Abstract

The cost of the coolant and its disposal cost are significant issues in metal machining processes. In biocompatible magnesium alloy-based medical implants and instrument manufacturing, the cost hikes are owing to the use of unconventional machining processes and computerised numerical control machines. This research aims to improve machinability performance and optimize process parameters for biocompatible magnesium implant manufacturing for biomedical applications using eco-friendly nanofluid of MoS2 nanoparticles suspended in waste coconut oil. The nanofluid was prepared from the multiple times used waste coconut oil (waste) and was mixed with MoS2 nanoparticles. The orthogonal array L16, Taguchi analysis, and analysis of variance were employed in experimental design and statistical optimization. The machinability performance was determined by measuring and comparing the responses like cutting force, feed force, surface roughness, cutting zone temperature, and tool wear. They were compared with machining using a nanofluid and conventional commercial coolant. The results reveal that the proposed method of machining improved machinability performance appreciably; therefore, the observations of the proposed method were used and the process parameters were optimized. Mathematical models were developed for the prediction of process parameters. The proposed method exhibited the average reduction of the cutting force by 68.23167 N, feed force requirements by 34.180 N, the cutting zone temperature by 60.435°C, the surface roughness by 0.118908 µm, and the tool wear by 039938 mg·h−1.

1 Introduction

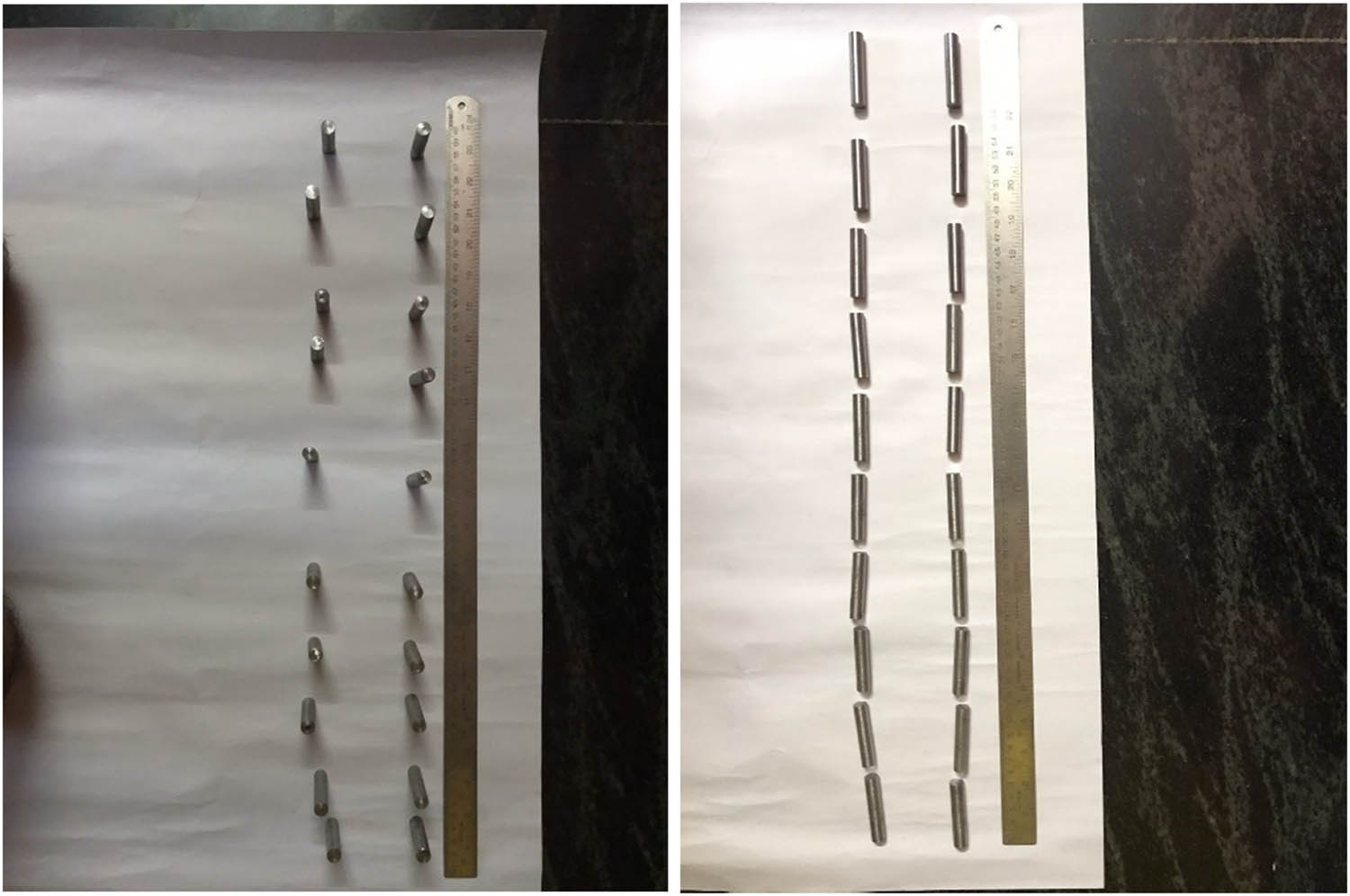

Recently, alloys have been employed in manufacturing medical implants, particularly orthopaedic implants. In orthopaedic implants, biodegradable magnesium alloys are widely and usually preferred over stainless steel, titanium alloys, and cobalt-based alloys for avoiding undesirable outcomes like metal ion release and stress shielding as well as reducing the cost and weight [1]. For critical bone fracture, permanent alloy implants are needed and usually titanium alloys and steels are preferred, though they are expensive and heavy [2,3]. As Mg alloy is the lightest metal (1.738 g·cm−3 density [4]) and compatible with the structural application for bones (as critical bone density is in the range of 1.75–2.10 1.738 g·cm−3 [1]), in last decade the research on Mg alloys augmented 491% [5]. Pure Mg is less corrosive (407 mm·year−1) than its alloy form [6]. The Mg alloy with aluminium and zinc-reinforced composite was synthesized and tested for biocompatibility and was found to be biocompatible [7]. Mg alloys are highly biodegradable and release hydrogen at approximately 0.01 mL·cm−2·day−1 [8,9]. In orthopaedic applications, usually, Mg is alloyed with Mn, Zn, Al, and Ca for use as biomaterials in place of pure Mg [10,11]. Young’s modulus is one of the most important properties, which is merely considered for the selection of alternate for bone. The Young’s modulus of human bone varies from 3 to 20 GPa and those of cobalt and chromium alloys were around 230 GPa, for titanium it ranged from 110 to 117 GPa, and for stainless steel, it ranged from 190 to 205 GPa; however, for Mg, it was 41–45 GPa, very close to the bone requirement [12,13]. Mg alloys are biocompatible, attractive, biodegradable, and possess appreciable mechanical properties [14–16]. They are light weight, less stress shielding, and their Young’s modulus values are close to that of the bone. Moreover, Mg alloys have low corrosion resistance and hydrogen is released at the time of degradation [17]. The material design requirements differ from permanent metal implants [18]. The scientific aspects are biosafety (alloying agents like aluminium are avoided as they are toxic in the final form) and biocompatibility. The mechanical properties like tensile strength greater than 200 GPa, elongation limit of up to 10%, wear rate of less than 05 mm per year in human biofluid at body temperature, and also its biodegradation should be controlled; life time requirements are minimum 90 days and double of it as maximum [19]. The samples of circular cross-sectional implants are shown in Figure 1.

Samples of the circular implants.

As with the selection of procurement source for procuring medically pure Mg, the selection of the manufacturing process is also essential. The selection includes machining accuracy, low cost of machining, harmless processing materials/chemicals used, and do not damage the implants thermally and chemically, and a search for mass production possibilities [19–26]. This research addresses the machining issue of circular-shaped implant manufacturing for meeting the above requirements.

The scientific evidence supports are presented in Table 1. The machinability could be improved by improving the tool hardness either by using coated tool [27,28] or by changing a much harder tool for machining. Alternatively, it can be done by reducing the tool wear. The tool wear could be reduced by supplying coolant and lubrication appropriately at the cutting zone. Coolant cost is one of the considerable costs in manufacturing. The literature suggested eco-friendly flood cooling [29], ultrasonically atomized cutting fluid [30], minimum quantity lubrication (MQL) [31,32], nanoparticles mixed flood cooling [33], hybrid nanoparticles mixed flood cooling, nanoparticles mixed MQL [34,35,36,37,38,39], hybrid nanoparticle mixed MQL [33,40–42], cryogenic cooling [43–45], and cryogenic/lubrication hybrid cooling [46].

Some related observations from the existing literature

| Problem | Intervention | Comparison | Outcome(s) | Ref. |

|---|---|---|---|---|

| Poor machinability of super duplex stainless steel | MQL for machining | Dry machining and flood, cooling | Low-stress corrosion cracking resistance | [31] |

| Poor machinability in C NC turning of AISI H13 tool steel | TiN-coated tool | Uncoated carbide tool for life tool wear | Less tool wear compared to the conventional uncoated carbide tool | [27] |

| Poor machinability of C NC turning of EN31 alloy steel | TiN-coated tool | Uncoated H SS tool | Higher chip thickness | [28] |

| Tool wear in machining titanium alloy Ti–6Al–4V | MQL for machining | Dry and flood coolant | The edge chipping and adhesion of chips to the cutting tools were reduced | [32] |

| Improper cooling at the cutting zone while machining alloys | Nano-additives: MQL for machining | Compared with MQL | Nano-additive-MQL system was found to be sustainable machining | [47] |

| To optimize the use of coolants instead of conventional flood cooling | MQL is composed of biodegradable oil with various nanoparticles for machining | Compared with dry and MQL | Achieved better surface finish, low power consumption, and fewer tool wear | [48] |

| To achieve environmentally sustainable manufacturing in pressure vessel carbon steel (SA516) using coated carbide inserts | MQL for machining | Compared with traditional flood coolant | Surface roughness and tool wear reduced significantly | [49] |

| Drilling on titanium | Cryogenic cooling conditions | Compared with traditional flood coolant | Drill maximum temperature reduced by 33–50% | [43] |

| Progressive tool wear while machining titanium alloy Ti6Al4V due to built-up edges, diffusion wear, and cutting forces | Cryogenic cutting with liquid nitrogen | Compared with conventional dry cutting and flood cutting | Eliminated the issues of BUE formation, diffusion wear, and cutting force fluctuation, especially under aggressive cutting conditions than flood cooling | [44] |

| Poor machinability for Ti–6Al–4V thin-wall components | Cryogenic MQL | MQL | Highly improved machinability, superior lubrication, and high cooling function | [45] |

| To develop sustainable and optimized machining of Ni-based industrial alloy | Adequate cooling/lubrication | Flood, MQL, and cryogenic | Improved surface quality and support for sustainable means of production | [46] |

| Machining of Hastelloy C-276 | MQL for machining | Compared with conventional dry cutting and flood cutting | Cooling environment influencing cutting zone temperature, surface finish, and material removal rate | [50] |

| Oil mist generation and endanger the health of workers | Flood cooling | Oil mist mass concentrations in MQL | 8.33–305.88 mg·m−3 in MQL, whereas 0.2–22.42 mg·m−3 in flood cooling | [29] |

| Poor surface quality in machining Hastelloy C-276 | Ultrasonically atomized cutting fluid | Compared with conventional dry cutting and flood cutting | Surface quality improved by 20% than dry machining (17.4%) | [30] |

| Poor surface finish in grinding of 100Cr6-steel | SiO2 nanofluids in MQL for machining | MQL | The surface finish improved significantly | [34] |

| Application of nanofluids for machining | Graphene oxide and paraffin- and soybean-based mixed with MoS2 nanoparticles and hybrid nanofluids, namely alumina-multiwalled carbon nanotubes and alumina-graphene in the MQL form | MQL machining | Imparting superior lubrication and cooling effects under MQL machining | [51] |

| AA 2024 T3 Al alloy | Mineral oil-based MoS2 nanofluid MQL | Dry cutting, base fluid MQL | Built-up layer and built-up edge formation significantly reduced | [35] |

| Poor surface integrity in internal-cooling-type grinding | MWCNTs and MoS2/water-based coolant in flood cooling | Compared with conventional flood cutting | Considerably fewer burrs and furrows, temperature reduced by 3.61% and surface roughness reduced by 2.39% | [33] |

| MQL-milling of Inconel X-750 superalloy | Boron nitride/graphite nanoparticle-based nanofluid in MQL | Boron nitride/MoS2 nanoparticle-based nanofluid graphite/MoS2 nanoparticle-based nanofluid in MQL | Tool life improved by 36.17% compared with other combinations | [40] |

| Review on nanoparticles in coolant for machining processes | Hybrid nanoparticles | Mono nanoparticles | Nanoparticle concentration in the range of 0.25–0.5% (low and economical concentrations) is the most repetitive for optimal cases in most of the machining processes. Hybrid nanofluids show more positive effects compared with conventional nanofluids and base fluids. Cutting zone temperature, cutting force, tool wear, and surface roughness experience 10–40% and in some cases 50–70% positive change after applying nanoparticles in turning processes. Milling process and SiO2, MoS2, and graphene nanoparticles are reported as the most applied and effective ones | [41] |

| Tribological issues while turning AISI 420 hardened steel with cermet tools | Al2O3 and MoS2 | Conventional fluid (base fluid) | Significant synergistic effect | [42] |

| High surface roughness and tool wear in CNC. turning of 617 alloys by AlTiN PVD carbide cutting inserts | Al2O3 nanofluid in coconut oil under MQL condition | Optimization of cutting force, surface roughness, and tool wear | Surface quality improved and tool wear was reduced significantly | [52] |

The research gap can be stated as follows: all proposed methods in the above-discussed literature would lead to additional machining costs. The MQL is costlier than flood cooling and cannot be reused. The addition of nanoparticles in the MQL mode leads to the additional cost of the coolant. Nanoparticles may mix in the environmental air after drying the coolant if not cleaned properly.

Hence, this investigation was innovatively approached to develop a cheap and effective coolant from the waste resource. A reusable nanofluid developed from the waste coconut oil was assorted with MoS2 nanoparticles to improve the machined surface quality, and reduce the tool wear, the cutting force, the feed force, and the cutting zone temperature. As this coolant contains edible oil, it is biodegradable and utilizes waste disposal. The performance of the proposed nanofluid is compared with the conventional coolant and it is found to be costlier. The commercial coolant was mixed with water. This coolant is 100% water-free and utilizes the used-edible oil of coconut oil (waste) for a valuable machining process.

This research aims to develop a low-cost, high-performance nanofluid for machining biodegradable, biocompatible, and safe manufacturing of circular Mg implants with the use of eco-friendly nanofluid coolants. This research discusses improving the machinability performance and optimizing the process parameters for biocompatible magnesium implant manufacturing for biomedical applications with eco-friendly nanofluid of MoS2 nanoparticles suspended in waste coconut oil. The machinability performances are observed under flood cooling conditions and compared with the conventional commercial coolant. Cutting fluid costs and the risk of disposing of them are major issues in flood cooling systems in metal machining processes. This investigation overcomes those issues by proposing to develop a coolant from the waste resource. Reusable nanofluid was developed from waste coconut oil and assorted with MoS2 nanoparticles to improve the machined surface quality and reduce the tool wear, cutting force, feed force, and cutting zone temperature. As this coolant contains content edible oil, it is biodegradable. The performance of the proposed nanofluid is compared with conventional, costlier, and commercial coolant oil mixed with water. This coolant is 100% water-free and utilizes multiple times used edible coconut oil (waste) for a valuable machining process.

Hence, the novelty statement is to develop an effective nanofluid for flood cooling of machining Mg implants; it was prepared by mixing waste oil (used coconut oil) and MoS2 nanoparticles at a low concentration, experimenting with a real-time application, statistically evaluating observations and comparing them with conventional coolant’s performance, and then optimizing the process parameters for computerised numerical control (CNC) machining of Mg implants with the help of Taguchi analysis and analysis of variance (ANOVA). The research background, the literature review, the research gap, and the novelty of this investigation are presented in Section 1; the materials and research methods followed and observations are illustrated in Section 2. The results are analysed and optimized for minimizing cutting force, feed force, surface roughness, cutting zone temperature, and tool wear and explained in Section 4. The findings and conclusion are based on the results of the experimental observational analysis and are presented in Section 5.

2 Materials and methods

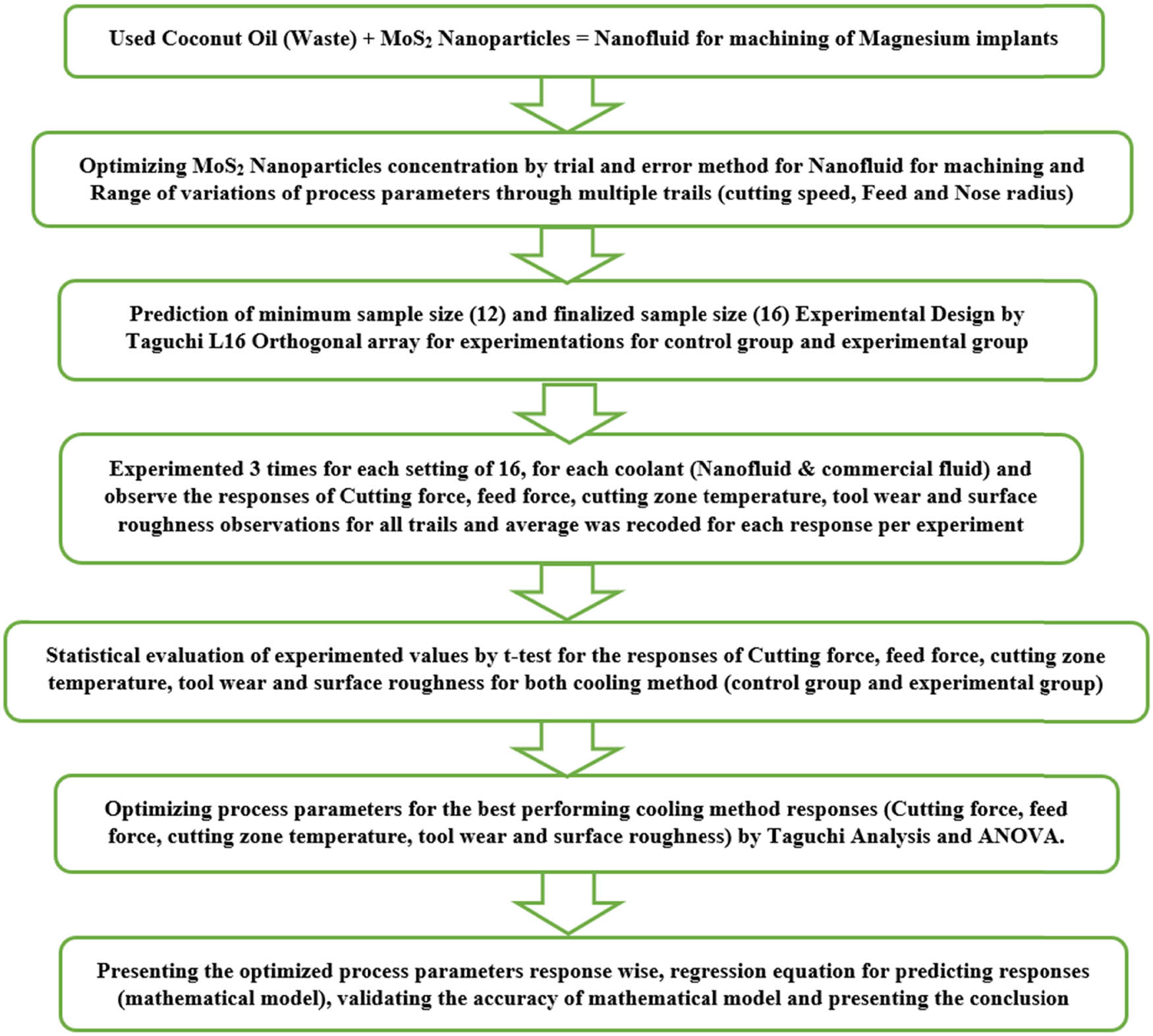

The flow of this investigation is presented in Figure 2. This investigation was carried out at the in-house research facility of high precision heavy duty (5HP) lathe (Figure 3).

Research flow diagram.

Experimental set-up of HMT heavy-duty lathe with a tool dynamometer.

The facility offers a high degree of accuracy in machining and can operate at eight different speeds in the range of 32–1,200 rpm and 18 variety automated feed (0.025–2.5 mm·rev−1) conditions. Medically pure Mg rods were utilized as samples for testing the machinability. The round rods of the Mg workpiece material were purchased from Pujara High-Quality Steels Pvt. Ltd, Chennai. The mechanical properties of Mg implant materials, namely the density and elastic modulus of magnesium implants were 1.82 g·cm−3 and 43.5 GPa, respectively, and it is equivalent to the mechanical properties of bone [12,53,54]. The sample length of machining was 50 mm long. The conventional cutting fluid is Castrol make, Syntilo 9930 grade Downers Grove, Synthetic Coolant type IL mixed with 5% water. For preparing the nanofluid coolant, the MoS2 nanoparticles were obtained from the chemical laboratory of Saveetha School of Engineering and reduced in particle size by grinding in a ball mill for 15 h. The waste coconut oil was obtained from Kerala Chips at Vadapalani, Chennai Branch, and filtered. The quantity of MoS2 added was limited to the viscosity requirements of the coolant oil so that the pump power would not affect and the rated flow could be achieved. The waste coconut oil (used coconut oil) was filtered and then the impurities were removed. By the iterative test, the 30 g per 1,000 g of waste coconut oil ratio was finalized. The inclusion of MoS2 not only improved the cooling and lubrication properties but also improved the fire point of the nanofluid. The nanofluid was prepared by mixing oil and nanoparticles of MoS2 (<5 nm in size) in the ball mill for 12 h, which allows the nanoparticles to float on the mixed oil, which is a nanofluid. The coolant flow rate was set at 3.5 L·min−1 and it was ensured that no fumes were generated while cutting and the proposed oil is biodegradable. As no human sample is involved in this research, no ethical approval was required for this investigation. Hence, MoS2 nanoparticles enriched with a waste coconut oil-based nanofluid in the flood-cooled machining process were verified and found to be very safe. The properties of the prepared nanofluid coolant were characterized and are furnished in Table 2. The mechanism behind the machining is cut by shearing and exposes the inner layer to the atmosphere at elevated temperatures [55,56]. If the water content coolant reacts with the surface, oxides may be produced and fumes generated. Hence, for this nanofluid, lubrication properties were considered to be a primary concern for the coolant (like coconut oil and MoS2) preparation.

Variable input parameters and their levels

| Process variable | First level | Second level | Third level | Fourth level |

|---|---|---|---|---|

| Cutting velocity (m·min−1) | 20 | 40 | 60 | 80 |

| Tool feed (mm·rev−1) | 0.025 | 0.050 | 0.075 | 0.100 |

| Nose radius (mm) | 0.30 | 0.60 | 0.90 | 1.20 |

The heat was measured as the temperature at the cutting zone. The mercury pool thermocouple technique is employed for the temperature measurement; mercury was filled in the blue colour container (refer to Figure 3, left).

The force encountered while machining was measured with a lathe tool dynamo meter, which operates with 12 strain gauges. Each strain-gauge possesses 350 Ω resistance. The gauge factor is 2 ± 1. The set-up measures forces in three directions and converts them into net force acting on the tool as output.

The surface roughness was measured by using SURFTEST SJ-410. Figure 4 shows the surface roughness tester (Mitutoyo, Japan), which is a portable type surface roughness tester, employed to measure the surface roughness with a setting of 4 mm inspecting length, 0.5 mm·s−1 speed, 0.8 mm cut-off length, 2 mm nose radius, 600° angle of the tip, and 6 and 3.5 mm height and width of the stylus, respectively. The precision balance of LC 0.01 mg was utilized to measure the tool wear (in mg·h−1) by dividing the machining time from the mass loss by the tool.

SURFTEST SJ-410 surface roughness tester.

3 Experimentation

The limiting values of input variables are fixed with trails at various feeds, speeds, and depths of cut employed while finishing the shaft manufacturing in industries at Ambattur, Chennai. The variable input parameters are cutting velocity (in m·min−1), nose radius (in mm), and feed rate (in mm·rev−1). The range and levels of parameter variation are shown in Table 2 [57–61]. The carbide tip tool was employed in machining all samples in all kinds of cutting environments and the fresh tool was used in each experiment. The L16 type experimental design was used for the choice of the Taguchi experimental design for three factors at four levels. The experiments were conducted accordingly, and observations of the cutting force, feed force, surface roughness, cutting zone temperature, and tool wear were noted. All measurements were taken at five different locations/stages of processing of the workpiece after/during experiments, and the average was taken at each experiment [62,63]. The observations are consolidated for the control group in Table 3 and those for the intervention group in Table 4.

Taguchi L16 experimental design type process inputs and experimental observations of the control group

| Expt. no. | Cutting velocity (m·min−1) | Tool feed (mm·rev−1) | Nose radius (mm) | Cutting force (N) | Feed force (N) | Surface roughness (µm) | Cutting zone temperature (°C) | Tool wear (mg·h−1) |

|---|---|---|---|---|---|---|---|---|

| 1 | 20 | 0.025 | 0.3 | 246.64 | 115.35 | 0.405 | 276.1 | 0.35 |

| 2 | 20 | 0.050 | 0.6 | 245.9 | 117.26 | 0.399 | 299.02 | 0.39 |

| 3 | 20 | 0.075 | 0.9 | 251.16 | 119.01 | 0.393 | 293.04 | 0.43 |

| 4 | 20 | 0.100 | 1.2 | 257.42 | 121.21 | 0.387 | 323.94 | 0.50 |

| 5 | 40 | 0.025 | 0.6 | 254.68 | 120.23 | 0.39 | 355.84 | 0.49 |

| 6 | 40 | 0.050 | 0.3 | 265.94 | 121.78 | 0.384 | 389.73 | 0.56 |

| 7 | 40 | 0.075 | 1.2 | 273.2 | 123.95 | 0.375 | 184.4 | 0.62 |

| 8 | 40 | 0.100 | 0.9 | 275.46 | 125.07 | 0.372 | 195.36 | 0.68 |

| 9 | 60 | 0.025 | 0.9 | 282.72 | 123.26 | 0.361 | 192.37 | 0.85 |

| 10 | 60 | 0.05 | 1.2 | 289.98 | 125.92 | 0.353 | 206.33 | 0.90 |

| 11 | 60 | 0.075 | 0.3 | 290.23 | 127.64 | 0.334 | 218.29 | 0.94 |

| 12 | 60 | 0.100 | 0.6 | 297.49 | 128.35 | 0.349 | 235.23 | 0.99 |

| 13 | 80 | 0.025 | 1.2 | 305.75 | 127.89 | 0.34 | 221.28 | 1.03 |

| 14 | 80 | 0.050 | 0.9 | 307.01 | 129.58 | 0.331 | 246.2 | 1.10 |

| 15 | 80 | 0.075 | 0.6 | 315.27 | 131.25 | 0.322 | 275.1 | 1.07 |

| 16 | 80 | 0.100 | 0.3 | 322.53 | 134.56 | 0.308 | 304.01 | 1.14 |

Taguchi L16 experimental design type process inputs and experimental observations of the intervention group

| Expt. no. | Cutting velocity (m·min−1) | Tool feed (mm·rev−1) | Nose radius (mm) | Cutting force (N) | Feed force (N) | Surface roughness (µm) | Cutting zone temperature (°C) | Tool wear (mg·h−1) |

|---|---|---|---|---|---|---|---|---|

| 1 | 20 | 0.025 | 0.3 | 132.98 | 85.03 | 0.272 | 175.04 | 0.06 |

| 2 | 20 | 0.05 | 0.6 | 142.1 | 86.98 | 0.268 | 180.76 | 0.08 |

| 3 | 20 | 0.075 | 0.9 | 148.42 | 87.73 | 0.263 | 185.46 | 0.13 |

| 4 | 20 | 0.100 | 1.2 | 157.54 | 88.33 | 0.256 | 189.14 | 0.18 |

| 5 | 40 | 0.025 | 0.6 | 170.42 | 87.55 | 0.263 | 182.18 | 0.21 |

| 6 | 40 | 0.05 | 0.3 | 179.3 | 88.94 | 0.257 | 190.76 | 0.24 |

| 7 | 40 | 0.075 | 1.2 | 189.61 | 89.35 | 0.252 | 197.13 | 0.29 |

| 8 | 40 | 0.100 | 0.9 | 215.61 | 90.11 | 0.248 | 202.32 | 0.33 |

| 9 | 60 | 0.025 | 0.9 | 216.87 | 90.98 | 0.249 | 199.34 | 0.34 |

| 10 | 60 | 0.050 | 1.2 | 229.79 | 91.16 | 0.24 | 205.25 | 0.39 |

| 11 | 60 | 0.075 | 0.3 | 246.38 | 92.72 | 0.231 | 213.32 | 0.44 |

| 12 | 60 | 0.100 | 0.6 | 258.33 | 93.55 | 0.233 | 221.26 | 0.50 |

| 13 | 80 | 0.025 | 1.2 | 266.16 | 91.97 | 0.227 | 210.78 | 0.53 |

| 14 | 80 | 0.050 | 0.9 | 274 | 92.34 | 0.221 | 221.26 | 0.58 |

| 15 | 80 | 0.075 | 0.6 | 276.22 | 93.81 | 0.215 | 231.42 | 0.64 |

| 16 | 80 | 0.100 | 0.3 | 285.94 | 94.88 | 0.207 | 243.86 | 0.71 |

4 Results and discussions

The properties of the prepared nanofluid coolant were characterized and are given in Table 5. The machinability improvement was ensured by analysing the results with the help of independent sample tests and Taguchi and ANOVA procedures with the responses of cutting force, feed force, cutting zone temperature, surface roughness, and tool wear. The inputs are common except for the coolant of wet machining for the control group and intervention group.

Thermophysical properties of waste coconut oil/MoS2 nano-coolant

| Description of properties | Value |

|---|---|

| Viscosity | 368 cS at 21°C |

| pH | 9.6 |

| Thermal conductivity | 1,356 W·m−1·K−1 |

| Surface tension | 68 mN·m−1 |

| Wettability | Good |

| Density | 1,087 kg·m−3 |

| Flash point | >500°C |

4.1 t-Test

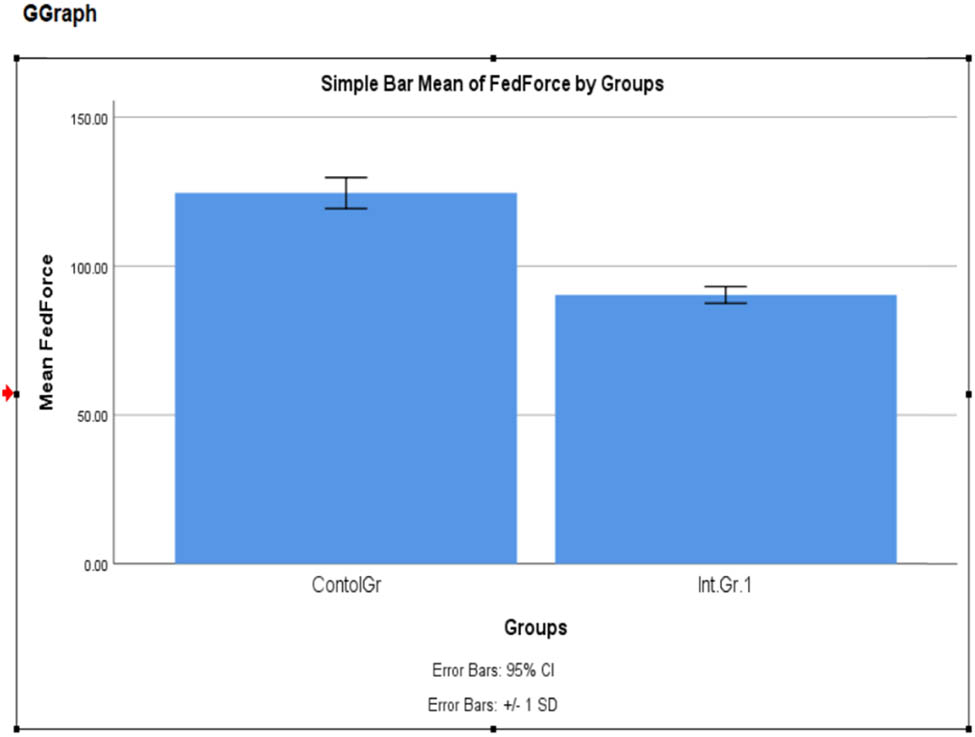

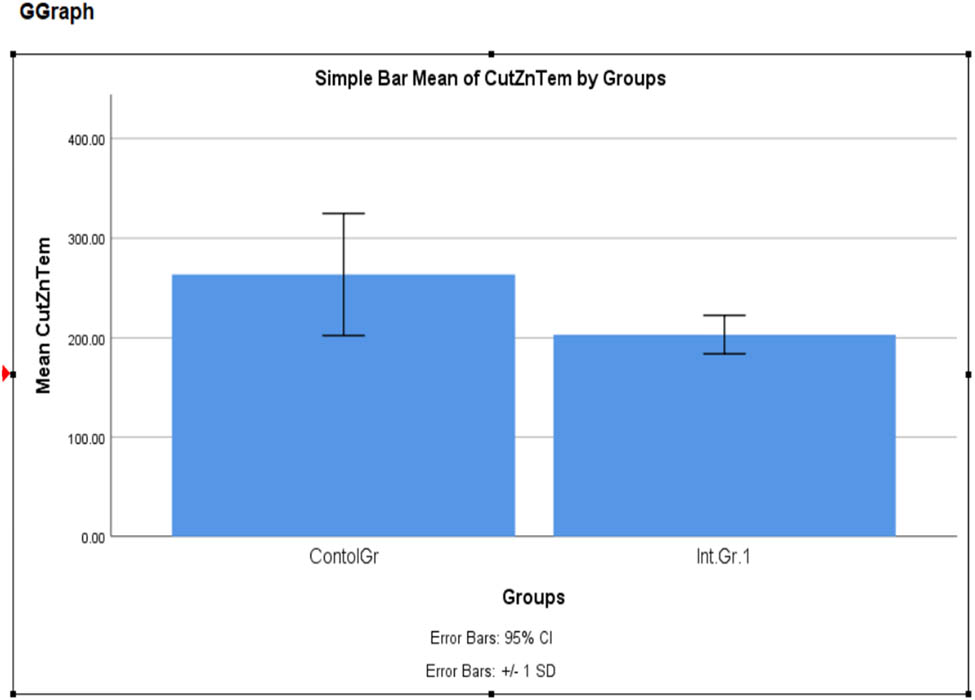

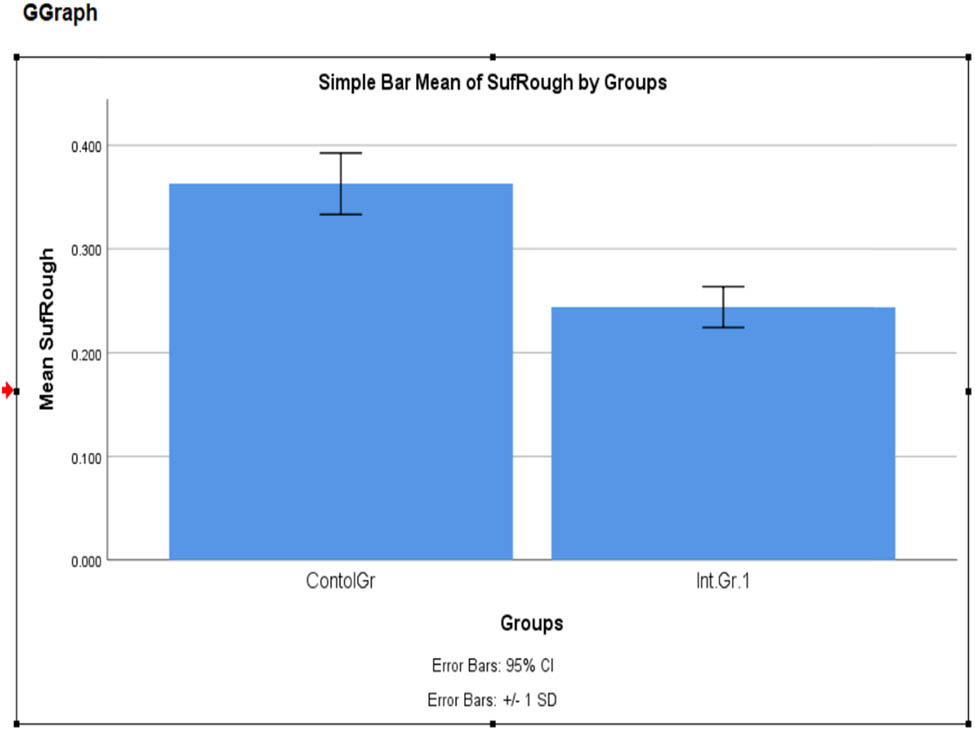

The machining performance was investigated for both machining methods by comparing the responses like cutting force, feed force, cutting zone temperature, surface roughness on machined surfaces, and wear of the tool. These results were statistically compared by performing one-way ANOVA, and a statistically significant difference was observed for material removal rate (p = 0.026, p < 0.05). Table 4 shows group statistics that are the results of the t-test. From this table, it is clear that the average (mean) cutting force reduced from 280.0863 to 211.8546 N with the use of the proposed nanofluid in place of a conventional commercial coolant (Figure 5). Similarly, the mean feed force decreased from 124.5194 to 90.3394 N (Figure 6), the mean cutting zone temperature from 263.5150 to 203.0800°C (Figure 7), the mean surface roughness from 0.36278 to 0.24387 µm (Figure 8), and the mean tool wear from 0.7525 to 0.3531 mg·h−1 (Figure 9). The above-discussed values are their mean values; Table 6 shows the improvement in the machinability average by using a nanofluid-based coolant obtained from the machining practice than the dry machining practice.

G-graph output comparing the mean values of the cutting force encountered at a 95% confidence level and error ±1% in the control group and the intervention group.

G-graph output comparing the mean values of the feed force encountered at a 95% confidence level and error ±1% in the control group and the intervention group.

G-graph output comparing the mean values of the cutting zone temperature encountered at a 95% confidence level and error ±1% in the control group and the intervention group.

G-graph output comparing the mean values of the surface roughness encountered at a 95% confidence level and error ±1% in the control group and the intervention group.

G-graph output comparing the mean values of tool wear encountered at a 95% confidence level and error ±1% in the control group and the intervention group.

Group statistics results of t-tests

| Group statistics | |||||

|---|---|---|---|---|---|

| Groups | N | Mean | Std. deviation | Std. error mean | |

| Cutting force | Control group | 16 | 280.0863 | 25.14723 | 6.28681 |

| Intervention group 1 | 16 | 211.8546 | 52.59007 | 13.14752 | |

| Feed force | Control group | 16 | 124.5194 | 5.264080 | 1.31602 |

| Intervention group 1 | 16 | 90.3394 | 2.798510 | 0.69963 | |

| Cutting zone temperature | Control group | 16 | 263.5150 | 61.28352 | 15.32088 |

| Intervention group 1 | 16 | 203.0800 | 19.53427 | 4.88357 | |

| Surface roughness | Control group | 16 | 0.36278 | 0.029805 | 0.007451 |

| Intervention group 1 | 16 | 0.24387 | 0.019671 | 0.004918 | |

| Tool wear | Control group | 16 | 0.7525 | 0.278270 | 0.06957 |

| Intervention group 1 | 16 | 0.3531 | 0.200190 | 0.05005 | |

Table 7 shows the results of the independent sample tests. It is evident from the table that the observations are significant, i.e. they did not violate statistical assumptions. As the value of significance (p) is 0.001 and it is less than 0.05, for cutting force observations of both groups (control and intervention groups), it can be confirmed that the observations obey statistical assumptions and are acceptable. Similarly, the significance value (p) is 0.023 (p < 0.05) for feed force observations.

Results of independent sample tests

| Independent sample tests | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Levene’s test for equality of variances | t-Test for equality of mean | |||||||||

| F | Sig. | t | DF | Sig. (2-tailed) | Mean difference | Std. error difference | 95% confidence interval of the difference | |||

| Lower | Upper | |||||||||

| Cutting force | Equal variances assumed | 12.780 | 0.001 | 4.682 | 30 | 0.000 | 68.23167 | 14.57330 | 38.46901 | 97.99432 |

| Equal variances not assumed | 4.682 | 21.519 | 0.000 | 68.23167 | 14.57330 | 37.96925 | 98.49409 | |||

| Feed force | Equal variances assumed | 5.746 | 0.023 | 22.933 | 30 | 0.000 | 34.18000 | 1.49043 | 31.13613 | 37.22387 |

| Equal variances not assumed | 22.933 | 22.852 | 0.000 | 34.18000 | 1.49043 | 31.09570 | 37.26430 | |||

| Cutting zone temperature | Equal variances assumed | 18.361 | 0.000 | 3.758 | 30 | 0.001 | 60.43500 | 16.08038 | 27.59448 | 93.27552 |

| Equal variances not assumed | 3.758 | 18.017 | 0.001 | 60.43500 | 16.08038 | 26.65365 | 94.21635 | |||

| Surface roughness | Equal variances assumed | 4.372 | 0.045 | 13.319 | 30 | 0.000 | 0.118908 | 0.008928 | 0.100675 | 0.137141 |

| Equal variances not assumed | 13.319 | 25.983 | 0.000 | 0.118908 | 0.008928 | 0.100556 | 0.137260 | |||

| Tool wear | Equal variances assumed | 5.311 | 0.028 | 4.660 | 30 | 0.000 | 0.39938 | 0.08570 | 0.22435 | 0.57440 |

| Equal variances not assumed | 4.660 | 27.246 | 0.000 | 0.39938 | 0.08570 | 0.22361 | 0.57514 | |||

It was observed that p = 0.0001 and p < 0.05 for the cutting zone temperature; p = 0.045 (p < 0.05) for surface roughness; and p = 0.028 (p < 0.05) for tool wear. Hence, observations were significant and acceptable as per the results of the independent sample tests.

As shown in Table 7, the positive mean values comparatively decrease the respective values than in the control group. It is understood that the cutting force at t 4.682 = 68.23167 N, i.e. 68.23167 N cutting force, averagely reduced with the use of the proposed nanofluid in place of a conventional commercial coolant; similarly, the feed force at t 22.933 = 34.18000 N, cutting zone temperature at t 3.758 = 60.43500°C, surface roughness at t 13.319 = 0.118908 µm, and tool wear t 4.660 = 0.39938 mg·h−1. Hence, the proposed method of processing significantly improved machinability.

Figure 5 shows the G-graph output by comparing the mean values of the cutting force encountered at a 95% confidence level and error ±1% in the control group and the intervention group. Similarly, Figures 6–9 show the G-graph output by comparing the mean values of the feed force, cutting zone temperature, surface roughness, and tool wear.

The minimum value of the responses, such as responses of the cutting force, feed force, cutting zone temperature, tool wear, and surface roughness, are preferred in the machining metals in the CNC lathe; therefore, the minimum value is best for obtaining the high-quality product, safe and reliable performance for a long time too [64–66]. Here, the optimization is to minimize the responses of the cutting force, feed force, cutting zone temperature, tool wear, and surface roughness, and the above-said responses are considered. In this investigation, it was suggested to minimize the responses; Hussain [53] and Naqiuddin et al. [54] proposed using the following signal-to-noise (S/N) ratio equation, where smaller values are preferred:

where the number of trails is expressed as

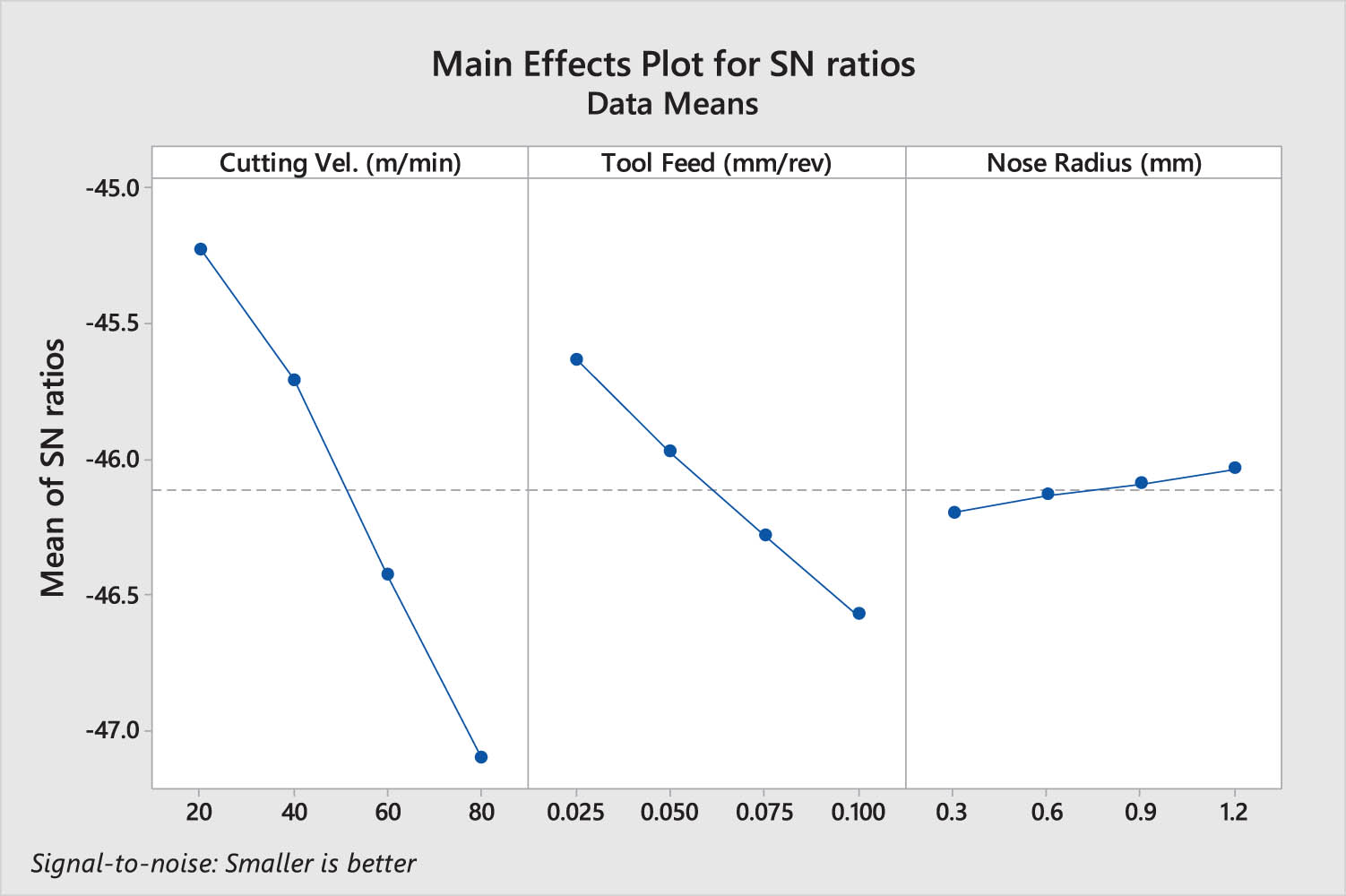

4.2 Taguchi analysis of the cutting force

Taguchi analysis gives the degree of possibilities to achieve the objective function. Here, the objective is to minimize the cutting force (the smaller the better) [21–26,67–70]. For this statistical model, the intervention group observations of cutting forces on 16 different experiments were used to optimize the proposed method. Figure 10 shows the main effect plots for the signal-to-noise ratio for the response observations of the cutting force during experiments with the proposed nanofluid. The above mean line indicates large signals (possibilities towards the objective function of reducing the cutting force) and the left-most graph for the cutting velocity shows an increase of the cutting force with the increase of the cutting velocity; in other words, a decrease of possibilities (signals) in minimizing the cutting force [71–73]. The decision could be made based on the highest signal-to-noise ratio. Hence, the input setting of the cutting velocity of 20 m·min−1 (S/N = −43.23), the feed rate of 0.025 mm·rev−1 (S/N = −45.58), and the nose radius tool of 0.3 mm (S/N = −46.13) gave a minimum cutting force (Figure 10). The variability is found to be higher in the cutting velocity input than in the tool feed and significantly less in the nose radius of the tool used [74–76]. Table 8 shows the results of the Taguchi analysis, which is the yield of S/N ratios.

Main effect plots for the signal-to-noise ratio for the response observations of the cutting force during experiments with the proposed nanofluid.

Taguchi analysis results for the observation of the cutting force

| Level of factors | Signal-to-noise ratio (the smaller the better) | ||

|---|---|---|---|

| Cutting velocity (m·min−1) | Tool feed (mm·rev−1) | Nose radius (mm) | |

| 1 | −43.23 | −45.58 | −46.13 |

| 2 | −45.48 | −46.03 | −46.19 |

| 3 | −47.51 | −47.00 | −46.40 |

| 4 | −48.80 | −46.41 | −46.31 |

| Delta | 5.58 | 1.41 | 0.27 |

| Rank | 1 | 2 | 3 |

Table 8 shows the classification of the process parameters based on their influence according to the delta value obtained in this statistical analysis. The higher delta value indicates a higher influence based on the delta value ranking of the process variable determined. As the delta value for the cutting velocity is 5.58 and greater than the data value of the tool feed and nose radius factors, the cutting velocity is the no. 1 factor (Rank 1) and influences the cutting force while machining. Accordingly, Rank 2 is for the tool feed (delta = 1.41) and Rank 3 is for the nose radius of the tool.

4.3 ANOVA results on the response of the cutting force

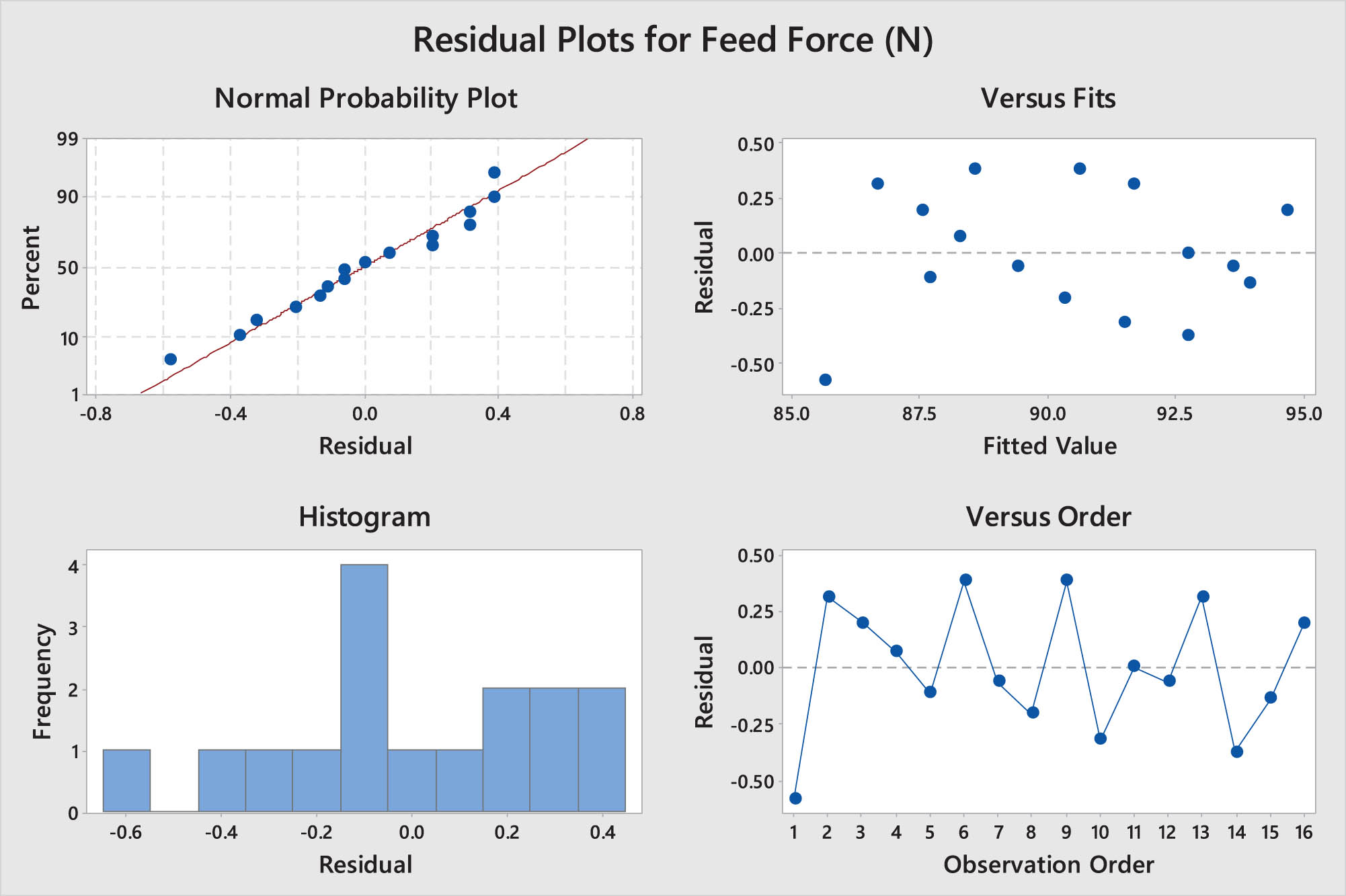

The residual plots for cutting force observations are shown in Figure 11. The normal probability plot shows the quality of observations [77–82]. No observations deviate much from the mean line and residual error in these observations. Hence, it is concluded that the observations are not violating the statistical assumption and are ensured as valid.

Residual plot for cutting force observations.

Table 9 shows the results of the ANOVA on the response of the cutting force for the decision on the influence of factors. In this stage, one can decide the factor level based on the p-value. Here, a minimum p-value indicates more influence. The decision criteria are as follows: if p < 0.05, the factor is significantly influencing the measured response, and p > 0.1 indicates an insignificant factor [83–85]. From the Taguchi analysis, it was observed that the cutting force was of Rank 1 and the significant value was 0.001 (very low); similarly, p = 0.004 (p < 0.05) for the tool feed. But, in the case of the nose radius, p = 0.940 (p > 0.1), so it was found to be insignificant. Table 9 shows the results of ANOVA at factor-level decision-making. This is a process that can be controlled for meeting the cutting force by altering the independent variables in which a highly sensitive independent variable has a low value of p; in other words, the independent variable which contributes more to alter the response of the cutting force has a higher F value [86–88]. Hence, the high contribution (F-240.72), a highly sensitive independent variable, is the cutting velocity (as F = 240.72 and p = 0.001 in Table 9). The next is the tool feed. But the nose radius is not significant as p = 0.940 > 0.10 [89–91], which means the change in the nose radius does not affect the cutting force considerably [92–94]. Hence, the contribution is very low (F = 0.13).

Results of the ANOVA on the response of the cutting force for a decision on influencing factors

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Cutting velocity (m·min−1) | 3 | 38822.6 | 12940.9 | 240.72 | 0.000 |

| Tool feed (mm·rev−1) | 3 | 2322.1 | 774.0 | 14.40 | 0.004 |

| Nose radius (mm) | 3 | 20.7 | 6.9 | 0.13 | 0.940 |

| Error | 6 | 322.6 | 53.8 | ||

| Total | 15 | 41488.0 |

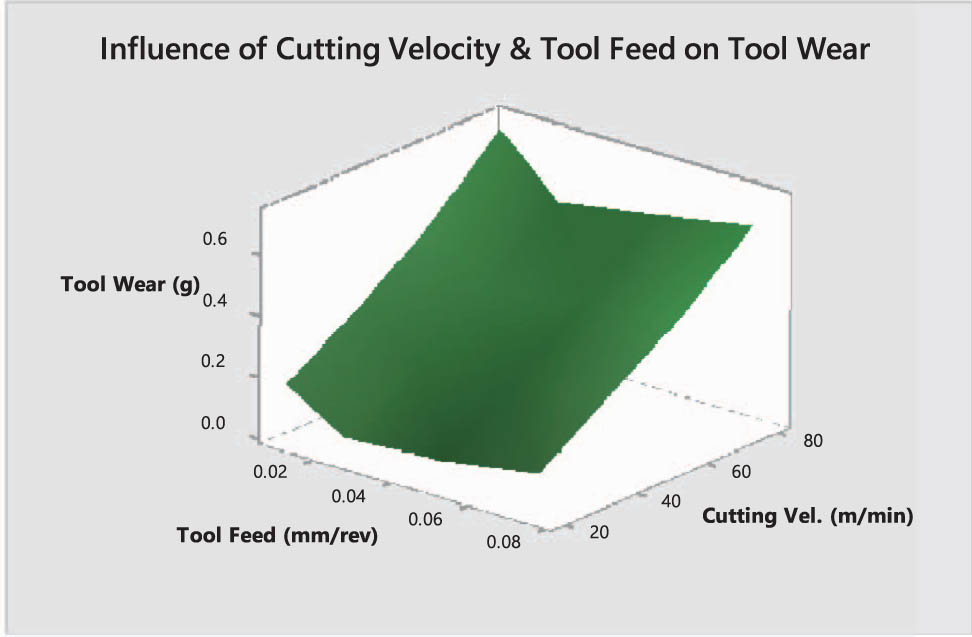

The table of coefficients is shown in Table 10, from which one can take a deep decision on the degree of influence of factor at its level of input. Similar to Table 9, here the p-value indicates the significance of the level of factors on the response. From this output, the influence factors can be observed. As p > 0.1, the tool feed of 0.050 mm·rev−1 (p = 0.131) and nose radii of 0.3 mm (p = 0.832), 0.6 mm (p = 0.979), and 0.9 mm (p = 0.577) are not significant, as the nose radius does not influence. The relation between the tool feed rate and cutting speed is depicted on the three-axis graphs surface plot in Figure 12. From this plot, the combined effects of both variables on the response of the cutting force at the cutting zone can be understood.

Results of ANOVA on the response of the cutting force for the decision on influence factors

| Term | Coefficient | SE coefficient | T-value | p-Value | V IF |

|---|---|---|---|---|---|

| Constant | 211.85 | 1.83 | 115.58 | 0.000 | |

| Cutting velocity (m·min −1 ) | |||||

| 20 | −66.59 | 3.17 | −20.98 | 0.000 | 1.50 |

| 40 | −23.12 | 3.17 | −7.28 | 0.000 | 1.50 |

| 60 | 25.99 | 3.17 | 8.19 | 0.000 | 1.50 |

| Tool feed (mm·rev −1 ) | |||||

| 0.010 | 17.50 | 3.17 | 5.51 | 0.001 | 1.50 |

| 0.025 | −15.25 | 3.17 | −4.80 | 0.003 | 1.50 |

| 0.050 | −5.56 | 3.17 | −1.75 | 0.131 | 1.50 |

| Nose radius (mm) | |||||

| 0.3 | −0.70 | 3.17 | −0.22 | 0.832 | 1.50 |

| 0.6 | −0.09 | 3.17 | −0.03 | 0.979 | 1.0 |

| 0.9 | 1.87 | 3.17 | 0.59 | 0.577 | 1.50 |

A 3D surface plot showing the relationship between the tool feed and cutting velocity in cutting force response.

4.4 Regression equation

The regression equation was developed based on the coefficients obtained in the ANOVA, and the results are shown in Table 11. The mathematical model is a mathematical equation from which anyone can interpret values of untested combinations or predict the process parameter levels for the desired response [95–97]. The developed regression model is given as follows:

Model summary for the Taguchi analysis on the cutting force response

| S | R 2 | R 2 (adj) | R 2 (pred) |

|---|---|---|---|

| 7.33211 | 99.22% | 98.06% | 94.47% |

The 3D surface plot (Figure 11) exhibits the relationship between the cutting velocity and tool feed inputs on the cutting force. The factor cannot be taken into account here as it is insignificant for the cutting force.

ANOVA results for validation of a statistical model for the cutting force response can be noticed from the R 2 value from the model summary (Table 8). The condition is that the R 2 value must be greater than 95% for a good model; in this case, the value of R 2 is 99.22% and hence the model is acceptable. It also indicates that there is a good agreement between the predicted and experimented values.

4.5 Taguchi analysis of the feed force

As known, Taguchi analysis offers some degree of possibility to achieve the objective of the function. Here, the aim is to minimize the feed force (smaller the best). For this statistical model, the intervention group observations of cutting forces on 16 different experiments were used to optimize the process parameters.

Figure 13 shows the main effect plots for the signal-to-noise ratio for the response observations of the feed force during experiments with the proposed nanofluid. Figure 13 shows that a higher S/N ratio implies the best possibility for obtaining a low feed force at a cutting velocity of 20 m·min−1, a feed rate of the tool of 0.025 mm·rev−1, and a nose radius tool of 0.9 or 1.2 mm. The ambiguity of the nose radius tool selection is clarified in Table 12. Level 4 has the highest signal-to-noise ratio of −39.10 in comparison with both Levels 1 and 3, respectively. So, a 1.2 mm radius offers a minimum feed force at the cutting zone.

Main effect plots for the signal-to-noise ratio of feed force response observations during experiments with the proposed nanofluid.

Taguchi analysis results for the observation of the feed force

| Level | Cutting velocity (m·min−1) | Tool feed (mm·rev−1) | Nose radius (mm) |

|---|---|---|---|

| 1 | −38.79 | −39.25 | −39.12 |

| 2 | −38.99 | −38.97 | −39.12 |

| 3 | −39.28 | −39.07 | −39.11 |

| 4 | −39.39 | −39.17 | −39.10 |

| Delta | 0.60 | 0.27 | 0.02 |

| Rank | 1 | 2 | 3 |

The mean line in Figure 13 indicates large signals (possibilities towards the objective function of reducing the feed force); the left-most graph for the cutting velocity shows an increase of feed force with the increase of cutting velocity; in other words, a decrease of possibilities (signals) in minimizing the feed force [98–100]. Hence, the input setting of 20 m·min−1 cutting velocity, 0.025 mm·rev−1 feed rate, and 0.3 mm nose radius tool gave a minimum feed force. The variability is found to be high in the cutting velocity input than in the tool feed and very low in the nose radius of the tool used [101–103]. Table 12 shows the results of the Taguchi analysis, which is the yield of S/N ratios.

Table 12 describes the process parameters based on their influence according to the delta value obtained statistically. The higher delta value indicates a higher influence based on the delta value ranking of the process variable determined. As the delta value for the cutting velocity is 0.6, which is greater than the data values of tool feed and nose radius factors, the cutting velocity is the no. 1 factor (Rank 1) influencing the feed force while machining. Accordingly, Rank 2 is for the tool feed (delta = 0.27), and Rank 3 is for the nose radius of the tool (delta = 0.02).

4.6 ANOVA results on the response of the feed force

The residual plots for feed force observations are shown in Figure 14. The normal probability plot shows the quality of observations. No observations deviate much from the mean line, and residual errors in these observations are in an acceptable range. But only one observation out of 16 was found to deviate (Table 13). Hence, observational accuracy was ensured from the statistical output of ANOVA, as shown in Figure 14.

Residual plot for feed force observations.

Fits and diagnostics for unusual observations of the feed force

| Obs | Feed force (N) | Fit | Residual | Std residual | |

|---|---|---|---|---|---|

| 1 | 85.030 | 85.614 | −0.584 | −2.09 | R is a large residual |

The results of the ANOVA on the response of the feed force for a decision on the influence of factors are explained in Table 14. In this stage, one decides factor-level decisions based on the p-value. Here, a minimum p-value indicates more influence. The decision criteria are as follows: if p < 0.05, the factor is significantly influencing the measured response; p > 0.1 indicates an insignificant factor. From Taguchi analysis, it was observed that the feed force was of Rank 1 and the significant value was 0.001 (very low); similarly, p = 0.001 (p < 0.05) for the tool feed. But, in the case of nose radius, p = 0.846 (p > 0.1) so it was found to be insignificant. Table 14 shows the results of ANOVA at factor level decision making. It can be understood from Table 14 that for controlling the process for obtaining the desired response of feed force, alter the cutting velocity than the tool feed rate. There is no use in varying the tool inserts with different nose radii [104–106].

Results of ANOVA for the analysis on the influence of factors

| Source | DF | Adj SS | Adj MS | F-value | p-Value |

|---|---|---|---|---|---|

| Cutting velocity (m·min−1) | 3 | 97.771 | 32.5904 | 157.29 | 0.000 |

| Tool feed (mm·rev−1) | 3 | 18.294 | 6.0979 | 29.43 | 0.001 |

| Nose radius (mm) | 3 | 0.167 | 0.0556 | 0.27 | 0.846 |

| Error | 6 | 1.243 | 0.2072 | ||

| Total | 15 | 117.475 |

The table of coefficients is shown in Table 15, from which one can take a deep decision on the degree of the influence of the factor at its level of input. Similar to Table 14, here, the p-value indicates the significance of the level of factors on the response. Table 15 gives much insight into the above decision that variation of tool feeds up to 0.025 is better than the range 0.025–0.050 for reduction of the feed force on the tool. Figure 15 shows the 3D surface plot of the relationship between the tool feed and cutting velocity in the feed force response.

Results of ANOVA on the response of the cutting force for a decision on the influence at the level of factors

| Term | Coefficient | SE coefficient | T-Value | p-Value | VIF |

|---|---|---|---|---|---|

| Constant | 90.339 | 0.114 | 793.86 | 0.000 | |

| Cutting velocity (m·min −1 ) | |||||

| 20 | −3.322 | 0.197 | −16.85 | 0.000 | 1.50 |

| 40 | −1.352 | 0.197 | −6.86 | 0.000 | 1.50 |

| 60 | 1.763 | 0.197 | 8.95 | 0.000 | 1.50 |

| Tool feed (mm·rev −1 ) | |||||

| 0.010 | 1.378 | 0.197 | 6.99 | 0.000 | 1.50 |

| 0.025 | −1.457 | 0.197 | −7.39 | 0.000 | 1.50 |

| 0.050 | −0.484 | 0.197 | −2.46 | 0.049 | 1.50 |

| Nose radius (mm) | |||||

| 0.3 | 0.053 | 0.197 | 0.27 | 0.797 | 1.50 |

| 0.6 | 0.133 | 0.197 | 0.68 | 0.525 | 1.50 |

| 0.9 | −0.049 | 0.197 | −0.25 | 0.811 | 1.50 |

A 3D surface plot showing the relationship between the tool feed and cutting velocity in the feed force response.

4.7 Regression equation

Table 15 mainly helps to form the mathematical model by generating the regression equation. The mathematical model helps one to interpret values of untested combinations or predict the process parameter levels for the desired response. The regression model is given as follows:

The validation of a statistical model for the feed force response can be observed from the R 2 value of the model summary (Table 16). The condition is that the R 2 value must be greater than 95% for a good model; in this case, the R 2 value is 98.94% and hence the model is acceptable. As R 2 > 95%, the regression equation is reliable and its prediction accuracy is high.

Model summary for the Taguchi analysis on the cutting force response

| S | R 2 | R 2 (adj) | R 2 (pred) |

|---|---|---|---|

| 0.455190 | 98.94% | 97.35% | 92.47% |

4.8 Taguchi analysis on the surface roughness

Taguchi analysis gives the degree of possibilities to achieve the objective function. Here, the objective is to minimize the surface roughness (the smaller the better). For this statistical model, the intervention group observations of the surface roughness in 16 different experiments were used to optimize the proposed method. Figure 16 shows the main effect plots for the signal-to-noise ratio for the response observations of the surface roughness during experiments with the proposed nanofluid. The mean line indicates large signals (possibilities towards the objective function of reducing the surface roughness), and the right-most graph for the cutting velocity shows that with an increase of surface roughness, there is a decrease in the cutting velocity, i.e. a decrease in the cutting speed possibilities (signals) increases the surface roughness [81,107–111]. Hence, the input setting of Level 4,80 m·min−1 cutting velocity (as maximum S/N ratio is −17.37), 0.100 mm·rev−1 (Level 4) feed rate (as maximum S/N ratio is −18.05), and 0.3 mm (Level 1) nose radius tool (as maximum S/N ratio is −18.25) gave a minimum surface roughness (Figure 16 and Table 17). The variability is found to be high in the cutting velocity input than in the tool feed and very low in the nose radius of the tool used [112–114]. Table 17 shows the results of the Taguchi analysis, which is the yield of S/N ratios.

Main effect plots for the signal-to-noise ratio for the response observations of surface roughness during experiments with the proposed nanofluid.

Taguchi analysis results for the observation of the surface roughness

| Level | Cutting velocity (m·min−1) | Tool feed (mm·rev−1) | Nose radius (mm) |

|---|---|---|---|

| 1 | −19.08 | −18.21 | −18.25 |

| 2 | −18.74 | −18.66 | −18.37 |

| 3 | −18.17 | −18.43 | −18.39 |

| 4 | −17.37 | −18.05 | −18.35 |

| Delta | 1.71 | 0.61 | 0.15 |

| Rank | 1 | 2 | 3 |

Table 17 ranks the process parameters based on their influence according to the delta value obtained in this statistical analysis. A higher delta value indicates a higher influence based on the delta value ranking of the process variable determined. Since the delta value for the cutting velocity is 1.71, which is greater than the data value of the tool feed and nose radius factors, the cutting velocity has the highest influence on the surface roughness during machining, ranking first (Rank 1). Accordingly, Rank 2 is for the tool feed (delta = 0.61), and Rank 3 is for the nose radius of the tool (delta = 0.15).

4.9 ANOVA results on the response of surface roughness

The residual plots for surface roughness observations are shown in Figure 17. The normal probability plot shows the quality of observations. No observations deviate much from the mean line, and residual errors in these observations are in the acceptable range. Hence, from Figure 17 and Table 18, it is evident that, except fifth observation, the remaining observations are acceptable as per the statistical verification by ANOVA.

Residual plot for surface roughness observations.

Fits and diagnostics for unusual observations of surface roughness

| Observation | Surface roughness (µm) | Fit | Residual | Std residual | |

|---|---|---|---|---|---|

| 5 | 8.9300 | 8.9987 | −0.0687 | −2.03 | R is a large residual |

Table 19 shows the results of the ANOVA on the response of surface roughness for the decision on the influence of factors. In this stage, one can take the decision on the factor level, based on the p-value. Here, a minimum p-value indicates more influence. The decision criteria are as follows: if p < 0.05, the factor is significantly influencing the measured response; p > 0.1 indicates an insignificant factor. From Taguchi analysis, it was observed that the surface roughness was of Rank 1 and the significant value was 0.001 (very low); similarly, p = 0.001 (p < 0.05) for the tool feed. But, in the case of the nose radius, p = 0.090 (0.05 < p < 0.1), and it did not influence considerably. Table 19 shows the results of ANOVA at a factor level decision making, which reveals that for obtaining the desired surface roughness, it is better to alter the cutting speed for the best response and alter the tool feed for fine tuning. The alternation tools with various nose radii should be avoided.

Results of ANOVA for the analysis on the influence of factors

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Cutting velocity (m·min−1) | 3 | 5.89082 | 1.96361 | 642.49 | 0.000 |

| Tool feed (mm·rev−1) | 3 | 0.75682 | 0.25227 | 82.54 | 0.000 |

| Nose radius (mm) | 3 | 0.03202 | 0.01067 | 3.49 | 0.090 |

| Error | 6 | 0.01834 | 0.00306 | ||

| Total | 15 | 6.69799 |

The table of coefficients is shown in Table 20, from which one can take a deep decision on the degree of influence of a factor at its level of input. Similar to Table 19, here, the p-value indicates the significance of the level of factors on the response. Table 20 recommends the use of a cutting tool with a nose radius of 0.3 mm for obtaining a significant response on the surface finish (lower surface roughness). The recommended range of cutting velocity is 20–60 m·min−1. Similarly, the tool feed from 0.10 to 0.025 mm·rev−1 will give appreciable results on the surface finish. Hence, the major contribution is the cutting velocity, and the tool feed rate inputs for the surface roughness and its interactive effects on the surface roughness on the job are depicted in Figure 18.

Results of ANOVA on the response of surface roughness for the decision on the influence at the level of factors

| Term | Coefficient | SE coefficient | T-Value | p-Value | VIF |

|---|---|---|---|---|---|

| Constant | 8.2844 | 0.0138 | 599.41 | 0.000 | |

| Cutting velocity (m·min −1 ) | |||||

| 20 | 0.7081 | 0.0239 | 29.58 | 0.000 | 1.50 |

| 40 | 0.3706 | 0.0239 | 15.48 | 0.000 | 1.50 |

| 60 | −0.1844 | 0.0239 | −7.70 | 0.000 | 1.50 |

| Tool feed (mm·rev −1 ) | |||||

| 0.010 | −0.2694 | 0.0239 | −11.25 | 0.000 | 1.50 |

| 0.025 | 0.3056 | 0.0239 | 12.77 | 0.000 | 1.50 |

| 0.050 | 0.0881 | 0.0239 | 3.68 | 0.010 | 1.50 |

| Nose radius (mm) | |||||

| 0.3 | −0.0694 | 0.0239 | −2.90 | 0.027 | 1.50 |

| 0.6 | 0.0381 | 0.0239 | 1.59 | 0.162 | 1.50 |

| 0.9 | 0.0406 | 0.0239 | 1.70 | 0.141 | 1.50 |

A 3D surface plot showing the relationship between the tool feed and cutting velocity in surface roughness response.

4.10 Regression equation

Table 20 mainly helps to form the mathematical model by generating the regression equation. From the mathematical model, one can interpret the values of untested combinations or predict the process parameter levels for the desired response. The regression model is given as follows:

The validation of a statistical model for the surface roughness response can be observed from the R 2 value of the model summary (Table 21). The condition is that the R 2 value must be greater than 95% for a good model; in this case, the R 2 value is 99.73%. Hence, the model is acceptable. The R 2 value also confirms the reliability of the mathematical model (Eq. (3)) in the prediction of the response of surface roughness.

Model summary for the Taguchi analysis on the surface roughness response

| S | R 2 | R 2 (adj) | R 2 (pred) |

|---|---|---|---|

| 0.0552834 | 99.73% | 99.32% | 98.05% |

4.11 Taguchi analysis on the cutting zone temperature

Taguchi analysis gives the degree of possibilities to achieve the objective function. Here, the objective is to minimize the cutting zone temperature (smaller is better in the signal-to-noise ratio). For this statistical model, the intervention group observations of cutting zone temperatures on 16 different experiments were used to optimize the proposed method. Figure 19 shows the main effect plots for signal-to-noise ratios for the response observations of the cutting zone temperature during experiments with the proposed nanofluid.

Main effect plots for signal-to-noise ratios for the response observations of the cutting zone temperature during experiments with the proposed nanofluid.

The mean line indicates large signals (possibilities towards the objective function of reducing the cutting zone temperature). The left-most graph for the cutting velocity shows an increase in the cutting zone temperature with an increase in the cutting velocity; in other words, a decrease of possibilities (signals) in minimizing the cutting zone temperature. Hence, the following input levels: level 1, 20 m·min−1 cutting velocity (as the maximum S/N ratio is −45.23); level 1, 0.025 mm·rev−1 feed rate (as maximum S/N ratio is −46.28); and level 4 of 0.3 mm nose radius tool (as maximum S/N ratio is −46.04) recorded a minimum cutting zone temperature (refer to Figure 19 and Table 22). The variability is found to be high in the cutting velocity input than the tool feed and very low in the nose radius of the tool used. Table 19 shows the results of the Taguchi analysis, which is the yield of S/N ratios.

Taguchi analysis results for the observation of the cutting zone temperature

| Level | Cutting velocity (m·min−1) | Tool feed (mm·rev−1) | Nose radius (mm) |

|---|---|---|---|

| 1 | −45.23 | −46.28 | −46.04 |

| 2 | −45.71 | −45.64 | −46.13 |

| 3 | −46.43 | −45.97 | −46.09 |

| 4 | −47.10 | −46.57 | −46.20 |

| Delta | 1.88 | 0.94 | 0.16 |

| Rank | 1 | 2 | 3 |

The process parameters based on their influence according to the delta value obtained in this statistical analysis are shown in Table 22. The higher delta value indicates a higher influence based on the delta value ranking of the process variable. As the delta value for the cutting velocity is 5.58 and is greater than the delta values of the tool feed and nose radius factors, the cutting velocity is the no. 1 factor (Rank 1) and influences the cutting zone temperature while machining. Accordingly, Rank 2 is for the tool feed (delta = 1.41), and Rank 3 is for the nose radius of the tool.

4.12 ANOVA results on the response of the cutting zone temperature

The residual plots for cutting zone temperature observations are shown in Figure 20. The normal probability plot shows the quality of observations. The number of observations deviates from the mean line and the number of residual errors was observed in these observations. Hence, these observations are statistically acceptable.

Residual plot for cutting zone temperature observations.

Table 23 shows the results of the ANOVA on the response of the cutting zone temperature for a decision on the influence of factors. In this stage, one can take a decision on the factor level based on the p-value. Here, a minimum p-value indicates more influence. The decision criteria are as follows: if p < 0.05, the factor is significantly influencing the measured response, and p > 0.1 indicates an insignificant factor. From Taguchi analysis, it was observed that the cutting zone temperature was of Rank 1 and the significant value was 0.001 (very low); similarly, p = 0.001 (p < 0.05) for the tool feed. But, in the case of the nose radius, p = 0.156 (p > 0.1), so it was found to be insignificant. Table 23 shows the results of ANOVA at the factor level decision making and it is concluded that all factors other than the nose radius of the tool are considered.

Results of ANOVA for the analysis on the influence of factors

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Cutting velocity (m·min−1) | 3 | 4512.80 | 1504.27 | 188.08 | 0.000 |

| Tool feed (mm·rev−1) | 3 | 1102.91 | 367.64 | 45.97 | 0.000 |

| Nose radius (mm) | 3 | 60.11 | 20.04 | 2.51 | 0.156 |

| Error | 6 | 47.99 | 8.00 | ||

| Total | 15 | 5723.82 |

The table of coefficients is shown in Table 24, from which one can take a deep decision on the degree of the influence of the factor at its level of input. Similar to Table 23, here, the p-value indicates the significance of the level of factors on the response. Table 24 reflects the same decision as in Table 20 with some insights into the recommended range of input variation on the cutting velocity of 20–60 m·min−1 and the tool feed of 0.010–0.025 mm·rev−1. Under unavoidable circumstances, the range may extend up to 0.050. The tool with a nose radius of 0.3 mm can be used for the minimum cutting zone temperature. Hence, the change in the tool radius is not recommended, and it is clear that there is a contribution from the cutting speed and tool feed, and the contribution from the nose radius of the tool used is negligible. The combined effects of the cutting speed and tool feed on the response of the cutting zone temperature are graphically depicted in Figure 21.

Results of ANOVA on the response of the cutting zone temperature for a decision on the influence at the level of factors

| Term | Coefficient | SE coefficient | T-Value | p-Value | VIF |

|---|---|---|---|---|---|

| Constant | 203.080 | 0.707 | 287.23 | 0.000 | |

| Cutting velocity (m·min −1 ) | |||||

| 20 | −20.48 | 1.22 | −16.72 | 0.000 | 1.50 |

| 40 | −9.98 | 1.22 | −8.15 | 0.000 | 1.50 |

| 60 | 6.71 | 1.22 | 5.48 | 0.002 | 1.50 |

| Tool feed (mm·rev −1 ) | |||||

| 0.010 | 11.07 | 1.22 | 9.04 | 0.000 | 1.50 |

| 0.025 | −11.24 | 1.22 | −9.18 | 0.000 | 1.50 |

| 0.050 | −3.57 | 1.22 | −2.92 | 0.027 | 1.50 |

| Nose radius (mm) | |||||

| 0.3 | 2.67 | 1.22 | 2.18 | 0.072 | 1.50 |

| 0.6 | 0.82 | 1.22 | 0.67 | 0.526 | 1.50 |

| 0.9 | −0.98 | 1.22 | −0.80 | 0.452 | 1.50 |

A 3D surface plot showing the relationship between the tool feed and cutting velocity in the cutting zone temperature response.

4.13 Regression equation

Table 24 mainly helps to form the mathematical model by generating the regression equation. From the mathematical model, one can interpret values of untested combinations or predict the process parameter levels for the desired response. The regression model is given as follows:

The validation of a statistical model for the cutting zone temperature response can be observed from the R 2 value of the model summary. Table 25 shows the model summary for the Taguchi analysis on the cutting zone temperature response. The condition is that the R 2 value must be greater than 95% for a good model. In this case, the R 2 value is 99.16%; hence, the model is acceptable. Apart from these, the R 2 values ensured the reliability of the mathematical model as shown in Eq. (4).

Model summary for the Taguchi analysis on the cutting zone temperature response

| S | R 2 | R 2 (adj) | R 2 (pred) |

|---|---|---|---|

| 2.82809 | 99.16% | 97.90% | 94.04% |

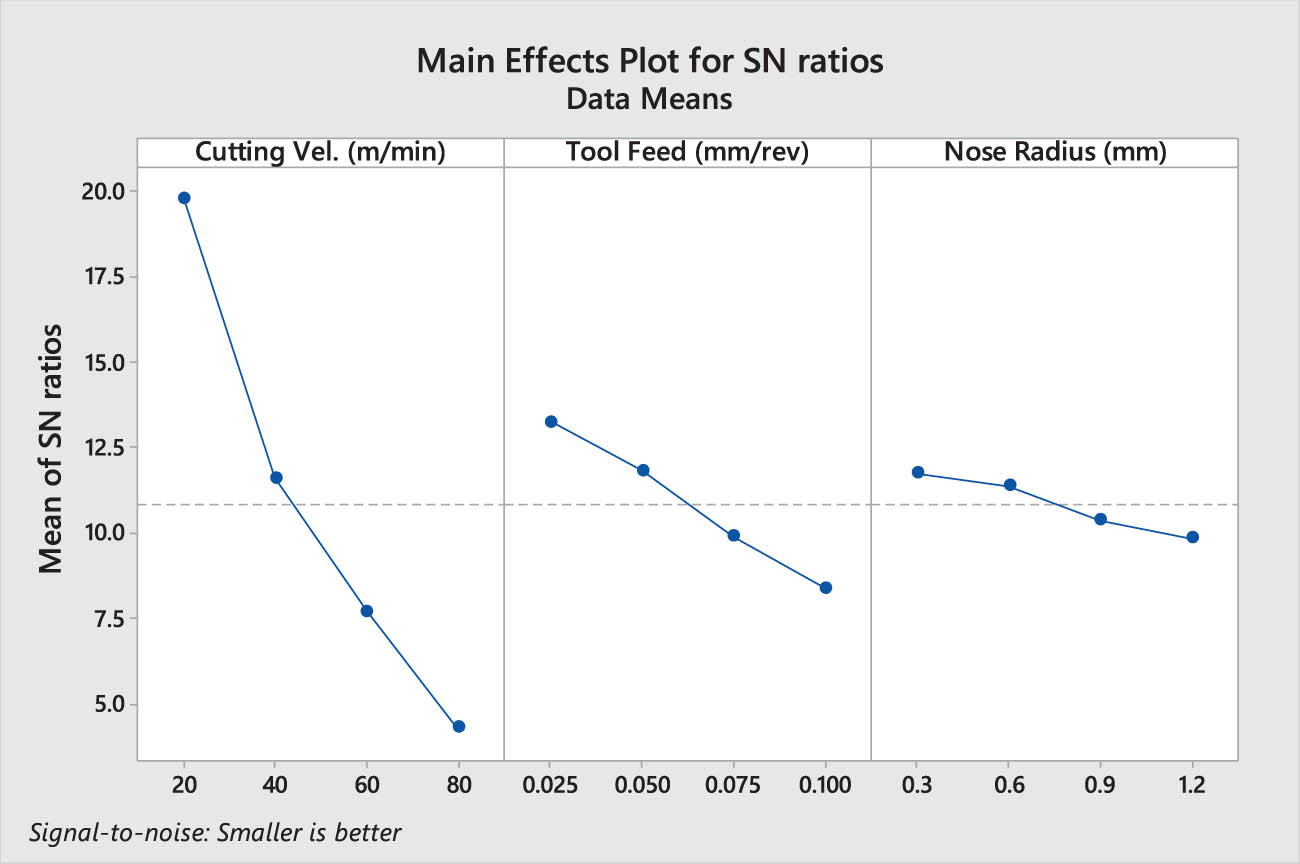

4.14 Taguchi analysis of the tool wear

Taguchi analysis gives the degree of possibilities to achieve the objective function. Here, the objective is to minimize the tool wear (the smaller the better).

For this statistical model, the intervention group observations of tool wear on 16 different experiments were used to optimize the proposed method. Figure 22 shows the main effect plots for signal-to-noise ratios for the response observations of tool wear during experiments with the proposed nanofluid. The mean line indicates large signals (possibilities towards the objective function of reducing the tool wear). The top leftmost graph for the cutting velocity shows an increase in tool wear with an increase in the cutting velocity; in other words, a decrease of possibilities (signals) when minimizing the tool wear. Hence, the input setting of Level 1, 20 m·min−1 (as the signal-to-noise ratio is 19.748) cutting velocity, 0.025 mm·rev−1 feed rate (as the signal-to-noise ratio is 13.219), and 0.3 mm nose radius of the tool (as the signal-to-noise ratio is 11.735) gave minimum tool wear (refer to Figure 22 and Table 26). The variability is found to be higher in the cutting velocity input than in the tool feed and lower in the nose radius of the tool used. Table 26 shows the results of the Taguchi analysis, which was the yield of S/N ratios.

Main effect plots for the signal-to-noise ratio for the response observations of tool wear during experiments with the proposed nanofluid.

Taguchi analysis results for the observation of the tool wear

| Level | Cutting velocity (m·min−1) | Tool feed (mm·rev−1) | Nose radius (mm) |

|---|---|---|---|

| 1 | 19.748 | 13.219 | 11.735 |

| 2 | 11.583 | 11.811 | 11.348 |

| 3 | 7.675 | 9.870 | 10.363 |

| 4 | 4.274 | 8.380 | 9.835 |

| Delta | 15.473 | 4.839 | 1.900 |

| Rank | 1 | 2 | 3 |

Figure 23 shows that all observations are statistically accepted as there is good nearness in the mean line in the residual plot. Table 27 illustrates the results of the ANOVA on the response of the tool wear for the decision on the influence of factors. In this stage, one can take a decision on the factor level based on the p-value. Here, the minimum p-value influences are more. The decision criteria are as follows: if p < 0.05, the factor is significantly influencing the measured response, and p > 0.1 indicates an insignificant factor. From Taguchi analysis, it was observed that the cutting velocity is of Rank 1 and its significant value is 0.001 (very low); similarly, p = 0.004 (p < 0.05) for the tool feed. But, in the case of nose radius, p = 0.940 (p > 0.1), so it was found to be insignificant. Table 27 shows the results of ANOVA at the factor level decision making and confirms that other than nose radius, all independent variables considered are significant and they can be used to control the process for rapid and fine-tuning for minimum tool wear. Figure 24 exhibits the 3D surface plot that shows the relationship between the tool feed and cutting velocity in the tool wear response.

Residual plot for tool wear observations.

Results of ANOVA for the analysis on the influence of factors on the tool wear

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Cutting velocity (m·min−1) | 3 | 0.551819 | 0.183940 | 1731.20 | 0.000 |

| Tool feed (mm·rev−1) | 3 | 0.047869 | 0.015956 | 150.18 | 0.000 |

| Nose radius (mm) | 3 | 0.000819 | 0.000273 | 2.57 | 0.150 |

| Error | 6 | 0.000637 | 0.000106 | ||

| Total | 15 | 0.601144 |

3D surface plot showing a relationship between the tool feed and cutting velocity in the tool wear response.

The table of coefficients is shown in Table 28, from which one can take a deep decision on the degree of influence of the factor at its level of input. As in Table 27, the p-value indicates the significance of the level of factors on the response. Though Table 28 gives the same decision, it also gives some deep insights for controlling the tool wear: the cutting velocity should be varied from 20 to 60 m·min−1, the tool wear from 0.010 to 0.050 mm·rev−1, and 0.03 mm nose radius should be used than other three types of tools.

Results of ANOVA on the response of the tool wear for a decision on the influence at the level of factors

| Term | Coefficient | SE coefficient | T-Value | p-Value | VIF |

|---|---|---|---|---|---|

| Constant | 0.35312 | 0.00258 | 137.03 | 0.000 | |

| Cutting velocity (m·min −1 ) | |||||

| 20 | −0.24063 | 0.00446 | −53.91 | 0.000 | 1.50 |

| 40 | −0.08562 | 0.00446 | −19.18 | 0.000 | 1.50 |

| 60 | 0.06438 | 0.00446 | 14.42 | 0.000 | 1.50 |

| Tool feed (mm·rev −1 ) | |||||

| 0.010 | 0.07688 | 0.00446 | 17.22 | 0.000 | 1.50 |

| 0.025 | −0.06812 | 0.00446 | −15.26 | 0.000 | 1.50 |

| 0.050 | −0.03063 | 0.00446 | −6.86 | 0.000 | 1.50 |

| Nose radius (mm) | |||||

| 0.3 | 0.00937 | 0.00446 | 2.10 | 0.080 | 1.50 |

| 0.6 | 0.00437 | 0.00446 | 0.98 | 0.365 | 1.50 |

| 0.9 | −0.00812 | 0.00446 | −1.82 | 0.119 | 1.50 |

4.15 Regression equation

Table 28 mainly helps to form the mathematical model by generating the regression equation. From the mathematical model, one can interpret the values of untested combinations or predict the process parameter levels for the desired response. The regression model is given as follows:

The validation of the statistical model for the tool wear response can be observed from the R 2 value of the model summary. Table 29 furnishes the model summary for the Taguchi analysis on the tool wear response. The condition is that the R 2 value must be greater than 95% for a good model. In this case, the value of R 2 is 99.89%. Hence, the model is acceptable. Moreover, the R 2 value also confirmed the reliability and accuracy of the prediction model (Eq. (5)).

Model summary for the Taguchi analysis on the tool wear response

| S | R 2 | R 2 (adj) | R 2 (pred) |

|---|---|---|---|

| 0.0103078 | 99.89% | 99.73% | 99.25% |

Hence, the proposed manufacturing process outperformed other methods. The machinability includes a reduction in all five aspects: the cutting force, feed force, cutting zone temperature, surface roughness, and tool wear [115,116]. The limitation of this study is that the influence of specially coated tool inserts was not included in the examinations. The harder tool suffers from less tool wear, and the machinability of the surface roughness will be reduced further. Another limitation is that too small implants could not be machined by using this processing method. The future scope shall include process variables that do not affect the quality of the implant thermally and chemically to improve the surface quality. The tested samples are exhibited in Figure 25.

Machinability investigated and tested samples.

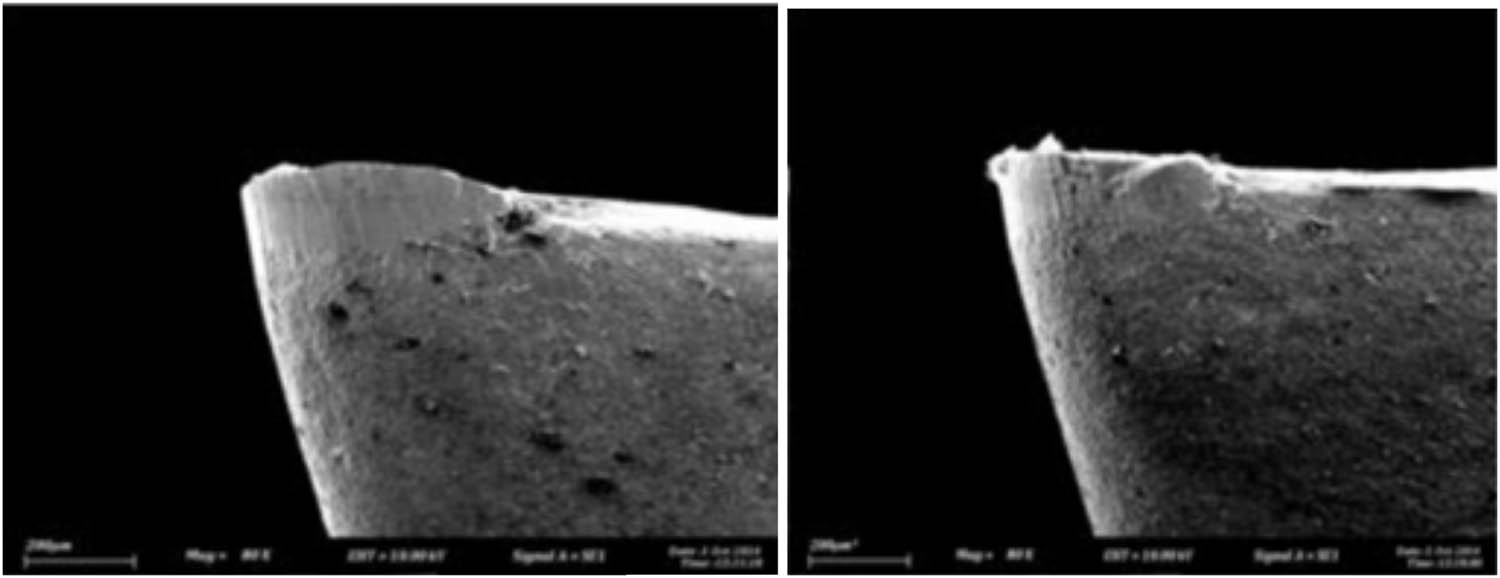

4.16 Scanning electron microscopy examination

Though we have considered the wear rate here, the scanning electron microscopy examination was carried out to observe the nature of the tool wear. The tool wear was observed at a low cutting speed (left side image in Figure 26) and high cutting speed. As the work material is softer compared to the tool material, the shape changes were not significant. But little flank wear was observed.

SEM images of the tool after machining at low speed (left) and high speed (right).

Venkatesan et al. [52] utilized fresh coconut oil for preparing the nanofluid by mixing 0.25 wt% Al2O3 nanoparticles for machining Inconel 617 by CNC turning. The process parameters, such as cutting speed and feed rate, were optimized based on their impact on cutting force, surface roughness, and tool wear. For their statistical models, the R 2 value was 82.27% for the surface roughness, 78.04% for the cutting force, and 72.31% for the tool wear, and no confirmation experimentation was reported. Yücel et al. [35] prepared the nanofluid by enhancing the commercial conventional nanofluid by mixing 0.6 vol% of MoS2 for machining the aluminium alloy 2024 T3. The temperature was reduced by 21°C in the MQL mode using a commercial fluid than dry machining and reduced by 43°C using MoS2-based nanofluid in the MQL mode. The surface roughness was reduced by 0.432 µm in the MQL mode using a commercial fluid than dry machining and reduced by 0.728 µm using a MoS2-based nanofluid in the MQL mode. Şirin and Kivak [40] utilized a concentration of 0.25 vol% for each kind of nanoparticle and maintained a total concentration of 50 vol%. The graphite, MoS2, and boron nitride nanoparticles were used in all three possible combinations for preparing the hybrid nanoparticle mixed nanofluid in MQL; for machining the graphite and boron nitride hybrid nanoparticles based nanofluid in MQL, the cutting force was reduced by 10.22 and 3.77%, the peak temperature by 6.92 and 10.78%, and the surface roughness by 14.95 and 8.21%, whereas tool life value improved by 36.17 and 6.08% compared to graphite/MoS2 and boron nitride.

This research utilized a low concentration of MoS2 nanoparticles (0.3 wt%) with waste oil (used coconut oil) as a base fluid to prepare the nanofluid for machining biocompatible magnesium implants for biomedical applications under flood cooling conditions. The nanofluid can be reused multiple times in flood cooling, whereas it cannot be reused under MQL conditions. The prepared nanofluid is not harmful to humans as it has edible oil as a base fluid and flood cooling generates less mist than MQL, so it exerts great care for the operator and other workers in the shop. It is a biodegradable coolant with no harm to environmental pollution. The experimental results were compared with the results using a commercial cutting fluid. This research contains two phases that first compared the performance of the proposed nanofluid with a conventional commercial nanofluid in terms of reduction of the cutting force, feed force, cutting zone temperature, tool wear, and surface roughness. Then, the process parameters were optimized for the best-performing method (the proposed nanofluid with a conventional commercial nanofluid under flood cooling conditions).

This research considered average performance under all cutting conditions for comparison for the recommendation. This improved the reliability of the decision. The proposed nanofluid averagely reduced the cutting force by 68.232 N, the feed force by 34.180 N, the surface roughness by 0.118908 µm, and the tool wear by 0.39938 mg·h−1 compared to the conventional commercial cutting fluid. The cost of cutting is a considerable expenditure in metal machining processes. The regression model was developed based on the experimental results of the cutting force, feed force, cutting zone temperature, surface roughness, and tool wear and presented. The accuracy of developed regression equations for predicting the responses was confirmed as follows. The statistical models were verified with ANOVA. The R 2 values were based on proposed nanofluid observations under flood cooling conditions: 99.22% for the cutting force model, 98.94% for the feed force model, 99.73% for the surface roughness model, 99.16% for the cutting zone temperature model, and 99.89% for the tool wear model. As the obtained R 2 values are greater than 95%, it indicates that there is good agreement between the predicted responses with the use of the regression model and experimental results.

From the Taguchi analysis, it was observed that the nose radius of the tool does not influence the responses significantly, and the best values were obtained at 0.3 mm nose radius. The other two factors were significantly influenced as they possess very low p values [36]. Hence, the cutting speed and tool feed were considered for surface plots. For better presentation, the 3D surface plot was used to reveal the relationship between the above-said variables for responses of cutting force, feed force, cutting zone temperature, tool wear, and surface roughness [37]. The highly influenced parameters were decided based on the experimental results based on Taguchi analysis results [38]. The ranking was based on the influence of the factor on the response. The ranking of variables is shown in Tables 8 and 12 and 17 and 22 and and 26 for the cutting force, feed force, surface roughness, cutting zone temperature, and tool wear responses. The higher delta values indicate a high influence of factors for the concerned response. Venkatesan et al. [52] recommended Taguchi analysis for optimizing the process parameters effectively. They also recommended ANOVA for obtaining the significance of influencing process parameters [39]. The process parameters were optimized with the help of the Taguchi analysis for all five responses and presented [37]. It was found that the cutting velocity and tool feed parameters were highly influenced in all five responses significantly [38]. However, the nose radius of 0.3 mm seems to be the best, as inferred from the Taguchi analysis.

The statistical evaluation showed the significance values p = 0.001, p = 0.023, p = 0.001, p = 0.045, and p = 0.028 for observations of the cutting force, feed force, surface roughness, cutting zone temperature, and tool wear by using the proposed nanofluid and conventional commercial coolant. All these p-values were less than 0.05. The comparison performed in this work was done on average values.

5 Conclusions

This work demonstrates the low-cost, high-performance cutting fluid (nanofluid) developed from the multiple times used coconut oil (waste) mixed with MoS2 nanoparticles. The concentration is optimized by the trial and error method. The prepared nanofluid was characterized well before experimentation. The prepared nanofluid was tested experimentally and compared with the performance of the conventional commercial coolant. These observations are statistically significant and confirm that these observations can be accepted. Hence, the use of the proposed nanofluid in place of a conventional commercial coolant averagely reduced the cutting force by 68.23167 N, the feed force by 34.180 N (as the nanofluid supplied sufficient lubrication action for minimizing the forces and absorbing some vibrational effects by maintaining a layer in between the tool and workpiece), the cutting zone temperature by 60.435°C (due to nanofluid lubrication for easy shearing of the material with a hard tool in supplement with cooling), the surface roughness by 0.118908 µm (the lubricated shearing allowed one to make fine cutting and prevented fast wear of sharp tool edges), and the tool wear by 0.39938 mg·h−1 (the lubricated cutting reduced the tool force and permitted the operation to occur smoothly). The proposed method (use of a nanofluid under flood cooling) outperformed other methods. To generalize these outcomes, the process parameters were optimized for using the proposed method for obtaining the best performance. The optimal conditions were presented, and mathematical models (regression equation) were developed to predict the responses. The mathematical models’ accuracies were verified with R 2 values. The R 2 values confirmed that the predictions of the developed models have good agreement with experimental results, and the model is accurate. The proposed nano coolant was prepared with extreme care for high-temperature application by concentrating MoS2 in used coconut oil without the water content by understanding the physical phenomenon of cutting processes. The expected outcomes are given in the experimental results. Within the limitation of this study, the coolant was tested for machining magnesium samples. In the future, this coolant will be inspected with the machining of precision materials, in CNC milling, CNC grinding, conventional milling, deep drilling processes, etc.

-

Funding information: The authors state no funding involved.

-

Author contributions: Conceptualization: RS, TS, VV, SR, SS; formal analysis: RS, TS, VV, SR, SS; investigation: RS, TS, VV, SR, SS; writing – original draft preparation: RS, TS, VV, SR, SS; writing – review and editing: SS, CL, YZ, KS, SME; supervision: SS, CL, YZ, KS, SME; project administration: SS, CL, YZ, KS, SME; funding acquisition: SS, SME. All authors have accepted responsibility for the entire content of this article and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Tsakiris, V., C. Tardei, and F. M. Clicinschi. Biodegradable Mg alloys for orthopedic implants – A review. Journal of Magnesium and Alloys, Vol. 9, No. 6, 2021, pp. 1884–1905.10.1016/j.jma.2021.06.024Search in Google Scholar

[2] Bishop, J. A., A. A. Palanca, M. J. Bellino, and D. W. Lowenberg. Assessment of compromised fracture healing. JAAOS-Journal of the American Academy of Orthopaedic Surgeons, Vol. 20, No. 5, 2012, pp. 273–282.10.5435/JAAOS-20-05-273Search in Google Scholar PubMed

[3] Kamrani, S. and C. Fleck. Biodegradable magnesium alloys as temporary orthopaedic implants: a review. Biometals, Vol. 32, No. 2, 2019, pp. 185–193.10.1007/s10534-019-00170-ySearch in Google Scholar PubMed

[4] The American Foundry Society Technical Dept Magnesium Alloys, The American Foundry Society, Schaumburg, IL; 2006.Search in Google Scholar

[5] Xu, T., Y. Yang, X. Peng, J. Song, and F. Pan. Overview of advancement and development trend on magnesium alloy. Journal of Magnesium and Alloys, Vol. 7, No. 3, 2019, pp. 536–544.10.1016/j.jma.2019.08.001Search in Google Scholar

[6] Husak, Y., J. Michalska, O. Oleshko, V. Korniienko, K. Grundsteins, B. Dryhval, et al. Bioactivity performance of pure mg after plasma electrolytic oxidation in silicate-based solutions. Molecules, Vol. 26, No. 7, 2021, id. 2094.10.3390/molecules26072094Search in Google Scholar PubMed PubMed Central