Abstract

This study examined the microstructure characteristics, electrical resistivity (ER), and mechanical properties of ultra-high-performance concrete (UHPC) made with nano-silica (NS), electric arc furnace slag (EAFS), and waste glass powder (WGP). Eight concrete mixtures of binary and ternary blends were assessed to investigate the possible relationships between the observed physical and microstructural features with the obtained compressive and flexural strengths. The individual and combined effects of NS, EAFS (up to 50% replacement of silica sand), and WGP (up to 30% cement replacement) on the examined properties were evaluated. Scanning electron microscopy (SEM), thermogravimetric (TG) analysis, X-ray diffraction (XRD), ER, and pH values, and measurements were employed. SEM examination indicated that using NS along with EAFS and WGP reduced gap space around the fiber, and the enormous single cracks turned into numerous small cracks, thereby improving bonding and flexural strength. TG and XRD studies supported this finding. The ER for the EAFS specimens was enhanced without compromising the alkalinity range of concrete, as proved by pH tests, which address the possible corrosion problem of reinforcement. Thus, sustainable UHPC is achievable.

1 Introduction

Ultra-high-performance concrete (UHPC) is a novel type of concrete developed in France in the 1990s [1]. The American Concrete Institute defines UHPC as an improved cementitious material that has a minimum specified compressive strength of 150 MPa, with improved durability, tensile ductility, and toughness due to the inclusion of fibers and extremely low porosity [2]. UHPC’s mechanical properties are enhanced by reducing the coarse aggregates and water/cement ratio, lowering the calcium silicate (CaO-SiO2) composition, and increasing particle homogeneity, porosity, and microstructure [3]. The limited water-to-binder (w/b) ratio of UHPC limits its hydration range to 30–55% [3]. With insufficient internal water, hydration reactions must be enhanced due to the mechanical and durability properties of UHPC, which depend on curing. Thermal treatment accelerates pozzolanic processes, transforming portlandite (CH) gel into calcium silicate hydrate (CSH) gel and changing the hydration products’ microstructure. Most UHPCs are commonly cured at 90°C and 90% humidity for 48 h. The high cement content of UHPC (up to 1,000 kg/m3) contributes to carbon dioxide (CO2) emissions, which raise environmental concerns [4] and consume natural resources. Thus, partial substitution of cement with supplementary cementitious material (SCM) or industrial by-products to reduce CO2 footprints [5] is highly preferable for sustainability because these compounds also fill bigger cement particle holes and minimize hydration heat cracking, generating a denser concrete matrix [3]. Sustainable UHPC is a cement-based material from agricultural and industrial waste that reduces energy consumption and promotes waste recovery. It has fresh-state and hardened-state features and can be designed to meet environmental demands while maintaining workability, mechanical properties, and durability. Sustainable UHPC has been developed using fly ash, ground-granulated blast furnace slag, limestone powder (LP), tailings, waste glass, and copper slag, which is popular due to its low embedded energy content [6,7]. Today, large amounts of glass garbage and electric arc furnace slag (EAFS) are generated annually and disposed in environmentally unsustainable locations. Glass is not usually recycled into new goods because it loses quality. However, its high silicon and calcium content in powder form can replace cement in concrete combinations, preventing it from being discarded as trash into the environment [3]. According to X-ray diffraction (XRD) and thermogravimetric (TG) analysis, the delicate glass powder formed CSH and consumed CH. Thus, glass concrete microstructures appear more compact and homogenous under scanning electron microscopy (SEM) image analysis, especially in the interfacial transition zone (ITZ). Concrete with 30% glass powder substituted cement had the highest strength and lowest porosity due to the glass powder’s pozzolanic reaction. This replacement reduces transport properties such as chloride diffusion, water penetration depth, and sorptivity. After 30% substitution, CH was insufficient for the glass powder pozzolanic reaction [8,9]. On the other hand, the pozzolanic reaction of glass powder is strongly affected by its particle size; a particle size of 13 µm can improve concrete microstructure [10]. Moreover, One ton of steel produces 200 kg of steel slag (e.g., EAFS) [11]. Typically, slag is more than 95% calcium, silica, aluminum, magnesium, and oxygen. EAFS with low amorphous silica and high iron oxide contents exhibits minor pozzolanic activity; thus, it can be used as an aggregate substitute instead of replacing cement [12]. The cement hydration degree rose from 39% for traditional UHPC to 66% for UHPC containing 54% limestone, as indicated by X-ray analysis and SEM [13]. Furthermore, as previously stated, EAFS is distinguished by its limited pozzolanic efficacy. However, its rough, spongy surface, interior curing, and better mechanical qualities improve the cement matrix’s bonding and connection to ITZ. However, it adds considerable voids to the mix when used as fine aggregate, which may reduce the strength of concrete and the modulus of elasticity. Consequently, UHPC was permitted to be produced with a restricted amount of sand substitution using EAFS [14]. Using nanoparticles is one way to decrease the size and quantity of voids in concrete and boost the effectiveness of pozzolanic. Nano-silica (NS) is a prevalent cement-based substance primarily chosen for its minute dimensions, extensive surface area, and ability to disperse. These characteristics render it well-suited for enhancing the microstructure and overall performance of concrete [15]. The NS nucleation promotes cement hydration and CSH gel production. So, the ideal amount of NS for UHPC formation with minor porosity strikes a balance between nucleation and air that gets trapped [16,17]. SEM shows that cured concrete contains many pores without NS, and CH has room to grow. With 4% NS, UHPC has a dense hardened matrix with tiny air pores, and the cement matrix hydration produces the foil-like CSH gel, not CH crystal. Due to the high viscosity of cementitious mixtures, 5% NS can trap a lot of air, resulting in the porousness of hardened concrete [16,18]. Moreover, in 60% slag replacement, CH could drop below 0.5%, suggesting that the remaining CH might not be sufficient to continue pozzolanic processes despite SEM micrographs showing many unreacted slag particles [19]. Also, the combined impact of NS’s improved pozzolanic activity and EAF aggregate’s more excellent ITZ bonding increases the HPC mixtures’ strength [14]. Finally, there is a direct correlation between electrical resistivity (ER) and the mixture’s durability; a higher resistivity indicates that the hardened mixture will be more resistant to ions and water penetrating the sample. ER testing can reveal the corrosion rate of embedded reinforcing steel in concrete due to chloride ions [20]. The ER of concrete depends on its permeability, pore interconnectivity, and pore solution ionic composition [21]. Also, microstructure features and micro-cracks of concrete affect its ER [22]. As electric resistance decreases, concrete ionic transport increases, causing the entry of destructive ions, presumably chloride Cl−, leading to corrosion [21]. According to AASHTO TP 95’s concrete ER criteria, chloride penetrability is classified as high (<12 kΩ cm), moderate (12–21 kΩ cm), low (21–37 kΩ cm), extremely low (37–254 kΩ cm), and insignificant (>254 kΩ cm) [23]. Based on the above literature, many by-product materials, such as EAFS (inert steel slag) and waste glass powder (WGP), are disposed in large quantities. So, their reuse to produce sustainable UHPC with low environmental impact by replacing a large proportion of cement with WGP and silica sand with EAFS is interesting. This study is aimed to investigate the synergistic effect of EAFS, WGP, and NS inclusion on the microstructure, ER, and strength performance of the produced UHPC. Evaluation methods included SEM, qualitative and quantitative XRD and TG, ER, and pH tests. An in-depth analysis of the microstructural and durability characteristics of UHPC offers crucial insights into the factors influencing its mechanical performance.

2 Experimental program

2.1 Materials

2.1.1 Cementitious materials and admixtures

Ordinary Portland cement (CEM) has a particular gravity (g) of 3.15 and an average diameter of particles (d50) of 12.63 μm. It meets the requirements of ASTM C150/C150M [24], and Table 1 shows its chemical structure. A reactive powder consisting of silica fumes (SF) with a pozzolanic activity index of 121%, 2.20 g, and a particle size of 0.16 μm was utilized, following the specifications of ASTM C1240-15 [25]. NS powder (AEROSIL 200) had a specific surface area of 200 m2/g, consisting of 99.9% silicon dioxide (SiO2), and had a pH value of 4.1. Local LP (2.73 g, 7.11 μm d50) and WGP (2.55 g, 13.24 μm d50) were used as SCMs. In this investigation, WGP is prepared locally after collecting and cleaning the waste glass sheets, and then crushing them by hand before being transferred to the Los Angeles apparatus. Once the sheets are crushed, they are ground into a fine powder using a silver crest grinder. An X-ray fluorescence (XFR) test was performed to ascertain the materials’ chemical compositions, as indicated in Table 1. Moreover, Figure 1 shows XRD analyses of the WGP and LP carried out to establish their mineralogical compositions. The diffractogram shows a significant amorphous phase in the WGP material, with a substantial deviation from the baseline value in the 10–35 2θ range. Crystalline components were recognized as wollastonite CaSiO3, calcite CaCO3, and quartz SiO2. It can be observed from Figure 1 that no explicit or individual sharp peaks appear in the WGP, confirming its amorphous nature. Furthermore, calcite peaks suggest that the limestone was predominantly composed of calcium, specifically calcite. Microsteel filaments that were straight and copper-coated were utilized in this research. With fiber lengths ranging from 15 to 17 mm, the aspect ratios were between 65 and 94, and the volume of fibers in the concrete was 2%. Hyperplast PC202 superplasticizer, known as high-performance polycarboxylic polymer-based, possesses a chloride-free nature, specific gravity of 1.07, pH 6, and 40% solids and are used as high range water reducing admixtures (HRWR).

Chemical components of Portland cement, SF, WGP, local LP, EAFS, and natural sand

| Oxide | Chemical analysis (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Abbreviation | CEM | SF | WGP | LP | EAFS | Sikadur 504 | Sikadur 507 | |

| Sodium oxide | Na2O | 1.87 | 0.67 | 3.51 | 0.80 | 1.34 | 0.01 | 0.02 |

| Magnesium oxide | MgO | 1.91 | 1.11 | 2.64 | 0.26 | 1.54 | — | — |

| Aluminum oxide | Al2O3 | 2.33 | 0.26 | 0.88 | 0.25 | 2.41 | 1.16 | 0.35 |

| Silicon dioxide | SiO2 | 17.70 | 82.43 | 65.76 | 2.82 | 14.94 | 63.59 | 66.24 |

| sulfur trioxide | SO3 | 3.77 | 1.86 | 0.25 | 0.05 | 0.76 | 0.23 | 0.08 |

| Potassium oxide | K2O | 1.02 | 3.83 | 0.25 | 0.02 | 0.08 | 0.01 | — |

| Calcium oxide | CaO | 68.38 | 1.82 | 10.53 | 59.88 | 26.49 | 0.71 | 0.19 |

| Titanium dioxide | TiO2 | 0.25 | 0.01 | 0.08 | 0.01 | 0.28 | 0.63 | 0.02 |

| Chromic oxide | Cr2O3 | 0.01 | — | — | — | 0.69 | — | — |

| Manganese dioxide | MnO2 | 0.23 | 0.09 | 0.02 | — | 3.23 | — | 0.01 |

| Iron trioxide | Fe2O3 | 5.10 | 1.02 | 0.81 | 0.17 | 32.13 | 0.16 | 0.06 |

| Loss on ignition | LOI | 1.60 | 1.74 | 1.10 | 35.70 | — | — | — |

EAFS, WGP, and LP X-ray diffractogram.

2.1.2 Natural fine aggregates and EAFS aggregate

The natural fine aggregates utilized in this study comprised two fractions of fine silica sand: 40% Sikadur 504 and 60% Sikadur 507 with a granularity gradation of (80 μm–0.2 mm) and (0.3–0.85 mm), respectively. The composite fine sand had a specific gravity of 2.7 and a density of 1,500 kg/m3. Also, EAFS was acquired from the Al Anmaa company in the Governorate of Basra. The ASTM C989 standard was employed to evaluate the pozzolanic efficacy. Table 1 contains the chemical constituents of the sand and EAFS gathered by the XFR assay. Furthermore, XRD analyses were performed on the EAFS to determine its crystal mineralogical structure, as illustrated in Figure 1.

The strength activity index of the EAFS test result was only 57%, which is less than the minimum ASTM requirement, which justified its non-use as a cement substitution. The EAFS contained the following elements: starkly crystalline corundum, magnetite, larnite, bredigite, gehlenite, and cristobalite (Figure 1). This crystallinity indicates low hydraulic activity and possible cementitious properties. EAFS was utilized primarily in this investigation as an aggregate substitute due to its high iron oxide and low amorphous silica content. Its elevated density confers advantages to retaining walls, acoustic barriers, bases, and bulwark blocks. Following the particle-size distribution of the replaced sand (Sikadur 504 and 507), the EAFS underwent crushing and sieving to achieve a particle-size distribution of 312.12 μm d50 and a specific gravity of 3.31.

2.2 Methods and parameters

To build the sustainable UHPC, a modified Andreasen and Andersen (MA&A) packing of particles model was implemented to conform the mixture constitution to an Andreasen curve featuring a size distribution coefficient q value (fuller exponent distribution modulus) of 0.264, which was determined through prior research [26,27]. EMMA Mix Analyzer (Elkem Materials EMMA software) access (www.elkem.com) was used to adjust the reference mixture S1 (without the inclusion of EAFS, WGP, or NS) by using MA&A according to Equation (1) to formulate adequately compacted material mixtures, as shown in Figure 2.

where D is the particle size; P(D) is the weight fraction of the total solids smaller than D; D max and D min are the maximum and minimum particle sizes, respectively; q is the Fuller exponent.

Particle-size distributions (EMMA Mix Analyzer).

Next the official material testing institute for the construction industry’s M3Q_210 formula was used to determine the remaining seven UHPC mixture proportions. The eight mixtures were divided into two sets. The first set was free of NS, coded S1, and the second group contained NS, coded S2. In both groups, when EAFS and WGP are present, the symbols E and G are added to the code, respectively. The sand-to-binder ratio is fixed at 0.95 and w/b ratio at 0.198. Moreover, all the mixes included 100 kg/m3 of LP as a quartz powder (QP) alternative, 150 kg/m3 of SF as a binder, and 146.21 kg/m3 of steel fiber based on previous literature [27,28,29]. Table 2 shows the other weight of the components of the eight mixtures (kg/m3).

Design criteria and ingredients mix quantities (kg/m3)

| Mix | Variable (%) | Composition of ingredients (kg/m3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| EAFS | WGP | NS | CEM | EAFS | WGP | NS | Total sand | Water | HRWR | |

| S1 | 0 | 0 | 0 | 800 | 0 | 0 | 0 | 902.50 | 169.58 | 30.88 |

| S1E | 50 | 0 | 0 | 800 | 451.25 | 0 | 0 | 451.25 | 168.15 | 33.25 |

| S1G | 0 | 30 | 0 | 560 | 0 | 240 | 0 | 902.50 | 165.30 | 38.00 |

| S1EG | 50 | 30 | 0 | 560 | 451.25 | 240 | 0 | 451.25 | 169.58 | 30.88 |

| S2 | 0 | 0 | 4 | 768 | 0 | 0 | 32 | 902.50 | 161.03 | 45.13 |

| S2E | 50 | 0 | 4 | 768 | 451.25 | 0 | 32 | 451.25 | 156.75 | 52.25 |

| S2G | 0 | 30 | 4 | 528 | 0 | 240 | 32 | 902.50 | 162.45 | 42.75 |

| S2EG | 50 | 30 | 4 | 528 | 451.25 | 240 | 32 | 451.25 | 158.18 | 49.88 |

2.3 Mix procedure, specimens, and curing conditions

After calculating the mixing proportions, the tiny nanoparticles were evenly distributed by manually rubbing and stirring cement and NS powders in a sealed plastic bag for 30 min. High-quality silica sand, EAFS fine aggregates, and powdered components (SF, LP, and WGP) are mixed with the blended cement-NS in a 10 L mortar mixer at low speed till a homogeneous dry mixture was achieved dry, mixing continued for at least 5 min. A medium-speed mixing was adopted while mixing water, and half the superplasticizer (by weight) was added to produce spherical moist particles in 10 min. After that, the remaining superplasticizer was gradually added and mixed for 5–10 min at high speeds until a homogeneous fresh mixture was established. Mix the microfibers evenly, and for 5 min, spread them throughout the fresh blend. After mixing, 50 mm × 50 mm × 50 mm cubes and 40 mm × 40 mm × 160 mm prism specimens were cast and cured to evaluate the compressive strength and flexural strength tests, respectively. As stated in the ACI committee report PRC-239R and by numerous authors, the molds were wholly enveloped in polythene for 24 h before being demolished and subjected to heat curing at 90 ± 2°C and 100% relative humidity (RH) for a further 48 h as recommended for producing UHPC units to minimize the delayed formation of ettringite [2,27,30]. After that, standard-curing at a temperature of 20 ± 2°C with 100% RH in water until testing (28 days) was adopted.

2.4 Evaluation methods

The ASTM C109/C109M-11b specifications [31] were adhered to using 3,000 kN compression testing equipment for compressive strength tests. A flexural strength test on prismatic specimens followed the procedure and guidelines outlined in ASTM C348-14 [32]. The study analyzed the microstructure of mixtures of UHPC using three primary methodologies. The first method involved direct observation using an SEM, which focused on fracture surface characteristics using an electron scanner with a distance of operation of 14 mm and a tungsten source with voltages up to 30 kV (FEI system). The SEM specimen sizes, 12 mm × 12 mm × 12 mm, were manually cut from the fracture surface of the flexural specimens and dried in an oven. Then, a gold coating was applied to prevent the formation of electrical charges and deformation. The second method involved a qualitative mineralogical investigation conducted using an XRD test. This test involved drilling powdered samples from a concrete cube, collecting 60 g of powder, passing through a 63 μm sieve, and drying in an oven at 60°C for 24 h. A Shimadzu X-ray diffractometer was used to probe the sample’s mineral composition, using a 2θ axis in a continuous scan mode with a range of 5°–90°. The third method involved the TG analysis, a LINSEIS apparatus with a temperature range of 25–900°C and a rate of 10°C/min under a molecular nitrogen (N2) environment records the TG and DTG values of UHPC powdered samples procured from the same sources and quantities as the XRD samples to examine the effect of parameters (EAFS, WGP, and NS) on the degree of UHPC hydration. The study also evaluated the durability characteristics of UHPC using ER and alkalinity measurements. ER was measured using two probes to measure resistance (ohmmeter). At the same time, the alkalinity of UHPC mixtures is assessed using small fragments from fractured concrete cubes. The fragments are crushed and ground into a fine powder, then passed through a 75 μm sieve. The Hanna 211 pH meter is used, and a 15 g sample of concrete powder with 15 g of distilled water is mixed. The pH values are recorded at different intervals. In conclusion, the study provides valuable insights into the relationship between engineering behavior, composition, durability, and microstructure in UHPC mixtures.

3 Results and discussion

3.1 Mechanical properties

Compressive and flexural strengths were determined at 28 days. Tested in triplicate, and the average results are shown in Figure 3a and b, respectively. The main finding in Figure 3a is that the EAFS and NS positively affected the UHPC compressive strengths, whereas WGP harmed these responses. With 50% EAFS substitution, mixture S1E showed the maximum strength, and more than 187 MPa of compressive strength was achieved. The improvement percentage was 1.7% compared to the waste-free mixture S1 (which has the same cement content of 800 kg/m3). This enhancement reflects the positive aspect of using EAFS instead of sand when the cement content in the mixture is constant due to the erratic form and roughness of the EAFS particles, along with their strength activity index of 57%, which enhances their bond with cement paste and densifies the ITZ, thereby increasing their compressive strength [28,33,34]. Furthermore, its hardness – corundum evident in the XRD study (Figure 1) – contributes to the EAFS’s increased compressive strength [35]. In contrast, the S1G mixture with 30% WGP replacement (cement content 560 kg/m3) had a lower compressive strength of 163 MPa, with a decline rate of 11.4% compared to the S1 mixture (cement content 800 kg/m3), and despite this adverse effect of locally prepared WGP, the strength is still higher than the minimum requirement of 150 MPa, taking into account a 30% reduction in cement content. The WGP’s negative behavior is due to WGP’s poor reactivity [28]. Also, the particle size distribution affects WGP’s partial cement replacement performance where the large particle sizes decrease reaction rates, leading to loose secondary CSH and reduced strength. Thus, WGP blended cement must enhance its early-age qualities because its low characteristics would restrict its high-volume usage [36,37]. Calmon et al. found that 5% WGP-containing mortar had 6% higher compressive strength than a control mortar without WGP, but higher substitution decreased strength [38]. Steel slag reduced the detrimental effects of recycled glass in concrete while increasing compressive strength [39]. Another conclusion is that the combined impact of EAFS and NS was unclear. As shown in Figure 3b, adding EAFS alone slightly affects the flexural strength, as is apparent in mixture S1E. Also, using NS alone led to a compressive strength decrease of 2.1% when comparing mixture S2 (cement content 768 kg/m3) with S1 (cement content 800 kg/m3). However, the combined effect of EAFS and NS on flexural strength is more evident than its effect on compressive strength. As observed in the S2E mixture (cement content 768 kg/m3), the flexural strength increased by 14.4%. This increase resulted from the rough surface and irregular texture of the EAFS particles, which increased their stickiness to the cement matrix, especially in the presence of NS [28,40,41,42,43]. NS establishes a densified ITZ between fibers and cement matrix, thus improving the fibrous composites’ residual post-cracking strength, concrete hardness, and pull-out performance [17,44]. Regarding WGP, it affects flexural strength similar to its implications on compressive strength. As noticed in Figure 3b, mixtures S1G (560 kg/m3 cement) and S2G (528 kg/m3 cement) had lower flexural strength among all the mixtures. The rate of decline was 10.3 and 9.1%, respectively, compared with the reference mixture S1. But the synergistic effect of both EAFS and NS overcame the adverse impact of WGP, as is evident in the mixture S2EG that had the second highest flexural strength of 34.625 MPa with a slightly decreasing rate (0.4%) compared to the mixture S2E, despite using 31.25% less cement.

(a) compressive and (b) flexural strength at 28 days.

To further understand the chemical compounds’ effect on the probability distribution of UHPC strength, probability density functions (PDF) of the UHPC strength are employed to compare chemical compounds’ key factors affecting their final performance as shown in Figure 4.

PDF distribution of chemical compounds for (a) compressive strength and (b) flexural strength. Note: SF, LP, and water with HRWR are constant in all mixtures.

It can be deduced from Figure 4a that the cement content significantly affects the compressive strength of UHPC. As was expected, the compressive strength increased with the increase in the cement content. Also, EAFS aggregates and NS have slightly affected compressive strength. On the other hand, it is clear to note the adverse impacts of WGP. In the same way as the compressive strength, Figure 4b shows the PDF for the flexural strength. The negative effect of WGP on flexural strength continues. In comparison, the enhancement role of the EAFS became more apparent and the role of cement has become less influential than its effect on compressive strength.

3.2 Analysis of microstructural features

Monitoring specific fracture surface characteristics in testing and control specimens can reveal matrix microstructural changes; this might assist in interpreting the strength change. This study employed SEM to identify plausible relationships. Figure 5 depicts UHPC specimen fracture surfaces with SEM images at 28 days in reference concrete, EAFS concrete, and WGP concrete. UHPC specimens were treated with 4% NS, and their large-scale fractured surfaces and SEM images are shown in Figure 6.

Fracture surfaces of UHPC specimens; (a and b) mixture S1 (reference); (c and d) mixture S1E (EAFS concrete); (e and f) mixture S1G (WGP concrete).

Fracture surfaces of UHPC specimens modified with 4% NS; (a and b) mixture S2 (reference); (c and d) mixture S2E (EAFS concrete); (e and f) mixture S2G (WGP concrete).

The reference UHPC concrete, made without waste, displayed a large gap between the matrix and the fiber, exhibiting varying-sized solitary cracks that appeared atypical in the matrix (Figure 5a and b, white arrows #1 and #2). The gap with the fiber began to decrease, and the large single cracks turned into multiple small cracks when EAFS and some amount of WGP were added (white arrows #1 and #3 in Figure 5c, d, and f). Moreover, small amounts connected to the fiber interface and cubic-like or floral forms defined the hydration products. (white arrows #4 Figure 5e). It is interesting to note that despite the adverse effects of WGP replacement with cement, as explained in Figure 3, its positive effects on the matrix microstructure and the ITZ with the fiber surface were significant due to the pozzolanic reaction with the CH hydrates.

The UHPC concrete, made with NS alone, displayed a large gap between the matrix and the fiber. However, this gap is small compared to mixture S1 (white arrows #1 in Figure 6a and b). Furthermore, a more dense matrix was identified. The gap with the fiber began to decrease and became tiny when EAFS was added, and multiple small cracks appeared with few quantities of flower-like or cubical form hydration products (white arrows #3 and #4 in Figure 6c and d). This reflects the high improvement in flexural results for the S2E and S2EG mixtures shown in Figure 3b, which gives an impression of the positive combined effect of both EAFS and NS. Furthermore, the hydration products showing cubic-like or floral forms and, in significant quantities, were connected to the fiber interface once WGP was used (white arrows #4 Figure 6e).

3.3 Analysis of TG results

Employing chemical composition measurements following high-temperature exposure, one may better grasp the matrix microstructure and its links to the strength characteristics. The matrix mass changes connected with a temperature rise were measured using a TG test. The observed variations reveal different hydrous minerals breaking down in the matrix. In the present study, Figures 7 and 8 display the TG and DTG test results for the reference UHPC (without waste), EAFS, and WGP-modified UHPC specimens. Figure 7 shows two primary endothermic peaks that align with the two significant drops in the TG curves: (I) at temperatures ranging from 30 to 200°C, they are specifically associated with the loss of free water, combined water initially from CSH (80–90°C), and dehydration of ettringite (AFt), aluminate-ferrite-monosubstituted phases (AFm) (130°C) [45]. (II) At 600–800°C, they are associated with decarbonizing calcium carbonate (CaCO3). Also, the decomposition of portlandite (CH) results in a secondary peak (III), which primarily occurs between 400 and 500°C [46].

TG profiles of the UHPC: (a) without NS; and (b) with NS.

DTG profiles of the UHPC: (a) without NS; and (b) with NS.

A more considerable mass loss in the first region from 30 to 200°C suggests a low crystal water content, indicating a higher reaction rate. Furthermore, for mixture S1E (have EAFS), a clear and sharper, high-intensity CSH peak around 80–90°C appears , followed by a second peak at 140°C as seen in Figure 8a; this implies that in mixture S1E, hydration products of CSH and/or ettringite phase increased [45]. These results indicated that the pozzolanic reaction increased when EAFS was used as a sand replacement. On the other hand, replacing the WGP with a portion of cement decreased the amount of CSH in the 30–200°C stage. As observed in Figure 8a, mixture S1G had a minor mass loss; this indicates a diluting effect on the pozzolanic reaction due to the use of WGP. These results are consistent with the strength results discussed previously. As shown in Figure 3a, S1E gave the highest strength, while the S1G mixture gave the lowest strength. Adding NS to UHPC mixtures slightly decreased the mass loss with less intense and broader peaks for mixtures S2E and S2EG that already have EAFS, as shown in Figure 8b when compared with mixture S1E and S1EG without NS (Figure 8a). Other than that, NS increased mass loss for the rest of mixtures S2 and S2G (Figure 8b) when compared with mixtures S1 and S1G (Figure 8a); this is an indication of an increase in the formation of CSH, which reflects the pozzolanic activity of NS due to the nucleation effect of NS on the hydration process [47].

Furthermore, using NS alone necessitates a large amount of HRWR admixture, which explains the lower reaction rate between calcium hydroxide and amorphous silica. Those mentioned above agreed with the strength results and SEM analysis. At temperatures ranging from 600 to 800°C, adding LP to the UHPC mixture typically results in a second peak that is more intense and wider [46]. The UHPC mixture containing EAFS, both with and without NS incorporation (e.g., mixtures S1E and S2E, as shown in Figure 8a and b), exhibits a maximum peak intensity due to calcium carbonates in EAFS [48]. Moreover, the addition of NS reduced the intensity and made the decomposition of carbonate phases occur in temperature ranges close to each other (Figure 7b). As shown in Figure 8b, the DTG peaks in the decomposition temperature range of 650–680°C differ only in shape.

Finally, calculating and analyzing CSH and CH from TG curves helps estimate hydration products. The TG curve mass decline at 400–500°C suggests CH water loss. Therefore, we can use TG curves and Equation (2) to calculate the CH content in specimens [46].

where M CH and M H represent the CH and water molecular weights, respectively, and Δm CH represents the mass loss as a percentage due to CH dehydration.

The TG curve shows water loss from CSH gel at various temperature ranges. Previous investigations suggested temperature ranges of 180–300°C, 200–400°C, and 105°C until water loss from CH dehydration occurs [49]. In this study, the percentage of CSH is calculated using weight loss between 150 and 400°C to minimize the impact of AFt and AFm, which decompose earlier. Therefore, CSH amounts are calculated using Equation (3) [46].

where M CSH and M H are CSH and water molecular weights, respectively, and Δm CSH is the mass loss in percentage due to CSH dehydration at 150–400 °C. Despite the chemical formula of CSH is being as C1.7SH4, some part of the 4 moles of water will be eliminated at temperatures below 150°C. The equilibrium composition of CSH is thus taken as C1.7SH2.1 as given in [49], which justifies the division by 2.1 used in Equation (3). The contents of CH and CSH by the total mass of the UHPC mixture are displayed in Figure 9a and b, respectively.

(a) Portlandite contents in UHPC and (b) CSH contents in UHPC.

From Figure 9a and b, it was concluded that adding EAFS (mixture S1E) increased the CH content and slightly decreased the CSH content by 21 and 7.6%, respectively, compared with the reference mixture S1; this may be related to the increase in the rate of hydration of cement at early ages due to the EAFS aggregate having a partial pozzolana activity compared with sand, this accelerated hydration generates large amounts of CH making the consumption of CH not good enough at an age of 28 days. The other main finding seen in Figure 9a and b, related to the use of WGP in UHPC (mixture S1G), resulted in a significant decrease in both CH and CSH by 50 and 60.4%, respectively, when compared with the reference mixture S1. Because of the dilution effect and the weak pozzolanic activity of the glass, it did not contribute to adding additional hydration products. Moreover, as shown in Figure 9a and b, incorporating NS in UHPC mixtures leads to decreased CH and increased CSH over time. This observation agrees with the strength result discussed above (Figure 3a and b), where mixture S1G (with WGP) has the lowest strength among all the eight mixtures. Also, the EAFS and NS UHPC have a higher compressive (mixture S1E) and higher flexural strength (mixture S2E and S2EG). Moreover, the results of the TG and DTG analyses were consistent with the main conclusions obtained from the SEM analysis examination, which showed, e.g., that the gap between the fiber began to decrease, so the large single cracks turned into multiple small cracks when EAFS, NS, and some amount of WGP were added, resulting in improving the flexural strength in mixture S2E and S2G.

3.4 XRD analysis

Figure 10 shows the XRD patterns for eight factorial mixture samples after 28 days of curing. These combinations covered the examined parameters with EAFS ratios of 0 and 50% as sand replacement, WGP ratios of 0 and 30%, and Ns doses of 0 and 4% based on cement weight. Most patterns exhibit five dominant peaks belonging to the quartz stage [50]. These patterns are caused by the different sources of quartz in all UHPC combinations, including silica sand, amorphous silica fume, and NS components that may have crystallized following hydration. Another prominent peak can also be observed clearly in all mixtures, as defined by the 2-theta value of 29.5°. This peak is due to the presence of calcite due to the addition of LP to produce UHPC instead of QP [13]. Figure 10b shows that adding NS reduced this peak’s intensity to a lower level than mixtures without NS, as shown in Figure 10a, consistent with what was observed when discussing the thermal analysis results, as mentioned previously in Figures 7 and 8.

XRD patterns of factorial mixtures under the combined effect of EAFS and WGP: (a) without NS; and (b) with 4% NS.

Another important finding of XRD patterns is the existence of highly un-hydrated C3S and C2S stage peaks with UHPC combinations. The intensities of C2S and C3S tended to decrease when WGP (mixtures S1G and S2G) was included, as shown in Figure 10a and b. Better clinker phase solubility is probably associated with decreased C2S and C3S peaks. Probably the most significant factor influencing the lower intensities of CH peaks was the pozzolanic reaction of portlandite with SF and WGP [10], supported by Figure 9a and the findings of the TG investigation on the CH content. The patterns of un-hydrated stages are noted to be slightly affected when 4% NS was added. Although the most significant decrease was seen between mixture S1E (containing EAFS only) and mixture S2E (containing EAFS and NS), as shown in Figure 10a and b, the positive mutual relationship between EAFS and NS was reflected in the improvement of the results of strength, and SEM and TG analysis, which were discussed earlier.

More information can be observed in the XRD pattern analysis related to the appearance of the ettringite with varying intensity. Still, the most incredible intensity was observed in mixture S1G (containing WGP), which explains the reason for the decrease in strength in this mixture. Also, using NS reduced the amount of ettringite in most cases. However, the most significant decrease was observed in mixture S2G (containing WGP and NS) compared to mixture S1G; the reduction rate was 47.5%.

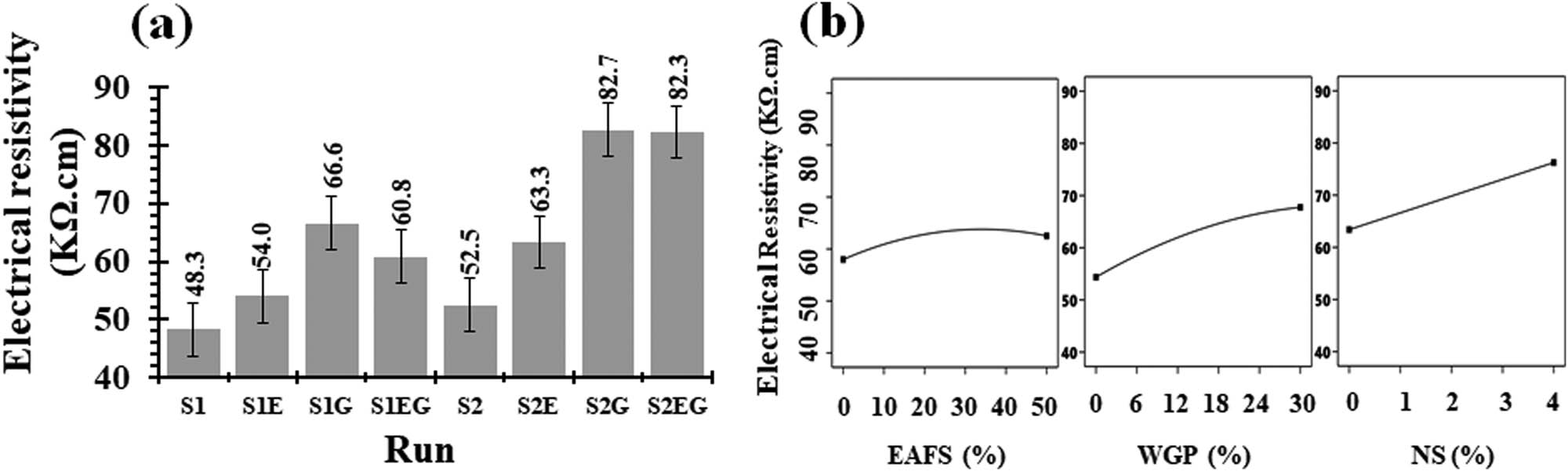

3.5 ER

Figure 11(a) summarizes the findings from the bulk ER tests. Figure 11(b) shows the general impact of the three parameters (EAFS, WGP, and NS) on the ER obtained by employed design experts13 program. All ER values exceeding 37 kΩ cm are similar to deficient levels of chloride penetration as assessed by the conventional rapid chloride permeability test [21,23].

The ER of UHPC: (a) Comparative ER of UHPC mixes; and (b) individual influence of parameters on ER at 2% NS, 15% WGP, and 25% EAFS.

Figure 11(a) and (b) concluded that the reference sample’s ER values were lowest at 48.3 KΩ cm. Incorporating EAFS, WGP, and NS increased the ER. This improvement may be due to two key factors: First, the development of hydration products affects pore size distribution and connectivity. Second, adding alternative materials might affect the ion concentration in the pore solution, lowering the concrete’s electric conductivity [21]. However, the WGP significantly improved the resistivity. As seen from Figure 11a, the rate of increase in mixture S1G compared to mixture S1 is approximately 38%. In comparison, the rate of ER increases for mixtures containing EAFS and NS (mixtures S1E and S2) is approximately 12 and 9%, respectively. This acceding reflects WGP’s influential role in increasing the concrete’s ER due to the feature of glass powder enhancement of the microstructure, where adding tiny glass particles improves particle packing despite their lower pozzolanic effectiveness, resulting in creating a denser and less porous microstructure [51]. The ER improvement significantly enhanced the penetration resistance of chloride ions, especially at the ITZ, where calcium hydroxide concentration is greater and more readily available for pozzolanic reaction [52,53]. It is also clear that the ER was effectively improved in the mixture that combined WGP and NS, as the rate of ER increase in mixture S2G was approximately 72% compared to reference mixture S1. Possible cause might be that NS generates a magnificent pore structure with a low level of ions in the pores solution and clog holes, causing delayed interaction with calcium hydroxide crystals and resulting in a less porous CSH gel combination. Adding NS to mortar results in smaller pore size distribution and lowers ionic concentration [20]. However, the ER decreased due to the NS agglomeration problem, and large pores created by the collected voids of NS might enhance the pore connection between nearby voids in concrete [54]. At the same time, mixing the EAFS with WGP reduced the electrical resistance as in mixture S1EG compared with mixture S1G. However, EAFS and NS in the same mix improved the resistance, as is evident in mixture S2E compared to mixtures S1E and S2. This behavior may result when an appropriate quantity is added. The steel slag serves as a filler and reduces the pores in concrete despite the low pozzolanic reactivity of the steel slag, causing decreased ER with increasing steel slag doses [22]. High dosages of steel slag form conductive networks more often. The steel slag has a more significant metal concentration. Thus, its dense metal particles are more likely to conduct electricity and create a conductive network, increasing the concrete’s electrical conductivity [55]. So, EAFS, as mineral addition and fine aggregate, performs better.

Resistivity exhibits the best improvement in the binary mix due to the reducing of the pores in the concrete matrix, resulting in the formation of a dense concrete structure and the SEM images analysis that discussed above support this trend. The ER of mixtures S2G and S2EG is relatively high compared to other mixes because of the thick structure and fewer micro-cracks.

3.6 Alkalinity test

Figure 12(a) summarizes the findings from the pH tests, and Figure 12(b) shows the general impact of the three parameters (EAFS, WGP, and NS) on the pH obtained by the employed design experts13 program. From the general trend shown in Figure 12b, the presence of EAFS led to a reduction in the basicity of the UHPC. On the other hand, WGP and NS positively affect basicity.

The pH values of UHPC: (a) comparative pH of UHPC mixes; and (b) individual influence of parameters on pH at 2% NS, 15% WGP, and 25% EAFS.

This behavior appears more clearly in Figure 12a, where mixture S1E containing 50% EAFS was at a lower pH of 11.4, with a decrease rate of approximately 5.8% compared to reference mixture S1; this could be due to the slag’s FeO concentration slows disintegration. Observations on FeO and crystallization in non-modified EAFS suggest that using them as intensely reactive SCMs requires changes in silica concentration and FeO reduction [56]. Also, as shown in Figure 12a, adding WGP (mixture S1G) increased the basicity by 6.6% compared to mixture S1. The improvement in the alkalinity of concrete is possibly attributed to the high sodium content in the WGP. Due to OH− ions in the interstitial solution, Alkali ions dissolve on the glass surface and easily penetrate aqueous media, increasing pH. The exothermic cement hydrated ion reaction raises the temperature of this alkaline media, causing glass amorphous silica to dissolve partially. Soluble silicates react with calcium ions to generate CSH after response [57]. The addition of NS (mixture S2) did not significantly affect the pH, as the increase was 0.1 unit compared to mixture S1, which agrees with the previous study [58]. Ultimately, the alkalinity of UHPC enhanced better in the ternary combination as mixture S2EG, with each of EAFS, WGP, and NS, had the highest pH value of 13.2, with an increase of 9.1% above reference mixture S1. The best proportions of EAFS, WGP, and NS used did not affect the capacity of steel reinforcement to corrode, as all concrete mixes had pH values over 12 units, which fall within the normal alkalinity range of concrete (12–13).

4 Conclusion

Employing recycled materials such as WGP as a binder and EAFS as a fine aggregate is receiving increased attention in the literature. Therefore, the authors conduct an experimental plan to assess the interactive role of two solid wastes (WGP and EAFS) on UHPC to address their technical feasibility. According to the experimental results, the following conclusions were drawn:

EAFS and NS benefitted UHPC’s compressive and flexural strengths, but WGP had a negative impact. Nonetheless, the combined effect of EAFS and NS is more pronounced regarding flexural strength than compressive strength.

SEM investigation illustrated a wide gap between the matrix and fiber with various-sized isolated cracks found in waste-free UHPC concrete. EAFS and WGP reduced the fiber gap and created several tiny fractures. Moreover, NS-only UHPC concrete had a narrower gap and denser matrix, and the combination of EAFS and NS proved beneficial.

The TG and TGA study found that the pozzolanic reaction increased with EAFS, while WGP decreased the amount of CSH in the 30–200°C stage, indicating that the pozzolanic response declined. Moreover, using NS alone required a large amount of HRWR admixture, resulting in lower reaction rates, but when combined with EAFS, the rate of hydration enhancement increased.

The addition of EAFS increased CH content and slightly decreased CSH content by 21 and 7.6%, possibly due to the increased rate of cement hydration at early ages.

Individually incorporating EAFS, WGP, and NS increased the ER. However, WGP significantly improved the resistivity (38% increase). The mixtures that combined WGP and NS showed a 72% increase in ER, but mixing EAFS with WGP reduced electrical resistance.

EAFS reduced the basicity of the concrete, while WGP and NS positively affected it. Mixture S1E with 50% EAFS had a lower pH of 11.4, possibly because the slag’s FeO concentration slowed disintegration. Meanwhile, WGP increased basicity by 6.6%, possibly due to its high sodium content. The alkalinity of UHPC improved in the ternary combination with mixture S2EG, which had the highest pH value of 13.2 and the best proportions of EAFS, WGP, and NS, not affecting steel reinforcement corrosion capacity.

The results of this study are expected to have remarkable benefits for site engineers and designers when they need to choose mixture proportions to make UHPC with steel slag as a fine aggregate and WGP as a cement replacement to enable sustainable concrete manufacturing. The applicability of such eco-friendly concrete and its durability properties is recommended to be further studied in future research.

Acknowledgements

The authors thank the Concrete Laboratory personnel at the Civil Engineering Department, University of Technology, Baghdad, Iraq, and the Civil Techniques Department personnel at Nasiriyah Technical Institute, Nasiriyah, Iraq, for their cooperation, support, and facilities.

-

Funding information: Authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewing all the results and approving the final version of the manuscript. Abbas J. Mohammed: Conceptualization, methodology, validation, investigation, resources, data curation, formal analysis, writing an original draft, and writing – review and editing. Maan Salman Hassan: Conceptualization, methodology, validation, data curation, supervision, writing – review and editing, and project administration. Hussein Al-Quraishi: supervision, writing – review and editing, and project administration.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Akhnoukh AK, Buckhalter C. Ultra-high-performance concrete: Constituents, mechanical properties, applications and current challenges. Case Stud Constr Mater. 2021;15:e00559. 10.1016/j.cscm.2021.e00559.Search in Google Scholar

[2] ACI-239R, editor. Ultra-high-performance concrete: An emerging technology report. Farmington Hills, Michigan: American Concrete Institute; 2018.Search in Google Scholar

[3] Bahmani H, Mostofinejad D. Microstructure of ultra-high-performance concrete (UHPC)–A review study. J Build Eng. 2022;50:104118. 10.1016/j.jobe.2022.104118.Search in Google Scholar

[4] Du J, Meng W, Khayat KH, Bao Y, Guo P, Lyu Z, et al. New development of ultra-high-performance concrete (UHPC). Compos Part B: Eng. 2021;224:109220. 10.1016/j.compositesb.2021.109220.Search in Google Scholar

[5] Elchalakani M, Basarir H, Karrech A. Green concrete with high-volume fly ash and slag with recycled aggregate and recycled water to build future sustainable cities. J Mater Civ Eng. 2017;29(2):04016219. 10.1061/(ASCE)MT.1943-5533.0001748.Search in Google Scholar

[6] Wang X, Wu D, Zhang J, Yu R, Hou D, Shui Z. Design of sustainable ultra-high performance concrete: A review. Constr Build Mater. 2021;307:124643. 10.1016/j.conbuildmat.2021.124643.Search in Google Scholar

[7] de Brito J, Kurda R. The past and future of sustainable concrete: A critical review and new strategies on cement-based materials. J Clean Prod. 2021;281:123558. 10.1016/j.jclepro.2020.123558.Search in Google Scholar

[8] Du H, Tan KH. Properties of high volume glass powder concrete. Cem Concr Compos. 2017;75:22–9. 10.1016/j.cemconcomp.2016.10.010.Search in Google Scholar

[9] Du H, Tan KH. Transport properties of concrete with glass powder as supplementary cementitious material. ACI Mater J. 2015;112(3):429. 10.14359/51687363.Search in Google Scholar

[10] Vaitkevičius V, Šerelis E, Hilbig H. The effect of glass powder on the microstructure of ultra high performance concrete. Constr Build Mater. 2014;68:102–9. 10.1016/j.conbuildmat.2014.05.101.Search in Google Scholar

[11] D’Amico B, Pomponi F, Hart J. Global potential for material substitution in building construction: The case of cross laminated timber. J Clean Prod. 2021;279:123487. 10.1016/j.jclepro.2020.123487.Search in Google Scholar

[12] Abeda ZM, Ahmedb HK, Khalila WI. Optimization of silica fume and slag in roller compacted concrete by Taguchi method. Eng Technol J. 2023;41(05):724–33. 10.30684/etj.2023.138600.1411.Search in Google Scholar

[13] Huang W, Kazemi-Kamyab H, Sun W, Scrivener K. Effect of cement substitution by limestone on the hydration and microstructural development of ultra-high performance concrete (UHPC). Cem Concr Compos. 2017;77:86–101. 10.1016/j.cemconcomp.2016.12.009.Search in Google Scholar

[14] Emad Abdelazzzim M, Abdelsame Eid M, Mohammed Hassan N. Properties of high strength concrete containing electric arc furnace steel slag aggregate. JES J Eng Sci. 2014;42(3):582–608.10.21608/jesaun.2014.115011Search in Google Scholar

[15] Abdulkareem RT, Hassan MS, Gorgis IN. Effect of steel fibers, polypropylene fibers and/or nanosilica on mechanical properties of self-consolidating concrete. Eng Technol J. 2016;34(3A):527–38. 10.30684/etj.34.3A.8.Search in Google Scholar

[16] Yu R, Spiesz P, Brouwers H. Effect of nano-silica on the hydration and microstructure development of Ultra-High Performance Concrete (UHPC) with a low binder amount. Constr Build Mater. 2014;65:140–50. 10.1016/j.conbuildmat.2014.04.063.Search in Google Scholar

[17] Albeer SJ, Hassan MS. Microstructure and strength of nanosilica-and microsilica-enhanced mortars under elevated temperatures. Arab J Sci Eng. 2024;49(4):5565–77. 10.1007/s13369-023-08430-3.Search in Google Scholar

[18] Du H, Du S, Liu X. Durability performances of concrete with nano-silica. Constr Build Mater. 2014;73:705–12. 10.1016/j.conbuildmat.2014.10.014.Search in Google Scholar

[19] Yalçınkaya Ç, Çopuroğlu O. Hydration heat, strength and microstructure characteristics of UHPC containing blast furnace slag. J Build Eng. 2021;34:101915. 10.1016/j.jobe.2020.101915.Search in Google Scholar

[20] Nasr D, Behforouz B, Borujeni PR, Borujeni SA, Zehtab B. Effect of nano-silica on mechanical properties and durability of self-compacting mortar containing natural zeolite: Experimental investigations and artificial neural network modeling. Constr Build Mater. 2019;229:116888. 10.1016/j.conbuildmat.2019.116888.Search in Google Scholar

[21] Marangu JM, Sharma M, Scheinherrová L, Kafodya I, Mutai VK, Latif E, et al. Durability of ternary blended concrete incorporating rice husk ash and calcined clay. Buildings. 2024;14(5):1201. 10.3390/buildings14051201.Search in Google Scholar

[22] Dubey M, Deo SV, Ramtekkar G. Effect of metakaolin and steel slag on performance of binary blended concrete. Res Eng Struct Mater. 2022;8(3):603–14. 10.17515/resm2022.389ma0120.Search in Google Scholar

[23] Solanki P, Long R, Hu X, editors. Effect of slag and glass on concrete properties. Proceedings of International Structural Engineering and Construction Holistic Overview of Structural Design and Construction. 2020.10.14455/ISEC.res.2020.7(1).MAT-14Search in Google Scholar

[24] ASTM-C150/C150M. Standard specification for Portland cement. West Conshohocken, Pennsylvania: American Society for Testing and Materials International; 2015.Search in Google Scholar

[25] ASTM-C1240. Standard specification for silica fume used in cementitious mixtures. West Conshohocken, Pennsylvania: American Society for Testing and Materials International; 2015.Search in Google Scholar

[26] Abellán J, Fernández J, Torres N, Núñez A. Statistical optimization of ultra-high-performance glass concrete. ACI Mater J. 2020;117(1):243–54. 10.14359/51720292.Search in Google Scholar

[27] Mohammed AJ, Hassan MS, Al-Quraishi H. Manufacturing of sustainable ultra-high-performance concrete using response surface methods. Eng Technol J. 2023;42(5):493–504. 10.30684/etj.2023.143595.1598.Search in Google Scholar

[28] Mohammed AJ, Hassan MS, Al-Quraishi H. Modelling the synergistic effect of waste glass and inert slag aggregate on ultrahigh-performance concrete tensile strength. Innov Infrastruct Solut. 2024;9(6):192. 10.1007/s41062-024-01512-7.Search in Google Scholar

[29] Aswed KK, Hassan MS, Al-Quraishi H. Optimisation and prediction of fresh ultra-high-performance concrete properties enhanced with nanosilica. J Adv Concr Technol. 2022;20(2):103–16. 10.3151/jact.20.103.Search in Google Scholar

[30] Aswed KK, Hassan MS, Al-Quraishi H. Effects of curing temperature and chemical admixture type on fresh properties and compressive strength of ultra high-performance concrete. Eng Technol J. 2022;40(11):1448–54. 10.30684/etj.2022.132300.1103.Search in Google Scholar

[31] ASTM-C109/C109M-16a. Standard test method for compressive strength of hydraulic cement mortars using 2-in. or 50-mm cube specimens. West Conshohocken, Pennsylvania: American Society for Testing and Materials International; 2016.Search in Google Scholar

[32] ASTM-C348. Standard test method for flexural strength of hydraulic-cement mortars. West Conshohocken, Pennsylvania: American Society for Testing and Materials International; 2014.Search in Google Scholar

[33] Dong Q, Wang G, Chen X, Tan J, Gu X. Recycling of steel slag aggregate in portland cement concrete: An overview. J Clean Prod. 2021;282:124447. 10.1016/j.jclepro.2020.124447.Search in Google Scholar

[34] Azeez AT, Hassan MS, Attiyah AAH. Modelling the complementary role of inert slag aggregate and waste glass on concrete mechanical strengths using the response surface and design-of-experiment approach. Constr Build Mater. 2023;409:134199. 10.1016/j.conbuildmat.2023.134199.Search in Google Scholar

[35] Wu H, Fang Q, Gong J, Liu J, Zhang J, Gong Z. Projectile impact resistance of corundum aggregated UHP-SFRC. Int J Impact Eng. 2015;84:38–53. 10.1016/j.ijimpeng.2015.05.007.Search in Google Scholar

[36] Lu J-X, Shen P, Zhang Y, Zheng H, Sun Y, Poon CS. Early-age and microstructural properties of glass powder blended cement paste: Improvement by seawater. Cem Concr Compos. 2021;122:104165. 10.1016/j.cemconcomp.2021.104165.Search in Google Scholar

[37] Mirzahosseini M, Riding KA. Influence of different particle sizes on reactivity of finely ground glass as supplementary cementitious material (SCM). Cem Concr Compos. 2015;56:95–105. 10.1016/j.cemconcomp.2014.10.004.Search in Google Scholar

[38] Calmon JL, Sauer AS, Vieira GL, Teixeira JESL. Effects of windshield waste glass on the properties of structural repair mortars. Cem Concr Compos. 2014;53:88–96. 10.1016/j.cemconcomp.2014.04.008.Search in Google Scholar

[39] Azeeza AT, Hassan MS, Atiyaha AA. Evaluation of the performance of steel slag and waste glass as a cement replacement. Eng Technol J. 2023;41(12):1567–77. 10.30684/etj.2023.143602.1597.Search in Google Scholar

[40] Rojas N, Bustamante M, Muñoz P, Godoy K, Letelier V. Study of properties and behavior of concrete containing EAF slag as coarse aggregate. Dev Built Environ. 2023;14:100137. 10.1016/j.dibe.2023.100137.Search in Google Scholar

[41] Abushanab A, Alnahhal W, Sohail MG, Alnuaimi N, Kahraman R, Altayeh N. Mechanical and durability properties of ultra-high performance steel FRC made with discarded materials. J Build Eng. 2021;44:103264. 10.1016/j.jobe.2021.103264.Search in Google Scholar

[42] Qasrawi H. The use of steel slag aggregate to enhance the mechanical properties of recycled aggregate concrete and retain the environment. Constr Build Mater. 2014;54:298–304. 10.1016/j.conbuildmat.2013.12.063.Search in Google Scholar

[43] Lim JS, Cheah CB, Ramli MB. The setting behavior, mechanical properties and drying shrinkage of ternary blended concrete containing granite quarry dust and processed steel slag aggregate. Constr Build Mater. 2019;215:447–61. 10.1016/j.conbuildmat.2019.04.162.Search in Google Scholar

[44] Di Maida P, Sciancalepore C, Radi E, Bondioli F. Effects of nano-silica treatment on the flexural post cracking behaviour of polypropylene macro-synthetic fibre reinforced concrete. Mech Res Commun. 2018;88:12–8. 10.1016/j.mechrescom.2018.01.004.Search in Google Scholar

[45] Wu Z, Shi C, Khayat K. Influence of silica fume content on microstructure development and bond to steel fiber in ultra-high strength cement-based materials (UHSC). Cem Concr Compos. 2016;71:97–109. 10.1016/j.cemconcomp.2016.05.005.Search in Google Scholar

[46] Li PP, Brouwers H, Chen W, Yu Q. Optimization and characterization of high-volume limestone powder in sustainable ultra-high performance concrete. Constr Build Mater. 2020;242:118112. 10.1016/j.conbuildmat.2020.118112.Search in Google Scholar

[47] Jagadisha A, Rao KB, Nayak G, Kamath M. Influence of nano-silica on the microstructural and mechanical properties of high-performance concrete containing EAF aggregate and processed quarry dust. Constr Build Mater. 2021;304:124392. 10.1016/j.conbuildmat.2021.124392.Search in Google Scholar

[48] Li S, Liu G, Yu Q. The role of carbonated steel slag on mechanical performance of ultra-high performance concrete containing coarse aggregates. Constr Build Mater. 2021;307:124903. 10.1016/j.conbuildmat.2021.124903.Search in Google Scholar

[49] Jain J, Neithalath N. Analysis of calcium leaching behavior of plain and modified cement pastes in pure water. Cem Concr Compos. 2009;31(3):176–85. 10.1016/j.cemconcomp.2009.01.003.Search in Google Scholar

[50] Sun Z, Yang S, Hang M, Wang J, Yang T. Optimization design of ultrahigh-performance concrete based on interaction analysis of multiple factors. Case Stud Constr Mater. 2022;16:e00858. 10.1016/j.cscm.2021.e00858.Search in Google Scholar

[51] Tariq S, Scott AN, Mackechnie JR, Shah V. Durability of high volume glass powder self-compacting concrete. Appl Sci. 2020;10(22):8058. 10.3390/app10228058.Search in Google Scholar

[52] Du H, Tan KH. Waste glass powder as cement replacement in concrete. J Adv Concr Technol. 2014;12(11):468–77. 10.3151/jact.12.468.Search in Google Scholar

[53] Kamali M, Ghahremaninezhad A. Effect of glass powders on the mechanical and durability properties of cementitious materials. Constr Build Mater. 2015;98:407–16. 10.1016/j.conbuildmat.2015.06.010.Search in Google Scholar

[54] Belkowitz JS, Belkowitz WB, Nawrocki K, Fisher FT. Impact of nanosilica size and surface area on concrete properties. ACI Mater J. 2015;112(3):419–28. 10.14359/51687397.Search in Google Scholar

[55] Yan F, Li L, Jiang Z, Ji Y, Feng L, He P, editors. Experimental study on the electrical conductivity of SSG composite concrete. IOP Conference Series: Earth and Environmental Science. IOP Publishing; 2019. 10.1088/1755-1315/358/5/052030.Search in Google Scholar

[56] Andersson A, Isaksson J, Lennartsson A, Engström F. Insights into the valorization of electric arc furnace slags as supplementary cementitious materials. J Sustain Metall. 2024;10(1):96–109. 10.1007/s40831-023-00778-y.Search in Google Scholar

[57] Tognonvi MT, Tagnit-Hamou A, Konan LK, Zidol A, N’Cho WC. Reactivity of recycled glass powder in a cementitious medium. New J Glas Ceram. 2020;10(3):29–44. 10.4236/njgc.2020.103003.Search in Google Scholar

[58] Nasr MS, Salih SA, Hassan MS. Some durability characteristics of micro silica and nano silica contained concrete. J Babylon Univ/Eng Sci. 2016;24(4):980–90.Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Modification of polymers to synthesize thermo-salt-resistant stabilizers of drilling fluids

- Study of the electronic stopping power of proton in different materials according to the Bohr and Bethe theories

- AI-driven UAV system for autonomous vehicle tracking and license plate recognition

- Enhancement of the output power of a small horizontal axis wind turbine based on the optimization approach

- Design of a vertically stacked double Luneburg lens-based beam-scanning antenna at 60 GHz

- Synergistic effect of nano-silica, steel slag, and waste glass on the microstructure, electrical resistivity, and strength of ultra-high-performance concrete

- Expert evaluation of attachments (caps) for orthopaedic equipment dedicated to pedestrian road users

- Performance and rheological characteristics of hot mix asphalt modified with melamine nanopowder polymer

- Second-order design of GNSS networks with different constraints using particle swarm optimization and genetic algorithms

- Impact of including a slab effect into a 2D RC frame on the seismic fragility assessment: A comparative study

- Analytical and numerical analysis of heat transfer from radial extended surface

- Comprehensive investigation of corrosion resistance of magnesium–titanium, aluminum, and aluminum–vanadium alloys in dilute electrolytes under zero-applied potential conditions

- Performance analysis of a novel design of an engine piston for a single cylinder

- Modeling performance of different sustainable self-compacting concrete pavement types utilizing various sample geometries

- The behavior of minors and road safety – case study of Poland

- The role of universities in efforts to increase the added value of recycled bucket tooth products through product design methods

- Adopting activated carbons on the PET depolymerization for purifying r-TPA

- Urban transportation challenges: Analysis and the mitigation strategies for road accidents, noise pollution and environmental impacts

- Enhancing the wear resistance and coefficient of friction of composite marine journal bearings utilizing nano-WC particles

- Sustainable bio-nanocomposite from lignocellulose nanofibers and HDPE for knee biomechanics: A tribological and mechanical properties study

- Effects of staggered transverse zigzag baffles and Al2O3–Cu hybrid nanofluid flow in a channel on thermofluid flow characteristics

- Mathematical modelling of Darcy–Forchheimer MHD Williamson nanofluid flow above a stretching/shrinking surface with slip conditions

- Energy efficiency and length modification of stilling basins with variable Baffle and chute block designs: A case study of the Fewa hydroelectric project

- Renewable-integrated power conversion architecture for urban heavy rail systems using bidirectional VSC and MPPT-controlled PV arrays as an auxiliary power source

- Exploitation of landfill gas vs refuse-derived fuel with landfill gas for electrical power generation in Basrah City/South of Iraq

- Two-phase numerical simulations of motile microorganisms in a 3D non-Newtonian nanofluid flow induced by chemical processes

- Sustainable cocoon waste epoxy composite solutions: Novel approach based on the deformation model using finite element analysis to determine Poisson’s ratio

- Impact and abrasion behavior of roller compacted concrete reinforced with different types of fibers

- Architectural design and its impact on daylighting in Gayo highland traditional mosques

- Structural and functional enhancement of Ni–Ti–Cu shape memory alloys via combined powder metallurgy techniques

- Design of an operational matrix method based on Haar wavelets and evolutionary algorithm for time-fractional advection–diffusion equations

- Design and optimization of a modified straight-tapered Vivaldi antenna using ANN for GPR system

- Analysis of operations of the antiresonance vibration mill of a circular trajectory of chamber vibrations

- Functions of changes in the mechanical properties of reinforcing steel under corrosive conditions

- 10.1515/eng-2025-0153

- Review Articles

- A modified adhesion evaluation method between asphalt and aggregate based on a pull off test and image processing

- Architectural practice process and artificial intelligence – an evolving practice

- Enhanced RRT motion planning for autonomous vehicles: a review on safety testing applications

- Special Issue: 51st KKBN - Part II

- The influence of storing mineral wool on its thermal conductivity in an open space

- Use of nondestructive test methods to determine the thickness and compressive strength of unilaterally accessible concrete components of building

- Use of modeling, BIM technology, and virtual reality in nondestructive testing and inventory, using the example of the Trzonolinowiec

- Tunable terahertz metasurface based on a modified Jerusalem cross for thin dielectric film evaluation

- Integration of SEM and acoustic emission methods in non-destructive evaluation of fiber–cement boards exposed to high temperatures

- Non-destructive method of characterizing nitrided layers in the 42CrMo4 steel using the amplitude-frequency technique of eddy currents

- Evaluation of braze welded joints using the ultrasonic method

- Analysis of the potential use of the passive magnetic method for detecting defects in welded joints made of X2CrNiMo17-12-2 steel

- Analysis of the possibility of applying a residual magnetic field for lack of fusion detection in welded joints of S235JR steel

- Eddy current methodology in the non-direct measurement of martensite during plastic deformation of SS316L

- Methodology for diagnosing hydraulic oil in production machines with the additional use of microfiltration

- Special Issue: IETAS 2024 - Part II

- Enhancing communication with elderly and stroke patients based on sign-gesture translation via audio-visual avatars

- Optimizing wireless charging for electric vehicles via a novel coil design and artificial intelligence techniques

- Evaluation of moisture damage for warm mix asphalt (WMA) containing reclaimed asphalt pavement (RAP)

- Comparative CFD case study on forced convection: Analysis of constant vs variable air properties in channel flow

- Evaluating sustainable indicators for urban street network: Al-Najaf network as a case study

- Node failure in self-organized sensor networks

- Comprehensive assessment of side friction impacts on urban traffic flow: A case study of Hilla City, Iraq

- Design a system to transfer alternating electric current using six channels of laser as an embedding and transmitting source

- Security and surveillance application in 3D modeling of a smart city: Kirkuk city as a case study

- Modified biochar derived from sewage sludge for purification of lead-contaminated water

- The future of space colonisation: Architectural considerations

- Design of a Tri-band Reconfigurable Antenna Using Metamaterials for IoT Applications

- Special Issue: AESMT-7 - Part II

- Experimental study on behavior of hybrid columns by using SIFCON under eccentric load

- Special Issue: ICESTA-2024 and ICCEEAS-2024

- A selective recovery of zinc and manganese from the spent primary battery black mass as zinc hydroxide and manganese carbonate

- Special Issue: REMO 2025 and BUDIN 2025

- Predictive modeling coupled with wireless sensor networks for sustainable marine ecosystem management using real-time remote monitoring of water quality

- Management strategies for refurbishment projects: A case study of an industrial heritage building

- Structural evaluation of historical masonry walls utilizing non-destructive techniques – Comprehensive analysis

Articles in the same Issue

- Research Articles

- Modification of polymers to synthesize thermo-salt-resistant stabilizers of drilling fluids

- Study of the electronic stopping power of proton in different materials according to the Bohr and Bethe theories

- AI-driven UAV system for autonomous vehicle tracking and license plate recognition

- Enhancement of the output power of a small horizontal axis wind turbine based on the optimization approach

- Design of a vertically stacked double Luneburg lens-based beam-scanning antenna at 60 GHz

- Synergistic effect of nano-silica, steel slag, and waste glass on the microstructure, electrical resistivity, and strength of ultra-high-performance concrete

- Expert evaluation of attachments (caps) for orthopaedic equipment dedicated to pedestrian road users

- Performance and rheological characteristics of hot mix asphalt modified with melamine nanopowder polymer

- Second-order design of GNSS networks with different constraints using particle swarm optimization and genetic algorithms

- Impact of including a slab effect into a 2D RC frame on the seismic fragility assessment: A comparative study

- Analytical and numerical analysis of heat transfer from radial extended surface

- Comprehensive investigation of corrosion resistance of magnesium–titanium, aluminum, and aluminum–vanadium alloys in dilute electrolytes under zero-applied potential conditions

- Performance analysis of a novel design of an engine piston for a single cylinder

- Modeling performance of different sustainable self-compacting concrete pavement types utilizing various sample geometries

- The behavior of minors and road safety – case study of Poland

- The role of universities in efforts to increase the added value of recycled bucket tooth products through product design methods

- Adopting activated carbons on the PET depolymerization for purifying r-TPA

- Urban transportation challenges: Analysis and the mitigation strategies for road accidents, noise pollution and environmental impacts

- Enhancing the wear resistance and coefficient of friction of composite marine journal bearings utilizing nano-WC particles

- Sustainable bio-nanocomposite from lignocellulose nanofibers and HDPE for knee biomechanics: A tribological and mechanical properties study

- Effects of staggered transverse zigzag baffles and Al2O3–Cu hybrid nanofluid flow in a channel on thermofluid flow characteristics

- Mathematical modelling of Darcy–Forchheimer MHD Williamson nanofluid flow above a stretching/shrinking surface with slip conditions

- Energy efficiency and length modification of stilling basins with variable Baffle and chute block designs: A case study of the Fewa hydroelectric project

- Renewable-integrated power conversion architecture for urban heavy rail systems using bidirectional VSC and MPPT-controlled PV arrays as an auxiliary power source

- Exploitation of landfill gas vs refuse-derived fuel with landfill gas for electrical power generation in Basrah City/South of Iraq

- Two-phase numerical simulations of motile microorganisms in a 3D non-Newtonian nanofluid flow induced by chemical processes

- Sustainable cocoon waste epoxy composite solutions: Novel approach based on the deformation model using finite element analysis to determine Poisson’s ratio

- Impact and abrasion behavior of roller compacted concrete reinforced with different types of fibers

- Architectural design and its impact on daylighting in Gayo highland traditional mosques

- Structural and functional enhancement of Ni–Ti–Cu shape memory alloys via combined powder metallurgy techniques

- Design of an operational matrix method based on Haar wavelets and evolutionary algorithm for time-fractional advection–diffusion equations

- Design and optimization of a modified straight-tapered Vivaldi antenna using ANN for GPR system

- Analysis of operations of the antiresonance vibration mill of a circular trajectory of chamber vibrations

- Functions of changes in the mechanical properties of reinforcing steel under corrosive conditions

- 10.1515/eng-2025-0153

- Review Articles

- A modified adhesion evaluation method between asphalt and aggregate based on a pull off test and image processing

- Architectural practice process and artificial intelligence – an evolving practice

- Enhanced RRT motion planning for autonomous vehicles: a review on safety testing applications

- Special Issue: 51st KKBN - Part II

- The influence of storing mineral wool on its thermal conductivity in an open space

- Use of nondestructive test methods to determine the thickness and compressive strength of unilaterally accessible concrete components of building

- Use of modeling, BIM technology, and virtual reality in nondestructive testing and inventory, using the example of the Trzonolinowiec

- Tunable terahertz metasurface based on a modified Jerusalem cross for thin dielectric film evaluation

- Integration of SEM and acoustic emission methods in non-destructive evaluation of fiber–cement boards exposed to high temperatures

- Non-destructive method of characterizing nitrided layers in the 42CrMo4 steel using the amplitude-frequency technique of eddy currents

- Evaluation of braze welded joints using the ultrasonic method

- Analysis of the potential use of the passive magnetic method for detecting defects in welded joints made of X2CrNiMo17-12-2 steel

- Analysis of the possibility of applying a residual magnetic field for lack of fusion detection in welded joints of S235JR steel

- Eddy current methodology in the non-direct measurement of martensite during plastic deformation of SS316L

- Methodology for diagnosing hydraulic oil in production machines with the additional use of microfiltration

- Special Issue: IETAS 2024 - Part II

- Enhancing communication with elderly and stroke patients based on sign-gesture translation via audio-visual avatars

- Optimizing wireless charging for electric vehicles via a novel coil design and artificial intelligence techniques

- Evaluation of moisture damage for warm mix asphalt (WMA) containing reclaimed asphalt pavement (RAP)

- Comparative CFD case study on forced convection: Analysis of constant vs variable air properties in channel flow

- Evaluating sustainable indicators for urban street network: Al-Najaf network as a case study

- Node failure in self-organized sensor networks

- Comprehensive assessment of side friction impacts on urban traffic flow: A case study of Hilla City, Iraq

- Design a system to transfer alternating electric current using six channels of laser as an embedding and transmitting source

- Security and surveillance application in 3D modeling of a smart city: Kirkuk city as a case study

- Modified biochar derived from sewage sludge for purification of lead-contaminated water

- The future of space colonisation: Architectural considerations

- Design of a Tri-band Reconfigurable Antenna Using Metamaterials for IoT Applications

- Special Issue: AESMT-7 - Part II

- Experimental study on behavior of hybrid columns by using SIFCON under eccentric load

- Special Issue: ICESTA-2024 and ICCEEAS-2024

- A selective recovery of zinc and manganese from the spent primary battery black mass as zinc hydroxide and manganese carbonate

- Special Issue: REMO 2025 and BUDIN 2025

- Predictive modeling coupled with wireless sensor networks for sustainable marine ecosystem management using real-time remote monitoring of water quality

- Management strategies for refurbishment projects: A case study of an industrial heritage building

- Structural evaluation of historical masonry walls utilizing non-destructive techniques – Comprehensive analysis