Abstract

This study used aluminum scraps to produce a secondary aluminum metal matrix for heat storage analyses. Silica and kaolin reinforced aluminum metal matrix composites were successfully produced via stir casting. The X-ray diffraction (XRD) and scanning electron microscopy (SEM) were employed for phase and microstructure characterization. XRD revealed alumina (corundum), aluminum and kyanite phases while SEM indicated pores in the composites. Density, average specific heat (from 30 to 200°C), thermal conductivity, and hardness tests were carried out. Total heat energy stored per kg, from 30 to 200°C, was obtained. The inclusion of 7.5 and 15 wt% kaolin increased the specific heat of the matrix from 474.3 to 564.57 J·kg−1·°C−1 and 474.3 to 679.03 J·kg−1·°C−1, respectively. Likewise, adding 7.5 and 15 wt% silica sand increased the thermal conductivity of the matrix from 154.99 to 175.62 W·m−1·°C−1 and 154.99 W·m−1·°C−1 to 181.38 W·m−1·°C−1, respectively. The addition of 7.5 wt% silica sand and 7.5 and 15 wt% kaolin increased the hardness value of the matrix from 72.11 to 73.11 HB, 72.11 to 81.38 HB, and 72.11 to 82 HB, respectively. Hardness of the composites reinforced with kaolin is higher than that of the composites reinforced with silica sand. This is attributed to the higher molecular weight of kaolin. Significant increase in specific heat and thermal conductivity was achieved.

1 Introduction

Recent studies have shown that automobile and aircraft parts are often disposed of habitually because they occupy a large amount of land resources and pose a severe ecological environmental threat [1]. Secondary (recycled) aluminum exists in the form of alloys compared with those obtained from industrial primary processes. Aluminum production via the primary process is usually done by electrolytic reduction, which involves very high energy consumption imposed by high current [2]. However, scrap aluminum alloy has a lower melting temperature, shorter melting time, lower metal burning loss, and less energy consumption which is much more economical in terms of production costs [2,3]. Apart from cost reduction, it also reduces the amount of CO2 emission, thereby lowering the global warming potential of mining pure aluminum [4]. Thus, it is essential to take advantage of cost reduction associated with scrap aluminum materials and improve its limiting properties.

In recent times, significant research and development is geared towards wrought aluminum alloys by using scrap aluminum recycling technology and equipment [4,5,6]. Meanwhile, the use of scrap aluminum alloy wheels as a matrix material for the fabrication of aluminum metal matrix composite has also gained significant research interest [7,8,9,10,11]. Secondary or recycled aluminum metal matrix composite has emerged as the material of choice for application in thermal management, aerospace, recreational, and infrastructure industries [12]. This is due to its high structural efficiency, excellent wear resistance, and attractive thermal and electrical characteristics [4,13,14,15,16].

Several research reports have been published on the fabrication of aluminum metal matrix composites using different approaches such as stir casting [11,13,17,18], squeeze casting [13,17,18], friction stir casting [19,20], and powder metallurgy [16]. Among these techniques, the stir casting process has been widely used to fabricate aluminum metal matrix composites due to its low-cost implication [21]. However, components produced from the stir casting method suffer from high porosity, thus, limiting their use for high strength components [18,19,20,21]. However, this limiting property of aluminum metal matrix composite can be improved by incorporating suitable reinforcement materials into the matrixes using appropriate technologies [22,23,24]. For instance, Farajollahi et al. [25] studied the effect of adding Ni on the microstructure and mechanical properties of aluminum alloy using the stir casting method at the speed of 300 rpm for 20 min at 750°C. For up to 4 wt% of nickel added, the significant increase in the hardness (from about 92 to 144.05 VHN) and strength of the as-cast aluminum alloy used was because of the formation of intermetallic compounds. Whereas, beyond 3 wt%, i.e., addition of up to 4.5 wt% of nickel resulted in Al6CuMg4 precipitates, which increased the porosity and reduced the hardness of the composites to 118.54 VHN.

Similarly, via the stir casting method, Shayan et al. [26] used TiO2, Al, and Cu powder mixture as reinforcement in an aluminum alloy matrix to test for the resulting mechanical properties of the fabricated composites. The stirring was carried out at 750°C for 15 min at a stirring speed of 500 rpm. As the quantity of reinforcements increased, they recorded an increase in hardness and ultimate tensile strength. Kumar et al. [27] reinforced aluminum matrix with 4, 8, and 12% Si3N4 by stir casting at 200 rpm. After treating the composites with heat, they observed a reduction in the porosity of the composites. Using stir casting at 800°C, Reddy et al. [28] varied the composition of SiC and B4C in an aluminum matrix and observed the effects on the mechanical properties of the composite. An improvement in the mechanical properties was reported with a higher concentration of reinforcements relative to the composites with a lower concentration of reinforcements, which then gave an increase in tensile strength and hardness of 107.64–128.24 MPa and 30.43–45.8 BHN, respectively.

In a study conducted by Shirvanimoghaddam et al. [29], the volume fraction of B4C, fabrication temperature, stirring time, and particle size were varied against the mechanical and physical properties of aluminum used as matrix. According to the results, an increase in the tensile strength and hardness were recorded. The wettability, agglomeration, and dispersion of the particles were affected by the temperature, stirring speed, and time of stirring. In a similar study by Selvakumar et al. [30], the tensile strength of the material increased from 222 to 303 MPa when 0, 6, 12, and 18 vol% of molybdenum particles were added to the aluminum matrix. Using the stir casting technique, Shuvho et al. [31] investigated the effect of reinforcing aluminum matrix with Al2O3, SiC, and TiO2 of average particle size (65 microns) on the mechanical properties of the resulting composites. The stirring process was carried out at about 660°C at 400 rpm for 8 min. The increase in the quantity of the SiC particles led to a corresponding increase in hardness, tensile and yield strengths of the matrix from 29.7 to 98.56 HB, 110.07 to 148.62 N·mm−2, and 78.6 to 109.8 N·mm−2, respectively.

Using stir casting technique while operating at 500 rpm and 750°C for 10 min, Daniel-Mkpume et al. [32] reinforced aluminum matrix with SiO2 particles of 53 microns average particle size in weight fractions of 3, 7, 11, 15, and 19 wt%. They observed a decrease in the density as the weight fraction of SiO2 increased. They also observed an increase in the ultimate tensile strength from 49.73 to 65.64 MPa. Mallikarjuna and Basavaraj [5] investigated the effects of varying SiO2 particle sizes (106, 150, 250, and 335 microns) and varying SiO2 weight fractions from 3 to 12 wt% on the mechanical properties of the resulting composites. However, no significant effect on the mechanical properties was observed due to the different particle sizes. Altinkok and Koker [6] studied the effect of reinforcing aluminum matrix with Al2O3/SiC on the resulting composite’s bending strength and hardness resistance. For 10 vol% of Al2O3/SiC, the bending strength and hardness resistance reduced from 481.2 to 378.3 MPa and 118 to 77 HB, respectively, as the SiC particle size increased. Pramod et al. [33] used 150 microns of Al2O3 to reinforce aluminum from 2 to 6% weight fraction by stir casting at 710°C for 10 min at a stirring speed of 400 rpm. This was done to observe the effect on density and wear height loss within an applied load and sliding distance. Judging from their results, the composite containing 6 wt% of reinforcement had the highest performance against wear resistance. Gupta et al. [34] investigated the effect of reinforcing pure aluminum and eutectic aluminum alloy with silica particles up to 25 wt% through stir casting on the mechanical properties of the composites. They observed a reaction between aluminum and silica which gave alumina and silicon as products at 723 K. Adding up to 20 wt% silica to the pure aluminum increased the hardness from 52 to 78 BHN but decreased the ultimate tensile strength from 92 to 62 MPa.

On the other hand, adding 20 wt% silica to the eutectic alloy did not affect the hardness but decreased the ultimate tensile stress from 184 to 112 MPa. Using the stir casting method, Hemanth [35] added 3, 6, 9, and 12 wt% quartz particles to aluminum alloy by stirring at 700 rpm at a temperature of 750°C in a bid to investigate their effects on the mechanical properties. Observation of uniform distribution of particulates from the microstructural analysis was made. The hardness, ultimate tensile strength, and Young’s modulus increased from 80 to 125 HV, 172 to 257 MPa, and 68 to 89 GPa, respectively for up to 9 vol% of quartz-reinforcements. The thermal conductivities of the composites reduced as the particles increased. Singh et al. [36] worked on varying the amount of silica in an aluminum alloy matrix and studied the effects on the mechanical properties of the resulting composites. They used the stir casting method with a stirring speed of 330 rpm at a temperature of 850 for 5 min and observed an increase in hardness (from 87 to 128.66 HV), tensile strength, and impact energy with the increase in reinforcement.

Although several articles have reported on the fabrication of aluminum metal matrix composites by stir casting method, only few reports are available on the thermal properties. Despite the large volume of literature available on the use of reinforcements in aluminum matrix for energy applications, no work has been done on the use of kaolin as reinforcement in relation to its application for thermal energy storage to the best of the author’s knowledge. Therefore, an effort is made in this study to investigate the effect of silica and kaolin as reinforcements in improving the thermal properties of the aluminum matrix for thermal storage. This work is aligned with the 7th, 8th, 9th, 13th, and 15th sustainable development goals of the United Nations.

2 Materials and methods

2.1 Feedstock material

The matrix material was obtained from aluminum waste. Silica sand used as reinforcement was obtained from the Silicon Research Group in Covenant University, Ota, Nigeria, and was crushed into very fine particles with a ball mill for 45 min and then sieved using a 45 µm sieve. The kaolin particle reinforcement was obtained from Apapa, Lagos, Nigeria.

2.2 Sample preparation

The matrix material was derived from aluminum waste. The waste was transferred into a steel crucible placed in an electric resistance furnace. At 800°C, the molten aluminum was rid of the oxide layer and then decanted into a mold to solidify at ambient conditions (room temperature of 27°C and no forced convection). Table 1 presents the thermal properties of the secondary aluminum, silica and kaolin used in this study. Table 2 shows the composition of the composites. The particulates were weighed according to the compositions in Table 2 and gently poured into molten aluminum at 800°C and stirred at 500 rpm for 10 min. After taking the crucible containing the molten composite out of the furnace, the mixture was stirred for 10 s. The molten composite was poured into molds and allowed to cool down to room temperature at ambient conditions.

Thermal properties of the prepared aluminum matrix and silica sand samples

| Average specific heat from 30 to 200°C (J·kg−1·°C−1) | Thermal conductivity (W·m−1·°C−1) | Density (kg·m−3) | |

|---|---|---|---|

| Aluminum matrix | 474.30 | 154.99 | 2649.38 |

| SiO2 | 368.95 | 0.06 | 1580.00 |

| Kaolin | 277.43 | 0.15 | 2340.00 |

Sample compositions

| S/N | Aluminum matrix (wt%) | Silica sand (wt%) | Kaolin (wt%) |

|---|---|---|---|

| 1 | 100 | 0 | 0 |

| 2 | 92.5 | 7.5 | 0 |

| 3 | 85 | 15 | 0 |

| 4 | 92.5 | 0 | 7.5 |

| 5 | 85 | 0 | 15 |

2.3 Sample characterization

The scanning electron microscopy (SEM) characterization was done using the Phenom ProX instrument. The samples were coated with gold and the morphology was examined. The phase analysis was carried out using XRD diffractometer (Rigaku MiniFlex 600). The analysis was done with K-Alpha radiation of 1.54060 Å using Cu as the anode. The samples were scanned from 2 to 90° at 2-theta angle with 0.02° steps.

Brinell’s hardness test was carried out on the samples (SADT HARTIP 3000) to determine the influence of the silica sand particulates on the matrix. The thermal conductivity of the composites was measured (Armfield equipment model HT12) to determine the heat transfer capability of the composites as influenced by the reinforcements. Differential scanning calorimetry (DSC) was done (Mettler Toledo DSC822e) with a heat supply rate of 20°C·min−1 in a nitrogen atmosphere at 20 psi. The specific heat of the samples from 30 to 200°C was obtained. The density measurement of the samples was carried out using the Archimedes principle.

3 Results and discussion

3.1 Microstructural and phase analysis

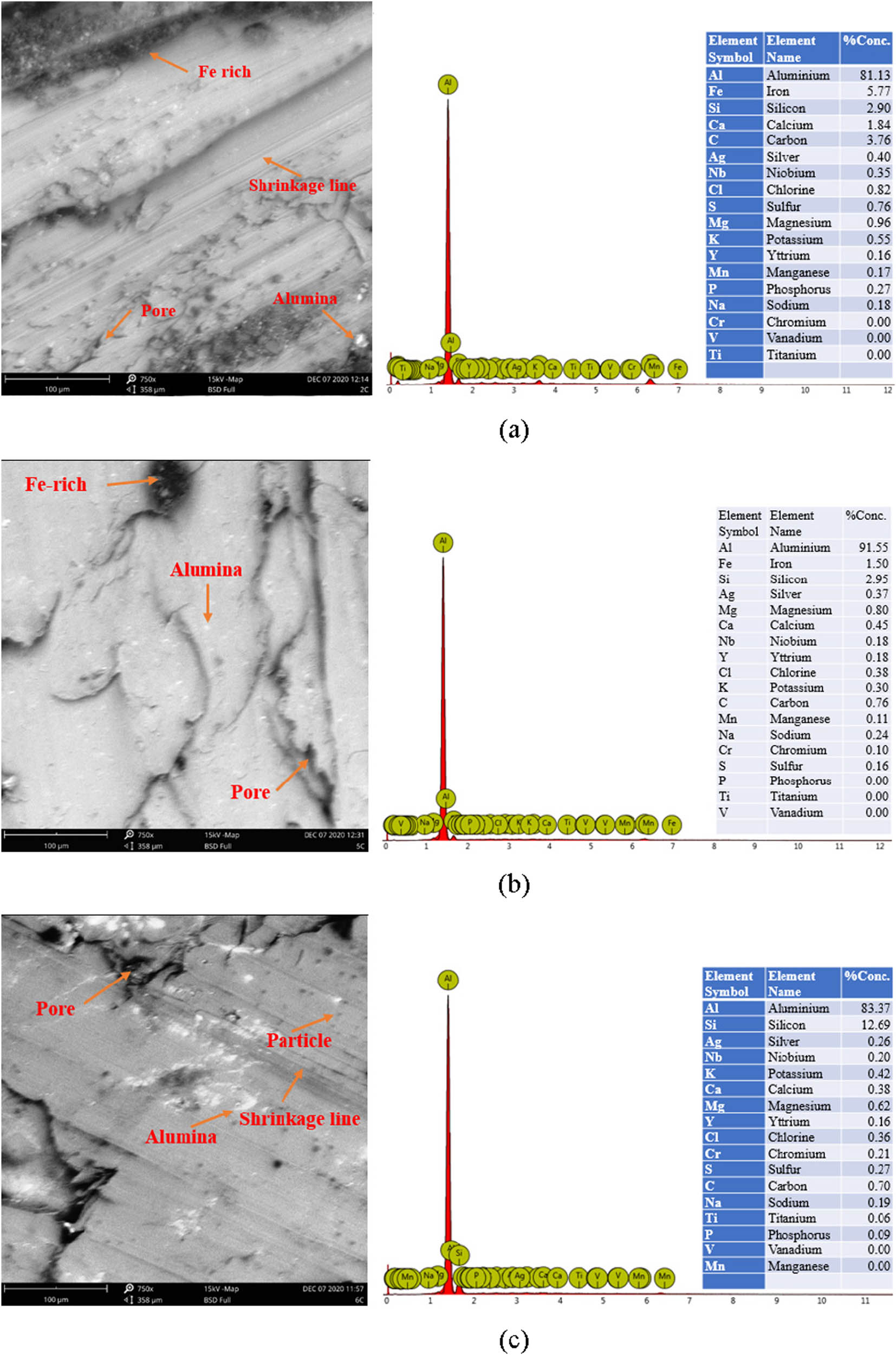

Figure 1a displays the SEM/EDS of the secondary aluminum used as matrix. The top left corner of the SEM image shows the Fe-rich phase precipitated during solidification of the matrix. The presence of Fe is confirmed in the EDS graph of the aluminum sample. The diagonal lines are caused by shrinkage of the melt during nucleation, which results in pores indicated at the lower left part of the image. Alumina formed during casting is shown at the lower left part of the image. The silica sand particles shown in Figure 1b are relatively more edgy with smooth surface morphology compared to the SEM of the kaolin sample in Figure 1c, which appears to be coarser.

SEM/EDS image of (a) the aluminum matrix obtained from waste aluminum materials; (b) silica sand sample; and (c) kaolin sample.

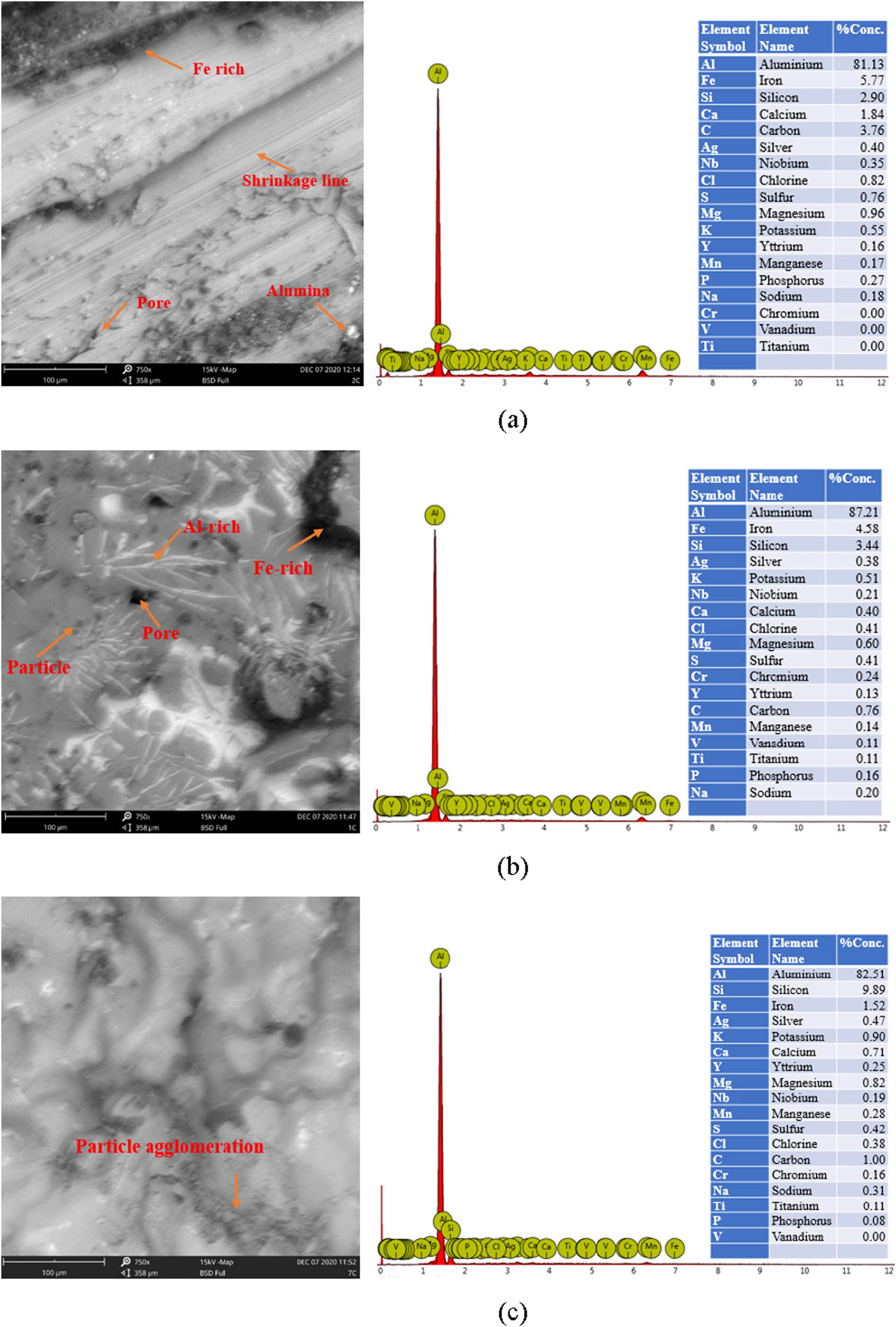

Figure 2(a–c) presents the SEM of the cast aluminum matrix, the cast aluminum matrix composite with 7.5 wt% silica sand and the cast aluminum matrix composite with 15 wt% silica sand, respectively. The SEM image of the secondary aluminum and the fabricated composites revealed alumina (corundum) phase was formed during and after the casting process. This is reasonably consistent with the XRD result. Fe-rich phase can be observed at the top middle region of Figure 2b. Confirmation of the presence of Fe can be observed in the EDS graph. The scaly features in Figure 2c are a consequence of shrinkage during nucleation. This results in pores as observed in the image. The diagonal lines caused by shrinkage of the composite during the cooling process is observed in the matrix presented in Figure 2c. Homogeneous distribution of the silica sand particulates is observed in the fabricated composite presented in Figure 2c. The scaly structure observed in Figure 2b is prevented in Figure 2c because it contains a higher amount of silica sand particulates which provide good enough mechanical reinforcement against shrinkage.

SEM/EDS image of (a) the aluminum matrix obtained from waste aluminum materials; (b) composite fabricated using secondary aluminum (92.5 wt%) and silica sand (7.5 wt%); and (c) composite fabricated using secondary aluminum (85 wt%) and silica sand (15 wt%).

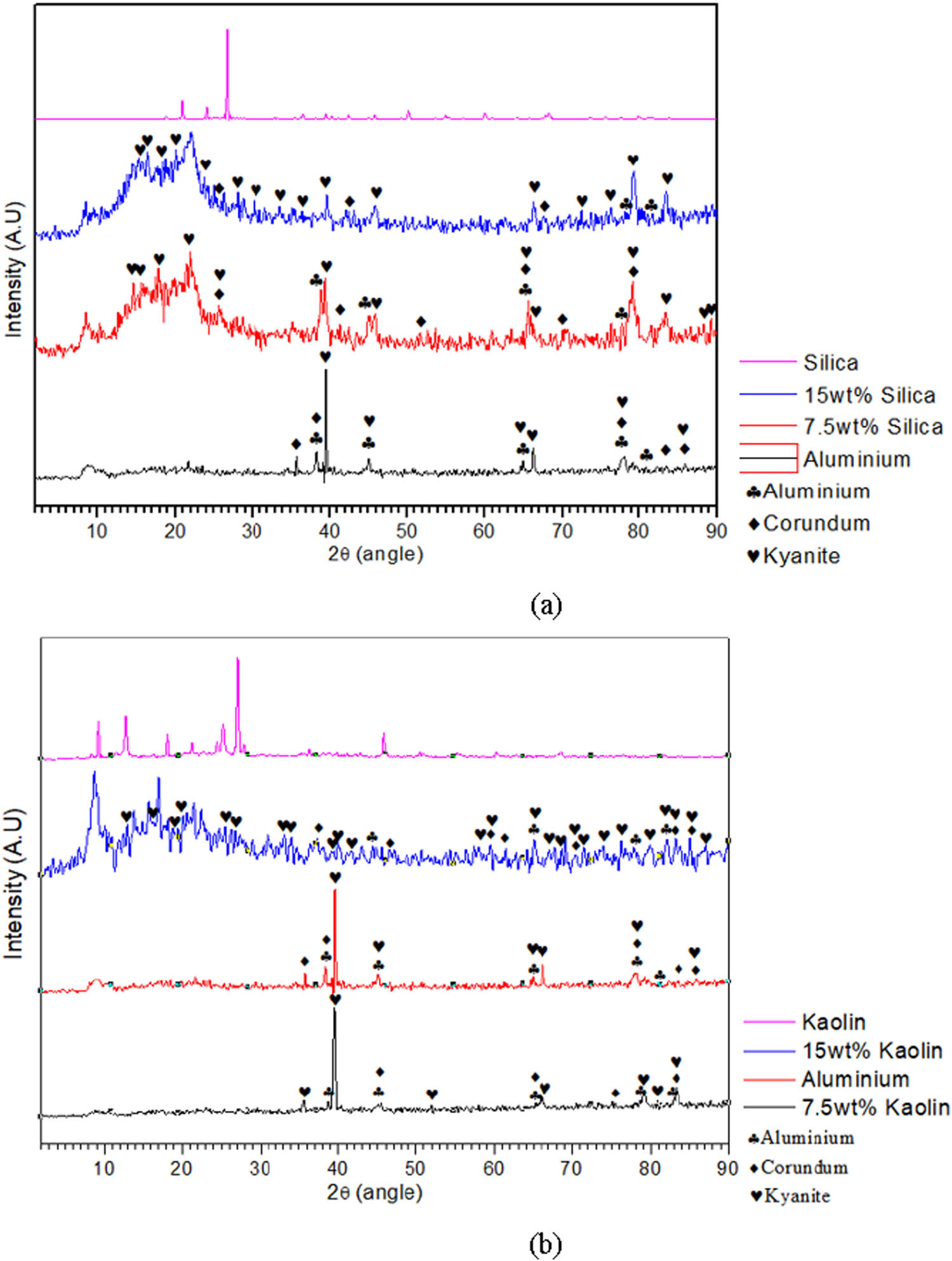

The composite fabricated with 92.5 wt% aluminum matrix and 7.5 wt% kaolin is presented in Figure 3b. Homogeneous distribution of the kaolin reinforcements can be seen in the image. Fe-rich phase can be observed at the top right corner of the image. Dendrites, which are phases rich in aluminum that solidify relatively faster due to a lower melting point, can be observed in the image [5,30,31]. The dendrites serve as core onto which surrounding materials crystallize during the solidification process of the composite. In contrast, the composite fabricated with 85 wt% aluminum matrix and 15 wt% kaolin shown in Figure 3c shows the inhomogeneous distribution of kaolin particulates and a relatively rougher surface compared to the rest of the composites. Figure 4(a and b) present the cast samples’ XRD results. The cast secondary aluminum sample and the composites with 7.5 and 15 wt% silica sand and kaolin, respectively, show the presence of unreacted aluminum, alumina (corundum), and kyanite. Kyanite forms from the crystallization of sillimanite, which was produced due to the reaction between alumina and silica at about 800°C.

SEM/EDS image of (a) the aluminum matrix obtained from waste aluminum materials; (b) composite fabricated using aluminum matrix (92.5 wt%) and kaolin (7.5 wt%); and (c) composite fabricated using aluminum matrix (85 wt%) and kaolin (15 wt%).

XRD result of (a) the silica sand sample, composites with 7.5 and 15 wt% silica sand and cast aluminum, and (b) kaolin sample, composites with 7.5 and 15 wt% kaolin and cast aluminum, showing the presence of unreacted aluminum, alumina (corundum), and kyanite.

3.2 Thermophysical properties

3.2.1 Specific heat

Table 3 presents the thermal properties of the samples. All the samples reinforced with silica sand had lower specific heat values when compared to the secondary aluminum matrix without silica sand reinforcements added. The addition of silica sand reduced the shrinkage of the composites, and this can be observed by comparing the severity of shrinkage between Figures 2b and 2c. Figure 2c had a higher amount of silica sand particulates which helped reduce shrinkage by mechanical reinforcement. Reduction in shrinkage by particulate reinforcement reduces porosity. Porous regions often serve as air traps that can store heat energy. This extra energy stored by pores can significantly increase the heat storage capacity of a material. Another similar reason for reduced specific heat can be attributed to the smooth surface of the silica sand particulates reducing the probability of interfacial air pores around them. These air pores can store heat energy with a specific heat of air higher than that of the secondary aluminum and silica sand. The higher specific heat of air is a consequence of it being a mixture of gases with the air molecules having a higher degree of freedom (or higher entropy) than solids. On the other hand, particulates with rougher surfaces with a higher probability of creating interfacial air pores will store higher amounts of heat energy in the air pores leading to a higher net specific heat of the material. The lowered specific heat of the matrix as a result of adding silica sand still makes it useful as a good heat transfer material suited for applications requiring fast charging and depletion of heat energy batteries.

Prepared samples and their properties

| Sample | Silica sand (wt%) | Kaolin (wt%) | Average specific heat from 30 to 200°C (J·kg−1·°C−1) | Thermal conductivity (W·m−1·°C−1) | Density (kg·m−3) | Hardness (HB) |

|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 474.3 | 154.99 | 2649.38 | 72.11 |

| 2 | 7.5 | 0 | 431.74 | 175.62 | 2443.47 | 73.11 |

| 3 | 15 | 0 | 382.98 | 181.38 | 2525.43 | 71.90 |

| 4 | 0 | 7.5 | 564.57 | 137.96 | 2540.83 | 81.38 |

| 5 | 0 | 15 | 679.03 | 148.74 | 2334.95 | 82.00 |

From Table 3, it can be observed that the increase in the amount of kaolin increases the specific heat of the matrix. Including 7.5 and 15 wt% kaolin increased the specific heat of the secondary aluminum matrix by 19% (from 474.3 to 564.57 J·kg−1·°C−1) and 43.2% (from 474.3 to 679.03 J·kg−1·°C−1), respectively. The irregularly shaped kaolin particles allow air pores at the interface between the particles and matrix. Air has higher specific heat than the matrix used, and the kaolin particulates (air is a mixture of gases with more degrees of freedom than solids) significantly add to the total heat capacity of the composite. Figure 5 presents the effect of kaolin on the specific heat of the matrix. The improved specific heat of the composites reinforced with kaolin makes them more suitable for thermal storage applications where long-term heat storage is a priority. For instance, heat energy can be stored in heat storage vehicles and transported to regions where the heat energy can be used for cooking, space heating, etc.

Specific heat of the matrix and composites reinforced with 7.5 and 15 wt% silica sand and kaolin.

3.2.2 Thermal conductivity

For the composites fabricated with silica sand, the thermal conductivity of the composites is higher than that of the secondary aluminum matrix, as shown in Table 3. The inclusion of 7.5 and 15 wt% silica sand increased the thermal conductivity of the matrix by 13.3% (from 154.99 to 175.62 W·m−1·°C−1) and 17% (from 154.99 to 181.38 W·m−1·°C−1), respectively. Air pores act as volumes of thermal resistance [37] and, as such, limit the flow of heat by electron transfer and phonon transfer. Two other mechanisms that limit heat transfer in materials are grain boundaries and dislocations. Smooth surface silica sand particles included in the aluminum matrix will result in a composite with a low probability of interfacial pores, reducing potential volumes of space that can impede heat transfer within the material.

The addition of kaolin to the composites reduced the thermal conductivity of the matrix. This is partly attributed to the interfacial air entrapments provided by the rough morphology of kaolin particulates serving as regions of thermal resistance to heat flow [37]. Another reason is the low thermal conductivity of the kaolin particulates. These two factors combined can have a detrimental effect on the net thermal conductivity of the composites. The effect of kaolin particulates on the thermal conductivity of the matrix is displayed in Figure 6.

Thermal conductivity of the matrix and composites reinforced with 7.5 and 15 wt% silica sand and kaolin.

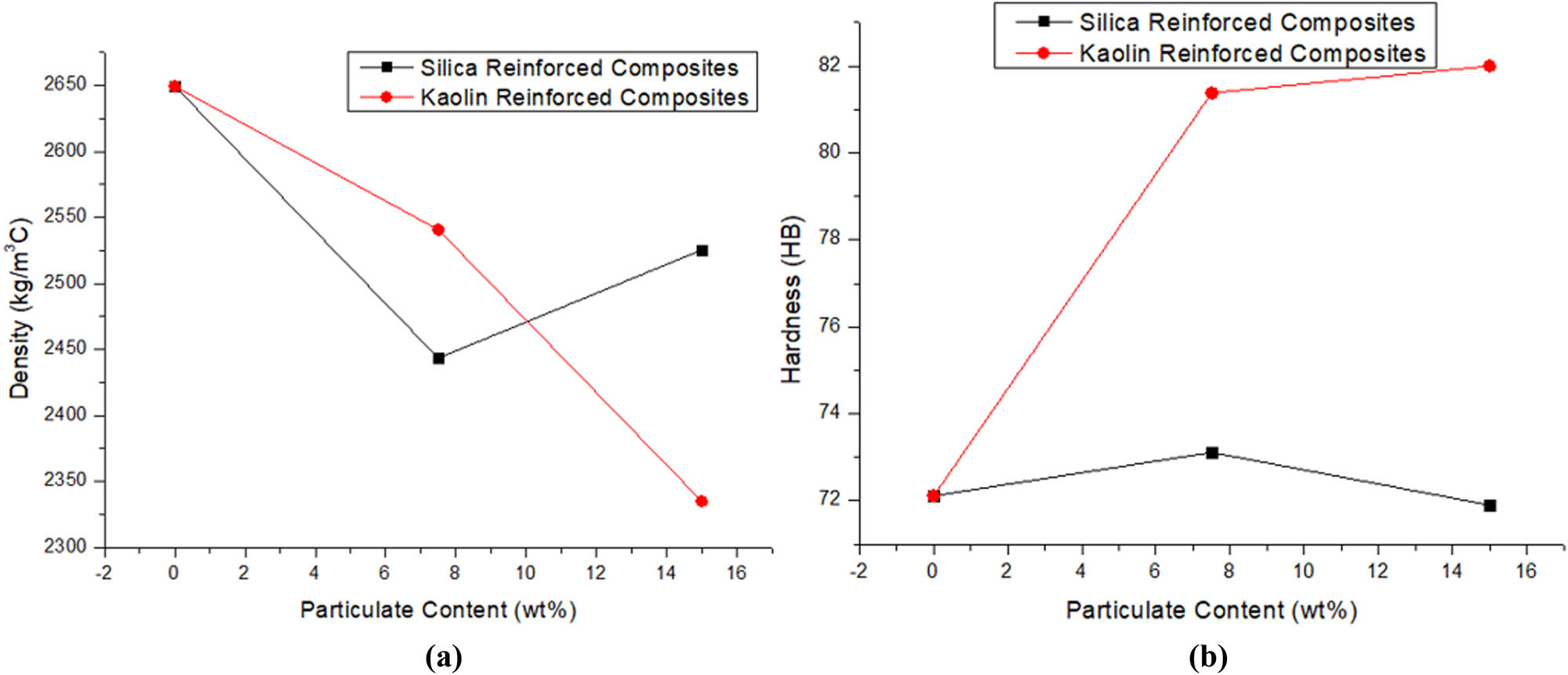

3.2.3 Density and hardness

The density of the matrix was reduced with the inclusion of silica sand and kaolin particulates as presented in Figure 7a. A similar reduction in matrix density with the addition of reinforcements was also observed in a previous study [32]. The stir casting fabrication method results in porous composites with gas trapped in pores. These composites will be lighter thermal storage materials than the matrix for a given volume. However, the addition of 7.5 wt% silica sand and 7.5 and 15 wt% kaolin increased the hardness value of the matrix by 1.39% (from 72.11 to 73.11 HB), 12.9% (from 72.11 to 81.38 HB), and 13.7% (from 72.11 to 82 HB) as presented in Figure 7b, respectively. The increase in hardness can be attributed to the fact that metakaolin (calcined kaolin) contains more elements per molecule with strong interatomic/molecular bonds. Reinforcing aluminum matrix with kaolin will make the resulting composite denser/more compact and more resistant to deformation compared to the composite reinforced with silica sand. More elements correspond to a higher number of bonds and this results in greater resistance to deformation [38].

(a) Density and (b) hardness of the matrix and composites reinforced with 7.5 and 15 wt% silica sand and kaolin.

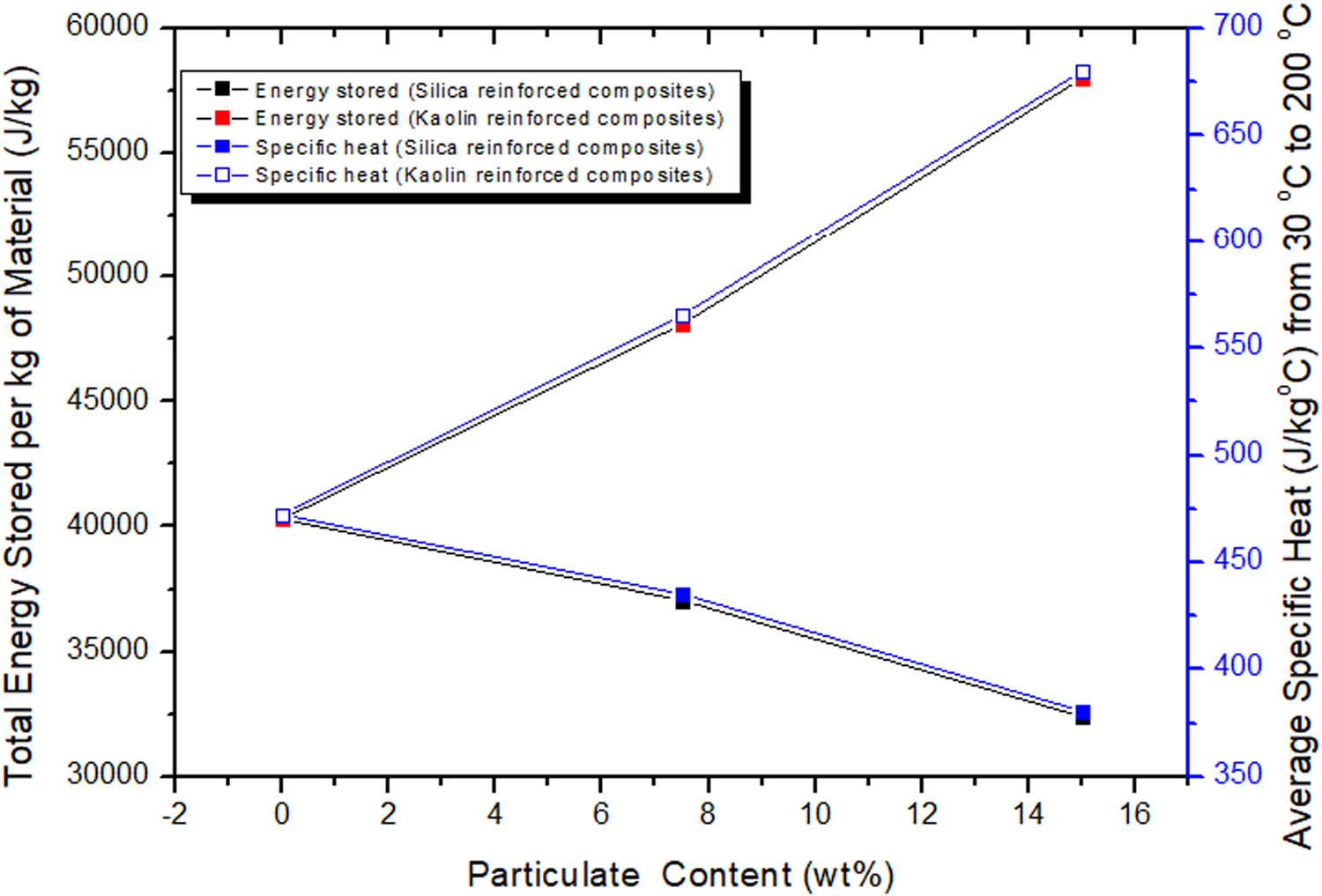

3.3 Heat energy stored in composites

Total heat energy stored in each composite from 30 to 200°C was determined for the compositions studied. The total heat energy is the amount of sensible energy stored by 1 kg of the materials within the specified temperature range. It can be observed from Figure 8 that the total energy stored by the materials shows a strong correlation with their average specific heat from 30 to 200°C. The composite with the highest amount of energy stored within the temperature range is the composite reinforced with 15 wt% kaolin. From the results obtained in this work, kaolin has been found to be an ideal reinforcement with the ability to enhance the heat energy storage capacity of secondary aluminum matrix. The chemical inertness between secondary aluminum and kaolin within 30–800°C makes the resulting composites suitable for heat storage applications at a wide temperature range. Such applications include heat supply to large Stirling engines and steam turbines. The application of kaolin and silica-reinforced waste aluminum will facilitate the shift from the dependence on fossil fuels to the abundant solar energy reaching the earth. This environmentally friendly shift has the potential to significantly reduce the production of greenhouse gases and cut costs required for mining and crude oil processing activities.

Total energy storage capacity in Joules·kg−1 by the composites compared with the average specific heat from 30 to 200°C.

The use of high-temperature thermal insulation materials studied in the work of Ndubuisi et al. [39] will help contain the heat energy trapped in the composite for practical applications. The advantages of aluminum as a heat storage material highlighted in Ogunrinola et al. [40] shows the need for further investigation on the compatibility of aluminum with thermal insulating materials at high temperatures.

4 Conclusion

The specific heat of the composites reinforced with silica sand was lower than that of the aluminum matrix. Silica sand used as reinforcement impeded the shrinkage of the material during solidification, and this reduced the formation of pores that could store heat within the material. Another reason similar to the first is the relatively smooth interfacial contact between the silica sand particulates and the matrix, leaving no space for trapped air bubbles which could increase the specific heat of the material. Compared with the aluminum matrix reinforced with silica sand, the specific heat of the aluminum matrix reinforced with kaolin increased due to the trapped air around the edges of the kaolin particulates.

The composites fabricated with silica sand particulates had higher thermal conductivity than the cast aluminum matrix. The thermal conductivity was negatively affected by interfacial pores, which acted as thermal resistance in addition to other mechanisms of thermal resistance such as grain boundaries and dislocations. The density of the matrix dropped with the inclusion of silica sand or kaolin. The hardness of the matrix was enhanced with the inclusion of kaolin reinforcements. The improvement in hardness with the addition of kaolin is attributed to its higher molecular mass compared to that of silica sand.

Enhancement of thermal conductivity can be achieved by including silica sand for better heat energy transfer. Low-density composites will make for lightweight thermal storage materials, whereas, the specific heat of secondary aluminum has been significantly increased by the addition of kaolin, giving this type of matrix possibilities for applications in thermal energy storage in the medium to high-temperature range. Pure aluminum, which is very costly to obtain, can be replaced by a significantly cheaper alternative (secondary aluminum) and doing this is environmentally friendly.

The specific heat of the composites reinforced with kaolin and the thermal conductivities of those reinforced with silica sand and kaolin show the possibility of increase if the matrix is reinforced with these particulates beyond the 15 wt% limit in this study. Second, the effect of mixing silica sand and kaolin together to reinforce the matrix to form a hybrid composite can be explored.

Acknowledgments

The authors gratefully acknowledge the Covenant University Center for Research, Innovation and Discovery for supporting this research work.

-

Funding information: The authors state no funding involved.

-

Author contributions: Iyanuoluwa Ogunrinola: investigation, methodology, resources, writing – original draft, and visualization; Marvel Akinyemi: supervision and writing – review and editing; Ahzegbobor Aizebeokhai: supervision and writing – review and editing; Rasidi Sule: conceptualization and writing – review and editing; Samuel Sanni: conceptualization and writing – review and editing; Henry Boyo: supervision, conceptualization, and methodology, Maxwell Omeje: methodology; Philip Babalola: resources. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Aircraft Fleet Recycling Association [Internet]. [cited 2022 Oct 3]. https://afraassociation.org/accreditation/the-afra-bmp/Search in Google Scholar

[2] Contribution of cooperative sector recycling to greenhouse gas emissions reduction: A case study of Ribeirão Pires, Brazil - ScienceDirect [Internet]. [cited 2022 Oct 3]. https://www.sciencedirect.com/science/article/pii/S0956053X13003759?casa_token=QvcxcKFL22oAAAAA:aZJmrksgsmbKUV4JL574cfiYCQubxImLY8GUlURyI1YSYbhIYS9iaEV11-RUY8Xdc7h_4Nqzj1U.Search in Google Scholar

[3] Miller, W. S., L. Zhuang, J. Bottema, A. Wittebrood, P. De Smet, A. Haszler, et al. Recent development in aluminium alloys for the automotive industry. Materials Science and Engineering: A., Vol. 280, No. 1, 2000, pp. 37–49.10.1016/S0921-5093(99)00653-XSearch in Google Scholar

[4] Zhou, B., B. Liu, S. Zhang, R. Lin, Y. Jiang, and X. Lan. Microstructure evolution of recycled 7075 aluminum alloy and its mechanical and corrosion properties. Journal of Alloys and Compounds, Vol. 879, 2021, id. 160407.10.1016/j.jallcom.2021.160407Search in Google Scholar

[5] Mallikarjuna, G. B. and E. Basavaraj. Preparation and characterization of aluminium-silica metal matrix composite. AIP Conference Proceedings, AIP Publishing LLC, 2018, p. 020105.10.1063/1.5029681Search in Google Scholar

[6] Altinkok, N. and R. Koker. Neural network approach to prediction of bending strength and hardening behaviour of particulate reinforced (Al–Si–Mg)-aluminium matrix composites. Materials & Design, Vol. 25, No. 7, 2004, pp. 595–602.10.1016/j.matdes.2004.02.014Search in Google Scholar

[7] Sharma, P., S. Sharma, and D. Khanduja. A study on microstructure of aluminium matrix composites. Journal of Asian Ceramic Societies, Vol. 3, No. 3, 2015, pp. 240–244.10.1016/j.jascer.2015.04.001Search in Google Scholar

[8] Babalola, P. O., C. A. Bolu, A. O. Inegbenebor, and K. M. Odunfa. Development of aluminium matrix composites: a review. Online International Journal of Engineering and Technology Research, Vol. 2, 2014, pp. 1–11.Search in Google Scholar

[9] Hashim, J., L. Looney, and M. S. J. Hashmi. The enhancement of wettability of SiC particles in cast aluminium matrix composites. Journal of Materials Processing Technology, Vol. 119, No. 1–3, 2001, pp. 329–335.10.1016/S0924-0136(01)00919-0Search in Google Scholar

[10] Ao, M., H. Liu, C. Dong, S. Feng, and J. Liu. Degradation mechanism of 6063 aluminium matrix composite reinforced with TiC and Al2O3 particles. Journal of Alloys and Compounds, Vol. 859, 2021, id. 157838.10.1016/j.jallcom.2020.157838Search in Google Scholar

[11] Kumar, S. D., M. Ravichandran, A. Jeevika, B. Stalin, C. Kailasanathan, and A. Karthick. Effect of ZrB2 on microstructural, mechanical and corrosion behaviour of aluminium (AA7178) alloy matrix composite prepared by the stir casting route. Ceramics International, Vol. 47, No. 9, 2021, pp. 12951–12962.10.1016/j.ceramint.2021.01.158Search in Google Scholar

[12] Miracle, D. B. Metal matrix composites–from science to technological significance. Composites science and technology, Vol. 65, No. 15–16, 2005, pp. 2526–2540.10.1016/j.compscitech.2005.05.027Search in Google Scholar

[13] Krishnan, P. K., J. V. Christy, R. Arunachalam, A. H. I. Mourad, R. Muraliraja, M. Al-Maharbi, et al. Production of aluminum alloy-based metal matrix composites using scrap aluminum alloy and waste materials: Influence on microstructure and mechanical properties. Journal of Alloys and Compounds, Vol. 784, 2019, pp. 1047–1061.10.1016/j.jallcom.2019.01.115Search in Google Scholar

[14] Campanella, B., E. Grifoni, S. Legnaioli, G. Lorenzetti, S. Pagnotta, F. Sorrentino, et al. Classification of wrought aluminum alloys by Artificial Neural Networks evaluation of Laser Induced Breakdown Spectroscopy spectra from aluminum scrap samples. Spectrochimica Acta Part B: Atomic Spectroscopy, Vol. 134, 2017, pp. 52–57.10.1016/j.sab.2017.06.003Search in Google Scholar

[15] Tabelin, C. B., V. J. T. Resabal, I. Park, M. G. B. Villanueva, S. Choi, R. Ebio, et al. Repurposing of aluminum scrap into magnetic Al0/ZVI bimetallic materials: Two-stage mechanical-chemical synthesis and characterization of products. Journal of Cleaner Production, Vol. 317, 2021, id. 128285.10.1016/j.jclepro.2021.128285Search in Google Scholar

[16] Enginsoy, H. M., E. Bayraktar, D. Katundi, F. Gatamorta, and I. Miskioglu. Comprehensive analysis and manufacture of recycled aluminum based hybrid metal matrix composites through the combined method; sintering and sintering + forging. Composites Part B: Engineering, Vol. 194, 2020, id. 108040.10.1016/j.compositesb.2020.108040Search in Google Scholar

[17] Zhu, J., W. Jiang, G. Li, F. Guan, Y. Yu, and Z. Fan. Microstructure and mechanical properties of SiCnp/Al6082 aluminum matrix composites prepared by squeeze casting combined with stir casting. Journal of Materials Processing Technology, Vol. 283, 2020, id. 116699.10.1016/j.jmatprotec.2020.116699Search in Google Scholar

[18] Jiang, W., J. Zhu, G. Li, F. Guan, Y. Yu, and Z. Fan. Enhanced mechanical properties of 6082 aluminum alloy via SiC addition combined with squeeze casting. Journal of Materials Science & Technology, Vol. 88, 2021, pp. 119–131.10.1016/j.jmst.2021.01.077Search in Google Scholar

[19] Akbari, M., P. Asadi, P. Zolghadr, and A. Khalkhali. Multicriteria optimization of mechanical properties of aluminum composites reinforced with different reinforcing particles type. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, Vol. 232, No. 3, 2018 Jun, pp. 323-337.10.1177/0954408917704994Search in Google Scholar

[20] Akbari, M. and P. Asadi. Simulation and experimental investigation of multi-walled carbon nanotubes/aluminum composite fabrication using friction stir processing. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, Vol. 235, No. 6, 2021, pp. 2165–2179.10.1177/09544089211034029Search in Google Scholar

[21] Kumar, A., S. Kumar, and N. K. Mukhopadhyay. Introduction to magnesium alloy processing technology and development of low-cost stir casting process for magnesium alloy and its composites. Journal of magnesium and Alloys, Vol. 6, No. 3, 2018, pp. 245–254.10.1016/j.jma.2018.05.006Search in Google Scholar

[22] Reddy, A. C. Stir Casting Process on Porosity Development and Micromechanical Properties of AA5050/Titanium Oxide Metal Matrix Composites. 5th National Conference on Materials and Manufacturing Processes, Hyderabad, 2006, pp. 9–10.Search in Google Scholar

[23] Lotfy, A., A. V. Pozdniakov, V. S. Zolotorevskiy, M. T. Abou El-khair, A. Daoud, and A. G. Mochugovskiy. Novel preparation of Al-5% Cu/BN and Si3N4 composites with analyzing microstructure, thermal and mechanical properties. Materials Characterization, Vol. 136, 2018, pp. 144–151.10.1016/j.matchar.2017.12.015Search in Google Scholar

[24] Idrisi, A. H. and A. H. I. Mourad. Conventional stir casting versus ultrasonic assisted stir casting process: Mechanical and physical characteristics of AMCs. Journal of Alloys and Compounds, Vol. 805, 2019, pp. 502–508.10.1016/j.jallcom.2019.07.076Search in Google Scholar

[25] Farajollahi, R., H. J. Aval, and R. Jamaati. Effects of Ni on the microstructure, mechanical and tribological properties of AA2024-Al3NiCu composite fabricated by stir casting process. Journal of Alloys and Compounds, Vol. 887, 2021, id. 161433.10.1016/j.jallcom.2021.161433Search in Google Scholar

[26] Shayan, M., B. Eghbali, and B. Niroumand. Fabrication of AA2024- TiO2 nanocomposites through stir casting process. Transactions of Nonferrous Metals Society of China, Vol. 30, No. 11, 2020, pp. 2891–2903.10.1016/S1003-6326(20)65429-2Search in Google Scholar

[27] Kumar, S. A., J. H. Vignesh, and S. P. Joshua. Investigating the effect of porosity on aluminium 7075 alloy reinforced with silicon nitride (Si3N4) metal matrix composites through stir casting process. Materials Today: Proceedings, Vol. 39, 2021, pp. 414–419.10.1016/j.matpr.2020.07.690Search in Google Scholar

[28] Reddy, P. S., R. Kesavan, and B. Vijaya Ramnath. Investigation of mechanical properties of aluminium 6061-silicon carbide, boron carbide metal matrix composite. Silicon, Vol. 10, No. 2, 2018, pp. 495–502.10.1007/s12633-016-9479-8Search in Google Scholar

[29] Shirvanimoghaddam, K., H. Khayyam, H. Abdizadeh, M. K. Akbari, A. H. Pakseresht, E. Ghasali, et al. Boron carbide reinforced aluminium matrix composite: Physical, mechanical characterization and mathematical modelling. Materials Science and Engineering: A., Vol. 658, 2016, pp. 135–149.10.1016/j.msea.2016.01.114Search in Google Scholar

[30] Selvakumar, S., I. Dinaharan, R. Palanivel, and B. G. Babu. Characterization of molybdenum particles reinforced Al6082 aluminum matrix composites with improved ductility produced using friction stir processing. Materials Characterization, Vol. 125, 2017, pp. 13–22.10.1016/j.matchar.2017.01.016Search in Google Scholar

[31] Shuvho, M. B. A., M. A. Chowdhury, M. Kchaou, B. K. Roy, A. Rahman, and M. A. Islam. Surface characterization and mechanical behavior of aluminum based metal matrix composite reinforced with nano Al2O3, SiC, TiO2 particles. Chemical Data Collections, Vol. 28, 2020, id. 100442.10.1016/j.cdc.2020.100442Search in Google Scholar

[32] Daniel-Mkpume, C. C., E. G. Okonkwo, V. S. Aigbodion, P. O. Offor, and K. C. Nnakwo. Silica sand modified aluminium composite: an empirical study of the physical, mechanical and morphological properties. Materials Research Express, Vol. 6, No. 7, 2019, id. 076539.10.1088/2053-1591/ab14c6Search in Google Scholar

[33] Pramod, R., G. V. Kumar, P. S. Gouda, and A. T. Mathew. A study on the Al2O3 reinforced Al7075 metal matrix composites wear behavior using artificial neural networks. Materials Today: Proceedings, Vol. 5, No. 5, 2018, pp. 11376–11385.10.1016/j.matpr.2018.02.105Search in Google Scholar

[34] Gupta, A. K., T. K. Dan, and P. K. Rohatgi. Aluminium alloy-silica sand composites: preparation and properties. Journal of materials science, Vol. 21, No. 10, 1986, pp. 3413–3419.10.1007/BF02402980Search in Google Scholar

[35] Hemanth, J. Quartz (SiO2p) reinforced chilled metal matrix composite (CMMC) for automotive applications. Materials & Design, Vol. 30, No. 2, 2009, pp. 323–329.10.1016/j.matdes.2008.04.064Search in Google Scholar

[36] Singh, B., S. Chandel, and P. Singhal. Investigation of mechanical properties of synthesized AA2024-T351/SiO2 metal matrix nano-composite. Materials Today: Proceedings, Vol. 26, 2020, pp. 1082–1086.10.1016/j.matpr.2020.02.214Search in Google Scholar

[37] Xu, B., J. Han, A. Kumar, P. Li, and Y. Yang. Thermal storage using sand saturated by thermal-conductive fluid and comparison with the use of concrete. Journal of Energy Storage, Vol. 13, 2017, pp. 85–95.10.1016/j.est.2017.06.010Search in Google Scholar

[38] Tian, Y., B. Xu, and Z. Zhao. Microscopic theory of hardness and design of novel superhard crystals. International Journal of Refractory Metals and Hard Materials, Vol. 33, 2012 Jul 1, pp. 93–106.10.1016/j.ijrmhm.2012.02.021Search in Google Scholar

[39] Ndubuisi, A. O., I. E. Ogunrinola, A. P. Aizebeokhai, A. O. Inegbenebor, and H. O. Boyo. Estimation of optimal insulation thickness for a cylindrical ceramic crucible. International Journal of Engineering Research and Technology, Vol. 12, 2019, id. 9.Search in Google Scholar

[40] Ogunrinola I. E., Ndubuisi A. O., Babalola P. O., Akinyemi M. L., Aizebeokhai A. P., and Inegbenebor A. Al-Si alloy for thermal storage applications-a review. Journal of Physics: Conference Series. IOP Publishing, 2019. p. 042038.10.1088/1742-6596/1378/4/042038Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants