Abstract

The aim of this work was to investigate the possibility of using the eddy current method, a technique for measuring voltage amplitude and resonant frequency, for non-destructive assessment of the thickness of the near-surface layer of iron nitrides in 42CrMo4 steel after gas nitriding. The scope of the work included preparation of test samples, chemical composition tests, surface roughness measurements, hardness distribution using the Vicker’s method and measurements of the thickness of nitrided layer on cross-sections, X-ray phase composition analysis, testing of nitrided layer using the eddy current method, analysis of the correlation of the results of destructive and non-destructive tests. The main research apparatus was the Wirotest M2 with the 25 kHz measuring head. Differences in electromagnetic parameters between the white layer and the rest of the nitrided material, as well as changes in the surface roughness of the layer, are factors influencing the eddy current signal, which allows indirect measurement of its thickness. The analysis of the voltage amplitude is more accurate, than the resonant frequency, in assessing the thickness of nitrides layer. With the increase in thickness of the nitrides layer, the voltage value of the signal of eddy currents increases. The research results also indicate the possibility of using the same measuring head to assess the roughness parameter Ra of the nitrided layer. The Wirotest M2 can be used in quality control of steel parts after nitriding.

1 Introduction

Nitriding is a thermo-chemical treatment of iron alloys, which enhances the mechanical properties of the material (hardness [1,2], resistance against abrasion [3], and material fatigue [4]) and increases its corrosion resistance [5,6]. The process relies on a diffusive saturation of metal surface with nitrogen. Nitriding creates an outer layer with a structure and phase composition that is dependent on temperature, time, and chemical composition of the object and atmosphere [7,8]. It is a process used for treatment of machine parts and tools.

The most common nitriding method used is gas nitriding. Other methods include: plasma nitriding, fluidized bed nitriding, nitriding in powders, and ion nitriding.

Gas nitriding is used on carbon steel, low alloy steel, and alloy steel. Nitriding atmosphere is created from ammonia, a mix of ammonia and dissociated ammonia or a mix of ammonia and nitrogen. This process relies on sustaining the correct thermodynamic activity of the nitriding atmosphere, which is conventionally determined by the value of the nitriding potential.

During the treatment, three basic processes occur: ammonia dissociation, and absorption and diffusion of nitrogen. Nitriding is performed in the temperature range of 420–600°C for several, up to several dozen, hours. The atmosphere parameters are the degree of ammonia dissociation or the nitrogen potential of the nitriding atmosphere. Changes in their values are dictated by the change in composition of inlet atmosphere or the intensity of its flow [9,10].

During the nitriding of ferritic iron or low-carbon steel, there is a possibility of forming of a layer consisting of three zones: zone α, zones γ′ + α, and zones ε + γ′ + α. During the nitriding of alloy steel, nitrogen oxides and carbonitrides of alloying elements will be created additionally.

Utility properties, such as resistance to abrasive wear and seizing, corrosion resistance, and fatigue strength are highly dependent on the phase composition. It is presumed that the near-surface zone of iron nitrides ε + γ′ increases the resistance to abrasive wear, seizing, and corrosion, while the diffusion zone α increases the fatigue strength [11,12].

Utility properties of the nitrided layer can be enhanced by shaping the proportions of ε and γ′ phases in nitrides zone, profiles of nitrogen concentration and hardness in the layer and stress in the layer and core.

The shaping of a phase composition of the nitrides layer is important and requires a precise adjustment of nitrogen supply into steel, and thus the adjustment of kinetics of layer growth.

With the increase in nitriding time in intense nitriding atmosphere, such as ammonia, the thickness of nitrides layer increases, as well as its porosity. Iron nitrides zone is an incremental and partially diffusive layer, and as a result, with the increase in its thickness, the external dimensions of the treated part also increase. This has to be taken into account when dealing with precise parts. The higher porosity of the nitrides layer worsens the hardness and lowers the resistance to corrosion. Thus, it is important to control the thickness of not only the diffusion zone but also the near-surface layer of iron nitrides, which is often omitted during the quality control of finished products [13].

Destructive testing (DT) and non-destructive testing (NDT) are used for examining the created nitrided layers.

The DT consists of metallographic tests on witness samples by using light and electron microscopy [14], hardness measurements on vertical cross-section [15], corrosion tests [16], and X-ray tests [17].

The method of measuring the thickness of the nitrided layer is defined by standards, internal procedures, and customer requirements. The thickness of the nitrides layer is measured directly at the cross section, with a microscope. The thickness of the diffusion zone is indirectly determined by the hardness distribution on the cross section of the sample. Destructive tests are time-consuming and do not allow for the inspection of all parts after the nitriding process.

NDT is a range of research methods and techniques used to determine the condition of the tested material in a non-invasive manner, i.e. without disturbing its microstructure or depriving it of its functional properties [18]. The advantage of the NDT is that they can be performed on finished parts. This is especially important when dealing with big, expensive, and important parts, such as moulds and matrices, aviation parts, etc. In previous works [19,20], the authors indicate the possibility of using the Barkhausen noise method to assess the thickness of the nitrided layer. Other NDT methods for assessing the thickness of this type of layers are ultrasonic [21,22] and eddy current testing [22]. In the study by Jing et al. [23], the acoustic emission and lock-in infrared thermography techniques are used to assess the damage evolution of nitrided steel.

One of the NDT methods, that is already used, to a limited extent, to evaluate the correctness of thermo-chemical treatment implementation is the eddy current testing [22]. This method offers several advantages over others. It is characterized by high sensitivity to various material changes and easy automation of the measurement process. It is fast, gives an immediate response compared to the penetrant method. It does not require a couplant, unlike ultrasonic testing. It allows testing of both ferromagnetic and non-ferromagnetic materials, which is not possible with the magnetic method. Additionally, it is safe for the operator and the environment compared to the radiographic method. The eddy current method allows for testing of conductive materials. If a defect or material change affects the electrical conductivity and/or magnetic permeability of the tested material, it can be detected using eddy currents.

The ε (Fe3N) and γ′ (Fe4N) phases, forming the nitrides near-surface layer, have different magnetic properties compared to 42CrMo4 steel. ɛ phase is ferromagnetic with the Curie temperature of 294°C [24]. The room-temperature saturation magnetization of bulk ɛ is 123 emu/g [24]. γ′ compound is also ferromagnetic below 488°C with the saturation magnetization of 186 emu/g at room temperature [24]. The room-temperature saturation magnetization of the 42CrMo4 steel is 191 emu/g [25]. The room-temperature electrical resistivity of nitrides (ρ ≈ 140–160 μΩ cm, e.g. for Fe4N ρ = 162 μΩ cm) is greater than that observed in pure iron (ρ ≈ 10 μΩ cm) and at least 2–3 times greater than those for high-grade silicon steels (ρ ≈ 40–60 μΩ cm) [26]. However, 42CrMo4 steel is characterized by lower resistance at room temperature, which is ρ = 21 μΩ cm [27].

Differences in electromagnetic properties allow us to assume that the thickness of the nitrides layer can be estimated by the eddy current method using the amplitude-frequency technique.

2 The purpose of the work

The purpose of the work is to develop a methodology and implement a control and measurement stand for non-destructive detection of the surface layer of nitrides (white layer) and measurement of its thickness in 42CrMo4 steel after gas nitriding. The implementation will be carried out in Łukasiewicz – WIT in a Centre dealing with thermo-chemical treatment. This implementation will allow for quality control of all parts after the gas nitriding process and for higher quality of provided services.

The scope of the work included the creation of test samples, chemical composition tests, roughness tests, hardness distributions using the Vicker’s method, thickness measurements of the nitrided layers on transverse microsections, tests of the phase composition of the nitrided layer using the X-ray diffraction method, description and creation of measurement heads, tests of nitrided layers using the eddy current method, analysis of result correlation between DT and NDT.

3 Methodology

The heat-treatable steel samples marked 42CrMo4 (AISI 4140) were the subject of the tests. The samples were cut from a steel rod and had the form of disks with the dimensions Ø38 × 10 mm. The chemical composition of the steel was specified with the use of spark spectrometer GNR S3 MiniLab 300. The average results from three measurements are shown in Table 1. Steel disks were subjected to hardening and tempering.

Chemical composition of 42CrMo4 steel, in weight %

| C | Cr | Mn | Si | Cu | Mo | Ni | P | S | W | V | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.38 | 0.97 | 0.78 | 0.18 | 0.17 | 0.16 | 0.07 | 0.01 | 0.01 | 0.01 | 0.01 | Bal. |

After heat treatment, the samples were subjected to gas nitriding in the NITREX NX-609 pit furnace. Five processes with varying parameters were performed to obtain samples with different nitrides layer thicknesses, where the diffusion zone thickness exceeds 200 µm. Parameters including temperature, time, and nitriding potential were adjusted (Table 2).

Technological parameters of the nitriding process

| No. | Stage | Parameters of the nitriding process | |||

|---|---|---|---|---|---|

| Temperature (°C) | Time (min) | Process atmosphere composition | Nitriding potential* | ||

| 1 | I | 520 | 60 | 100% NH3 | 8.5 |

| II | 520 | 600 | 35% NH3 – 65% NH3diss | 0.9 | |

| 2 | I | 520 | 300 | 100% NH3 | 11.0 |

| II | — | — | — | — | |

| 3 | I | 560 | 20 | 100% NH3 | 8.5 |

| II | 560 | 520 | 30% NH3 – 70% NH3diss | 0.8 | |

| 4 | I | 540 | 120 | 100% NH3 | 17.0 |

| II | 540 | 1,020 | 70% NH3 – 30% NH3diss | 1.4 | |

| 5 | I | 570 | 330 | 100% NH3 | 2.5 |

| II | — | — | — | — | |

*Nitriding potential N p – is a parameter that controls and regulates the nitriding atmosphere. N p determines the quotient of partial pressures NH3 and H2 in the atmosphere.

DT was conducted for an unequivocal evaluation of the nitrided layer. From each group, one sample was selected, from which a transverse metallographic sample was made.

Samples were etched using Nital with 2% concentration. Using a light microscope Keyence VHX 5000, a picture of the nitrides layer was recorded with a magnification of 1,000–2,500×, and after that the thickness of the layer was measured in ten places using software. The average values of the thickness of the nitrides layer for individual samples are shown in Table 3.

List of reference samples

| No. | Nitrides zone thickness (µm) | Diffusion zone thickness (µm) | Roughness parameter Ra (µm) |

|---|---|---|---|

| 1 | 7.3 | 240 | 0.22 |

| 2 | 10.3 | 240 | 0.25 |

| 3 | 14.8 | 380 | 0.26 |

| 4 | 20.5 | 535 | 0.29 |

| 5 | 25.3 | 370 | 0.31 |

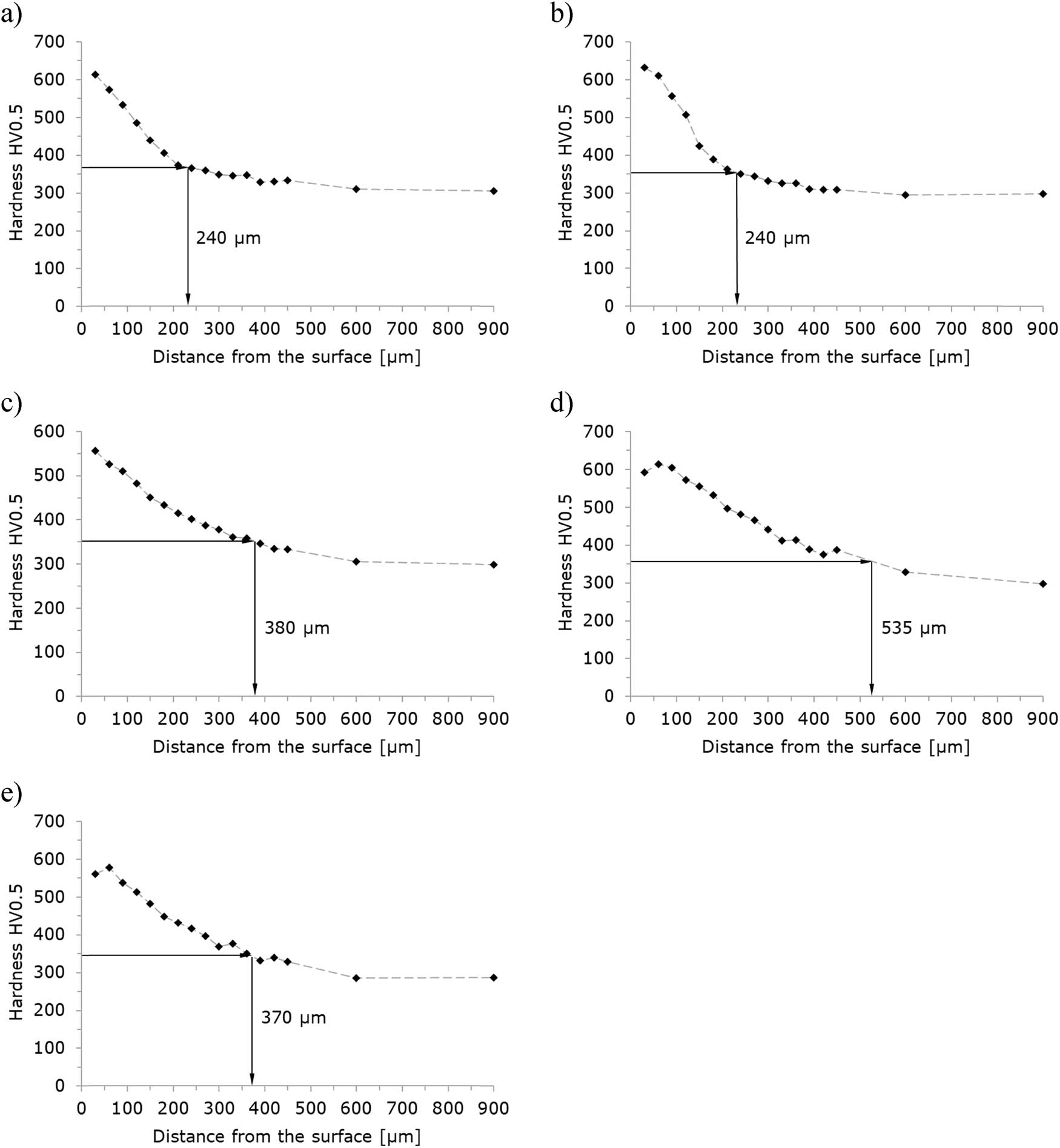

On a transverse metallographic sample, before etching, the hardness of the core was measured in three places and a hardness distribution was done using the Vicker’s method with a load of HV0.5, using an automatic hardness tester Struers DuraScan-70. The thickness of diffusion zone was determined by hardness distribution graph. The value of thickness was defined as the distance from the surface to the point where the hardness reaches the core hardness value increased by 50 HV0.5. The values of thickness of diffusion zone for individual reference samples are shown in Table 3.

Measurements of parameter Ra for individual samples were done with portable roughness tester Mitutoyo Surftest SJ-210 in accordance with ISO1997. The length of elementary section lr corresponded with the length of wave λc = 0.8 mm and speed of measurement 0.5 mm/s, and the length of measurement section was 2.5 mm. Ten measurements were done for each sample. The average values of the Ra parameter are shown in Table 3.

The analysis of phase composition of nitrides layer was performed on an X-ray diffractometer Anton Paar XRDynamic 500, equipped with a cobalt lamp (CoKα), in an angle range of 20°–120° and step 0.02° (time per step: 80 s, type of scanning: coupled scan, beam geometry: parallel, detector mode: linear). The phase identification and determining of percentage share of phases were done using SIeve + software suite with PDF-4/Axiom base.

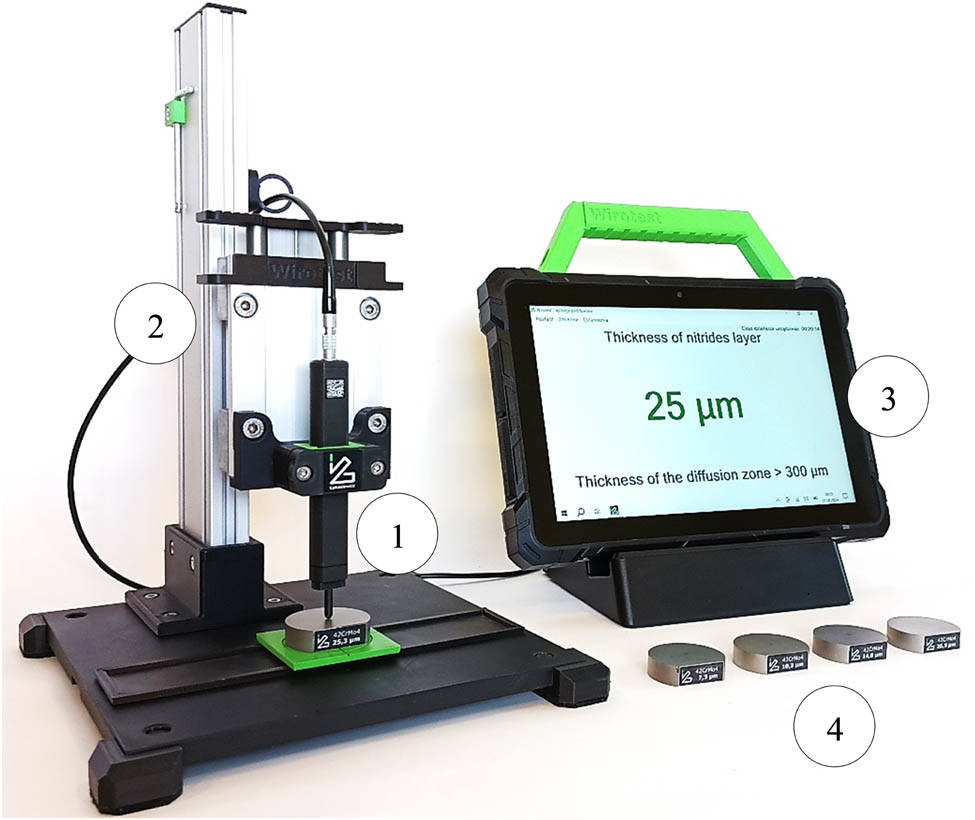

The main method of NDTs of samples after nitriding was the eddy current method. The research equipment consisted of a miniaturized measuring device Wirotest M2, made by Łukasiewicz – WIT, which uses a technique of measuring voltage amplitude and resonance frequency. A holder with guide was designed and made for a repeatable and perpendicular positioning of the head against the testing surface. It provided a continuous pressure of the head. The measuring system is presented in Figure 1. In the preliminary tests, surface heads with the following excitation frequencies were used: 15, 25, 52, 102, 153, 293, 840 kHz, and 1.26 MHz. As a result, the 25 kHz measuring head was selected as the most accurate, i.e. for which the highest correlation coefficient of the eddy current signal from the iron nitrides layer thickness was obtained. Then, detailed measurements were carried out for this frequency, the results of which are presented in this study.

The eddy current measuring system: (1) Wirotest M2 with surface head, (2) holder with guide, (3) tablet with measuring application, and (4) reference samples.

4 Results and discussion

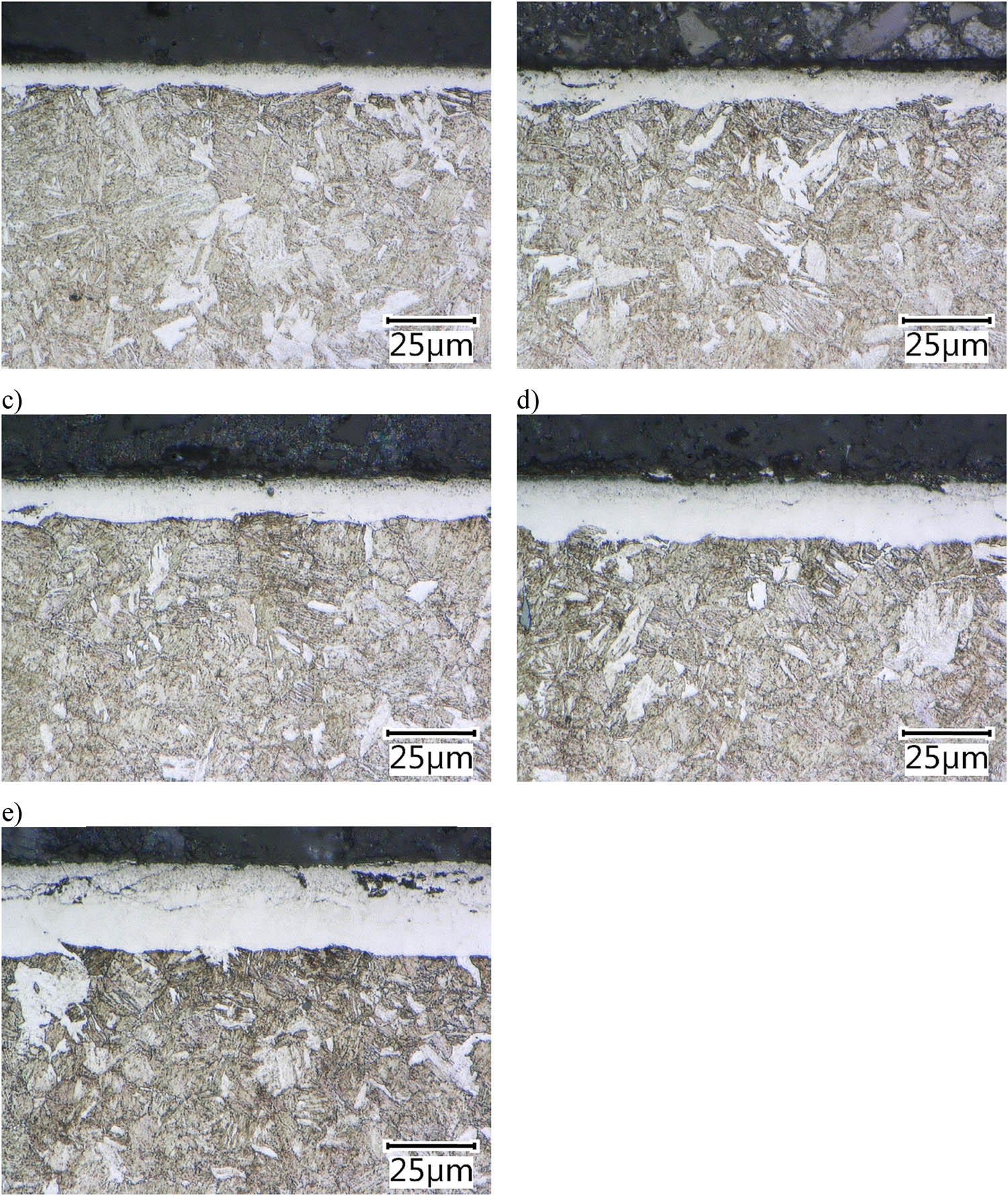

In Figure 2, there are microscopic pictures of transverse microsections of five reference samples. The pictures were made with 2,500× magnification and show white layers of different thicknesses (from 7.3 to 25.3 μm). The thickest layer has significant porosity. As the thickness of the iron nitrides layer increases, porosity also increases. For thin layers (<10 µm), it is possible to avoid porosity by applying an appropriate nitriding potential. However, with thicker layers, this becomes challenging, and beyond a certain thickness (>20 µm), it is impossible under industrial conditions. In the case of 42CrMo4 steel, the white layer is homogeneous in structure and thickness, and clearly separated from the diffusion zone. The precipitates visible under the nitrides layer are carbonitrides of alloying elements.

Microscopic images of iron nitrides layers with medium thicknesses: (a) 7.3 μm, (b) 10.3 μm, (c) 14.8 μm, (d) 20.5 μm, and (e) 25.3 μm.

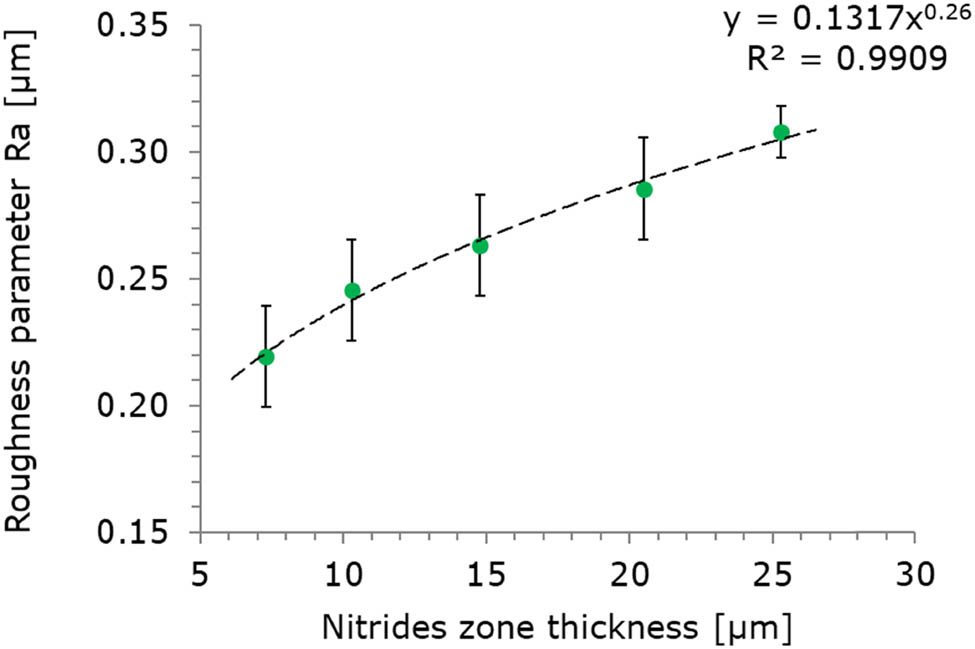

With the increase in nitriding potential, the thickness of white layer increases. With the increase in nitrides layer thickness, the surface roughness parameter Ra also increases (Figure 3).

The scatter plot of roughness parameter Ra vs nitrides zone thickness.

In Figure 4, the hardness distributions of five samples are shown, based on which the thicknesses of the diffusion zones were determined. No clear correlation was found between the thickness of the near-surface nitrides zone and the diffusion zone. A simultaneous increase in the thickness of the surface nitrides layer and the diffusion zone was observed up to a certain point.

Hardness distributions for samples with a layer of iron nitrides with thicknesses: (a) 7.3 μm, (b) 10.3 μm, (c) 14.8 μm, (d) 20.5 μm, and (e) 25.3 μm.

In Figure 5, diffractograms for five reference samples are shown. The presence of two phases: Fe3N (ε) and Fe4N (γ′) was identified for all layers. The percentage share of individual phases for the given nitrides layer thickness is shown in Table 4. This share does not depend on the thickness of nitrites layer, but on the parameters of gas nitriding process, such as temperature, time and, above all, nitriding potential. In the case of process number 2 (Table 2), due to the high nitriding potential during the process, the content of ε phase was 78% (Table 4). However, in the case of process number 3 (Table 2), which was carried out at a higher temperature but with a low nitriding potential in the second stage, a much lower ε phase content was obtained, the share of which in the near-surface zone was 26%.

X-ray diffraction patterns for samples with a layer of iron nitrides with thicknesses: (a) 7.3 μm, (b) 10.3 μm, (c) 14.8 μm, (d) 20.5 μm, and (e) 25.3 μm.

Percentage of the phases in iron nitrides layers

| No. | Thickness of the iron nitrides layer (μm) | The phase percentage (%) | |

|---|---|---|---|

| Fe3N (ε) | Fe4N (γ′) | ||

| 1 | 7.3 | 29 | 71 |

| 2 | 10.3 | 78 | 22 |

| 3 | 14.8 | 26 | 74 |

| 4 | 20.5 | 73 | 27 |

| 5 | 25.3 | 86 | 14 |

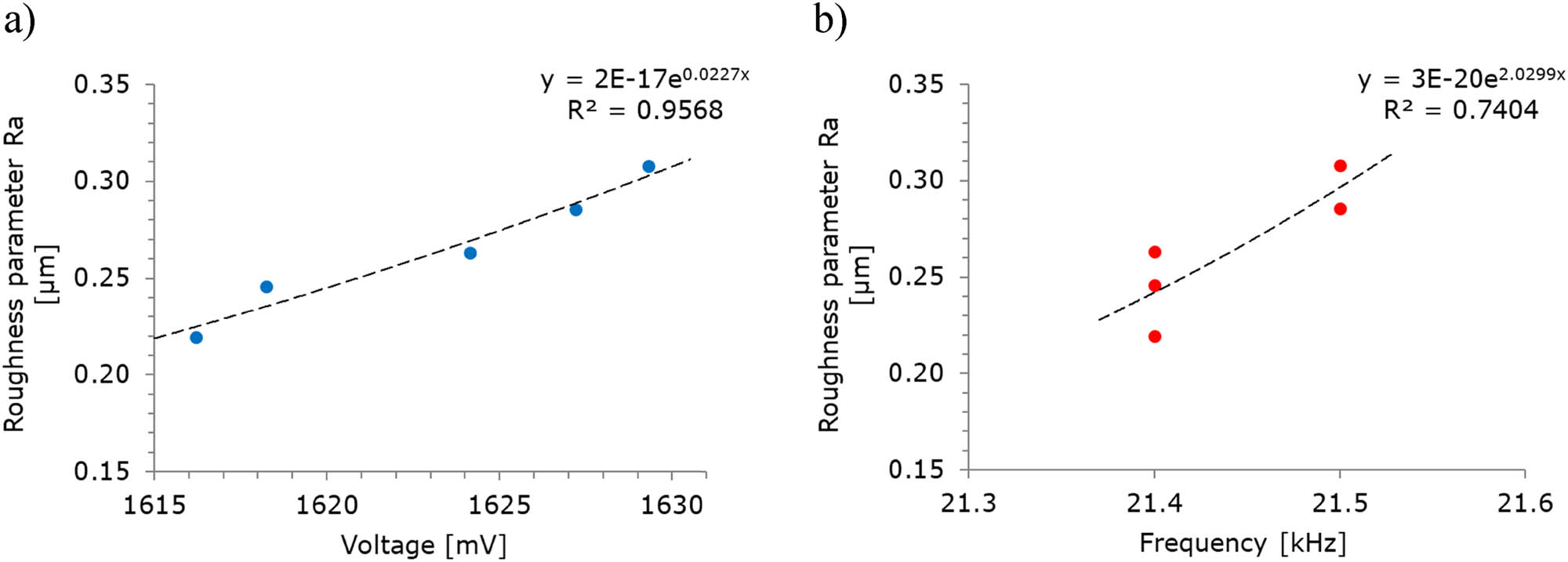

In Figures 6–8, there are scatter plots of the dependency of voltage amplitude and resonance frequency on the average thicknesses and roughness parameters Ra of nitrides layers. Plots contain trend lines fitted by using an exponential function, with the equations shown above the dependency curves. Values of the determination coefficient R 2 and the correlation coefficient r are shown in Table 5.

The scatter plot of voltage amplitude (a) and resonance frequency (b) vs nitrides zone thickness for the 25 kHz measuring head.

The scatter plot of voltage amplitude (a) and resonance frequency (b) vs diffusion zone thickness for the 25 kHz measuring head.

The scatter plot of roughness parameter Ra vs voltage amplitude (a) and resonance frequency (b) for the 25 kHz measuring head.

Dependency of eddy current parameters on the average thicknesses and roughness parameters of nitrided layers

| Dependence | Coefficient of determination R 2 |

|---|---|

| Voltage amplitude – nitrides zone thickness | 0.9887 |

| Resonance frequency – nitrides zone thickness | 0.8145 |

| Voltage amplitude – diffusion zone thickness | 0.5988 |

| Resonance frequency – diffusion zone thickness | 0.5530 |

| Voltage amplitude – roughness parameter Ra | 0.9568 |

| Resonance frequency – roughness parameter Ra | 0.7404 |

No satisfactory correlation was obtained for the dependence of the eddy current signal on the diffusion zone thickness. To effectively assess the thickness of this zone using the amplitude-frequency technique, it is necessary to choose the optimal operating frequency for the measuring head. Theory suggests that the frequency should be lowered to allow the eddy currents to penetrate deeper and cover an area at a depth greater than the expected thickest diffusion zone. Nonetheless, non-destructive measurement of the diffusion zone thickness poses a challenge. This layer contains a higher concentration of carbonitrides and nitrogen-forming elements, which can affect the eddy current signal. The influence of the steel’s chemical composition can significantly impact measurements of the diffusion layer thickness. This issue does not arise when measuring the thickness of the surface layer of iron nitrides in low-alloy steel, which can contain a maximum of two phases: ε and γ′.

The surface roughness of the nitrides layer increases with its thickness. Roughness affects the eddy currents signal, the intensity of which is greatest at the surface. Good correlation was obtained for the dependence of the voltage amplitude on the roughness parameter Ra (Table 5). With the increase in nitrides layer roughness, the voltage amplitude increases (Figure 8a).

Differences in electromagnetic parameters between the white layer and the rest of the nitrided material, as well as changes in the surface roughness of the layer, are factors influencing the eddy current signal, which allows indirect measurement of its thickness. The best correlation was obtained for the dependence of the voltage amplitude on the nitrides layer thickness. For exponential regression, the value of coefficient of determination R 2 was 0.9897. After changing the regression type to linear (Figure 9), the value of coefficient of determination R 2 is also high and equal to 0.9597, which gives the Pearson correlation coefficient r = 0.9796. This indicates a very strong positive correlation between these two parameters. With the increase in thickness of the nitrides layer, the voltage value of the signal of eddy currents increases.

The scatter plot of voltage amplitude vs nitrides zone thickness with linear regression.

5 Conclusion

Evaluation of the iron nitrides layer thickness requires selection of the appropriate operating frequency of the measuring head. The depth of eddy current penetration depends on this parameter. As the frequency increases, the depth of eddy current penetration decreases. It is desirable that the induced currents cover the areas being tested in such a way that the indirectly measured quantity has the strongest influence on the eddy current signal.

In the case of eddy current testing of ferromagnets, determining the optimal frequency is difficult because it is necessary to measure the electrical conductivity γ and the relative magnetic permeability µ r of the tested material. An additional difficulty during testing with the Wirotest M2 device (i.e. a resonant system) is that the operating frequency of the head changes as it is brought closer to the tested material. This means that the selection of the optimal frequency is limited to experimental tests. In the future, databases created from these experiments, along with computer simulations, and AI technology may assist in selecting the optimal frequency.

Differences in electromagnetic parameters between the white layer and the rest of the nitrided material are the main factors influencing the eddy current signal. Iron nitrides have lower magnetic saturation and electrical conductivity compared to 42CrMo4 steel. These differences allow for the indirect measurement of the white layer’s thickness.

Based on the measurement results, the 25 kHz measuring head was selected as the most accurate for estimating the thickness of the iron nitrides layer in 42CrMo4 steel. The analysis of the voltage amplitude is more accurate, than the resonant frequency, in assessing the thickness of this layer. With the increase in thickness of the nitrides layer, the voltage value of the signal of eddy currents increases.

Roughness affects the eddy currents signal. The surface roughness of the nitrides layer increases with its thickness. The research results indicate the possibility of using the same measuring head to assess the roughness parameter Ra of the nitrided layer. As roughness increases, the amplitude of the eddy current signal also increases. To enhance the correlation coefficient of this relationship, the operating frequency of the measuring head should be increased. This will reduce the depth of penetration of the eddy currents, thereby limiting the influence of the thickness of the nitrides layer and increasing the impact of the roughness parameter on the signal.

Porosity affects the electrical conductivity of the material, which can influence the eddy current signal during the measurement of the iron nitrides layer thickness. This factor was not included in the analysis. Additional studies should be performed to determine the effect of porosity on the eddy current signal.

The produced iron nitrides layers on 42CrMo4 steel had a two-phase structure, regardless of the layer thickness. Depending on the nitriding parameters used, mainly the nitriding potential, different percentage shares of the phases forming the white layer were obtained. This share did not depend on the layer thickness. The results of the conducted studies did not show influence of the proportions of phases ε and γ′ on the eddy current signal. Despite these differences, measuring the thickness of the iron nitrides layer is possible using the amplitude technique.

The Wirotest M2 can be used in quality control of steel parts after nitriding to detect the near-surface layer of iron nitrides and to measure its thickness. Its areas of application include tool, automotive, and aviation industries. NDT using the eddy current method allows for the inspection of all manufactured parts and can replace costly and time-consuming DT, which is performed only on selected elements from a given production batch.

-

Funding information: This research was financially supported by the Łukasiewicz Research Network – Warsaw Institute of Technology. This research is a part of the doctoral dissertation “Non-invasive method for characterizing nitrided layers in technical iron alloys using the amplitude-frequency technique of eddy currents,” carried out under the “Implementation Doctorate” program established and financed by the Ministry of Science and Higher Education. This research used devices developed as part of the project entitled “Development of technology for high-pressure gas hardening of satellite gears of the epicyclic aircraft gearbox of the FDGS engine, made of Pyrowear 53 steel and operating under long-term and cyclically variable operating loads” financed under the TECHMASTRATEG II competition by the National Centre for Research and Development (No.: TECHMATSTRATEG2/406725/1/NCBR/2020).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results, and approved the final version of the manuscript. A.K. designed and manufactured the measurement system, performed DT and NDT on the test samples, and prepared the manuscript with the participation of all co-authors. D.K. designed the methodology for measuring the thickness of the nitrides layer by the eddy current method. P.W. selected the parameters and performed the gas nitriding processes of the test samples. A.Z. designed the methodology for characterizing the reference samples by destructive methods.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The datasets generated during the current study are available from the corresponding author on reasonable request.

References

[1] Tamil Moli L, Wahab N, Gopinathan M, Karmegam K, Maniyarasi M. Effects of gaseous nitriding AISI 4140 alloy steel on corrosion and hardness properties. IOP Conf Ser: Mater Sci Eng. 2016;152:012059.10.1088/1757-899X/152/1/012059Search in Google Scholar

[2] Syla N, Aliaj F, Rama M. Hardness curves for 31CrMoV9 steel after gas nitriding. Acta Phys Pol A. 2017;132:484–6.10.12693/APhysPolA.132.484Search in Google Scholar

[3] Dan N, Hussain P, Kakooei S. Nitriding of duplex stainless steel for reduction corrosion and wear. In: Korada VS, Hamid NHB, editors. Engineering applications of nanotechnology. Topics in mining, metallurgy and materials engineering. Cham: Springer; 2017. p. 225–34.10.1007/978-3-319-29761-3_9Search in Google Scholar

[4] Yetim AF, Kovacı H, Tekdir H, Seçer Kavasoğlu Y, Bozkurt YB, Çelik A. Enhancing high cycle fatigue performance of plasma nitrided AISI 4140 steel by post-aging treatment and direct current magnetic field. Materials Today. Communications. 2024;40:109704.10.1016/j.mtcomm.2024.109704Search in Google Scholar

[5] Wach P, Michalski J, Burdyński K, Ciski A. Anticorrosion nitrided layers on unalloyed and alloyed steels. IOP Conf Ser: Mater Sci Eng. 2017;179:012069.10.1088/1757-899X/179/1/012069Search in Google Scholar

[6] Kapuścińska A, Kwiatkowski L, Wach P, Mazurek A, Diduszko R. Anticorrosion properties and morphology of phosphate coating formed on nitrided surface of 42CrMo4 steel. Arch Metall Mater. 2020;65(1):471–7.10.24425/amm.2020.131749Search in Google Scholar

[7] Jasiński JJ, Frączek T, Kurpaska L, Lubas M, Sitarz M. Effects of different nitriding methods on nitrided layer structure and morphology. Arch Metall Mater. 2018;63(1):337–45.10.24425/118946Search in Google Scholar

[8] Michalski J, Wach P, Tacikowski J, Betiuk M, Burdyński K, Kowalski S, et al. Contemporary industrial application of nitriding and its modifications. Mater Manuf Process. 2009;24(7–8):855–8.10.1080/10426910902844203Search in Google Scholar

[9] Wołowiec-Korecka E, Michalski J, Januszewicz B. The stability of the layer nitrided in low-pressure nitriding process. Coatings. 2023;13(2):257.10.3390/coatings13020257Search in Google Scholar

[10] Frączek T, Prusak R, Michalski J, Skuza Z, Ogórek M. The impact of heating rate on the kinetics of the nitriding process for 52100 steel. Materials. 2023;16(20):6708.10.3390/ma16206708Search in Google Scholar PubMed PubMed Central

[11] Takagi S, Tonozuka Y, Nakamura N, Itou T. Effect of crystal structure of surface compound layer on fatigue strength of nitrided SCM 435 steel. Tetsu-to-Hagane. 2018;104(10):594–601.10.2355/tetsutohagane.TETSU-2018-011Search in Google Scholar

[12] Hiraoka Y, Ishida A. Effect of compound layer thickness composed of γ′-Fe4N on rotated-bending fatigue strength in gas-nitrided JIS-SCM435 steel. Mater Trans. 2017;58(7):993–9.10.2320/matertrans.M2017098Search in Google Scholar

[13] Hoja S, Steinbacher M, Zoch HW. Compound layer design for deep nitrided gearings. Metals. 2020;10(4):455.10.3390/met10040455Search in Google Scholar

[14] Tang D, Zhang C, Zhan H, Huang W, Ding Z, Chen D, et al. High-efficient gas nitridation of AISI 316L austenitic stainless steel by a novel critical temperature nitriding process. Coatings. 2023;13(10):1708.10.3390/coatings13101708Search in Google Scholar

[15] Dudziński W, Medyński D, Sacher P. Effect of machine pin-manufacturing process parameters by plasma nitriding on microstructure and hardness of working surfaces. Crystals. 2023;13(7):1091.10.3390/cryst13071091Search in Google Scholar

[16] Silva LGL, Naeem M, Costa THC, Libório MS, Bandeira RM, Ferreira NS, et al. Wear and corrosion of UNS S32750 steel subjected to nitriding and cathodic cage deposition. J Mater Eng Perform. 2023;32:9011–8.10.1007/s11665-022-07792-3Search in Google Scholar

[17] Manova D, Mändl S. Initial phase formation during nitriding of austenitic stainless steel. Surf Coat Technol. 2023;456:129258.10.1016/j.surfcoat.2023.129258Search in Google Scholar

[18] Gupta M, Khan MA, Butola R, Singari RM. Advances in applications of Non-Destructive Testing (NDT): A review. Adv Mater Process Technol. 2021;8(2):2286–307.10.1080/2374068X.2021.1909332Search in Google Scholar

[19] Stupakov A, Farda R, Neslušan M, Perevertov A, Uchimoto T. Evaluation of a nitrided case depth by the magnetic Barkhausen noise. J Nondestruct Eval. 2017;36:73.10.1007/s10921-017-0452-2Search in Google Scholar

[20] Sorsa A, Santa-aho S, Aylott C, Shaw BA, Vippola M, Leiviskä K. Case depth prediction of nitrided samples with Barkhausen noise measurement. Metals. 2019;9(3):325.10.3390/met9030325Search in Google Scholar

[21] Li X, Bi Y, Tang W, Mao H, Huang Z. Nitriding layer depth detection based on mixing frequency nonlinear ultrasonic parameters. Meas Sci Technol. 2024;35(4):045022.10.1088/1361-6501/ad1ba5Search in Google Scholar

[22] Beneš P, Vítovec V. Selected NDT techniques in heat treatment control. Manuf Technol. 2021;21(1):20–8.10.21062/mft.2021.007Search in Google Scholar

[23] Jing J, Dong L, Wang H, Di Y, Xu Y. Damage evolution and rupture prediction of 42CrMoA nitrided steel by acoustic emission and infrared thermography techniques. Nondestr Test Eval. 2018;33(4):376–92.10.1080/10589759.2018.1484920Search in Google Scholar

[24] Huang W, Wu J, Guo W, Li R, Cui L. Preparation and magnetic properties of nanoscale ε-Fe3N particles. J Alloy Compd. 2007;443(1):48–52.10.1016/j.jallcom.2007.01.151Search in Google Scholar

[25] Bulin T, Svabenska E, Hapla M, Roupcova P, Ondrusek C, Schneeweiss O. Magnetic properties of 42CrMo4 steel. IOP Conf Ser Mater Sci Eng. 2017;179(1):012010.10.1088/1757-899X/179/1/012010Search in Google Scholar

[26] Chen SK, Jin S, Tiefel TH, Hsieh YF, Gyorgy EM, Johnson DW. Magnetic properties and microstructure of Fe4N and (Fe,Ni)4N. J Appl Phys. 1991;70(10):6247–9.10.1063/1.350010Search in Google Scholar

[27] Areitioaurtena M, Segurajauregi U, Fisk M, Cabello MJ, Ukar E. Numerical and experimental investigation of residual stresses during the induction hardening of 42CrMo4 steel. Eur J Mech – A/Solids. 2022;96:104766.10.1016/j.euromechsol.2022.104766Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Modification of polymers to synthesize thermo-salt-resistant stabilizers of drilling fluids

- Study of the electronic stopping power of proton in different materials according to the Bohr and Bethe theories

- AI-driven UAV system for autonomous vehicle tracking and license plate recognition

- Enhancement of the output power of a small horizontal axis wind turbine based on the optimization approach

- Design of a vertically stacked double Luneburg lens-based beam-scanning antenna at 60 GHz

- Synergistic effect of nano-silica, steel slag, and waste glass on the microstructure, electrical resistivity, and strength of ultra-high-performance concrete

- Expert evaluation of attachments (caps) for orthopaedic equipment dedicated to pedestrian road users

- Performance and rheological characteristics of hot mix asphalt modified with melamine nanopowder polymer

- Second-order design of GNSS networks with different constraints using particle swarm optimization and genetic algorithms

- Impact of including a slab effect into a 2D RC frame on the seismic fragility assessment: A comparative study

- Analytical and numerical analysis of heat transfer from radial extended surface

- Comprehensive investigation of corrosion resistance of magnesium–titanium, aluminum, and aluminum–vanadium alloys in dilute electrolytes under zero-applied potential conditions

- Performance analysis of a novel design of an engine piston for a single cylinder

- Modeling performance of different sustainable self-compacting concrete pavement types utilizing various sample geometries

- The behavior of minors and road safety – case study of Poland

- The role of universities in efforts to increase the added value of recycled bucket tooth products through product design methods

- Adopting activated carbons on the PET depolymerization for purifying r-TPA

- Urban transportation challenges: Analysis and the mitigation strategies for road accidents, noise pollution and environmental impacts

- Enhancing the wear resistance and coefficient of friction of composite marine journal bearings utilizing nano-WC particles

- Sustainable bio-nanocomposite from lignocellulose nanofibers and HDPE for knee biomechanics: A tribological and mechanical properties study

- Effects of staggered transverse zigzag baffles and Al2O3–Cu hybrid nanofluid flow in a channel on thermofluid flow characteristics

- Mathematical modelling of Darcy–Forchheimer MHD Williamson nanofluid flow above a stretching/shrinking surface with slip conditions

- Energy efficiency and length modification of stilling basins with variable Baffle and chute block designs: A case study of the Fewa hydroelectric project

- Renewable-integrated power conversion architecture for urban heavy rail systems using bidirectional VSC and MPPT-controlled PV arrays as an auxiliary power source

- Exploitation of landfill gas vs refuse-derived fuel with landfill gas for electrical power generation in Basrah City/South of Iraq

- Two-phase numerical simulations of motile microorganisms in a 3D non-Newtonian nanofluid flow induced by chemical processes

- Sustainable cocoon waste epoxy composite solutions: Novel approach based on the deformation model using finite element analysis to determine Poisson’s ratio

- Impact and abrasion behavior of roller compacted concrete reinforced with different types of fibers

- Architectural design and its impact on daylighting in Gayo highland traditional mosques

- Structural and functional enhancement of Ni–Ti–Cu shape memory alloys via combined powder metallurgy techniques

- Design of an operational matrix method based on Haar wavelets and evolutionary algorithm for time-fractional advection–diffusion equations

- Design and optimization of a modified straight-tapered Vivaldi antenna using ANN for GPR system

- Analysis of operations of the antiresonance vibration mill of a circular trajectory of chamber vibrations

- Functions of changes in the mechanical properties of reinforcing steel under corrosive conditions

- 10.1515/eng-2025-0153

- Hybrid mechanics-informed machine learning models for predicting mechanical failure in graphene sponge: a low-data strategy for mechanical engineering applications

- Review Articles

- A modified adhesion evaluation method between asphalt and aggregate based on a pull off test and image processing

- Architectural practice process and artificial intelligence – an evolving practice

- Enhanced RRT motion planning for autonomous vehicles: a review on safety testing applications

- Special Issue: 51st KKBN - Part II

- The influence of storing mineral wool on its thermal conductivity in an open space

- Use of nondestructive test methods to determine the thickness and compressive strength of unilaterally accessible concrete components of building

- Use of modeling, BIM technology, and virtual reality in nondestructive testing and inventory, using the example of the Trzonolinowiec

- Tunable terahertz metasurface based on a modified Jerusalem cross for thin dielectric film evaluation

- Integration of SEM and acoustic emission methods in non-destructive evaluation of fiber–cement boards exposed to high temperatures

- Non-destructive method of characterizing nitrided layers in the 42CrMo4 steel using the amplitude-frequency technique of eddy currents

- Evaluation of braze welded joints using the ultrasonic method

- Analysis of the potential use of the passive magnetic method for detecting defects in welded joints made of X2CrNiMo17-12-2 steel

- Analysis of the possibility of applying a residual magnetic field for lack of fusion detection in welded joints of S235JR steel

- Eddy current methodology in the non-direct measurement of martensite during plastic deformation of SS316L

- Methodology for diagnosing hydraulic oil in production machines with the additional use of microfiltration

- Special Issue: IETAS 2024 - Part II

- Enhancing communication with elderly and stroke patients based on sign-gesture translation via audio-visual avatars

- Optimizing wireless charging for electric vehicles via a novel coil design and artificial intelligence techniques

- Evaluation of moisture damage for warm mix asphalt (WMA) containing reclaimed asphalt pavement (RAP)

- Comparative CFD case study on forced convection: Analysis of constant vs variable air properties in channel flow

- Evaluating sustainable indicators for urban street network: Al-Najaf network as a case study

- Node failure in self-organized sensor networks

- Comprehensive assessment of side friction impacts on urban traffic flow: A case study of Hilla City, Iraq

- Design a system to transfer alternating electric current using six channels of laser as an embedding and transmitting source

- Security and surveillance application in 3D modeling of a smart city: Kirkuk city as a case study

- Modified biochar derived from sewage sludge for purification of lead-contaminated water

- The future of space colonisation: Architectural considerations

- Design of a Tri-band Reconfigurable Antenna Using Metamaterials for IoT Applications

- Special Issue: AESMT-7 - Part II

- Experimental study on behavior of hybrid columns by using SIFCON under eccentric load

- Special Issue: ICESTA-2024 and ICCEEAS-2024

- A selective recovery of zinc and manganese from the spent primary battery black mass as zinc hydroxide and manganese carbonate

- Special Issue: REMO 2025 and BUDIN 2025

- Predictive modeling coupled with wireless sensor networks for sustainable marine ecosystem management using real-time remote monitoring of water quality

- Management strategies for refurbishment projects: A case study of an industrial heritage building

- Structural evaluation of historical masonry walls utilizing non-destructive techniques – Comprehensive analysis

Articles in the same Issue

- Research Articles

- Modification of polymers to synthesize thermo-salt-resistant stabilizers of drilling fluids

- Study of the electronic stopping power of proton in different materials according to the Bohr and Bethe theories

- AI-driven UAV system for autonomous vehicle tracking and license plate recognition

- Enhancement of the output power of a small horizontal axis wind turbine based on the optimization approach

- Design of a vertically stacked double Luneburg lens-based beam-scanning antenna at 60 GHz

- Synergistic effect of nano-silica, steel slag, and waste glass on the microstructure, electrical resistivity, and strength of ultra-high-performance concrete

- Expert evaluation of attachments (caps) for orthopaedic equipment dedicated to pedestrian road users

- Performance and rheological characteristics of hot mix asphalt modified with melamine nanopowder polymer

- Second-order design of GNSS networks with different constraints using particle swarm optimization and genetic algorithms

- Impact of including a slab effect into a 2D RC frame on the seismic fragility assessment: A comparative study

- Analytical and numerical analysis of heat transfer from radial extended surface

- Comprehensive investigation of corrosion resistance of magnesium–titanium, aluminum, and aluminum–vanadium alloys in dilute electrolytes under zero-applied potential conditions

- Performance analysis of a novel design of an engine piston for a single cylinder

- Modeling performance of different sustainable self-compacting concrete pavement types utilizing various sample geometries

- The behavior of minors and road safety – case study of Poland

- The role of universities in efforts to increase the added value of recycled bucket tooth products through product design methods

- Adopting activated carbons on the PET depolymerization for purifying r-TPA

- Urban transportation challenges: Analysis and the mitigation strategies for road accidents, noise pollution and environmental impacts

- Enhancing the wear resistance and coefficient of friction of composite marine journal bearings utilizing nano-WC particles

- Sustainable bio-nanocomposite from lignocellulose nanofibers and HDPE for knee biomechanics: A tribological and mechanical properties study

- Effects of staggered transverse zigzag baffles and Al2O3–Cu hybrid nanofluid flow in a channel on thermofluid flow characteristics

- Mathematical modelling of Darcy–Forchheimer MHD Williamson nanofluid flow above a stretching/shrinking surface with slip conditions

- Energy efficiency and length modification of stilling basins with variable Baffle and chute block designs: A case study of the Fewa hydroelectric project

- Renewable-integrated power conversion architecture for urban heavy rail systems using bidirectional VSC and MPPT-controlled PV arrays as an auxiliary power source

- Exploitation of landfill gas vs refuse-derived fuel with landfill gas for electrical power generation in Basrah City/South of Iraq

- Two-phase numerical simulations of motile microorganisms in a 3D non-Newtonian nanofluid flow induced by chemical processes

- Sustainable cocoon waste epoxy composite solutions: Novel approach based on the deformation model using finite element analysis to determine Poisson’s ratio

- Impact and abrasion behavior of roller compacted concrete reinforced with different types of fibers

- Architectural design and its impact on daylighting in Gayo highland traditional mosques

- Structural and functional enhancement of Ni–Ti–Cu shape memory alloys via combined powder metallurgy techniques

- Design of an operational matrix method based on Haar wavelets and evolutionary algorithm for time-fractional advection–diffusion equations

- Design and optimization of a modified straight-tapered Vivaldi antenna using ANN for GPR system

- Analysis of operations of the antiresonance vibration mill of a circular trajectory of chamber vibrations

- Functions of changes in the mechanical properties of reinforcing steel under corrosive conditions

- 10.1515/eng-2025-0153

- Hybrid mechanics-informed machine learning models for predicting mechanical failure in graphene sponge: a low-data strategy for mechanical engineering applications

- Review Articles

- A modified adhesion evaluation method between asphalt and aggregate based on a pull off test and image processing

- Architectural practice process and artificial intelligence – an evolving practice

- Enhanced RRT motion planning for autonomous vehicles: a review on safety testing applications

- Special Issue: 51st KKBN - Part II

- The influence of storing mineral wool on its thermal conductivity in an open space

- Use of nondestructive test methods to determine the thickness and compressive strength of unilaterally accessible concrete components of building

- Use of modeling, BIM technology, and virtual reality in nondestructive testing and inventory, using the example of the Trzonolinowiec

- Tunable terahertz metasurface based on a modified Jerusalem cross for thin dielectric film evaluation

- Integration of SEM and acoustic emission methods in non-destructive evaluation of fiber–cement boards exposed to high temperatures

- Non-destructive method of characterizing nitrided layers in the 42CrMo4 steel using the amplitude-frequency technique of eddy currents

- Evaluation of braze welded joints using the ultrasonic method

- Analysis of the potential use of the passive magnetic method for detecting defects in welded joints made of X2CrNiMo17-12-2 steel

- Analysis of the possibility of applying a residual magnetic field for lack of fusion detection in welded joints of S235JR steel

- Eddy current methodology in the non-direct measurement of martensite during plastic deformation of SS316L

- Methodology for diagnosing hydraulic oil in production machines with the additional use of microfiltration

- Special Issue: IETAS 2024 - Part II

- Enhancing communication with elderly and stroke patients based on sign-gesture translation via audio-visual avatars

- Optimizing wireless charging for electric vehicles via a novel coil design and artificial intelligence techniques

- Evaluation of moisture damage for warm mix asphalt (WMA) containing reclaimed asphalt pavement (RAP)

- Comparative CFD case study on forced convection: Analysis of constant vs variable air properties in channel flow

- Evaluating sustainable indicators for urban street network: Al-Najaf network as a case study

- Node failure in self-organized sensor networks

- Comprehensive assessment of side friction impacts on urban traffic flow: A case study of Hilla City, Iraq

- Design a system to transfer alternating electric current using six channels of laser as an embedding and transmitting source

- Security and surveillance application in 3D modeling of a smart city: Kirkuk city as a case study

- Modified biochar derived from sewage sludge for purification of lead-contaminated water

- The future of space colonisation: Architectural considerations

- Design of a Tri-band Reconfigurable Antenna Using Metamaterials for IoT Applications

- Special Issue: AESMT-7 - Part II

- Experimental study on behavior of hybrid columns by using SIFCON under eccentric load

- Special Issue: ICESTA-2024 and ICCEEAS-2024

- A selective recovery of zinc and manganese from the spent primary battery black mass as zinc hydroxide and manganese carbonate

- Special Issue: REMO 2025 and BUDIN 2025

- Predictive modeling coupled with wireless sensor networks for sustainable marine ecosystem management using real-time remote monitoring of water quality

- Management strategies for refurbishment projects: A case study of an industrial heritage building

- Structural evaluation of historical masonry walls utilizing non-destructive techniques – Comprehensive analysis