Abstract

In engineering practice, a common problem is the lack of space on the construction site for the proper storage of building materials. The consequence of this is that building materials are stored in open spaces, where they are exposed to external atmospheric factors. This study analyses the effect of storing mineral wool for 18 months under the external conditions of moderate climate occurring in Poland on its thermal conductivity. Thirty-five samples were non-destructively tested in terms of maintaining the thermal conductivity coefficient declared by the manufacturer. The tests were performed for material with a thickness of 50 and 80 mm, and the effect of wrapping pallets in foils in maintaining thermal conductivity was also examined. The thermal conductivity coefficient was measured in standard non-destructive tests using the FOX314 plate apparatus. Despite the impact of the external environment on the mineral wool for a period of 18 months, the tests confirmed that there was no significant effect of atmospheric conditions on the thermal conductivity coefficient. The measured parameter was within the limit values specified by the manufacturer and included in the technical data sheets of the products.

1 Introduction

Current market realities exert immense pressure on manufacturers, distributors, and retailers to maintain a high level of availability and diversity of the products they sell. This is driven by increasingly higher consumer expectations. Unfortunately, the market for building materials is also subject to these demands. Storing materials in warehouses is becoming increasingly troublesome and costly. A common way to address this issue is to store products in open, uncovered storage yards or for extended periods on construction sites.

The methods of material storage can impact their performance parameters. A key aspect is the duration during which the material was exposed to environmental conditions. The climate of the area, including factors such as precipitation, air humidity, and UV radiation, also plays a significant role. In most cases, building materials are, according to the manufacturer's data, resistant to the effects of external atmospheric conditions. However, prolonged exposure, despite assurances, can affect performance parameters such as thermal insulation. Thermal insulation of building partitions directly affects the energy efficiency of construction, which is currently a significant global problem. The entire construction industry strives for sustainability, using various technical solutions, including those in the field of recycling [1]. Maintaining the thermal conductivity of thermal insulation materials during storage is one of the key aspects of sustainable construction.

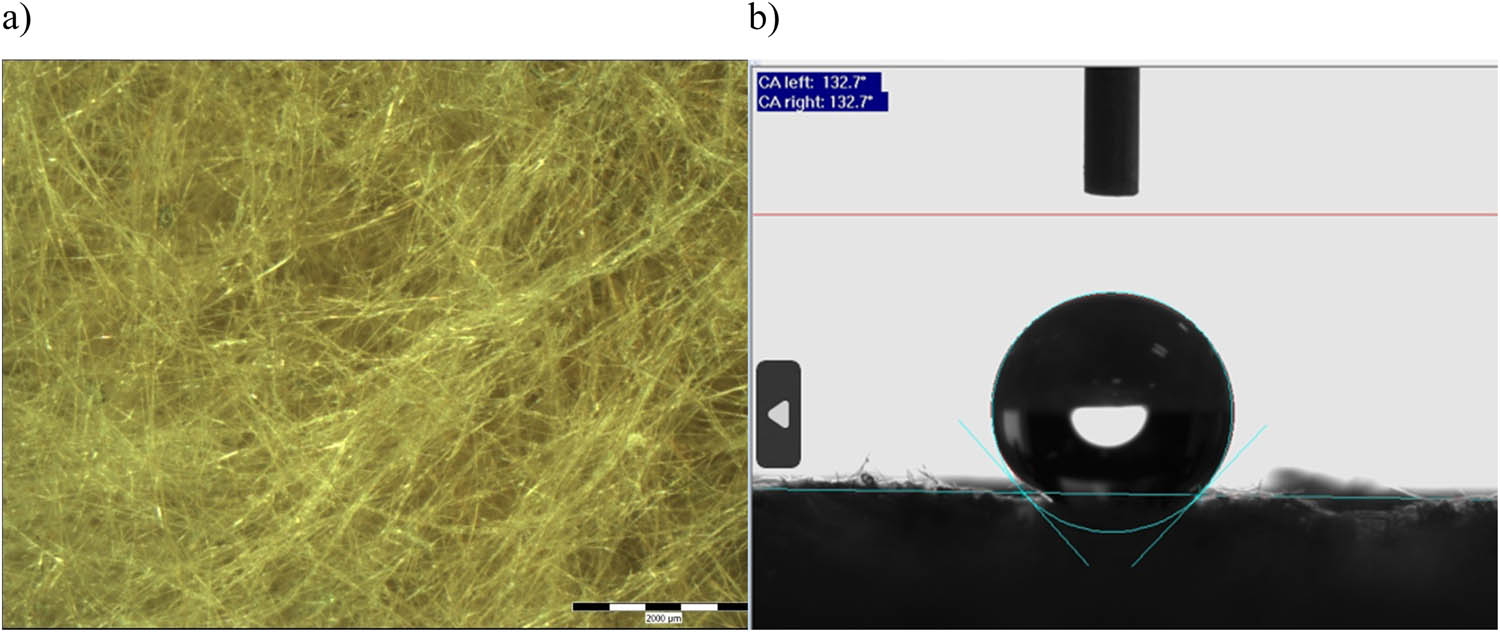

Mineral wool, along with polystyrene, is one of the primary thermal insulation materials used in construction. It is estimated that together with glass wool, they make up 60% of the global market for all materials used for insulation [2]. Mineral wool is an organic material produced through the thermal processing of basalt rocks with additions like gabbro, dolomite, or limestone. It is characterized by a fibrous structure (Figure 1a) and a thermal conductivity ranging from 0.03 to 0.046 W/m K [3]. It is thermally stable as long as a few basic requirements are met. Manufacturers [4] declare a range of very good properties of mineral wool in contact with moisture, emphasizing, among other things, the production hydrophobization of the wool (Figure 1b), its structure that allows for quick evaporation of excess moisture, and the stability of its parameters even after flooding – once the material is fully dried.

(a) Photograph of mineral wool under magnification and (b) determination of the contact angle of the wool (own source).

The parameters describing the thermal insulation of wool, according to industry standards, are the declared and calculated values of the thermal conductivity coefficient [5]. The declared value is calculated based on the measurement data and may also be subjected to conversion due to reference conditions. It also takes into account temperature and humidity and must correspond to an appropriate confidence level. Statistically, during testing on a specific sample, a normal distribution of the population is obtained. The declared value of mineral wool is determined under laboratory conditions and is measured in a dry state.

The calculated value of the thermal conductivity of materials, on the other hand, is determined under certain conditions that, according to technical knowledge, are considered typical for specific applications (a state of thermodynamic equilibrium with air at 80% humidity). In this case, the actual insulation values, accounting for the working conditions of the material, are obtained [6,7].

Conversion of the results also allows for determining declared values from the calculated values (and vice versa). The procedure provided in the standard [5] specifies the methodology for performing calculations. It is necessary to first determine the thickness, density, test temperature, and moisture content in the sample during testing, and if the materials have undergone an aging procedure, then the age of the sample and the conditions of seasoning are also determined.

The calculation procedure involving the conversion of thermal values should be carried out in accordance with the following equations:

where

Then, taking into account the mass moisture content (as a mass to mass ratio), the conversion is carried out according to the following formula:

where f u is the conversion factor due to mass moisture, u 1 is the mass moisture content for the first set of samples, and u 2 is the mass moisture content for the second set of samples. The sorption moisture content in installed materials depends on the hygroscopic equilibrium between the two media, which are the material and its surrounding environment [8]. In studies discussed in the literature regarding thermal parameters, the results indicate that under normal working conditions of thermal insulation [9], sorption does not affect the change in the material’s insulation properties. However, in the study of Nagy et al. [10], it was shown that mineral wool samples can absorb moisture from the air up to nearly 0.07% of their initial mass at the highest levels of relative humidity. At lower levels of relative humidity (from 40 to 80%), the increase in the sample mass was about 0.01–0.02%. In the study of Huculak-Mączka et al. [11], tests were conducted on the drying speed of the waste mineral wool. The results proved that depending on the relative humidity of the surrounding air, the moisture content in the wet sample decreased.

The main factor affecting the thermal parameters of thermal insulation materials is their moisture content. In the literature, many authors have addressed this issue [3,9,10,12,13,14,15,16]. The conclusion in this regard is unequivocal – moisture increases the value of the thermal conductivity coefficient. The aim of this study is to assess the impact of storing mineral wool in open spaces on its thermal conductivity. The study seeks to fill the knowledge gap regarding the long-term effects of atmospheric conditions on the insulation properties of mineral wool. The research hypotheses include the following:

Storing mineral wool in open spaces for a period of 18 months does not cause a significant change in its thermal conductivity.

Wrapping pallets of mineral wool in foil does not have a significant impact on maintaining its insulation properties.

2 Methods

To actual standards, the recommended method for measuring thermal conductivity is the guarded hot plate method with a heat flux sensor in a plate apparatus. This method is nondestructive and suited for materials with high and medium thermal resistance [17]. There are, of course, other methods based on both stationary and non-stationary heat flow measurements. Descriptions of the advantages, disadvantages, and limitations of these methods can be found in the ITB (Building Research Institute) publication [18].

During the measurement of the thermal conductivity (λ), and consequently, the thermal resistance (R), it is crucial to achieve a unidirectional, constant, and uniform heat flux (steady-state heat flow conditions). The measuring device, known as the plate apparatus, consists of several sections, with the most important being the central section where the actual measurement is conducted. During the tests, a constant measurement of the temperature difference across both sides of the sample with parallel faces is performed. Measurements are taken using temperature sensors (thermocouples) located within the device. The final value obtained from the calculations is the average thermal conductivity for the central measurement area of the tested material sample.

According to the standard [17], for measurements conducted on loose materials, the total thickness of the sample subjected to testing should be at least ten times the average grain size. Materials prepared for testing should have a flat surface and maintain parallel edges. It is recommended that samples be seasoned to achieve a constant mass before testing. It is permissible to enclose samples in airtight moisture-proof coatings to prevent moisture migration to or from the sample during the test.

3 Description of the test material

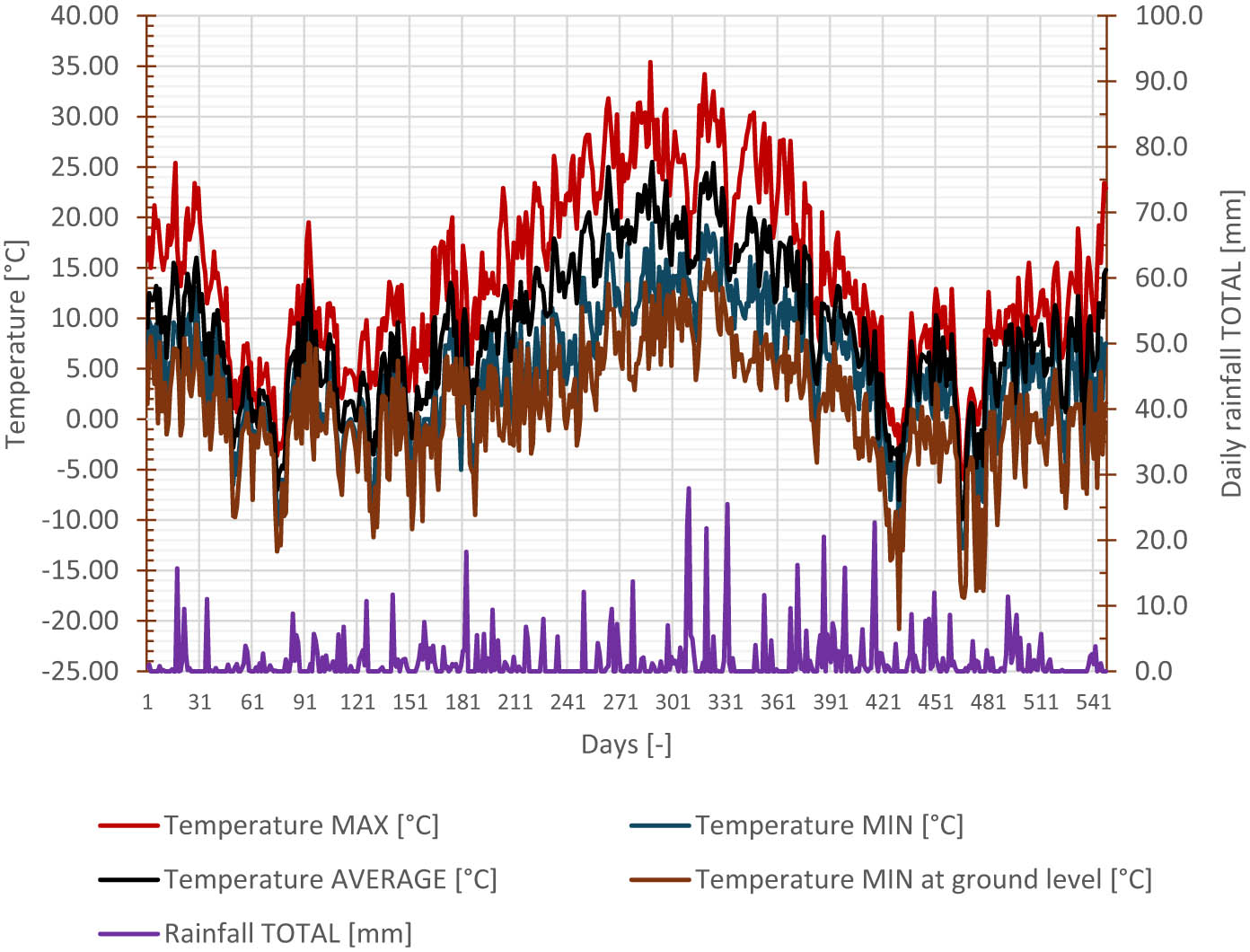

The tested mineral wool in the form of boards was intended to insulate the flat roof of a large industrial hall in western Poland. The research material was located on the construction site and was not separated from the effects of weather conditions. It was stored for 18 months. Some of the stored pallets with the material were not wrapped in foil, and the mineral wool was directly exposed to atmospheric precipitation. Figure 2 shows the daily maximum, minimum, and average temperatures for outdoor air. Additionally, the graph shows the time variability of the temperature at the ground level and the daily total of atmospheric precipitation in mm. The data are historical data recorded for the region where the sample was stored for a period of 18 months, i.e. from October 2022 to March 2024.

Daily values of temperature and precipitation (period from 10.2022 to 03.2024 – 18 months).

Three weeks before sampling, all the material was transported to the interior of an unheated hall. Samples were taken for testing from randomly selected pallets divided into the following four categories:

50 mm-thick samples from pallets wrapped in foil;

50 mm-thick samples from pallets not wrapped in foil;

80 mm-thick samples from pallets wrapped in foil;

80 mm-thick samples from pallets not wrapped in foil.

From each randomly selected pallet, samples were taken from the third layer of the mineral wool board from the top (Figure 3). The pallet selection methodology consisted of randomly selecting 35 pallets from several hundred stored in a covered hall. The random selection of pallets was made by two independent groups of the investment process, i.e. the main contractor and the investor. This allowed for avoiding bias in the selection of pallets. The first two layers from the top showed damage in the form of colour changes (moisture) and increased brittleness. The above defects in the first two layers of mineral wool boards classify the material as unsuitable for installation in a building due to the lack of maintenance of thermal conductivity parameters and strength parameters, i.e. compressive strength. The samples were cut with a mineral wool knife according to a 300 mm × 300 mm pattern (the size was dictated by the size of the measuring field of the device for measuring the thermal conductivity coefficient).

Photograph of example research samples (own source).

4 Experimental research

The standard FOX314 device was used for thermal conductivity tests. According to the technical data sheet of the device provided by the manufacturer (TA Instruments), the FOX 314 device is characterized by determining thermal conductivity with an accuracy of 1% and a measurement repeatability of 0.5%. The tests were performed in accordance with the standard [17] after reaching a steady state in the measurement space of the plate apparatus. Thermal conductivity is determined by the device based on the measurement of the heat flux and the measurement field through which this flux passes under the specified boundary temperature conditions.

The measurements were performed at an average sample temperature of 10°C, a temperature difference across the sample thickness of 20 K, and heat movement from the bottom to the top on samples with dimensions of 300 mm × 300 mm × 80 mm and 300 mm × 300 mm × 50 mm. The samples were tested for the humidity state at the moment of sampling from the place where they were stored.

The measurement station during the tests consisted of a plate apparatus for measuring thermal conductivity and a cooler stabilizing the temperature of the hotplate (Figure 4).

Photograph of the measurement stand: (a) plate apparatus for testing thermal conductivity, (b) refrigerator stabilizing the temperature of the hot plate, and (c) test sample (own source).

5 Results

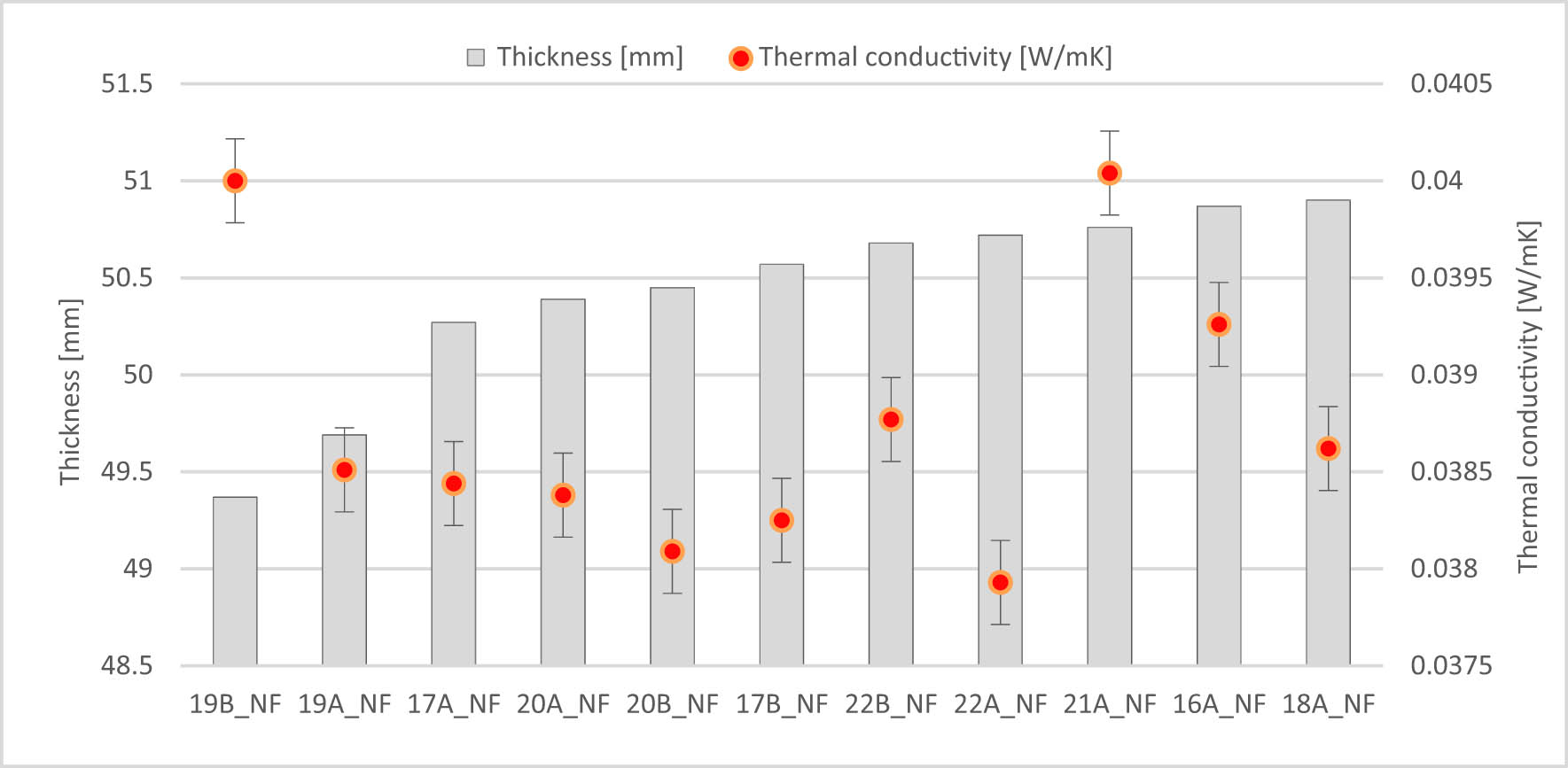

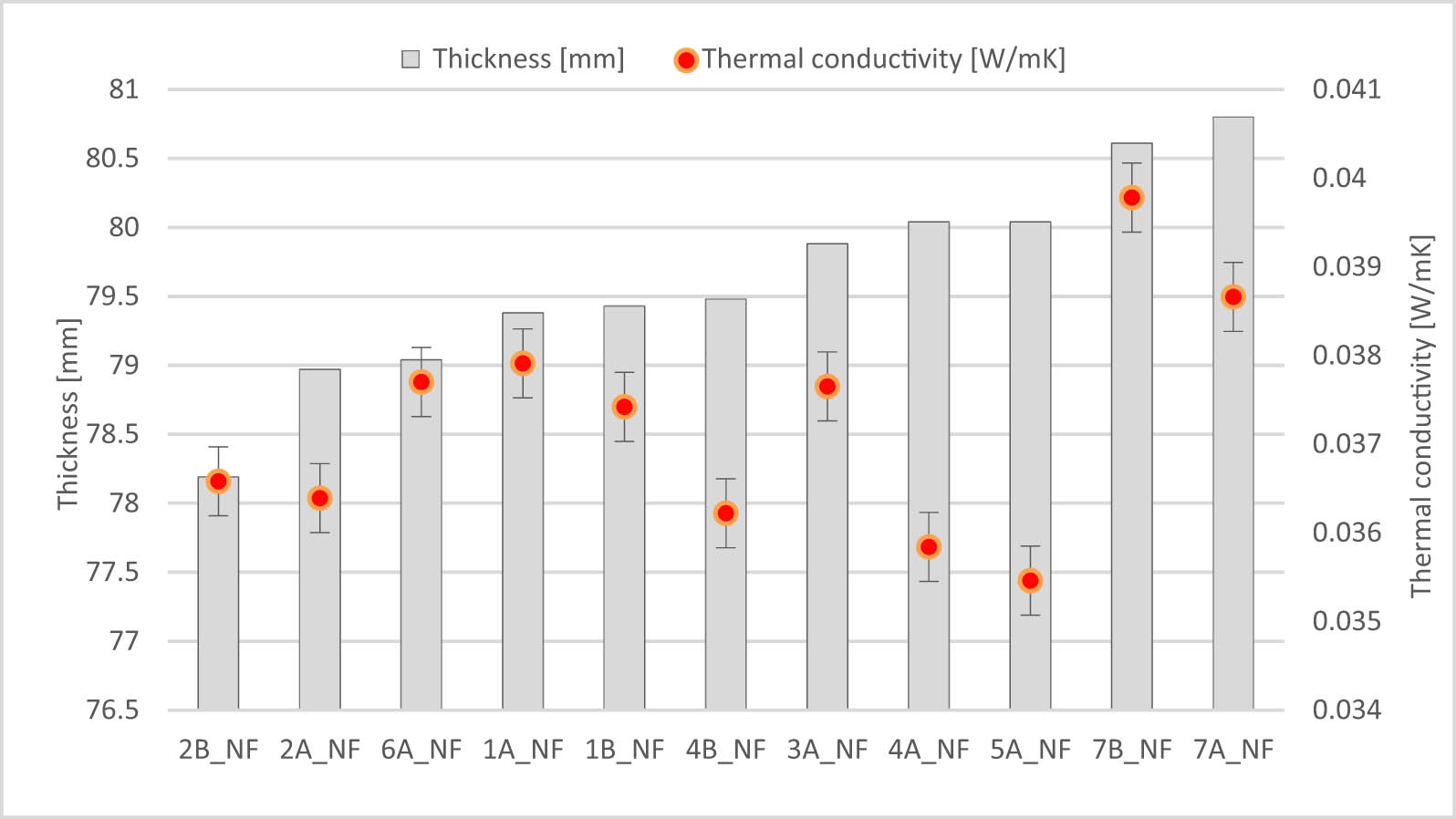

After conducting laboratory tests on research samples, the following measurement results were obtained (Figures 5–8). The samples were divided according to the thickness and packaging method. The first group consists of unwrapped samples, and the second group consists of wrapped samples. The considered thicknesses were approximately 50 and 80 mm.

Unwrapped samples with a thickness of about 50 mm.

Unwrapped samples with a thickness of about 80 mm.

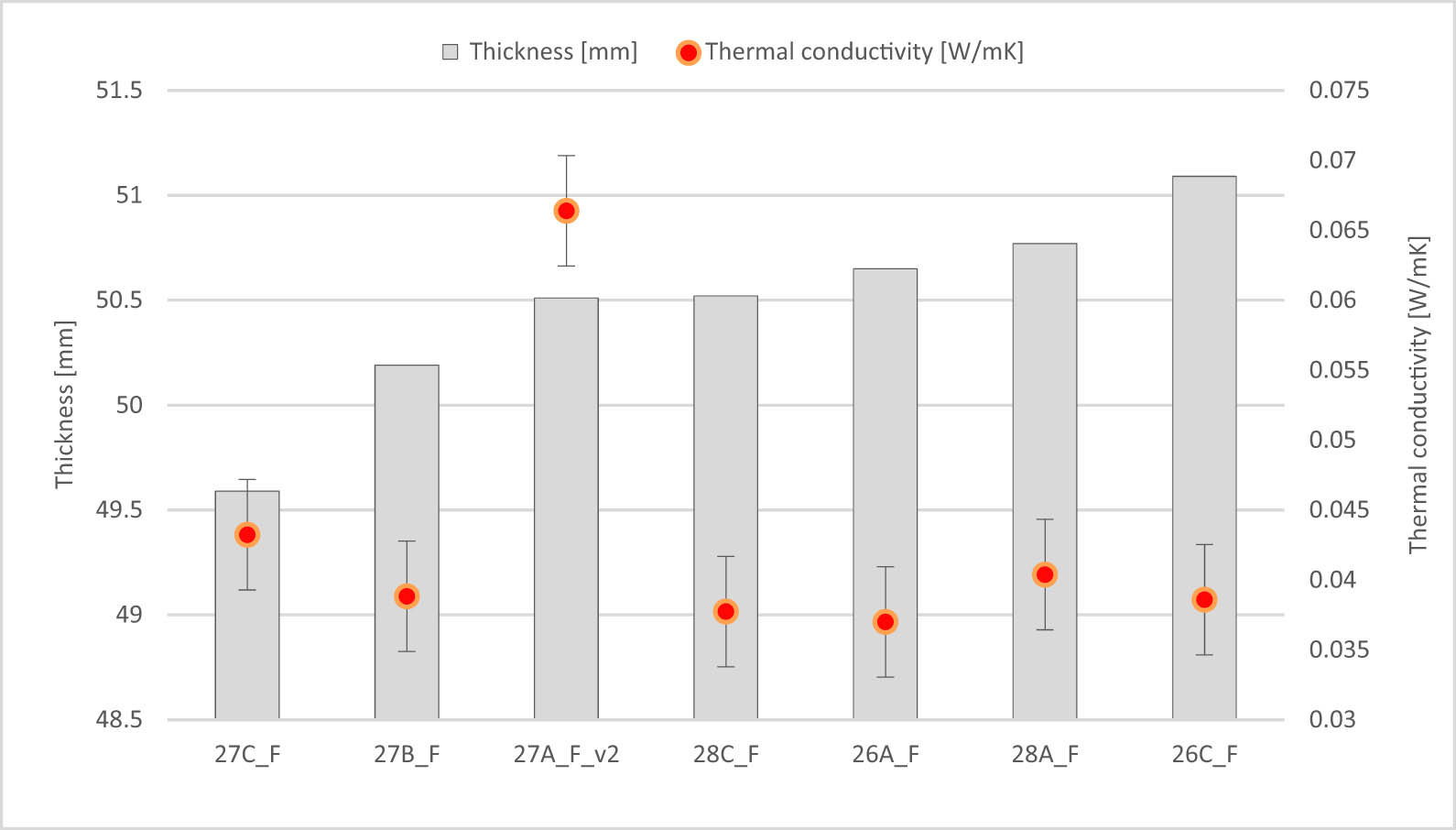

Foiled samples with a thickness of about 50 mm.

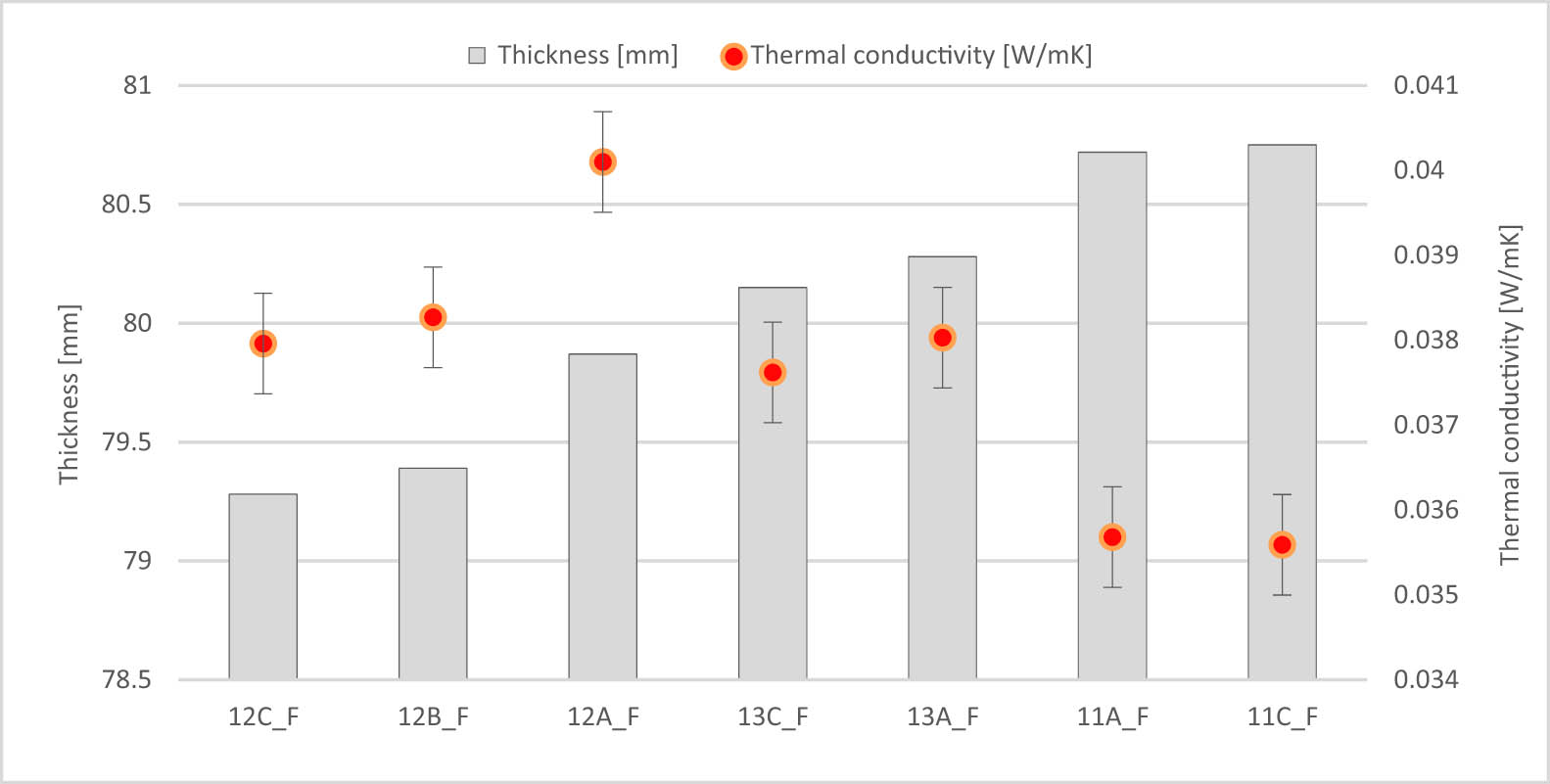

Foiled samples with a thickness of about 80 mm.

The thermal conductivity values in the 50 mm-thick samples (unwrapped pallets) range from approximately 0.03793 to 0.04004 W/m K. For the 80 mm thick samples (unwrapped pallets), the range is from 0.03546 to 0.03978 W/m K. The average material thickness in Figure 5 is 50.14 ± 0.76 mm, while in Figure 6, the thickness is 79.92 mm, and the deviation is 0.88 mm.

The results for the foiled samples are shown in the following Figures 7 and 8. The thermal conductivity values for 50 mm-thick samples (wrapped pallets) range from approximately 0.0370 to 0.06639 W/m K (Figure 7). For 80 mm-thick samples (wrapped pallets), the range is from 0.03559 to 0.0401 W/m K (Figure 8). The measured thickness of the samples taken for testing in the table ranges from 49.59 to 51.09 mm, and the thickness in the table ranges from 79.28 to 80.75 mm.

6 Discussion

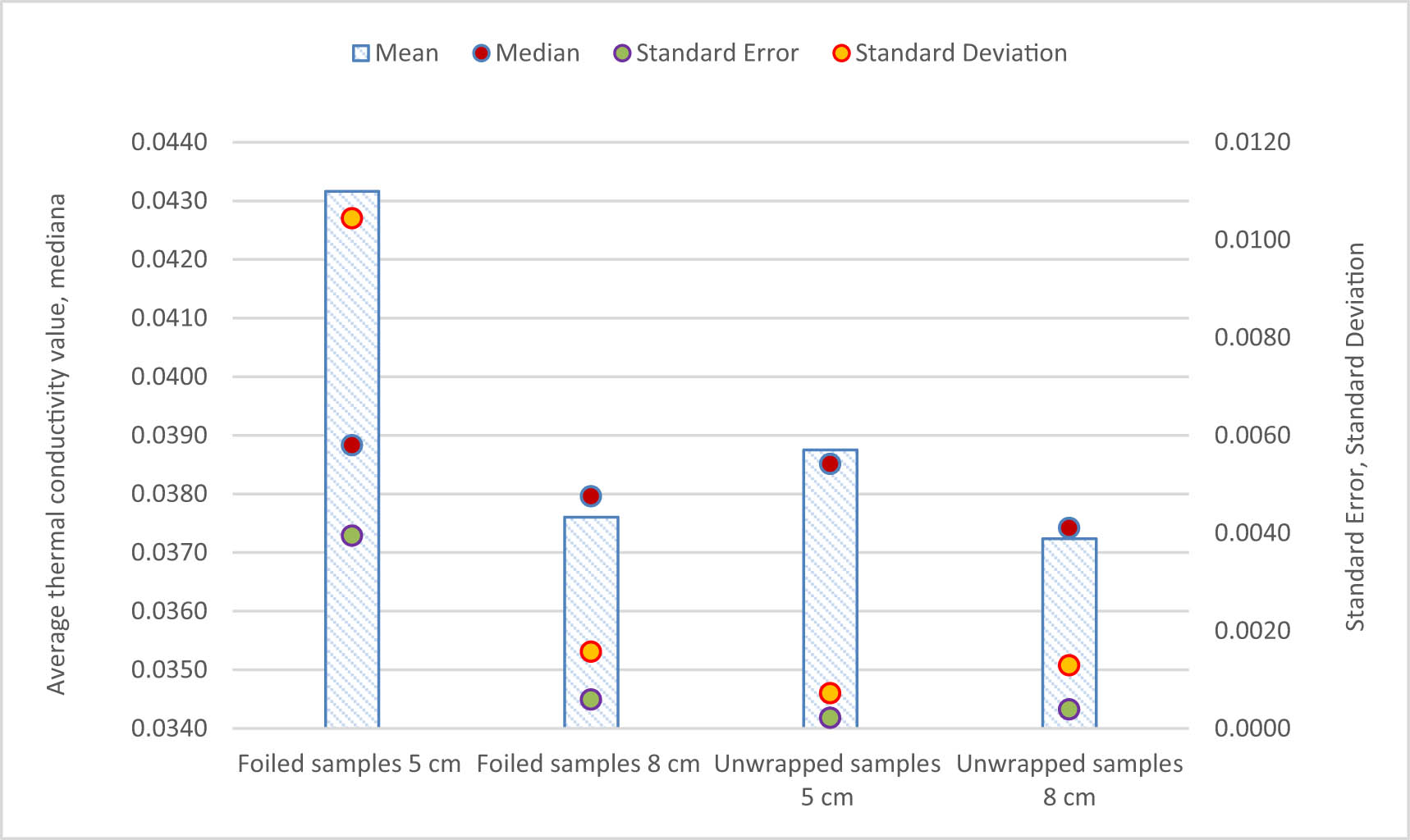

Figure 9 shows a summary chart along with the statistical analysis of the data. All obtained results were used for statistical analysis. There were 7 wrapped samples for both 50 and 80 mm thicknesses, while there were 11 unwrapped samples for both 50 and 80 mm thicknesses.

Summary of results with statistical analysis.

The average thermal conductivity values ranged from 0.04351 to 0.0371 W/m K. The median thermal conductivity indicates that all samples have similar values in the range of approximately 0.038 ± 0.001. The largest standard error and standard deviation were observed in the wrapped 50 mm-thick samples, with values of 0.039 W/m K for the standard error and 0.0104 for the standard deviation, suggesting that the data are the most dispersed (in terms of value range). The smallest differences in numerical values for standard deviation and standard error were found for the unwrapped 50 mm samples, indicating minimal data variability. The discrepancy in the standard deviation (standard error) may result from the diversity of samples, which may come from different production batches – which often leads to minor differences in physical and chemical properties, and the consequence of these differences is a change in the thermal conductivity value. It is worth noting that despite performing all tests using the same measurement technique, the standard error may also be affected by minor measurement errors.

In the results of other researchers, similar measurement results were obtained in the scope of the damp material. As indicated in the publication [9,19], the nature and changes in thermal conductivity in relation to dampness were analogous. Similar results were presented in the study of Jiřičková and Černý [20], in which, in relation to the moisture content [kg/kg], the changes in thermal conductivity were about 0.01–0.03 W/m K in relation to the new thermal insulation material using mineral wool.

To verify the results, computational values of thermal conductivity were determined. The conversion was performed using a methodology that accounted for the impact of moisture content. Initially, the samples were divided into two groups: the first group consisted of 50 mm-thick samples, and the second group consisted of 80 mm-thick samples. The mean values for both groups were calculated and are presented in Table 1.

Arithmetic average thermal conductivity for a given sample thickness

| Group | Sample thickness (mm) | Average thermal conductivity coefficient λ (W/m K) |

|---|---|---|

| 1 | 80 | 0.03742 |

| 2 | 50 | 0.04096 |

Calculations were then performed by comparing the measured values with the calculated values according to the standard procedure presented in Table 2.

Conversion parameters used for calculating computational values

| Parameter | Group 1 (80 mm) | Group 2 (50 mm) |

|---|---|---|

| Declared thermal conductivity value (by the manufacturer) | 0.036 | 0.04 |

| Moisture content in insulation (at RH 80%) (kg/m³) | 1.79 | 1.79 |

| Moisture content (kg/kg) | 0.01193 | 0.01053 |

| Temperature for Condition 1 | 10 | 10 |

| Temperature for Condition 2 | 10 | 10 |

| Conversion factor for temperature | 0.0053 | 0.0053 |

| Moisture content as mass ratio for the first set of conditions | 0 | 0 |

| Moisture content as mass ratio for the second set of conditions | 0.01193 | 0.01053 |

| Conversion factor for moisture as mass ratio | 4 | 4 |

| Conversion factor for temperature | 1 | 1 |

| Conversion factor for moisture | 1.049 | 1.043 |

| Conversion factor for aging | 1 | 1 |

| Calculated value | 0.0378 | 0.0417 |

| Measured value | 0.0374 | 0.0410 |

The moisture content of the insulation (at relative humidity RH = 80%) is 1.79 kg/m³ for both groups, which means that both groups have the same level of volumetric moisture. The moisture content expressed as the ratio of the mass of moisture to the mass of dry material is higher for Group 1 (0.01193 kg/kg) compared to Group 2 (0.01053 kg/kg). The moisture correction for Group 1 is 1.049, and that for Group 2 is 1.043, which indicates a slightly greater influence of moisture on the thermal conductivity of Group 1. Material ageing has no effect; therefore, the ageing correction factor is 1 for both groups. The calculated value of the thermal conductivity coefficient based on Formula (2) is 0.0377 W/m K for a thickness of 80 mm and 0.0417 W/m K for a thickness of 50 mm, while the measured values are 0.0374 and 0.0409 W/m K, respectively.

7 Summary and conclusions

Although the study provides valuable insights into the thermal conductivity of mineral wool stored in open spaces, it is important to acknowledge certain limitations. One significant limitation is the specific climate conditions of the storage location. The study was conducted in a moderate climate typical of Poland, characterized by seasonal variations in temperature, humidity, and precipitation. These conditions may not be representative of other climates, such as tropical, arid, or extremely cold regions, where the impact of environmental factors on thermal conductivity could differ significantly.

Additionally, the study focused on a specific duration of 18 months. Longer-term storage or exposure to more extreme weather conditions could potentially yield different results. Future research could explore the effects of varying climates and extended storage periods to provide a more comprehensive understanding of the durability and performance of mineral wool under diverse environmental conditions.

The measurements and their analysis presented in the study allow for the following conclusions:

Based on the laboratory measurement of thermal conductivity using the non-destructive standard method in the FOX 314 plate apparatus, it can be stated that the measured thermal conductivity values for both 80 and 50 mm-thick mineral wool are lower than the calculated values and are within the manufacturer’s declared error limit of the declared value of ±10% of the thermal conductivity coefficient.

Storing mineral wool in an open space, in contact with atmospheric factors, does not cause the loss of its thermal parameters – which has been proven in the calculations.

The first two layers of mineral wool placed on top of the pallet, which was affected by atmospheric factors, are not suitable for use.

No effect of additional protection of the pallets with foil on the thermal conductivity of the stored mineral wool was found.

The conducted studies show that getting mineral wool wet and exposing it to low temperatures does not lead to its complete degradation. Such wool does not have to be disposed of; it is good practice to have an independent laboratory perform thermal conductivity tests of thermal insulation in order to verify that its declared parameters are maintained.

To sum up, hard mineral wool intended for insulation of flat roofs does not lose its thermal properties under the influence of atmospheric conditions when stored in an open space. The general, practical conclusion from the conducted research is that the method and period of storage of thermal insulation material in the form of hard mineral wool do not affect the deterioration of its thermal parameters. The results of our study can be generalized to regions with similar moderate climates; however, differences may occur under other climatic conditions. We recommend conducting additional studies in various climatic conditions to better understand the impact of long-term storage on the properties of mineral wool.

The study does not address the issue of maintaining the mechanical strength and fire resistance of mineral wool during outdoor storage. The influence of other factors on thermal conductivity, such as UV radiation or the number of freezing cycles of the material, has not been investigated. These are the right directions for the development of the subject discussed in the work and the possibilities for the development of future research.

Acknowledgements

The authors would like to acknowledge the assistance and encouragement from colleagues for giving us support and sharing their knowledge and enriching research experience.

-

Funding information: Authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results, and approved the final version of the manuscript. PN: data acquisition, methodology, writing, visualization, and interpretation; KS: methodology, conceptualization, writing – reviewing and editing, guidance, critical revision, and interpretation; MT: methodology, writing – original draft, visualization, validation, and interpretation.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The datasets generated during and analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Qaidi SMA, Mohammed AS, Ahmed HU, Faraj RH, Emad W, Tayeh BA, et al. Rubberized geopolymer composites: A comprehensive review. Ceram Int. 2022;48:24234–59.10.1016/j.ceramint.2022.06.123Search in Google Scholar

[2] Villasmil W, Fischer LJ, Worlitschek J. A review and evaluation of thermal insulation materials and methods for thermal energy storage systems. Renew Sustain Energy Rev. 2019 Apr;103:71–84.10.1016/j.rser.2018.12.040Search in Google Scholar

[3] Hung Anh LD, Pásztory Z. An overview of factors influencing thermal conductivity of building insulation materials. J Build Eng. 2021 Dec;44:102604.10.1016/j.jobe.2021.102604Search in Google Scholar

[4] 10 facts about the influence of moisture on stone wool. https://www.rockwool.com/globalassets/why-stone-wool/fact-sheets/factsheet_moisture.pdf [Internet].Search in Google Scholar

[5] PN-EN ISO 10456:2009. Materiały i wyroby budowlane – Właściwości cieplno-wilgotnościowe – Tabelaryczne wartości obliczeniowe i procedury określania deklarowanych i obliczeniowych wartości cieplnych. Warszawa: Polski Komitet Normalizacyjny; 2002.Search in Google Scholar

[6] Firkowicz-Pogorzelska K. Metodyka określania wartości obliczeniowej współczynnika przewodzenia ciepła materiałów budowlanych. Pracuilding Res Inst. 2001;3:33–53.Search in Google Scholar

[7] Bobociński A. Dyskusja czynników konwersji współczynnika przewodzenia ciepła z uwagi na zawartość wilgoci. Build Res Inst. 2006;3:45–55.Search in Google Scholar

[8] Karoglou M, Moropoulou A, Maroulis ZB, Krokida MK. Water sorption isotherms of some building materials. Dry Technol. 2005 Feb;23(1–2):289–303.10.1081/DRT-200047948Search in Google Scholar

[9] Jerman M, Černý R. Effect of moisture content on heat and moisture transport and storage properties of thermal insulation materials. Energy Build. 2012 Oct;53:39–46.10.1016/j.enbuild.2012.07.002Search in Google Scholar

[10] Nagy B, Simon TK, Nemea R. Effect of built-in mineral wool insulations durability on its thermal and mechanical performance. Therm Anal Calorim. 2020 Jan;139(1):169–81.10.1007/s10973-019-08384-5Search in Google Scholar

[11] Huculak-Mączka M, Kaniewski M, Grzesiak D, Hoffmann J. Assessment of speed of moisture sorption by mineral wool waste. Proc ECOpole. 2017;11(1):141–7.Search in Google Scholar

[12] Nagy B, Szagri D, Bakonyi D. Hygrothermal analysis of mineral wool insulated building constructions based on in situ measurements. Appl Mech Mater. 2019 Jan;887:605–12.10.4028/www.scientific.net/AMM.887.605Search in Google Scholar

[13] Kosiński P. Moisture transport in loose fibrous insulations under steady-state boundary conditions. Materials. 2023 Dec;16(24):7656.10.3390/ma16247656Search in Google Scholar PubMed PubMed Central

[14] Janssen H, Scheffler GA, Plagge R. Experimental study of dynamic effects in moisture transfer in building materials. Int J Heat Mass Transf. 2016 Jul;98:141–9.10.1016/j.ijheatmasstransfer.2016.03.031Search in Google Scholar

[15] Phillipson MC, Baker PH, Davies M, Ye Z, McNaughtan A, Galbraith GH, et al. Moisture measurement in building materials: an overview of current methods and new approaches. Build Serv Eng Res Technol. 2007 Nov;28(4):303–16.10.1177/0143624407084184Search in Google Scholar

[16] Straube J, Smegal J, Smith J. Moisture-safe unvented wood roof systems. In Washington: Proceedings of Building Enclosure Science & Technology, Oreg, Portland, 12–14 April 2010; 2010.Search in Google Scholar

[17] PN-EN 12667:2002. Właściwości cieplne materiałów i wyrobów budowlanych – Określanie oporu cieplnego metodami osłoniętej płyty grzejnej i czujnika strumienia cieplnego – Wyroby o dużym i średnim oporze cieplnym. 83-243-0490-8. Warszawa: Polski Komitet Normalizacyjny; 2002.Search in Google Scholar

[18] Pogorzelski JA. Ostrożnie z niestacjonarnymi badanami przewodności cieplnej. Pracuilding Res Inst. 2000;1:38–52.Search in Google Scholar

[19] Lakatos Á. Moisture induced changes in the building physics parameters of insulation materials. Sci Technol Built Environ. 2016;22(3):252–60.10.1080/23744731.2016.1131567Search in Google Scholar

[20] Jiřičková M, Černý R. Effect of hydrophilic admixtures on moisture and heat transport and storage parameters of mineral wool. Constr Build Mater. 2006 July;20(6):425–34.10.1016/j.conbuildmat.2005.01.055Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Article

- Modification of polymers to synthesize thermo-salt-resistant stabilizers of drilling fluids

- Study of the electronic stopping power of proton in different materials according to the Bohr and Bethe theories

- AI-driven UAV system for autonomous vehicle tracking and license plate recognition

- Enhancement of the output power of a small horizontal axis wind turbine based on the optimization approach

- Design of a vertically stacked double Luneburg lens-based beam-scanning antenna at 60 GHz

- Synergistic effect of nano-silica, steel slag, and waste glass on the microstructure, electrical resistivity, and strength of ultra-high-performance concrete

- Expert evaluation of attachments (caps) for orthopaedic equipment dedicated to pedestrian road users

- Performance and rheological characteristics of hot mix asphalt modified with melamine nanopowder polymer

- Second-order design of GNSS networks with different constraints using particle swarm optimization and genetic algorithms

- Impact of including a slab effect into a 2D RC frame on the seismic fragility assessment: A comparative study

- Analytical and numerical analysis of heat transfer from radial extended surface

- Comprehensive investigation of corrosion resistance of magnesium–titanium, aluminum, and aluminum–vanadium alloys in dilute electrolytes under zero-applied potential conditions

- Performance analysis of a novel design of an engine piston for a single cylinder

- Modeling performance of different sustainable self-compacting concrete pavement types utilizing various sample geometries

- The behavior of minors and road safety – case study of Poland

- The role of universities in efforts to increase the added value of recycled bucket tooth products through product design methods

- Adopting activated carbons on the PET depolymerization for purifying r-TPA

- Urban transportation challenges: Analysis and the mitigation strategies for road accidents, noise pollution and environmental impacts

- Enhancing the wear resistance and coefficient of friction of composite marine journal bearings utilizing nano-WC particles

- Sustainable bio-nanocomposite from lignocellulose nanofibers and HDPE for knee biomechanics: A tribological and mechanical properties study

- Effects of staggered transverse zigzag baffles and Al2O3–Cu hybrid nanofluid flow in a channel on thermofluid flow characteristics

- Mathematical modelling of Darcy–Forchheimer MHD Williamson nanofluid flow above a stretching/shrinking surface with slip conditions

- Energy efficiency and length modification of stilling basins with variable Baffle and chute block designs: A case study of the Fewa hydroelectric project

- Renewable-integrated power conversion architecture for urban heavy rail systems using bidirectional VSC and MPPT-controlled PV arrays as an auxiliary power source

- Exploitation of landfill gas vs refuse-derived fuel with landfill gas for electrical power generation in Basrah City/South of Iraq

- Two-phase numerical simulations of motile microorganisms in a 3D non-Newtonian nanofluid flow induced by chemical processes

- Sustainable cocoon waste epoxy composite solutions: Novel approach based on the deformation model using finite element analysis to determine Poisson’s ratio

- Impact and abrasion behavior of roller compacted concrete reinforced with different types of fibers

- Architectural design and its impact on daylighting in Gayo highland traditional mosques

- Structural and functional enhancement of Ni–Ti–Cu shape memory alloys via combined powder metallurgy techniques

- Design of an operational matrix method based on Haar wavelets and evolutionary algorithm for time-fractional advection–diffusion equations

- Design and optimization of a modified straight-tapered Vivaldi antenna using ANN for GPR system

- Analysis of operations of the antiresonance vibration mill of a circular trajectory of chamber vibrations

- Review Articles

- A modified adhesion evaluation method between asphalt and aggregate based on a pull off test and image processing

- Architectural practice process and artificial intelligence – an evolving practice

- Special Issue: 51st KKBN - Part II

- The influence of storing mineral wool on its thermal conductivity in an open space

- Use of nondestructive test methods to determine the thickness and compressive strength of unilaterally accessible concrete components of building

- Use of modeling, BIM technology, and virtual reality in nondestructive testing and inventory, using the example of the Trzonolinowiec

- Tunable terahertz metasurface based on a modified Jerusalem cross for thin dielectric film evaluation

- Integration of SEM and acoustic emission methods in non-destructive evaluation of fiber–cement boards exposed to high temperatures

- Non-destructive method of characterizing nitrided layers in the 42CrMo4 steel using the amplitude-frequency technique of eddy currents

- Evaluation of braze welded joints using the ultrasonic method

- Analysis of the potential use of the passive magnetic method for detecting defects in welded joints made of X2CrNiMo17-12-2 steel

- Analysis of the possibility of applying a residual magnetic field for lack of fusion detection in welded joints of S235JR steel

- Eddy current methodology in the non-direct measurement of martensite during plastic deformation of SS316L

- Methodology for diagnosing hydraulic oil in production machines with the additional use of microfiltration

- Special Issue: IETAS 2024 - Part II

- Enhancing communication with elderly and stroke patients based on sign-gesture translation via audio-visual avatars

- Optimizing wireless charging for electric vehicles via a novel coil design and artificial intelligence techniques

- Evaluation of moisture damage for warm mix asphalt (WMA) containing reclaimed asphalt pavement (RAP)

- Comparative CFD case study on forced convection: Analysis of constant vs variable air properties in channel flow

- Evaluating sustainable indicators for urban street network: Al-Najaf network as a case study

- Node failure in self-organized sensor networks

- Comprehensive assessment of side friction impacts on urban traffic flow: A case study of Hilla City, Iraq

- Design a system to transfer alternating electric current using six channels of laser as an embedding and transmitting source

- Security and surveillance application in 3D modeling of a smart city: Kirkuk city as a case study

- Modified biochar derived from sewage sludge for purification of lead-contaminated water

- The future of space colonisation: Architectural considerations

- Design of a Tri-band Reconfigurable Antenna Using Metamaterials for IoT Applications

- Special Issue: AESMT-7 - Part II

- Experimental study on behavior of hybrid columns by using SIFCON under eccentric load

- Special Issue: ICESTA-2024 and ICCEEAS-2024

- A selective recovery of zinc and manganese from the spent primary battery black mass as zinc hydroxide and manganese carbonate

- Special Issue: REMO 2025 and BUDIN 2025

- Predictive modeling coupled with wireless sensor networks for sustainable marine ecosystem management using real-time remote monitoring of water quality

- Management strategies for refurbishment projects: A case study of an industrial heritage building

- Structural evaluation of historical masonry walls utilizing non-destructive techniques – Comprehensive analysis

Articles in the same Issue

- Research Article

- Modification of polymers to synthesize thermo-salt-resistant stabilizers of drilling fluids

- Study of the electronic stopping power of proton in different materials according to the Bohr and Bethe theories

- AI-driven UAV system for autonomous vehicle tracking and license plate recognition

- Enhancement of the output power of a small horizontal axis wind turbine based on the optimization approach

- Design of a vertically stacked double Luneburg lens-based beam-scanning antenna at 60 GHz

- Synergistic effect of nano-silica, steel slag, and waste glass on the microstructure, electrical resistivity, and strength of ultra-high-performance concrete

- Expert evaluation of attachments (caps) for orthopaedic equipment dedicated to pedestrian road users

- Performance and rheological characteristics of hot mix asphalt modified with melamine nanopowder polymer

- Second-order design of GNSS networks with different constraints using particle swarm optimization and genetic algorithms

- Impact of including a slab effect into a 2D RC frame on the seismic fragility assessment: A comparative study

- Analytical and numerical analysis of heat transfer from radial extended surface

- Comprehensive investigation of corrosion resistance of magnesium–titanium, aluminum, and aluminum–vanadium alloys in dilute electrolytes under zero-applied potential conditions

- Performance analysis of a novel design of an engine piston for a single cylinder

- Modeling performance of different sustainable self-compacting concrete pavement types utilizing various sample geometries

- The behavior of minors and road safety – case study of Poland

- The role of universities in efforts to increase the added value of recycled bucket tooth products through product design methods

- Adopting activated carbons on the PET depolymerization for purifying r-TPA

- Urban transportation challenges: Analysis and the mitigation strategies for road accidents, noise pollution and environmental impacts

- Enhancing the wear resistance and coefficient of friction of composite marine journal bearings utilizing nano-WC particles

- Sustainable bio-nanocomposite from lignocellulose nanofibers and HDPE for knee biomechanics: A tribological and mechanical properties study

- Effects of staggered transverse zigzag baffles and Al2O3–Cu hybrid nanofluid flow in a channel on thermofluid flow characteristics

- Mathematical modelling of Darcy–Forchheimer MHD Williamson nanofluid flow above a stretching/shrinking surface with slip conditions

- Energy efficiency and length modification of stilling basins with variable Baffle and chute block designs: A case study of the Fewa hydroelectric project

- Renewable-integrated power conversion architecture for urban heavy rail systems using bidirectional VSC and MPPT-controlled PV arrays as an auxiliary power source

- Exploitation of landfill gas vs refuse-derived fuel with landfill gas for electrical power generation in Basrah City/South of Iraq

- Two-phase numerical simulations of motile microorganisms in a 3D non-Newtonian nanofluid flow induced by chemical processes

- Sustainable cocoon waste epoxy composite solutions: Novel approach based on the deformation model using finite element analysis to determine Poisson’s ratio

- Impact and abrasion behavior of roller compacted concrete reinforced with different types of fibers

- Architectural design and its impact on daylighting in Gayo highland traditional mosques

- Structural and functional enhancement of Ni–Ti–Cu shape memory alloys via combined powder metallurgy techniques

- Design of an operational matrix method based on Haar wavelets and evolutionary algorithm for time-fractional advection–diffusion equations

- Design and optimization of a modified straight-tapered Vivaldi antenna using ANN for GPR system

- Analysis of operations of the antiresonance vibration mill of a circular trajectory of chamber vibrations

- Review Articles

- A modified adhesion evaluation method between asphalt and aggregate based on a pull off test and image processing

- Architectural practice process and artificial intelligence – an evolving practice

- Special Issue: 51st KKBN - Part II

- The influence of storing mineral wool on its thermal conductivity in an open space

- Use of nondestructive test methods to determine the thickness and compressive strength of unilaterally accessible concrete components of building

- Use of modeling, BIM technology, and virtual reality in nondestructive testing and inventory, using the example of the Trzonolinowiec

- Tunable terahertz metasurface based on a modified Jerusalem cross for thin dielectric film evaluation

- Integration of SEM and acoustic emission methods in non-destructive evaluation of fiber–cement boards exposed to high temperatures

- Non-destructive method of characterizing nitrided layers in the 42CrMo4 steel using the amplitude-frequency technique of eddy currents

- Evaluation of braze welded joints using the ultrasonic method

- Analysis of the potential use of the passive magnetic method for detecting defects in welded joints made of X2CrNiMo17-12-2 steel

- Analysis of the possibility of applying a residual magnetic field for lack of fusion detection in welded joints of S235JR steel

- Eddy current methodology in the non-direct measurement of martensite during plastic deformation of SS316L

- Methodology for diagnosing hydraulic oil in production machines with the additional use of microfiltration

- Special Issue: IETAS 2024 - Part II

- Enhancing communication with elderly and stroke patients based on sign-gesture translation via audio-visual avatars

- Optimizing wireless charging for electric vehicles via a novel coil design and artificial intelligence techniques

- Evaluation of moisture damage for warm mix asphalt (WMA) containing reclaimed asphalt pavement (RAP)

- Comparative CFD case study on forced convection: Analysis of constant vs variable air properties in channel flow

- Evaluating sustainable indicators for urban street network: Al-Najaf network as a case study

- Node failure in self-organized sensor networks

- Comprehensive assessment of side friction impacts on urban traffic flow: A case study of Hilla City, Iraq

- Design a system to transfer alternating electric current using six channels of laser as an embedding and transmitting source

- Security and surveillance application in 3D modeling of a smart city: Kirkuk city as a case study

- Modified biochar derived from sewage sludge for purification of lead-contaminated water

- The future of space colonisation: Architectural considerations

- Design of a Tri-band Reconfigurable Antenna Using Metamaterials for IoT Applications

- Special Issue: AESMT-7 - Part II

- Experimental study on behavior of hybrid columns by using SIFCON under eccentric load

- Special Issue: ICESTA-2024 and ICCEEAS-2024

- A selective recovery of zinc and manganese from the spent primary battery black mass as zinc hydroxide and manganese carbonate

- Special Issue: REMO 2025 and BUDIN 2025

- Predictive modeling coupled with wireless sensor networks for sustainable marine ecosystem management using real-time remote monitoring of water quality

- Management strategies for refurbishment projects: A case study of an industrial heritage building

- Structural evaluation of historical masonry walls utilizing non-destructive techniques – Comprehensive analysis