Abstract

In this research, an experimental study was conducted to investigate the behavior of hybrid reinforced concrete columns. This study consisted of adding slurry infiltrated fiber concrete (SIFCON) at the same time as casting the column. The program comprised eight specimens. All of them are identical in dimensions (100 × 100 × 970 mm), but different in reinforcement group A use ρ = 0.0113 and group B use ρ = 0.0226. The SIFCON layer was cast with different thickness of 50, 37.5, and 25 mm from dimensions of the column, six columns were cast as a hybrid concrete column (normal strength concrete and SIFCON), while two others were cast of normal strength concrete as control specimen. The hybrid column was cast horizontally, first by pouring the normal concrete and then adding SIFCON with 8% straight steel fiber. All specimens were tested under eccentric loading with 30 mm away from the column’s center. The test results showed that using the SIFCON enhances the general behavior of the specimens. In group A, the enhancement was around 103%, and in group B, it reached 62.9% compared to the control column.

1 Introduction

Most concrete buildings consist of different structural members. Column is the most vital structural member. Therefore, any damage to it may lead to failure and possibly collapse of the building because the column is subject to compression load that moves vertically through it to the soil. In civil engineering, concrete is the primary material used in most infrastructure projects. With the evolution of modern civil engineering and structural design, the demand for high-strength materials has risen, especially for tall buildings. Engineers now seek materials that offer exceptional strength, durability, toughness, and energy absorption [1,2,3,4].

Based on the position of the load on the cross-section, columns are classified as concentrically loaded or eccentrically loaded columns. Eccentrically loaded columns are subjected to moments, in addition to axial force. This combination leads to lateral deflection, increasing shear failure risk, reducing load capacity, and enhancing susceptibility to buckling, thus speeding up failure. There are many methods used to improve the behavior of eccentrically loaded columns, such as “fiber-reinforced polymer, steel bracing, external post-tensioning, adding new structural elements, etc.” There is no ideal way. Every technique has drawbacks. Over the last several decades, scientists have created a concrete type known as slurry infiltrated fiber concrete (SIFCON), which has demonstrated potential for usage in a variety of applications, including the strengthening and repair of reinforced concrete components, pavement overlays, and earthquake-resistant structures [5].

The use of SIFCON offers several advantages. By eliminating coarse aggregates and gradually adding steel fibers to the concrete mixture, the interlocking effect caused by the high volume of fibers can be overcome where coarse aggregates can hinder the dispersion of steel fibers and lead to clustering or uneven distribution, which may compromise the performance of the concrete. Gradually adding steel fibers helps to mitigate this issue, allowing for a more effective integration of fibers within the concrete matrix, resulting in a homogeneous mixture where the fibers permeate well with the slurry. This specialized production methodology has led to the creation of SIFCON, a composite material that combines the benefits of a cementitious matrix and discrete steel fibers. The slurry is often made more flowable using superplasticizers to ensure thorough infiltration without increasing the water/cement ratio. Steel fibers are added to increase ductility and residual tensile strength, bridging cracks and improving crack control by mixing steel fiber with slurry [6,7,8].

Previous studies looked at using SIFCON to strengthen different types of reinforced concrete members. Sisupalan investigated the use of precast SIFCON layers to strengthen a beam made of regular reinforced concrete and another made of fiber-reinforced composite (FRC). Under the effect of a two-point load test, these layers are adhered to the sides and bottom of the beam using epoxy (5, 7, 9, and 11%) used steel fibers with hooked ends. The best outcomes were obtained with a ratio of 5%. The findings showed that adding SIFCON reinforcement to FRC and RC beams significantly increased their load capability [9].

Dalya investigated the ductility, toughness, and bending strength of prisms composed of normal concrete (NC) reinforced with SIFCON layers. Prisms with steel fiber by (6, 7.5, and 9%) were coated solely from the bottom, from the top, and from all sides at varying thicknesses (3.5, 2.5, and 1.5 cm). The findings showed that “load-bearing capacity, toughness, and ductility” are improved when the SIFCON layer is thicker and contains more steel fiber. The best results were attained when the prism was fully strengthened with SIFCON, where it was 23 times higher than control prism [10].

Numerous investigations on strengthening NSC columns have been conducted. However, as far as the authors are aware, only one numerical work has looked at how NSC columns reinforced as hybrid columns with an SIFCON layer behave by Kamath and Shilpa. They employed the ANSYS program to simulate the behavior of hybrid RC-SIFCON columns, investigating various proportions of SIFCON and reinforced concrete. The study found that varying the proportion of SIFCON resulted in differences in critical buckling load and deflection under increased load, with the 40% SIFCON column demonstrating the maximum critical buckling load and the 100% SIFCON column exhibiting the highest deflection. These findings provide valuable insights into the behavior and performance of hybrid columns with SIFCON, laying the foundation for further research and development in this field [11]. More experimental studies are needed to gain a comprehensive understanding of this specific combination’s performance. In order to give important information and a better understanding of hybrid columns’ behavior, the current investigation’s objective is to investigate an experiment on hybrid column behavior using SIFCON under eccentric load. Furthermore, the study investigated the effects with various parameters, including the thickness of the SIFCON layer (50, 37.5, and 25 mm) in the column and its influence on the structural behavior. Additionally, it investigates the effect of SIFCON on various reinforcement ratios (ρ1 = 0.01, ρ2 = 0.02) and evaluates its behavior in comparison with NSC columns.

2 Experimental program

The experimental program includes the definition of the materials used, their testing, and the determination of the optimum mixing ratio, and then preparation specimens. All columns were tested under eccentric load. It can be presented with a flowchart in Figure 1.

Flow chart of the research plan.

2.1 Description of the tested columns

The test program involved evaluating eight-column specimens, consisting of two types: NC–SIFCON hybrid (Normal-SIFCON) and plain NC. These columns were cast in the laboratory and subjected to eccentric loading. The purpose was to compare the behavior of the Normal-SIFCON columns with the reference NC columns. All column specimens had fixed dimensions of 100 × 100 × 996 mm. Out of the eight columns, six were Normal-SIFCON hybrid columns, and three of them were reinforced with 4Ø6 mm bars, while the remaining were reinforced with 8Ø6 mm bars as longitudinal reinforcement, as shown in Figure 2. Transverse reinforcement (ties) was achieved using Ø4 mm bars with a spacing of 90 mm between ties. To enable easy comparison among the numerous column specimens investigated in this research, a unique identification system was used. Each column is represented by three symbols. The first symbol corresponds to the type of concrete (hybrid or normal), the second symbol indicates the reinforcement ratio (0.0113 or 0.0226), and the final symbol displays the SIFCON layer’s thickness (Table 1).

Reinforcement details of tested column.

Description of columns

| Type of concrete | Symbol | Reinforcement ratio (ρ) | Thickness of SIFCON layer | Details |

|---|---|---|---|---|

| NC | NC1-0 | 0.0113 | 0 |

|

| NC2-0 | 0.0226 | |||

| Hybrid concrete | Hc1-25 | 0.0113 | 25 mm |

|

| HC2-25 | 0.0226 | |||

| Hybrid concrete | HC1-37 | 0.0113 | 37.5 mm |

|

| HC2-37 | 0.0226 | |||

| Hybrid concrete | HC1-50 | 0.0113 | 50 mm |

|

| HC1-50 | 0.0226 |

2.2 Materials used for cast specimens and concrete mix

In the experimental study, the researchers tested various slurry mixtures to determine appropriate mixing proportions. They used limestone Portland cement (Lafarge) (CEM II/A-L-42.5 R), following IQS No. 5/2019 [12] specifications. Natural local sand meeting the requirements of Iraqi specification No. 45/1984 [13] was utilized. Only extra-fine particles passing through a 600 µm sieve were used to prepare the mortar, removing coarser particles. The study used Mega Add MS (D), a commercially available silica fume from CONMIX. The silica fume was added at a replacement rate of 10% by weight of the cement, and it met the requirements of American society for testing and materials (ASTM) C1240-05 (2015) [14]. Hyperplast PC200, a high-range water-reducing admixture manufactured by Don construction products and meeting ASTM C494/C494 M [15] requirements, was used in mortar preparation. Additionally, straight steel fibers with a volume fraction of 8% were used in the study. The details are summarized in Table 2.

Mix proportions

| Mix type | Mix proportion | ||||||

|---|---|---|---|---|---|---|---|

| Cement (kg/m3) | Sand (kg/m3) | Silica fume (kg/m3) 10% Rep | Gravel (kg/m3) | Steel fiber (%) | w/b or w/c ratio | SP (by wt. of binder) % | |

| SIFCON | 872 | 969 | 96.9 | — | 8 | 0.3 | 2.2 |

| NC | 400 | 720 | — | 1072 | — | 0.4 | — |

2.3 Preparation specimens

The experimental work involves casting eight columns, two of which are used as references and six of which are hybrid columns with SIFCON. All tested specimens, which have a square column with a dimension of 100 × 100 × 970 mm, use two flexural reinforcements, ρ1 = 0.113 and ρ2 = 0.0226. Straight steel fiber was used with a volume fraction of 8%, and the thickness of the SIFCON layer was 50, 37.5, and 25 mm (from the dimension of the column). The casting process involves several stages:

Prior to each casting, the plywood and steel molds were prepared by cleaning and lightly lubricating the internal surfaces with oil to prevent adhesion to hardened concrete. The molds were then placed on a horizontal surface.

After preparing the reinforcement of columns and molds as shown in Figure 3, reinforcing steel with ρ1 = 0.113 and ρ2 = 0.226 was placed inside the molds and centered with a cover of 20 mm in all directions.

Normal-strength concrete was prepared following the established guidelines. Several trials of the casting mortar-infiltrated fiber concrete technique were conducted in the laboratory, and the gradual mix method was adopted to mix steel fiber with the slurry, as shown in Figure 4.

The hybrid column was cast horizontally, first by pouring the NC and then adding SIFCON (slurry-infiltrated fiber concrete) after the initial primary sclerosis. Please refer to Figure 5 for a visual representation of the process.

All the columns were allowed to cure for 28 days before testing.

Reinforcement of tested column and casting molds.

Mix SIFCON.

Cast hybrid column.

2.4 Test of column

All the tested columns were under eccentric load with 30 mm from the center of the column. All specimens underwent testing using a hydraulic jack with a loading capacity specifically designed for 2,000 kN at the University of Kerala, as presented in Figure 6. The deflection of the column was measured using an electronically controlled gage (linear variable differential transformer, or LVDT) in the middle of the column. The data for load and deflection were collected by a computer system programmed by LABVIEW software.

Universal testing machine in the laboratory of Kerbala University.

3 Results and discussion

3.1 Results of cast columns

The eight specimens were tested, and the result is shown in Table 3.

Result of column test

| Group | Specimen | Ultimate load (KN) | Max. deflection (mm) | Increase in ultimate load (Pu) respect to control % | Percentage in deflection (Δu) with respect to control % | ||

|---|---|---|---|---|---|---|---|

| Pu | Lateral def. | Vertical def. | Lateral def. | Vertical def. | |||

| Group A | NC1-0 | 130 | 8.35 | 9.98 | Reference | Reference | Reference |

| HC1-50 | 265 | 7.75 | 7.1 | 103.8 | −7.185 | −28.8 | |

| HC1-37.5 | 244 | 7.73 | 6.22 | 87.7 | −7.425 | −37.67 | |

| HC1-25 | 216 | 7.9 | 7.9 | 66.15 | −5.389 | −20.84 | |

| Group B | NC2-0 | 170 | 9.13 | 8.85 | Reference | Reference | Reference |

| HC2-50 | 277 | 6.8 | 6.7 | 62.9 | −15.5 | −17.5 | |

| HC2-37.5 | 261 | 6.68 | 5.5 | 53.5 | −26.8 | −37.8 | |

| HC2-25 | 241 | 7.71 | 7.3 | 41.7 | −25.5 | −24.3 | |

3.2 Ultimate load (Pu)

The results of the study demonstrate significant improvements in the ultimate load for the hybrid columns compared to those in the control column. In group A, where the reinforcement ratio is smaller, the ultimate load for HC1-50, HC1-37.5, and HC1-25 increased by approximately 103.8, 87.7, and 66.15%, respectively, in comparison with NC1-0. Similarly, in group B, where the reinforcement ratio is larger, the ultimate load for HC2-50, HC2-37.5, and HC2-25 increased by approximately 62.9, 53.5, and 41.7%, respectively, compared to NC2-0.

Finally, it is observed that increasing the thickness of the SIFCON layer increases the ultimate load for all columns. The increase in the ultimate load is attributed to the carrying capacity of the SIFCON being higher than normal. When the load is beginning to increase, it is absorbed by the layer of the hybrid SIFCON in the columns, leading to a delay in the failure of the specimen. This is the reason for the high ultimate load values for all the hybrid columns when compared with the reference column.

3.3 Ultimate displacement (∆u)

According to Table 3, the vertical and horizontal displacement decreased in both groups compared to the control specimen. This suggests that the inclusion of a SIFCON layer in the hybrid columns improved their resistance to lateral forces. The SIFCON layer acted as a strengthening element and helped to reduce the lateral deflection, indicating enhanced structural stability.

3.4 Load–displacement curves

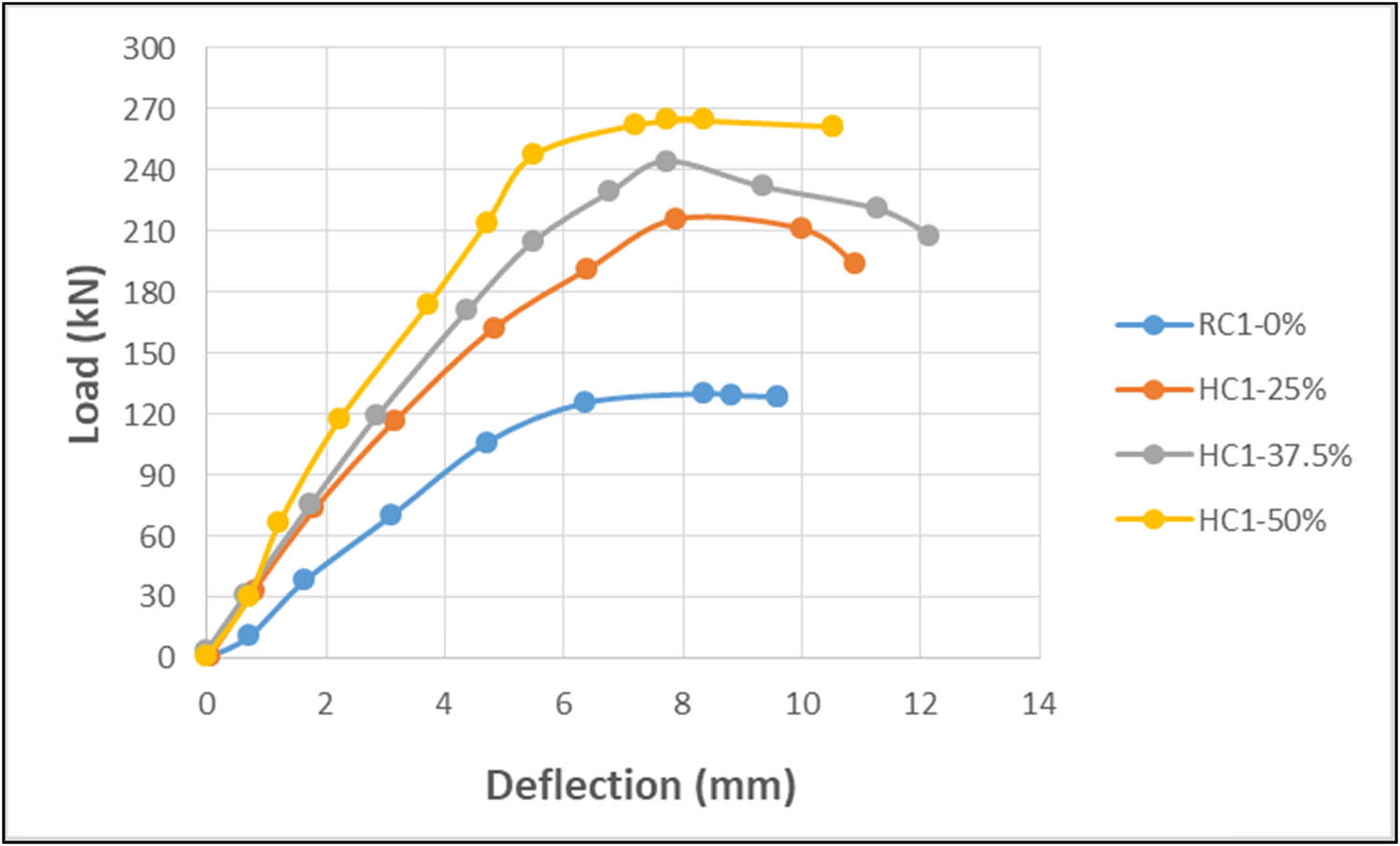

In group A, the lateral deflection decreased in specimens HC1-50, HC1-37.5, and HC1-25 by 7.185, 7.425, and 5.389%, respectively. Whenever a column is loaded incrementally, at first the deflection will increase at a constant rate (elastic region), then after (generation and development of cracks), the deflection will increase at a rate faster and continue to grow until yielding tension steel reinforcement, and then, the slope of the curve will decrease and the test will be terminated when the deflection increases without an increase in the applied load. Figure 7 shows the relation between the axial displacement and applied axial load for all tested columns and the effect of SIFCON thickness. It is illustrated that the ascending portion of the curve for the NSC specimens is linear, and while the descending curve drops rapidly in a short range of deformation. Also, the curve for the NSC specimens is flatter than SIFCON one. It is observed that increasing the thickness of the SIFCON layer increases the ultimate load for all columns.

Load–displacement curves in group A (lateral deflection).

In group B, the lateral deflection decreased in specimens HC2-50, HC2-37.5, and HC2-25 by 15.5, 26.8, and 25.5%, respectively. In the elastic stage, SIFCON behaves in a way that it can absorb and redistribute stress without causing any permanent deformation or damage. During this stage, the SIFCON layer in a hybrid columns helps in increasing the ductility of the columns and increases the load at the final load stage. In the plastic stage, when the load exceeds the elastic limit of the concrete, the SIFCON layer undergoes plastic deformation and behaves similarly to a fiber composite. The fibers in the SIFCON layer resist the tensile stresses, while the concrete matrix undertakes the compressive stresses. This allows the SIFCON layer to provide additional load-carrying capacity to the hybrid columns and delay the failure of the columns. Figure 8 shows the relationship between the axial displacement and applied axial load for all tested columns and the effect of SIFCON thickness.

Load–displacement curves in group B (lateral deflection).

Figures 9 and 10 likely show the load–displacement curves for columns cast with different thicknesses of SIFCON. The results indicate that the addition of a SIFCON layer to the hybrid columns in both group A and group B led to a decrease in vertical deflection compared to the control columns.

Load–displacement curves in group A (vertical deflection).

Load–displacement curves in group B (vertical deflection).

In group A, where the specimens were labeled HC1-50, HC1-37.5, and HC1-25, the vertical deflection decreased by 28.8, 37.67, and 20.84%, respectively. This shows that as the SIFCON layer thickness reduces, the percentage decrease in deflection also reduces.

In group B, where the specimens were labeled HC2-50, HC2-37.5, and HC2-25, the vertical deflection decreased by 17.5, 37.8, and 24.3%, respectively. Unlike group A, the percentage decrease in deflection appears to vary more inconsistently with the thickness of the SIFCON layer. This might be attributed to other factors, such as the composition or application of the SIFCON layer.

Overall, according to the results, incorporating the SIFCON layer has a beneficial impact on reducing the vertical deflection of the hybrid columns. The SIFCON layer acts as an additional reinforcement, enhancing the overall stiffness and structural integrity of the columns. It helps distribute applied loads more efficiently, resulting in decreased deflection.

3.5 Mode of failure

Figure 11 is shown below. In the case of NSC columns, the occurrence of cover spelling and buckling of longitudinal reinforcement may be seen. In hybrid columns, the occurrence of surface spalling was seen to be lower compared to NC columns, which may be attributed to the influence of steel fibers. The failure mode of the control specimens, which did not have a SIFCON layer, was observed to occur close to the head of the column. This suggests that the failure predominantly happened at or near the top connection of the column. This failure mode is typical for columns that do not have any additional strengthening elements. In contrast, the hybrid columns, which had a SIFCON layer, exhibited a different failure mode. The failure was observed to occur in the middle of the column, indicating that the SIFCON layer played a role in redistributing the stresses and altering the location of the failure plane. The failure mode in the hybrid columns was characterized by buckling. The findings indicate that the SIFCON layer played a significant role in augmenting the load-carrying capacity of the columns. The outcomes further reveal that the mode of failure in the hybrid columns was affected by the thickness of the SIFCON layer. It is observed that the failure occurred in the middle of the column. The exact location of the failure plane may vary depending on the thickness of the SIFCON layer. These findings suggest that the addition of a SIFCON layer can alter the failure mode of the columns, resulting in a more localized buckling failure compared to the control specimens. The SIFCON layer enhances the capacity of the column to resist compressive forces, leading to a different failure mechanism.

Final shape for tested columns.

3.6 Stiffness of the tested columns

The stiffness is defined as the amount of load needed for a structural element to undergo deformation. It was determined by calculating it at the service load equivalent to 70% of the ultimate load using the load–deflection curve [16,17]. Table 4 displays the stiffness values for all columns.

K r = Stiffness of the reference slab, K i = Stiffness of the hybrid slab.

Stiffness of the column tested

| Group | Specimen | 0.7 pu | Deflection at 0.7 pu | Stiffness (K) | Increase in stiffness respect to control |

|---|---|---|---|---|---|

| (KN) | (mm) | (KN/mm) | (%) | ||

| Group A | NC1-0 | 91 | 4.2 | 18.2 | Reference |

| HC1-50 | 185.5 | 4.3 | 43.13 | 136.97 | |

| HC1-37.5 | 170.8 | 4.5 | 37.9 | 108.24 | |

| HC1-25 | 151.2 | 4.5 | 33.6 | 84.61 | |

| Group B | NC2-0 | 119 | 3.5 | 34 | Reference |

| HC2-50 | 193.9 | 2.9 | 66.86 | 96.64 | |

| HC2-37.5 | 182.7 | 3 | 60.9 | 79.11 | |

| HC2-25 | 168.7 | 4.3 | 39.23 | 15.38 |

The results of the study indicate that in group A, which consists of hybrid columns with a SIFCON (slurry-infiltrated fibrous concrete) layer, the stiffness of the columns increases as the thickness of the SIFCON layer increases when compared to the control column NC1-0. Specifically, the stiffness of specimens HC1-25, HC1-37.5, and HC1-50 increased by approximately 84.16, 108.24, and 136.97%, respectively.

The increase in stiffness can be attributed to the presence of the SIFCON layer, which provides additional strength and rigidity to the columns. The thicker the SIFCON layer, the greater the enhancement in stiffness. This additional stiffness helps in increasing the ultimate load capacity of the specimens and reducing their deflection. The SIFCON layer acts as a bearing capacity for the column, delaying the onset of failure and requiring more load to cause failure. As a result, the columns with thicker SIFCON layers can withstand higher loads before failure occurs, leading to an increase in stiffness.

Moving on to group B, which also includes hybrid columns with SIFCON layers, it is observed that the stiffness of all specimens increases compared to the control column NC2-0. The stiffness of specimens HC2-25, HC2-37.5, and HC2-50 increased by approximately 15.38, 79.11, and 96.64%, respectively. The presence of the SIFCON layer still contributes to improved stiffness.

Overall, the results demonstrate that the inclusion of a SIFCON layer in hybrid columns leads to an increase in stiffness, regardless of the group. The thicker the SIFCON layer, the greater the improvement in stiffness and load-bearing capacity, which is desired.

4 Conclusions

The effect of thickness of SIFCON layer and the effect of SIFCON on different reinforcement ratio were investigated in this study. Eight columns were cast and tested under eccentric load. The following conclusions were drawn based on the test results:

Using SIFCON is beneficial for all columns by improving its behavior in certain cases, depending on the thickness of the SIFCON used.

Increasing the thickness of the SFCON layer leads to an increase in the ultimate load-carrying capacity. For SIFCON thickness of 25 mm, the maximum percentage of increase in ultimate load-carrying capacity was up to 84.61%, while the maximum improvement in the ultimate load-carrying capacity was 108.24% for 37 mm thickness. Finally, in 50 mm thickness of SIFCON, the maximum improvement in the ultimate load-carrying capacity was 136.97.

Although group A has a lower reinforcement ratio than group B, it showed a greater percentage increase in maximum load bearing and stiffness than group B compared to the reference column, and this is due to the high contribution of the SEFCON layer for the lack of reinforcement.

Using SIFCON in hybrid columns leads to a decrease in vertical and horizontal deflection.

The experimental results show that the maximum percentage of increase in stiffness index of specimens with SIFCON is up to 97% in group A and up to 96.64% in group B compared to the control specimens.

The results indicate that the failure mode of the hybrid columns with a SIFCON layer is different from that of the control specimens. The presence of the SIFCON layer leads to a buckling failure in the middle of the column, indicating an improved load-carrying capacity. The specific location of the failure plane may vary depending on the thickness of the SIFCON layer. These findings highlight the effectiveness of the SIFCON layer in enhancing the structural behavior of the columns and should be considered for further research and application in structural design.

It is feasible to decrease the quantity of reinforcing steel by 50% while simultaneously increasing the thickness of the SIFCON layer by either 50 or 33%. This modification leads to enhanced bearing strength.

Acknowledgments

The authors conducted the specimen test in the Civil Engineering Department’s structural laboratory at Kerbala University. They extend their thanks and appreciation to the establishment for its support. Additionally, they are grateful to all the friends who assisted in completing this work.

-

Funding information: Authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results, and approved the final version of the manuscript. HAA: Making an experimental program of the manuscript which contains (testing the materials used, casting the specimens, give a properties of the concrete mix used, and exceuting the studied structural specimens), writing the manuscript after analyzed results. LSR analyzed the results after the specimens execution and made a discussion for the results, then assisted to writing the manuscript. WAA provided a substantial contribution in writing, and critical revision of the work.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: Most datasets generated and analyzed in this study are in this submitted manuscript. The other datasets are available on reasonable request from the corresponding author with the attached information.

References

[1] Farnam Y, Moosavi M, Shekarchi M, Babanajad S, Bagherzadeh A. Behaviour of slurry infiltrated fibre concrete (SIFCON) under triaxial compression. Cem Concr Res. 2010;40(11):1571–81.10.1016/j.cemconres.2010.06.009Search in Google Scholar

[2] Jayashree S, Rakul B, Helen S. Flexural behavior of SIFCON beams. Int J Eng Res Technol. 2013;2(2):1–7.Search in Google Scholar

[3] Abdulraheem MS, Kadhum MM. Experimental and numerical study on post-fire behaviour of concentrically loaded reinforced reactive powder concrete columns. Constr Build Mater. 2018;168:877–92.10.1016/j.conbuildmat.2018.02.123Search in Google Scholar

[4] Kadhum M, Essa M, Fawzi N. Behaviour of fire exposed reinforced concrete columns. J Eng. 2011;17(3):412–29.10.31026/j.eng.2011.03.05Search in Google Scholar

[5] Salih S, Frayyeh Q, Ali M. Fresh and some mechanical properties of SIFCON containing silica fume. MATEC Web of Conferences; 2018.10.1051/matecconf/201816202003Search in Google Scholar

[6] Ali MAAW. Properties of slurry infiltrated fiber concrete (SIFCON) [Ph.D. thesis]. Baghdad: University of Technology; 2018.Search in Google Scholar

[7] Jensen SMF. Numerical investigation of a post-tensioned flat slab with steel fibre reinforcement [Master’s thesis]. Norwegian University of Science and Technology - NTNU; 2013.Search in Google Scholar

[8] Alsheameri AM, Alsaad AJ, Rasheed LS. Mechanical characteristics of slurry infiltrated fiber concrete. Eng Technol Appl Sci Res. 2023;13(2):10548–52.10.48084/etasr.5734Search in Google Scholar

[9] Sisupalan A, Paul MM. Strengthening of RC and FRC beams with precast SIFCON laminates-An experimental study. Int Res J Eng Technol (IRJET). 2019;6(4):4336–42.Search in Google Scholar

[10] Hameed DH, Salih SA, Habeeb GM. Upgrading of normal concrete service life by using SIFCON layers. IOP Conference Series: Materials Science and Engineering; 2020.10.1088/1757-899X/737/1/012045Search in Google Scholar

[11] Kamath R, Shilpa S. Nonlinear buckling analysis of Rcsifcon column subjected to lateral and axial loading. Int Res J Eng Technol. 2017;4(9):894–9.Search in Google Scholar

[12] Ministry of Planning, Central Organization for Standardization and Quality Control. Iraqi Specification No.5/(2019): Portland cement; 2019.Search in Google Scholar

[13] Ministry of Planning, Central Organization for Standardization and Quality Control. IQS No. 45/(1984): Iraqi Specifications for Aggregates of Natural Resources used for Concrete and Construction; 1984.Search in Google Scholar

[14] ASTM International. ASTM C1240-05 (2015). Standard Specification for Chemical Admixtures for Concrete; 2015.Search in Google Scholar

[15] ASTM International. ASTM C494/C494M (2017). Standard Specification for Chemical Admixtures for Concrete; 2017.Search in Google Scholar

[16] Muthuswamy K, Thirugnanam G. Structural behaviour of hybrid fibre reinforced concrete exterior Beam-Column joint subjected to cyclic loading. Int J Civ Struct Eng. 2014;4:262.Search in Google Scholar

[17] Daňková J, Mec P, Majstríková T. Stiffness analysis of glued connection of the timber-concrete structure. Open Eng. 2016;6(1):241–9. 10.1515/eng-2016-0028.Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Modification of polymers to synthesize thermo-salt-resistant stabilizers of drilling fluids

- Study of the electronic stopping power of proton in different materials according to the Bohr and Bethe theories

- AI-driven UAV system for autonomous vehicle tracking and license plate recognition

- Enhancement of the output power of a small horizontal axis wind turbine based on the optimization approach

- Design of a vertically stacked double Luneburg lens-based beam-scanning antenna at 60 GHz

- Synergistic effect of nano-silica, steel slag, and waste glass on the microstructure, electrical resistivity, and strength of ultra-high-performance concrete

- Expert evaluation of attachments (caps) for orthopaedic equipment dedicated to pedestrian road users

- Performance and rheological characteristics of hot mix asphalt modified with melamine nanopowder polymer

- Second-order design of GNSS networks with different constraints using particle swarm optimization and genetic algorithms

- Impact of including a slab effect into a 2D RC frame on the seismic fragility assessment: A comparative study

- Analytical and numerical analysis of heat transfer from radial extended surface

- Comprehensive investigation of corrosion resistance of magnesium–titanium, aluminum, and aluminum–vanadium alloys in dilute electrolytes under zero-applied potential conditions

- Performance analysis of a novel design of an engine piston for a single cylinder

- Modeling performance of different sustainable self-compacting concrete pavement types utilizing various sample geometries

- The behavior of minors and road safety – case study of Poland

- The role of universities in efforts to increase the added value of recycled bucket tooth products through product design methods

- Adopting activated carbons on the PET depolymerization for purifying r-TPA

- Urban transportation challenges: Analysis and the mitigation strategies for road accidents, noise pollution and environmental impacts

- Enhancing the wear resistance and coefficient of friction of composite marine journal bearings utilizing nano-WC particles

- Sustainable bio-nanocomposite from lignocellulose nanofibers and HDPE for knee biomechanics: A tribological and mechanical properties study

- Effects of staggered transverse zigzag baffles and Al2O3–Cu hybrid nanofluid flow in a channel on thermofluid flow characteristics

- Mathematical modelling of Darcy–Forchheimer MHD Williamson nanofluid flow above a stretching/shrinking surface with slip conditions

- Energy efficiency and length modification of stilling basins with variable Baffle and chute block designs: A case study of the Fewa hydroelectric project

- Renewable-integrated power conversion architecture for urban heavy rail systems using bidirectional VSC and MPPT-controlled PV arrays as an auxiliary power source

- Exploitation of landfill gas vs refuse-derived fuel with landfill gas for electrical power generation in Basrah City/South of Iraq

- Two-phase numerical simulations of motile microorganisms in a 3D non-Newtonian nanofluid flow induced by chemical processes

- Sustainable cocoon waste epoxy composite solutions: Novel approach based on the deformation model using finite element analysis to determine Poisson’s ratio

- Impact and abrasion behavior of roller compacted concrete reinforced with different types of fibers

- Architectural design and its impact on daylighting in Gayo highland traditional mosques

- Structural and functional enhancement of Ni–Ti–Cu shape memory alloys via combined powder metallurgy techniques

- Design of an operational matrix method based on Haar wavelets and evolutionary algorithm for time-fractional advection–diffusion equations

- Design and optimization of a modified straight-tapered Vivaldi antenna using ANN for GPR system

- Analysis of operations of the antiresonance vibration mill of a circular trajectory of chamber vibrations

- Functions of changes in the mechanical properties of reinforcing steel under corrosive conditions

- Enhanced PAPR reduction in NOMA systems using modified SLM and PTS techniques for power-efficient 5G and beyond networks

- Hybrid mechanics-informed machine learning models for predicting mechanical failure in graphene sponge: a low-data strategy for mechanical engineering applications

- Design of shafts of a two-piece chain conveyor as a part of a modification of a mobile working machine

- Review Articles

- A modified adhesion evaluation method between asphalt and aggregate based on a pull off test and image processing

- Architectural practice process and artificial intelligence – an evolving practice

- 10.1515/eng-2025-0148

- Special Issue: 51st KKBN - Part II

- The influence of storing mineral wool on its thermal conductivity in an open space

- Use of nondestructive test methods to determine the thickness and compressive strength of unilaterally accessible concrete components of building

- Use of modeling, BIM technology, and virtual reality in nondestructive testing and inventory, using the example of the Trzonolinowiec

- Tunable terahertz metasurface based on a modified Jerusalem cross for thin dielectric film evaluation

- Integration of SEM and acoustic emission methods in non-destructive evaluation of fiber–cement boards exposed to high temperatures

- Non-destructive method of characterizing nitrided layers in the 42CrMo4 steel using the amplitude-frequency technique of eddy currents

- Evaluation of braze welded joints using the ultrasonic method

- Analysis of the potential use of the passive magnetic method for detecting defects in welded joints made of X2CrNiMo17-12-2 steel

- Analysis of the possibility of applying a residual magnetic field for lack of fusion detection in welded joints of S235JR steel

- Eddy current methodology in the non-direct measurement of martensite during plastic deformation of SS316L

- Methodology for diagnosing hydraulic oil in production machines with the additional use of microfiltration

- Special Issue: IETAS 2024 - Part II

- Enhancing communication with elderly and stroke patients based on sign-gesture translation via audio-visual avatars

- Optimizing wireless charging for electric vehicles via a novel coil design and artificial intelligence techniques

- Evaluation of moisture damage for warm mix asphalt (WMA) containing reclaimed asphalt pavement (RAP)

- Comparative CFD case study on forced convection: Analysis of constant vs variable air properties in channel flow

- Evaluating sustainable indicators for urban street network: Al-Najaf network as a case study

- Node failure in self-organized sensor networks

- Comprehensive assessment of side friction impacts on urban traffic flow: A case study of Hilla City, Iraq

- Design a system to transfer alternating electric current using six channels of laser as an embedding and transmitting source

- Security and surveillance application in 3D modeling of a smart city: Kirkuk city as a case study

- Modified biochar derived from sewage sludge for purification of lead-contaminated water

- The future of space colonisation: Architectural considerations

- Design of a Tri-band Reconfigurable Antenna Using Metamaterials for IoT Applications

- Special Issue: AESMT-7 - Part II

- Experimental study on behavior of hybrid columns by using SIFCON under eccentric load

- Special Issue: ICESTA-2024 and ICCEEAS-2024

- A selective recovery of zinc and manganese from the spent primary battery black mass as zinc hydroxide and manganese carbonate

- Special Issue: REMO 2025 and BUDIN 2025

- Predictive modeling coupled with wireless sensor networks for sustainable marine ecosystem management using real-time remote monitoring of water quality

- Management strategies for refurbishment projects: A case study of an industrial heritage building

- Structural evaluation of historical masonry walls utilizing non-destructive techniques – Comprehensive analysis

Articles in the same Issue

- Research Articles

- Modification of polymers to synthesize thermo-salt-resistant stabilizers of drilling fluids

- Study of the electronic stopping power of proton in different materials according to the Bohr and Bethe theories

- AI-driven UAV system for autonomous vehicle tracking and license plate recognition

- Enhancement of the output power of a small horizontal axis wind turbine based on the optimization approach

- Design of a vertically stacked double Luneburg lens-based beam-scanning antenna at 60 GHz

- Synergistic effect of nano-silica, steel slag, and waste glass on the microstructure, electrical resistivity, and strength of ultra-high-performance concrete

- Expert evaluation of attachments (caps) for orthopaedic equipment dedicated to pedestrian road users

- Performance and rheological characteristics of hot mix asphalt modified with melamine nanopowder polymer

- Second-order design of GNSS networks with different constraints using particle swarm optimization and genetic algorithms

- Impact of including a slab effect into a 2D RC frame on the seismic fragility assessment: A comparative study

- Analytical and numerical analysis of heat transfer from radial extended surface

- Comprehensive investigation of corrosion resistance of magnesium–titanium, aluminum, and aluminum–vanadium alloys in dilute electrolytes under zero-applied potential conditions

- Performance analysis of a novel design of an engine piston for a single cylinder

- Modeling performance of different sustainable self-compacting concrete pavement types utilizing various sample geometries

- The behavior of minors and road safety – case study of Poland

- The role of universities in efforts to increase the added value of recycled bucket tooth products through product design methods

- Adopting activated carbons on the PET depolymerization for purifying r-TPA

- Urban transportation challenges: Analysis and the mitigation strategies for road accidents, noise pollution and environmental impacts

- Enhancing the wear resistance and coefficient of friction of composite marine journal bearings utilizing nano-WC particles

- Sustainable bio-nanocomposite from lignocellulose nanofibers and HDPE for knee biomechanics: A tribological and mechanical properties study

- Effects of staggered transverse zigzag baffles and Al2O3–Cu hybrid nanofluid flow in a channel on thermofluid flow characteristics

- Mathematical modelling of Darcy–Forchheimer MHD Williamson nanofluid flow above a stretching/shrinking surface with slip conditions

- Energy efficiency and length modification of stilling basins with variable Baffle and chute block designs: A case study of the Fewa hydroelectric project

- Renewable-integrated power conversion architecture for urban heavy rail systems using bidirectional VSC and MPPT-controlled PV arrays as an auxiliary power source

- Exploitation of landfill gas vs refuse-derived fuel with landfill gas for electrical power generation in Basrah City/South of Iraq

- Two-phase numerical simulations of motile microorganisms in a 3D non-Newtonian nanofluid flow induced by chemical processes

- Sustainable cocoon waste epoxy composite solutions: Novel approach based on the deformation model using finite element analysis to determine Poisson’s ratio

- Impact and abrasion behavior of roller compacted concrete reinforced with different types of fibers

- Architectural design and its impact on daylighting in Gayo highland traditional mosques

- Structural and functional enhancement of Ni–Ti–Cu shape memory alloys via combined powder metallurgy techniques

- Design of an operational matrix method based on Haar wavelets and evolutionary algorithm for time-fractional advection–diffusion equations

- Design and optimization of a modified straight-tapered Vivaldi antenna using ANN for GPR system

- Analysis of operations of the antiresonance vibration mill of a circular trajectory of chamber vibrations

- Functions of changes in the mechanical properties of reinforcing steel under corrosive conditions

- Enhanced PAPR reduction in NOMA systems using modified SLM and PTS techniques for power-efficient 5G and beyond networks

- Hybrid mechanics-informed machine learning models for predicting mechanical failure in graphene sponge: a low-data strategy for mechanical engineering applications

- Design of shafts of a two-piece chain conveyor as a part of a modification of a mobile working machine

- Review Articles

- A modified adhesion evaluation method between asphalt and aggregate based on a pull off test and image processing

- Architectural practice process and artificial intelligence – an evolving practice

- 10.1515/eng-2025-0148

- Special Issue: 51st KKBN - Part II

- The influence of storing mineral wool on its thermal conductivity in an open space

- Use of nondestructive test methods to determine the thickness and compressive strength of unilaterally accessible concrete components of building

- Use of modeling, BIM technology, and virtual reality in nondestructive testing and inventory, using the example of the Trzonolinowiec

- Tunable terahertz metasurface based on a modified Jerusalem cross for thin dielectric film evaluation

- Integration of SEM and acoustic emission methods in non-destructive evaluation of fiber–cement boards exposed to high temperatures

- Non-destructive method of characterizing nitrided layers in the 42CrMo4 steel using the amplitude-frequency technique of eddy currents

- Evaluation of braze welded joints using the ultrasonic method

- Analysis of the potential use of the passive magnetic method for detecting defects in welded joints made of X2CrNiMo17-12-2 steel

- Analysis of the possibility of applying a residual magnetic field for lack of fusion detection in welded joints of S235JR steel

- Eddy current methodology in the non-direct measurement of martensite during plastic deformation of SS316L

- Methodology for diagnosing hydraulic oil in production machines with the additional use of microfiltration

- Special Issue: IETAS 2024 - Part II

- Enhancing communication with elderly and stroke patients based on sign-gesture translation via audio-visual avatars

- Optimizing wireless charging for electric vehicles via a novel coil design and artificial intelligence techniques

- Evaluation of moisture damage for warm mix asphalt (WMA) containing reclaimed asphalt pavement (RAP)

- Comparative CFD case study on forced convection: Analysis of constant vs variable air properties in channel flow

- Evaluating sustainable indicators for urban street network: Al-Najaf network as a case study

- Node failure in self-organized sensor networks

- Comprehensive assessment of side friction impacts on urban traffic flow: A case study of Hilla City, Iraq

- Design a system to transfer alternating electric current using six channels of laser as an embedding and transmitting source

- Security and surveillance application in 3D modeling of a smart city: Kirkuk city as a case study

- Modified biochar derived from sewage sludge for purification of lead-contaminated water

- The future of space colonisation: Architectural considerations

- Design of a Tri-band Reconfigurable Antenna Using Metamaterials for IoT Applications

- Special Issue: AESMT-7 - Part II

- Experimental study on behavior of hybrid columns by using SIFCON under eccentric load

- Special Issue: ICESTA-2024 and ICCEEAS-2024

- A selective recovery of zinc and manganese from the spent primary battery black mass as zinc hydroxide and manganese carbonate

- Special Issue: REMO 2025 and BUDIN 2025

- Predictive modeling coupled with wireless sensor networks for sustainable marine ecosystem management using real-time remote monitoring of water quality

- Management strategies for refurbishment projects: A case study of an industrial heritage building

- Structural evaluation of historical masonry walls utilizing non-destructive techniques – Comprehensive analysis