Abstract

Grouting material is the core force transfer medium of grouting sealing and anchorage reinforcement methods for cracks in earthen sites; the performance of grouting slurry is the key to affecting the reinforcement effect. To solve the problems of poor flexural strength, easy shrinkage and cracking of existing grouting slurry, using Glutinous Rice Pulp, Calcined Ginger Nuts, and Loess Soil as substrates, and choosing the content and length of basalt fiber (BF) as control variables, 13 groups of specimens were designed by orthogonal test method to explore the influence of mixed fiber on the mobility, shrinkage, compressive, and flexural strength. The microstructure was analyzed by SEM to explain the strengthening mechanism from physical and chemical perspectives. The results show that the mobility decreases linearly with the increase in BF content and length; after mixing BF, the shrinkage rate is significantly reduced, but when the fiber length and content are relatively high, the surface is prone to cracking. The excellent bridging ability of BF can effectively improve the compressive and flexural strength of the specimen. When the fiber length and content are high, the specimen shows certain ductile failure characteristics, and the fracture energy increases more than 10 times.

1 Introduction

The earthen sites are important historical and cultural heritages along the Eurasian Silk Road, serving as a link for the cultural integration of countries along the Silk Road and carrying rich historical and cultural information [1,2]. However, due to the impact of severe climatic environments such as earthquakes, wind erosion, and extreme rainfall [3,4], as well as the widespread presence of cracks in earthen sites, which seriously weaken the structural integrity [5,6].

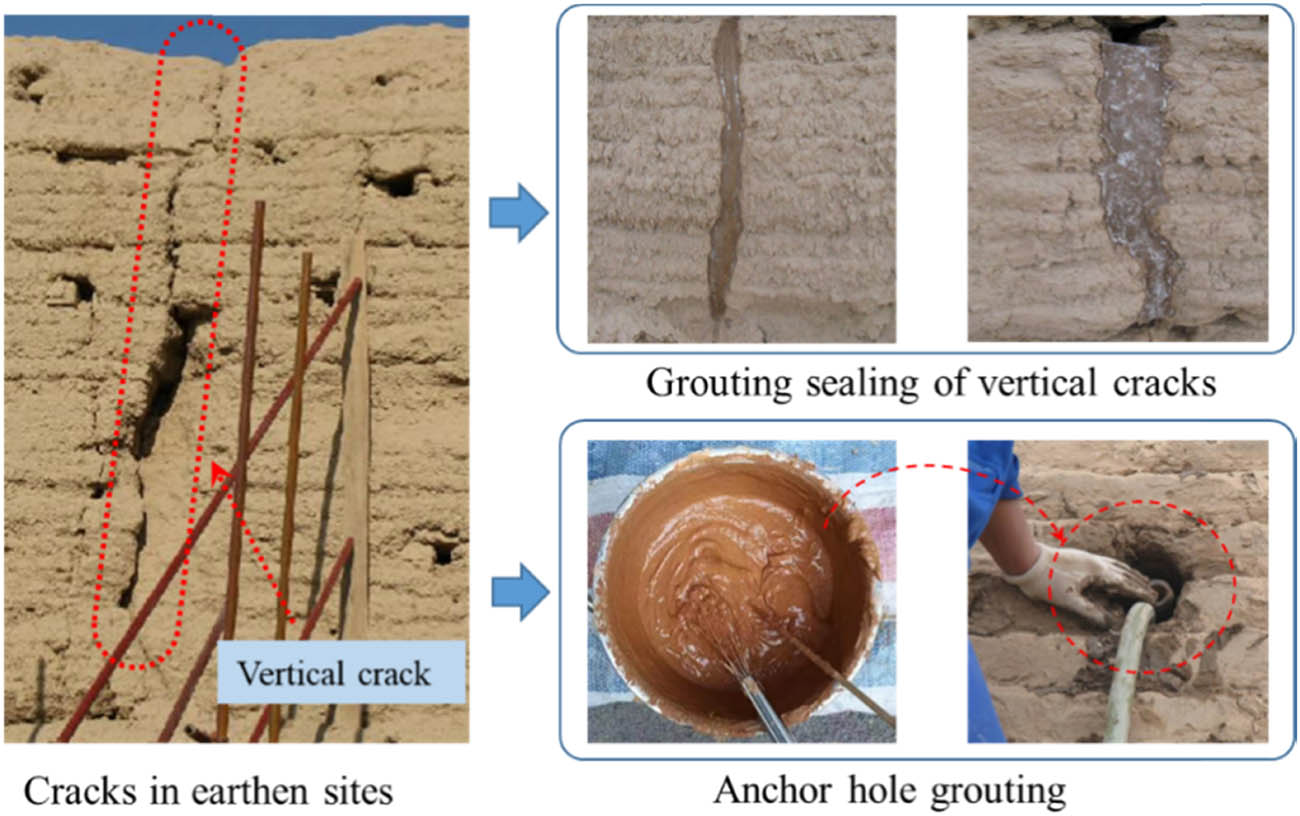

At present, the reinforcement method for cracks mainly includes anchor rod bonding [7,8] and grouting sealing [9], as shown in Figure 1. The reinforcement effect of the above method mainly depends on the performance of grouting materials. In traditional geotechnical engineering, the performance of polymer fiber reinforced cement mortar has been deeply studied and widely applied in fields such as anchoring grouting and prefabricated structure connections [10,11]. However, there is a significant difference in strength between the cement mortar mentioned above and the site soil, making it difficult to coordinate the deformation, which can easily cause cracking and other damage. In addition, cement-based materials can seriously change the mineral composition of the site soil, causing sites pollution, which is go against the requirement of preserving cultural relics: “Do not change the original materials and construction methods [12]”.

The vertical cracks of earthen sites repaired by the method of grouting sealing and anchorage.

In view of this, heritage conservationists have developed various new grouting materials suitable for earthen sites and conducted in-depth research on their performance [13,14]. Dunhuang Research Institutions and Lanzhou University have developed a new type of soil curing agent Potassium Silicate (PS) solution, on this basis, a series of grouting materials such as PS–F [15,16], PS–(C + F) [17], and PS–C [18] were developed, which have achieved excellent mechanical strength in the conservation of Jiaohe ancient city. However, the slurry modified by PS has drawbacks such as easy shelling and high shrinkage rate. To improve the above problems, researchers tried to use polyvinylalcohol (SH) solution instead of PS solution, mixed with fly ash and quicklime as grouting materials, and found that SH–(C + F + CaO) slurry has a low shrinkage rate, strong mechanical strength, and good durability, especially suitable for the alkaline environment in the northwest region, China [19].

Although the grouting materials mixed with PS or SH solution exhibit good physical and mechanical performance, they inevitably use artificially prepared organic or inorganic composite materials. Their durability and long-term mechanical properties are not yet clear and may change the original mineral composition of the sites. Therefore, using the original natural materials used during the sites construction becomes the optimal choice for grouting material preparation.

Natural cementing materials such as Glutinous Rice Pulp (GRP) and Calcined Ginger Nuts (CGN) are widely used in earthen sites [20]. The grouting material with CGN as the main agent has good mobility, small shrinkage, high mechanical strength, and good compatibility with soil [21,22]. Whereas GRP has strong viscosity, and after solidification and drying, it can effectively improve the early strength of grouting material which use CGN and quicklime as a cementitious agent and will effectively limit their shrinkage deformation [23,24] and can also be used to artificially prepare sites soil [26]. However, the slurry prepared with CGN and GRP has low tensile and flexural strength, and poor ductility, showing significant brittle failure mode, which is difficult to meet the reinforcement demands of the sites.

Adding fibers to adobe and rammed earth is an effective way to improve the tensile, ductility, and cracking properties. Abolfazl et al. [25] improved the mechanical properties and erosion resistance of building adobe materials by mixing palm fibers, and the anti-shrinkage cracking performance of adobe materials was also significantly improved. Mario et al. [26], Bouhicha et al. [27], and Fulvio et al. [28] conducted experiment research showing that jute fabric and barley straw fiber-reinforced soil have better integrity, mechanical strength, and ductility. Castrillo et al. [29] pointed out that sawdust fiber has a more significant improvement in the mechanical properties (compressive and flexural strength) of adobe compared to straw fiber. However, it should be noted that when the fiber length and content are large, which can cause aggregation and clustering phenomena, increase the adobe porosity, and reduce its density and mechanical strength [25,30,31].

To sum up, the content and length of fiber will significantly affect the mobility and shrinkage (precure), density and mechanical properties (after curing) of the slurry. Therefore, how to comprehensively balance the performance mentioned above and determine the fiber content and length to meet the conservation engineering demands is the key issue that needs to be considered for the fiber-reinforced grouting slurry.

