are deciding factors for influencing the strength of the material [40,41]. Orowan model indicated the followingrelationship between phases and shear-resistant:

where τ is the shear stress, G is the shear modulus, and b is the Burgess vector. The most critical factor in determining the yield strength is λ, which is the effective distance between precipitated phases.

Zhu and Starke [42] derived the following relationship between θ′ phases and yield strengths under other constant conditions:

where Δσ is the yield strength and r, h, and f v are the diameter, thickness, and volume fraction of the θ′ phase, respectively, M is the Taylor factor, G is shear modulus, b. is Burgess vector, and r 0 is the radius of the dislocation core near the θ′ phase [43]. The value of M = ∼3.1, G = 27 GPa, r 0 = ∼4.5 nm [44], and b = 0.286 nm. After calculation, when cold deformations are carried out, the increase in yield strengths is calculated to be ∼14 MPa as the volume fraction and size of the θ′ phase change. The calculated yield strength of CR and cold compression sample is close. The effective distance of the θ′ phase is determined by the diameter, thickness, and volume fraction. The θ′ phase of the cold compression sample is denser (the distance between particles is smaller, reducing the effective distance), but with a larger width (when the dislocation bypasses the particle, the bigger the particle, the smaller the curvature radius of the dislocation movement, resulting in an increase in the effective distance), leading a relatively close effective distance [45,46].

In addition, the deformation resistance during cold deformation is large, resulting in local damage [47]. As shown in Figure 13, after the rolling process, the Al matrix moves around the coarse phase, and the moving distance of the Al matrix differs in the circumferential and radial directions, resulting in larger microfissures around the coarse phase [48,49]. The microfissures in the tensile process under stress concentration may result in a local failure drastic fluctuation in mechanical properties [50,51] and reduction in the average mechanical properties [52,53]. Conversely, during cold compression, the similar circumferential and radial movements of the Al matrix around the coarse phase prevent local failures [54].

Comparison of Al2Cu phases and brittle fractures. (a) and (b) Cold deformation mode under CR and cold compression.

5 Conclusions

The effects of cold deformation modes on the microstructure (dislocation accumulation, grain structures, and second-phase distribution), and their role in variations in mechanical properties of large 2219 Al–Cu alloy rings were studied. The main conclusions of this study are as follows:

Compared with CR, cold compression causes a smaller increase in the dislocation density. However, the dislocation densities at the core are higher than in other areas, leading to a more uniform grain structure as well as uniform elongation in the axial and radial directions.

The CR deformation contributes to the dissolution of the coarse phase. The cold compression strongly contributes to the dissolution of the secondary phase, leading to denser and finer precipitates of cold-compressed samples, resulting in improved strength. Brittle fractures on the 5% CR samples reduce the mechanical properties due to the deformation mechanism of CR.

Deformation induced by both CR and cold compression can improve the mechanical properties of large rings, but the cold-compressed sample exhibits more uniform microstructures and higher comprehensive mechanical properties (the elongation increased from 7.1 to 11.2%; the IPA decreased from 36.6 to 8.9%) without brittle fractures.

The cold deformation with a small deformation amount adopted in this study is easier to realize in industrial large-ring manufacturing. This process has application prospects for mechanical properties improvement of other large components.

Acknowledgments

The authors acknowledge funding by the National Natural Science Foundation of China [grant number 52275267] and the National Natural Science Foundation of Hubei province [grant number 2022CFB617]. The authors thank Editage [www.editage.cn] for English language editing.

-

Funding information: This study was funded by the National Natural Science Foundation of China [grant number 52275267] and the National Natural Science Foundation of Hubei pro-vince [grant number 2022CFB617].

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] He, H. L., Y. P. Yi, S. Q. Huang, and Y. X. Zhang. An improved process for grain refinement of large 2219 Al alloy rings and its influence on mechanical properties. Journal of Materials Science & Technology (Shenyang, China), Vol. 35, 2019, pp. 55–63.10.1016/j.jmst.2018.09.007Search in Google Scholar

[2] Mao, X. C., H. L. He, and Y. P. Yi. Second phase particles and mechanical properties of 2219 aluminum alloys processed by an improved ring manufacturing process. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 781, 2020, id. 139226.10.1016/j.msea.2020.139226Search in Google Scholar

[3] Guo, W. F., Y. P. Yi, and S. Q. Huang. Effects of deformation temperature on the evolution of second-phase and mechanical properties of large 2219 Al-Cu alloy rings. Materials Characterization, Vol. 160, 2020, id. 110094.10.1016/j.matchar.2019.110094Search in Google Scholar

[4] Shaterani, P., A. Zarei-Hanzaki, S. M. Fatemi-Varzaneh, and S. B. Hassas-Irani. The second phase particles and mechanical properties of 2124 aluminum alloy processed by accumulative back extrusion. Materials & Design, Vol. 58, 2014, pp. 535–542.10.1016/j.matdes.2014.01.078Search in Google Scholar

[5] Kaibyshev, R., O. Sitdikova, I. Mazurina, and D. R. Lesuer. Deformation behaviour of a 2219 Al alloy. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 334, No. 1, 2002, pp. 104–113.10.1016/S0921-5093(01)01777-4Search in Google Scholar

[6] Seo, H. Y., R. L. Jiang, G. K. Chung, and J. K. Chul. Effect of compression process of mwcnt-reinforced al6061 powder on densification characteristics and its mechanical properties. Metals, Vol. 7, No. 10, 2017, id. 437.10.3390/met7100437Search in Google Scholar

[7] Li, H. J., Z. Y. Jiang, D. B. Wei, and X. J. Gao. Surface asperity evolution and microstructure analysis of Al 6061T5 alloy in a quasi-static cold uniaxial planar compression (CUPC). Applied Surface Science A, Vol. 347, 2015, pp. 193–201.10.1016/j.apsusc.2015.04.043Search in Google Scholar

[8] Lu, Y., Z. Xu, and X. Xu. The dynamic evolution of microstructure and mechanical properties of an Al-Cu-Li alloy during multi-axial compression. Journal of Materials Research and Technology, Vol. 14, 2021, pp. 2513–2521.10.1016/j.jmrt.2021.07.106Search in Google Scholar

[9] Dong, F., Y. P. Yi, and S. Q. Huang. Influence of cryogenic deformation on second-phase particles, grain structure, and mechanical properties of Al–Cu–Mn alloy. Journal of Alloys and Compounds, Vol. 827, 2020, id. 154300.10.1016/j.jallcom.2020.154300Search in Google Scholar

[10] Li, Z. Z., H. G. Yan, J. H. Chen, W. J. Xia, and H. Z. Zhu. Enhancing damping capacity and mechanical properties of Al-Mg alloy by high strain rate hot rolling and subsequent cold rolling – sciencedirect. Journal of Alloys and Compounds, Vol. 908, No. 5, 2022, id. 164677.10.1016/j.jallcom.2022.164677Search in Google Scholar

[11] Kazemi-Navaee, A., R. Jamaati, and H. J. Aval. Asymmetric cold rolling of AA7075 alloy: The evolution of microstructure, crystallographic texture, and mechanical properties. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 824, 2021, id. 141801.10.1016/j.msea.2021.141801Search in Google Scholar

[12] Changela, K., H. Krishnaswamy, and R. K. Digavalli. Development of combined groove pressing and rolling to produce ultra-fine grained al alloys and comparison with cryorolling. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 760, No. 8, 2019, pp. 7–18.10.1016/j.msea.2019.05.088Search in Google Scholar

[13] Immanuel, R. J., S. K. Panigrahi, and C. James. Malas Chapter 5-Materials development for sustainable manufacturing. Sustainable Manufacturing Processes, Vol. 5, 2023, pp. 155–194.10.1016/B978-0-323-99990-8.00011-4Search in Google Scholar

[14] Fujita, S., H. Sato, and S. Motozuka. Deformation type during the ball milling process: A comparative study of the microstructures formed by ball milling, uniaxial compression, and rolling. Powder Technology, Vol. 426, No. 1, 2023, id. 118598.10.1016/j.powtec.2023.118598Search in Google Scholar

[15] Zecevic, M., M. Knezevic, I. J. Beyerlein, and R. J. McCabe. Texture formation in orthorhombic alpha-uranium under simple compression and rolling to high strains. Journal of Nuclear Materials, Vol. 473, 2016, pp. 143–156.10.1016/j.jnucmat.2016.02.021Search in Google Scholar

[16] Lan, J., Z. Han, and L. Hua. Effects of cold deformations on strength and ductility of extruded Al-Cu-Mg-Si alloy. Materials Letters, Vol. 300, No. 3, 2021, id. 130188.10.1016/j.matlet.2021.130188Search in Google Scholar

[17] Guo, W. F., H. L. He, Y. P. Yi, S. Q. Huang, X. C. Mao, and J. Fang. Effects of axial cold-compression on microstructure uniformity and mechanical property enhancement of large 2219 Al-Cu alloy rings. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 798, No. 4, 2020, id. 140233.10.1016/j.msea.2020.140233Search in Google Scholar

[18] Guo, W. F., Y. P. Yi, S. Q. Huang, X. C. Mao, and J. Fang. Manufacturing large 2219 Al–Cu alloy rings by a cold rolling process. Materials and Manufacturing Processes, Vol. 35, 2020, pp. 291–302.10.1080/10426914.2020.1718696Search in Google Scholar

[19] Youssef, K. M., R. O. Scattergood, K. L. Murty, and C. C. Koch. Nanocrystalline Al–Mg Alloy with ultrahigh strength and good ductility. Scripta Materialia, Vol. 54, No. 2, 2006, pp. 251–256.10.1016/j.scriptamat.2005.09.028Search in Google Scholar

[20] Xu, X. J., J. Q. Cao, X. N. Cheng, and J. P. Mo. Tensile properties of 2024 Al alloy processed by enhanced solid-solution and equal-channel angular pressing. Chinese Journal of Nonferrous Metals, Vol. 35, No. s2, 2006, pp. 395–397.Search in Google Scholar

[21] Feng, Y. F., X. Chen, Y. Q. Hao, and B. Chen. Ageing evolution process of the -phase in Al-Si-Cu-Mg alloys: Atomic-scale observations and first-principles calculations. Journal of Alloys and Compounds, Vol. 968, 2023, id. 171787.10.1016/j.jallcom.2023.171787Search in Google Scholar

[22] Niu, G. D., L. J. Zhu, W. R. Ren, and Y. Wang. Elevated temperature microstructural stability in Al-7Cu-0.5Mn-0.2Zr alloys through Ce addition: Enhanced coherent interfacial stability of cu-rich θ’/α-Al interface. Materials Characterization, Vol. 200, 2023, id. 112908.10.1016/j.matchar.2023.112908Search in Google Scholar

[23] Guo, W. F., Y. P. Yi, S. Q. Huang, and H. L. He. Effects of warm rolling deformation on the microstructure and ductility of large 2219 Al-Cu alloy rings. Metals And Materials International, Vol. 26, 2020, pp. 56–68.10.1007/s12540-019-00303-5Search in Google Scholar

[24] Huang, J. W., Y. P. Yi, and S. Q. Huang. Effects of cryogenic deformation on second-Phase Al2Cu particles and mechanical properties of 2219 Al–Cu alloy rings. Metals And Materials International, Vol. 27, 2021, pp. 815–824.10.1007/s12540-019-00468-zSearch in Google Scholar

[25] Sharma, V. M. J., K. S. Kumar, B. N. Rao, and S. D. Pathak. Effect of microstructure and strength on the fracture behavior of AA2219 alloy. Materials Science and Engineering A. Vol. 502, No. 1–2, 2009, pp. 45–53.10.1016/j.msea.2008.11.024Search in Google Scholar

[26] Günen, A., S. Bayar, and M. S. Karakaş. Effect of different arc welding processes on the metallurgical and mechanical properties of RAMOR 500 armor steel. Journal of Engineering Materials and Technology, Vol. 142, No. 2, 2019, pp. 1–23.10.1115/1.4045569Search in Google Scholar

[27] Günen, A., B. Kurt, İ. Somunkιran, E. Kanca, and N. Orhan. The effect of process conditions in heatassisted boronizing treatment on the tensile and bending strength characteristics of the AISI304 austenitic stainless steell. The Physics of Metals and Metallography, Vol. 116, 2015, pp. 896–907.10.1134/S0031918X15090021Search in Google Scholar

[28] Chen, L. H., C. H. Liu, P. P. Ma, J. S. Yang, L. H. Zhan, and M. H. Huang. Strong in-plane anisotropy of creep ageing behavior in largely pre-deformed Al-Cu alloy: experiments and constitutive modeling. International Journal of Plasticity, Vol. 152, 2022, id. 103245.10.1016/j.ijplas.2022.103245Search in Google Scholar

[29] Meyers, M. and K. Chawla. Mechanical behavior of materials, 2nd edn, Cambridge University Press, USA, 2009.10.1017/CBO9780511810947Search in Google Scholar

[30] Qasaimeh, M., D. Ravoori, and A. Jain. Modeling the effect of in situ nozzle-integrated compression rolling on the void reduction and filaments-filament adhesion in Fused Filament Fabrication (FFF). Multiscale Science and Engineering, Vol. 4, 2022, pp. 37–54.10.1007/s42493-022-00073-0Search in Google Scholar

[31] Shen, J., X. Chen, V. Hammond, L. J. Kecskes, S. N. Mathaudhu, K. Kondoh, et al. The effect of rolling on the microstructure and compression behavior of AA5083 subjected to large-scale ECAE 2017. Journal of Alloys and Compounds, Vol. 695, No. 25, 2017, pp. 3589–3597.10.1016/j.jallcom.2016.11.406Search in Google Scholar

[32] Li, X. C. Microstructure and metallographic map of aluminum alloy, Metallurgical Industry Press, China, 2010.Search in Google Scholar

[33] Yu, S. W., X. L. An, and S. N. M. Song. Effects of temperature and loading direction on deformation mechanism of Ti-10at%Al alloy subjected to rolling and high speed compression. Journal of Alloys and Compounds, Vol. 925, 2022, id. 166801.10.1016/j.jallcom.2022.166801Search in Google Scholar

[34] Li, F., G. N. Chu, and X. J. Liu. Deformation division of metal flow behavior during extrusion process of 7075 aluminum alloy. Chinese Journal of Nonferrous Metals, Vol. 16, No. 5, 2009, pp. 738–742.10.1007/s11771-009-0122-3Search in Google Scholar

[35] Liu, Q., F. G. Qi, Q. H. M. Wang, and K. Y. Ding. The Influence of particles size and its distribution on the degree of stress concentration in particulate reinforced metal matrix composites. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 731, No. 25, 2018, pp. 351–359.10.1016/j.msea.2018.06.067Search in Google Scholar

[36] Zuo, J. R., L. G. Hou, J. T. Shi, H. Cui, L. Z. Zhuang, and J. S. Zhang. The mechanism of grain refinement and plasticity enhancement by an improved thermomechanical treatment of 7055 Al Alloy. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 702, 2017, pp. 42–52.10.1016/j.msea.2017.06.106Search in Google Scholar

[37] Vinod Kumar, G. S., B. S. Murty, and M. Chakraborty. Effect of TiAl3 particles size and distribution on their settling and dissolution behavior in aluminium. Journal of Materials Science, Vol. 45, 2010, pp. 2921–2929.10.1007/s10853-010-4284-zSearch in Google Scholar

[38] Thomason, P. F. A Three-dimensional model for ductile fracture by the growth and coalescence of microvoids. Acta Metallurgica, Vol. 33, No. 6, 1985, pp. 1087–1095.10.1016/0001-6160(85)90202-0Search in Google Scholar

[39] Hansen, N. Hall–Petch relation and boundary strengthening. Scripta Materialia, Vol. 51, 2004, pp. 801–806.10.1016/j.scriptamat.2004.06.002Search in Google Scholar

[40] Li, H., L. H. Zhan, M. H. Huang, and X. Zhao. unified constitutive model for multiphase precipitation and multi-stage creep ageing behavior of Al−Li−S4 alloy. Transactions of Nonferrous Metals Society of China, Vol. 31, 2021, pp. 1217–1234.10.1016/S1003-6326(21)65573-5Search in Google Scholar

[41] Ghosh, M., A. Miroux, and L. A. Kestens. Experimental study and modelling of the role of solutes, precipitates and temperature on the work-hardening of AA6xxx aluminium alloys. Materials Science and Engineering A, Vol. 805, 2021, id. 140615.10.1016/j.msea.2020.140615Search in Google Scholar

[42] Zhu, A. W. and E. A. Starke. Strengthening effect of unshearable particles of finite size: a computer experimental study. Acta Materialia, Vol. 47, No. 11, 1999, pp. 3269–3269.10.1016/S1359-6454(99)00179-2Search in Google Scholar

[43] Wang, S. C. and M. J. Starink. Precipitates and intermetallic phases in precipitation hardening Al–Cu–Mg–(Li) based alloys. International Materials Reviews, Vol. 50, No. 4, 2005, pp. 193–215.10.1179/174328005X14357Search in Google Scholar

[44] Medlin, D. L., N. Yang, and C. D. Spataru. Unraveling the dislocation core structure at a van der Waals gap in bismuth telluride. Nature Communications, Vol. 10, 2019, id. 1820.10.1038/s41467-019-09815-5Search in Google Scholar PubMed PubMed Central

[45] Ambriz, R. R. and D. Jaramillo. Mechanical behavior of precipitation hardened aluminum alloys welds. Light Metal Alloys Applications, Vol. 1, 2014, pp. 2–5.10.5772/58418Search in Google Scholar

[46] Fribourg, G., Y. Bréchet, A. Deschamps, and A. Simar. Micorstructure-based modelling of isotropic and kinematic strain hardening in a precipitation-hardened aluminum alloy. Acta Materialia, Vol. 59, No. 9, 2011, pp. 3621–3635.10.1016/j.actamat.2011.02.035Search in Google Scholar

[47] Ng, K. C. and H. L. Chen. Numerical modelling of brittle fracture using lattice particle method with applications to fluid structure interaction problems via SPH coupling. Engineering Fracture Mechanics, Vol. 289, No. 1, 2023, p. 109453.10.1016/j.engfracmech.2023.109453Search in Google Scholar

[48] Mbati, M., T. Gerasimov, and L. De Lorenzis. A review on phase-field models of brittle fracture and a new fast hybrid formulation. Computational Mechanics, Vol. 55, 2015, pp. 383–405.10.1007/s00466-014-1109-ySearch in Google Scholar

[49] Zhou, M. Z. Research of relationship between heat-treatment and fatigue property of Aerial 2E12 Aluminum Alloy, PhD, Central South University, 2010.Search in Google Scholar

[50] Wang, B. Effect of grain size and residual stress on fatigue properties of 2E12 aluminum alloy, M. A. Sc, Central South University, 2014.Search in Google Scholar

[51] Ma, G. H., R. X. Li, and R. D. Li. Effects of stress concentration on low-temperature fracture behaviour of A356 Alloy. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 667, 2016, pp. 459–467.10.1016/j.msea.2016.05.026Search in Google Scholar

[52] Rahimi, M. N. and G. Moutsanidis. A smoothed particle hydrodynamics approach for phase field modeling of brittle fracture. Computer Methods in Applied Mechanics and Engineering, Vol. 398, No. 1, 2022, id. 115191.10.1016/j.cma.2022.115191Search in Google Scholar

[53] Zhao, X. X., W. Zhang, C. Q. Wang, W. Liu, and C. J. Hang. Effect of the second-phase particle distribution on the brittle fracture behavior of Sn-3Ag-0.5Cu solder. Journal of Electronic Materials, Vol. 52, 2023, pp. 3394–3400.10.1007/s11664-023-10319-8Search in Google Scholar

[54] Y., Zhao, Z. Q. Zhou, J. Bi, and C. L. Wang. Simulation of brittle fractures using energy-bond-based smoothed particle hydrodynamics, International Journal of Mechanical Sciences, Vol. 248, No. 15, 2023, id. 108236.10.1016/j.ijmecsci.2023.108236Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling