Abstract

The article presents the results of a study on the non-destructive evaluation of fiber–cement boards exposed to high temperatures, conducted using integrated methods such as scanning electron microscopy (SEM) and acoustic emission (AE). Fiber–cement, widely used as facade cladding in construction, undergoes significant microstructural and mechanical changes when exposed to high temperatures, particularly in the degradation of synthetic fibers such as polypropylene (PP) and polyvinyl alcohol (PVA). This study showed that the AE method allows for the early detection of damage, such as microcracks and the separation of fibers from the cement matrix, before these changes become visible in SEM analysis. In turn, SEM provided detailed images of microstructural damage, including cracks and porosity. The results confirm the effectiveness of integrating SEM and AE methods, allowing for a more accurate assessment of the material’s technical condition after exposure to high temperatures.

1 Introduction

Fiber–cement boards are widely used in construction, especially for ventilated facades, due to their thermal insulation properties, durability, and aesthetic appeal. These materials are highly resistant to weather conditions and mechanical damage, making them a popular choice in the building industry. However, exposure to extreme conditions, such as fire, causes significant changes in their microstructure, which can greatly reduce the material’s strength. Evaluating the technical condition of fiber–cement boards after fire exposure is essential to ensure the safe future use of the building.

Fiber–cement is a multi-phase composite consisting of a cement matrix, usually based on Portland cement, and a dispersed phase of fibers, including cellulose and synthetic fibers, such as polypropylene (PP) and polyvinyl alcohol (PVA) [1,2]. Cellulose fibers reinforce the material by forming a fiber network, which increases its bending strength and resistance to other mechanical loads [3]. On the other hand, synthetic fibers improve the material’s flexibility and resistance to dynamic loads [4]. However, as shown by Schabowicz et al. [5], these properties are highly dependent on the operating conditions, especially exposure to high temperatures.

To evaluate the technical condition of fiber–cement after fire exposure, non-destructive testing (NDT) methods are increasingly used. The most common techniques include scanning electron microscopy (SEM), which allows for the analysis of microstructures, and acoustic emission (AE), which monitors crack propagation in real-time. The integration of these two methods can provide detailed information on the material’s degradation process under high temperatures and is a foundation for assessing its further usability [6,7].

2 Literature review

2.1 Fiber–cement as a composite material

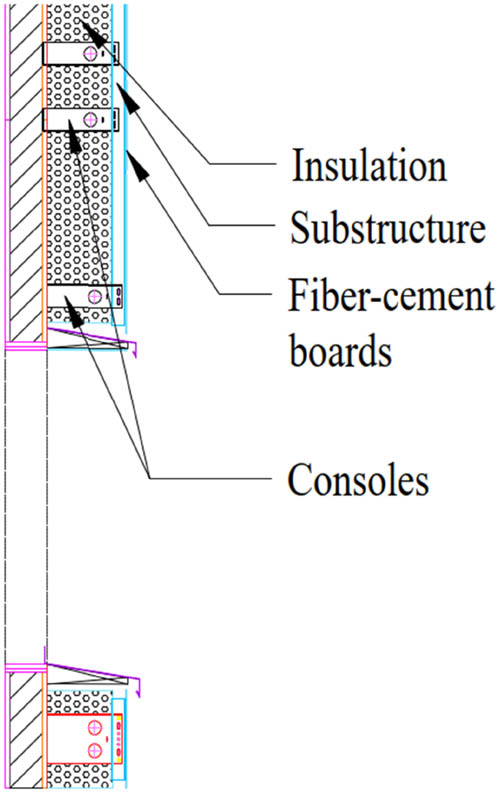

Fiber–cement is widely used in building facades due to its combination of mechanical durability and resistance to varying atmospheric conditions. Its structure is based on a cement matrix reinforced by cellulose and synthetic fibers (PP and PVA), which provide structural reinforcement [2]. Cellulose fibers enhance the material’s bending strength and dynamic load resistance, while synthetic fibers like PP and PVA are more vulnerable to high temperatures, which significantly affect the composite’s degradation under extreme conditions [4]. Figure 1 shows a schematic representation of the two phases of the composite – fiber–cement boards.

![Figure 1

Two phases of the fiber–cement boards [2].](/document/doi/10.1515/eng-2025-0108/asset/graphic/j_eng-2025-0108_fig_001.jpg)

Two phases of the fiber–cement boards [2].

2.2 Degradation of fiber–cement composites under high temperatures

High temperatures, such as those experienced during fires, significantly impact the microstructure and mechanical properties of fiber–cement. Synthetic fibers degrade at relatively low temperatures – PP at 175°C and PVA at 220°C [2]. This degradation reduces the load-bearing capacity of the composite, weakening its structural integrity. Cellulose fibers, although more thermally resistant, start decomposing at around 260–270°C [8,9]. The degradation of fibers leads to the formation of microcracks and the separation of fibers from the cement matrix, reducing the material’s overall strength [7]. Studies indicate that above 400°C, the material begins to lose significant strength, confirmed by both bending tests and microstructural analyses [8]. When temperatures reach 600–800°C, these materials may undergo complete delamination, resulting in a drastic reduction in load-bearing capacity [9,10]. Degradation under such conditions depends on both synthetic and cellulose fibers, which play a key role in maintaining structural integrity [11].

2.3 NDT methods in composite analysis

In assessing composite materials like fiber–cement, NDT methods play a key role in evaluating the structural and mechanical properties without damaging the material. Techniques such as SEM and AE are particularly useful in the study of composites after fire exposure. SEM provides high-resolution images that identify microcracks, delaminations, and changes in the cement matrix and reinforcing fibers [12]. SEM can successfully be used to analyze the microstructural damage of composites, especially after exposure to high temperatures. AE is a technique that monitors dynamic changes in the material by recording acoustic waves generated by crack propagation [13,14]. This method allows for real-time tracking of degradation processes in composites exposed to high temperatures [15]. AE can effectively detect early stages of cracking in fiber composites.

2.4 Integration of SEM and AE methods

Integrating SEM and AE techniques enables the collection of detailed data about the technical condition of a material, encompassing both microstructural damage and cracking processes. Gorzelańczyk et al. [14] showed that AE allows for the monitoring of dynamic processes, such as crack propagation, while SEM provides visual data on microstructural degradation.

The correlation between microstructural changes detected by SEM and the intensity of AE signals is based on the combined monitoring of material degradation processes. Both approaches provide insights into damage mechanisms, albeit at different levels of detail:

Microstructural variability:

SEM identification: SEM enables the detection of microscopic defects such as microcracks, fiber–matrix separation, decohesion, and changes in material texture.

Degradation stages: Observed changes can be attributed to specific stages of material degradation, such as crack initiation, propagation, or final delamination.

AE signal intensity:

Monitoring AEs: AE tracks acoustic waves generated during mechanical processes like cracking, friction, or tearing within the structure.

Signal dynamics: High-intensity AE signals indicate dynamic processes such as rapid crack propagation, while low-intensity signals may suggest the slow accumulation of damage.

Correlation mechanisms:

Onset of degradation: Initial signs of decohesion at the microstructural level (SEM) are correlated with low but detectable AE signal intensities.

Crack propagation: Increasing crack number and length, as observed via SEM, corresponds to a noticeable increase in AE signal intensity, especially during abrupt structural changes like crack coalescence.

Final failure: Peak AE intensities are observed during critical structural collapse, which is visualized using SEM as extensive microcracking and complete fiber–matrix separation.

The correlation between AE data and microstructural features identified through SEM can be utilized to develop reliable predictive models for real-time material degradation monitoring. These models have potential applications in structural health monitoring, enabling early detection of potential failures and enhancing safety in construction and material usage.

2.5 Other NDT techniques used in fiber–cement composite studies

Apart from SEM and AE, other NDT techniques are used to assess fiber–cement composites, including ultrasonic testing, thermography, and computed tomography (CT). Ultrasonic tests allow for the evaluation of internal defects, such as cracks or delaminations. Thermography analyzes the temperature distribution on the material’s surface, which is particularly useful in evaluating thermal changes after fire exposure. CT offers advanced 3D analysis of the material’s interior, which is essential in detecting internal defects.

3 Research methodology

3.1 Research objective

The objective of this study was to evaluate the structural and mechanical changes in fiber–cement boards subjected to high temperatures, simulating real fire conditions. The research focused on assessing the effectiveness of non-destructive methods, such as SEM and AE, in monitoring the degradation of materials in full-scale facade models. The key research tasks included the following:

Identification of microstructural damage in fiber–cement boards resulting from high-temperature exposure.

Analysis of cracking mechanisms and fiber separation from the cement matrix, which can lead to material degradation.

Evaluation of the suitability of SEM and AE methods as tools for the early detection of damage in fiber–cement boards.

Drawing practical conclusions regarding the potential use of these methods for assessing the safety of facades after a fire and evaluating their continued usability.

3.2 Materials and samples

The study utilized fiber–cement boards, commonly used as facade cladding in buildings. The material of the boards consisted of a cement matrix based on Portland cement and dispersed fibers, including cellulose, PP, and PVA. Each of these components played a different role in the composite structure:

Cellulose fibers reinforced the board, increasing its resistance to bending and dynamic forces.

PP and PVA fibers enhanced the material’s flexibility and improved its resistance to variable mechanical and thermal loads.

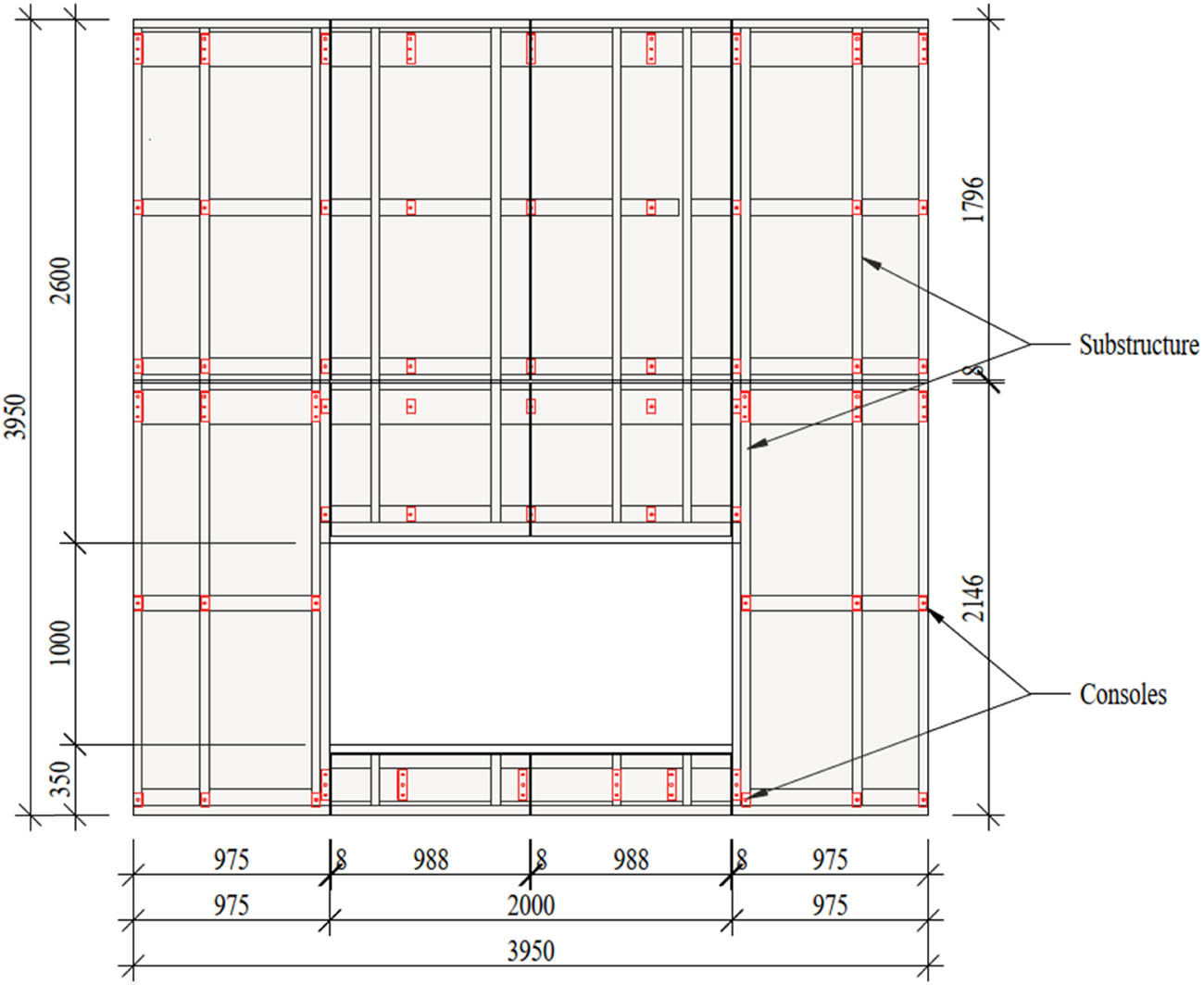

This research was conducted on full-scale facade models designed to replicate the actual installation conditions of ventilated facades in buildings. The models measured 5 m in height and 3 m in width, corresponding to typical facades of multi-story buildings. The models included all relevant structural elements:

Metal frameworks, onto which the facade boards were mounted

Thermal insulation in the form of mineral wool to simulate real thermal insulation conditions

Ventilation space is characteristic of ventilated building facades.

A schematic cross-section of the full-scale model is presented in Figure 2.

Schematic cross-section of a full-scale ventilated facade model.

For the study, both control samples and those exposed to high temperatures were prepared. The fiber–cement boards were mounted on metal frames according to the technical requirements specified by the manufacturer. The research included reference samples that were not exposed to fire, as well as samples that simulated real fire conditions.

3.3 Large-scale façade test

The large-scale facade tests were conducted in a specialized laboratory that allows for simulating real fire conditions in buildings. The facade model, clad with fiber–cement panels, was exposed to flames following an external temperature curve. The aim of these tests was to closely replicate the fire conditions that occur in buildings. The simulation lasted 60 min, after which the samples, taken for further analysis, remained on the model for an additional 32 min until they detached.

Large-scale testing was employed to accurately replicate the real threats that can occur in buildings with fiber–cement facades. The facade material was directly exposed to flames and high temperatures, allowing for an assessment of the interaction between fire and the facade surface as well as the impact of air circulation.

The exposure time to high temperatures and the heat distribution across the surface of the samples was monitored using thermocouples placed at strategic points on the facade model. This precise monitoring allowed for more realistic data compared to traditional laboratory methods, such as heating samples in a furnace. Figure 3 illustrates the setup for the full-scale facade test.

Diagram of the full-scale fire simulation setup.

3.4 Sample collection

To conduct a detailed analysis of microstructural and mechanical changes, two samples were collected after testing on full-scale models from the element that detached from the location indicated in Figure 4. The samples were cut into strips measuring 2 cm in width and 10 cm in length. The material was extracted along the board’s primary orientation to ensure identical fiber alignment in each sample. According to the manufacturing process of fiber–cement boards, this direction represents the main fiber orientation, where most fibers are arranged parallel to each other.

Location of degraded sample collection.

In addition to the samples taken from the test model, reference samples of the same dimensions were also prepared. These reference samples were not subjected to any testing. Both the degraded and reference samples were cut in the same direction to ensure comparability of results. All samples were extracted using identical tools to eliminate any potential impact of cutting differences on their properties.

The samples were prepared in accordance with guidelines for NDT to enable further analysis using SEM and AE methods. Each sample was properly labeled to ensure precise mapping of its original location on the facade model. The dimensions of the samples were tailored to the requirements of the testing equipment, allowing for detailed analysis of microstructure, crack propagation, and fiber-matrix separation in the cementitious composite.

3.5 AE analysis

Fragments of the most damaged areas of the facade were collected and prepared for AE analysis. The AE method involves recording elastic waves generated within a material as a result of the release of accumulated elastic energy [16]. It is a passive method, meaning that AE equipment does not emit signals or interfere with the physical state of the tested object but rather records naturally occurring phenomena, such as damage or structural changes. Sources of AE signals include the propagation of microcracks, corrosion processes, and the breaking of strands in prestressed structures. The elastic waves generated by these phenomena propagate through the material and are detected on its surface using transducers that convert them into electrical signals [17]. In engineering studies, sensors operating within a frequency range of 30–450 kHz are commonly used. AE enables the detection of material defects and discontinuities throughout the entire volume of the tested element while also allowing for real-time monitoring of its condition, which is critical for assessing external impacts.

The AE data recorded were analyzed in terms of the number of acoustic events and signal intensity, which enabled the identification of the crack initiation moments. The AE data were also correlated with the results obtained from SEM analysis, allowing for a more detailed understanding of the damage mechanisms. The schematic of the test setup is shown in Figure 5.

AE test setup.

3.6 SEM analysis

The fragments of samples previously analyzed using AE methods were subsequently subjected to SEM for a detailed investigation. These samples were obtained from both degraded and reference materials. The primary goal of the SEM analysis was to examine microstructural damage, including cracks in the cement matrix, fiber–matrix separation, and changes in material porosity caused by exposure to high temperatures.

The SEM analysis was conducted using a Carl Zeiss Sigma 500 VP scanning electron microscope. To ensure high-quality imaging and reliable results, the samples underwent meticulous preparation. Two types of samples were prepared: polished cross-sections (zgłady) and fracture surfaces (przełamy), each offering unique perspectives on the structural changes in the material.

Gold coating – To enhance sample conductivity and prevent charging during SEM imaging, a thin layer of gold was applied to the sample surfaces using a Quorum Q 150 R ES sputtering device, as shown in Figure 4. This coating process was essential for achieving high-resolution imaging and accurate analytical results.

Fracture surfaces were prepared by mechanically breaking the samples to expose natural fracture paths. These surfaces provided direct insights into crack propagation and fiber-matrix interaction under thermal stress.

Imaging setup – The SEM was equipped with advanced detectors, including secondary electron (SE) and backscattered electron (BSE) detectors, as well as an Ultim Max 40 energy-dispersive X-ray spectroscopy (EDX) detector (Oxford Instruments). SE detectors captured surface topography, BSE detectors highlighted compositional contrasts, and EDX enabled the identification of elemental changes resulting from high-temperature exposure.

The SEM analysis concentrated on the following key aspects of the degraded samples:

Cracks in the cement matrix: Microstructural cracks, primarily caused by thermal expansion and dehydration of the cement matrix, were observed.

Fiber–matrix separation: Exposure to high temperatures led to significant detachment of fibers from the cement matrix, which compromised the mechanical integrity of the composite material.

Changes in material porosity: An increase in porosity was detected, further contributing to the degradation of structural performance.

Figures 6 and 7 illustrate the SEM setup and the prepared samples, respectively. By integrating advanced imaging techniques with a systematic sample preparation process, the analysis provided critical insights into the microstructural degradation of fiber–cement boards exposed to extreme conditions. These findings lay the groundwork for further research aimed at enhancing the durability and thermal resilience of these materials.

SEM test setup.

Prepared samples.

3.7 Correlation of SEM and AE results

The data obtained from SEM and AE analyses were compared to identify the relationship between the microstructural damage and acoustic activity. The research focused on a detailed analysis of facade areas that were most exposed to high temperatures and those that experienced the most significant damage.

Through SEM analysis, it was possible to precisely examine the following:

The size and nature of the cracks

Changes in the microstructure of synthetic and cellulose fibers

Separation of fibers from the cement matrix

Formation of porosity due to water evaporation and other physicochemical phenomena.

The correlation of SEM and AE data provided a better understanding of cracking mechanisms under real fire conditions, which is crucial for assessing the durability and future use of fiber–cement boards after fire exposure.

4 Research results

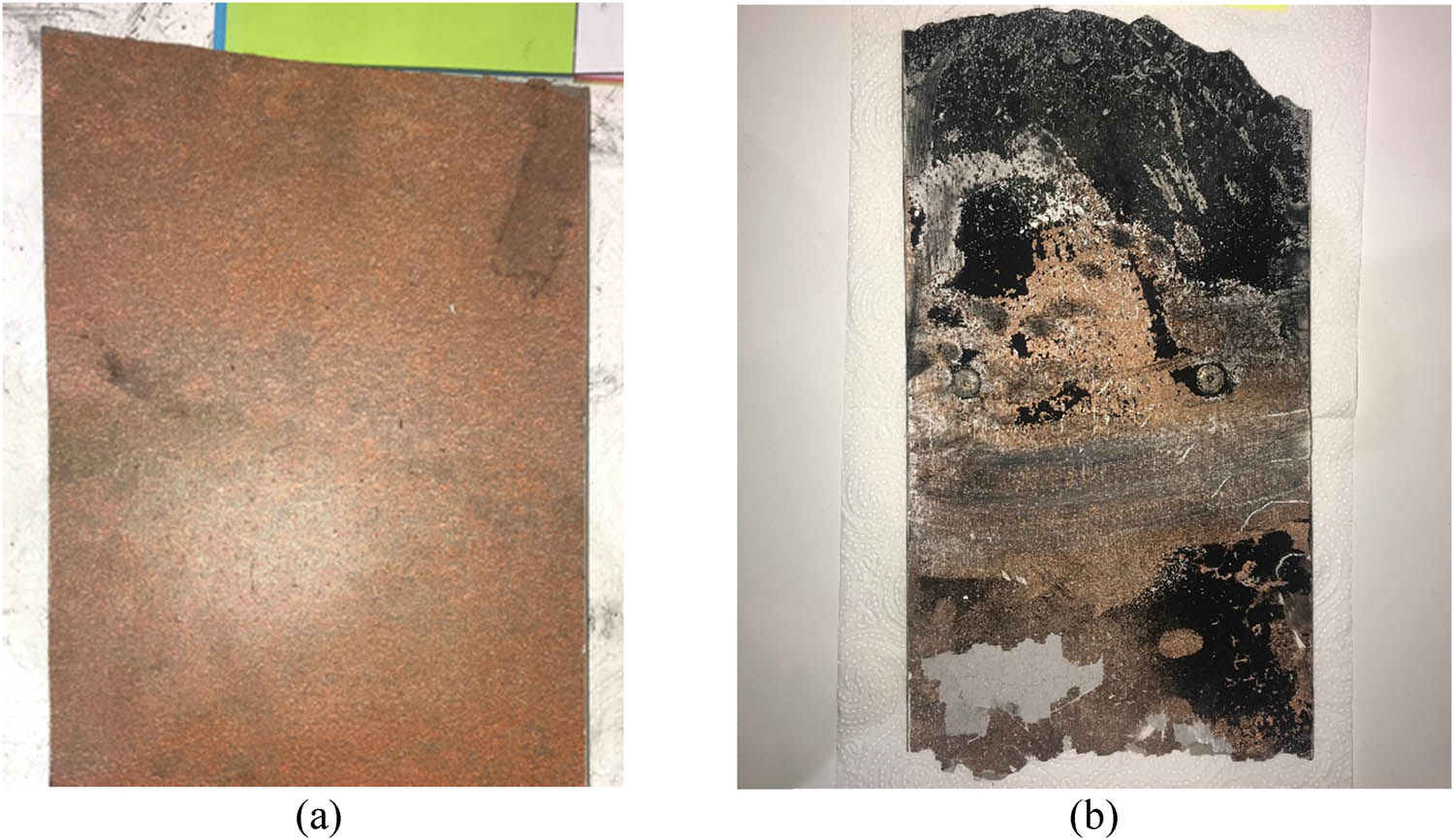

For the analysis, two reference samples and two degraded samples were selected, taken from areas where the temperatures ranged between 300 and 400°C. The dimensions of the collected samples were 20 mm × 100 mm, with a thickness of 8 mm. The exposure time for the samples was 34 min until they detached from the full-scale model. The element that detached and from which the sample was prepared is shown in Figure 8.

Plates selected for further analysis: (a) reference plate and (b) degraded plate.

4.1 Results of microstructural analysis using SEM

The microstructural analysis of fiber–cement, conducted using SEM, revealed significant changes in the microstructure of the material subjected to high temperatures. In samples exposed to temperatures ranging from 300 to 400°C, small surface microcracks were observed, primarily confined to the cement matrix. These temperatures were critical for the fibers, which largely underwent complete pyrolysis. This pyrolysis is clearly visible in Figure 9, where the black voids indicate the empty spaces left behind. These voids are notably more abundant in the degraded sample (b).

Images of the analyzed reference and degraded samples’ structures: (a) reference sample – section’s BSD images and (b) degraded sample – section’s BSD images.

The view obtained using SEM, with significantly higher magnification, is shown in Figure 10. In this figure, it is evident that in the degraded sample exposed to high temperatures, almost no fibers are present – they were completely destroyed during the pyrolysis process due to exposure to elevated temperatures.

Images of the analyzed reference and degraded samples’ structures: (a) reference sample – section’s EDX map and (b) degraded sample – section’s EDX map.

4.2 Results from AE testing

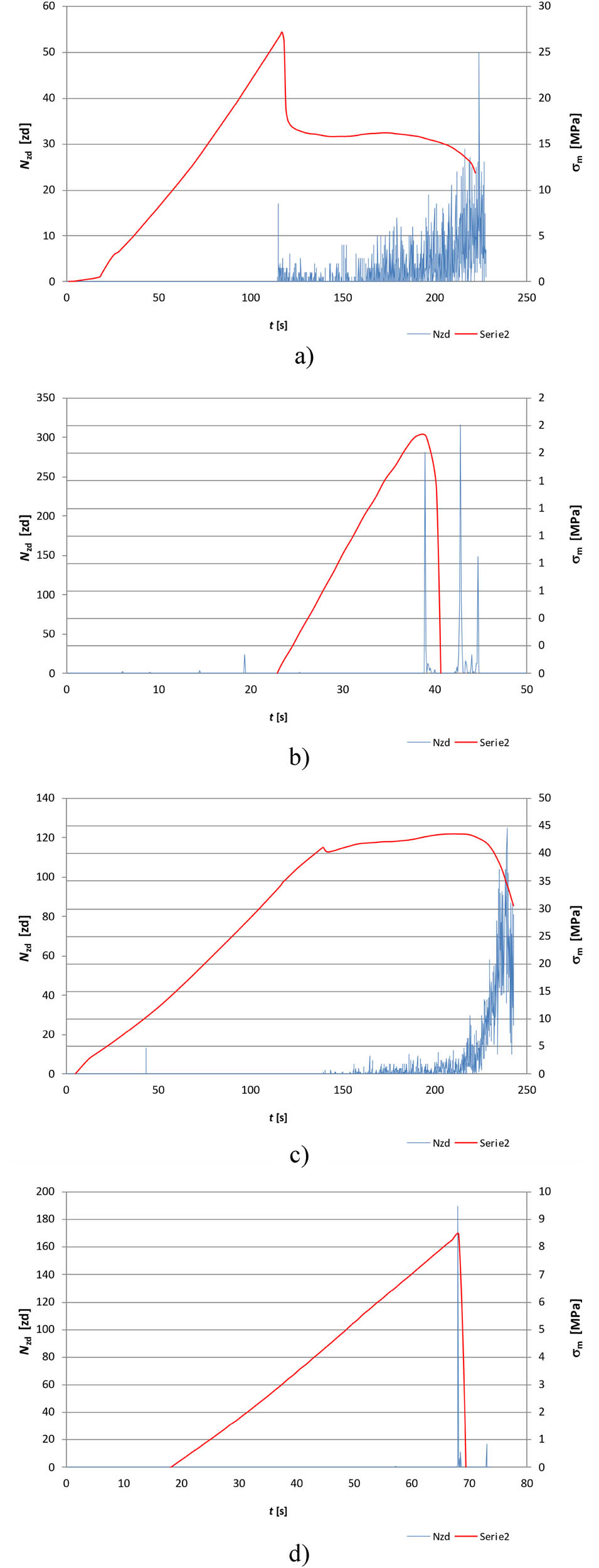

The AE analysis during the three-point bending test provided crucial insights into the cracking and degradation processes of fiber–cement boards exposed to high temperatures. The trends observed in Table 1 highlight the substantial impact of thermal exposure on both the flexural strength and the acoustic activity of the samples.

Summary of average bending strength (MOR) and an example event sum ∑N zd

| Sample marking | Bending strength (MOR) (MPa) | Sum of events ∑N zd (–) |

|---|---|---|

| Reference sample no. 1 | 27.15 | 3,463 |

| Reference sample no. 2 | 43.45 | 10,010 |

| Degraded sample no. 1 | 1.72 | 1,207 |

| Degraded sample no. 2 | 14.83 | 228 |

A significant decrease in the number of acoustic events (∑N zd) was recorded for the samples subjected to high temperatures, with reference samples consistently displaying much higher event counts compared to degraded samples. This trend indicates that the pyrolysis of fibers and thermal damage to the matrix drastically reduce the material’s ability to dissipate energy during deformation, a key function of fiber reinforcement. For instance, reference sample no. 2 exhibited a bending strength (MOR) of 43.45 MPa and an acoustic event count of 10,010, while degraded sample no. 2, exposed to high temperatures, showed a drastically reduced MOR of 14.83 MPa and only 228 acoustic events.

The reduction in the number of acoustic events in degraded samples, coupled with the lowered bending strength, points to a weakened structural integrity. This is primarily due to the loss of fiber–matrix cohesion and the breakdown of fiber reinforcement, as evidenced by the pyrolysis of fibers and matrix cracking during high-temperature exposure. The reference samples, which retained their original structural integrity, exhibited significantly higher acoustic event counts, reflecting their ability to resist crack propagation and accommodate energy release in a controlled manner.

The AE analysis also revealed differences in the failure mechanisms between the reference and degraded samples. The reference samples demonstrated high-energy fracturing, with a gradual accumulation of acoustic events leading to a definitive failure point. In contrast, the degraded samples displayed abrupt failure with fewer preceding acoustic events, indicative of a brittle fracture mechanism due to the absence of effective fiber reinforcement.

These findings are further illustrated in Figure 11, where the event rate (N zd) and bending stress (σ m) are plotted against time. The graphs for the reference samples (a and b) show a more extended duration of stress accumulation and a higher frequency of AE events, indicating a ductile failure mode. Conversely, the degraded samples (c and d) exhibit a steep stress drop and fewer AE events, confirming the brittle nature of their failure.

Recording of the event rate Nzd and bending stress σ m versus time for (a) reference sample no. 1, (b) degraded sample no. 1, (c) reference sample no. 2, and (d) degraded sample no. 2.

The trends in Table 1 underscore the importance of fiber reinforcement in maintaining the mechanical integrity of fiber–cement boards, particularly under flexural loading. The drastic differences in acoustic activity and bending strength between reference and degraded samples highlight the critical role of fibers in energy dissipation and crack control. These results also underscore the potential of AE analysis as a diagnostic tool for evaluating the structural health of fiber-reinforced cementitious composites, particularly in post-fire scenarios. The ability to quantify and interpret AE event patterns provides valuable insights into damage mechanisms, enabling the development of predictive models for material performance under varying thermal and mechanical conditions.

5 Discussion

5.1 Degradation of fiber–cement under the influence of temperature

The results of the conducted studies indicate significant microstructural and mechanical degradation of fiber–cement boards subjected to high temperatures. Microstructural degradation of the fiber–cement composite was observed consistently across both methods employed – SEM and AE.

However, a more in-depth analysis of the degradation differences between PP, PVA, and cellulose fibers is required. Each of these fiber types exhibits distinct thermal and mechanical properties, as well as varying resistance to high temperatures, which significantly influence their behavior within the cement matrix. PP fibers, due to their lower thermal stability, tend to undergo earlier decohesion and melting, increasing susceptibility to cracking and delamination. PVA fibers, being more thermally stable, may maintain better integration with the matrix at elevated temperatures, although their eventual degradation also weakens the composite structure. Cellulose fibers, while prone to carbonization, exhibit unique degradation mechanisms stemming from their organic nature and lower thermal stability compared to synthetic fibers.

To gain a comprehensive understanding of the role of different fiber types in the degradation of fiber–cement boards, a detailed comparative analysis is essential. This should focus on differences in cracking mechanisms, decohesion processes, and structural changes in the cement matrix. SEM data can provide detailed insights into microstructural changes, such as fiber–matrix separation, crack formation, and the characteristics of degraded surfaces. Concurrently, AE signal analysis offers the advantage of dynamically tracking degradation processes in real-time, enabling the identification of distinct damage mechanisms for each fiber type.

Including cellulose fibers as an additional point of analysis will enhance the understanding of potential applications for fiber–cement materials, depending on environmental conditions and thermal resistance requirements. Expanding research in this direction could contribute to the development of more efficient construction materials, optimized for fire safety and durability under extreme conditions.

5.2 Integration of SEM and AE results in fiber–cement assessment

The integrated use of SEM and AE methods proved to be highly valuable for assessing the technical condition of fiber–cement. SEM provided detailed information on microstructural changes, such as microcracks and fiber delamination, while AE enabled real-time monitoring of dynamic cracking processes. The integration of various NDT techniques, like SEM and AE, significantly enhances the accuracy and efficiency of evaluating the conditions of cementitious composites.

By combining both techniques, a more comprehensive assessment of the technical state of fiber–cement exposed to high temperatures was achieved. These results align with previous literature, suggesting that the integration of SEM and AE methods greatly improves the precision of diagnosing damage in composite materials, especially in structural evaluations following fires.

As shown in the study’s results, it is difficult to observe full consistency in parameters such as flexural strength or the number of acoustic events, even within the reference samples (see Table 1). A more detailed analysis is needed to understand the behavior of fiber–cement boards and their structural changes over time, as reflected in the graphs.

Figure 12 presents key events to be monitored during AE analysis. Sudden increases in the number of acoustic events are typically associated with cracking of the matrix phase (cement matrix). Fiber rupture, on the other hand, is usually characterized by relatively fewer events over a longer period.

Recording of the event rate Nzd and bending stress σ m versus time for (a) reference sample no. 1 and (b) reference sample no. 2.

Figure 13 illustrates key events for samples degraded due to exposure to high temperatures. Sudden increases in the number of acoustic events are most commonly associated with cracking (scratching) of the matrix phase, i.e., the cement matrix. In contrast to the reference samples, the degraded samples show almost no characteristic events related to fiber rupture. These degraded samples are marked by a low number of acoustic events over a longer period, indicating significant structural degradation and the material’s inability to transfer stress through the fibers.

Recording of the event rate Nzd and bending stress σ m versus time for (a) degraded sample no. 1 and (b) degraded sample no. 2.

Despite the numerical differences between each sample, both reference and degraded, the studies conducted using AE and SEM revealed similar trends. It would not have been possible to fully determine the extent of material degradation based solely on bending strength parameters. However, performing such comprehensive analyses enabled conclusions to be drawn regarding the advancement of material degradation. The results indicate that the AE method provides more comprehensive and detailed information than SEM analysis. AE allows for the monitoring of dynamic cracking and degradation processes, but its effective use requires a deep understanding of the material and the ability to interpret the recorded data accurately.

5.3 Comparison with global literature

AE studies confirmed that this method is an effective tool for early detection of microcracks and fiber separation from the cement matrix. Research by Gorzelańczyk et al. [14] highlights that AE can detect material structure changes in earlier stages of degradation than traditional non-destructive methods such as SEM or ultrasonic testing, which is consistent with our findings. The results align with global studies on fiber–cement, demonstrating that AE can be an effective method for monitoring the structural integrity of building materials, especially after exposure to extreme environmental conditions [13,18,19,20].

Our research is consistent with many other studies on this topic. Previous studies [6,8] showed that fiber–cement subjected to high temperatures suffers similar damage, including fiber separation and matrix degradation. Additionally, studies [21,22] emphasized the need for further optimization of synthetic fibers in cement composites to enhance their resistance to fire, which could improve the durability of building structures.

There is also growing interest in the literature regarding the integration of NDT methods, such as SEM, AE, ultrasound, and CT, to provide a more comprehensive assessment of the technical condition of building materials after exposure to extreme conditions [13,18]. Our studies confirm that SEM and AE can be critical techniques for diagnosing and monitoring the degradation of fiber–cement.

A comparison of the results from SEM and AE tests shows a strong correlation between microstructural degradation and the acoustic activity recorded during the tests. AE signals allowed for the detection of early stages of material degradation before the damage became visible in SEM images.

The integrated use of both techniques enabled a more accurate assessment of the technical condition of fiber–cement exposed to high temperatures. These findings are consistent with the literature, where the integration of SEM and AE methods has been recognized as an effective tool for diagnosing composite material damage, especially in the context of post-fire structural assessments [6].

6 Conclusion

Microstructural degradation of fiber–cement under high temperatures: The study revealed that SEM and AE methods confirmed significant microstructural changes in fiber–cement boards exposed to high temperatures. Synthetic fibers, such as PP and PVA, underwent pyrolysis at temperatures ranging from 300 to 400°C, resulting in the formation of voids within the cement matrix. These synthetic fibers have low resistance to high temperatures, which leads to their rapid degradation.

The importance of NDT in evaluating the technical condition of fiber–cement: The integrated use of SEM and AE methods provided comprehensive information on the microstructural and mechanical changes in fiber–cement boards. SEM enabled precise analysis of cracks and the separation of fibers from the cement matrix, while AE allowed for real-time monitoring of dynamic cracking processes. The integration of SEM and AE significantly improves the diagnosis of damage in composite materials, as confirmed by our findings.

Early detection of microcracks using AE: AE has proven to be an effective method for the early detection of microcracks and fiber separation before these issues become visible in SEM analysis. AE enables the identification of changes in the material’s structure at the initial stages of degradation, making it a crucial tool for monitoring the technical condition of building materials exposed to extreme environmental conditions.

Importance of integrating different NDT methods: The integration of SEM and AE methods significantly enhances the accuracy of evaluating the technical condition of fiber–cement materials. SEM provides detailed insights into the microstructure, while AE allows real-time monitoring of dynamic cracking and damage processes. Combining these methods is crucial in the diagnostics of composite materials, particularly for assessing fire-induced damage.

The use of AE in monitoring technical conditions: The research also demonstrates that AE can serve as an effective method for early warning of material degradation, even before these changes become visible in SEM images. This key advantage of AE lies in its ability to monitor the technical condition of building materials in real-time. Due to this feature, AE proves to be a valuable tool for preventive diagnostics and long-term monitoring of structures exposed to extreme environmental conditions.

Broader implications and limitations of NDT methods: While SEM and AE demonstrate utility in diagnosing the condition of fiber–cement facades post-fire, their broader application requires addressing potential limitations. AE analysis, while effective, demands specialized technical expertise and can be cost-prohibitive for large-scale implementations. Scalability is another challenge, particularly for widespread monitoring of facade safety in urban environments. SEM analysis, though precise, is time-consuming and requires extensive sample preparation. Future studies should explore streamlined approaches to reduce costs and enhance the accessibility of these techniques, enabling their broader adoption in facade safety assessments and other critical applications.

By addressing these limitations and building on the insights gained from this research, the integration of NDT methods can be further optimized to enhance the resilience and safety of construction materials in extreme conditions.

7 Recommendations for future research

Based on the results, it is recommended to further optimize synthetic fibers in cement composites to enhance their resistance to high temperatures. Previous studies [11,15] highlight the need for developing NDT methods such as AE, SEM, ultrasound, and CT to obtain a more comprehensive understanding of the technical condition of building materials exposed to extreme environmental conditions.

8 Practical applications of the results

The use of SEM and AE in engineering practice can be particularly useful for monitoring the technical conditions of building facades. AE provides insights into dynamic degradation processes, enabling early detection of damage before it becomes critical. The findings from these studies can contribute to improving maintenance methods for buildings exposed to fire, which is crucial for the safety of structural systems in construction.

-

Funding information: The author states no funding involved.

-

Author contribution: The author confirms the sole responsibility for the conception of the study, presented results and manuscript preparation.

-

Conflict of interest: The author states no conflict of interest.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Schabowicz K. [in Polish] Elewacje wentylowane: Technologia produkcji i metody badania płyt włóknisto-cementowych. Wrocław: Oficyna Wydawnicza Politechniki Wrocławskiej; 2018.Suche in Google Scholar

[2] Callister WD, Tethwisch DG. Materials science and engineering: An introduction. 10th edn. Utah: John Wiley & Sons; 2009.Suche in Google Scholar

[3] Page CL, Page MM. Durability of concrete and cement composites. Cambridge: Woodhead Publishing Limited; 2007.10.1201/9781439824467Suche in Google Scholar

[4] Naaman AE, Reinhardt HW. High performance fiber reinforced cement composites HPFRCC-4: International RILEM workshop. Mat Struct. 2003;36:710–2.10.1007/BF02479507Suche in Google Scholar

[5] Schabowicz K, Gorzelańczyk T, Szymków MJ. Identification of the degree of fibre-cement boards degradation under the influence of high temperature. Autom Constr. 2019;101:190–8.10.1016/j.autcon.2019.01.021Suche in Google Scholar

[6] Li X, Bao Y, Wu L, Yan Q, Ma H, Chen G, et al. Thermal and mechanical properties of high-performance fiber-reinforced cementitious composites after exposure to high temperatures. Constr Build Mater. 2017;157:829–38.10.1016/j.conbuildmat.2017.09.125Suche in Google Scholar

[7] Çavdar A. A study on the effects of high temperature on mechanical properties of fiber reinforced cementitious composites. Compos Part B: Eng. 2021;43(5):2452–63.10.1016/j.compositesb.2011.10.005Suche in Google Scholar

[8] Szymków M. [in Polish] Identyfikacja stopnia destrukcji płyt włóknisto-cementowych pod wpływem oddziaływania wysokiej temperatury. Raport serii PRE nr 9/2018 - Praca doktorska, Wydział Budownictwa Lądowego i Wodnego, Politechnika Wrocławska; 2018.Suche in Google Scholar

[9] Sulik P, Zawiślak Ł, Krzysztof S. Identification of the destruction model of ventilated facade under the influence of fire. Materials. 2020;10(13):2387.10.3390/ma13102387Suche in Google Scholar PubMed PubMed Central

[10] Schabowicz K, Sulik P, Gorzelańczyk T, Zawiślak Ł. Assessment of the destruction of a fibre cement board subjected to fire in a large-scale study. Materials. 2022;8(15):2929.10.3390/ma15082929Suche in Google Scholar PubMed PubMed Central

[11] Sulik P, Zawiślak Ł, Krzysztof S. Reduction of load capacity of fiber cement board facade cladding under the influence of fire. Materials. 2021;14(7):1769.10.3390/ma14071769Suche in Google Scholar PubMed PubMed Central

[12] Kumar S, Mahto DG. Recent trends in industrial and other engineering applications of non destructive testing: A review. Int J Sci & Eng Res. 2013;4(9):183–95.Suche in Google Scholar

[13] Holford KM. Acoustic emission in structural health monitoring. KEM. 2009;413–414:15–28.10.4028/www.scientific.net/KEM.413-414.15Suche in Google Scholar

[14] Gorzelańczyk T, Schabowicz S, Szymków MJ. Application of the acoustic emission method and artificial neural networks to assess the damaging effect of high temperature on the structure of fibre-cement boards. Materials. 2022;15(18):1–16.10.3390/ma15186460Suche in Google Scholar PubMed PubMed Central

[15] Ortiz JD, Dolati SSK, Malla P, Mehrabi A, Nanni A. Nondestructive Testing (NDT) for damage detection in concrete elements with externally bonded fiber-reinforced polymer. Buildings. 2023;14(1).10.3390/buildings14010246Suche in Google Scholar

[16] Malecki I, Ranachowski J. [in Polish] Emisja akustyczna, źródła, metody, zastosowanie. Warszawa: KBN; 1994.Suche in Google Scholar

[17] Ranachowski Z. [in Polish] Emisja akustyczna w diagnostyce obiektów budowlanych. Drogi i Mosty. 2022;2:151–73.Suche in Google Scholar

[18] Łopato P, Chady T, Sikora R. Testing of composite materials using advanced NDT methods. COMPEL – Int J Comput Math Electr Electron Eng. 2011;30(4):1260–70.10.1108/03321641111133172Suche in Google Scholar

[19] Adamczak-Bugno A, Gorzelańczyk T, Krampikowska A, Szymków M. Non-destructive testing of the structure of fibre-cement materials by means of a scanning electron microscope. Badania Nieniszczące i Diagnostyka. 2017;3:20–3.Suche in Google Scholar

[20] Adamczak-Bugno A, Krampikowska A. The acoustic emission method implementation proposition to confirm the presence and assessment of reinforcement quality and strength of fiber–cement composites. Materials. 2020;13(13):2966.10.3390/ma13132966Suche in Google Scholar PubMed PubMed Central

[21] Pakravan H, Ozbakkaloglu T. Synthetic fibers for cementitious composites: A critical and in-depth review of recent advances. Constr Build Mater. 2019;207:491–518.10.1016/j.conbuildmat.2019.02.078Suche in Google Scholar

[22] Schabowicz K, Gorzelańczyk T, Zawiślak Ł, Chyliński F. Influence of fire exposition of fibre-cement boards on their microstructure. Materials. 2023;16(18):6153.10.3390/ma16186153Suche in Google Scholar PubMed PubMed Central

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Modification of polymers to synthesize thermo-salt-resistant stabilizers of drilling fluids

- Study of the electronic stopping power of proton in different materials according to the Bohr and Bethe theories

- AI-driven UAV system for autonomous vehicle tracking and license plate recognition

- Enhancement of the output power of a small horizontal axis wind turbine based on the optimization approach

- Design of a vertically stacked double Luneburg lens-based beam-scanning antenna at 60 GHz

- Synergistic effect of nano-silica, steel slag, and waste glass on the microstructure, electrical resistivity, and strength of ultra-high-performance concrete

- Expert evaluation of attachments (caps) for orthopaedic equipment dedicated to pedestrian road users

- Performance and rheological characteristics of hot mix asphalt modified with melamine nanopowder polymer

- Second-order design of GNSS networks with different constraints using particle swarm optimization and genetic algorithms

- Impact of including a slab effect into a 2D RC frame on the seismic fragility assessment: A comparative study

- Analytical and numerical analysis of heat transfer from radial extended surface

- Comprehensive investigation of corrosion resistance of magnesium–titanium, aluminum, and aluminum–vanadium alloys in dilute electrolytes under zero-applied potential conditions

- Performance analysis of a novel design of an engine piston for a single cylinder

- Modeling performance of different sustainable self-compacting concrete pavement types utilizing various sample geometries

- The behavior of minors and road safety – case study of Poland

- The role of universities in efforts to increase the added value of recycled bucket tooth products through product design methods

- Adopting activated carbons on the PET depolymerization for purifying r-TPA

- Urban transportation challenges: Analysis and the mitigation strategies for road accidents, noise pollution and environmental impacts

- Enhancing the wear resistance and coefficient of friction of composite marine journal bearings utilizing nano-WC particles

- Sustainable bio-nanocomposite from lignocellulose nanofibers and HDPE for knee biomechanics: A tribological and mechanical properties study

- Effects of staggered transverse zigzag baffles and Al2O3–Cu hybrid nanofluid flow in a channel on thermofluid flow characteristics

- Mathematical modelling of Darcy–Forchheimer MHD Williamson nanofluid flow above a stretching/shrinking surface with slip conditions

- Energy efficiency and length modification of stilling basins with variable Baffle and chute block designs: A case study of the Fewa hydroelectric project

- Renewable-integrated power conversion architecture for urban heavy rail systems using bidirectional VSC and MPPT-controlled PV arrays as an auxiliary power source

- Exploitation of landfill gas vs refuse-derived fuel with landfill gas for electrical power generation in Basrah City/South of Iraq

- Two-phase numerical simulations of motile microorganisms in a 3D non-Newtonian nanofluid flow induced by chemical processes

- Sustainable cocoon waste epoxy composite solutions: Novel approach based on the deformation model using finite element analysis to determine Poisson’s ratio

- Impact and abrasion behavior of roller compacted concrete reinforced with different types of fibers

- Architectural design and its impact on daylighting in Gayo highland traditional mosques

- Structural and functional enhancement of Ni–Ti–Cu shape memory alloys via combined powder metallurgy techniques

- Design of an operational matrix method based on Haar wavelets and evolutionary algorithm for time-fractional advection–diffusion equations

- Design and optimization of a modified straight-tapered Vivaldi antenna using ANN for GPR system

- Analysis of operations of the antiresonance vibration mill of a circular trajectory of chamber vibrations

- Functions of changes in the mechanical properties of reinforcing steel under corrosive conditions

- 10.1515/eng-2025-0153

- Review Articles

- A modified adhesion evaluation method between asphalt and aggregate based on a pull off test and image processing

- Architectural practice process and artificial intelligence – an evolving practice

- Enhanced RRT motion planning for autonomous vehicles: a review on safety testing applications

- Special Issue: 51st KKBN - Part II

- The influence of storing mineral wool on its thermal conductivity in an open space

- Use of nondestructive test methods to determine the thickness and compressive strength of unilaterally accessible concrete components of building

- Use of modeling, BIM technology, and virtual reality in nondestructive testing and inventory, using the example of the Trzonolinowiec

- Tunable terahertz metasurface based on a modified Jerusalem cross for thin dielectric film evaluation

- Integration of SEM and acoustic emission methods in non-destructive evaluation of fiber–cement boards exposed to high temperatures

- Non-destructive method of characterizing nitrided layers in the 42CrMo4 steel using the amplitude-frequency technique of eddy currents

- Evaluation of braze welded joints using the ultrasonic method

- Analysis of the potential use of the passive magnetic method for detecting defects in welded joints made of X2CrNiMo17-12-2 steel

- Analysis of the possibility of applying a residual magnetic field for lack of fusion detection in welded joints of S235JR steel

- Eddy current methodology in the non-direct measurement of martensite during plastic deformation of SS316L

- Methodology for diagnosing hydraulic oil in production machines with the additional use of microfiltration

- Special Issue: IETAS 2024 - Part II

- Enhancing communication with elderly and stroke patients based on sign-gesture translation via audio-visual avatars

- Optimizing wireless charging for electric vehicles via a novel coil design and artificial intelligence techniques

- Evaluation of moisture damage for warm mix asphalt (WMA) containing reclaimed asphalt pavement (RAP)

- Comparative CFD case study on forced convection: Analysis of constant vs variable air properties in channel flow

- Evaluating sustainable indicators for urban street network: Al-Najaf network as a case study

- Node failure in self-organized sensor networks

- Comprehensive assessment of side friction impacts on urban traffic flow: A case study of Hilla City, Iraq

- Design a system to transfer alternating electric current using six channels of laser as an embedding and transmitting source

- Security and surveillance application in 3D modeling of a smart city: Kirkuk city as a case study

- Modified biochar derived from sewage sludge for purification of lead-contaminated water

- The future of space colonisation: Architectural considerations

- Design of a Tri-band Reconfigurable Antenna Using Metamaterials for IoT Applications

- Special Issue: AESMT-7 - Part II

- Experimental study on behavior of hybrid columns by using SIFCON under eccentric load

- Special Issue: ICESTA-2024 and ICCEEAS-2024

- A selective recovery of zinc and manganese from the spent primary battery black mass as zinc hydroxide and manganese carbonate

- Special Issue: REMO 2025 and BUDIN 2025

- Predictive modeling coupled with wireless sensor networks for sustainable marine ecosystem management using real-time remote monitoring of water quality

- Management strategies for refurbishment projects: A case study of an industrial heritage building

- Structural evaluation of historical masonry walls utilizing non-destructive techniques – Comprehensive analysis

Artikel in diesem Heft

- Research Articles

- Modification of polymers to synthesize thermo-salt-resistant stabilizers of drilling fluids

- Study of the electronic stopping power of proton in different materials according to the Bohr and Bethe theories

- AI-driven UAV system for autonomous vehicle tracking and license plate recognition

- Enhancement of the output power of a small horizontal axis wind turbine based on the optimization approach

- Design of a vertically stacked double Luneburg lens-based beam-scanning antenna at 60 GHz

- Synergistic effect of nano-silica, steel slag, and waste glass on the microstructure, electrical resistivity, and strength of ultra-high-performance concrete

- Expert evaluation of attachments (caps) for orthopaedic equipment dedicated to pedestrian road users

- Performance and rheological characteristics of hot mix asphalt modified with melamine nanopowder polymer

- Second-order design of GNSS networks with different constraints using particle swarm optimization and genetic algorithms

- Impact of including a slab effect into a 2D RC frame on the seismic fragility assessment: A comparative study

- Analytical and numerical analysis of heat transfer from radial extended surface

- Comprehensive investigation of corrosion resistance of magnesium–titanium, aluminum, and aluminum–vanadium alloys in dilute electrolytes under zero-applied potential conditions

- Performance analysis of a novel design of an engine piston for a single cylinder

- Modeling performance of different sustainable self-compacting concrete pavement types utilizing various sample geometries

- The behavior of minors and road safety – case study of Poland

- The role of universities in efforts to increase the added value of recycled bucket tooth products through product design methods

- Adopting activated carbons on the PET depolymerization for purifying r-TPA

- Urban transportation challenges: Analysis and the mitigation strategies for road accidents, noise pollution and environmental impacts

- Enhancing the wear resistance and coefficient of friction of composite marine journal bearings utilizing nano-WC particles

- Sustainable bio-nanocomposite from lignocellulose nanofibers and HDPE for knee biomechanics: A tribological and mechanical properties study

- Effects of staggered transverse zigzag baffles and Al2O3–Cu hybrid nanofluid flow in a channel on thermofluid flow characteristics

- Mathematical modelling of Darcy–Forchheimer MHD Williamson nanofluid flow above a stretching/shrinking surface with slip conditions

- Energy efficiency and length modification of stilling basins with variable Baffle and chute block designs: A case study of the Fewa hydroelectric project

- Renewable-integrated power conversion architecture for urban heavy rail systems using bidirectional VSC and MPPT-controlled PV arrays as an auxiliary power source

- Exploitation of landfill gas vs refuse-derived fuel with landfill gas for electrical power generation in Basrah City/South of Iraq

- Two-phase numerical simulations of motile microorganisms in a 3D non-Newtonian nanofluid flow induced by chemical processes

- Sustainable cocoon waste epoxy composite solutions: Novel approach based on the deformation model using finite element analysis to determine Poisson’s ratio

- Impact and abrasion behavior of roller compacted concrete reinforced with different types of fibers

- Architectural design and its impact on daylighting in Gayo highland traditional mosques

- Structural and functional enhancement of Ni–Ti–Cu shape memory alloys via combined powder metallurgy techniques

- Design of an operational matrix method based on Haar wavelets and evolutionary algorithm for time-fractional advection–diffusion equations

- Design and optimization of a modified straight-tapered Vivaldi antenna using ANN for GPR system

- Analysis of operations of the antiresonance vibration mill of a circular trajectory of chamber vibrations

- Functions of changes in the mechanical properties of reinforcing steel under corrosive conditions

- 10.1515/eng-2025-0153

- Review Articles

- A modified adhesion evaluation method between asphalt and aggregate based on a pull off test and image processing

- Architectural practice process and artificial intelligence – an evolving practice

- Enhanced RRT motion planning for autonomous vehicles: a review on safety testing applications

- Special Issue: 51st KKBN - Part II

- The influence of storing mineral wool on its thermal conductivity in an open space

- Use of nondestructive test methods to determine the thickness and compressive strength of unilaterally accessible concrete components of building

- Use of modeling, BIM technology, and virtual reality in nondestructive testing and inventory, using the example of the Trzonolinowiec

- Tunable terahertz metasurface based on a modified Jerusalem cross for thin dielectric film evaluation

- Integration of SEM and acoustic emission methods in non-destructive evaluation of fiber–cement boards exposed to high temperatures

- Non-destructive method of characterizing nitrided layers in the 42CrMo4 steel using the amplitude-frequency technique of eddy currents

- Evaluation of braze welded joints using the ultrasonic method

- Analysis of the potential use of the passive magnetic method for detecting defects in welded joints made of X2CrNiMo17-12-2 steel

- Analysis of the possibility of applying a residual magnetic field for lack of fusion detection in welded joints of S235JR steel

- Eddy current methodology in the non-direct measurement of martensite during plastic deformation of SS316L

- Methodology for diagnosing hydraulic oil in production machines with the additional use of microfiltration

- Special Issue: IETAS 2024 - Part II

- Enhancing communication with elderly and stroke patients based on sign-gesture translation via audio-visual avatars

- Optimizing wireless charging for electric vehicles via a novel coil design and artificial intelligence techniques

- Evaluation of moisture damage for warm mix asphalt (WMA) containing reclaimed asphalt pavement (RAP)

- Comparative CFD case study on forced convection: Analysis of constant vs variable air properties in channel flow

- Evaluating sustainable indicators for urban street network: Al-Najaf network as a case study

- Node failure in self-organized sensor networks

- Comprehensive assessment of side friction impacts on urban traffic flow: A case study of Hilla City, Iraq

- Design a system to transfer alternating electric current using six channels of laser as an embedding and transmitting source

- Security and surveillance application in 3D modeling of a smart city: Kirkuk city as a case study

- Modified biochar derived from sewage sludge for purification of lead-contaminated water

- The future of space colonisation: Architectural considerations

- Design of a Tri-band Reconfigurable Antenna Using Metamaterials for IoT Applications

- Special Issue: AESMT-7 - Part II

- Experimental study on behavior of hybrid columns by using SIFCON under eccentric load

- Special Issue: ICESTA-2024 and ICCEEAS-2024

- A selective recovery of zinc and manganese from the spent primary battery black mass as zinc hydroxide and manganese carbonate

- Special Issue: REMO 2025 and BUDIN 2025

- Predictive modeling coupled with wireless sensor networks for sustainable marine ecosystem management using real-time remote monitoring of water quality

- Management strategies for refurbishment projects: A case study of an industrial heritage building

- Structural evaluation of historical masonry walls utilizing non-destructive techniques – Comprehensive analysis