Therefore, conducting research on the optimization ratio of fiber content and length can provide essential basic grouting materials for crack sealing, anchor rod reinforcement, and other conservation projects in earthen sites. In addition, it can also provide a new way for the production of various forms of adobe, which can support repairing foundation erosion and filling stolen holes and arch rings and is of great significance for the current large-scale “preventive protection” of earthen sites.

Basalt fiber (BF) has both natural properties, good dispersion, easy processing, high strength, and fracture toughness [32]; it especially meets the requirements of earthen sites grouting materials. In view of this, this study adopts BF as reinforcement materials, and Loess Soil (LS), GRP, and CGN as substrates to prepare grouting slurry. The effects of BF length and content on mobility, shrinkage, unconfined compressive strength (UCS), and flexural strength of ecological grouting slurry for earthen sites are systematically studied.

2 Specimen preparation and test scheme

2.1 Raw materials treatment

1) Treatment of LS. Q3 LS from the vicinity of the Xi’an Ming dynasty City Wall site was selected for the test, after crushing and air-drying, which was passed through by a 1 mm sieve. According to “Standard for Geotechnical Test Methods” (GB/T 50123-2019) [33], the average physical parameters of three groups of soil specimens are obtained through a laboratory test, as shown in Table 1.

Basic physical parameters of the test soil

| Water content (%) | Density (g·cm−3) | Liquid limit (%) | plastic limit (%) | Plasticity index | Particle gradation (%) | Maximum dry density (g·cm−3) | ||

|---|---|---|---|---|---|---|---|---|

| <0.005 mm | 0.005–0.075 mm | >0.075 mm | ||||||

| 2.87 | 1.17 | 47.2 | 35.5 | 11.8 | 19.56 | 79.21 | 1.23 | 1.69 |

2) Treatment of CGN. To facilitate the heat transfer during roasting, the original Ginger Nuts were broken into small pieces of 3–5 cm. To maximize the acquisition of both hydraulic and air-hardening components, while considering the working conditions and cooling time of the muffle furnace, the CGN calcination temperature is determined to be 1,000°C and the duration is 3 h [34]. After cooling, the Ginger Nuts was removed and ground into powder by a 200 mesh grinding mill. X-ray diffraction (XRD) analysis was carried out on CGN powder, and it was clear that it mainly included air-hardening components (CaO) and hydraulic components (β-CaO·SiO2 and CaO·Al2O3·SiO2), while other components have less content and no significant cementitious function, and almost no effect on the improvement of slurry mechanical strength [8,34]. Therefore, other components are not listed in detail. The XRD analysis results and contents of each component are shown in Figure 2.

XRD analysis results of CGN.

3) Treatment of GRP. According to the recommendation of Mao et al. [23], when the concentration of GRP is 6%, the mechanical strength of CGN-based slurry is the best, so the concentration of GRP in this research is determined to be 6%. During preparation, measure the corresponding weight of Glutinous Rice dry powder and water. To ensure the full and uniform fusion of the solution, 1,000 mL GRP was prepared each time. Record the initial liquid level of GRP in the pot and then boil for 1 h. To avoid water evaporation affecting the concentration of the GRP, water was continuously added to the initial mark position and stirred during boiling to maintain the liquid level.

4) Treatment of BF. The BF used are the strip-shaped fibers compressed from bundle-shaped monofilament. BF with lengths 6, 12, and 18 mm are purchased according to the test specimen requirements. The basic physical and mechanical parameters of BF as shown in Table 2.

Basic physical and mechanical parameters of BF [35]

| Fiber diameter (μm) | Density (g·cm−3) | Tensile strength (MPa) | Rupture elongation (%) | Elastic modulus (GPa) | Maximum working temperature (°C) |

|---|---|---|---|---|---|

| 17 | 2.65 | 3,000–4,800 | 1.5–3.2 | 91–110 | 650 |

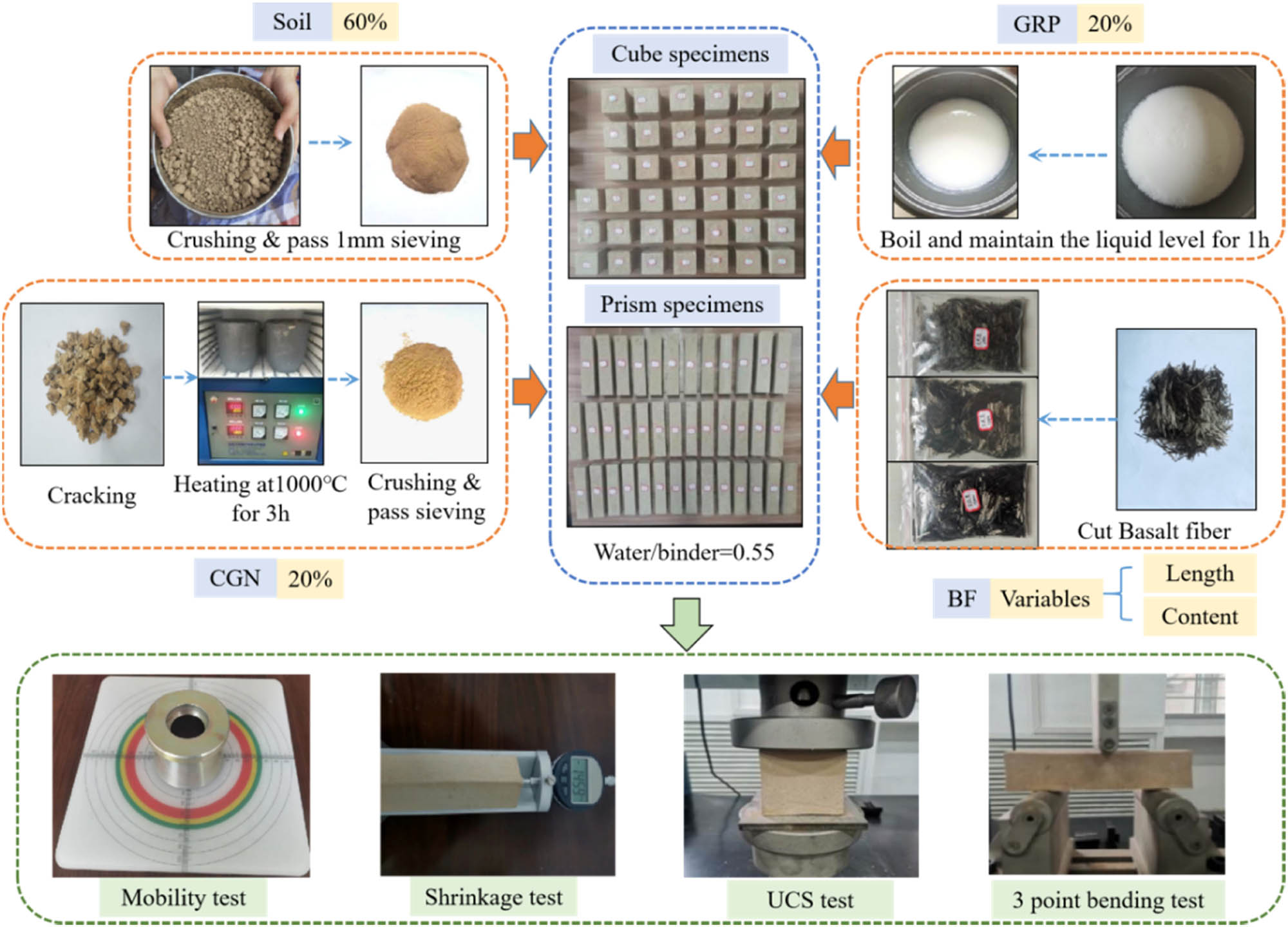

When preparing the specimen, the treated raw materials are thoroughly mixed according to the design ratio, referring to the research results [36] and conduct pre-tests to determine a water–binder ratio of 0.55, mixing with water and stirring for 30 min and pouring in the mold. Remove the mold after 1 week of membrane curing and then continue to maintain it under natural conditions for 3 weeks. It should be noted that to maximize the restoration of the grouting reinforcement situation of earthen sites, the specimens were poured with free-flow filling and did not undergo vibration compaction. The preparation process of all raw materials and the specimen test scheme are shown in Figure 3.

Specimen preparation and test scheme of grouting slurry for earthen sites.

2.2 Test specimen setting

A full-factorial orthogonal experiment can effectively obtain the changing trends of each performance under different BF length and content combinations, which provides a basis for multi-objective combinatorial optimization of fiber parameters with different engineering expected characteristics [37].

This research considering the two influencing factors of BF length and content, three length levels, and four content levels was selected for orthogonal experimental design. A fiber-free control group was also reserved for comparison, and a total of 13 groups of specimens were set up, as shown in Table 3. The composition of the grouting slurry substrate is as follows: GRP content of 20%, CGN content of 20%, and LS content of 60%; the water–binder ratio is 0.55; and GRP concentration is 6%. On this basis, an additional BF with a certain mass ratio was mixed. The specimen numbers of each group were represented by BF–A–B, where BF represents basalt fiber, A represents BF length (mm), and B represents BF content (mass ratio (‰)), as shown in Table 3. The mobility, 0–28 days shrinkage rate, UCS, and flexural strength of each group were tested sequentially.

Factor level of BF and specimen setting

| Serial | Level | Factors | CGN (%) | GRP (%) | LS (%) | Water/binder ratio | Number of parallel specimens for each group | |

|---|---|---|---|---|---|---|---|---|

| A (mm) | B (‰) | |||||||

| BF–A–B | L1 | 0* | 2 | 20 | 20 | 60 | 0.55 | 3 for UCS and flexural test |

| L2 | 6 | 4 | ||||||

| L3 | 12 | 6 | 2 for mobility and shrinkage test | |||||

| L4 | 18 | 8 | ||||||

Note: *The length of zero indicates the control group without BF. The percentages shown in the table are all mass ratios.

2.3 Test scheme

2.3.1 Mobility and shrinkage test

The mobility test was conducted under the requirements of the GB/T 50448-2015 [38]. The specifications of the truncated circular mold used for the mobility test were 36 mm in diameter at the top, 60 mm in diameter at the bottom, and 60 mm in height. When testing, first place the glass plate horizontally, wet the glass plate and the truncated circular mold with a damp cloth, but no flowing water droplets appear. Then, put the large diameter of the mold downward in the center of the glass plate and cover it with a damp cloth for the spare. Manually stir the slurry for 30 min and quickly inject the mixed grouting slurry into the mold, making the surface of the slurry flush with the top surface of the mold. Lift the truncated cone circular mold vertically for 30 s and use a vernier caliper to measure the average of the maximum diameters of the two mutually perpendicular directions of the slurry as the mobility of the grouting material.

Since there is no relevant standard specially used for shrinkage testing of grouting materials for earthen sites, this study is mainly carried out with reference to GB/T 29417-2012 [39] and EN680:2005 [40]. The specimen size of the shrinkage rate test is 40 mm × 40 mm × 160 mm, and the ambient temperature during preparation and curing is 20 ± 5°C, with a relative humidity greater than 50%. The measuring tool is a length comparator with a standard length of 176 mm, with an accuracy of 0.001 mm. The testing cycle is to continuously measure every 12 hours within 0–28 days. The self-drying shrinkage rate for each test is calculated as Eq. (1), the arithmetic mean value measured by two specimens was taken as the final shrinkage rate of self-drying.

where

2.3.2 Mechanical performance test

The mechanical performance test includes the UCS test and three-point bending test of grouting slurry, which should be conducted under GB/T 17671-2021 [41]. UCS test adopted 70.7 mm × 70.7 mm × 70.7 mm cube specimens, and three-point bending test adopted 40 mm × 40 mm × 160 mm prism specimens. Test the specimen’s mechanical strength after curing for 28 days.

UCS test adopts 3 mm·min−1 uniform monotone loading scheme until the specimen is failure. The three-point bending test adopts the center loading method, the spacing between support points is 100 mm, and the specimen is uniformly and monotonically loaded at 1 mm·min−1 until it is failure.

The UCS is calculated as follows [42]:

where R c is the UCS of the specimen (MPa); F c is the compressive failure load of the specimen (N); and A is the contact area between the specimen and the pressure plate (mm2).

The flexural strength is calculated as follows [42]:

where R f is the flexural strength of the specimen (MPa); F f is the maximum load applied to the middle of the prism specimen during fracture (N); L is the spacing of the support points (mm); and b is the side length of the square section of the prism specimen (mm).

3 Test results and discussion

3.1 Mobility

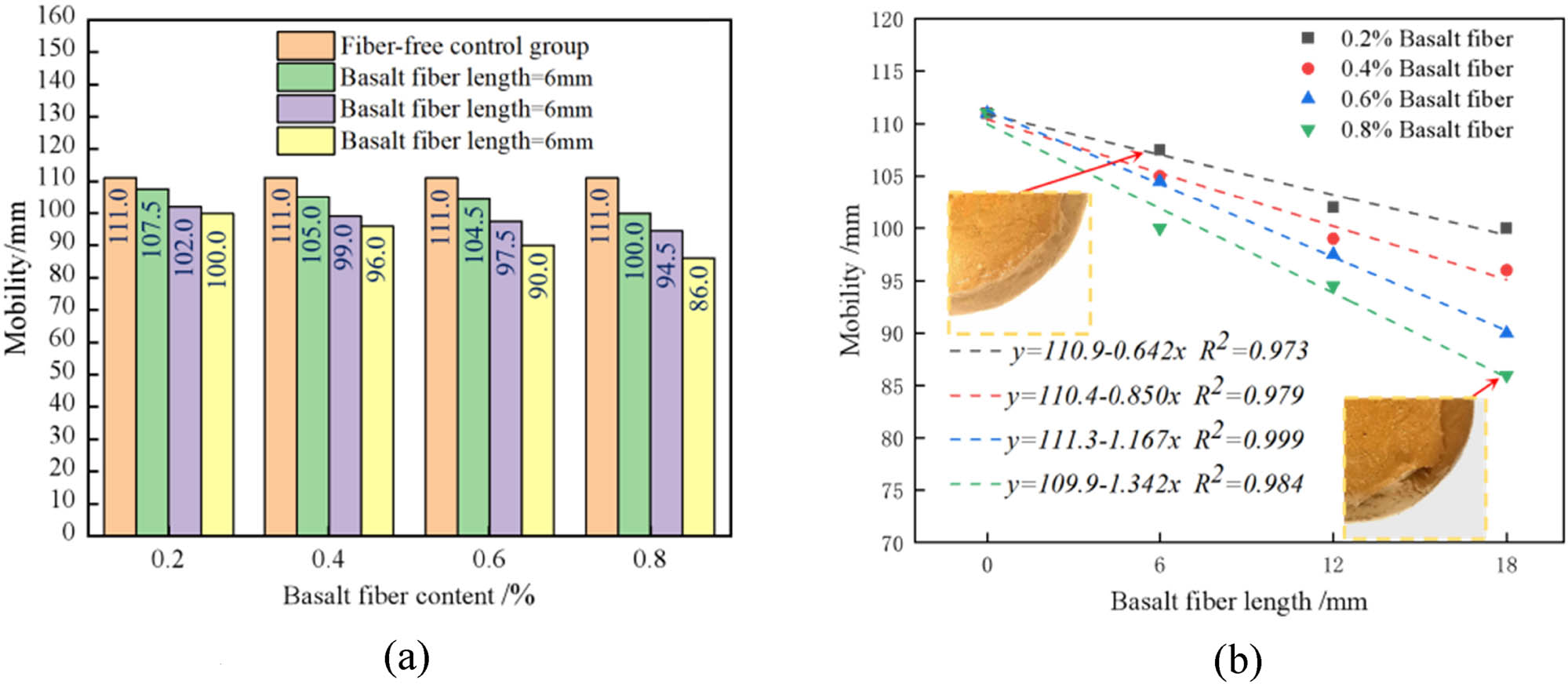

The variation law of slurry mobility under different BF lengths and content is shown in Figure 4(a). With the increase in fiber length and content, the mobility of slurry decreases approximately linearly, which can be fitted by a linear function curve, as shown in Figure 4(b), with R 2 > 0.97.

The influence of BF length and content on the mobility of the slurry. (a) Mobility value of specimen. (b) Linear fit results and slurry barrier boundaries.

According to Figure 4(a), the mobility decreased approximately linearly with the increase of fiber content, mainly because the more fiber content, the larger the comparative area and the fuller contact with the slurry. After BF fiber was mixed as a dry matter, the moisture content of the mix was reduced, and the fiber itself had a small water absorption, which reduced the free water in the mixture. Therefore, the mobility is approximately proportional to the water absorption of the fiber, and this phenomenon is more significant when the natural plant fiber with higher water absorption is mixed [25,26], which verifies the superiority of using BF.

The influence of fiber length on mobility is more significant compared to the content. When the BF length is less than 6 mm, the mobility is concentrated between 100–110 mm. This is mainly because when the fiber content is small, even if the fiber length changes within the range of 0–18 mm, the fibers can still be evenly dispersed in the slurry, and there is less overlap between BF. When the fiber content is higher, the influence of fiber length on mobility is more significant. When the fiber content reaches 0.8%, even if the fiber length is 6 mm, the mobility will be less than 0.2% in content and 18 mm in length. This is mainly due to the increase in fiber density in the slurry when the content is high, and even shorter fibers will have overlapping and interweaving phenomena. Taking the fiber length of 18 mm as an example, its length is close to 1/3 bottom diameter of the truncated circular mold. Therefore, it is prone to curling and stacking to form a fiber network structure. In addition, the surface tension of the slurry and the adsorption force of fibers will limit the flow rate of slurry, which will significantly reduce the mobility of the slurry.

It is worth noting that the mobility of BF–18–8 specimens has decreased to less than 90 mm, which cannot meet the grouting conservation needs of sites [43]. Future research will attempt to improve mobility by adding fly ash, water-reducing agent, and other methods.

Figure 4(b) supports the above analysis, when the BF content is low and the length is short, the fiber is easy to disperse in the substrate, and the boundary of slurry is smooth and has less impact on the mobility, such as BF–6–2. However, the longer length and high content of BF have a higher density in the slurry, which usually requires stirring for more than 30 min to disperse evenly. However, as pouring time increases, the fibers are still prone to gravity deposition, and during the flow process, they are easy to curl up and bend or even stack and agglomeration, forming an obvious barrier boundary around the slurry edge, which limits and hinders the free flow of the slurry, thereby reducing the mobility of the slurry. In Figure 4(b), it can be seen that the edge of the slurry in the BF–18–8 group exhibits a wrapping effect due to the fiber barrier.

3.2 Shrinkage rate

After mixing BF, the shrinkage rates of the specimens were significantly reduced, and they were all less than 2.0%, meeting the requirements for cracks grouting in earthen sites conservation [43] and the requirement in the JG/T333-2011 [44] that the volume shrinkage rate of polymer-based grouting materials should not exceed 3%.

The trend of shrinkage rate changes of the specimen from 0 to 28 days can be roughly divided into three stages: dehydration period, slowing period, and stable period. The dehydration period is roughly within 7 days, and with the strong evaporation of water, the shrinkage rate increases approximately linearly, accounting for over 70% of the total shrinkage amount; the slowing period is roughly between 7 and 12/14 days, during which the water loss rate of the slurry slows down, and the increase in specimen shrinkage gradually decreases; after 12/14 days, the shrinkage rate of the mixed fiber specimen remained stable between 0.86 and 1.94%. This is mainly due to the low content of the hydraulic component of 20% CGN. In the early stage of pouring (dehydration period), the hydration reaction is not sufficient, and the speed of water absorption in the hydration reaction becomes less than that absorbed by the soil [45]. A large amount of free water in the slurry is subjected to strong evaporation effect and hydration of hydraulic components, the sample volume rapidly decreases, and the shrinkage rate significantly increases. When the sample enters the slowing period, the free water content in the slurry is relatively low, and the hydration effect of the CGN is the strongest, the hydraulic components of β-CaO·SiO2 and CaO·Al2O3·SiO2 rapidly react with H2O in the slurry and generate β-CaO·SiO2·nH2O and CaO·Al2O3·SiO2·nH2O [45]. The increase in sample shrinkage gradually decreases. After 12/14 days, the sample moisture experiences an obvious decrease, the hydration reaction is basically completed, and the shrinkage rate tends to stabilize. The later strength of the sample is mainly provided by the air-hardening component.

However, the effect of BF content on shrinkage rate is not the same under different BF lengths. According to Figure 5(a), when the length is 6 mm, the shrinkage rate of slurry decreases significantly, with a decrease of over 38.6%. This is mainly due to the fact that, under the condition of the same fiber weight, when the fiber length is shorter, it has more quantity in the slurry and is more easily to dispersed, resulting in a larger contact area with free water in the slurry. Through fiber adsorption, the free water content is reduced, and the free flow of the slurry around the fiber is restricted, which has a significant limiting effect on the dehydration shrinkage of the slurry. However, the difference in shrinkage rate of the specimens under different fiber content is not significant, and the surface cracking degree is in a controllable range. For the specimen with BF lengths 12 and 18 mm, the shrinkage rate will gradually decrease with the increase in fiber content, and the shrinkage rate will be less than 1% (BF–12–8, BF–18–6, BF–18–8) when the content is high. Meanwhile, the crack number, cracking degree, and cracking area of the specimen surface will gradually increase with the decrease of the shrinkage rate, as shown in Figure 5(b) and (c). This is mainly due to the formation of a three-dimensional network skeleton in the specimen after the addition of many long fibers, which limits the shrinkage of the slurry. In addition, the higher the fiber content, the denser the network skeleton formed by the fibers, the stronger their ability to resist shrinkage deformation. Therefore, when the fiber length is large, the shrinkage rate gradually decreases with the increase in the content. However, after the hydration and evaporation of the slurry, the volume of the substrate tends to decrease, and the material is mainly subjected to tensile stress, so the slurry is more prone to cracking when the shrinkage rate is small. When the earthen sites are subjected to external forces, the presence of cracks can easily cause stress concentration in the slurry, promote crack expansion, and ultimately lead to premature failure. To avoid initial cracking, secondary grouting by embedded pipes can be used for sites conservation projects.

The influence of BF length and content on specimen shrinkage and surface cracking. (a) L = 6 mm, (b) L = 12 mm, and (c) L = 18 mm.

3.3 UCS

According to Figure 6(a), the UCS of BF mixed grouting slurry is generally higher than that of the control group without reinforcement, among which, the UCS of specimens with BF length of 6 mm increases by more than 50%, and the maximum increase of 77.27% (BF–6–2). However, as the BF length increases, the strength shows a decreasing trend. According to Figure 6(b)–(d), under the same length, the UCS of specimen increases first, then decreases, and finally gradually increases with the increase of BF content, which can be fitted by the cubic function curve. It is particularly noteworthy that when the content is 0.2%, the UCS of the specimen is most significantly improved, with corresponding increases of 77.27, 53.63, and 25.45% for lengths 6, 12, and 18 mm, respectively.

UCS variation and failure characteristics of specimens under different lengths and content of BF. (a) Effect of length and content of BF on UCS, (b) influence of BF content (L = 6 mm), (c) influence of BF content (L = 12 mm), and (d) influence of BF content (L = 18 mm).

When the content increases to 0.4%, the strength decreases significantly. However, as the BF content continues to increase, the strength gradually increases. But limited to the experimental design and test conditions, the upper limit of the content set in this study is only 0.8%. It can be predicted that as the content continues to increase, there is still space for further improvement in the UCS of specimens.

According to the failure mode of the specimens in Figure 6(b)–(d), the failure process of the specimens in the fiber-free group is relatively sudden. When the loading reaches the peak value, the substrate on the surface and edge of the specimens instantly collapses, and large vertical through cracks appear inside, which is a typical brittle failure mode. When the fiber length was 6 mm, the failure mode of the specimens with different BF content was consistent. The cracks of the specimens expanded inwardly from the top or bottom edge of the specimens during loading and ultimately connected leading to failure. This process was also relatively rapid, but the crack width decreased significantly compared with that of the fiber-free group, which was mainly due to the bridging effect of the BF at the crack interface.

When the fiber length exceeds 12 mm, multiple cracks appear and gradually expand with the increase of load on the specimen. Under the peak load, although the specimen undergoes significant compression deformation, it still maintains good integrity, the cracks are evenly distributed, and the width is small, showing a certain ductility failure characteristic. This is because under external forces, relative sliding occurs easily among substrate particles. However, the BF has good tensile strength and toughness, and its length is relatively long. The bonding contact between the fiber and the substrate is sufficient, effectively pulling the substrate on both sides of the cracking interface, which improves the strength and ductility of the specimen. However, it should be noted that excessive fiber content can easily cause overlap and aggregation, reduce slurry density, increase porosity, and reduce the cohesive force of substrate, resulting in a substantial reduction in UCS [46,47].

3.4 Flexural strength

The flexural strength of reinforced specimens is generally higher than that of fiber-free specimens, but under different BF content, with the increase in fiber length, the variation of strength is slightly different. When the content is less than 0.4%, the optimal fiber length is 6 mm and the strength can be increased by 62.26%. When the content is 0.6–0.8%, the optimal fiber length is about 12 mm, as shown in Figure 7(a).

Variation of flexural strength and failure characteristics under different lengths and content of BF. (a) Effect of length and content of BF on flexural strength, (b) influence of BF content (L = 6 mm), (c) influence of BF content (L = 12 mm), and (d) influence of BF content (L = 18 mm).

To analyze the influence of BF content in detail, the cubic function was used to fit the variation trend of mean breaking strength (Ave) with the content. According to Figure 7(b)–(d), it can be seen that the flexural strength at the BF length of 6 mm shows a similar trend to the compressive strength, and the strength increases greatly at the content of 0.2 and 0.8%. At this fiber length, the crack initiation load and peak load of the specimen are both increased, and the cracks spread and penetrate rapidly from the bottom span to the top. During failure, a large amount of fibers at the bottom of the crack section are pulled out.

When the BF length exceeds 12 mm, the flexural strength increases monotonically with the increase of fiber content, but the failure process and failure mode are relatively consistent. Multiple small vertical cracks first appear at the bottom of the specimen, and then one of the cracks gradually expands and penetrates, ultimately causing failure. However, for the specimen with higher fiber content, the fibers are still not fully pulled out after the crack penetrates. The tensile effect is still significant; therefore, it can still maintain a certain residual bearing capacity.

When the BF content is 0.8%, the strength improvement rates of specimens with different fiber lengths are similar, ranging from 54.74 to 64.15%, indicating that the influence of BF length on flexural strength is limited when the BF content is high. It should be noted that this study only tested the flexural strength of the specimen with a maximum BF content of 0.8%. However, according to the strength variation trend, after increasing the BF content, its flexural strength, like UCS, will continue to increase. The optimal content needs to be further explored in subsequent research.

To analyze the ductility (represented by the mid-span deflection at fracture failure, D) and fracture energy (represented by curves and coordinate axis enclosed area, A) of the specimens, the load–displacement (L–D) curves of the specimens under different BF lengths and content are drawn in Figure 8. It can be seen that when the BF length is relatively short (6 mm), the peak load and fracture energy increase with the increase in the fiber content, but the brittle failure characteristics are still present when the fiber content is low (A = 50–99, content ≤0.6). When the fiber content reaches 0.8%, the maximum mid-span deflection is still only about 1.8 mm, and the improvement of ductility is limited. This is mainly due to the short fiber length, which is easy to pull out after cracking.

Load–displacement (L–D) curve and fracture energy of specimens in 3-point bending test under different lengths and content of BF. (a) L–D curve (L = 6 mm), (b) L–D curve (L = 12 mm), and (c) L–D curve (L = 18 mm).

When the BF length is 12mm, compared to the control group (BF-0-0), the peak load and fracture energy are significantly increased with the increase of the BF content. When the fiber content is 0.8%, the fracture energy reaches maximum (A = 627), which is more than 12 times higher than the control group (A = 50). The mid-span deflection will increase from 0.65 mm to more than 2.8 mm, showing strong deformation capacity, and the failure mode gradually changes from brittleness to ductility.

When the BF length is 18 mm, the specimen with a content of less than 0.4% still exhibits brittle fracture characteristics. However, with a further increase in the content, the fracture energy significantly increases, which is 11–12 times higher than the fiber-free group. The main reason for this phenomenon is that, under a certain BF content, the longer the BF is, the fewer fibers at the crack section. Therefore, when the content of BF is less, meanwhile the length of BF is long, the less number of fibers dispersed in the specimen, resulting in a insufficient number of fibers that play a bridging role at the cracking section. These fibers does not significantly improve the deformation ability of the specimen, and the specimen still exhibits brittle fracture failure characteristics.

4 Micro-structure and fiber reinforcement mechanism

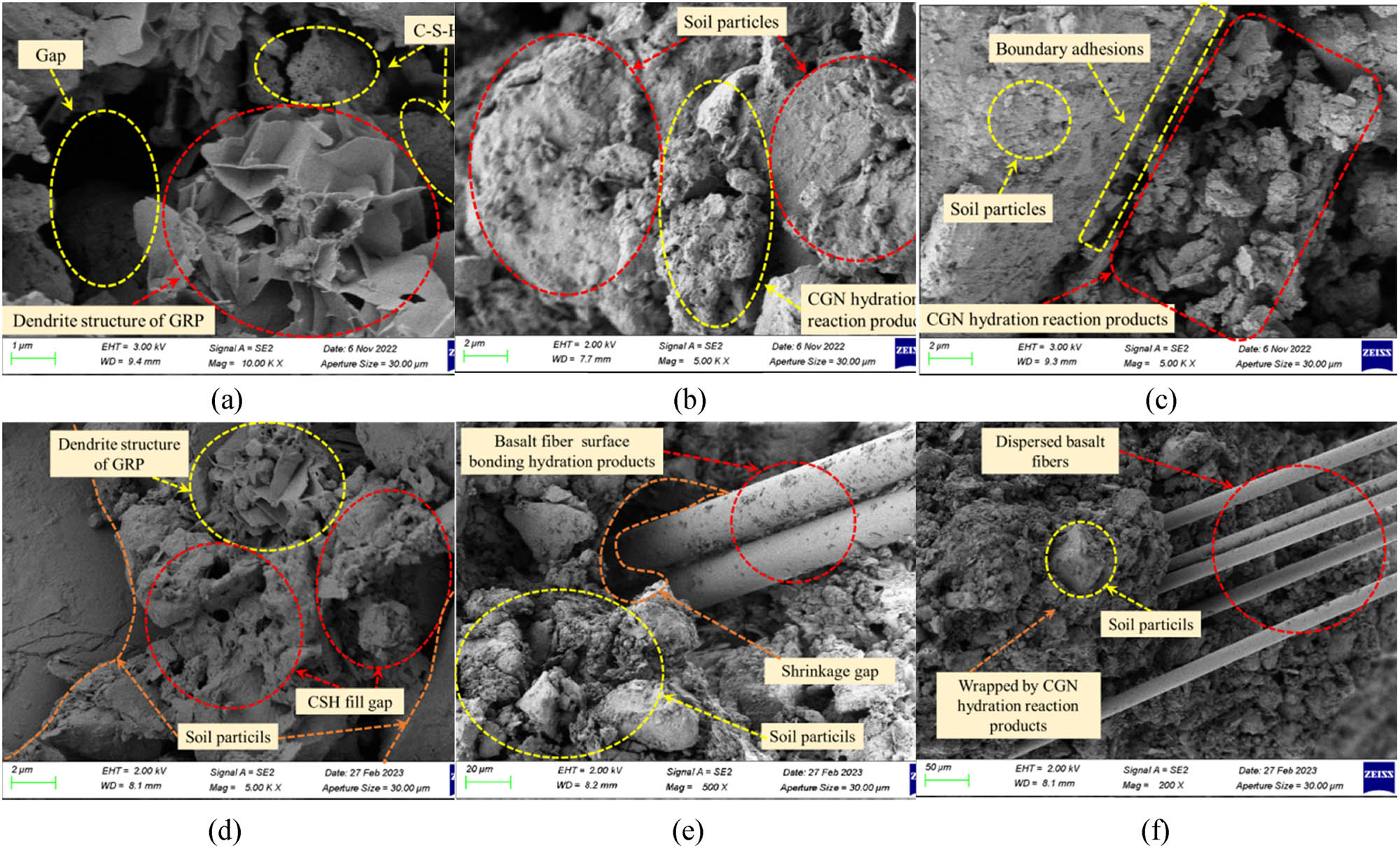

The strengthening mechanism of BF-reinforced ecological grouting slurry of earthen sites can be attributed to two aspects: (a) the hydration, cementation, and filling effects of substrates such as CGN and GRP [23] and (b) the bridging effect of BF and the displacement limitation effect of the overall network skeleton on the substrate.

To reveal the micro-structure and reinforcement mechanism of the grouting slurry, SEM analysis was conducted on prism specimens. Before testing, the selected specimens were dried and cut into 10 mm × 10 mm × 5 mm blocks and gold was sprayed on the surface.

4.1 Cementation strengthening mechanism of the substrate by hydration and air-hardening

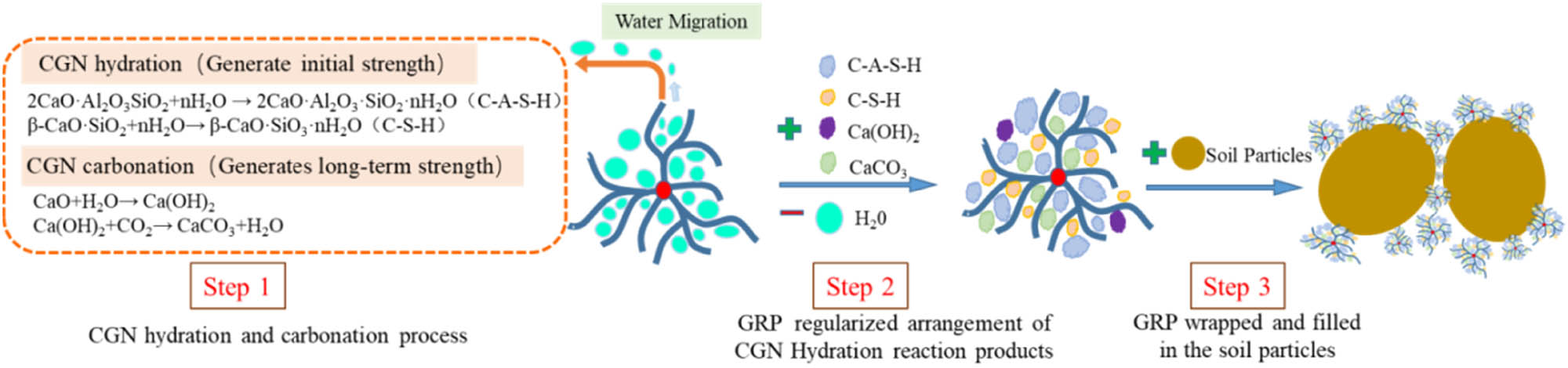

1) The hardening process of the water-hardness and air-hardness components in CGN reacting with water and CO2, as well as the cementation, encapsulation, and filling effects of the reaction products on soil particles.

The main components of hydraulic cementitious materials β-CaO·SiO2 and CaO·Al2O3·SiO2 which are produced after calcination of raw materials undergo an immediate hydration reaction with water to produce β-CaO·SiO2·nH2O(C–S–H) and CaO·Al2O3·SiO2·nH2O (C–A–S–H) [8,48], which have small particles and high viscosity, fully contact with soil particles, bond and wrap surrounding soil particles to form larger blocks, playing a role in sealing pores and compacting the soil, thereby quickly bonding the slurry to produce initial strength [49], as shown in Figure 9(a)–(c).

SEM analysis of BF-reinforced ecological grouting slurry. (a) 10,000×, (b) 5,000×, (c) 5,000×, (d) 5,000× (e) 500×, and (f) 200×.

In addition, CaO, the main component of the CGN air hardness cementitious material, reacts with water to generate Ca(OH)2, and with the participation of CO2 in the air, CaCO3 crystals are generated, forming a grid framework for cementitious soil particles [48]. At the same time, Ca2+ reacts with SiO2 and Al2O3 in the soil to generate C–A–S–H, which is arranged in a dendritic structure with the participation of GRP, and then can effectively wrap and fill soil particles [23].

2) The bonding and regularization arrangement effect of GRP on reaction products of CGN, and ultimately form a dendritic particle framework structure [23].

The main component of GRP is amylopectin. When glutinous rice flour absorbs water and gelatinizes after heating, its volume increases significantly. After mixing with CGN, the water contained in GRP participates in the hydration reaction of CGN cementitious components. At the same time, after the amylopectin loses water, the starch particles decompose and break, forming a lamellar dendritic state, as shown in Figure 9(a) and (d); since amylopectin is completely melted at high temperature and the intermolecular interaction is intense, the viscosity of GRP reaches the highest level [24,49]. After the GRP is gelatinized, the hydrated products of CGN are firmly bonded and arranged in a dendritic manner to better wrap the fibers and soil and fill the gaps, as shown in Figure 9(b) and (d). Then, it increases the compactness of the soil, thus giving the soil high mechanical strength and anti-shrinkage ability.

In addition, during the air-hardening process of the CGN component, the hydroxyl functional groups at the end of the branched starch in GRP can also provide coordination sites for Ca2+, promoting the generation of C–A–S–H [23].

The reinforcement mechanism of the substrate by water hardening and air hardening can be shown in Figure 10.

Reinforcement mechanism of water hardening and air hardening in the substrate of ecological grouting slurry.

4.2 Bridging reinforcement mechanism of BF

4.2.1 The bridging effect of BF on the substrate

As can be seen from Figure 9(e) and (f), compared with natural plant fibers [25,26], BF has good dispersion in the grouting materials of soil sites and is in full contact with soil particles and other substrates. GRP and hydration products of CGN adhere to the surface of BF, and the substrates on both sides of the potential cracking surface are firmly pulled together through bonding, friction, and mechanical occlusion effects [50]. At the same time, the BF can greatly improve the flexural strength, fracture toughness, and maximum deflection of the specimen due to its excellent tensile strength and toughness. However, although the BF is evenly distributed in the slurry substrate, there is still a gap between the fibers and the substrate, as shown in Figure 9(e). This is mainly due to the fact that the BF have poor water absorption capacity, while the hardening process of the substrates is prone to shrinkage due to water loss [45], but this volume change difference is very small and does not significantly weaken the macroscopic mechanical properties of the slurry.

4.2.2 The displacement limitation effect of the whole network fiber skeleton formed by fibers on the substrate

The randomly distributed BF form a three-dimensional spatial network structure, which restricts the deformation of the substrate. Therefore, when the fiber content in the slurry is high, the mobility of the specimen gradually decreases. In the hardening process, the dimensional change rate of the specimen’s external profile is small, while the internal slurry loses water and shrinks, resulting in more significant cracking. When the slurry is subjected to external forces, the BF is mainly pulled in the same direction within local areas such as the cracking section. The fibers in different positions and orientations have multi-direction compression effects on the wrapped substrates, which effectively limits the deformation and slip of substrate particles and improves the macroscopic mechanical properties of the slurry. The displacement limiting effect of the whole mesh fiber skeleton on the substrates is shown in Figure 11.

Displacement limiting effect of the overall network skeleton composed of BF on the substrate particles.

In addition, it should be noted that when the fiber content is the same but the fiber length is short, the number of fibers increases, and the fiber on the potential cracking section is sufficient. The initial crack occurrence time will be delayed, and the flexural strength will increase. However, due to the shorter fiber bonding length, it is easier to be pulled out, so the improvement in ductility is limited, and the increase of fracture energy is relatively small. When the fiber content is high and the length is long, due to the BF having good tensile strength and toughness, the fiber can still maintain a certain residual bond strength after sliding in the substrates, the ductility of the specimen is greatly improved, and the flexural strength and fracture energy of the specimen are greatly increased. But it can be predicted that when the fiber content and length exceed a certain value, the fibers will bend and agglomerate, which will reduce the slurry compactness and form local voids and other weak points, which will have a negative impact on the cohesion and friction between the fibers and the substrates [30,31,51].

5 Conclusion

The physical and mechanical properties of 13 groups of earthen sites ecological grouting slurry mixed with BF were tested, and the macro–micro strengthening mechanisms were analyzed to clarify the influence of fiber content and length on the slurry performance. The main conclusions are as follows:

With the increase in BF content and length, the mobility of grouting slurry decreases approximately linearly. When the length and content of BF are at a high level, the fibers are prone to agglomerate at the edges of the slurry, forming a barrier boundary similar to the wrapping effect, thereby reducing mobility. It is recommended to improve it by adding fly ash, water-reducing agents, etc.

The variation trend of the shrinkage rate of the specimen after the addition of fibers can be divided into three stages: dehydration period, slowing period, and stable period. After stabilization, the shrinkage rate decreases significantly and is less than 2.0%, which meets the conservation requirements. However, the changing trend of the shrinkage rate varies greatly with the different fiber lengths. When the fiber length is short, the influence of the content on the shrinkage rate is relatively limited; When the fiber length is long, the shrinkage rate will gradually decrease with the increase of fiber content, and the surface cracking also tends to be serious, so it is suggested to repair through the secondary grouting method.

After mixing BF, the UCS of the specimens was significantly improved. When the fiber length was 6 mm, the UCS increased by over 50%, and the peak strength was 1.95 MPa; when the fiber length is the same, the UCS shows a trend of first increasing, then decreasing, and then continuously increasing with the increase of BF content. Moreover, if the BF content continues to increase, the UCS still has room for further improvement.

The influence of BF length on the flexural strength was slightly different under different content. When the content was 0.4% or 0.6–0.8%, the optimal fiber length was 6 and 12 mm, respectively. When the fiber length was constant, the flexural strength showed a similar trend as the UCS, but the influence of fiber length on the flexural strength was limited when the fiber content exceeded 0.8%. The ductility and fracture energy of the slurry are closely related to the fiber length. Shorter fibers can effectively improve the peak load, but the ductility and fracture energy of the slurry are limited. However, when the fiber content and length are large, the fracture energy increases significantly, which can reach more than 12 times.

The strengthening mechanism of BF on ecological grouting slurry can be explained from two aspects: (a) the hydration products of CGN are arranged in a dendritic pattern under the influence of amylopectin of GRP and are wrapped in soil particles and filled in pores. At the same time, they are agglomerated and bonded on the surface of BF to form a multi-level skeleton structure. (b) The randomly distributed fibers in the matrix weave the slurry into a three-dimensional overall network structure. After the local section is cracked by external force, the fibers squeeze the intermediate substrates so that it is in a multi-directional compression state, effectively limiting the deformation and slip among substrate particles.

BF-reinforced grouting material has excellent mobility, mechanical strength, and ductility, which has a wide application prospect in the reinforcement and protection engineering of damaged earthen sites. When applied to crack grouting sealing, it can significantly improve the defect of slurry being prone to cracking and breaking and limit the local deformation of the rammed earth around the cracks; when used as the grouting material of anchor hole in anchorage engineering, it can greatly improve the shear and compressive strength of the slurry, so as to enhance the pull-out capacity of the anchoring system and enhance the structural integrity.

Acknowledgments

The authors of this article gratefully acknowledge the funding support received from the National Natural Science Foundation of China (Grant No. 52008332), the China Postdoctoral Science Foundation (Grant No. 2021M693877), the Natural Science Foundation of Shaanxi Province of China (Grant No. 2020JQ-671), the Independent Research and Development Project of State Key Laboratory of Green Building in Western China (Grant No. LSZZ202225), Jin Ling Institute of Technology (Grant No. jit-b-201916), and Jiangsu Province Department of Education (Grant No. 20KJD560003).

-

Funding information: The National Natural Science Foundation of China (Grant No. 52008332), the China Postdoctoral Science Foundation (Grant No. 2021M693877), the Natural Science Foundation of Shaanxi Province of China (Grant No. 2020JQ-671), the Independent Research and Development Project of State Key Laboratory of Green Building in Western China (Grant No. LSZZ202225), Jin Ling Institute of Technology (Grant No. jit-b-201916), and Jiangsu Province Department of Education (Grant No. 20KJD560003).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Sun, M. L., X. D. Wang, and Z. X. Li. A preliminary discussion on the conservation of earthen sites, Science Press, Beijing, 2010 (in Chinese).Search in Google Scholar

[2] Xue, Q. F., X. B. Jin, Y. N. Chen, X. H. Yang, X. Jia, and Y. K. Zhou. The historical process of the masonry city walls construction in China during 1st to 17th centuries AD. Plos One, Vol. 14, No. 3, 2019, id. e0214119.10.1371/journal.pone.0214119Search in Google Scholar PubMed PubMed Central

[3] Pan, C. G., K. Y. Chen, D. T. Chen, S. C. Xi, J. Geng, and D. Y. Zhu. Research progress on in-situ protection status and technology of earthen sites in moisty environment. Construction and Building Materials, Vol. 253, 2020, id. 119219.10.1016/j.conbuildmat.2020.119219Search in Google Scholar

[4] Guo, Q. L., Y. W. Wang, W. W. Chen, Q. Q. Pei, M. L. Sun, S. L. Yang, et al. Key issues and research progress on the deterioration processes and protection technology of earthen sites under multi-field coupling. Coatings, Vol. 12, No. 11, 2022, id. 1677.10.3390/coatings12111677Search in Google Scholar

[5] Du, Y. M., W. W. Chen, K. Cui, and K. W. Zhang. Study on damage assessment of earthen sites of the ming great wall in Qinghai province based on Fuzzy-AHP and AHP-TOPSIS. International Journal of Architectural Heritage, Vol. 14, No. 6, 2020, pp. 903–916.10.1080/15583058.2019.1576241Search in Google Scholar

[6] Kong, D. Q., R. Wan, J. X. Chen, Y. L. Jing, W. M. Huang, and Y. H. Wang. The study on engineering characteristics and compression mechanisms of typical historical earthen site soil. Construction and Building Materials, Vol. 213, 2019, pp. 386–403.10.1016/j.conbuildmat.2019.04.028Search in Google Scholar

[7] Lu, W., D. Zhao, D. B. Li, and H. T. Jiang. Evaluation on anchoring force demands of typical damaged rammed earth city wall sites under earthquake. Arabian Journal of Geosciences, Vol. 14, 2021, id. 692.10.1007/s12517-021-06889-8Search in Google Scholar

[8] Zhang, J. K., W. W. Chen, Z. X. Li, X. D. Wang, Q. L. Guo, and N. Wang. Study on workability and durability of calcined ginger nuts-based grouts used in anchoring conservation of earthen sites. Journal of Cultural Heritage, Vol. 16, No. 6, 2015, pp. 831–837.10.1016/j.culher.2015.02.007Search in Google Scholar

[9] Cui, K., F. Feng, W. W. Chen, D. H. Wang, and X. H. Wang. Slurry and technology optimization for grouting fissures in Earthen Sites with quicklime. Advances in Materials Science and Engineering, Vol. 2019, 2019, id. 9076760.10.1155/2019/9076760Search in Google Scholar

[10] Rathod, R. S. B., P. Sahoo, and S. Gupta. Application of micro-crystalline cellulose as additive in portland cement-based and alkali activated slag-fly ash mortar: Comparison of compressive strength, hydration and shrinkage. Construction and Building Materials, Vol. 385, 2023, id. 131531.10.1016/j.conbuildmat.2023.131531Search in Google Scholar

[11] Ameri, F., S. A. Zareei, and B. Behforouz. Zero-cement vs. cementitious mortars: An experimental comparative study on engineering and environmental properties. Journal of Building Engineering, Vol. 32, 2020, id. 101620.10.1016/j.jobe.2020.101620Search in Google Scholar

[12] ICOMS China. Principles for the conservation of heritage sites in China(Rivised 2015), Culture Relics Press, Beijing, 2015 (in Chinese).Search in Google Scholar

[13] Illampas, R., I. Ioannou, and D. C. Charmpis. Overview of the pathology, repair and strengthening of adobe structures. International Journal of Architectural Heritage, Vol. 7, No. 2, 2013, pp. 165–188.10.1080/15583058.2011.624254Search in Google Scholar

[14] Guo, Q. L., Q. Q. Pei, and W. W. Chen. Study on the integration and effect evaluation of a set of the conservation technologies of Earthen Sites in arid regions, Science Press, Beijing, 2021 (in Chinese).Search in Google Scholar

[15] Zhang, J. K., Z. X. Li, W. W. Chen, X. D. Wang, Q. L. Guo, and N. Wang. Pull-out behaviour of wood bolt fully grouted by PS-F slurry in rammed earth heritages. Geomechanics and Geoengineering: An International Journal, Vol. 12, No. 4, 2017, pp. 270–290.10.1080/17486025.2016.1224934Search in Google Scholar

[16] Zhang, J. K., Z. X. Li, W. W. Chen, X. D. Wang, M. L. Sun, and Q. L. Guo. The properties of potassium silicate/fly ash slurry used in the conservation of adobe structures. Studies in Conservation, Vol. 62, No. 2, 2017, pp. 114–121.10.1080/00393630.2016.1149912Search in Google Scholar

[17] He, F. G., W. W. Chen, H. Y. Zhao, M. L. Sun, and J. K. Zhang. Experimental research of PS reinforcing earthen architecture. Journal of Central South University (Science and Technology), Vol. 41, No. 3, 2010, pp. 1132–1138 (in Chinese).Search in Google Scholar

[18] Yang, L., M. L. Sun, J. H. Huang, T. Zeng, and Y. Gao. Groutability of PS-C Grout for Jiaohe ruins. Chinese Journal of Geotechnical Engineering, Vol. 32, No. 3, 2010, pp. 397–400 (in Chinese).Search in Google Scholar

[19] Chen, W. W., J. Liu, S. Y. Gong, G. Yang, D. Y. Wang, and G. C. Lin. Researches on the durability of the SH-(C + F + CaO) slurry applied to reinforce the cracks in earthen sites. Chinese Journal of Rock Mechanics and Engineering, Vol. 35, No. S2, 2016, pp. 4310–4317 (in Chinese).Search in Google Scholar

[20] Li, Z. X., L. Y. Zhao, and L. Li. Light weight concrete of Yangshao Period of China: The earliest concrete in the world. Science China (Technological Sciences), Vol. 55, No. 3, 2012, pp. 629–639.10.1007/s11431-011-4725-1Search in Google Scholar

[21] Li, L., L. Y. Zhao, J. H. Wang, and Z. X. Li. Research on physical and mechanical characteristics of two traditional silicate materials in Chinese ancient buildings. Chinese Journal of Rock Mechanics and Engineering, Vol. 30, No. 10, 2011, pp. 2120–2127 (in Chinese).Search in Google Scholar

[22] Zhang, J. K., L. X. Zhang, L. Y. Zhao, D. Liu, Q. L. Guo, and Q. Q. Pei. Property changes of anchor grout Calcined Ginger Nuts admixed with fly ash and quartz sand after accelerated ageing tests. Journal of Central South University, Vol. 26, No. 11, 2019, pp. 3114–3125.10.1007/s11771-019-4240-2Search in Google Scholar

[23] Mao, X. F., Y. Y. Zhang, F. L. Hu, X. Li, and J. C. Lu. Experimental research on the mechanical properties of glutinous rice slurry modified Calcined Ginger Nuts grouting material. Chinese Journal of Applied Mechanics, Vol. 39, No. 5, 2022, pp. 965–973 (in Chinese).Search in Google Scholar

[24] Pei, Q. Q., X. D. Wang, Q. L. Guo, L. Y. Zhao, B. Zhang, and Z. P. Li. Action mechanism of sticky rice-paste-modified site soil: a traditional Chinese cementitious material. Studies in Conservation, Vol. 65, No. 4, 2020, pp. 238–250.10.1080/00393630.2020.1722517Search in Google Scholar

[25] Abolfazl, E., M. Hosein, and M. B. Hosein. Palm fiber as a natural reinforcement for improving the properties of traditional adobe bricks. Construction and Building Materials, Vol. 325, 2022, id. 126808.10.1016/j.conbuildmat.2022.126808Search in Google Scholar

[26] Mario, F., K. Harald, L. Federica, and Z. R. Giovanna. Jute fabric as a reinforcement for rammed earth structures. Composites Part B: Engineering, Vol. 175, 2019, id. 107064.10.1016/j.compositesb.2019.107064Search in Google Scholar

[27] Bouhicha, M., F. Aouissi, and S. Kenai. Performance of composite soil reinforced with barley straw. Cement and Concrete Composites, Vol. 27, 2005, pp. 617–621.10.1016/j.cemconcomp.2004.09.013Search in Google Scholar

[28] Fulvio, P., A. Domenico, F. Luigi, and P. Andrea. Experimental characterization of Italian composite adobe bricks reinforced with straw fibers. Composite Structures, Vol. 122, 2015, pp. 200–207.10.1016/j.compstruct.2014.11.060Search in Google Scholar

[29] Castrillo, M. C., I. Ioannou, and M. Philokyprou. Reproduction of traditional adobes using varying percentage contents of straw and sawdust. Construction and Building Materials, Vol. 294, 2021, id. 123516.10.1016/j.conbuildmat.2021.123516Search in Google Scholar

[30] Araya-Letelier, G., J. Concha-Riedel, F. C. Antico, C. Valdes, and G. Caceres. Influence of natural fiber dosage and length on adobe mixes damage-mechanical behavior. Construction and Building Materials, Vol. 174, 2018, pp. 645–655.10.1016/j.conbuildmat.2018.04.151Search in Google Scholar

[31] Burbano-Garcia, C., G. Araya-Letelier, R. Astroza, and Y. F. Silva. Adobe mixtures reinforced with fibrillated polypropylene fibers: Physical mechanical fracture durability performance and its limits due to fiber clustering. Construction and Building Materials, Vol. 343, 2022, id. 128102.10.1016/j.conbuildmat.2022.128102Search in Google Scholar

[32] Wang, S. N., Q. P. Xue, W. Ma, K. Zhao, and Z. J. Wu. Experimental study on mechanical properties of fiber-reinforced and geopolymer-stabilized clay soil. Construction and Building Materials, Vol. 272, 2021, id. 121914.10.1016/j.conbuildmat.2020.121914Search in Google Scholar

[33] Ministry of Water Resources of the People’s Republic of China. Standard for Geotechnical Test Methods (GB/T 50123-2019), China Planning Press, Beijing, 2019.Search in Google Scholar

[34] Zhao, L. Y., L. Li, Z. X. Li, and J. H. Wang. Research on two traditional silicate materials in China’s ancient building. Journal of Inorganic Materials, Vol. 26, No. 12, 2011, pp. 1327–1334 (in Chinese).10.3724/SP.J.1077.2011.01327Search in Google Scholar

[35] Jin, Y. F., Y. Tao, D. Chai, S. X. Xu, and L.H. Li. Fracture performance of basalt fiber concrete three-point bending beam. Journal of Civil and Environmental Engineering, Vol. 45, No. 2, 2023, pp. 150–157 (in Chinese).Search in Google Scholar

[36] Chen, W. W., Q. Y. Zhang, H. W. Liu, and P. P. Yang. Influence of temperature on glutinous rice slurry strengthening site soil by sticky rice-lime mortar. Chinese Journal of Rock Mechanics and Engineering, Vol. 36, No. S2, 2017, pp. 4244–4250 (in Chinese).Search in Google Scholar

[37] Abd-El Hameed, M. F., M. F. Ghazy, and M. A. Abd Elaty. Optimisation of adhesive anchors in concrete by desirability function. Magazine of Concrete Research, Vol. 67, No. 20, 2015, pp. 1101–1111.10.1680/macr.14.00397Search in Google Scholar

[38] Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical code for application of cementitious grout (GB/T 50448-2015), China Architecture and Building Press, Beijing, 2015 (in Chinese).Search in Google Scholar

[39] General Administration of Quality Supervision, Inspection and Quarantine of People’s Republic of China. Standard test methods for dry shrinkage stress and cracking possibility of cement mortar and concrete (GB/T 29417-2012), China Standard Press, Beijing, 2012 (in Chinese).Search in Google Scholar

[40] EN 680-2005. Determination of the drying shrinkage of autoclaved aerated concrete, 2005.Search in Google Scholar

[41] State Administration of Market Supervision and Administration. Test Method of Cement Mortar Strength (ISO Method) (GB/T 17671-2021), China Standards Press, Beijing, 2021 (in Chinese).Search in Google Scholar

[42] Wang, D. H. Research on optimization and mechanism of full-length bond anchorage system for Earthen Sites. Ph.D. thesis. Lanzhou University of Technology, Lanzhou, 2020 (in Chinese).Search in Google Scholar

[43] Li, Z. X., X. D. Wang, and M. L. Sun. Research on consolidation techniques for conserving the ancient city of Jiaohe, Science Press, Beijing, China, 2008 (in Chinese).Search in Google Scholar

[44] Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical specification of injection materials for repair of cracks in concrete (JG/T 333-2011), China Quality Inspection Press, Beijing, 2011 (in Chinese).Search in Google Scholar

[45] Wang, N., W. W. Chen, J. K. Zhang, R. X. Liao, J. F. Li, L. Y. Zhao, et al. Evolution of properties under realistic curing conditions of calcined ginger nut grouting mortars used in anchoring conservation of earthen sites. Journal of Cultural Heritage, Vol. 40, 2019, pp. 69–79.10.1016/j.culher.2019.06.002Search in Google Scholar

[46] Khiem, Q. T., S. Tomoaki, and T. Hiroshi. Improvement of mechanical behavior of cemented soil reinforced with waste cornsilk fibers. Construction and Building Materials, Vol. 178, 2018, pp. 204–210.10.1016/j.conbuildmat.2018.05.104Search in Google Scholar

[47] Tiziano, L. P., K. Dennis, W. Jaap, K. Lambertus, and S. J. Lambertus. The mechanical performance of traditional adobe masonry components: An experimental analytical characterization of soil bricks and mud mortar. Journal of Green Building, Vol. 13, No. 3, 2018, pp. 17–44.10.3992/1943-4618.13.3.17Search in Google Scholar

[48] Zhang, J. K., N. Wang, M. Fan, X. R. Ren, Z. X. Li, and L. Y. Zhao. Experimental study on age properties of fissure grouting material composed of Calcined Ginger Nuts and earthen site soil. Chinese Journal of Rock Mechanics and Engineering, Vol. 37, No. 1, 2018, pp. 220–229 (in Chinese).Search in Google Scholar

[49] Wei, G. F., S. Q. Fang, B. J. Zhang, X. Q. Wang, and Z. G. Li. Study on the mechanism of Liesegang pattern development during carbonating of traditional stiky rice-lime mortar. Spectroscopy and Spectral Analysis, Vol. 32, No. 8, 2012, pp. 2181–2184 (in Chinese).Search in Google Scholar

[50] Danso, H., D. B. Martinson, M. Ali, and J. B. Williams. Mechanisms by which the inclusion of natural fibers enhance the properties of soil blocks for construction. Journal of Composite Materials, Vol. 51, No. 27, 2017, pp. 1–11.10.1177/0021998317693293Search in Google Scholar

[51] Olubisi, I. and D. Humphrey. Physico-mechanical and thermal gravimetric analysis of adobe masonry units reinforced with plantain pseudo-stem fibres for sustainable construction. Construction and Building Materials, Vol. 273, 2021, id. 121686.10.1016/j.conbuildmat.2020.121686Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete