Abstract

In the face of fierce competition in the automotive market, severe environmental problems, and the consistent enhancement of consumer demands for vehicle performance, research and development for new automotive materials have increased. Fiber metal laminate (FML) is a representative hybrid composite in recent years but the application of FMLs in the automotive industry is still rare. In order to boost the strengths and applications of FMLs, a lot of effort has been put into enhancing their mechanical properties. In this review article, up-to-date information on the mechanical performance of FMLs for automotive components is presented. The mechanical testing methods, materials selection, structure design, fabrication methods, and the application of hybrid FMLs were explored. The objective of this review article is to study different factors that influence the mechanical properties of FMLs and provide some optimization directions from various aspects. From recent research, there will be great opportunities for hybrid FMLs utilizing natural fibers and bio-polymers in the automotive field in the future.

1 Introduction

In the automobile industry because of the formulation of emission reduction regulations and energy-saving strategies, manufacturers have explored different approaches for meeting fuel economy standards and consumer expectations without compromising performance [1]. Reducing weight is one of the most effective measures to reduce energy consumption and emissions, especially CO2 emissions [2]. According to research, a 25% reduction in weight would save 250 million barrels of crude oil for vehicles [3], and composites with a huge strength-to-weight ratio can contribute to weight savings ranging from 15 to 40% over metals [4]. Advanced metal alloy and fiber-reinforced polymer composites (FRP) are both competitive materials for automotive and are potentially able to achieve weight savings without compromising car safety or performance, hence reducing the final cost [5,6]. However, these materials have certain disadvantages, such as poor fatigue performance of metal alloys and poor residual and impact strength of FRP. Thus, automotive manufacturers are keen on innovating novel materials to replace traditional metals, which will help them in meeting increasingly stringent performance and weight targets that will ultimately improve fuel efficiency and reduce manufacturing costs without compromising safety [7,8].

The idea of fiber metal laminates (FMLs) was born at the Delft University of Technology in the late 1970s to partially combine the benefits of metal and FRP as well as overcome the shortcomings of both materials. Subsequently, the study of single materials has been slowed down as more and more research is being done on FML composites [9,10,11]. FMLs are composed of several metal layers stacked with alternating fiber composite layers that have various structures, including the sandwich structure, interlacing structure, and multi-stack structure [10]. The first FMLs were aramid fiber-reinforced aluminum laminates, and then the other well-known FMLs were glass laminate aluminum-reinforced epoxy (GLARE), carbon-reinforced aluminum laminate, titanium (Ti) and graphite fibers [12,13,14], etc. Compared to monolithic metals, FMLs have many advantages, including lower density, higher tensile strength, higher fatigue strength, and better impact damage resistance [11]. In addition, because of the increase in demand and the enhancement of environmental awareness, researchers are also committed to the research and development of bio-FMLs, which utilize natural resources such as natural fibers or bio-polymers [9,15,16,17]. However, the use of fully biobased FMLs is still limited due to insufficient mechanical properties and sensitivity to environmental impacts such as temperature, humidity, microbial population, and nutrient availability [18]. Thus, hybrid bio/synthetic FMLs (FML hybrid bio-materials with synthetic materials) are explored at present, and research studies have already proved that hybrid bio/synthetic FMLs have competitive mechanical performance compared to traditional FMLs, which could directly contribute to the principles of circular economy and sustainable development [19,20,21].

The mechanical performance of hybrid FMLs remains a major concern in automotive practice applications because of the interaction and interfacial bonding behavior of hybrid FMLs. It further gets complicated because of the diversity of material selection, the designability of structures, the selectivity of production methods, etc., Thus, more information is needed for the desired applications through continuous studies of different factors that influence the mechanical properties. In this review article, the latest developments in the mechanical performance of hybrid FMLs for the automotive industry were studied. The mechanical testing methods, materials selection, materials modification, structure design, fabrication methods, and the application of hybrid FMLs in the automotive industry were explored. In addition, some cutting-edge research on FMLs, such as nanoparticle-reinforced FMLs and three-dimensional (3D) fiber fabrics, was also discussed. This review pointed out the optimization directions for improving the adhesion of interfacial bonding from different aspects and helps readers recognize the great potential of hybrid FMLs utilizing bio-materials in the automotive industry that can aid in the development of innovative design and technology in this field of study.

2 Mechanical testing of FMLs

FMLs must undergo a variety of mechanical testing to ensure the safety and reliability of FMLs in the automotive field. In mechanical testing, mechanical performance is assessed to determine whether the material satisfies the requirements established by automotive manufacturers. Basically, hardness test, tensile test, bending test, interlaminar shear strength (ILSS) test, impact test, fatigue test, and vibration test are used to evaluate the mechanical performance of the FMLs for automotive applications. The recent research on the mechanical performance of FMLs is shown in Table 1. The tensile test applies a controlled tension to the sample until it fails completely. This method can obtain Young’s modulus, ultimate tensile strength, ductility, and Poisson’s ratio of the inverted material [15,22,23,24]. The flexural test determines the material’s mechanical properties when the composite is subjected to bending loads. The bending deformation between the plies and the bending modulus is highly dependent on layer delamination [25,26,27]. ILSS measures the resistance of composites to delamination under shear forces parallel to the laminate layer, and the ILSS testing can show the resistance of the interface adhesion of FMLs; a more adhesive interface means a higher ILSS value [16,28,29]. The fatigue test is indispensable to predict the fatigue life of FMLs and mainly includes fatigue crack initiation, fatigue crack propagation, and delamination [30]. The unique structure of FMLs results in a bridging effect during fatigue, which increases the crack propagation life by reducing the crack-tip effective stress intensity factor [31]. Thereby, FMLs usually exhibit excellent fatigue properties over metals and allow for flexible structural designs [30]. The impact test is a technique for determining the notch sensitivity and fracture toughness of composites. The impact resistance of FMLs varies depending on the fiber/matrix type, layering type, material thickness, sample geometry, and interface conditions [32]. In addition, one of the basic challenges for automotive design is vibration control in structures. The vibration test is a non-destructive dynamic mechanical test to evaluate the elasticity of composite materials [19,33]. Furthermore, natural fibers usually have a higher degree of variation in physical and mechanical performances. However, experimental studies on the dynamic behavior of natural fiber-reinforced composites are scarce in the literature [34].

Latest research studies on the mechanical performance of FMLs

| Fiber | Metal | Polymer | Fabrication | Mechanical tests | Ref. |

|---|---|---|---|---|---|

| Basalt/jute | Aluminum (Al) | Epoxy | Hand lay-up | Tensile, ILSS | [16] |

| Glass fiber (GF) | Aluminum–lithium alloys | Epoxy | Hot compression molding | Fatigue | [30] |

| Carbon fiber (CF) | Ti, Al | Epoxy | Autoclave | Impact | [35] |

| CF/bamboo, GF/bamboo, CF | Al | Epoxy | Hand lay-up | Vibration | [19] |

| Sisal | Al | Epoxy | Hand lay-up | Impact | [36] |

| Pineapple leaf | Al | Polypropylene (PP) | Hot compression molding | Tensile, flexural, impact | [15] |

| GF | Al | Epoxy | Vacuum-assisted resin transfer molding (VARTM) | Tensile, flexural | [26] |

| Coir/hemp | Al (plate and mesh) | Nanoparticles-modified epoxy | Autoclave | Tensile | [37] |

| GF | Al | Nanoparticles-modified epoxy | Hand lay-up | Tensile, fatigue | [38] |

| GF | Steel | Epoxy | Hand lay-up | ILSS | [29] |

| Kevlar, CF, GF | Al | Epoxy | VARTM | ILSS | [28] |

| Kenaf | Al | PP | Compression | Tensile | [9] |

| 3D GF | Magnesium (Mg), steel | Epoxy | Hand lay-up | Buckling Impact | [39] |

| CF | Al | Epoxy | Compression molding | Tensile, flexural, impact | [25] |

| Jute, aramid, CF | Al | Epoxy, polyvinyl butyral | Hot compression molding | Impact | [40] |

| CF, GF | Al | Epoxy | Hot press | Tensile, vibration | [33] |

| Jute/basalt | Al | Carbon nanotubes (CNTs)-modified epoxy | Hand lay-up | Flexural, ILSS | [41] |

3 Factors determining the mechanical properties of FMLs

Mechanical properties are essential properties in automotive material design. FMLs used in automotive parts must withstand high amounts of loads in different aspects to ensure the safety of the car. Researchers have shown that there are many parameters that influence mechanical properties, such as hybridization, fiber weight ratio, fiber orientation, layering sequence, layer thickness, fabrication method, etc. In total, there are four primary elements that determine the mechanical properties of FMLs, including the choice of materials, fabrication method, structure design, and surface modification. This part will discuss these four relevant factors through the latest research.

3.1 Choice of materials

The combination of dissimilar materials will directly determine the mechanical performance of FMLs. Therefore, choosing the materials used in FMLs is very important and should be considered in conjunction with the application. FMLs are mainly composed of three materials: metals, fiber reinforcements, and polymers.

3.1.1 Fiber reinforcements

Fibers usually have linear elasticity and are often used as reinforcing phases in composite materials to improve the mechanical properties of matrix materials. Fiber reinforcements can be divided into synthetic fibers and natural fibers. Synthetic fibers are made of synthetic polymer compounds, which have superior performance such as lightweight, high strength, good elasticity, and good resistance to water, heat, and chemical damage [35,42,43]. Due to these advantages, synthetic fiber composites have been applied to automobile ceilings, instrument panels, seat back, sound insulation [44], thermal insulation [45], damping materials [46], etc., and have started to be used in exterior car parts like tailgates and bumpers [35,42,47,48]. The characteristics of some common synthetic fibers are illustrated in Table 2. Among them, glass fiber-reinforced composites (GFRP) and carbon fiber-reinforced composites (CFRP), which have the potential to reduce mass by 25–35 and 40–70%, respectively, have gradually taken the lead as the preferred plastic body materials [48,49]. Nevertheless, synthetic fiber composites have many well-known drawbacks, such as their high cost, lack of energy-saving production, and some environmental damage caused by production and disposal.

Mechanical properties and the density of the commonly used synthetic fibers

| Fibers | Fiber diameter (µm) | Density (g·cm−3) | Tensile strength (MPa) | Tensile modulus (GPa) | Elongation at break (%) | Ref. |

|---|---|---|---|---|---|---|

| Acrylic | — | 1.17 | 207–1,000 | 14.6–19.6 | 7.5–50.0 | [50] |

| Aramid | — | 1.44 | 3,620 | 62–117 | 2.5–4.4 | [50] |

| Carbon | 5 | 1.765 | 3,144 | 265 | 1.18 | [51] |

| E-Glass | — | 2.3 | 2,000–2,800 | 71–76 | 2.2–2.6 | [1] |

| Kevlar | — | 1.33 | 532.08 | 38.52 | 1.59 | [52] |

| Nylon | 10–15 | 1.16 | 900 | 1.57 | — | [53] |

| Polyvinyl alcohol | — | 1.29–1.3 | 1,000–1,600 | 20–42.8 | 6–7 | [54] |

| PP | — | 0.91 | 240–900 | 1.5–12 | 15–80 | [54] |

| Polyethylene (PE) | — | 0.92–0.96 | 80–600 | 5–100 | 4–100 | [54] |

| Rock wool | — | 2.7 | 490–770 | 70–119 | 0.6 | [50] |

| Steel | 220 | 7.8 | 2,850 | 203 | — | [55] |

Compared to synthetic fibers, natural fiber has attracted much attention in the automotive industry in recent years due to its low-cost, lightweight, availability in abundance, eco-friendliness, and no brittle fracture, which can improve the safety of the car [50,51,56,57]. Researchers have already proved that the mechanical properties of some natural fiber-reinforced polymer composite (NFRP) obtain similar values to the currently used materials with lower weights and are expected to replace traditional materials in the automobile industry [52]. Depending on their sources, natural fibers can be divided into three categories: animal, mineral, and plant [53]. Some characteristics of the prevalent natural fibers are shown in Table 3. Launched in 2013, the BMW I3 is the first mass-produced car using natural fibers for the door panels and dashboard covers. After that, different natural fibers like banana, hemp, bamboo, flax, and jute have been used in door panels, backrests, dashboards, hoods, and other parts [3,54,55,56]. Ishak et al. [9] fabricated an automobile hood that consists of Al 5052 as the face sheet and two layers of woven kenaf fabric-reinforced PP. The results indicate that FMLs with natural fibers have greater potential to be shaped into complicated shapes compared to an Al sheet due to their superior formability. Meanwhile, the cost of NFRP is 5% lower than that of GFRP [7]. However, the mechanical properties of most natural fibers have drawbacks, such as degradation under thermal and moisture environments, higher variation, etc., and experimental studies on the dynamic behavior of NFRP are scarce in the literature [34]. Thus, the practical use of natural fibers in the automotive industry is constrained.

Mechanical properties and the density of the commonly used natural fibers

| Fibers | Fiber diameter (µm) | Density (g·cm−3) | Tensile strength (MPa) | Young’s modulus (GPa) | Elongation at break (%) | Ref. |

|---|---|---|---|---|---|---|

| Abaca | — | 1.5 | 400–677 | 34.4–41 | 3.4–11.1 | [58] |

| Bamboo | 10–50 | 0.6–1.1 | 540–630 | 11–17 | — | [59] |

| Banana | 80–250 | 1.35 | 529–759 | 8.20 | 1–3.5 | [6] |

| Basalt | 20 | 2.65 | 3,800–4,840 | 93.1–110 | — | [55] |

| Coir | 100–460 | 1.15 | 108–252 | 4–6 | 15–40 | [6] |

| Flax | — | 1.4–1.5 | 595–1,500 | 40–60 | 1.3–2.6 | [60] |

| Hemp | — | 1.48 | 690 | 70.0 | 1.6 | [59] |

| Jute | — | 1.2–1.5 | 138–550 | 20–60 | 0.4–1.8 | [60] |

| Kenaf | 81 | 1.4 | 250 | 4.3 | 4–5 | [6] |

| Oil palm | — | 0.7–1.55 | 248 | 25.0 | 3.2 | [59] |

| Pineapple | 5–80 | 1.44–1.526 | 170–1,627 | 6.26–82.5 | 0.8–1.6 | [61] |

| Ramie | 76–112 | 1.45–1.65 | 693–737 | 60–112 | 5–9 | [62] |

| Sisal | 50–300 | 1.45 | 227–400 | 9–20 | 2–14 | [6] |

To overcome the drawbacks and combine the benefits of synthetic and natural fibers, hybrid fibers are created by reinforcing two or more fibers. Many research results indicate that hybrid fiber-reinforced composites are incomparable to those that are possessed by single-fiber composites. Hybrid fibers can lower the restrictions of single fibers and balance the thermal properties, mechanical properties, and biodegradability of composites that can be widely used in automotive applications [47,63,64,65]. The combinations of hybrid fibers are diverse, involving heterogeneous fiber hybridization (natural fibers with synthetic fiber), and homogeneous fiber hybridization (natural fibers with natural fibers and synthetic fibers with synthetic fibers). Murugu Nachippan et al. [66] showed that hybrid heterogeneous fiber (GF with hemp)-reinforced polymers can be used for car bodies and bumpers, which have good impact strength compared to single GF composites and will be able to mitigate the negative impact on the driver in the event of a collision. Helaili et al. [22] also pointed out that the hybridization of a low volume ratio of natural fibers with GF has little effect on tensile strength. Natural fibers usually exhibit greater variation in mechanical properties and hybridization can minimize the effect [50]. Dadej and Bieniaś [47] carried out homogeneous fiber hybridization of GF/CF/Al composites and they proved that the hybridization of GF with CF improves the mechanical fatigue of FMLs. Besides, homogeneous hybridization of different natural fibers can be employed in car components that do not require extremely high mechanical properties but do require lightweight and recyclability such as internal door panels [67].

3.1.2 Polymers

The choice of polymer is crucial for bonding and strengthening FMLs. The high stiffness, strength, and impact resistance of these plastics make the vehicles safer and comply with modern government safety standards [68]. Polymers act as “binders” and protective agents that effectively hold fibers together to produce composites with outstanding performance [69]. Polymer matrix composites can be further divided into thermosetting plastics and thermoplastics [5]. Thermoplastic polymers are the most commonly used non-reinforced polymers that can be repeatedly softened by heating and then solidified by cooling. PP, polyamide, polyvinyl chloride, polyurethane, PE, and polycarbonate belong to the class of thermoplastics. Thermoplastics have a wide range of applications because they have high impact resistance and can be formed and reformed in so many shapes such as automobile bumpers, oil tanks, wheel covers, door panels, spoilers, etc. [8]. Thermosetting resin does not melt when heated but may eventually decompose. The commonly used thermosetting plastics are epoxy, polyester, and vinyl ester resins. Thermosetting polymers are strong and durable and they are primarily used in varnishes, automobiles, boat hulls, glues, and construction. In recent years, much research is done on bio-polymers for manufacturing green automotive products, such as polylactic acid, PP terephthalate, polybutylene succinate, polyethylene 2,5-furandicarboxylate, etc. [17]. Previous studies [58,59] proved that bio-polymer may be substituted for synthetic polymers in semi-structural applications such as automotive and structural applications.

3.1.3 Metals

Metals also play an important role in FMLs, which provide good strength, good thermal properties, high dimensional stability, and so on. Stainless steel, Ti, Mg, and Al are the currently used metals [60]. Steel alloy is widely used in the automobile industry but it is noticeably heavier than Mg and Al alloys [39]. Stainless steel-based FMLs were taken into consideration during the fabrication of FMLs in combination with CF. With the addition of steel plate layers to CFRP, the hybrid FMLs have a higher strain compared to CFRP, which can delay the premature failure of CFRP by up to 58.5% [61]. Ti has high stiffness, fatigue, yield stress, and impact resistance at high temperatures, which can meet the requirement in harsh environmental conditions. Mg alloy has a lower density than other metal constituents but the unique characteristics of Mg-based FMLs do not differ considerably from those of Al-based FMLs. So far, Al and its alloys are still the preferred choices due to their low density, good corrosion resistance, high specific tensile strength, electrical conductivities, and high damping capacity. Thus, Al alloy and its composites have been widely used in several automotive parts such as piston rings, engine block liners, bearings, rods, bonnets, gears, drive shafts, pumps, etc. [62,70].

In conclusion, metals, fiber reinforcements, and polymers are the three major components of FMLs, and the selection and combination of materials lead to a wide range of final composite mechanical properties. Furthermore, as environmental consciousness grows, more eco-friendly materials, such as natural fibers and bio-polymers, are being used in FML research. Aside from the research and development of entirely biobased materials, the hybridization of bio-materials and synthetic materials can combine the advantages and minimize the drawbacks of both materials that can be used in the automotive industry in the future for a better balance of performance, cost, and sustainability.

3.2 Structure design

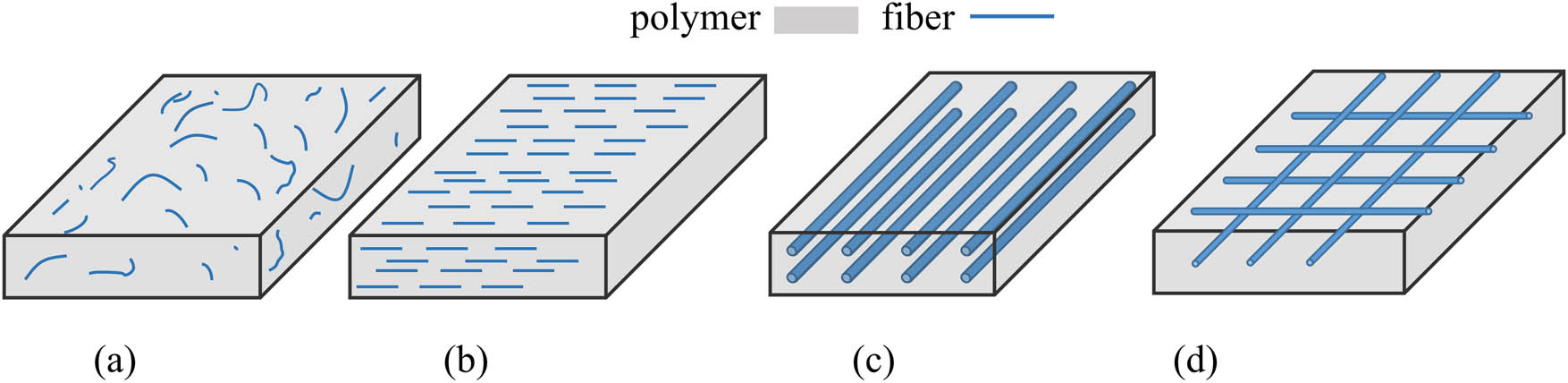

The structure of FMLs has a lot of design freedom, which includes the elements such as fiber distribution, layer orientation, fiber volume fraction, and stacking sequence. At first, the distribution and the orientation of the fiber in the matrix are indispensable in determining the mechanical properties of FMLs. Regardless of the fiber type, fiber distribution in the matrix can often be continuous or discontinuous. Figure 1 displays typical fiber-reinforced arrangements, which include discontinuous (short) fiber-reinforced materials with random and biased orientation, as well as continuous fiber-reinforced materials with unidirectional (UD) orientation or woven fabric [11]. Usually, the composite with UD fiber orientation is noticeably stiffer in the fiber direction than the composite with multiple fiber orientations [71]. In other words, fiber orientation perpendicular to the load direction (0° direction) gives better mechanical performance than the other fiber directions of composites [23].

Schematic illustration of typical fiber distribution in the matrix: (a) random orientation, (b) biased orientation, (c) UD, and (d) woven.

Second, the mechanical characteristics of FMLs are significantly influenced by the stacking sequence of the composites. During FML fabrication, there are various layering sequences such as sandwich, interlacing, and multi-stack that lead to various mechanical performances [10]. Hynes et al. [25] compared two different stacking sequences of CLARE. The results show that Al/CF/Al/CF/Al has significantly better tensile, impact, and ultimate load-bearing properties compared to CF/Al/CF/Al/CF. Zareei et al. [16] fabricated FMLs utilizing basalt (B), jute (J), and Al, and they compared the mechanical properties of two intercalated structures (Al/J/B/J/B/J/B/Al and Al/B/J/B/J/B/J/Al) and two sandwiched structures (Al/J/J/B/B/J/J/Al and Al/B/B/J/J/B/B/Al). The results showed that the sandwich structure (Al/J/J/B/B/J/J/Al) had the highest tensile strength, elastic modulus, and ILSS values. Recently, Prakash and Jaisingh [72] came up with the idea of embedding Al mesh into a GF layer to increase the viscosity and toughness of the interface by increasing the contact area of the metal with polymer resin. Megahed et al. [13] followed a similar idea of incorporating Al wire meshes with GF/epoxy, and they found that different locations of Al layers significantly affected the adhesion properties of FMLs. Dariushi et al. [73] fabricated FMLs with VARTM. The results show that drilled Al sheets can facilitate better resin infiltration into dry fiber layers. However, it is worth mentioning that while holes in metal sheets can improve the bonding between metal and resin, they can also reduce their mechanical properties and resistance to environmental impact. As a result, the number and size of holes must be carefully designed to avoid degrading mechanical properties.

The number of layers also influences the mechanical performance of FMLs. The special structure of FMLs results in a bridging effect during fatigue, which increases the crack propagation life by reducing the effective stress intensity factor at the crack tip [31]. Thereby, FMLs usually exhibit excellent fatigue properties over metals and allow for flexible designs [30]. Under the same loading conditions, the bridging effect of FMLs becomes more evident as increasing the number of layers, which improves the mechanical properties of the composite [30]. However, the number of layers should be controlled to some extent and need to be considered in conjunction with the layer sequence. Annamalai et al. [24] concluded that a specimen of a 3/4 layup sequence of GLARE displayed superior flexural and tensile strength than a 5/4 layup sequence GLARE. This result shows that the mechanical properties will decrease because of poor interfacial bonding between the metal layer and FRP layer, which leads to delamination of FMLs that makes it evident that more number of layers lead to more bridging effect. Besides, the volume ratio of each component in FMLs, including the ratio of fiber, metal, and polymer, will also affect the mechanical properties of the composite. In addition, when utilizing natural fibers, the natural fiber’s volume ratio should be designed carefully. In most cases, composites with a lower volume ratio of the natural fiber have higher strength values [23].

In addition, three-dimensional fiber metal laminates (3DFMLs) have been attracting much attention in recent years [39,40,74]. As we know, delamination is the most common failure of traditional FMLs (2 DFMLs), which have no reinforcing fiber between adjacent plies so that they are held together solely by the matrix polymer. The development of composites where a polymer matrix is reinforced by a three-dimensional woven fabric is a promising approach for avoiding these disadvantages. The comparison of conventional FMLs and 3DFMLs is shown in Figure 2. Well-designed 3DFMLs have better debonding resistance, can provide better damage tolerance, and have higher impact resistance than stitched or traditional 2D woven fabrics. One of the usual types of 3DFMLs is formed by using a truly 3D GF fabric [74]. De Cicco and Taheri [39] investigated two different 3DFMLs: the Mg/3D GF/epoxy and steel/3D GF/epoxy FMLs. They recommended incorporating relatively softer and thicker skins when developing a 3D-FML for a certain stiffness, which the inherent inhomogeneity of the 3D GF fabric component of the FMLs could induce. Furthermore, a recent study also found that natural fibers can be made into 3D characters that can be used as FML reinforcements. Hussain et al. [40] fabricated novel FMLs, which is a hybrid Al/plain–woven skin (made with jute, aramid, CFs)/3D woven jute core-reinforced polymer. From the low-velocity impact test, the FMLs reinforced with aramid/3D–jute core offered superior LVI resistance as compared to other reinforcements.

The comparison of conventional FMLs (2DFMLs) with 3DFMLs: (a) 2DFMLs and (b) 3DFMLs.

In summary, structure design parameters like fiber orientation, layer sequence, number of layers, and materials ratio will directly influence the performance of FMLs, and thus, should be determined in a reasonable range. In addition, in order to optimize the poor adhesion disadvantages of FMLs, some novel trails such as drilling holes in the metal layer, mesh structure, 3DFMLs, etc., are explored in recent research.

3.3 Fabrication methods for FMLs

Until 2000, the main manufacturing methods of FMLs were bending and layering techniques that allow the fabrication of FMLs with simple geometry only. Since the twenty-first century, researchers started to pay attention to the forming process of FMLs with complex shapes, especially the die-forming technology. The authors proved that adhesively bonded technology is far more fatigue-resistant than mechanically bonded technology during the bonding of FMLs. In terms of current technology, for the production of large-size automotive products, based on the consideration of production cost and production efficiency, many manufacturers still use some traditional processing methods to fabricate FMLs [75]. Hand lay-up is one of the common techniques of FML fabrication in the automotive industry. The first operation is to apply a release film to the single-side mold in order to easily de-mold. Subsequently, adding the Gelcoat protects the final product from the external environment and a clear exterior surface is obtained. The laminates are then laid by hand and the resin is poured or sprayed. Finally, FMLs are obtained by the curing reaction [76]. The hand lay-up technique can quickly startup, requiring simple equipment and tooling, and thus, the cost of hand lay-up is lower than other manufacturing processes. Moreover, the hand lay-up technique can make very large and complex parts and hence is widely used in the production of FMLs [19,27,77]. However, the disadvantages of the hand lay-up technique are high cycle time, poor production environment, and the quality dependent on the skill of the employee, which often results in uneven mechanical strength of composites [78].

The autoclave was invented by Charles Chamberland in 1879 and is also a popular fabrication method for FMLs which requires higher temperatures and pressures [47,79]. In the autoclave process, prepregs are laid up with designed layers and bagged under a vacuum. Then, the setup is placed in an autoclave and heated, allowing the resin to melt and flow, thereby curing the laminate. The autoclave process can produce high-performance components, which makes it suitable for aircraft and automotive components. However, the temperature and pressure of the prepreg need to be studied, and the isotherm temperature will obviously affect the final degree of density, cure, and void portion of laminate composites by autoclaves [80]. Second, it is easy to generate compressive residual stress in FMLs due to the different thermal expansion coefficients of alloys and composites. Moreover, the process has high operating costs, requires high-temperature and high-pressure energy consumption, and is not appropriate for the production of large components.

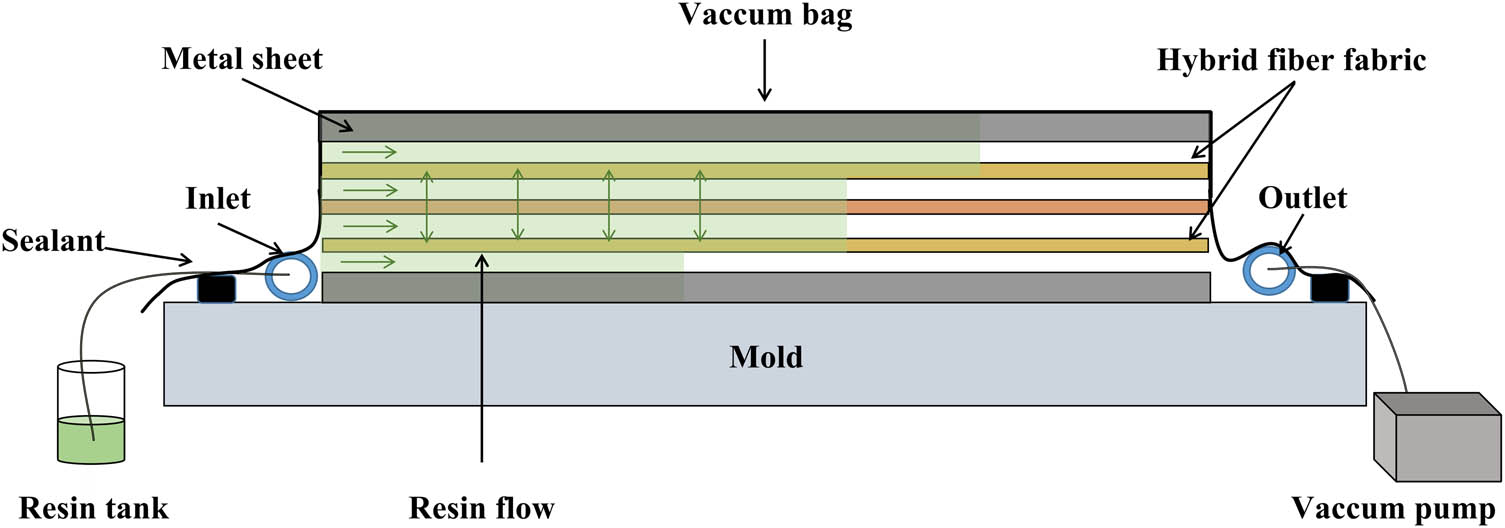

VARTM also uses a one-sided rigid die, and the dry fiber and metal sheet are laid on the template in order and covered with flexible bag film (Figure 3). The resin is drawn into the mold by making a vacuum in the mold. After filling the cavity with the resin, the resin is cured and solidified into a composite [75]. VARTM is an improvement of resin transfer molding and has several processing advantages. First, VARTM can fully wet FMLs with a high fiber volume fraction and provide good interfacial bonding [81]. The final FML composites exhibited excellent properties that can be apparently attributed to the intimate contact between each layer, ensuring good consolidation to remove void or dry spots [26]. In addition, VARTM can fabricate composites ranging from simple to complex, saving processing time. Essentially, VARTM has a good balance of properties, accuracy, and cost [60]. Thus, VARTM is considered to be used for manufacturing larger structures such as car hoods, ship hulls, and turbine blades [7]. However, the location of the inlet and outlet, curing time, temperature, etc., must be considered in VARTM in order to produce high-quality FMLs [28]. In addition, the surface finish at the vacuum bag side is not as perfect as the mold side surface, and continuous inspection is essential throughout the infusion process [82].

Schematic illustration of VARTM for FML fabrication.

In summary, autoclaves have high product performance and dimensional tolerances, and low defects but the cost is high. Hand lay-up is the cheapest and easy to operate and is suitable for manufacturing large products, but open molding has a poor working environment and unstable product quality. VARTM is a very efficient and low-cost molding method for products with low porosity and good performance that has become one of the main fabrication processes for automotive composites.

3.4 Metal surface modification and fiber treatment

FMLs for the automotive industry should have the ability to face inadvertent issues such as sudden drop-offs, vibration, and impacts. However, the interfacial bonding of FMLs has prevented their wider applications. Therefore, considerable research efforts have been devoted to increasing the interfacial bonding for extending the service lives of FMLs. According to previous studies, the interfacial bonding of FMLs can be strengthened by fiber treatment and metal surface modification for improving mechanical performance.

3.4.1 Metal surface modification

One of the main drawbacks of FMLs is the poor adhesion of metal with the polymer. Metal surface modification is a common method to improve the adhesion of metal with the matrix. Generally, metal surface treatments can be categorized into mechanical treatments, chemical treatments, electrochemical treatments, applying adhesion prompter, etc. Grinding or abrading Al sheets is the simplest way to improve the interfacial adhesion between Al and the FRP. The surface roughness of metal can be enhanced by abrading, which increases the adhesion strength of laminates [83]. Compared with degreasing and sanding, chemical treatment improves the adhesion of thermoplastic-based FMLs more effectively because chemically treated surfaces tend to be wetter, coarser, and cleaner [84]. With the improvement of technology, some unconventional metal surface modification methods emerged, such as anodizing, plasma, forest product laboratory (FPL), etc. Lin et al. [85] found that the plasma surface treatment increased the interfacial adhesion of the Al alloy sheet and the GF-reinforced PP layer, and they also pointed out that plasma surface treatment outperforms phosphoric anodic oxidation in the production of FMLs. Karunagaran et al. [29] observed the ILSS behavior of steel wire mesh/GF-reinforced composites, in which the GF was treated by sulfuric corrosive and sodium hydroxide independently and the metal was treated by electropolishing and sandblasting. The results showed that the ILSS values of FMLs in both GF and metal treated were higher than that in non-treated samples, and the acid-treated GF/sandblast mesh reinforced composite exhibited higher ILSS than other hybrid laminates. Zhu et al. [86] explored AA6061-based FMLs by sanding, silane surface modification, and anodizing. The results revealed that the strongest interfacial bonding was found in FMLs after anodizing. The nano-porous anodized film on the Al surface increased the wettability of CFRP on Al sheets. Shamohammadi Maryan et al. [83] compared the fatigue life of FMLs where the Al was treated by alkaline etching, mechanical abrading, anodizing surface modification, and FPL. Based on the fatigue results, the FPL surface modification resulted in the highest fatigue cycles of 2155.

3.4.2 Fiber treatment

Fiber treatment is another effective preparation method for the better mechanical performance of FMLs containing natural fibers by increasing the durability and modifying the characteristics of natural fibers [56]. The weak adhesion between the hydrophilic fiber and the hydrophobic polymer matrix is the main disadvantage of natural FMLs. Chemical treatment is the most commonly used method for natural fiber treatment that can effectively improve both the mechanical and morphological properties of the composite [87]. The fiber–alkali solution reaction is accountable for the removal of fiber constituents such as lignin, hemicellulose, pectin, surface impurities, and so on [88]. After the treatment, the crystallinity of the treated fiber changed slightly compared with the untreated fiber, and the treated fiber has the largest surface roughness and tensile strength [89]. NaOH and KOH treatments are effective in modifying the natural fiber surface. Senthilkumar et al. found that KOH-treated composites have better damping properties than NaOH-treated and untreated composites [88]. In addition, recent works have greatly increased the number of other modification methods such as grafting, silane treatment, plasma treating, electrochemical, and gamma radiation. Silane treatments of natural fiber surfaces involve a chemical reaction in the liquid or vapor phases. Youbi et al. [90] studied the effect of silane treatments and alkali on Raphia vinifera fibers and they found that compared with chemical treatment, the 5% silane in 60 min presents the best surface energy without deteriorating the surface of the fiber. Sepe et al. [91] also evaluated the impact of silane treatment and alkali on the mechanical performance of hemp fiber-reinforced epoxy composites. However, compared with untreated and alkali-treated fiber composites, silane treatment was found to have a limited effect on the composites’ mechanical properties. Plasma surface activation involves replacing surface polymer functional groups with some other atoms of ions in the plasma to boost surface energy. Plasma contains high levels of UV radiation, which creates additional free radicals on the natural fiber surface [92]. Gamma radiation is another effective and economical modification method to rearrange the internal structure of the natural fiber and reduce its hydrophilic nature through strong ionizing radiation. Patra et al. [93] used gamma irradiation to modify Luffa Cylindrica fibers; the flexural and tensile strengths were improved by 155 and 60%, respectively. However, because an excessive radiation dose gradually diminishes the properties of natural fibers, a precise level of radiation dosage must be carefully designed [94].

Therefore, metal surface modification and fiber treatment are common methods for improving the interfacial bonding of FMLs. Among various treatment methods, chemical treatment is an effective, straightforward, and cost-effective treatment procedure before the fabrication of FMLs.

3.5 Nanoparticles in FMLs

A remedy for improving the fracture toughness and stiffness of polymers can be provided by nanoparticles, which have higher hardness and strength. To date, a number of studies demonstrated that the addition of nanoparticles into FMLs can significantly enhance the mechanical properties of FMLs [38,95,96,97]. Generally, nanoparticles can be added to the matrix or to the interface of the metal layers and the composite core [41]. Previous studies have already discussed some well-known toughening micro-mechanisms of nanoparticles such as crack tip pinning, microcracks, crack bridging, plastic void growth, etc. [98]. Recent works have focused on improving the strength of nanoparticles on FMLs.

It is worth mentioning that the types of nanoparticles had a significant effect on the mechanical properties of FMLs. One of the well-known nanoparticles in the reinforcement of FMLs was carbon-based nanomaterials such as CNTs and graphene nanoplatelets (GNPs) due to their remarkable mechanical, thermal, and electrical performances [95,99,100,101,102,103,104]. Mirzamohammadi et al. [97] evaluated the effect of CNT addition in hybrid jute/basalt/Al laminates, and the results suggest that hybrid FMLs with 0.3 wt% CNTs improved the most in tensile strength, elastic modulus, and impact energy. Wang et al. [95] investigated the impact of GNPs on CF-reinforced metal laminates. The experimental analysis revealed that FMLs containing 0.3 wt% GNPs had the best impact properties, while FMLs containing 0.5 wt% GNPs had the greatest improvement in fracture strain, flexural strength, and modulus.

Besides carbon-based nanoparticles, other nanomaterials such as nano-clay (NC), oxide nanoparticles, and metal nanoparticles have also been studied for FMLs by many researchers [105,106,107]. Prasad et al. [38] observed the influence of nanoalumina on GLARE, and their findings indicate that the inclusion of nanoalumina greatly improved the tensile strength, stiffness, and fatigue life of FMLs by enhancing the matrix and interfacial characteristics. In addition, compared to carbon-based nanofillers, nanoalumina needs less fabrication cost with good thermal and mechanical performances. Megahed et al. [107] studied the effects of metal nanoparticles (aluminum and copper), titanium oxide (TiO2), silica (SiO2), aluminum oxide (Al2O3), and NC on the mechanical properties of GLARE. The results demonstrate that GLARE filled with SiO2 generated the most remarkable improvement in strength, modulus, and toughness when compared to neat GLARE, and GLARE filled with Al2O3 nanoparticles caused the greatest increase in ILSS. However, adding TiO2 and NC weakened interfacial bonding, resulting in a drop in the FML mechanical characteristics. Saleh et al. [106] compared the effect of CNTs and SiO2 on the quasi-static behavior of FMLs. The results indicate that the energy absorption capacity of FMLs obviously increased with the addition of 0.6 wt% CNT and 3 wt% SiO2. Rahmani et al. [108] proved that the impact characteristics of Al/CF/epoxy laminates improved the most when 3 wt% nano-zirconia (ZrO2) was added to the laminates. Furthermore, it is worth noting that surface modification of nanoparticles had a substantial impact on the performance of the FML. Bahari-Sambran et al. [105] examined the mechanical characteristics of Al/CF/epoxy laminates with modified and unaltered NC particles. The results indicate that the flexural and impact properties of FMLs with 3 wt%-modified NC were significantly superior to those of FMLs with unmodified NC. Furthermore, they compared the effects of different weight percentages of modified NC and found that increasing the nanoparticle weight percentage enhanced the flexural modulus.

In summary, the inclusion of nanoparticles in FMLs boosts the mechanical performance of composites. Some parameters such as the types of nanoparticles, nanoparticle concentration, size, etc., will affect the enhancing impact and thus should be regulated during reinforcement. In future research, innovative nanoparticles, such as co-reinforced and modified nanoparticles, should be developed. In addition, the dispersion methods of nanoparticles in FMLs must be explored because the ideal uniform dispersion in FMLs remains challenging to achieve in practice. Furthermore, additional research is necessary to investigate how the nanoparticles affect FMLs in atypical environmental conditions, such as thermal and moisture [102].

4 Recent developments of FMLs in the automotive industry

In the automotive industry, FMLs are suitable for mass production [109] and have a high potential for achieving comparable structural properties with weight reduction by around 25% compared to a full-metal material [10]. In recent years, researchers have been constantly exploring advanced processing methods, new materials, and novel structures of FMLs for the automotive industry. For fabrication methods, Heggemann and Homberg [110] fabricated hybrid high-strength steel alloys/CFRP laminates by deep drawing, and they stated that deep drawing is appropriate for the flat bottom parts, which can be used for large-scale production of the lightweight car body. Harhash et al. [111] fabricated top-hat “crash boxes” of FMLs (Al or steel/GF) by one-step hot-forming technology, which can be used as crash absorbers in the automotive fields. In addition, many novel features and structures of FMLs such as metal foam, honeycomb, and 3DFMLs emerged and have been developed and also can be used for automotive components [112]. Besides the conventional FMLs, in order to achieve sustainable development, green automotive composite materials such as FMLs utilizing natural fibers and bio-polymers have emerged and been introduced to the market as eco-friendly substitutes for non-biodegradable materials [12,13]. Natural fibers in FMLs are already being for automotive components, and the results show that the natural FMLs are more formable than a single Al sheet and can be formed into more complex shapes [9]. Feng et al. [15] fabricated a novel structure of Al laminates based on the cellulosic woven pineapple leaf fiber. The findings demonstrated that the FMLs utilizing PALF could be considered promising and sustainable materials in future structural applications. Some bio-composites are also used in the automotive industry such as body-shell, full-electric vehicles, automobile interiors, and frame structural parts [52].

5 Conclusion

To summarize, faced with the requirement of high performance and low fuel consumption in the automotive industry, the research on the development of hybrid FMLs to create lighter and better-performance automotive products is at a rapid pace. The excellent mechanical properties are the premise and assurance of automotive safety; thus, the optimization of the mechanical performance of hybrid FMLs has seen a lot of research. This review studied many works to date on hybrid FMLs and provides a thorough survey and evaluation of the mechanical performance of hybrid FMLs. The commonly used mechanical testing methods were reviewed, and several factors that influence the mechanical performance of FMLs are summarized as follows:

The selections of materials for FMLs are diverse, and the mechanical properties are different with different fibers, metals, and polymers. Hybridization of bio-materials and synthetic materials can combine the advantages and minimize the drawbacks of both materials for a better balance of comprehensive performance, cost, and sustainability in the automotive industry in the future.

The structure design space of FMLs is infinite. The fiber distribution, layer orientation, materials ratio, and layer sequence will significantly affect the mechanical properties of FMLs, which need to be designed carefully.

For fabrication methods, many conventional methods still account for a large part of the automotive industry due to the balance of mass production and cost.

Interfacial adhesion should be emphasized for good mechanical properties of FMLs. Fiber treatment and metal surface modification will improve interfacial bonding. Besides, hybridization, increasing the contact area between the metal and resin, 3DFMLs, and the addition of nanoparticles all benefit to strengthen the interfacial adhesion, thus improving the mechanical properties.

However, research on FMLs in the automotive industry remains rare. To expand the practice and application of FMLs in the automobile industry, additional research is required. Based on recent research, fully bio-based FMLs, hybrid bio/synthetic FMLs, novel architectures, and multi-hybrid FMLs (such as hybrid fibers and the addition of nanoparticles simultaneously) are a trend. It is worth noting that when combining FMLs with bio-materials, the balance of density, mechanical performance, water absorption, thermal properties, and cost needs to be considered based on the practice applications in the future.

Acknowledgments

The authors would like to thank the Department of Aerospace Engineering, Faculty of Engineering, Universiti Putra Malaysia, and Laboratory of Biocomposite Technology, Institute of Tropical Forestry and Forest Product (INTROP - HICOE), Universiti Putra Malaysia for the close collaboration in this research.

-

Funding information: The authors would like to thank Universiti Putra Malaysia for the financial support through Geran Inisiatif Putra Siswazah (GP-IPS) with grant number 9739200.

-

Author contributions: Hanyue Xiao: conceptualization, writing – original draft, writing – review and editing; Mohamed Thariq Hameed Sultan: supervision, writing – review and editing, funding; Farah Syazwani Shahar: supervision, writing – review and editing, project administration; Milan Gaff: writing – review and editing, funding; David Hui: writing – review and editing, funding. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: David Hui, who is the co-author of this article, is a current Editorial Board member of Nanotechnology Reviews on Advanced Materials Science. This fact did not affect the peer-review process. The authors declare no other conflict of interest.

-

Data availability statement: Data sharing is not applicable to this article as no new data were created or analyzed in this study.

References

[1] Khalid, M. Y., A. Al Rashid, Z. U. Arif, M. F. Sheikh, H. Arshad, and M. A. Nasir. Tensile strength evaluation of glass/jute fibers reinforced composites: An experimental and numerical approach. Results in Engineering, Vol. 10, 2021, id. 100232.10.1016/j.rineng.2021.100232Search in Google Scholar

[2] Hagnell, M. K., S. Kumaraswamy, T. Nyman, and M. Åkermo. From aviation to automotive – A study on material selection and its implication on cost and weight efficient structural composite and sandwich designs. Heliyon, Vol. 6, No. 3, 2020, id. e03716.10.1016/j.heliyon.2020.e03716Search in Google Scholar PubMed PubMed Central

[3] Omar, M. F., H. Jaya, and N. N. Zulkepli. Kenaf fiber reinforced composite in the automotive industry. In Encyclopedia of renewable and sustainable materials, Hashmi, S. and I. A. Choudhury, eds., Elsevier, Oxford, 2020, pp. 95–101.10.1016/B978-0-12-803581-8.11429-8Search in Google Scholar

[4] Zhang, W. and J. Xu. Advanced lightweight materials for automobiles: A review. Materials & Design, Vol. 221, 2022, id. 110994.10.1016/j.matdes.2022.110994Search in Google Scholar

[5] Rajak, D. K., D. D. Pagar, P. L. Menezes, and E. Linul. Fiber-reinforced polymer composites: manufacturing, properties, and applications. Polymers, Vol. 11, No. 10, 2019, pp. 1–37.10.3390/polym11101667Search in Google Scholar PubMed PubMed Central

[6] Sreenivas, H. T., N. Krishnamurthy, and G. R. Arpitha. A comprehensive review on light weight kenaf fiber for automobiles. International Journal of Lightweight Materials and Manufacture, Vol. 3, No. 4, 2020, pp. 328–337.10.1016/j.ijlmm.2020.05.003Search in Google Scholar

[7] Sarfraz, M. S., H. Hong, and S. S. Kim. Recent developments in the manufacturing technologies of composite components and their cost-effectiveness in the automotive industry: A review study. Composite Structures, Vol. 266, 2021, id. 113864.10.1016/j.compstruct.2021.113864Search in Google Scholar

[8] Girijappa, Y. G. T., V. Ayyappan, M. Puttegowda, S. M. Rangappa, J. Parameswaranpillai, and S. Siengchin. Plastics in automotive applications. In Encyclopedia of materials: Plastics and polymers, Hashmi, M. S. J. ed., Elsevier, Oxford, 2022, pp. 103–113.10.1016/B978-0-12-820352-1.00052-3Search in Google Scholar

[9] Ishak, N. M., S. Dhar Malingam, M. R. Mansor, N. Razali, Z. Mustafa, and A. F. Ab Ghani. Investigation of natural fibre metal laminate as car front hood. Materials Research Express, Vol. 8, No. 2, 2021, id. 025303.10.1088/2053-1591/abe49dSearch in Google Scholar

[10] Ding, Z., H. Wang, J. Luo, and N. Li. A review on forming technologies of fibre metal laminates. International Journal of Lightweight Materials and Manufacture, Vol. 4, No. 1, 2021, pp. 110–126.10.1016/j.ijlmm.2020.06.006Search in Google Scholar

[11] Vasiliev, V. V. and E. V. Morozov. Chapter 4 - Failure criteria and strength of laminates. In Advanced mechanics of composite materials and structures, 4th edn, Vasiliev, V. V. and E. V. Morozov, eds., Elsevier, United Kingdom, 2018, pp. 243–294.10.1016/B978-0-08-102209-2.00004-9Search in Google Scholar

[12] Koh, L. M. and S. M. Khor. Current state and future prospects of sensors for evaluating polymer biodegradability and sensors made from biodegradable polymers: A review. Analytica Chimica Acta, Vol. 1217, 2022, id. 339989.10.1016/j.aca.2022.339989Search in Google Scholar PubMed

[13] Megahed, A. A., F. Abd El-Wadoud, A. Wagih, and A. M. Kabeel. Effect of incorporating aluminum wire mesh on the notched and un-notched strengths of glass fiber/epoxy composites. Composite Structures, Vol. 263, 2021, id. 113695.10.1016/j.compstruct.2021.113695Search in Google Scholar

[14] Podolak, P., P. Jakubczak, and J. Bieniaś. Influence of constitutive metal model on the numerical prediction of the impact behaviour of titanium-based Fibre Metal Laminates. International Journal of Impact Engineering, Vol. 169, 2022, id. 104342.10.1016/j.ijimpeng.2022.104342Search in Google Scholar

[15] Feng, N. L., S. Dhar Malingam, N. Mohd Ishak, and K. Subramaniam. Novel sandwich structure of composite-metal laminates based on cellulosic woven pineapple leaf fibre. Journal of Sandwich Structures & Materials, Vol. 23, No. 7, 2020, pp. 3450–3465.10.1177/1099636220931479Search in Google Scholar

[16] Zareei, N., A. Geranmayeh, and R. Eslami-Farsani. Interlaminar shear strength and tensile properties of environmentally-friendly fiber metal laminates reinforced by hybrid basalt and jute fibers. Polymer Testing, Vol. 75, 2019, pp. 205–212.10.1016/j.polymertesting.2019.02.002Search in Google Scholar

[17] Ding, W., Y. Li, M. Chen, R. Chen, X. Tian, H. Yin, et al. Bio-based polyesters: Recent progress and future prospects. Progress in Polymer Science, Vol. 120, 2021, id. 101430.10.1016/j.progpolymsci.2021.101430Search in Google Scholar

[18] Brebu, M. Environmental degradation of plastic composites with natural fillers—A review. Polymers, Vol. 12, No. 1, 2020, id. 166.10.3390/polym12010166Search in Google Scholar PubMed PubMed Central

[19] Kali, N., S. Pathak, and S. Korla. Effect on vibration characteristics of fiber metal laminates sandwiched with natural fibers. Materials Today: Proceedings, Vol. 28, 2020, pp. 1092–1096.10.1016/j.matpr.2020.01.088Search in Google Scholar

[20] Wong, M., H. Hei, S. Z. Lim, and E. Y. Ng. Mechanical characterization of aluminum sandwich structures with woven-ply pineapple leaf/glass fiber-reinforced hybrid composite core. Journal of Natural Fibers, Vol. 20, No. 1, 2023, id. 2160404.10.1080/15440478.2022.2160404Search in Google Scholar

[21] Germano Braga, G., F. Assunção Rosa, J. César dos Santos, G. G. del Pino, T. H. Panzera, and F. Scarpa. Fully biobased composite and fiber-metal laminates reinforced with Cynodon spp. fibers. Polymer Composites, Vol. 44, No. 1, 2023, pp. 453–464.10.1002/pc.27109Search in Google Scholar

[22] Helaili, S., M. Chafra, and Y. Chevalier. Natural fiber alfa/epoxy randomly reinforced composite mechanical properties identification. Structures, Vol. 34, 2021, pp. 542–549.10.1016/j.istruc.2021.07.095Search in Google Scholar

[23] Batu, T. and H. Lemu. Investigation of mechanical properties of false banana/glass fiber reinforced hybrid composite materials. Results in Materials, Vol. 8, 2020, id. 100152.10.1016/j.rinma.2020.100152Search in Google Scholar

[24] Annamalai, I., K. Karthik, N. Kumar, S. Muthuselvan, M. Vignesh, and Y. J. Dhanush. Experimental investigation of mechanical properties of GLARE composite with different layup sequences. Materials Today: Proceedings, Vol. 46, 2021, pp. 1371–1375.10.1016/j.matpr.2021.02.487Search in Google Scholar

[25] Hynes, N. R. J., N. J. Vignesh, J. T. W. Jappes, P. S. Velu, C. Barile, M. A. Ali, et al. Effect of stacking sequence of fibre metal laminates with carbon fibre reinforced composites on mechanical attributes: Numerical simulations and experimental validation. Composites Science and Technology, Vol. 221, 2022, id. 109303.10.1016/j.compscitech.2022.109303Search in Google Scholar

[26] Vasudevan, A., B. Navin Kumar, M. Victor Depoures, T. Maridurai, and V. Mohanavel. Tensile and flexural behaviour of glass fibre reinforced plastic – Aluminium hybrid laminate manufactured by vacuum resin transfer moulding technique (VARTM). Materials Today: Proceedings, Vol. 37, 2021, pp. 2132–2140.10.1016/j.matpr.2020.07.573Search in Google Scholar

[27] Dhanaraj, R., N. Venkateshwaran, M. Chenthil, M. S. Natarajan, V. Santhanam, and S. Baskar. Experimental investigation on the mechanical properties of glass fiber with perforated aluminum sheet reinforced epoxy composite. Materials Today: Proceedings, Vol. 37, 2021, pp. 1880–1883.10.1016/j.matpr.2020.07.456Search in Google Scholar

[28] Khalid, M. Y., Z. U. Arif, A. Al Rashid, M. I. Shahid, W. Ahmed, A. F. Tariq, et al. Interlaminar shear strength (ILSS) characterization of fiber metal laminates (FMLs) manufactured through VARTM process. Forces in Mechanics, Vol. 4, 2021, id. 100038.10.1016/j.finmec.2021.100038Search in Google Scholar

[29] Karunagaran, N., G. Bharathiraja, A. Muniappan, and P. NanthaKumar. Interlaminar shear strength behaviour of surface treated steel wire mesh/glass fibre reinforced hybrid composite laminate. Materials Today: Proceedings, Vol. 46, 2021, pp. 3993–3996.10.1016/j.matpr.2021.02.528Search in Google Scholar

[30] Meng, W., Y. Li, X. Zhang, Y. Zhang, Y. Wang, and X. Huang. Analysis and prediction on total fatigue life problems of fiber reinforced metal laminates under two-stage loading. Composite Structures, Vol. 237, 2020, id. 111960.10.1016/j.compstruct.2020.111960Search in Google Scholar

[31] Kadhim, M. M. and F. A. Alshamma. Investigation of analytical model of crack propagation under multi axial fatigue in fiber metal laminate. Composites Part C: Open Access, Vol. 9, 2022, id. 100305.10.1016/j.jcomc.2022.100305Search in Google Scholar

[32] Andrew, J. J., S. M. Srinivasan, A. Arockiarajan, and H. N. Dhakal. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review. Composite Structures, Vol. 224, 2019, id. 111007.10.1016/j.compstruct.2019.111007Search in Google Scholar

[33] Merzuki, M. N. M., Q. Ma, M. R. M. Rejab, M. S. M. Sani, and B. Zhang. Experimental and numerical investigation of fibre-metal-laminates (FMLs) under free vibration analysis. Materials Today: Proceedings, Vol. 48, 2022, pp. 854–860.10.1016/j.matpr.2021.02.409Search in Google Scholar

[34] Prasad, E. and S. Sahu. Vibration analysis of woven fiber metal laminated plates—experimental and numerical studies. International Journal of Structural Stability and Dynamics, Vol. 18, No. 11, 2018, id. 1850144.10.1142/S0219455418501444Search in Google Scholar

[35] Raghav Arvind, T., D. Roshann Ram Dayal, K. L. Hari Krishna, and S. Survesh. Mechanical characterization and comparison of glass fibre and glass fibre reinforced with aluminium alloy (GFRAA) for automotive application. Materials Today: Proceedings, Vol. 46, 2021, pp. 1181–1186.10.1016/j.matpr.2021.02.062Search in Google Scholar

[36] Rashidi, S., C. Vieira, R. Tuteja, R. Mansouri, M. Ali-Hassanzadeh, A. Muro, et al. Impact properties of novel natural fibre metal laminated composite materials. Applied Sciences, Vol. 12, 2022, pp. 1–11.10.3390/app12041869Search in Google Scholar

[37] Naveen, R., M. Kumar, C. Shwetha, and R. Rishekesh. Sound absorbing performance of hybrid fiber metal laminate composites. In ASCEND 2020, American Institute of Aeronautics and Astronautics, 2020.Search in Google Scholar

[38] Prasad, E. V., C. Sivateja, and S. K. Sahu. Effect of nanoalumina on fatigue characteristics of fiber metal laminates. Polymer Testing, Vol. 85, 2020, id. 106441.10.1016/j.polymertesting.2020.106441Search in Google Scholar

[39] De Cicco, D. and F. Taheri. Performances of magnesium- and steel-based 3D fiber-metal laminates under various loading conditions. Composite Structures, Vol. 229, 2019, id. 111390.10.1016/j.compstruct.2019.111390Search in Google Scholar

[40] Hussain, M., A. Imad, Y. Nawab, A. Saouab, C. Herbelot, and T. Kanit. Effect of matrix and hybrid reinforcement on fibre metal laminates under low–velocity impact loading. Composite Structures, Vol. 288, 2022, id. 115371.10.1016/j.compstruct.2022.115371Search in Google Scholar

[41] Mirzamohammadi, S., R. Eslami-Farsani, and H. Ebrahimnezhad-Khaljiri. The characterization of the flexural and shear performances of laminated aluminum/jute–basalt fibers epoxy composites containing carbon nanotubes: As multi-scale hybrid structures. Thin-Walled Structures, Vol. 179, 2022, id. 109690.10.1016/j.tws.2022.109690Search in Google Scholar

[42] Shao, Y., M. Matsushita, Y. Lyu, and Y. Yang. Flexural properties and low-cycle bending fatigue of anisotropic carbon fiber mat reinforced composites. Journal of Physics: Conference Series, Vol. 1790, No. 1, 2021, id. 012077.10.1088/1742-6596/1790/1/012077Search in Google Scholar

[43] Radhakrishnan, G. and S. Mathialagan. Effect of fiber orientation on mechanical behavior of glass fiber reinforced polyethylene terephthalate foam sandwich composite. Materials Today: Proceedings, Vol. 62, 2022, pp. 624–628.10.1016/j.matpr.2022.03.623Search in Google Scholar

[44] Qian, L., T. Liang, L. Jinzhe, C. Yao, X. Zhengkang, L. Jiatong, et al. Multifunctional aramid nanofibers reinforced RGO aerogels integrated with high-efficiency microwave absorption, sound absorption and heat insulation performance. Journal of Materials Science & Technology, Vol. 130, 2022, pp. 166–175.10.1016/j.jmst.2022.05.014Search in Google Scholar

[45] Sun, Y., J. Pei, X. Chen, M. Lin, Y. Pan, Y. Zhang, et al. Experimental investigation of C-shaped glass-fiber-reinforced polymer connectors for sandwich insulation wall panels. Engineering Structures, Vol. 250, 2022, id. 113462.10.1016/j.engstruct.2021.113462Search in Google Scholar

[46] Karthik, K., N. K. Unnam, J. Thamilarasan, S. Kolappan, and R. Rameshkumar. Design and analysis of cantilever beam used Kevlar fiber composite for automobile applications. Materials Today: Proceedings, Vol. 59, 2022, pp. 1817–1823.10.1016/j.matpr.2022.04.389Search in Google Scholar

[47] Dadej, K. and J. Bieniaś. On fatigue stress-cycle curves of carbon, glass and hybrid carbon/glass-reinforced fibre metal laminates. International Journal of Fatigue, Vol. 140, 2020, id. 105843.10.1016/j.ijfatigue.2020.105843Search in Google Scholar

[48] Bernardi, C., B. Toury, M. Salvia, E. Contraires, F. Dubreuil, F. Virelizier, et al. Effects of flaming on polypropylene long glass fiber composites for automotive bonding applications with polyurethane. International Journal of Adhesion and Adhesives, Vol. 113, 2022, id. 103033.10.1016/j.ijadhadh.2021.103033Search in Google Scholar

[49] Kim, J., J. Lee, C. Jo, and C. Kang. Development of low cost carbon fibers based on chlorinated polyvinyl chloride(CPVC) for automotive applications. Materials & Design, Vol. 204, 2021, id. 109682.10.1016/j.matdes.2021.109682Search in Google Scholar

[50] Jesthi, D. K., S. Nayak, S. Saroj, and J. Sadarang. Evaluation of flexural and vibration property of glass/bamboo/jute hybrid fiber composite in hydrothermal environment. Materials Today: Proceedings, Vol. 49, 2022, pp. 491–496.10.1016/j.matpr.2021.03.062Search in Google Scholar

[51] Selvaraj, R., A. Maneengam, and M. Sathiyamoorthy. Characterization of mechanical and dynamic properties of natural fiber reinforced laminated composite multiple-core sandwich plates. Composite Structures, Vol. 284, 2022, id. 115141.10.1016/j.compstruct.2021.115141Search in Google Scholar

[52] Oliver-Ortega, H., F. Julian, F. X. Espinach, Q. Tarrés, M. Ardanuy, and P. Mutjé. Research on the use of lignocellulosic fibers reinforced bio-polyamide 11 with composites for automotive parts: Car door handle case study. Journal of Cleaner Production, Vol. 226, 2019, pp. 64–73.10.1016/j.jclepro.2019.04.047Search in Google Scholar

[53] Nurazzi, N. M., M. Asyraf, S. F. Athiyah, S. S. Shazleen, S. A. Rafiqah, M. M. Harussani, et al. A review on mechanical performance of hybrid natural fiber polymer composites for structural applications. Polymers, Vol. 13, No. 13, 2021, pp. 1–47.10.3390/polym13132170Search in Google Scholar PubMed PubMed Central

[54] Singh, S., G. Singh, C. Prakash, S. Ramakrishna, L. Lamberti, and C. I. Pruncu. 3D printed biodegradable composites: An insight into mechanical properties of PLA/chitosan scaffold. Polymer Testing, Vol. 89, 2020, id. 106722.10.1016/j.polymertesting.2020.106722Search in Google Scholar

[55] Bhowmik, R., S. Das, D. Mallick, and S. S. Gautam. Predicting the elastic properties of hemp fiber – A comparative study on different polymer composite. Materials Today: Proceedings, Vol. 50, 2022, pp. 2510–2514.10.1016/j.matpr.2021.09.562Search in Google Scholar

[56] Sahu, P. and M. Gupta. A review on the properties of natural fibres and its bio-composites: Effect of alkali treatment. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, Vol. 234, No. 1, 2020, pp. 198–217.10.1177/1464420719875163Search in Google Scholar

[57] Asim, M., M. T. Paridah, M. Chandrasekar, R. M. Shahroze, M. Jawaid, M. Nasir, et al. Thermal stability of natural fibers and their polymer composites. Iranian Polymer Journal, Vol. 29, No. 7, 2020, pp. 625–648.10.1007/s13726-020-00824-6Search in Google Scholar

[58] Yorseng, K., S. Mavinkere Rangappa, J. Parameswaranpillai, and S. Siengchin. Towards green composites: Bioepoxy composites reinforced with bamboo/basalt/carbon fabrics. Journal of Cleaner Production, Vol. 363, 2022, id. 132314.10.1016/j.jclepro.2022.132314Search in Google Scholar

[59] George, A., M. R. Sanjay, R. Srisuk, J. Parameswaranpillai, and S. Siengchin. A comprehensive review on chemical properties and applications of biopolymers and their composites. International Journal of Biological Macromolecules, Vol. 154, 2020, pp. 329–338.10.1016/j.ijbiomac.2020.03.120Search in Google Scholar PubMed

[60] Kazemi, M. E., L. Shanmugam, L. Yang, and J. Yang. A review on the hybrid titanium composite laminates (HTCLs) with focuses on surface treatments, fabrications, and mechanical properties. Composites Part A: Applied Science and Manufacturing, Vol. 128, 2020, id. 105679.10.1016/j.compositesa.2019.105679Search in Google Scholar

[61] Muflikhun, M. A., R. Higuchi, T. Yokozeki, and T. Aoki. The evaluation of failure mode behavior of CFRP/Adhesive/SPCC hybrid thin laminates under axial and flexural loading for structural applications. Composites Part B: Engineering, Vol. 185, 2020, id. 107747.10.1016/j.compositesb.2020.107747Search in Google Scholar

[62] Xie, X., S. Yin, R. Raoelison, C. Chen, C. Verdy, W. Li, et al. Al matrix composites fabricated by solid-state cold spray deposition: A critical review. Journal of Materials Science & Technology, Vol. 86, 2021, pp. 20–55.10.1016/j.jmst.2021.01.026Search in Google Scholar

[63] Ravi, Y. V., N. Kapilan, S. Rajole, Y. S. Balaji, N. Varun Kumar Reddy, and B. K. Venkatesha. Damage resistance evaluation of E-glass and hybrid hemp-banana natural fiber composite helmet using drop weight impact test. Materials Today: Proceedings, Vol. 54, 2022, pp. 330–335.10.1016/j.matpr.2021.09.213Search in Google Scholar

[64] Ahmadijokani, F., A. Shojaei, S. Dordanihaghighi, E. Jafarpour, S. Mohammadi, and M. Arjmand. Effects of hybrid carbon-aramid fiber on performance of non-asbestos organic brake friction composites. Wear, Vol. 452–453, 2020, id. 203280.10.1016/j.wear.2020.203280Search in Google Scholar

[65] Lawrence Sy, B., D. Oguamanam, and H. Bougherara. Impact response of a new kevlar/flax/epoxy hybrid composite using infrared thermography and high-speed imaging. Composite Structures, Vol. 280, 2022, id. 114885.10.1016/j.compstruct.2021.114885Search in Google Scholar

[66] Murugu Nachippan, N., M. Alphonse, V. K. Bupesh Raja, S. Shasidhar, G. Varun Teja, and R. Harinath Reddy. Experimental investigation of hemp fiber hybrid composite material for automotive application. Materials Today: Proceedings, Vol. 44, 2021, pp. 3666–3672.10.1016/j.matpr.2020.10.798Search in Google Scholar

[67] Getu, D., R. B. Nallamothu, M. Masresha, S. K. Nallamothu, and A. K. Nallamothu. Production and characterization of bamboo and sisal fiber reinforced hybrid composite for interior automotive body application. Materials Today: Proceedings, Vol. 38, 2021, pp. 2853–2860.10.1016/j.matpr.2020.08.780Search in Google Scholar

[68] Farfan-Cabrera, L. I., M. Tapia-Gaspar, and J. Pérez-González. Tribology of polymer matrix composites within the automotive industry. In Encyclopedia of materials: Composites, D. Brabazon, ed., Elsevier, Oxford, 2021, pp. 970–982.10.1016/B978-0-12-819724-0.00029-XSearch in Google Scholar

[69] Shi, X.-H., X. L. Li, Y. M. Li, Z. Li, and D. Y. Wang. Flame-retardant strategy and mechanism of fiber reinforced polymeric composite: A review. Composites Part B: Engineering, Vol. 233, 2022, id. 109663.10.1016/j.compositesb.2022.109663Search in Google Scholar

[70] Imran, M. and A. R. A. Khan. Characterization of Al-7075 metal matrix composites: a review. Journal of Materials Research and Technology, Vol. 8, No. 3, 2019, pp. 3347–3356.10.1016/j.jmrt.2017.10.012Search in Google Scholar

[71] Swolfs, Y., I. Verpoest, and L. Gorbatikh. Recent advances in fibre-hybrid composites: materials selection, opportunities and applications. International Materials Reviews, Vol. 64, No. 4, 2019, pp. 181–215.10.1080/09506608.2018.1467365Search in Google Scholar

[72] Prakash, V. R. A. and S. J. Jaisingh. Mechanical strength behaviour of silane treated e-glass fibre/Al 6061 & SS-304 wire mesh reinforced epoxy resin hybrid composite. Silicon, Vol. 10, No. 5, 2018, pp. 2279–2286.10.1007/s12633-018-9762-ySearch in Google Scholar

[73] Dariushi, S., S. Farahmandnia, and A. M. Rezadoust. An experimental investigation on infusion time and strength of fiber metal laminates made by vacuum infusion process. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, Vol. 235, No. 8, 2020, pp. 1800–1808.10.1177/1464420720941890Search in Google Scholar

[74] Asaee, Z. and F. Taheri. A practical analytical model for predicting the low-velocity impact response of 3D-fiber metal laminates. Mechanics of Advanced Materials and Structures, Vol. 27, No. 1, 2020, pp. 20–33.10.1080/15376494.2018.1472328Search in Google Scholar

[75] Kumar, A. and D. Kumar. Vacuum assisted resin transfer Moulding process review and variability analysis using Taguchi optimization technique. Materials Today: Proceedings, Vol. 50, 2022, pp. 1472–1479.10.1016/j.matpr.2021.09.055Search in Google Scholar

[76] Raji, M., H. Abdellaoui, H. Essabir, C. -A. Kakou, R. Bouhfid, and A. Qaiss. 3 - Prediction of the cyclic durability of woven-hybrid composites. In Durability and life prediction in biocomposites, fibre-reinforced composites and hybrid composites, M. Jawaid, Thariq, M., Saba, N., eds., Woodhead Publishing, United Kingdom, 2019, pp. 27–62.10.1016/B978-0-08-102290-0.00003-9Search in Google Scholar

[77] Hasan, M. Z. Experimental and analytical assessment of the hypervelocity impact damage of GLAss fiber REinforced aluminum. Defence Technology, Vol. 18, No. 7, 2022, pp. 1232–1246.10.1016/j.dt.2021.05.018Search in Google Scholar

[78] Balasubramanian, K., M. T. H. Sultan, and N. Rajeswari. 4 - Manufacturing techniques of composites for aerospace applications. In Sustainable composites for aerospace applications, Jawaid M. and M. Thariq, eds., Woodhead Publishing, United Kingdom, 2018, pp. 55–67.10.1016/B978-0-08-102131-6.00004-9Search in Google Scholar

[79] Al-Furjan, M. S. H., L. Shan, X. Shen, M. S. Zarei, M. H. Hajmohammad, and R. Kolahchi. A review on fabrication techniques and tensile properties of glass, carbon, and Kevlar fiber reinforced rolymer composites. Journal of Materials Research and Technology, Vol. 19, 2022, pp. 2930–2959.10.1016/j.jmrt.2022.06.008Search in Google Scholar

[80] Baghad, A. and K. El Mabrouk. The isothermal curing kinetics of a new carbon fiber/epoxy resin and the physical properties of its autoclaved composite laminates. Materials Today: Proceedings, Vol. 57, 2022, pp. 922–929.10.1016/j.matpr.2022.03.050Search in Google Scholar

[81] Mamalis, D., W. Obande, V. Koutsos, J. R. Blackford, C. M. Ó. Brádaigh, and D. Ray. Novel thermoplastic fibre-metal laminates manufactured by vacuum resin infusion: The effect of surface treatments on interfacial bonding. Materials & Design, Vol. 162, 2019, pp. 331–344.10.1016/j.matdes.2018.11.048Search in Google Scholar

[82] Tamakuwala, V. R. Manufacturing of fiber reinforced polymer by using VARTM process: A review. Materials Today: Proceedings, Vol. 44, 2021, pp. 987–993.10.1016/j.matpr.2020.11.102Search in Google Scholar

[83] Shamohammadi Maryan, M., H. Ebrahimnezhad-Khaljiri, and R. Eslami-Farsani. The experimental assessment of the various surface modifications on the tensile and fatigue behaviors of laminated aluminum/aramid fibers-epoxy composites. International Journal of Fatigue, Vol. 154, 2022, id. 106560.10.1016/j.ijfatigue.2021.106560Search in Google Scholar

[84] Gonzalez-Canche, N. G., E. A. Flores-Johnson, P. Cortes, and J. G. Carrillo. Evaluation of surface treatments on 5052-H32 aluminum alloy for enhancing the interfacial adhesion of thermoplastic-based fiber metal laminates. International Journal of Adhesion and Adhesives, Vol. 82, 2018, pp. 90–99.10.1016/j.ijadhadh.2018.01.003Search in Google Scholar

[85] Lin, Y., H. Li, Q. Wang, Z. Gong, and J. Tao. Effect of plasma surface treatment of aluminum alloy sheet on the properties of Al/Gf/PP laminates. Applied Surface Science, Vol. 507, 2020, id. 145062.10.1016/j.apsusc.2019.145062Search in Google Scholar

[86] Zhu, W., H. Xiao, J. Wang, and C. Fu. Characterization and properties of AA6061-based fiber metal laminates with different aluminum-surface pretreatments. Composite Structures, Vol. 227, 2019, id. 111321.10.1016/j.compstruct.2019.111321Search in Google Scholar

[87] Senthilkumar, K., N. Rajini, N. Saba, M. Chandrasekar, M. Jawaid, and S. Siengchin. Effect of alkali treatment on mechanical and morphological properties of pineapple leaf fibre/polyester composites. Journal of Polymers and the Environment, Vol. 27, No. 6, 2019, pp. 1191–1201.10.1007/s10924-019-01418-xSearch in Google Scholar

[88] Senthilkumar, K., N. Saba, M. Chandrasekar, M. Jawaid, N. Rajini, S. Siengchin, et al. Compressive, dynamic and thermo-mechanical properties of cellulosic pineapple leaf fibre/polyester composites: Influence of alkali treatment on adhesion. International Journal of Adhesion and Adhesives, Vol. 106, 2021, id. 102823.10.1016/j.ijadhadh.2021.102823Search in Google Scholar

[89] Najeeb, M. I., M. T. H. Sultan, Y. Andou, A. U. M. Shah, K. Eksiler, M. Jawaid, et al. Characterization of silane treated Malaysian Yankee Pineapple AC6 leaf fiber (PALF) towards industrial applications. Journal of Materials Research and Technology, Vol. 9, No. 3, 2020, pp. 3128–3139.10.1016/j.jmrt.2020.01.058Search in Google Scholar

[90] Youbi, S. B. T., N. R. S. Tagne, O. Harzallah, P. W. M. Huisken, T. T. Stanislas, E. Njeugna, et al. Effect of alkali and silane treatments on the surface energy and mechanical performances of Raphia vinifera fibres. Industrial Crops and Products, Vol. 190, 2022, id. 115854.10.1016/j.indcrop.2022.115854Search in Google Scholar

[91] Sepe, R., F. Bollino, L. Boccarusso, and F. Caputo. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Composites Part B: Engineering, Vol. 133, 2018, pp. 210–217.10.1016/j.compositesb.2017.09.030Search in Google Scholar

[92] Ravi, M., R. R. Dubey, A. Shome, S. Guha, and C. Anil Kumar. Effect of surface treatment on Natural fibers composite. IOP Conference Series: Materials Science and Engineering, Vol. 376, No. 1, 2018, id. 012053.10.1088/1757-899X/376/1/012053Search in Google Scholar

[93] Patra, S., K. L. Mohanta, and C. Parida. Mechanical analysis of bio-composites using gamma irradiated fibers of Luffa Cylindrica. In ICICCT 2019 – System Reliability, Quality Control, Safety, Maintenance and Management, Springer Singapore, Singapore, 2020.10.1007/978-981-13-8461-5_28Search in Google Scholar

[94] Motaleb, K. Z. M. A., R. Milašius, and A. Ahad. Influence of Gamma Radiation on Mechanical Properties of Jute Fabric-Reinforced Polymer Composites. Fibers, Vol. 8, 2020, id. 58.10.3390/fib8090058Search in Google Scholar

[95] Wang, S., M. Cao, H. Xue, S. Araby, F. Abbassi, Y. He, et al. Investigation on graphene addition on the quasi-static and dynamic responses of carbon fibre-reinforced metal laminates. Thin-Walled Structures, Vol. 174, 2022, id. 109092.10.1016/j.tws.2022.109092Search in Google Scholar

[96] Kali, N., R. Korla, and S. Korla. Influence of nanoparticles on mechanical properties of hybrid polymer-layered fibre metal laminates (FMLs). Transactions of the Indian Institute of Metals, Vol. 75, No. 8, 2022, pp. 1979–1988.10.1007/s12666-022-02584-8Search in Google Scholar

[97] Mirzamohammadi, S., R. Eslami-Farsani, and H. Ebrahimnezhad-Khaljiri. The experimental assessment of carbon nanotubes incorporation on the tensile and impact properties of fiber metal laminate fabricated by jute/basalt fabrics-aluminum layers: As hybrid structures. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, Vol. 237, No. 8, pp. 1877–1886.10.1177/09544062221134223Search in Google Scholar

[98] Tsang, W. L. and A. C. Taylor. Fracture and toughening mechanisms of silica- and core–shell rubber-toughened epoxy at ambient and low temperature. Journal of Materials Science, Vol. 54, No. 22, 2019, pp. 13938–13958.10.1007/s10853-019-03893-ySearch in Google Scholar

[99] Khoramishad, H., H. Alikhani, and S. Dariushi. An experimental study on the effect of adding multi-walled carbon nanotubes on high-velocity impact behavior of fiber metal laminates. Composite Structures, Vol. 201, 2018, pp. 561–569.10.1016/j.compstruct.2018.06.085Search in Google Scholar

[100] De Cicco, D. and F. Taheri. Effect of functionalized graphene nanoplatelets on the delamination-buckling and delamination propagation resistance of 3D fiber-metal laminates under different loading rates. Nanomaterials, Vol. 9, 2019, pp. 1–23.10.3390/nano9101482Search in Google Scholar PubMed PubMed Central

[101] Araby, S., B. Philips, Q. Meng, J. Ma, T. Laoui, and C. H. Wang. Recent advances in carbon-based nanomaterials for flame retardant polymers and composites. Composites Part B: Engineering, Vol. 212, 2021, id. 108675.10.1016/j.compositesb.2021.108675Search in Google Scholar

[102] Eslami-Farsani, R., H. Aghamohammadi, S. M. R. Khalili, H. Ebrahimnezhad-Khaljiri, and H. Jalali. Recent trend in developing advanced fiber metal laminates reinforced with nanoparticles: A review study. Journal of Industrial Textiles, Vol. 51, No. 5_suppl, 2020, pp. 7374S–7408S.10.1177/1528083720947106Search in Google Scholar

[103] Meng, Q., V. Kenelak, A. Chand, H. Kang, S. Han, and T. Liu. A highly flexible, electrically conductive, and mechanically robust graphene/epoxy composite film for its self-damage detection. Journal of Applied Polymer Science, Vol. 137, No. 34, 2020, id. 48991.10.1002/app.48991Search in Google Scholar