Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

-

Ying Li

, Siren Guo

Abstract

Helical carbon nanotubes (HCNTs) are chiral materials that can form an induced magnetic field when current passes through them, making them a desirable material for absorbing microwaves. However, poor electrical properties and inert surfaces limit the application of HCNTs as sole materials. In this study, we develop HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres synthesized using an electrospinning-assisted ice template method. The modified surfaces of the HCNTs form hydrogen bonds with Ti3C2T x MXenes to produce hybrid aerogel microspheres. Because of the different functionalized surfaces of HCNTs (F-HCNTs), F-HCNTs@Ti3C2T x MXenes could be adjusted to obtain effective reflection loss (RL) of microwaves ranging from 2 to 18 GHz. The observed advantageous RL is attributed to the modified surface of the HCNTs, their porous structure, and the optimized impedance matching derived from the synergistic effect between HCNTs and Ti3C2T x MXenes. Successful assembly method for the 3D architectures of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres significantly widens the practical applications of HCNTs in microwave absorption.

1 Introduction

Helical carbon nanotubes (HCNTs) have drawn considerable research interest in terms of electromagnetic interference shielding due to their unique chiral features, low density, high theoretical microwave absorption (MA), and multiple attenuating mechanisms [1,2]. Chiral parameters are adjustable and typically cause circular dichroism and optical rotation due to the generation of cross-coupling effects in external alternating electromagnetic fields [3,4]. In addition, the unique chiral feature can arouse cross-polarization and leads to resonance losses in microwave fields, and the carbonaceous nanostructures can induce cross-conductive losses [5,6,7]. However, the carbonaceous nature leads to high dielectric loss and weak impedance matching. The mainstream strategy used to optimize impedance matching is to construct HCNT-based composites by incorporating with magnetic or dielectric materials, such as cooperating magnetic metals and metal oxides, on the surfaces of helical carbon nanofibers [8,9], or to introduce defects to adjust their dielectric properties [10,11,12]. However, magnetic metals or metal oxides are dense and readily corrosive, and introducing defects is a laborious process done at the expense of raw materials [13,14].

Constructing 3D porous structures is an ideal approach for adjusting the impedance characteristics of dielectric MA materials. The porous interior has the same characteristics as air, which results in optimized impedance matching with air. With the aid of 2D/1D materials such as graphene and nanofibers used as skeletons, 1D fibers can be used in 3D architectures with high mechanical performance [15,16,17]. In addition, skeleton materials can form heterointerfaces that cause polarization loss, and their dielectric, electrical, and magnetic properties can optimize the impedance-matching characteristics [18,19,20]. Ti3C2T x MXenes, which is a flexible 2D material with high theoretical conductivity and active surface properties, has proven to be a potential material for use in electromagnetic protection [21,22], and the rich functional groups on its surface enable it to be modified with other materials without harming the intrinsic properties or destroying the structures of those materials [23,24,25]. Based on its active surface character, Ti3C2T x MXenes have been used as a promising dielectric mediator to enhance the MA performance of absorbers [26,27]. Therefore, a 3D hybrid constructed with HCNTs and Ti3C2T x MXenes would take advantage of both 2D and chiral microstructural materials and further improve MA performance due to the enhancement of the dielectric loss capability and optimized impedance matching driven from the newly formed heterointerfaces and pore structures as well as the introduction of Ti3C2T x MXenes as the conductive loss component.

In this article, the construction of novel HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres by integrating HCNTs with Ti3C2T x MXenes through a freeze-drying-assisted electrostatic spinning technique is demonstrated for the first time. Due to the hydrogen bonds between the functional HCNTs (F-HCNTs) and Ti3C2T x MXenes layers, the Ti3C2T x MXenes layers are well assembled with HCNTs to form heterogeneous structures. Molecular dynamic simulations are performed to investigate these interactions. A series of HCNTs@Ti3C2T x MXenes with different interlayer structures are obtained by altering the treatment times of the HCNTs. Accordingly, the structures and MA performances are studied and optimized. Successful assembly methods for the 3D architectures of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres significantly widen the practical applications of HCNTs in MA.

2 Experimental section

2.1 Preparation of HCNTs and Ti3C2T x MXenes

The original HCNTs (O-HCNTs) were prepared in our laboratory through chemical vapor deposition [28,29]. Before use, the O-HCNTs were annealed (denoted as A-HCNTs) and washed (denoted as H-HCNTs) to remove amorphous carbon and excess precursors. The F-HCNTs were prepared by immersing the H-HCNTs in a mixed acid (HNO3/H2SO4 = 1/3 by volume) at various set times (0.5, 1, 3, and 6 h). The F-HCNTs modified under different times are denoted as F-HCNTs-X h. Ti3C2T x MXenes were prepared based on the method described in the study of Alhabeb et al. [30].

2.2 Preparation of HCNTs@Ti3C2T x MXenes aerogel microspheres

Totally, 18 mg of HCNTs and 8.4 mL of water were added to 1.6 mL of the Ti3C2T x MXenes dispersion (5 mg·mL−1) and stirred for 5 min. The mixture was then placed in a polypropylene syringe, and the spinning process was started immediately at a voltage of approximately 5 kV under an injection rate of approximately 0.08 mL·min−1. The ice in the frozen droplets was sublimed in a vacuum freeze dryer for 2 days, and hybrid aerogel microspheres were obtained. These aerogels were stored in a sealed vial at −20℃ to avoid oxidization of MXenes.

2.3 Characterization

Scanning electron microscopy (SEM; JEOL JSM-7800F) and transmission electron microscopy (TEM; JEOL JEM-2100) were used to characterize the morphologies. Raman spectra were recorded using a Renishaw InVia Reflex instrument at an excitation wavelength of 532 nm to explore the structure of HCNTs and MXenes. Fourier transform infrared spectroscopy (FT-IR) (Bruker Tensor II) was performed to investigate the structural change of HCNTs after surface treatments. The pore size distribution and specific surface areas were obtained by using conventional nitrogen physisorption measurements (Gold APP V-Sorb 2800P) based on Barrett–Joyner–Halenda (BJH) and Brunauer–Emmett–Teller (BET) methods. The electromagnetic parameters were collected by the coaxial-line method. A vector network analyzer (VNA, Agilent 15071C) was used, and the testing range is 2–18 GHz. The samples were prepared by the same method as the previous work [10].

3 Results and discussion

3.1 Fabrication of HCNTs@MXene

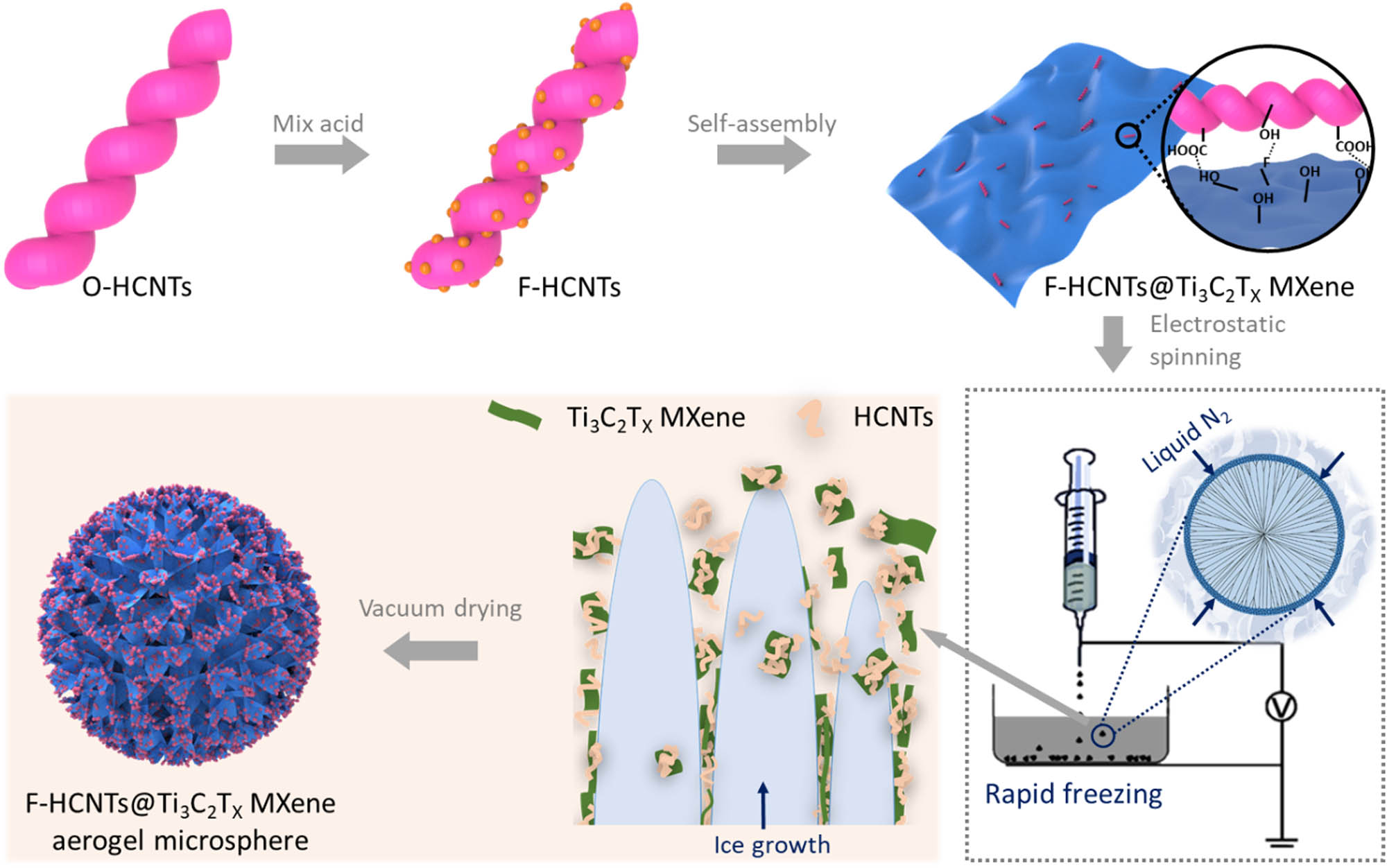

Figure 1a shows the structural evolution of HCNTs and the preparation of HCNTs@MXenes. To form a 3D structure, HCNTs were expected to react with MXenes; thus, a mixed acid was introduced to activate the surfaces [31]. Surface characteristics are crucial not only for constructing 3D structures but also for tuning the MA performance. Of the original HCNTs, the O-HCNTs presented a mirror-symmetrical morphology with unilateral nanotubes in a kink-like helical shape, which has previously been demonstrated to be favorable to the absorption of microwaves (Figure S1a) [32]. When treated with mixed acid, the morphologies, structures, and properties of HCNTs exhibit remarkable changes [33]. This enables better dispersion in water and cooperation with MXenes due to the grafting of oxygen-containing groups. The MXenes used in this study is a type of large-scale 2D nanoflake (Figure S1b) whose surface contains abundant hydroxyl groups, thus offering a large area to hold HCNTs and form 3D architectures. During mixing, HCNTs and MXenes nanoflakes are homogeneously dispersed in water. During electrospinning, the combined force of electric and gravity fields causes the spinning solution to form a Taylor cone at the needle tip. When the voltage is high enough, this Taylor cone breaks away from the needle tip and is immediately frozen in a liquid nitrogen bath [18]. The particles in the spinning solution containing F-HCNTs and MXenes nanoflakes are concentrated on the ice grain boundaries and squeezed to form 3D networks [34]. Because the temperature gradient is from the surface to the center of the droplet, ice grows directionally, and therefore the spatial distribution of MXenes as determined by the grain boundary is radial [35]. In our study, after the ice was sublimated in a vacuum freeze dryer, aerogel microspheres with directional pores were obtained (Figure S2). The specific surface areas were calculated from N2 adsorption using the BET method (Figure S3). A 3D network structure of aerogel microspheres consisting of macropores was constructed by HCNTs@MXenes junctions. In addition, the MXenes layers are stacked on each other during the dispersion and freeze-drying process. This method hardly forms micropores and mesopores, as confirmed by the BJH pore size distribution. Therefore, the specific surface area measured through N2 adsorption is relatively low. The specific surface area of pure MXene aerogel microsphere is 137.6 m2·g−1, which got remarkable improvement after adding F-HCNTs, such as the specific surface area of F-HCNTs-0.5 h@MXenes is 252.6 m2·g−1. However, the specific surface area showed a decreasing trend as extending the treating time of F-HCNTs. For F-HCNTs-1.0 h@MXenes, the specific surface area is 248.1 m2·g−1, F-HCNTs-3.0 h@MXenes is 246.9 m2·g−1, and F-HCNTs-6.0 h@MXenes is 208.3 m2·g−1, indicating that the treatment of mixing acid on HCNTs was favorable to increasing porosity. As mentioned in previous work [33], the morphologies and structures of HCNTs would be destroyed after excessive treatment by mixing acid, resulting in shortened and cut-open nanotubes, which, therefore, causes a decrease in the specific surface area [36].

Schematic of preparing HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres.

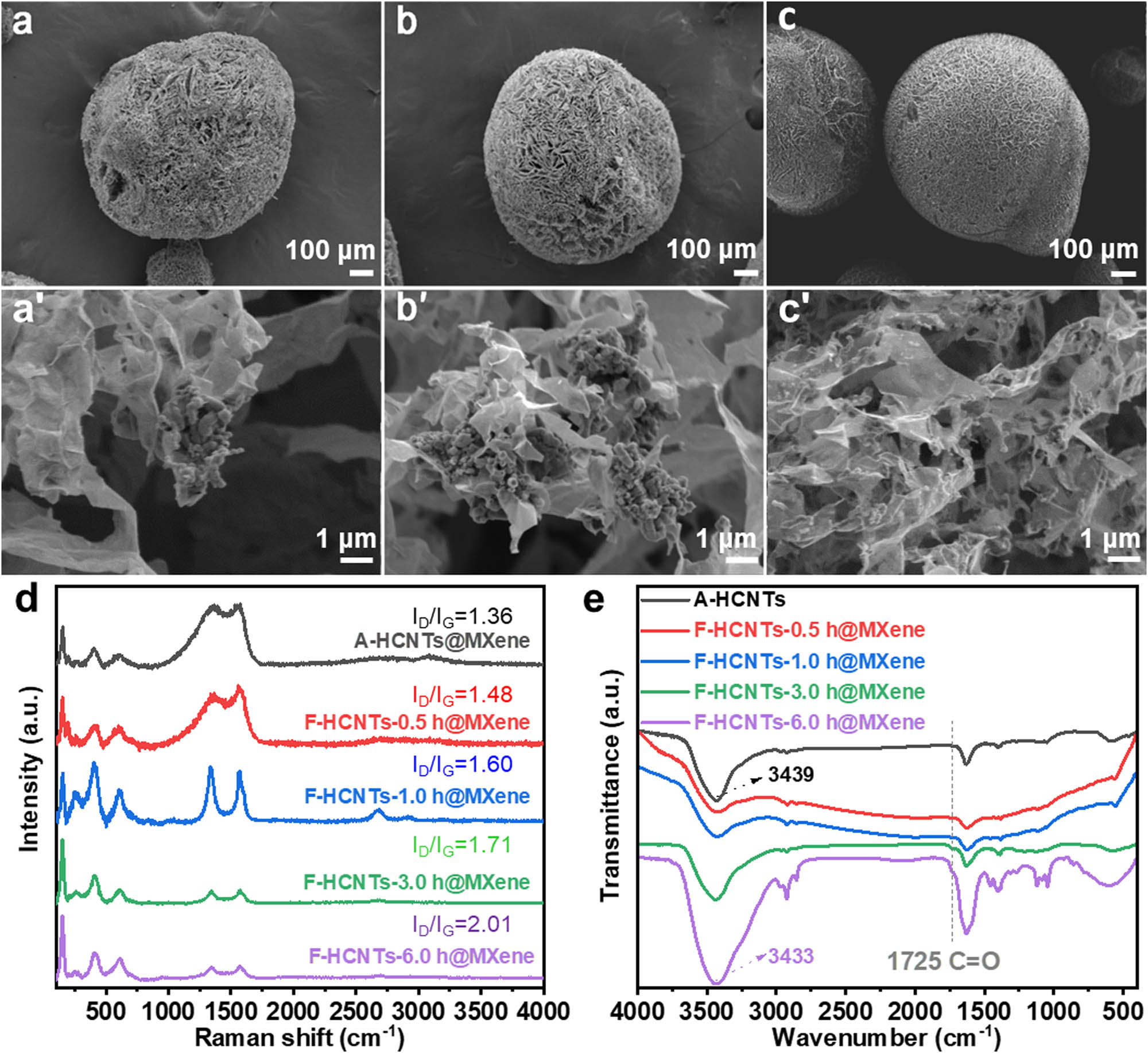

The obtained aerogel microspheres are presented in Figure 2a–c. Because of the balance force between electric and gravitational fields, the diameters of microdroplets are approximately 800 μm after the droplets exit the needle tip. In addition, the droplets are round, which may be due to comprehensive factors such as uneven liquid nitrogen levels and the vaporization microenvironment [18]. After sublimation, air replaces the ice crystals, and the remaining droplets are porous. The structure of a 3D porous network is significantly affected by the particle properties, which cause entrapment or repulsion by different interaction forces between the particles and solidification fronts [37]. The MXenes flakes are hydrophilic and thus tend to become entrapped by solidification fronts, resulting in curved cell walls inside the HCNTs@MXenes aerogels (Figure 2a′–c′). The oxidation of HCNTs renders them more hydrophilic, which is beneficial in avoiding self-aggregation and binding to MXenes through hydrogen bonding. As the enlarged views show, the HCNTs became more uniformly dispersed on the MXenes flakes as the treatment time increased. However, the aggregation of HCNTs could not be completely avoided. As Figure 2a′–c′ shows, HCNT aggregates dispersed on the MXenes skeleton instead of on single tubes. However, the aggregates were dispersed more evenly when the HCNTs were treated for a longer time, which in turn improved the dispersion of the F-HCNTs in water and their interaction with MXenes. The interactions between the HCNTs and MXenes were confirmed by the Raman spectra, where the characteristic peaks of the graphite structure (D and G bands) at 1,349 and 1,586 cm−1 [38] and peaks of Ti3C2T x MXenes at approximately 200 and 400 cm−1, respectively, could be found [39] (Figure 2d). More importantly, after integration, the widths of the D and G bands broadened, and the I D/I G ratio increased from 1.36 to 2.01, which was much higher than the value after modification by acid mixing [33]. The higher I D/I G ratio for the F-HCNTs@MXenes was attributed to the introduction of MXenes, which interacted with the F-HCNTs and caused an increase in disordered carbon in these samples [40]. An improved I D/I G ratio implied the formation of more defects, which can serve as polarization centers and improve polarization loss. Figure 2e shows the FT-IR spectra of the F-HCNTs@MXenes. The peak at approximately 1,725 cm−1 represents the vibration of C═O in –COOH and demonstrates the successful modification of F-HCNTs. More importantly, the shift of the C–OH vibration bonds from 3,436 to 3,428 cm−1 shows the hydrogen bond interactions among F-HCNTs and MXenes [41].

Morphological and structural analysis of HCNTs@MXenes hybrid aerogels. SEM images of (a) A-HCNTs@MXenes, (b) F-HCNTs-1 h@MXenes, and (c) F-HCNTs-6 h@MXenes. (a′)–(c′) provide details of (a)–(c) under a high magnification, respectively. (d) Raman spectra and (e) FT-IR spectra of HCNTs@MXenes.

3.2 MA performance

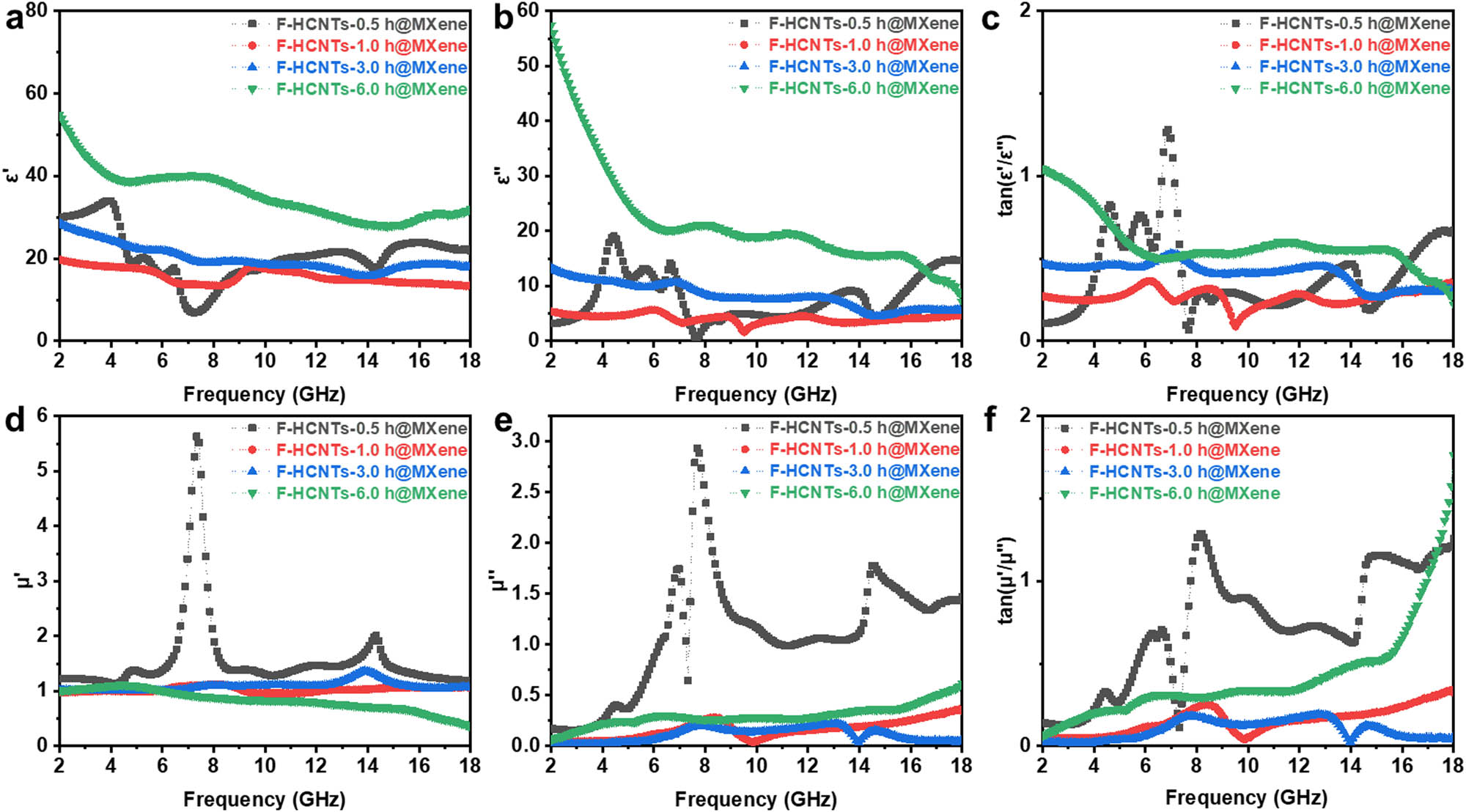

The MA performance of F-HCNTs@MXenes was studied based on the transmission line theory by evaluating the experimental data, which includes the complex permittivity (ε = ε′ − jε″) and permeability (μ = μ′ − jμ″). Electromagnetic parameters (2–18 GHz) were collected by the coaxial-line method on VNA. The real and image parts of ε(ε′) and μ(μ′) and their loss tangents (calculated by Eqs. (1) and (2)) of F-HCNTs@MXenes wax composites with different treatment times are shown in Figure 3. Here, ε′ represents the dielectric and polarization properties of materials. In addition, the increase of ε′ indicates that the material is more susceptible to polarization in the magnetic/electric fields. ε′′ represents the dielectric loss ability of materials. In Figure 3a, ε′ tends to decrease with increasing frequency, which can be explained by the hysteresis increase of polarization relative to electric-field changes at higher frequencies [42,43]. It is noteworthy that strong resonance peaks of F-HCNTs-0.5 h@MXenes exist over the entire testing frequency range, particularly in the low-frequency band. However, the curves of the other F-HCNTs@MXenes are relatively flat. In addition, the variation law of the ε″ shows a similar rising trend to ε′ in the testing frequency range, as shown in Figure 3b. Obviously, multiple resonance peaks exist at 2–18 GHz in the ε″ curves. This phenomenon can be explained in two respects. First, interfacial polarization relaxation occurred at the heterointerfaces and junction regions between the HCNTs and Ti3C2T

x

MXenes. On the other hand, the microwave dissipation ability of absorbers was unstable, resulting in severe fluctuation of the ε″ curves [44,45]. In addition, ε′ of F-HCNTs@MXenes increased with an increase in treatment time of the F-HCNTs from 1 to 6 h, which was contrary to the results of the F-HCNTs. The enhanced dielectric and polarization properties of F-HCNTs@MXenes may have benefitted from the improved dispersion of F-HCNTs on MXenes, which also contributed to ε″, indicating that an increase in the treatment time was beneficial to electromagnetic wave loss. The contribution of conductive and polarization loss to dielectric loss can be analyzed and calculated through Debye's theory. As shown in Eq. (3), ε″ can be classified as

Measured frequency dependence of (a) ε′, (b) ε″, (c) tan(ε′/ε″), (d) μ′, (e) μ″, and (f) tan(μ′/μ″) of F-HCNTs@MXenes.

The tan δ of hybrids is displayed in Figure 3c, demonstrating an obvious dependence on treatment time and implying a remarkable improvement in surface modification and dispersion of F-HCNTs on MXenes to transform electromagnetic energy to other forms [47]. Figure 3d shows a decreasing trend of the μ, and the F-HCNTs-0.5 h@MXenes exhibited the highest capacity in terms of storing and converting electromagnetic energy and had many response peaks in the whole testing range (Figure 3e–f). The magnetic loss capability originated from the catalysts inside the HCNTs. Note that previous studies have shown that ferrite used for catalysis can attenuate electromagnetic energy [5,28]. However, after prolonged treatment with mixed acid, a portion of the catalysis was etched, weakening magnetic loss capability.

Reflection loss (RL) values that directly reflect the MA performance were calculated using Eqs. (4) and (5), where Z 0 is the impedance of free space, Z in is the impedance of input-characteristic, μ r and ε r are the measured complex permeability and permittivity, respectively, d is the thickness of the tested sample, f is the microwave frequency, and c is the speed of light, respectively

As Figure 4a–b shows, the RL of pristine HCNTs and MXenes is less than −10.0 dB that is the basic requirement of practical use. After integrating them into aerogels, the MA performance can be significantly enhanced. It reached −31.8 dB at 9.7 GHz for the minimal RL (RLmin) of F-HCNTs-0.5 h@MXenes with a thickness of 0.7 mm (Figure 4c), and the high MA performance was maintained with increasing thickness. Interestingly, the effective RL shifted to a low-frequency band when the thickness was greater than 3.5 mm, which is desirable for modern MA materials [48]. When the surface treatment time increased to 1 h (Figure 4d), the MA performance decreased slightly. However, as the treatment time increased, the MA capacity shifted to a high-frequency band. For F-HCNTs-3.0 h@MXenes, an RLmin of −35.5 dB at 10.6 GHz was reached with a thickness of 2.2 mm, and the effective bandwidth was 2.2 GHz (9.7–11.9 GHz). For F-HCNTs-6.0 h@MXenes, the RLmin reached −26.4 dB covering 13.0–16.0 GHz with a thickness of 1.2 mm.

Calculated RL: (a) H-HCNTs, (b) Ti3C2T x MXenes, (c) F-HCNTs-0.5 h@MXenes, (d) F-HCNTs-1.0 h@MXenes, (e) F-HCNTs-3.0 h@MXenes, and (f) F-HCNTs-6.0 h@MXenes.

To explain the difference in MA of the F-HCNTs@MXenes, the corresponding parameters were analyzed. The dielectric loss mainly comes from dipole, ion, and electron polarization, where electron and ion polarization were relatively weaker in the microwave range. As mentioned before, the main role of dielectric loss is electric dipole polarization, whose relaxation process can be expressed by Debye dipole relaxation, which is the Cole semicircle:

where ε ∞ and ε s are the dielectric constant at the infinite frequency and static dielectric constant, respectively. Thus, ε′ and ε″ can be described by

Then, the relationship between ε′ and ε″ can be derived from [49]:

As shown in Eq. (9), the relationship between ε′ and ε″ is similar to the equation of circles in the first quadrant, in which each semicircle represents a Debye relaxation process. Figure 5a depicts the semicircles for F-HCNTs@MXenes, indicating the existence of multiple dielectric relaxations. In addition, the radius of semicircles increased as the treatment time increased, which may have derived from an increase in the number of contact interfaces, defects, surface groups, and the amount of conductive loss. The relatively high value of F-HCNTs-0.5 h@MXenes may have derived from the residual ferrite. Conductivity is also a critical factor affecting the dielectric loss of hybrids, and the existence of a tail in the Cole–Cole curves confirmed the increase in conductive loss derived from the highly conductive Ti3C2T x MXenes. The semicircles indicate the relaxation processes derived from the interfaces between the HCNTs and Ti3C2T x MXenes flakes. Approximately six types of relaxation processes occurred in the hybrids, where a detailed explanation of each semicircle is provided as follows. Only when the material exhibits impedance matching and loss characteristics excellent MA performance can be achieved. To explain the excellent MA performance of F-HCNTs-0.5 h@MXenes, the loss characteristics (attenuation constant α) using Eq. (10) (Figure 5b) were first evaluated, where α showed the same trend as the electric constant, implying that the balance between the residual catalysts and surface groups of HCNTs when adjusted by the treatment time was vital to the microwave loss capability. A more efficient loss characterization may have resulted from the conductive loss. Second, the impedance matching degree (delta Δ) using Eq. (11) was calculated, where M and K can be obtained using Eqs. (12) and (13). An excellent impedance matching degree of MA absorbers should be equal to or close to the impedance matching degree of the free-space interfaces. An excessive impedance matching degree causes reflection, and low impedance matching degree causes transmission of most electromagnetic waves, where a condition of Δ < 0.2 is acceptable [50]. As Figure 5c–f shows, F-HCNTs-1.0 h had the largest area, indicating a superior impedance matching degree, whereas the MA performance was poor due to its low attenuation capability (Figure 5b). The impedance matching degree agreed with the aforementioned RL results, and more importantly, the high impedance matching degree in the S band was the critical factor that endowed the F-HCNTs@MXenes with excellent MA performance in the low-frequency band

(a) Cole–Cole curves and (b) attenuation factors of F-HCNTs@MXenes, (c)–(f) impedance matching degree of F-HCNTs-0.5 h@MXenes, F-HCNTs-1.0 h@MXenes, F-HCNTs-3.0 h@MXenes and F-HCNTs-6.0 h@MXenes, respectively.

In summary, the controllable structural design promotes the controllable MA performance of F-HCNTs@MXenes, which is derived from the impedance matching and attenuation constant that are optimized in the process of structural regulation. The surface groups, defects, and conductive loss of both Ti3C2T x MXenes and HCNTs and interfacial polarization between the two components and themselves attribute to the dielectric loss. In addition, the surface modification of HCNTs affected the dielectric loss capability of F-HCNTs@MXenes, which was mainly caused by competition between the residual catalysts, conductive loss, and polarization loss. According to the aforementioned results, a possible MA mechanism for the F-HCNTs@MXenes hybrids is shown in Figure 6: (1) the polarization at interfaces derived from the moving velocities of different induced charges on Ti3C2T x MXenes and HCNTs; (2) the polarization loss resulting from the dipoles of heterointerfaces, defects, amorphous carbon, TiO2, and surface groups; (3) the conductive loss derived from the HCNTs and Ti3C2T x MXenes flakes; and (4) the pores that optimize the impedance matching and elongate the multiple reflection and scattering.

Schematic of the potential MA mechanisms of HCNTs@MXenes.

4 Conclusion

In this study, novel functional HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for MA were demonstrated. The study showed that through surface modification, active F-HCNTs could interact with Ti3C2T x MXenes and form a 3D porous architecture based on the ice template method. The heterointerface formed by the F-HCNTs and Ti3C2T x MXenes, the porosity of the 3D structure, and the composition of the two materials led to adjustable MA performance. The RLmin value reached −35.5 dB at 10.6 GHz was reached with a thickness of 2.2 mm, and the effective bandwidth was 2.2 GHz (9.7–11.9 GHz). These hybrid aerogel microspheres also exhibited excellent MA performance in the S band when the loading of MXenes was tuned. The successful assembly of these hybrids expands the absorption band of HCNT-based materials for both the C–Ku and S bands. Thus, it has the potential to serve as microwave absorbers for army, satellite, and daily protection applications.

Acknowledgments

The authors thank the Ying's Group staff members who supported the processes necessary to carry out the project. In addition, they thank the anonymous reviewers for their fruitful suggestions to improve the article.

-

Funding information: This work was financially supported by the National Natural Science Foundation of China (No. 52202083), the Science and Technology Planning Project of Longquanyi, Chengdu (No. LQXKJ-KJXM-2022-04), the Natural Science Foundation of Sichuan Province (2022NSFSC0321 and 2022NSFSC0346), and the 2022 Natural Scientific Research Project of Chengdu Aeronautic Polytechnic (No. 06221025).

-

Author contributions: Conceptualization, methodology, validation, formal analysis, investigation, resources, data curation, writing – original draft preparation, writing – review and editing, visualization, supervision: Ying Li, Siren Guo, Yudi Li, Kaiyou Wu Linlin Zhao, Xi Liu, Pan Wang, Yuxin Yang and Yan Sun; project administration and funding acquisition: Ying Li, Xi Liu, Xulin Yang and Zihao Mou. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Wang, D.-C., Y. Lei, W. Jiao, Y.-F. Liu, C.-H. Mu, and X. Jian. A review of helical carbon materials structure, synthesis and applications. Rare Metals, Vol. 40, No. 1, 2020, pp. 3–19.10.1007/s12598-020-01622-ySuche in Google Scholar

[2] Wu, N., Q. Hu, R. Wei, X. Mai, N. Naik, D. Pan, et al. Review on the electromagnetic interference shielding properties of carbon based materials and their novel composites: Recent progress, challenges and prospects. Carbon, Vol. 176, 2021, pp. 88–105.10.1016/j.carbon.2021.01.124Suche in Google Scholar

[3] Chen, X., H. Liu, D. Hu, H. Liu, and W. Ma. Recent advances in carbon nanotubes-based microwave absorbing composites. Ceramics International, Vol. 4717, 2021, pp. 23749–23761.10.1016/j.ceramint.2021.05.219Suche in Google Scholar

[4] Zhao, Y., H. Zhang, X. Yang, H. Huang, G. Zhao, T. Cong, et al. In situ construction of hierarchical core–shell Fe3O4@C nanoparticles–helical carbon nanocoil hybrid composites for highly efficient electromagnetic wave absorption. Carbon, Vol. 171, 2021, pp. 395–408.10.1016/j.carbon.2020.09.036Suche in Google Scholar

[5] Tian, X., F. Meng, F. Meng, X. Chen, Y. Guo, Y. Wang, et al. Synergistic enhancement of microwave absorption using hybridized polyaniline@helical CNTs with dual chirality. ACS Appllied Materials & Interfaces, Vol. 9, No. 18, 2017, pp. 15711–15718.10.1021/acsami.7b02607Suche in Google Scholar PubMed

[6] Huang, L., Y. Duan, Y. Shi, X. Ma, H. Pang, Q. Zeng, et al. Chiral asymmetric polarizations generated by bioinspired helical carbon fibers to induce broadband microwave absorption and multispectral photonic manipulation. Advanced Optical Materials, Vol. 1011, 2022, id. 2200249.10.1002/adom.202200249Suche in Google Scholar

[7] Barathi Dassan, E. G., A. Anjang Ab Rahman, M. S. Z. Abidin, and H. M. Akil. Carbon nanotube–reinforced polymer composite for electromagnetic interference application: A review. Nanotechnology Reviews, Vol. 9, No. 1, 2020, pp. 768–788.10.1515/ntrev-2020-0064Suche in Google Scholar

[8] Tang, H., X. Jian, B. Wu, S. Liu, Z. Jiang, X. Chen, et al. Fe3C/helical carbon nanotube hybrid: Facile synthesis and spin-induced enhancement in microwave-absorbing properties. Composites Part B: Engineering, Vol. 107, 2016, pp. 51–58.10.1016/j.compositesb.2016.09.003Suche in Google Scholar

[9] Dong, M., M. Peng, W. Wei, H. Xu, C. Liu, and C. Shen. Improved microwave absorption performance of double helical C/Co@CNT nanocomposite with hierarchical structures. Journal of Materials Chemistry C, Vol. 9, No. 6, 2021, pp. 2178–2189.10.1039/D0TC05811DSuche in Google Scholar

[10] Tao, J., Z. Jiao, L. Xu, P. Yi, Z. Yao, F. Yang, et al. Construction of MOF-Derived Co/C shell on carbon fiber surface to enhance multi-polarization effect towards efficient broadband electromagnetic wave absorption. Carbon, Vol. 184, 2021, pp. 571–582.10.1016/j.carbon.2021.08.064Suche in Google Scholar

[11] Zhang, X., Y. Hao, and W. Zhong. Boron-doped helical carbon nanotubes: lightweight and efficient microwave absorbers. Journal of Materials Science: Materials in Electronics, Vol. 32, No. 21, 2021, pp. 26161–26172.10.1007/s10854-021-06560-8Suche in Google Scholar

[12] Liu, Q., L. Tang, J. Li, Y. Chen, Z. Xu, J. Li, et al. Multifunctional aramid nanofibers reinforced RGO aerogels integrated with high-efficiency microwave absorption, sound absorption and heat insulation performance. Journal of Materials Science & Technology, Vol. 130, 2022, pp. 166–175.10.1016/j.jmst.2022.05.014Suche in Google Scholar

[13] Wu, F., K. Yang, Q. Li, T. Shah, M. Ahmad, Q. Zhang, et al. Biomass-derived 3D magnetic porous carbon fibers with a helical/chiral structure toward superior microwave absorption. Carbon, Vol. 173, 2021, pp. 918–931.10.1016/j.carbon.2020.11.088Suche in Google Scholar

[14] Zhao, Y., X. Zuo, Y. Guo, H. Huang, H. Zhang, T. Wang, et al. Structural engineering of hierarchical aerogels comprised of multi-dimensional gradient carbon nanoarchitectures for highly efficient microwave absorption. Nano-micro Letters, Vol. 13, No. 1, 2021, id. 144.10.1007/s40820-021-00667-7Suche in Google Scholar PubMed PubMed Central

[15] Han, J., J. Yang, W. Gao, and H. Bai. Ice‐templated, large‐area silver nanowire pattern for flexible transparent electrode. Advanced Functional Materials, Vol. 31, No. 16, 2021, id. 2010155.10.1002/adfm.202010155Suche in Google Scholar

[16] Chhetri, K., S. Subedi, A. Muthurasu, T. H. Ko, B. Dahal, and H. Y. Kim. A review on nanofiber reinforced aerogels for energy storage and conversion applications. Journal of Energy Storage, Vol. 46, 2022, id. 103927.10.1016/j.est.2021.103927Suche in Google Scholar

[17] Iqbal, A., T. Hassan, Z. Gao, F. Shahzad, and C. M. Koo. MXene-incorporated 1D/2D nano-carbons for electromagnetic shielding: A review. Carbon, Vol. 203, 2023, pp. 542–560.10.1016/j.carbon.2022.11.104Suche in Google Scholar

[18] Li, Y., F. Meng, Y. Mei, H. Wang, Y. Guo, Y. Wang, et al. Electrospun generation of Ti3C2Tx MXene@graphene oxide hybrid aerogel microspheres for tunable high-performance microwave absorption. Chemical Engineering Journal, Vol. 391, 2020, id. 123512.10.1016/j.cej.2019.123512Suche in Google Scholar

[19] Zhao, X., J. Yan, Y. Huang, X. Liu, L. Ding, M. Zong, et al. Magnetic porous CoNi@C derived from bamboo fiber combined with metal-organic-framework for enhanced electromagnetic wave absorption. Journal of Colloid and Interface Science, Vol. 595, 2021, pp. 78–87.10.1016/j.jcis.2021.03.109Suche in Google Scholar PubMed

[20] Wu, F., Z. Liu, T. Xiu, B. Zhu, I. Khan, P. Liu, et al. Fabrication of ultralight helical porous carbon fibers with CNTs-confined Ni nanoparticles for enhanced microwave absorption. Composites Part B: Engineering, Vol. 215, 2021, id. 108814.10.1016/j.compositesb.2021.108814Suche in Google Scholar

[21] Cao, M.-S., Y.-Z. Cai, P. He, J.-C. Shu, W.-Q. Cao, and J. Yuan. 2D MXenes: Electromagnetic property for microwave absorption and electromagnetic interference shielding. Chemical Engineering Journal, Vol. 359, 2019, pp. 1265–1302.10.1016/j.cej.2018.11.051Suche in Google Scholar

[22] Guan, X., Z. Yang, M. Zhou, L. Yang, R. Peymanfar, B. Aslibeiki, et al. 2D MXene Nanomaterials: Synthesis, Mechanism, and Multifunctional Applications in Microwave Absorption. Small Structures, Vol. 310, 2022, id. 2200102.10.1002/sstr.202200102Suche in Google Scholar

[23] Couly, C., M. Alhabeb, K. L. Van Aken, N. Kurra, L. Gomes, A. M. Navarro-Suárez, et al. Asymmetric flexible mxene-reduced graphene oxide micro-supercapacitor. Advanced Electronic Materials, Vol. 4, No. 1, 2018, id. 1700339.10.1002/aelm.201700339Suche in Google Scholar

[24] Si, Y., L. Wang, X. Wang, N. Tang, J. Yu, and B. Ding. Ultrahigh-water-content, superelastic, and shape-memory nanofiber-assembled hydrogels exhibiting pressure-responsive conductivity. Advanced Materials, Vol. 29, No. 24, 2017, id. 1700339.10.1002/adma.201700339Suche in Google Scholar PubMed

[25] Mou, Z. H., R. X. Yan, J. Peng, Y. Li, Z. Y. Huang, Z. J. Wang, et al. Synthesis of polyzwitterionic carbon dots with superior friction and fatigue control behaviors under water lubrication. Chemical Engineering Journal, Vol. 465, 2023, id. 142986.10.1016/j.cej.2023.142986Suche in Google Scholar

[26] Zhao, S., H. B. Zhang, J. Q. Luo, Q. W. Wang, B. Xu, S. Hong, et al. Highly electrically conductive three-dimensional Ti3C2Tx MXene/reduced graphene oxide hybrid aerogels with excellent electromagnetic interference shielding performances. ACS Nano, Vol. 1211, 2018, pp. 11193–11202.10.1021/acsnano.8b05739Suche in Google Scholar PubMed

[27] Li, X., X. Yin, C. Song, M. Han, H. Xu, W. Duan, et al. Self-assembly core-shell graphene-bridged hollow MXenes spheres 3D foam with ultrahigh specific EM absorption performance. Advanced Functional Materials, Vol. 28, No. 41, 2018, id. 1803938.10.1002/adfm.201803938Suche in Google Scholar

[28] Meng, F., Y. Wang, Q. Wang, X. Xu, M. Jiang, X. Zhou, et al. High-purity helical carbon nanotubes by trace-water-assisted chemical vapor deposition: Large-scale synthesis and growth mechanism. Nano Research, Vol. 11, No. 6, 2018, pp. 3327–3339.10.1007/s12274-017-1897-4Suche in Google Scholar

[29] Chen, X., Y. Li, Y. Wang, D. Song, Z. Zhou, and D. Hui. An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs. Nanotechnology Reviews, Vol. 10, No. 1, 2021, pp. 282–291.10.1515/ntrev-2021-0025Suche in Google Scholar

[30] Alhabeb, M., K. Maleski, B. Anasori, P. Lelyukh, L. Clark, S. Sin, et al. Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2Tx MXene). Chemistry of Materials, Vol. 29, No. 18, 2017, pp. 7633–7644.10.1021/acs.chemmater.7b02847Suche in Google Scholar

[31] Zhang, Y., Z. Shi, Z. Gu, and S. Iijima. Structure modification of single-wall carbon nanotubes. Carbon, Vol. 3815, 2000, pp. 2055–2059.10.1016/S0008-6223(00)00047-6Suche in Google Scholar

[32] Feng, J., Y. Wang, Y. Hou, J. Li, and L. Li. Synthesis and microwave absorption properties of coiled carbon nanotubes/CoFe2O4 composites. Ceramics International, Vol. 4215, 2016, pp. 17814–17821.10.1016/j.ceramint.2016.08.110Suche in Google Scholar

[33] Li, Y., Z. Xu, A. Jia, X. Yang, W. Feng, P. Wang, et al. Controllable modification of helical carbon nanotubes for high-performance microwave absorption. Nanotechnology Reviews, Vol. 10, No. 1, 2021, pp. 671–679.10.1515/ntrev-2021-0045Suche in Google Scholar

[34] Qiu, L., J. Z. Liu, S. L. Chang, Y. Wu, and D. Li. Biomimetic superelastic graphene-based cellular monoliths. Nature Communication, Vol. 3, 2012, id. 1241.10.1038/ncomms2251Suche in Google Scholar PubMed

[35] Bouville, F., E. Maire, and S. Deville. Self-assembly of faceted particles triggered by a moving ice front. Langmuir, Vol. 30, No. 29, 2014, pp. 8656–63.10.1021/la404426dSuche in Google Scholar PubMed

[36] Chen, M., H.-W. Yu, J.-H. Chen, and H.-S. Koo. Effect of purification treatment on adsorption characteristics of carbon nanotubes. Diamond and Related Materials, Vol. 16, No. 4–7, 2007, pp. 1110–1115.10.1016/j.diamond.2006.12.061Suche in Google Scholar

[37] Körber, C., G. Rau, M. D. Cosman, and E. G. Cravalho. Interaction of particles and a moving ice-liquid interface. Journal of Crystal Growth, Vol. 72, No. 3, 1985, pp. 649–662.10.1016/0022-0248(85)90217-9Suche in Google Scholar

[38] Hembram, K., J. G. Kim, S. G. Lee, J. Park, and J. K. Lee. Radial-tangential mode of single-wall carbon nanotubes manifested by Landau regulation: Reinterpretation of low- and intermediate-frequency Raman signals. Scientific Reports, Vol. 13, No. 1, 2023, id. 5012.10.1038/s41598-023-32018-4Suche in Google Scholar PubMed PubMed Central

[39] Sarycheva, A., M. Shanmugasundaram, A. Krayev, and Y. Gogotsi. Tip-enhanced Raman scattering imaging of single- to few-layer Ti(3)C(2)T(x) MXene. ACS Nano, Vol. 16, No. 4, 2022, pp. 6858–6865.10.1021/acsnano.2c01868Suche in Google Scholar PubMed

[40] Li, B., Z. Ma, J. Xu, X. Zhang, Y. Chen, and C. Zhu. Regulation of impedance matching and dielectric loss properties of N-doped carbon hollow nanospheres modified with atomically dispersed cobalt sites for microwave energy attenuation. Small, Vol. 19, No. 28, 2023, id. e2301226.10.1002/smll.202301226Suche in Google Scholar PubMed

[41] Fu, Z. Z., S. J. Guo, C. X. Li, K. Wang, Q. Zhang, and Q. Fu. Hydrogen-bond-dominated mechanical stretchability in PVA films: From phenomenological to numerical insights. Physical Chemistry Chemical Physics, Vol. 24, No. 3, 2022, pp. 1885–1895.10.1039/D1CP03893ASuche in Google Scholar PubMed

[42] Quan, B., X. Liang, G. Ji, J. Ma, P. Ouyang, H. Gong, et al. Strong electromagnetic wave response derived from the construction of dielectric/magnetic media heterostructure and multiple interfaces. ACS Appl Mater Interfaces, Vol. 911, 2017, pp. 9964–9974.10.1021/acsami.6b15788Suche in Google Scholar PubMed

[43] Smyth, C. P. Dielectric behavior and structure, McGraw-Hill Book Co., Inc., New York, 1955.Suche in Google Scholar

[44] Tian, W., X. Zhang, Y. Guo, C. Mu, P. Zhou, L. Yin, et al. Hybrid silica-carbon bilayers anchoring on FeSiAl surface with bifunctions of enhanced anti-corrosion and microwave absorption. Carbon, Vol. 173, 2021, pp. 185–193.10.1016/j.carbon.2020.11.002Suche in Google Scholar

[45] Tian, Y., D. Zhi, T. Li, J. Li, J. Li, Z. Xu, et al. Graphene-based aerogel microspheres with annual ring-like structures for broadband electromagnetic attenuation. Chemical Engineering Journal, Vol. 464, 2023, id. 142644.10.1016/j.cej.2023.142644Suche in Google Scholar

[46] Li, T., J. Li, Z. Xu, Y. Tian, J. Li, J. Du, et al. Electromagnetic response of multistage-helical nano-micro conducting polymer structures and their enhanced attenuation mechanism of multiscale-chiral synergistic effect. Small, Vol. 19, No. 21, 2023, id. e2300233.10.1002/smll.202300233Suche in Google Scholar PubMed

[47] Sun, H., R. Che, X. You, Y. Jiang, Z. Yang, J. Deng, et al. Cross-stacking aligned carbon-nanotube films to tune microwave absorption frequencies and increase absorption intensities. Advanced Materials, Vol. 26, No. 48, 2014, pp. 8120–8125.10.1002/adma.201403735Suche in Google Scholar PubMed

[48] Lv, H., Z. Yang, P. L. Wang, G. Ji, J. Song, L. Zheng, et al. A voltage-boosting strategy enabling a low-frequency, flexible electromagnetic wave absorption device. Advanced Materials, Vol. 30, No. 15, 2018, id. e1706343.10.1002/adma.201706343Suche in Google Scholar PubMed

[49] Xu, H., X. Yin, M. Li, F. Ye, M. Han, Z. Hou, et al. Mesoporous carbon hollow microspheres with red blood cell like morphology for efficient microwave absorption at elevated temperature. Carbon, Vol. 132, 2018, pp. 343–351.10.1016/j.carbon.2018.02.040Suche in Google Scholar

[50] Ma, Z., C.-T. Cao, Q.-F. Liu, and J.-B. Wang. A new method to calculate the degree of electromagnetic impedance matching in one-layer microwave absorbers. Chinese Physics Letters, Vol. 29, No. 3, 2012, id. 038401.10.1088/0256-307X/29/3/038401Suche in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Artikel in diesem Heft

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants