Abstract

As a representative flexible piezoelectric polymer, polyvinylidene fluoride (PVDF) and its copolymers have been widely used in energy harvesters and piezoelectric sensors. In this work, hybrid nanocomposite films were prepared by adding a small amount of carbon black (CB) and Ni nanoparticles to the poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) matrix using the solution casting method, followed by stretching and poling to increase the electroactive β-phase content. The results show that the hybrid fillers consisting of 0.3 wt% CB and 0.1 wt% Ni nanoparticles exhibit the best piezoelectric performance. The maximum output voltage of the PVDF-HFP/CB/Ni films reaches 3.5 V under 1 mm micro-vibration, which is 75% higher than that of pure PVDF-HFP films. Characterization results by X-ray diffraction analysis, Fourier-transform infrared spectrometry, and differential scanning calorimeter analysis show that the hybrid fillers are more effective in promoting the phase transformation from the α-phase to the β-phase in the matrix due to synergistic effect.

1 Introduction

Piezoelectric energy harvesters can convert low-frequency mechanical energy from the environment into electrical energy to enable self-powered micro-devices [1]. Compared with traditional piezoelectric ceramics, polyvinylidene fluoride (PVDF) and its copolymers offer numerous advantages such as high flexibility, substantial piezoelectricity, and high ductility, which make them highly suitable for applications that require large bending and twisting capabilities [2,3,4]. Therefore, nanocomposites based on PVDF and its copolymers are considered ideal materials for manufacturing flexible piezoelectric energy harvesters. PVDF is a semi-crystalline polymer that possesses at least five polymorphs, i.e., α, β, γ, δ, and ε. Among these, the α-phase has the semi-trans (TGTG′) conformation that is non-polar and exhibits no piezoelectricity, while the β-phase has the all-trans (TTTT) conformation that is highly polar and contributes the most to piezoelectric performance. However, solution-processed pristine PVDF thin films are non-ferroelectric because the most thermodynamically stable (majority) polymorph is the non-polar α-phase [5,6]. Therefore, increasing the content of the piezoelectric β-phase of PVDF has become a major focus of research at this stage. In recent decades, various processes have been developed to increase the content of the β-phases, such as mechanical stretching [7,8], annealing treatment [9], and high electric field poling [10]. Among these methods, mechanical stretching is the most commonly used approach for transforming the α-phase to the β-phase. During the stretching process, the applied stress to the film results in the re-alignment of polymer chains into a fiber-like structure, by which the all-trans (TTTT) conformation is induced. Additionally, stretching forces the dipoles of the polymer chains to align normally to the stretching direction [7,11]. Furthermore, many studies have found that the introduction of nanofillers (such as graphene [12,13,14], carbon nanotubes [15,16], and CB [carbon black] [17]) can alter the crystal structure of the matrix, thereby enhancing the piezoelectricity. Wu et al. incorporated graphene into PVDF-trifluoroethylene (TrFE) by the solution casting method to prepare piezoelectric nanocomposite films. The PVDF-TrFE/graphene (0.15 wt%) film generated a calibrated open-circuit voltage of 12.43 V, which was 104% higher than that of pure PVDF-TrFE films and the harvested power density was increased by 302% (AC circuit) and 359% (DC circuit), respectively [18]. Gan and Majid prepared PVDF/TiO2 composite films and observed that the DC conductivity of the polymer matrix was increased, greatly lowering the requirement of the poling electric field (decreasing from 260 to 120 MV·m−1) [19]. Recently, Lei et al. incorporated Ni nanofillers into the poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) matrix and applied high voltage poling (E max = 130 MV·m−1), by which the relative fraction of the β-phase increased to 98%, and the calibrated open-circuit voltage reached 3.84 V [10].

In general, the mechanisms for enhancing phase transformation by nanofillers mainly include inherent piezoelectric properties, nucleating effect and interface coupling effect [20]. However, due to the different interfaces between nanofillers and PVDF matrix, there are still some challenges that need to be overcome to completely understand the mechanism. For example, the van der Waals force between fillers can lead to uneven distribution and agglomeration of the nanofillers, which requires further chemical or physical modification of the nanofillers [21,22]. Besides, high-conductive fillers are usually more likely to cause breakdown failure during poling [23,24], while poor conductive nanofillers limit their piezoelectric properties to some extent [25].

The efficacy of hybrid nanofillers has been confirmed by a large number of studies [26,27,28]. Cai et al. prepared PVDF-HFP/CB/GO composite films and found that the hybrid fillers could effectively promote the phase transition in the initial stage of crystallization. As a result, the films can reach a higher β-phase fraction at a lower concentration, and the maximum output voltage and collected power density are 181 and 329% of the neat PVDF-HFP films, respectively [29]. Similarly, Khalifa et al. added ZnO-modified single-walled carbon nanotubes (SWCNT) to PVDF to prepare piezoelectric films with high power generation capabilities. The synergistic effect between the hybrid fillers results in the adsorption of the TTTT chains on the surfaces of the carbon nanotubes (CNT), leading to highly ordered β-crystals with significantly increased generated voltage [30]. Additionally, GO-Ag nanocomposites have been reported to exhibit different piezoelectric properties under lighting and blackout conditions due to the interaction of PVDF matrix, Ag nanoparticles, and GO nanoparticles [31]. The highly conductive CB has also shown a significant effect on the piezoelectricity of PVDF-HFP due to its abundant functional groups on its surface, which is beneficial for good dispersion in polar solvents [29,32,33]. Similarly, modified Ni nanoparticles, which possess hydroxyl groups on their surfaces, can induce the formation of the polar phase of PVDF-HFP [10,34,35]. Therefore, in this work, these two nanofillers were selected to improve the piezoelectricity of the composite films. The comparison of the performance of the PVDF-HFP composite films in our previous works [10,25,29,36,37] is given in Table 1. For other research groups, due to the differences in the preparation methods and measurement conditions, the results are quite different from each other, as shown in Table 2 [38,39,40,41,42,43,44].

Comparison of research on piezoelectric properties of PVDF–HFP with various processes of poling

| Material | Poling electric field (MV·m−1) | Calibrated open-circuit voltage (V) | Ref. |

|---|---|---|---|

| PVDF-HFP/Ni | 130 | 3.84 | [10] |

| PVDF-HFP/rGO | 90 | 3.56 | [36] |

| PVDF-HFP/AgNW | 70 | 2.14 | [37] |

| PVDF-HFP/VGCF | 60 | 1.25 | [25] |

| PVDF-HFP/MWCNT | 60 | 1.35 | [25] |

| PVDF-HFP/CB/FLG | 90 | 4.14 | [29] |

| PVDFHFP/CB/Ni | 120 | 4.17 | This work |

Comparison of the power capability of PVDF and its copolymer-based composites

| Material | Output voltage (V p-p) | Power density (W·m−3) | Remarks | Ref. |

|---|---|---|---|---|

| PVDF/Al2O3-rGO | 36 | 28.0 | Poling free | [38] |

| PVDF | 6 | 0.48 | Electrospun | [39] |

| PVDF/rGO | 16 | 28 | Electrospun | [40] |

| PVDF/CsPbBr3/Ti3C2T x | 300 | 0.36 | Self-polarization | [41] |

| PVDF-HFP/NiFe2O4 | 5 | — | Electrospun | [42] |

| PVDF/NaNbO3/rGO | 2.16 | — | Poling free | [43] |

| PVDF/Y-ZnO | 25 | 36 | Corona poling | [44] |

In recent years, hybrid nanofillers have been used as nucleating agents to further improve phase transformation based on their synergistic effects. In this study, PVDF-HFP/CB/Ni composite piezoelectric films were prepared by the solution casting method. By adjusting the ratio of CB and Ni nanoparticles in the composite, we aimed to explore the effect of CB/Ni hybrid fillers on the initial crystallization, stretching, and poling processes of the films.

2 Experimental

2.1 Materials

Compared to PVDF, PVDF-HFP has the advantages such as better flexibility, lower cost, and higher pyroelectric coefficient. In this work, PVDF-HFP was utilized as the piezoelectric matrix.

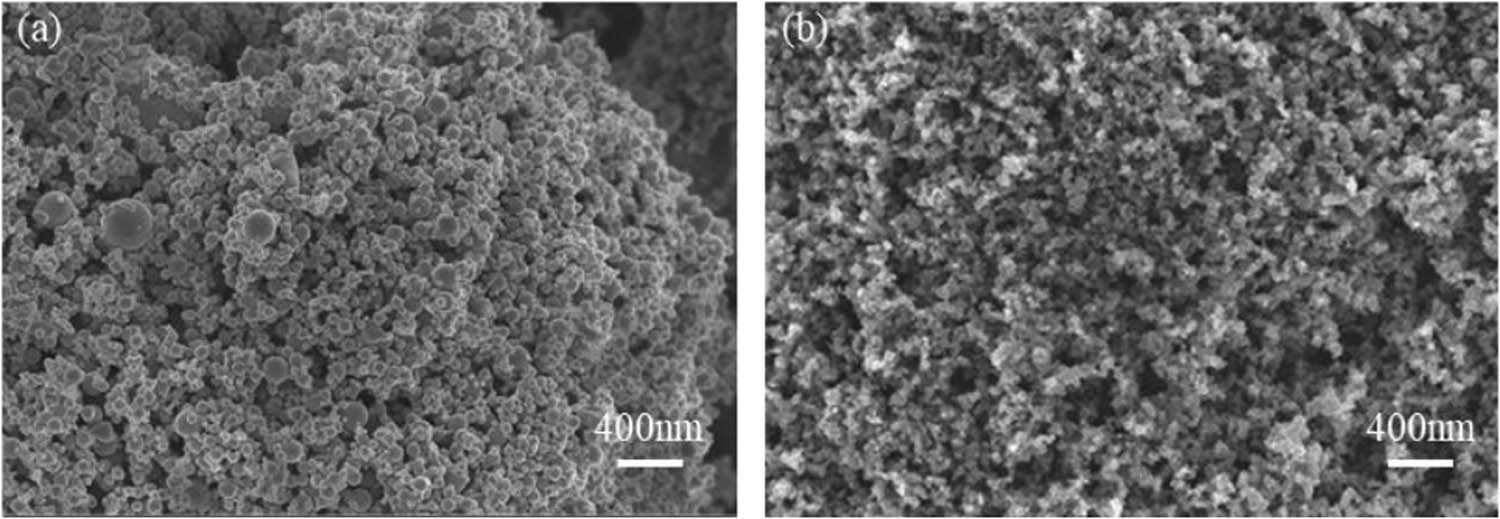

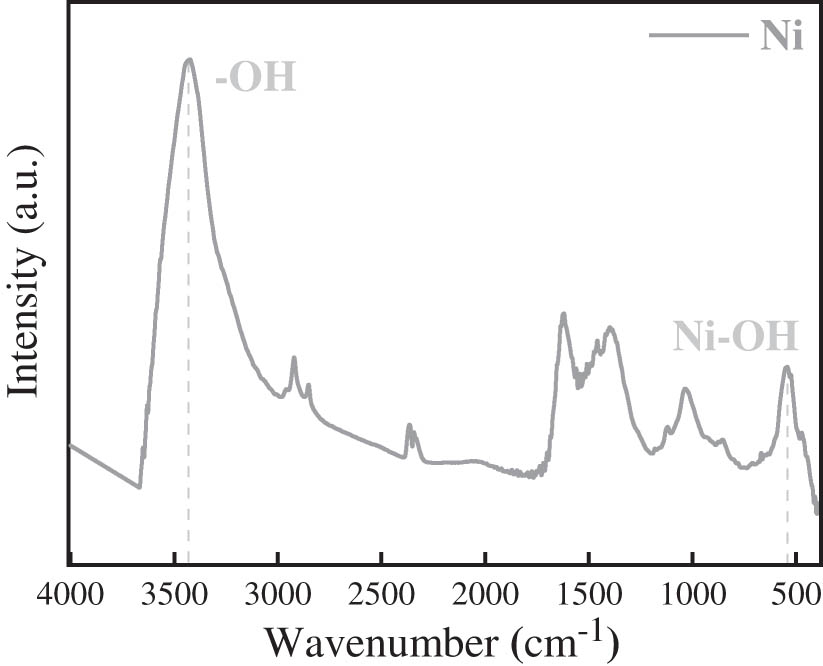

PVDF-HFP was purchased from Arkema Inc. Its melting temperature is 140–145°C, and the melt flow rate (232°C, 125 kg) is 0.35–0.75 g·min−1. Dimethylformamide (DMF) was provided by Shanghai Titan Scientific Co. Ltd., spherical Ni nanoparticles (purity: 99.9%; size: 20–100 nm) were purchased from XF NANO Inc., and CB (size: 30–45 nm, specific surface area: 120–130 m2·g−1) was purchased from Macklin Inc. scanning electron microscopy (SEM) images of Ni and CB nanoparticles are shown in Figure 1. The Fourier-transform infrared (FTIR) spectrum of Ni nanoparticles is shown in Figure 2. The characteristic peak at 543 cm−1 corresponds to Ni nanoparticles, while the characteristic peak near 3,424 cm−1 corresponds to the stretching vibration of hydroxyl (–OH) groups on the surface of Ni nanoparticles. Some published studies have shown that hydroxyl groups can effectively improve the dispersion of nanoparticles in the PVDF-HFP matrix due to the interaction between the molecular chains and the hydroxyl groups, thus inducing the formation of β-phases [10]. All materials were used as received.

SEM images of nanofillers: (a) Ni and (b) CB.

FT-IR spectrum of Ni nanoparticles.

2.2 Preparation of PVDF-HFP/CB/Ni nanocomposite films

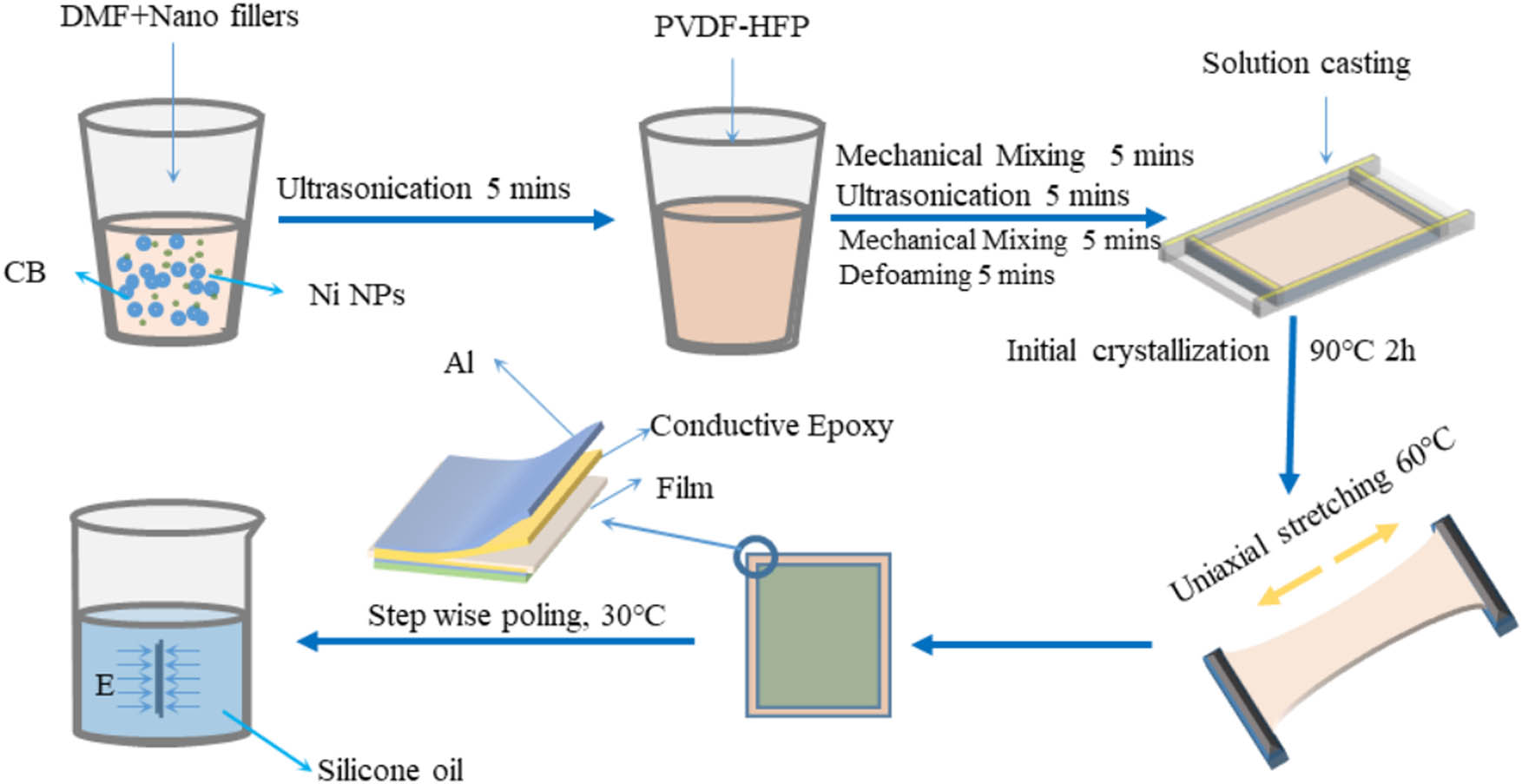

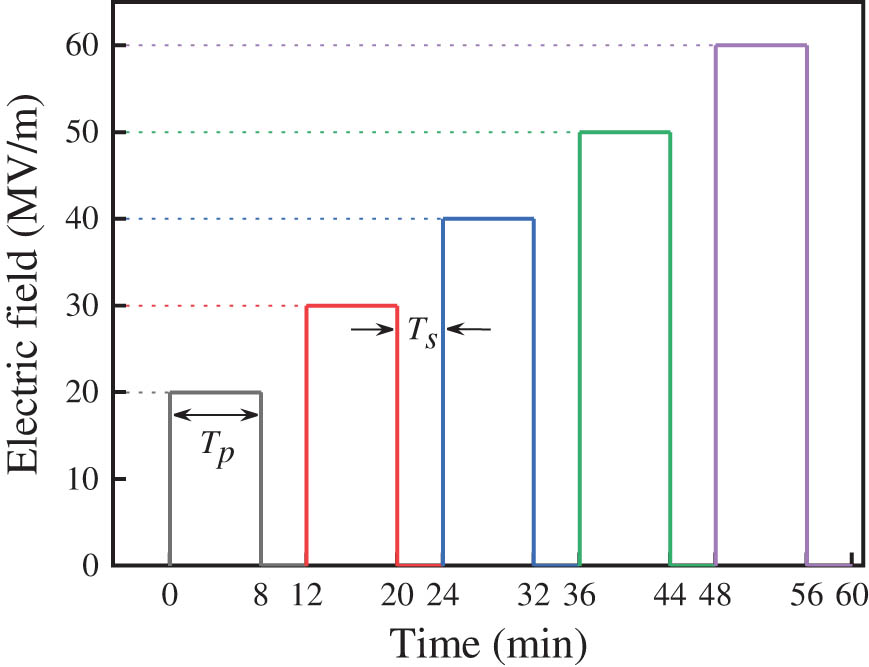

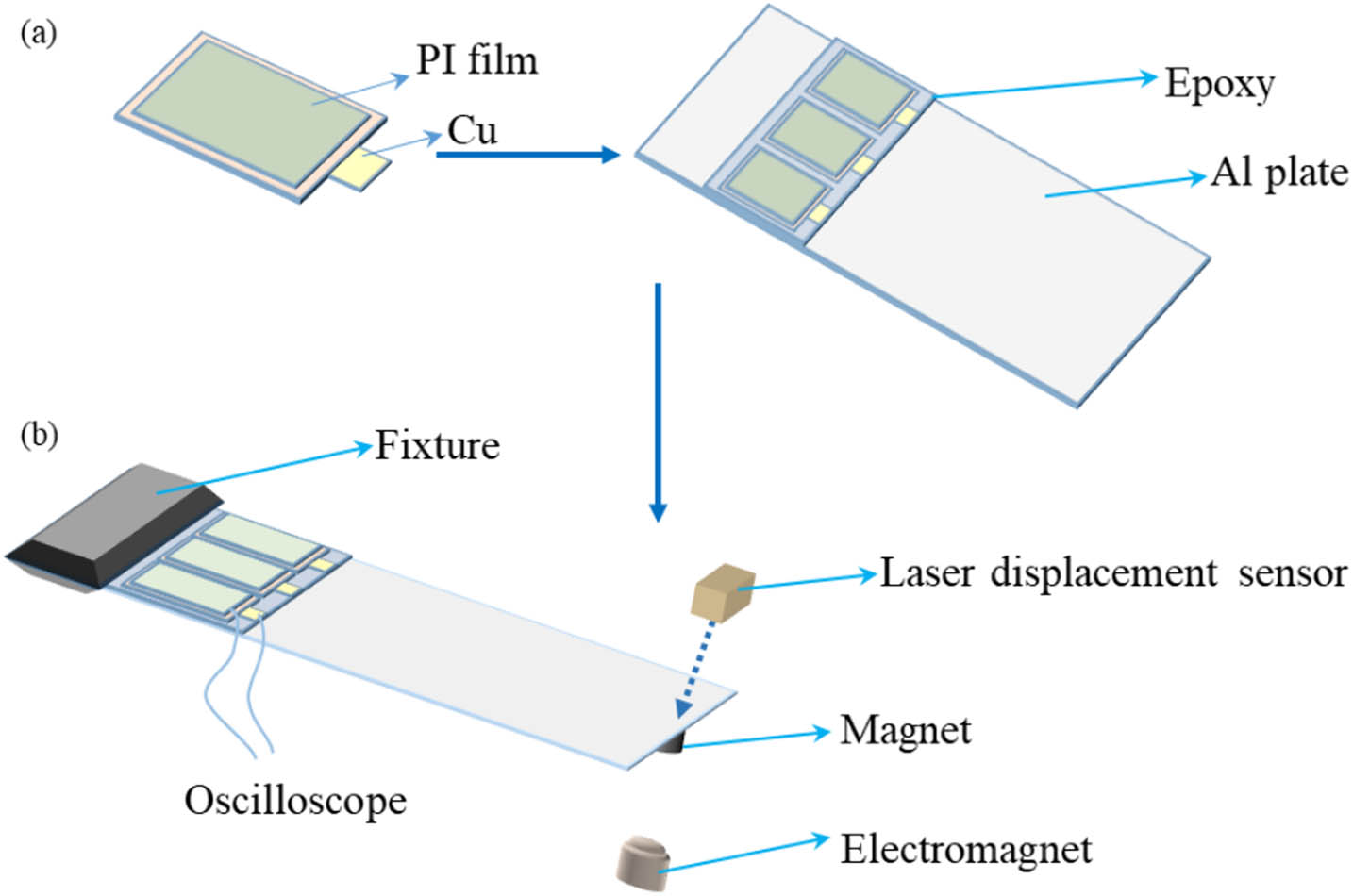

PVDF-HFP films usually require stretching and poling to generate piezoelectric properties. Among the fabrication methods of PVDF films, electrospinning is an effective method that carries both stretching and poling simultaneously. However, the cost is higher, and it is obviously affected by the environmental and operating conditions, resulting in an unstable output. The simultaneous stretching and poling were also reported by other researchers [45,46]. Mahadeva et al. applied sequential stretching and corona poling to fabricate piezoelectric PVDF thin films and investigated the effects of poling time and grid voltage on the phase transformation and piezoelectricity. It was found that the poling time and the grid have no substantial influences on the phase transformation, indicating that the phase transformation mainly occurs during the stretching process. However, the poling has decisive effects on the piezoelectricity because of its function in dipole moment alignment [45]. The simultaneous stretching and poling were also developed in the 3D printing technique in recent years. Lee and Tarbutton developed an innovative method to print PVDF filament rods under a strong electric field in which poling and stretching can be carried out simultaneously. A high electric field is applied to the molten polymer column between the nozzle tip and the printing bed (poling) during extrusion (stretching), which leads to the molecular chain alignment and the phase transformation to β-phase [46]. The solution casting method is used to prepare films by separating uniaxial stretching and poling. Although the process is relatively cumbersome, the operation is simple and suitable for large-scale industrial production. Therefore, the solution casting method is utilized to prepare initial crystalline films in this work. The preparation process of PVDF-HFP-based composite films is similar to that previously reported [17,25] (Figure 3), and can be described briefly as follows: (a) The determined mass of CB and Ni nanoparticles (calculated by the nanofiller content in the matrix) is added into 24 g of DMF, then ultra-sonication is applied for 5 min to achieve uniform dispersion, and then 8 g of the PVDF-HFP powder is added into the DMF/CB/Ni suspension by planetary stirring, ultrasonic stirring and mechanical defoaming in sequence. (b) The mixed solution is poured onto an Al plate (thickness: 1 mm) and heated to 90°C for 2 h for initial crystallization. (c) Uniaxial thermal stretching (60°C) is applied on the films at a tensile rate of 10 mm·min−1 and an elongation ratio of 4.5–5. The thicknesses of the films prepared range from 250 to 270 μm. During the uniaxial stretching process, the film and fixture will experience relative sliding, when the stretching stroke is set to 100 mm, the elongation of the film can be maintained at 4.5–5. (d) The films are cut into sizes of 2.5 cm × 3 cm (in the stretching direction), and two Al foils are pasted on both sides of the films by conductive epoxy adhesive (ITW Chemtronics CW2400). (e) Poling in silicone oil is applied by a step-wise method. The initial electric field is 10 MV·m−1, the increment for each step is 10 MV·m−1 and the maximum electric field is 120 MV·m−1. The schematic of the step-wise poling method is shown in Figure 4. The photo of the poling process is shown in the Supplementary information.

The preparation process of PVDF-HFP/CB/Ni composite films.

Schematic of the electric field during the step-wise poling (T p: poling time; T s: pause time).

For simplicity, the samples are named by the nanofiller content. For example, C0.3N0.1 represents a sample containing 0.3 wt% CB and 0.1 wt% Ni nanoparticles. In this work, the maximum poling electric field of pure PVDF-HFP, C0.3, and C0.5 films is 100 MV·m−1, and the maximum poling electric field of C0N0.1, C0.5N0.1, and C0.3N0.1 is 120 MV·m−1.

2.3 Electrical experiments

The structure of the test plate and the measurement mechanism of the generated output voltage are shown in Figure 5. In the experiment, a copper foil electrode is drawn from one side of the piezoelectric film. Different from previous reports, in this work, we encapsulated the prepared films by PI films to avoid bubbles between the epoxy resin (adhesive) and the piezoelectric film. Three pieces of piezoelectric films with the same component were glued by epoxy resin on the Al plate with wires connected for the measurement of the output voltage. The measurement mechanism of the generated voltage is shown in Figure 5(b). The equipment involved in the test includes a signal generator (AFG3022), a power amplifier (HAS0112), a displacement sensor (CD5-125/LW25), and an oscilloscope (TDS3034B). The testing process is as follows. At first, a magnet is attached to the underside of the Al plate; then, the electromagnet under the magnet is excited by a sinusoidal signal (f: 25–27 Hz) to induce harmonious vibration of the Al plate, which in turn produces a periodical strain on the piezoelectric film. Under the excitation of a magnetic field, the film generates a periodical voltage. Finally, the generated voltage is recorded with an oscilloscope [17]. Due to the periodic sinusoidal vibration of the aluminum plate, the root mean square of the output voltage can be directly read from the oscilloscope, which is called the effective output voltage of the film.

The measurement mechanism of the generated output voltage. (a) The preparation of the vibration plate; (b) Schematic of the measurement setup.

2.4 Characterization of PVDF-HFP/CB/Ni composite films

A field emission SEM (SEM TM4000 Plus II) was used to observe the cross-sectional morphologies of the samples. Before observation, the sample surface was sputter-coated with gold using a magnetron.

An FTIR spectrometer (FTIR Nicolet IS50) was used to characterize the crystal structure of the polymers. The relative fraction of the β-phase (F(β)) in the composite films is calculated by the following formula:

where

X-ray diffraction (XRD; X’Pert Powder) was used to characterize the structure of the piezoelectric composite films, which was operated at 40 kV and 40 mA with CuKα (λ = 1.5418 Å).

Differential scanning calorimeter (DSC; DSC3+) was used to investigate the crystallization degree and melting behavior of the samples. The measurements were conducted from 40 to 200°C at heating and cooling rates of 10°C·min−1. The crystallinity degree X c of the PVDF-HFP films can be calculated by the following formula:

where

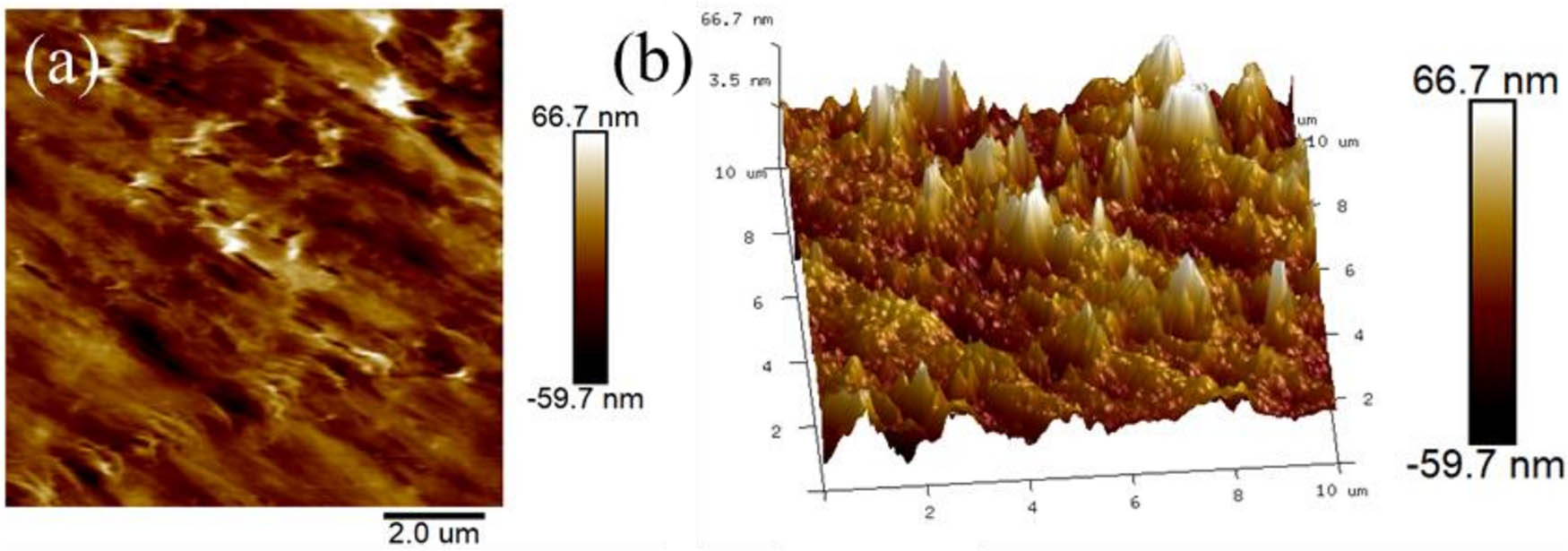

In order to verify that the mechanism of the output voltage is piezoelectricity, the PVDF-HFP/C0.3N0.1 composite film is characterized by a piezoelectric force microscope (PFM; Bruker Icon). In the test, the PFM works in the contact mode, and the scanning area is 10 μm × 10 μm. The bias voltage is from −10 to 10 V, and the scanning frequency is 1 Hz.

In this study, “U”, “S,” and “P” represent samples in three stages: initial crystallization film (unstretched), after stretching (stretched), and after stretching and polarization (poled), respectively.

3 Results and discussion

3.1 Structure and morphology of PVDF-HFP/CB/Ni composite films

Figure 6 shows the SEM images of the cross-section of the initial crystallization films. The distribution of the nanofillers in the polymer matrix is a critical factor in determining the piezoelectric properties of the film [49]. Figure 6(a) and (b) shows the morphology of the C0.3 composite film. It can be seen that the CB particles are agglomerated within the matrix. In contrast, Figure 6(c) and (d) depicts the morphology of the composite film N0.1, which demonstrates that Ni nanoparticles exhibit good compatibility with the matrix, and almost no agglomeration is observed. Previous studies have suggested that the surface of Ni nanoparticles contains –OH groups that have a large specific surface area and a large coverage area, leading to good compatibility with the PVDF matrix [10]. Figure 6(e) and (f) presents the morphology of the film C0.3N0.1, and it is apparent that the hybrid nanofillers form weaker agglomerations compared to the mono-filler. The agglomeration may affect the synergistic effect to some extent.

Cross-sectional SEM images of PVDF-HFP/CB/Ni composite films (initial crystallization): (a) C0.3, (b) C0.3 (high magnification), (c) N0.1, (d) N0.1 (high magnification), (e) C0.3N0.1, and (f) C0.3N0.1 (high magnification).

3.2 Phase transformation of PVDF-HFP/CB/Ni composite films

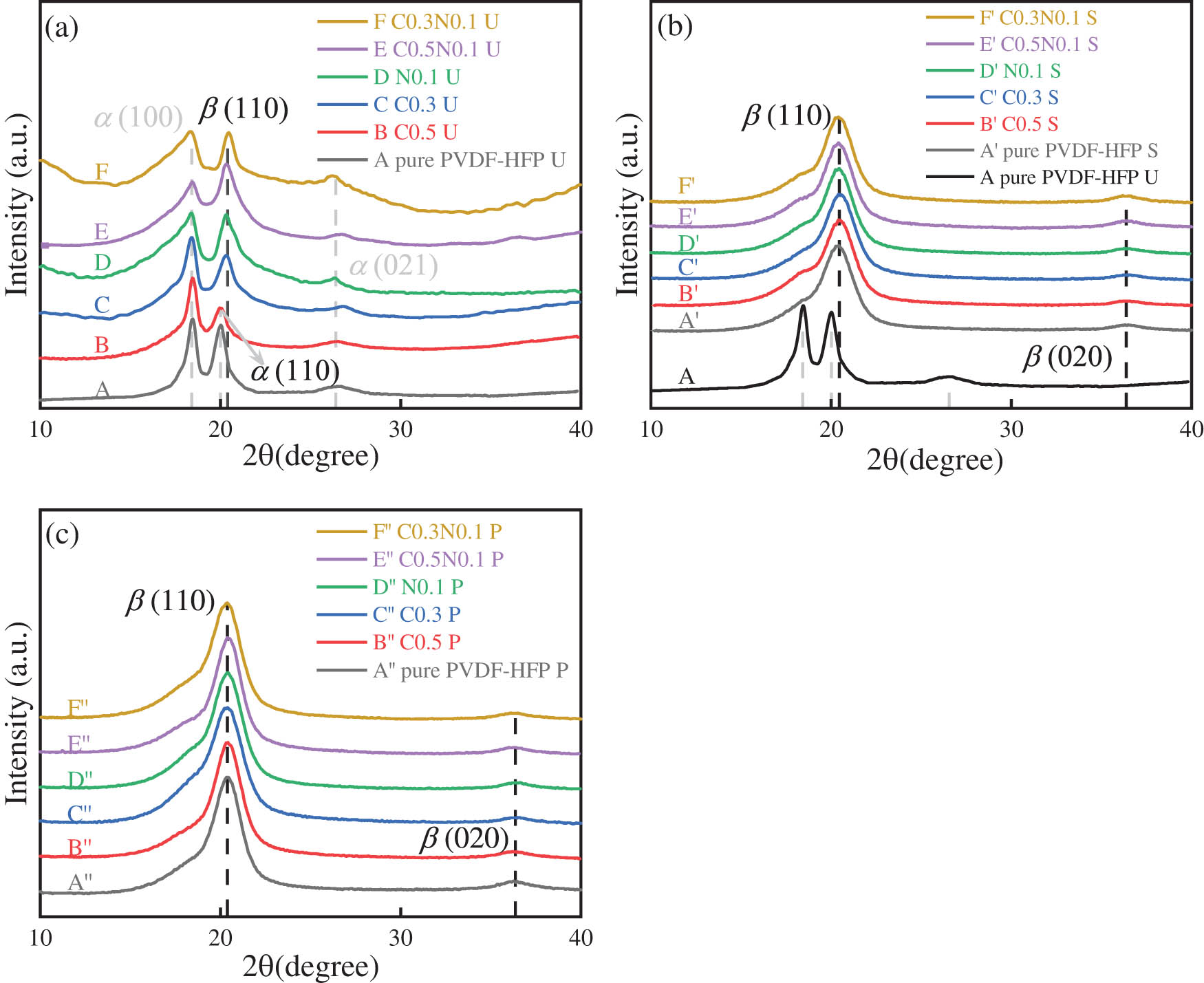

3.2.1 XRD

Figure 7 depicts the XRD pattern of the composite films at three stages with marked characteristic peaks corresponding to α- and β-phases [9]. Figure 7(a) shows that the initial crystallization of pure PVDF-HFP film is predominantly in the α-phase, as evidenced by the clear characteristic peaks of the α-phase. However, in the composite films, the characteristic peaks of the α-phase nearly disappear, indicating a phase transformation from α-phase to β-phase after the addition of nanofillers. Figure 7(b) and (c) shows the spectra of the stretched films and polarized films, respectively. Strong β-phase characteristic peaks are observed in all spectra, indicating that stretching can effectively increase the fraction of the polar β-phase. In order to further analyze the function of nanofiller addition, the relative fraction of the β-phase F(β) is calculated from the FT-IR spectra.

XRD spectra of PVDF-HFP/CB/Ni composite films: (a) unstretched films, (b) stretched films, and (c) stretched plus polarized films.

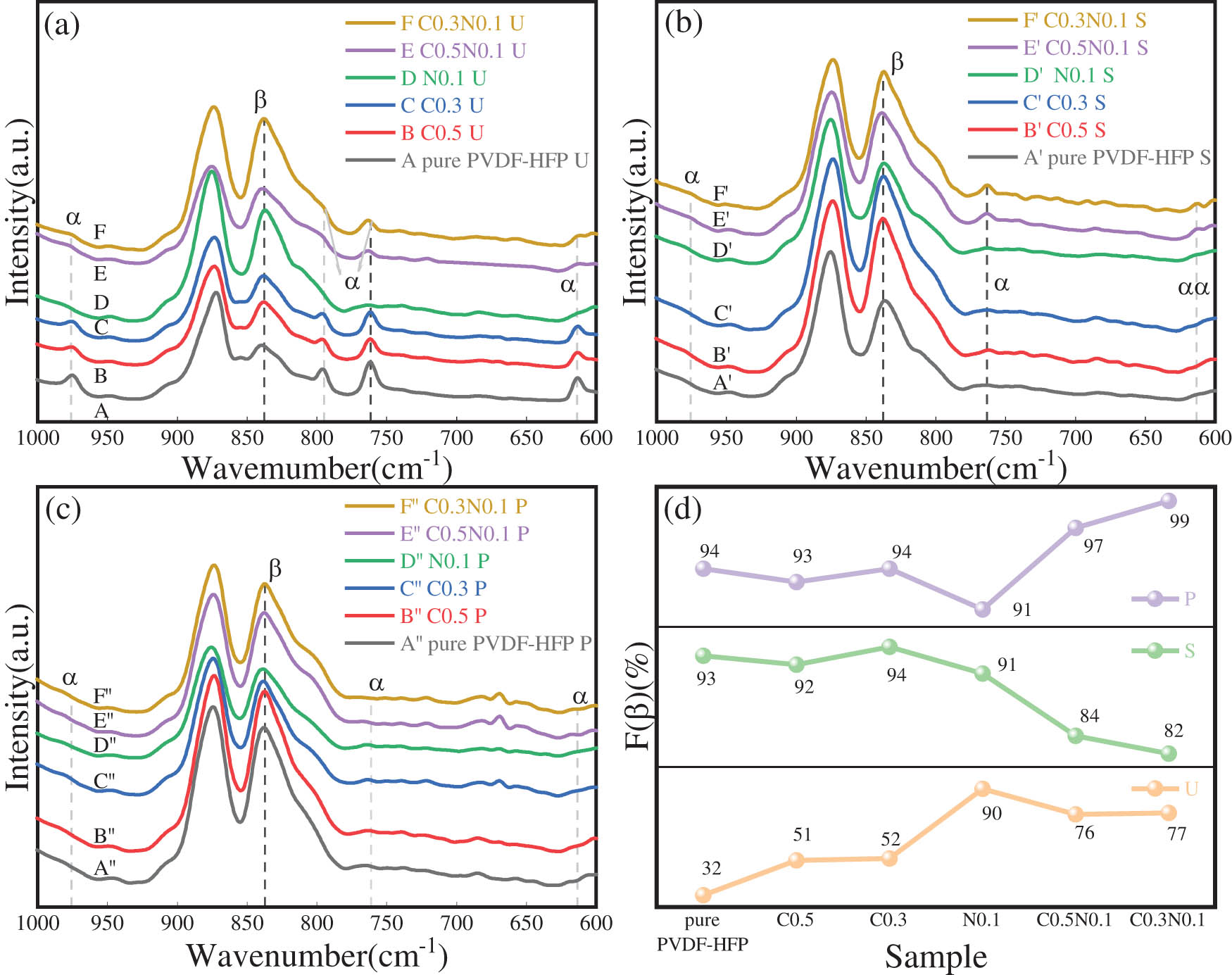

3.2.2 FT-IR

FT-IR spectra of the composite films in the wavenumber range from 1,000 to 600 cm−1 are shown in Figure 8. The peaks at 615, 765, 795, and 975 cm−1 correspond to the α-phase, and the peaks at 840 cm−1 correspond to the β-phase [47]. In pure PVDF-HFP films, the α-phase dominates. However, with the addition of CB/Ni hybrid fillers, the α-phase characteristic peaks are significantly weakened, while the β-phase characteristic peaks become more obvious. The spectra of both stretched films and stretched + poled films (Figure 8(b) and (c)) show that the α-phase characteristic peaks almost disappear, indicating the phase transformation is fully completed during the stretching process.

FT-IR spectra of PVDF-HFP/CB/Ni composite films: (a) unstretched films; (b) stretched films; and (c) stretched and polarized films. (d) The relative fraction of the β-phase F(β) of the composite film at each stage.

In order to gain further insight into the mechanism underlying the enhancement of piezoelectric performance in polymer films by hybrid fillers, the relative fraction of the β-phase F(β) at each stage of the composites was calculated by Eq. (1) and is presented in Figure 8(d). The results show that while the α-phase dominates, a small amount of the β-phase is present in the unstretched pure PVDF-HFP films, owing to the formation of β-phase molecular chains induced by the polar solvent DMF. For films containing CB or Ni nanoparticles, CB or Ni nanoparticles have a large specific surface area, which can affect the orientation and arrangement of matrix molecular chains, promoting the formation of β-phase. Therefore, F(β) increases primarily due to the nucleate function of nanofillers. In the composites containing both nanofillers, the synergistic effect can combine the advantages of both nanofillers to promote the formation of β-phase and the crystallinity degree [10,24]. Compared to the composite film with CB and Ni added separately, the introduction of mixed fillers has a more complex effect on the films, as shown in Figure 8(d). For the initial crystalline films, the F(β) of the composite films containing 0.3 and 0.5 wt% CB increased to over 50%, higher than that of pure film. When CB is co-doped with 0.1 wt% Ni, F(β) reached over 75%, reflecting the impact of hybrid fillers on the promoting effect of β-phase formation. It is worth mentioning that in films containing 0.1 wt% Ni (PVDF-HFP/N0.1), F(β) reached 90%, higher than the PVDF-HFP/CB/Ni film. The SEM characterization results indicate that this may be caused by the inevitable aggregation of mixed fillers, but overall, the F(β) of the hybrid filler film was significantly higher than pure films.

For the unstretched samples, the crystal region is dominated by the α-phase (spherical structure). During the stretching process, the applied stress (concentrated on the interface between the nanofillers and the matrix) forces the spherical structure to form a fiber-like structure, which is beneficial for the formation of zigzag conformation (TTTT, corresponding to β-phase) [50]. Poling is a necessary condition for obtaining piezoelectric properties of piezoelectric films. The added nanofillers can form micro-capacitors to induce a strong local electric field, which can improve the effect of poling [51].

In the stretched films and stretched + poled films, F(β) increased dramatically, compared to the unstretched films. It is worth mentioning that in PVDF-HFP/CB/Ni hybrid films, the tensile process has a minimal effect on the transformation from the α-phase to the β-phase. In contrast, poling can significantly increase F(β), probably due to the negative effect of hybrid filler aggregation during the stretching process [52,53].

In summary, the enhancement mechanism of PVDF phase transition at each stage can be summarized as follows. (a) The added nanofillers act as nucleation agents during the initial crystallization of PVDF-HFP, thereby increasing the crystallization rate and promoting the formation of β-phase. (b) During the stretching process, the stress concentration on the surfaces between the nanofillers and the matrix forces the elongation of the molecular chains, which is beneficial for the transformation from the α-phase to the β-phase. (c) The energy provided by the polarization process promotes the full conversion of a portion of the α-phase to the β-phase, thereby further increasing the F(β). This study demonstrates that CB and Ni nanoparticles have a synergistic effect on promoting the formation of β-phases, resulting in increased output voltage compared with monoparticle systems.

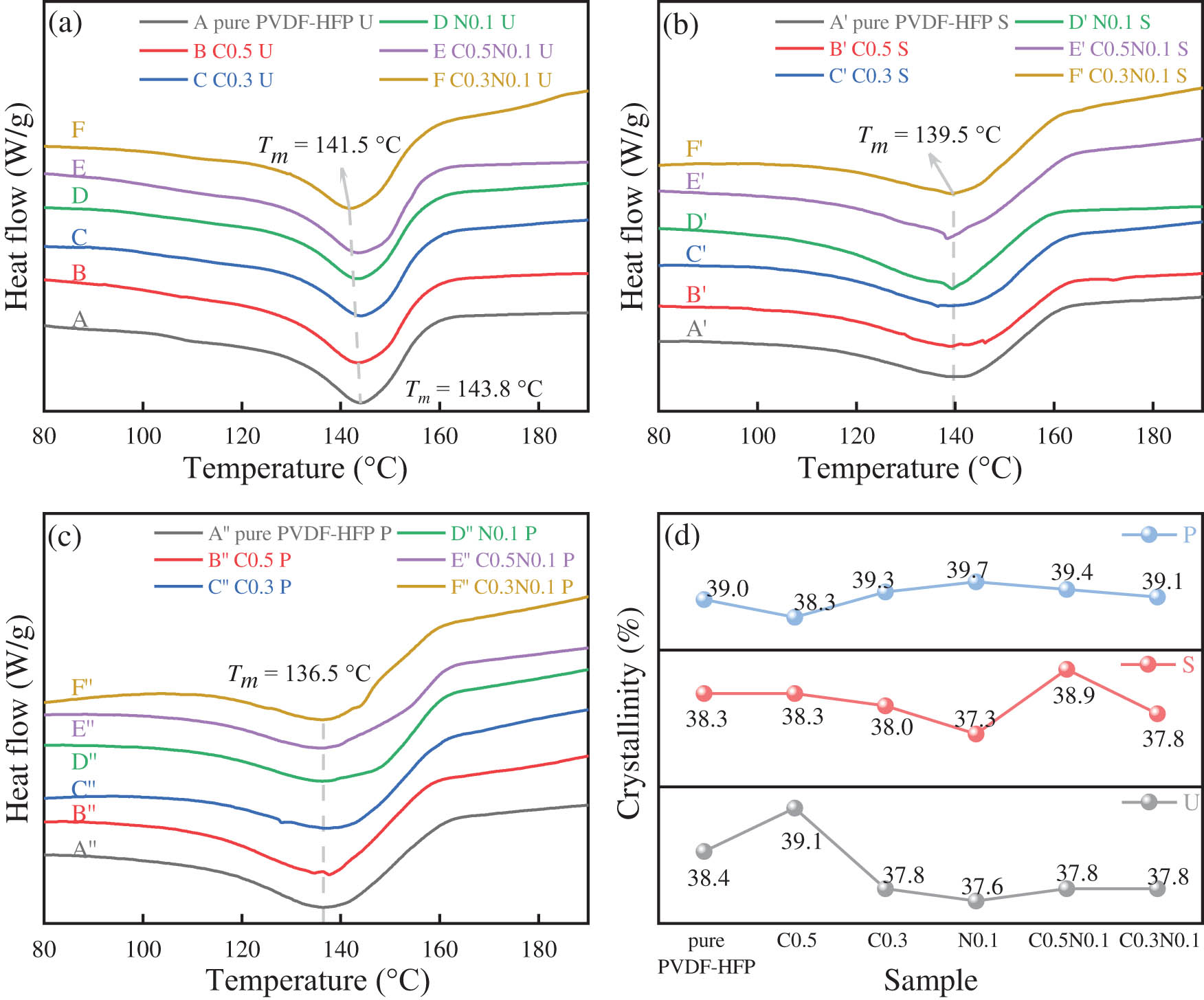

3.2.3 DSC

Figure 9(a)–(c) shows the DSC thermograms of the nanocomposite films at each stage, where T m represents the melting temperature of the material. After the addition of the nanofillers, the melting temperature of the composite shows a decrement trend due to the change in crystallinity and crystal structure. Figure 9(d) shows the crystallinity degree X c of the composite film at each stage, calculated by Eq. (2). In general, the crystallinity degrees in all films are close to 40%. In the initial crystallization films, the crystallinity degree of the hybrid film decreases slightly, which may be caused by multiple factors, such as the size, distribution, and curvature of the additive [33]. For the stretched and poled films, the crystallinity degree is slightly increased. Although the process of stretching and poling induces molecular chain re-orientation and the formation of a new crystalline region, these processes also amplify defects within the material. As a result, it is challenging to predict the exact evolution of crystallinity change.

DSC thermograms of PVDF-HFP/CB/Ni composite films: (a) unstretched films (U), (b) stretched films (S), and (c) stretched and polarized films (P). (d) Crystallinity degree of PVDF-HFP/CB/Ni composite films at each stage.

3.2.4 PFM

Figure 10 shows the PFM images of stretched and poled PVDF-HFP/CB/Ni composite films. With the applied AC bias between the PFM tip and bottom electrodes, the piezoelectric response of the films led to the deflection in the PFM cantilever at the same frequency. The magnitude of the vibration amplitude can be used to estimate the magnitude of the local piezoelectric coefficient. As shown in Figure 10(a), several obvious bright areas (high deflection amplitude) can be seen in the figure, which are considered piezoelectric-active areas. From the 3D amplitude image (Figure 10(b)), more obvious deflection amplitude peaks can be observed more intuitively. However, the distribution of each peak in the tested area is not uniform, which may be due to the uneven dispersion of nanoparticles in the composite films, resulting in higher piezoelectric response in local areas. Combining the two images, it is confirmed that the voltage output of the prepared films in this article is generated from the piezoelectricity.

PFM images of PVDF-HFP/CB/Ni composite films: (a) 2D amplitude and (b) 3D amplitude.

3.3 Piezoelectric properties of PVDF-HFP/CB/Ni composite films

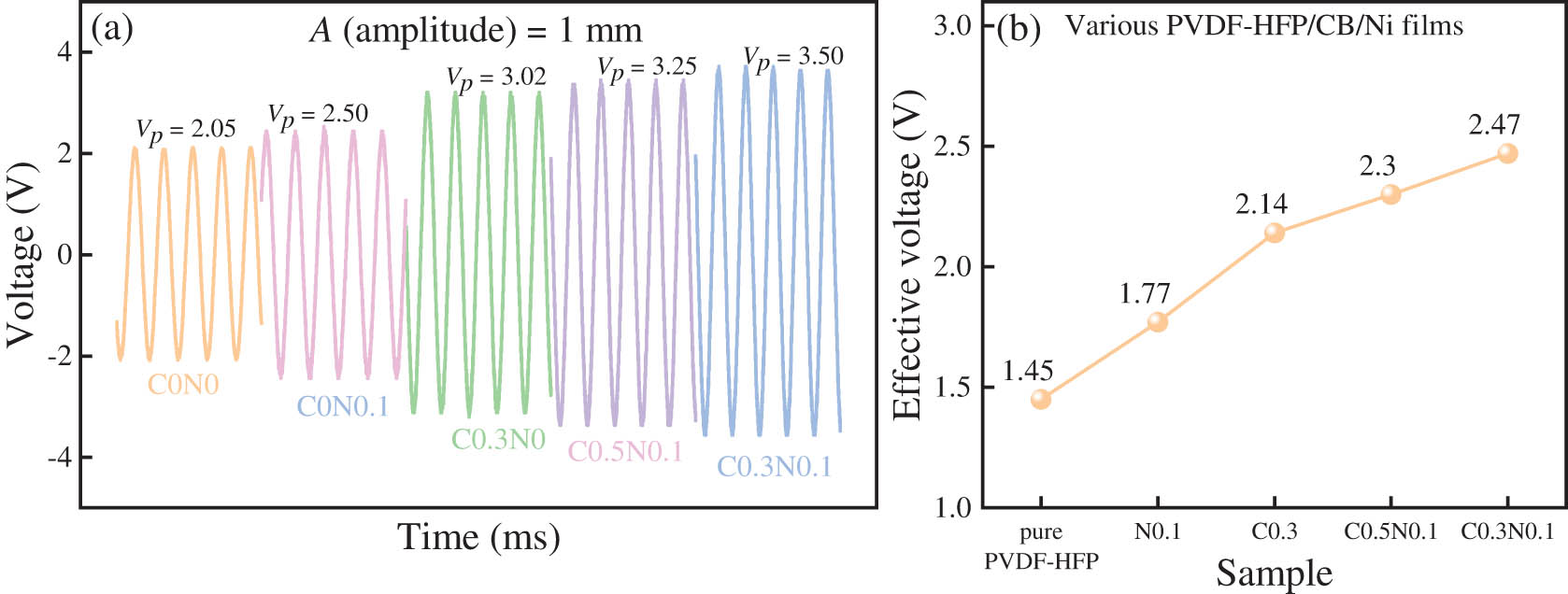

Figure 11 shows the open-circuit voltage and the effective voltage of the composite films (the vibration amplitude of the plate end is close to 1 mm). Notably, the piezoelectric performance of PVDF-HFP/Ni and PVDF-HFP/CB composite films exceeds that of pure PVDF-HFP films. However, there were slight variations in the thickness of the films and the vibration amplitude of the plate end during the experiments. To further investigate the impact of nanofillers on the piezoelectric properties of PVDF-HFP, the calibrated open-circuit voltage was calculated as follows:

where u is the vibration amplitude of the plate end, t is the piezoelectric film thickness, u 0 = 1 mm is the standard vibration amplitude, and t 0 = 100 μm is the standard film thickness. The calibrated open-circuit voltage for the composite film is shown in Figure 12.

(a) The output voltage of PVDF-HFP/CB/Ni composite films containing different nanofillers. (b) The effective voltage of PVDF-HFP/CB/Ni composite films containing different nanofillers.

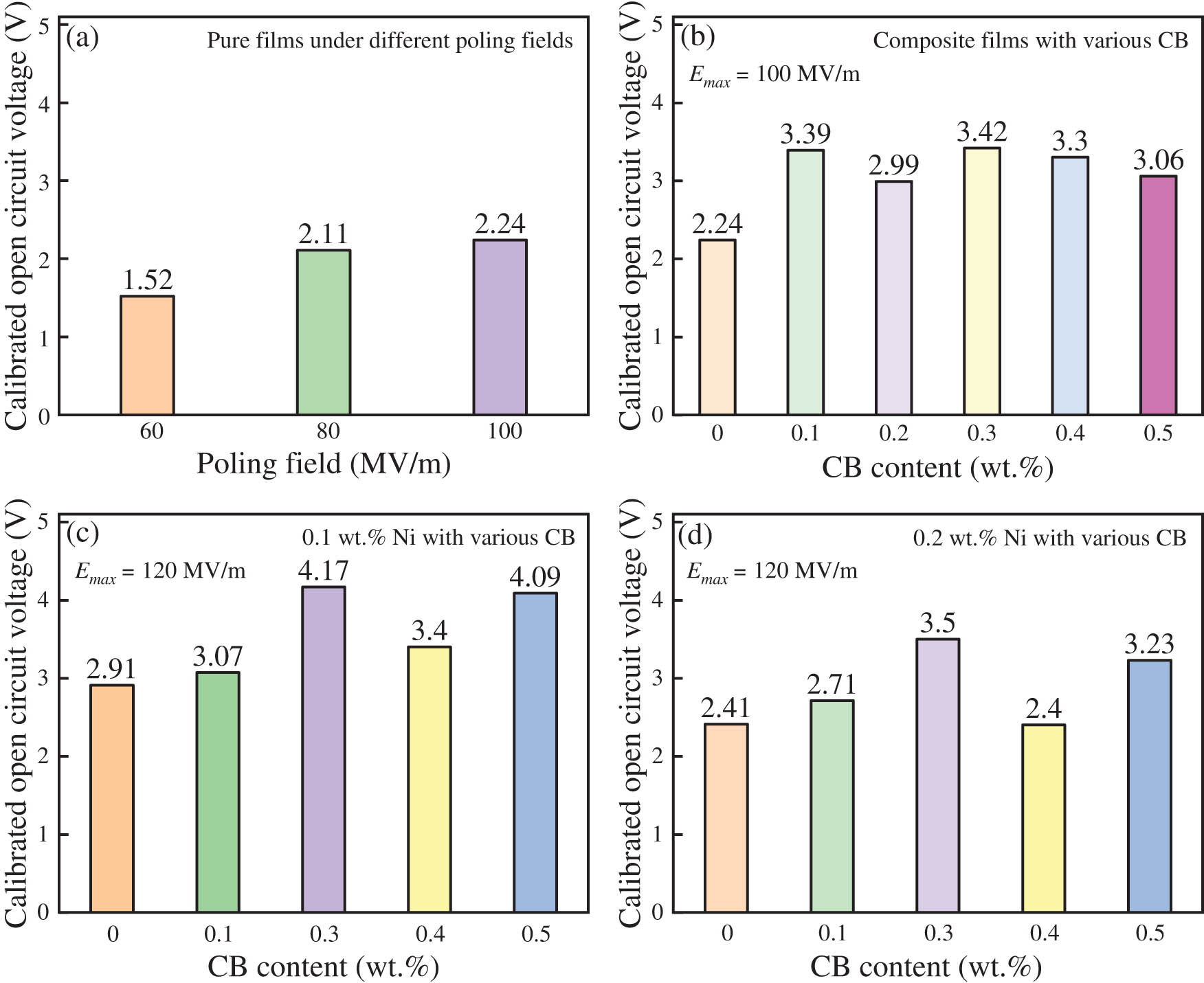

The calibrated open-circuit output voltage of PVDF-HFP/CB/Ni films: (a) neat PVDF-HFP films under different poling electric fields; (b) PVDF-HFP/CB/Ni composites with various CB loadings; (c) PVDF-HFP/CB/Ni composites with 0.1 wt% Ni nanoparticles and various CB loadings; and (d) PVDF-HFP/CB/Ni composites with 0.2 wt% Ni nanoparticles and various CB loadings.

Figure 12(a) shows the calibrated open-circuit voltage of pure PVDF-HFP piezoelectric films under different maximum polarized electric fields E max. Notably, when E max = 100 MV·m−1, the calibrated open-circuit voltage increased to 2.24 V, highlighting the decisive effect of poling on piezoelectric performance. A high poling electric field induces a high degree of internal dipole moment orientation of the polymer along the direction of the electric field (i.e., perpendicular to the surface of the film), thereby improving the voltage generation capability. Studies have shown that the dipole moment of the initial crystallization film is randomly distributed within the matrix, resulting in mutual offset and an overall lack of piezoelectricity [54,55]. For PVDF-HFP/CB composite films, as shown in Figure 12(b), the maximum V c is 3.42 V (0.3 wt% CB, E max = 100 MV·m−1). For PVDF-HFP/Ni composite films, it is only 2.91 V (0.1 wt% Ni, E max = 120 MV·m−1). Figure 12(c) and (d) shows the V c of the PVDF-HFP/CB/Ni composite films. It is found that V c can reach a much higher value when the hybrid nanofillers are added (C0.3 + N0.1:4.17 V; C0.5 + N0.1:4.09 V). From Figure 12, it is found that the increment of the Ni nanofiller content has a negative effect on the piezoelectric performance, which may be caused by the poor dispersion of magnetic nanoparticles. Generally speaking, the piezoelectricity depends on the fraction of the polar β-phase and the orientation of its dipole moments. The addition of conductive CB can form a conductive pathway in the matrix, which can generate stronger interfacial polarization during the poling process to improve the polarization and the degree of dipole moment orientation. However, it also reduces its breakdown electric field strength. In the composite film of PVDF-HFP/CB, the maximum poling electric field is 100 MV·m−1. Under this electric field, the calibrated open-circuit voltage reaches a maximum of 3.5 V. In the experiment, we found that the breakdown failure rate of the film with only CB added is too high. The main reason is that the CB agglomeration area forms an uneven local electric field under the action of the electric field, making it easier to break down. It has been reported that under an external electric field, Ni nanoparticles are prone to form Coulomb islands, which can induce the Coulomb blockade effect and increase the breakdown electric field strength of composite materials, so a higher poling electric field can be applied to improve piezoelectricity [56]. Therefore, the composite film with mixed fillers exhibits a higher breakdown electric field strength and lower breakdown failure rate.

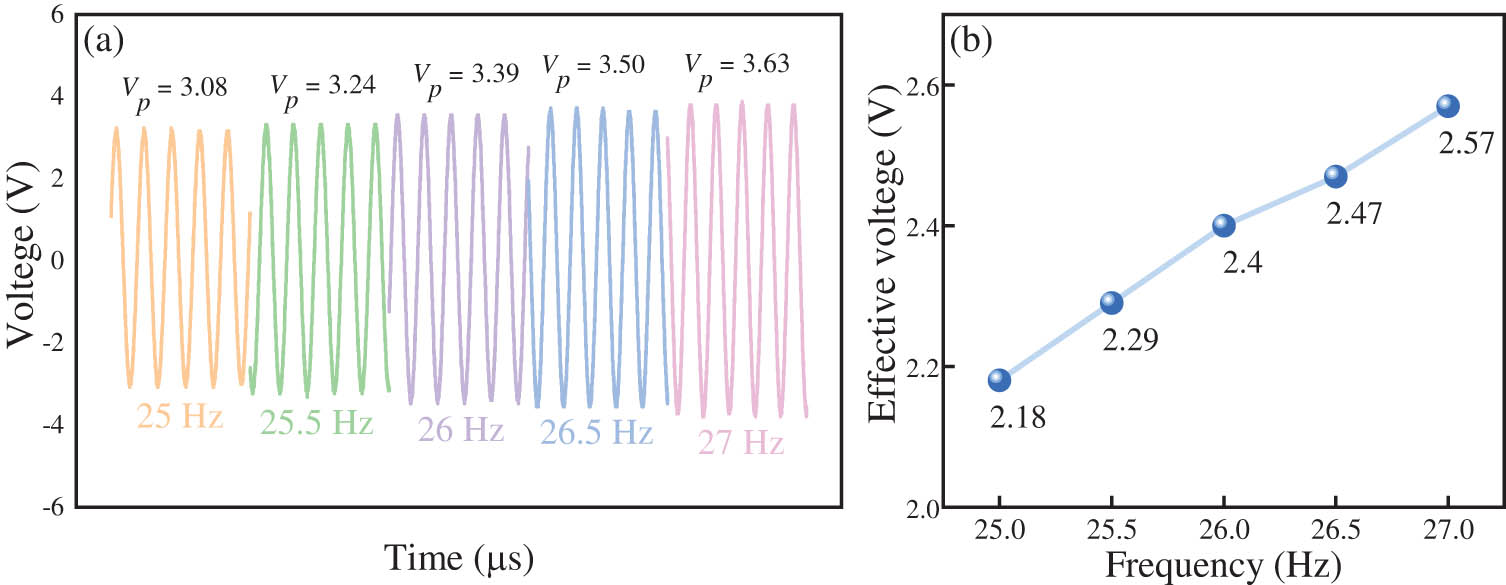

We investigated the open-circuit voltage of PVDF-HFP/C0.3N0.1 composite films near the first-order frequency of the plate by adjusting the vibration frequency of the measurement plate, as shown in Figure 13. The film exhibited varying output voltages as the vibration frequency changed. The highest effective voltage of 2.57 V was observed at a frequency f of 27 Hz. Notably, at a frequency f of 26.5 Hz, which corresponds to the first-order resonance frequency, the measurement plate attained the maximum vibration amplitude under the same excitation voltage.

(a) The open-circuit voltage of PVDF-HFP/CB0.3N0.1 composite films vibrated at different frequencies. (b) The effective voltage of PVDF-HFP/CB0.3N0.1 composite films.

3.4 Piezoelectric enhancement mechanism

Hybrid fillers play a nucleation role in the initial crystallization stage, which can effectively promote the formation of the β-phase. In the tensile stage, stress concentration occurs at the interface between the nanofillers and the matrix, which induces the transformation of the α-phase to the β-phase. In the process of poling, Ni nanoparticles improve the breakdown electric field strength of the film. It has been reported that under an external electric field, Ni nanoparticles are prone to form Coulomb islands, which can induce the Coulomb blockade effect and improve the breakdown electric field strength of the composite materials, facilitating the polarization of the films under high electric fields. However, CB nanofillers form a conductive network in the composites, and a larger local electric field is formed near the nanofillers due to the micro-capacitor effect, resulting in stronger interfacial polarization to improve the polarization. As a result, the synergistic effect of the hybrid fillers leads to a higher voltage output.

4 Conclusions

This study uses a solution casting method to prepare PVDF-HFP piezoelectric composite films with high β-phase content and excellent piezoelectric performance. The effects of added nanofillers are discussed in detail. The results show that in the output voltage measurement, the PVDF-HFP/C0.3N0.1 (E max = 120 MV·m−1) composite film exhibits a calibrated open-circuit voltage of 4.17 V, which is 86% higher than that of pure PVDF-HFP films (E max = 100 MV·m−1, 2.24 V), 43% higher than that of PVDF-HFP/Ni(0.1) composite films (2.91 V), and 22% higher than that of PVDF-HFP/CB (0.3) (E max = 100 MV·m−1, 3.42 V) composite films.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51703015) and Fundamental Research Funds for the Central Universities (No. 2020CDJQY-A008).

-

Funding information: This work was financially supported by the National Natural Science Foundation of China (No. 51703015) and Fundamental Research Funds for the Central Universities (No. 2020CDJQY-A008).

-

Author contributions: Yang Wang: experiments, writing and editing; Dan Lei: writing and editing; Liangke Wu: funding acquisition, writing-review and editing; Ning Hu: funding acquisition and writing; Huiming Ning, Alamusi, and Yaolu Liu: technical support. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Zhang, Y., M. Xie, V. Adamaki, and H. K. R. Bowen. Control of electro-chemical processes using energy harvesting materials and devices. Chemical Society Reviews, Vol. 46, No. 24, 2017, pp. 7757–7786.10.1039/C7CS00387KSearch in Google Scholar PubMed

[2] Guo, S., X. Duan, M. Xie, K. C. Aw, and Q. Xue. Composites, fabrication and application of polyvinylidene fluoride for flexible electromechanical devices: A Review. Micromachines, Vol. 11, No. 12, 2020, id. 1076.10.3390/mi11121076Search in Google Scholar PubMed PubMed Central

[3] Mokhtari, F., G. M. Spinks, C. Fay, Z. Cheng, R. Raad, J. Xi, et al. Wearable electronic textiles from nanostructured piezoelectric fibers. Advanced Materials Technologies, Vol. 5, 2020, id. 1900900.10.1002/admt.201900900Search in Google Scholar

[4] Mokhtari, F., G. M. Spinks, S. Sayyar, Z. X. Cheng, A. Ruhparwar, and J. Foroughi. Highly stretchable self-powered wearable electrical energy generator and sensors. Advanced Materials Technologies, Vol. 6, 2021, id. 2000841.10.1002/admt.202000841Search in Google Scholar

[5] Li, M., H. J. Wondergem, M. Spijkman, K. Asadi, I. Katsouras, P. W. Blom, et al. Revisiting the delta-phase of poly(vinylidene fluoride) for solution-processed ferroelectric thin films. Nature Materials, Vol. 12, No. 5, 2013, pp. 433–438.10.1038/nmat3577Search in Google Scholar PubMed

[6] Jin, L., S. Ma, W. Deng, C. Yan, T. Yang, X. Chu, et al. Polarization-free high-crystallization ss-PVDF piezoelectric nanogenerator toward self-powered 3D acceleration sensor. Nano Energy, Vol. 50, 2018, pp. 632–638.10.1016/j.nanoen.2018.05.068Search in Google Scholar

[7] Khan, F., T. Kowalchik, and S. R. Warren. Stretching-induced phase transitions in barium titanate-poly(vinylidene fluoride) flexible composite piezoelectric films. Scripta Materialia, Vol. 193, 2021, pp. 64–70.10.1016/j.scriptamat.2020.10.036Search in Google Scholar

[8] Mishra, S., R. Sahoo, L. Unnikrishnan, A. Ramadoss, and S. M. K. Nayak. Investigation of the electroactive phase content and dielectric behaviour of mechanically stretched PVDF-GO and PVDF-rGO composites. Materials Research Bulletin, Vol. 124, 2020, id. 110732.10.1016/j.materresbull.2019.110732Search in Google Scholar

[9] Mahdi, R. I., W. C. Gan, and W. H. Abd Majid. Hot plate annealing at a low temperature of a thin ferroelectric P(VDF-TrFE) film with an improved crystalline structure for sensors and actuators. Sensors, Vol. 14, No. 10, 2014, pp. 19115–19127.10.3390/s141019115Search in Google Scholar PubMed PubMed Central

[10] Lei, D., N. Hu, L. Wu, R. Huang, A. Lee, Z. Jin, et al. Preparation of efficient piezoelectric PVDF-HFP/Ni composite films by high electric field poling. Nanotechnology Reviews, Vol. 11, No. 1, 2022, pp. 452–462.10.1515/ntrev-2022-0025Search in Google Scholar

[11] Salimi, A. and A. A. Yousefi. Analysis method: FTIR studies of β-phase crystal formation in stretched PVDF films. Polymer Testing, Vol. 22, No. 6, 2003, pp. 699–704.10.1016/S0142-9418(03)00003-5Search in Google Scholar

[12] Sabira, K., P. Saheeda, M. C. Divyasree, and S. Jayalekshmi. Impressive nonlinear optical response exhibited by poly(vinylidene fluoride) (PVDF)/reduced graphene oxide (RGO) nanocomposite films. Optics and Laser Technology, Vol. 97, 2017, pp. 77–83.10.1016/j.optlastec.2017.06.008Search in Google Scholar

[13] Fakhri, P., H. Mahmood, and B. J. Pegoretti. Improved electroactive phase content and dielectric properties of flexible PVDF nanocomposite films filled with Au- and Cu-doped graphene oxide hybrid nanofiller. Synthetic Metals, Vol. 220, 2016, pp. 653–660.10.1016/j.synthmet.2016.08.008Search in Google Scholar

[14] Hu, X., Z. Ding, L. Fei, Y. Xiang, and Y. Lin. Wearable piezoelectric nanogenerators based on reduced graphene oxide and in situ polarization-enhanced PVDF-TrFE films. Journal of Materials Science, Vol. 54, No. 8, 2019, pp. 6401–6409.10.1007/s10853-019-03339-5Search in Google Scholar

[15] Wu, C. and M. H. Chou. Polymorphism, piezoelectricity and sound absorption of electrospun PVDF membranes with and without carbon nanotubes. Composites Science and Technology, Vol. 127, 2016, pp. 127–133.10.1016/j.compscitech.2016.03.001Search in Google Scholar

[16] Davand, R. and M. Frounchi. Composites of carbon nanotubes with the blend of poly(vinylidene fluoride)/poly(vinyl acetate). Polymer-Korea, Vol. 40, No. 2, 2016, pp. 232–237.10.7317/pk.2016.40.2.232Search in Google Scholar

[17] Wu, L., W. Yuan, N. Hu, Z. Wang, C. Chen, J. Qiu, et al. Improved piezoelectricity of PVDF-HFP/carbon black composite films. Journal of Physics D-Applied Physics, Vol. 47, No. 13, 2014, id. 135303.10.1088/0022-3727/47/13/135302Search in Google Scholar

[18] Wu, L., M. Jing, Y. Liu, H. Ning, X. Liu, S. Liu, et al. Power generation by PVDF-TrFE/graphene nanocomposite films. Composites Part B-Engineering, Vol. 164, 2019, pp. 703–709.10.1016/j.compositesb.2019.01.055Search in Google Scholar

[19] Gan, W. C. and W. H. A. Majid. Effect of TiO2 on enhanced pyroelectric activity of PVDF composite. Smart Materials and Structures, Vol. 23, No. 4, 2014, id. 045026.10.1088/0964-1726/23/4/045026Search in Google Scholar

[20] Ponnamma, D., A. Erturk, H. Parangusan, K. Deshmukh, M. B. Ahamed, and M. A. Ali Al-Maadeed. Stretchable quaternary phasic PVDF-HFP nanocomposite films containing graphene-titania-SrTiO3 for mechanical energy harvesting. Emergent Materials, Vol. 1, No. 1–2, 2018, pp. 55–65.10.1007/s42247-018-0007-zSearch in Google Scholar

[21] Yue, L., G. Pircheraghi, S. A. MonemianIca, and M. Z. Ica. Epoxy composites with carbon nanotubes and graphene nanoplatelets – Dispersion and synergy effects. Carbon, Vol. 78, 2014, pp. 268–278.10.1016/j.carbon.2014.07.003Search in Google Scholar

[22] Ma, P., N. A. Siddiqui, G. Marom, and J. Kim. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Composites Part a-Applied Science and Manufacturing, Vol. 41, No. 10, 2010, pp. 1345–1367.10.1016/j.compositesa.2010.07.003Search in Google Scholar

[23] Yang, L., Q. Zhao, Y. Hou, R. Sun, M. Cheng, M. Shen, et al. High breakdown strength and outstanding piezoelectric performance in flexible PVDF based percolative nanocomposites through the synergistic effect of topological-structure and composition modulations. Composites Part a-Applied Science and Manufacturing, Vol. 114, 2018, pp. 13–20.10.1016/j.compositesa.2018.07.039Search in Google Scholar

[24] Yang, L., M. Cheng, W. Lyu, M. Shen, J. Qiu, H. Ji, et al. Tunable piezoelectric performance of flexible PVDF based nanocomposites from MWCNTs/graphene/MnO2 three-dimensional architectures under low poling electric fields. Composites Part a-Applied Science and Manufacturing, Vol. 107, 2018, pp. 536–544.10.1016/j.compositesa.2018.02.004Search in Google Scholar

[25] Wu, L., W. Yuan, T. Nakamura, S. Atobe, N. Hu, H. Fukunaga, et al. Enhancement of PVDF’s piezoelectricity by VGCF and MWNT. Advanced Composite Materials, Vol. 22, No. 1, 2013, pp. 49–63.10.1080/09243046.2013.764780Search in Google Scholar

[26] Al-Saygh, A., D. Ponnamma, M. A. AlMaadeed, P. P. Vijayan, A. Karim, and M. K. Hassan. Flexible pressure sensor based on PVDF nanocomposites containing reduced graphene oxide- Titania hybrid nanolayers. Polymers, Vol. 9, No. 2, 2017, id. 33.10.3390/polym9020033Search in Google Scholar PubMed PubMed Central

[27] Chen, H., S. Han, C. Liu, Z. Luo, H. D. Shieh, R. Hsiao, et al. Investigation of PVDF-TrFE composite with nanofillers for sensitivity improvement. Sensors and Actuators a-Physical, Vol. 245, 2016, pp. 135–139.10.1016/j.sna.2016.04.056Search in Google Scholar

[28] Song, S., Z. Zheng, Y. Bi, X. Lv, and S. Sun. Improving the electroactive phase, thermal and dielectric properties of PVDF/graphene oxide composites by using methyl methacrylate-co-glycidyl methacrylate copolymers as compatibilizer. Journal of Materials Science, Vol. 54, No. 5, 2019, pp. 3832–3846.10.1007/s10853-018-3075-9Search in Google Scholar

[29] Cai, J., N. Hu, L. Wu, Y. Liu, Y. Li, H. Ning, et al. Preparing carbon black/graphene/PVDF-HFP hybrid composite films of high piezoelectricity for energy harvesting technology. Composites Part a-Applied Science and Manufacturing, Vol. 121, 2019, pp. 223–231.10.1016/j.compositesa.2019.03.031Search in Google Scholar

[30] Khalifa, M., S. Peravali, S. Varsha, and S. Anandhan. Piezoelectric energy harvesting using flexible self-poled electroactive nanofabrics based on PVDF/ZnO-decorated SWCNT nanocomposites. JOM, Vol. 74, No. 8, 2022, pp. 3162–3171.10.1007/s11837-022-05342-9Search in Google Scholar

[31] Sinha, T. K., S. K. Ghosh, R. Maiti, S. Jana, B. Adhikari, D. Mandal, et al. Graphene-silver-induced self-polarized PVDF-based flexible plasmonic nanogenerator toward the realization for new class of self powered optical sensor. ACS Applied Materials & Interfaces, Vol. 8, No. 24, 2016, pp. 14986–14993.10.1021/acsami.6b01547Search in Google Scholar PubMed

[32] Moezzi, M. D., M. Karrabi, and Y. Jahani. Influence of adding carbon black on electrical conductivity in dynamically vulcanized of poly (vinylidene fluoride)/fluoroelastomer composites. International Journal of Plastics Technology, Vol. 23, No. 1, 2019, pp. 46–55.10.1007/s12588-019-09235-6Search in Google Scholar

[33] Ke, K., P. Poetschke, N. Wiegand, B. Krause, and B. Voit. Tuning the network structure in poly(vinylidene fluoride)/carbon nanotube nanocomposites using carbon black: Toward improvements of conductivity and piezoresistive sensitivity. ACS Applied Materials & Interfaces, Vol. 8, No. 22, 2016, pp. 14190–14199.10.1021/acsami.6b03451Search in Google Scholar PubMed

[34] Li, T., W. Zhou, Y. Li, D. Cao, Y. Wang, G. Cao, et al. Synergy improvement of dielectric properties and thermal conductivity in PVDF composites with core-shell structured Ni@SiO2. Journal of Materials Science-Materials in Electronics, Vol. 32, No. 4, 2021, pp. 4076–4089.10.1007/s10854-020-05149-xSearch in Google Scholar

[35] Senthilkumar, N., K. J. Babu, G. G. Kumar, A. R. Kim, and D. J. Yoo. Flexible electrospun PVdF-HFP/Ni/Co membranes for efficient and highly selective enzyme free glucose detection. Industrial & Engineering Chemistry Research, Vol. 53, No. 25, 2014, pp. 10347–10357.10.1021/ie500755mSearch in Google Scholar

[36] Wu, L., Alamusi, J. Xue, T. Itoi, N. Hu, Y. Li, et al. Improved energy harvesting capability of poly(vinylidene fluoride) films modified by reduced graphene oxide. Journal of Intelligent Material Systems and Structures, Vol. 25, No. 14, 2014, pp. 1813–1824.10.1177/1045389X14529609Search in Google Scholar

[37] Wu, L., G. Huang, N. Hu, S. Fu, J. Qiu, Z. Wang, et al. Improvement of the piezoelectric properties of PVDF-HFP using AgNWs. Rsc Advances, Vol. 4, No. 68, 2014, pp. 35896–35903.10.1039/C4RA03382ESearch in Google Scholar

[38] Karan, S. K., R. Bera, S. Paria, A. K. Das, S. Maiti, and A. Maitra. An approach to design highly durable piezoelectric nanogenerator based on self-poled PVDF/AlO-rGO flexible nanocomposite with high power density and energy conversion efficiency. Advanced Energy Materials, Vol. 6, 2016, id. 1601016.10.1002/aenm.201601016Search in Google Scholar

[39] He, L., J. Lu, C. Han, X. Liu, J. Liu, and C. Zhang. Electrohydrodynamic pulling consolidated high-efficiency 3D printing to architect unusual self-polarized β-PVDF arrays for advanced piezoelectric sensing. Small, Vol. 18, 2022, id. 2200114.10.1002/smll.202200114Search in Google Scholar PubMed

[40] Yang, J., Y. Zhang, Y. Li, Z. Wang, W. Wang, Q. An, et al. Piezoelectric nanogenerators based on graphene oxide/PVDF electrospun nanofiber with enhanced performances by in-situ reduction. Materials Today Communications, Vol. 26, 2021, id. 101629.10.1016/j.mtcomm.2020.101629Search in Google Scholar

[41] Xue, Y., T. Yang, Y. Zheng, K. Wang, E. Wang, H. Wang, et al. Heterojunction engineering enhanced self-polarizaiton of PVDF/CsPbBr3/Ti3C2Tx composite fiber for ultra-high voltage piezoelectric nanogenerator. Advanced Science, Vol. 10, 2023, id. 2300650.10.1002/advs.202300650Search in Google Scholar PubMed PubMed Central

[42] Ponnamma, D., O. Aljarod, and H. Parangusan. Reduction in piezoelectric voltage generation for the cerium doped nickel ferrite nanoparticles filled with PVDF-HFP nanocomposite. Results in Physics, Vol. 13, 2019, id. 102130.10.1016/j.rinp.2019.02.066Search in Google Scholar

[43] Singh, H. D., S. Singh, and N. Khare. Design of flexible PVDF/NaNbO3/RGO nanogenerator and understanding the role of nanofillers in the output voltage signal. Composites Science and Technology, Vol. 149, 2017, pp. 127–133.10.1016/j.compscitech.2017.06.013Search in Google Scholar

[44] Yi, Y., Y. Song, S. Zhang, Z. Cao, C. Li, and C. Xiong. Corona-poled porous electrospun films of Gram-scale Y-doped ZnO and PVDF composites for piezoelectric nanogenerators. Polymers, Vol. 14, id. 3912.10.3390/polym14183912Search in Google Scholar PubMed PubMed Central

[45] Mahadeva, S., J. Berring, K. Walus, and B. Stoeber. Effect of poling time and grid voltage on phase transition and piezoelectricity of poly(vinylidene fluoride) thin films using corona poling. Journal of Physics D-Applied Physics, Vol. 46, No. 28, 2013, id. 285305.10.1088/0022-3727/46/28/285305Search in Google Scholar

[46] Lee, C. and J. Tarbutton. Electric poling-assisted additive manufacturing process for PVDF polymer-based piezoelectric device applications. Smart materials and structures, Vol. 23, No. 9, 2014, id. 095044.10.1088/0964-1726/23/9/095044Search in Google Scholar

[47] Li, L., M. Zhang, M. Rong, and W. Ruan. Studies on the transformation process of PVDF from alpha to beta phase by stretching. Rsc Advances, Vol. 4, No. 8, 2014, pp. 3938–3943.10.1039/C3RA45134HSearch in Google Scholar

[48] Lanceros-Mendez, S., J. F. Mano, A. M. Costa, and V. H. Schmidt. FTIR and DSC studies of mechanically deformed beta-PVDF films. Journal of Macromolecular Science-Physics, Vol. B40, No. 3–4, 2001, pp. 517–527.10.1081/MB-100106174Search in Google Scholar

[49] Tong, W., Y. Zhang, L. Yu, X. Luan, Q. An, Q. Zhang, et al. Novel method for the fabrication of flexible film with oriented arrays of graphene in poly(vinylidene fluoride-co-hexafluoropropylene) with low dielectric loss. Journal of Physical Chemistry C, Vol. 118, No. 20, 2014, pp. 10567–10573.10.1021/jp411828eSearch in Google Scholar

[50] Sencadas, V., R. Jr Gregorio, and S. Lanceros-Mendez. alpha to beta phase transformation and microestructural changes of PVDF films induced by uniaxial stretch. Journal of Macromolecular Science Part B-Physics, Vol. 48, No. 3, 2009, pp. 514–525.10.1080/00222340902837527Search in Google Scholar

[51] Mishra, S., L. Unnikrishnan, S. Nayak, and S. Mohanty. Advances in piezoelectric polymer composites for energy harvesting applications: a systematic review. Macromolecular Materials and Engineering, Vol. 304, No. 1, id. 1800463.10.1002/mame.201800463Search in Google Scholar

[52] Wang, W., H. Fan, and Y. Ye. Effect of electric field on the structure and piezoelectric properties of poly(vinylidene fluoride) studied by density functional theory. Polymer, Vol. 51, No. 15, 2010, pp. 3575–3581.10.1016/j.polymer.2010.05.021Search in Google Scholar

[53] Wu, L., Z. Jin, Y. Liu, H. Ning, X. Liu, Alamusi, et al. Recent advances in the preparation of PVDF-based piezoelectric materials. Nanotechnology Reviews, Vol. 11, No. 1, 2022, pp. 1386–1407.10.1515/ntrev-2022-0082Search in Google Scholar

[54] Furukawa, T. Ferroelectric properties of vinylidene fluoride copolymers. Phase Transitions: A Multinational Journal, Vol. 18, 2006, pp. 143–211.10.1080/01411598908206863Search in Google Scholar

[55] Garain, S., S. Jana, T. K. Sinha, and D. Mandal. Design of in situ poled Ce3+ -doped electrospun PVDF/graphene composite nanofibers for fabrication of nanopressure sensor and ultrasensitive acoustic nanogenerator. ACS Applied Materials & Interfaces, Vol. 8, No. 7, 2016, pp. 4532–4540.10.1021/acsami.5b11356Search in Google Scholar PubMed

[56] Zheng, H., X. Liu, X. Dou, and J. Chen. Effect of employing Ni and Ag nanoparticles as third phase on dielectric breakdown strength of BaTiO3/PVDF composites. Acta Materials Composite Sinica, Vol. 31, No. 1, 2014, pp. 146–151.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants