Abstract

The textile and clothing industry is undergoing a shift towards a circular business model, driven by new European Commission regulations, which mandates that by 2030, textile products available on the European Union (EU) market must be recyclable and sustainable. To facilitate data collection, storage, and sharing throughout the entire product lifecycle and ensure product traceability and sustainability, the use of Digital Product Passports (DPPs) will be required. This article presents an analysis of the most commonly known digital data technologies from the perspective of their use in digital garment labelling, describing their advantages and limitations. The analysis is complemented by practical insights gathered from semi-structured interviews with garment producers in the Baltic Sea region. The survey revealed that producers prioritise sustainability and are prepared to digitise product information but are awaiting EU’s clear guidance. Despite the challenges posed by DPP implementation from the global, producer, and customer perspectives, upcoming regulations are seen as providing new competitive opportunities for products and services. Both the technology analysis and the expert survey indicate that QR (quick response)-based smart tags are potentially the most straightforward solution for the initial phase of DPP implementation.

1 Introduction

The European Commission (EC) adopted the new Circular Economy Action Plan (CEAP) [1] in 2020 outlining the transition of European economy from recent linear structures to a circular model. It is one of the key documents of the European Green Deal for sustainable growth of Europe.

The EC identified textiles (clothing and fabrics) as a priority product category within a circular economy [2]. The textile and clothing industry has significant environmental impacts, and a circular business model will require effective policies to reduce the negative impact of the huge volume of textile products on the environment, economy, and human lifestyle [3]. To redesign a business model to a circular one, the challenge will be to promote sustainability at each stage of the product development chain, making it more understandable, predictable, and accessible to producers and consumers.

The EU Strategy for Sustainable and Circular Textiles aims to ensure that by 2030, textile products available on the European Union (EU) market are recyclable and sustainable [2,4]. Requirements for textile products include a specific eco-design to minimise carbon and environmental footprints, extending mandatory producer responsibility and requiring more user-focused information [4]. The approach of digitalising product information is fully in line with the production and consumption model of the circular economy, the main goal of which is to extend the product’s life cycle. The implementation of Digital Product Passports (DPPs) enables data collection, storage, and share all the relevant information along the entire life cycle of the product [5,6], so that the product becomes traceable and more sustainable: easier to reuse, remake, and recycle, because its origin is known.

Starting from the concept of DPP, the current article analyses the most commonly known technologies from the perspective of its use in digital garment labelling and describes its advantages and limitations. The literature-based analysis is complemented by the practical insights from clothing producers’ side on the upcoming requirements to transform the industry and ensure circular garment lifecycle. The semi-structured interviews with companies in the Baltic Sea region revealed producers’ attitudes towards sustainability issues and their willingness to take action. The concluding discussion on the challenges for DPP implementation in the textile and clothing business from the global, producer, and customer perspectives is presented.

2 DPP in the textile and fashion sector

DPP becomes a centre of the discussions aiming the transition of textile and fashion sector towards circularity [7,8] and digitisation [7,9].

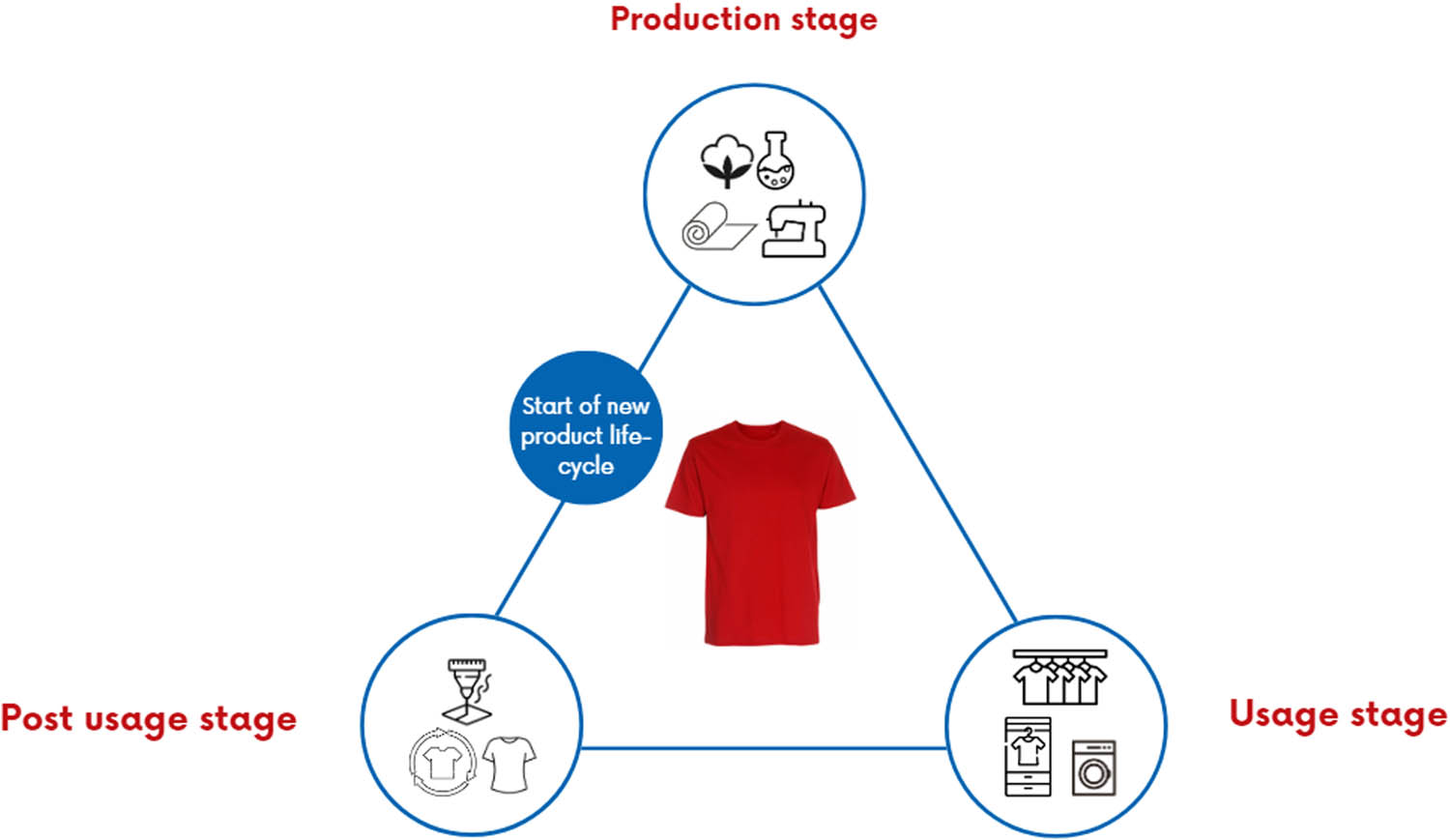

DPP has been identified as a tool that integrates different datasets about a garment from all its lifecycle stages [10]. It is expected that the system based on DPP will provide data from garment production, usage, and post-usage stages [4,9] (Figure 1). DPP opens the opportunity to provide technical and environmental information about garment production stage, instructions for garment care during usage stage and recommendations how garment or various parts of it can be recycled or disposed of at the end of garment usage. As currently envisioned, DPP would prominently involve consumers as active participants to ensure the circularity of the garment lifecycle.

Stages of clothing lifecycle and circularity.

DPP will allow us to trace the entire production stage from material to retail, and these data will add significant input to customers’ decision on buying a more sustainable and durable product. The consumer engagement in sustainability will be provided by DPP data from garment usage stage. DPP could ensure product authenticity and increase of the secondary market, as well as initiate new product lifecycle and secure a circular fashion business model (Figure 1) [4,11,12].

Most product-related data across the entire life cycle from production to usage, reuse, and recycling exist but are currently not accessible to all actors along the value chain [13]. DPP could be accessed online by a physical tag of the product coupled to a unique data identifier (such as a bar code, QR [quick response] code, or other data-capture media) via a mobile device.

Both technological and information management challenges need to be overcome to successfully implement the DPP in a specific textile product market. In recent years, a number of studies have been carried out to develop a framework for DPP implementation. However, the technical integration of DPP in the textile and clothing sector has been analysed in a very fragmented way.

3 Analysis of potential technologies for DPP

Different data sharing and management technologies in the form of digital tags do exist on the market, each with its own unique features and limitations. Already existing commercial smart tags are applied for renting of uniforms and workwear, or hospitality linen management. Several fashion brands are already in the process of implementing digital labelling; however, a unified solution for the mass implementation of DPP in the textile industry has not yet been proposed. The most commonly known technologies were chosen for analysis based on their use in textile and clothing business.

3.1 Barcodes

A barcode is the most visually recognisable Universal Product Code (UPC) represented as multiple vertical lines (barcode) and a 12-digit UPC number. Later, using different geometric patterns, two-dimensional (2D) QR codes were developed. QR codes are effective for inventory management and assessing product availability and are widely used in the internal processes of different companies. First of all, labelling with QR codes was adapted to improve the customer experience in the retail by providing specific information about product and attracting attention. For example, the customer can learn more about the features of functional clothing through the QR code used in the garment label [14,15].

An online archive for the textile companies to keep detailed information about the fabrics could be available through the QR Code Fabric Tag system [16]. The CEO of H&M Karl-Johan Persson was considering a QR code system for clothing labels to trace the environmental and social footprint of H&M garments in 2015 [17]. The Fabapp® platform accessed via QR scanning was used to simulate a smart tag framework for textile products [18]. The information on production processes, as well as guidance for users and manufacturers in the post-usage stage for recycling, aiming to reintegrate these products into a new lifecycle was provided by a digital tag.

QR codes may carry access to a variety of information. To achieve the goal of QR code utilisation, it is crucial that the codes can be applied on different surfaces, even on textiles [14,19], using printing [15], heat transfer, embroidery [20], and other applicable techniques.

QR scanners were used to read the information on the code, but nowadays any consumer who has a digital device – a smartphone or tablet with a built-in camera – can read the information stored on the code. This feature is very important for convenient QR code usage by customers.

3.2 Radio-frequency identification (RFID)

RFID tags are commonly used in both commercial and consumer sectors. RFID technology enables supply chain management and enhances visibility by tracking products from manufacturing to retail. Producers employ them to detect and track products automatically during production processes to determine bottlenecks and retailers to trace products in warehouses and points of sales. Tags vary greatly in size, shape, and frequency range: low, high, and ultra-high. A special wireless RFID reader is used to pick up an RF signal and to read it.

While active RFID tags cost up to tens of euros, a passive RFID tag only costs a few cents. RFID solutions such as paper tags [21], button tags [22], plastic tags [23], embroidered tags [24], and others can even offer washable and ironable options. The RFID tag in the form of a thread is offered by RFiD THREADS®, and the company states that a micro-chip could stay with the product for life and can continue to collect full life cycle assessment (LCA) data [25].

RFID tags, as opposed to QR codes, may store a lot more data, including product details, special identification numbers, and even location data. However, still they are more expensive than QR codes, which can be an issue for textile and clothing business.

3.3 Near-field communication (NFC)

NFC is a widely recognised wireless technology used to transfer data, share media, and perform other functions between two nearby devices. NFC offers a faster and more secure alternative to QR codes for many short-range applications, including mobile payments [26]. NFC permits two-way communication as opposed to QR and RFID, which only permits one-way communication [27]. NFC tags can wirelessly accept power from an NFC reader through electromagnetic induction [27]. The simplest NFC tags are frequently constructed in the form of squares or circular and are available in a very wide range of formats from iron-on textile stickers to sew-on buttons [28,29]. NFC tags can withstand bending, washing, dry cleaning, and ironing, making them suitable for garment labelling [30,31] or for authentication to prevent URL copying and unauthorised use [28].

Near-field-responsive patterns were developed using printed and computer-embroidered conductive threads [32]. These patterns were utilised to create textile-based smart tags that are free of fragile components and offer significant tactile benefits, seamlessly integrating with clothing. Digital labels as textile product ID cards have already been tested by the brand Désirée, which adopted the NFC technology inside their product label [33].

NFC operates within a limited range, typically around 10 cm. To overcome this limitation, researchers at the University of California, Irvine (UCI), have developed a novel high-tech fabric and extended the range of wireless transmission technology to more than 120 cm [34].

3.4 Blockchain technology (BT)

BT has the potential to significantly accelerate the transition to a circular economy as this technology is already being used in many industries to increase transparency and traceability [35]. The BT has been examined in food [36,37], pharmaceutical [38], and fashion sectors [39,40,41].

The smart tags (QR or RFID) integrated with blockchain could ensure that each production process is recorded and registered, and consumers can track the entire information and verify the authenticity of the product not only during the retail stage but also when initiating the post-usage stage by offering the product to resale or reusage.

The patent obtained by Nike company [42] has shown that a unique digital asset code could serve as a form of DPP for blockchain-secured retail products. In 2018, a limited edition Nike sneakers with an embedded NFC chip were offered for consumers through the NikeConnect app to obtain the certificate of authenticity and detailed product information [43]. Few years earlier, in 2015, Greats x Beastmode 2.0 Royale Chukka sneakers were produced with smart labels recorded on the blockchain and could be scanned with a smartphone [44]. The VeChain app was used to verify the authenticity of Babyghost product that had either an NFC chip or a QR code. In 2019, LVMH launched a first luxury blockchain platform Aura [45] to provide the traceability and authenticity of luxury goods’ production process. A blockchain-based LCA framework was analysed using leather handbags as a case study to explore circularity opportunities through enhanced traceability and data sharing [40]. The research highlighted the critical role of supply chain actors’ collaboration in establishing transparency and trust and noted the lack of specific protocols in the textile and fashion sector.

3.5 Comparison from the perspective of DPP usage

The potential of current data management technologies to contribute to achieving the sustainability goals of the industry through DPPs depends on addressing producers’ interests, protecting the uniqueness of the product, and providing consumers with sufficient information about the product at different stages of its usage. From the exploitation side, smart tags suitable for the clothing garments should be durable in the wearing and laundry environments, of low cost, flexible, easy to mass produce, and comfortable for flexible textile items [46].

More specifically, Table 1 presents an analysis of the pros and cons of utilising digital technologies from the perspective of DPP usage to secure garment traceability throughout the entire lifecycle.

Comparison of technologies

| Pros | Cons | |

|---|---|---|

| QR code | Globally recognised certificate | One-way communication |

| For producers, known technology that is used to access existing databases | Cannot be used to trace data of garment usage | |

| Customers are convenient with the technology | Nonsecured access to data (no confidential or personal sensitive information could be provided) | |

| Smart phone as a reader needed to access data | ||

| Easy implementation and production | ||

| Low cost | ||

| Applicable for different techniques (printing, heat transfer, sublimation, and embroidery) | ||

| Labels durable to washing and wear | ||

| RFID | Technology already applied and used by producers and convenient for customers | One way communication |

| Various types: tags, buttons, embroidered, and printed | Needs a special reader | |

| Can be used to access data and for automatic process tracking | More expensive than QR codes | |

| Labels durable and washable | ||

| Has different distances to be activated and can provide only personal access to data | ||

| Passive and active type | ||

| Could be used with the QR code to secure benefits of each technology | ||

| NFC | Two way or one way communication | Needs a special reader |

| High security level and prevents from copying | Short range application | |

| Quick access to data | Costly | |

| Labels with an iron-on sticker or buttons | Woven type; under development | |

| Durable and washable |

While RFID tags have higher functionality and connectivity (e.g. scannable in bulk remotely), QR tags are often a lot cheaper, and a fashion retailer can tag every piece of clothing in a store with it. The QR code is more practical as it is easier to generate. NFC technology is reliable and cost effective; however, woven or printed on textile NFC antennas/tags are not ready for mass production, and such technologies are still under development.

Several brands and researchers are developing new traceability solutions to adapt digital data sharing technologies to the requirements of textile products. The University of Borås has announced that Tarun Kumar Agrawal developed unique “cryptotags” containing tiny particles, which randomly form a unique pattern [47]. The tag was successfully tested at the lab scale. A group of Chinese scientists tested a new technical solution of hybrid tag where the barcode and RFID technologies are combined [48].

Since the analysed technologies are already used in businesses, a survey of company experts was conducted.

4 Study of producers’ experience

In order to fulfil results of the literature-based analysis with practical insights from the experts in the field, the interviews of clothing production companies in the Baltic Sea region were carried out.

4.1 Experts’ survey

To explore the producers’ attitude towards the EC’s call for textile companies to take responsibility by introducing product labelling based on upcoming DPP requirements, semi-structured interviews with ten experts of Lithuania and Latvia companies were conducted between June and August 2023. To strengthen the power of situation analysis, the information provided in the company’s website and public statements of company representatives were collected and examined. The interview started with questions to collect general information about company’s profile, followed by a more specific discussion based on five questions with short introduction to each of them. The representatives of production companies were asked “[…] to describe the company’s attitude towards the European Commission’s call for textile companies to take responsibility and take action to reduce their carbon and environmental footprints, and how this call is relevant in the company,” and “what actions being done to make it happen?” The second question was “What activities are carried out in company to ensure the sustainability of the product and the full cycle of the product circulation?” The last three questions were related to scenarios of technological implementation: it was asked, whether “the company is bound by the European Commission’s recommendation on the implementation of DPP,” “what benefits and risks are assessed for the implementation in practice,” “whether the company is committed to implementing DPP,” and “what technology would be the most suitable” to fulfil upcoming garment traceability requirements.

4.2 Producers’ attitude towards sustainability and DPP

The answers of producers showed a positive attitude to EC’s CEAP to launch a new strategy to make textiles more durable, repairable, reusable, and recyclable. Experts of companies confirm that they regularly review their operations, eliminate deficiencies, and hire external consultants to analyse the business impact of other EU Green Deal initiatives.

With the second question of the interview, the experts were invited to discuss about the activities that are carried out to ensure the sustainability of their product. The labels provide customers with the information of product origin country, material’s composition, and product care requirements, as well as a visible certificate of the fabric quality, whether the fabric is organic or, for example, recycled. However, before the new labelling regulations come into force, there are already discussions that the existing labelling of garments is insufficient and does not provide customers with relevant information about production ethics and how rights of workers are protected [14]. The identification of the composition of material is necessary in order to ensure efficient recycling of used textiles. Although the raw material must be indicated on the garment label, that information is not enough, and it is claimed that information about raw material is still a barrier to implement the circular economy in the textile sector [49]. The active involvement of the customers is necessary to ensure the sorting and recycling process of end-of-use textile garment. Encouraging consumers to classify garments based on the type of textile fibre before disposal is crucial. The low reliability of the current garment labels is a significant factor affecting consumer participation in textile recycling efforts [50].

Sustainability is an important issue for producers. Company “A” (Latvia) says: “we only use fabrics from recycled plastic waste, we only buy fabrics in white and dye them ourselves with the help of sublimation (it’s a waterless system), we use scraps and leftovers for new products, we donate our waste to new products, we only produce custom-made clothes, we avoid microplastics, we re-use packaging.” Company “B” (Latvia) provides CMT (cut, make, and trim) services for fashion brands and does not engage in direct product design. However, the company confirmed that the operation of production equipment and the transportation of materials were carried out using modern technologies that are friendly to the environment and secure a lower CO2 footprint.

Clothing production companies in Latvia and Lithuania are increasingly thinking about sustainable design, sticking to frugal, practical, and classic values in design development, as well as taking care of the quality of fabric and sewing, so that the clothes last for a long time. The experts also agreed that additional information on materials sustainability or recommendations for sustainable care, as well as recommendations for garment disposal or reuse, could be valuable to their consumers and add higher value to their products. However, this information is not currently mandatory and is not provided by brands and producers.

In the technology section of the interview, three topics were discussed with experts: whether the company is committed to implementing DPP in accordance with forthcoming EC regulations, how the whole process could work in practice, and which technology would be most suitable. It must be admitted that the questions in this section were somewhat more confusing for experts. The companies participating in the survey were fairly unanimous in recognising that the EC recommendations are binding, however only two of them were more convenient with the DPP, while others stated that they were waiting for more precise guidance and support from local legislation on how the EC recommendations should be implemented. Consequently, it was mentioned that the actions related to these issues and how they should be taken are not entirely clear. The companies are ready to implement a DPP, as long as there is additional support for producers to take all the necessary steps.

At the same time, however, it was also noted that companies store data related to the garment production in various databases: for example, products are tagged with RFID tags for inventory purposes in warehouses, while QR codes work well at the level of product orders. In order to successfully implement DPP, it is necessary to understand how to combine the existing technologies and databases with each other, what information should be directly disclosed to the customer, and for how long this information needs to be provided. Discussions with experts revealed that companies are concerned about the workforce they will need to fulfil upcoming requirements. The implementation of the DPP is not only about technology but also about a fundamental reorganisation of the entire existing system. In order to achieve this in a unified and successful manner, it is essential that the EU develops uniform guidelines for the next steps.

Lithuanian company “C” states that they are aware of the implementation of DPP and take it into account as some of their customers are interested in DPP, but the company also notes that there are currently no uniform rules at the EU level and therefore it is not entirely clear what actions should be taken. The company is working more on risk management related to the implementation of the DPP. International standards and certification need to be implemented for the garments produced outside the EU market, and these production volumes are high.

Company “D” (Lithuania) has revealed the experience of the LTP Group [51] utilising sustainability and transparency. The company developed a mobile application Consciously Crafted® app and a concept “tailored to individual brands, … designed specifically for the end-consumer and … accessible via QR codes featured on labels and hangtags, developed to provide insight for customers to verify marketing claims, the app can provide vital information about the manufacturer behind the garment, environmental and social conditions, material choices, how to care for the products etc.” [51]. However, the application that was created in 2020 is still under limited access.

The survey indicates that companies regularly monitor requirements, especially those related to sustainability requirements for products and production. Producers are concerned about sustainable production and are willing to take on more responsibility, but they lack clear guidance on how the process will be done and how producers’ competitiveness will be protected. It should also be mentioned that the technological side of the forthcoming requirements to implement product traceability based on DPP is unclear. Garment production companies are ready to adapt their processes digitalising product information, but EU documentation is awaited first, as there is a lack of clear guidance on how to proceed. Textile and clothing companies are ready to respond flexibly to consumer demand for more detailed, user-orientated information about products and to share their experience on how to reduce the environmental impact of their products throughout the entire lifecycle. With the upcoming EU regulations, Lithuanian and Latvian producers see new competitive opportunities for their products and CMT services, although they agree that DPP could be a good practice to introduce circular business models and increase the added value of products.

5 Discussion

Although the forthcoming EU regulations indicate that the main objective of DPP is to increase the sustainability of the textile and clothing business, however, in reality, this will be difficult to achieve. First of all, the products of the industry are very diverse and reflect different user expectations in terms of both durability and sustainability.

DPP should be tailored to each specific product, considering different approaches depending on whether the garment is a high value-added branded or functional sportswear garment, or a lower value-added garment. For mass-produced lower-value products, it is more likely that DPP will be created for a particular batch or product series [52]. Meanwhile, DPP could provide exclusivity to expensive niche garments, associating them with a higher added value and a circular product lifecycle. Similar to the electronics or automotive industry, such products could be individually tracked to create detailed usage histories, enabling producers to offer lifetime product warranties and repair services. Sorting and recycling processes for such end-of-life products would become clearer and easier to manage. Additionally, it is observed that DPP can play an important role in developing the second-hand marketplace [11].

Challenges for DPP implementation from the global perspective:

In globally distributed supply chain where stakeholders are geographically remote and operate in many countries with different regulations and legal systems.

A huge variety of garments are produced globally and items are sold in the global market. As a result, there are very large volumes of products circulating in the market and keeping track of them and storing information about them for a long period of time is an inconceivable task.

A universal system to store and manage data needs to be aligned with existing processes and gradually transitioned to it.

Gradual transition to DPP will not ensure a rapid reduction in waste. The increasing focus on reuse, repairs, etc. is likely to increase the amount of used products on the market that are not tracked and documented in any way.

Challenges for DPP implementation from the producers’ perspective:

The complex multi-stage supply chain involves a number of processes to transform materials into garments, so there is a need to standardise the data required;

A transparent system to verify processes, materials, and accessories across the value chain;

Technological capabilities and capacities;

Sustainability requirements – despite the DPP’s ambition to increase sustainability and reduce emissions, the choice of technology is also a challenge for producers, on whose shoulders the sustainability requirements are transferred;

Cost-related resources to set up the system, collect the data, and verify access to the data over time. The availability of data for the entire garment lifecycle must be considered.

Challenges for DPP implementation from the consumer perspective:

Sensitive personal data and continuous tracking. Consumers care about whether their data are stored securely and whether the technology used is secure and compliant;

How attractive is the additional requirement for consumers to check product information not only at the point of purchase but also when the product is put in the washing machine or thrown in the bin? How to ensure that this does not become an unused expensive option? On the other hand, millennials are already constantly checking everything online, and smart homes are adopting advanced technologies that can potentially automatically link the clothes you buy to a smart wardrobe, smart washing machine, waste management system, etc. Responsible consumers can easily be rewarded for the sustainable use of their clothes;

A technological solution that works reliably and is user-friendly. While technologies such as QR or RFID are known, available to consumers, and used by producers, there is a lack of technological readiness to scale them up to meet fashion’s ambitious sustainability goals.

6 Conclusions

Both an analysis of digital labelling technologies and a survey of producers show that QR-based smart tags are potentially the easiest to apply for the DPP implementation. The labelling created on the basis of QR codes would perfectly meet the requirements of DPP during the initial phase of implementation. As it was assumed in DPP in the textile sector, Draft version STOA Panel meeting 14 March 2024 [11], the first phase could be attributed to the simplified DPP which is mainly based on dissemination of mandatory information and completed by additional information for lifecycle analysis. The advanced DPP would be designed to collect more information throughout the garment lifecycle, contributing to phase 2 [11]. Meanwhile, in the transition from simplified to advanced DPP, more sophisticated smart labelling technology should be chosen and a framework to collect data through the product lifecycle tested during the next phase of DPP implementation has to be ready for the final introduction of circular DPP. The integrated system of the circular DPP must therefore be aligned with the capabilities and interests of producers, tailored to the specifications of the garment itself, and meet consumer preferences for engagement in the process.

-

Funding information: The part of the research has received funding from the Research Council of Lithuania (LMTLT), agreement No. P-SV-23-410.

-

Author contributions: Jurgita Domskienė: Conceptualization, Methodology, Writing – Reviewing and Editing, Supervision. Eliza Gaidule: Methodology, Investigation, Formal analysis, Writing – Original draft preparation.

-

Conflict of interest: The authors declare no conflict of interest.

-

Ethical approval: The conducted research was not related to either human or animal use.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A new Circular Economy Action Plan. 2020, Brussels. Retrieved 05, 2024. Web site: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN.Suche in Google Scholar

[2] ETC/WMGE Report 6/2019: Textiles and the environment in a circular economy.Suche in Google Scholar

[3] Coscieme, L., Manshoven, S., Gillabel, J., Grossi, F., Mortensen, L. F. (2022). A framework of circular business models for fashion and textiles: the role of business-model, technical, and social innovation. Sustainability: Science, Practice and Policy, 18(1), 451–462. 10.1080/15487733.2022.2083792.Suche in Google Scholar

[4] University of Cambridge Institute for Sustainability Leadership (CISL) and the Wuppertal Institute. (2022). Digital Product Passport: the ticket to achieving a climate neutral and circular European economy?. CLG Europe, Cambridge, UK, Retrieved 05, 2024. https://epub.wupperinst.org/frontdoor/deliver/index/docId/8049/file/8049_Digital_Product_Passport.pdf.Suche in Google Scholar

[5] European Commission. (2022, March 30). COMMISSION STAFF WORKING DOCUMENT IM-PACT ASSESSMENT Accompanying the document Proposal for a Regulation of the European Parliament and of the Council establishing a framework for setting ecodesign requirements for sustainable products and repealing Directive 2009/125/EC. Retrieved 05, 2024. https://op.eu-ropa.eu/en/publication-detail/-/publication/ccd71fda-b1b5-11ec-9d96-01aa75ed71a1.Suche in Google Scholar

[6] European Commission. (2022, March 30). Green Deal: New proposals to make sustainable products the norm and boost Europe’s resource independence. European Commission. Retrieved 05, 2024. https://ec.europa.eu/commission/presscorner/detail/en/ip_22_2013.Suche in Google Scholar

[7] Gotz, T., Berg, H., Jansen, M., Adisorn, T., Cembero, D., Markkanen, S., Chowdhury, T. (2022). Digital Product Passport: The Ticket to Achieving a Climate Neutral and Circular European Economy? Retrieved 05, 2024. https://www.ipoint-systems.com/solutions/digital-product-passport/ (accessed on 22 September 2022).Suche in Google Scholar

[8] Adisorn, T., Tholen, L., Götz, T. (2021). Towards a digital product passport fit for contributing to a circular economy. Energies, 14, 2289.10.3390/en14082289Suche in Google Scholar

[9] Digital circular economy as a cornerstone of a sustainable European industry transformation. (2020). Retrieved 05, 2024. https://www.era-min.eu/sites/default/files/publications/201023_ecera_white_paper_on_digital_circular_economy.pdf.Suche in Google Scholar

[10] Walden, J., Steinbrecher, A., Marinkovic, M. (2021). Digital product passports as enabler of the circular economy. Chemie Ingenieur Technik, 93, 1717–1727.10.1002/cite.202100121Suche in Google Scholar

[11] Digital Product Passport in the textile sector. Draft version STOA Panel meeting 14 March 2024. Retrieved 05, 2024. https://www.europarl.europa.eu/cmsdata/281452/05.1.a.%20EPRS_STOA_STUD_757808_DPP_textile_DraftPanel.pdf.Suche in Google Scholar

[12] Ecodesign for Sustainable Products Regulation – preliminary study on new product priorities. Technical Report. 2023. Retrieved 05, 2024. https://susproc.jrc.ec.europa.eu/product-bureau/sites/default/files/2023-01/Preliminary%20ESPR%20WP%20Report_MERGED_CLEAN_pdf.Suche in Google Scholar

[13] Saari, L., Heilala, J., Heikkilä, T., Kääriäinen, J., Pulkkinen, A., Rantala, T. (2022). Digital Product Passport promotes sustainable manufacturing, Retrieved 05.15, 2024, https://cris.vtt.fi/ws/portalfiles/portal/67162320/DPP_white_paper.pdf.Suche in Google Scholar

[14] Santos-Roldán, L., Palacios-Florencio, B., Berbel-Pineda, J. M. (2020). The textile products labelling analysis and requirements. Fashion and Textiles, 7(11), 1–24. 10.1186/s40691-019-0202-4.Suche in Google Scholar

[15] Nofal, R. (2020). Initiating android phone technology using QR codes to make innovative functional clothes. International Journal of Clothing Science and Technology, 32, 935–951. 10.1108/IJCST-12-2018-0153.Suche in Google Scholar

[16] Abdulova, V., Özyazgan, V., Bilgin, S. (2016). QR Code fabric tag for textile companies in Turkey. Asian Journal of Computer and Information Systems, 23(102), 126–139. 10.7216/1300759920162310206.Suche in Google Scholar

[17] Confino, J. (2014). Can barcodes make fashion more transparent – and will consumers care? Retrieved 05.15, 2024. https://www.theguardian.com/sustainable-business/fashion-companies-sustainability-barcode-clothing-labels.Suche in Google Scholar

[18] Duarte, A. Y. S., Lima, F. S., Queiroz, R. S., Sanches, R. A. (2022) Smart tags as a tool for circular economy in the textile and fashion chain. Pages on Arts and Design, 15(22), 69–85.Suche in Google Scholar

[19] Emran, M., Abd Jamil, A. (2015). QR code design: Characteristic for branding. Conference Proceeding: 1st International Conference on Creative Media, Design and Technology (REKA2014), vol. 1, p. 73–79.Suche in Google Scholar

[20] Kuusk, K., Wensveen, S., Tomico, O. (2014). Crafting qualities in designing QR-coded embroidery and bedtime stories. Conference: The Art of Research, p. 1–12.Suche in Google Scholar

[21] RFID Paper Ticket. Retrieved 05.15, 2024. https://www.rfidhy.com/rfid-products/rfid-paper-ticket/.Suche in Google Scholar

[22] Laundry RFID Button Tag for Clothing Tracking. Retrieved 05.15, 2024. https://huayuansh.com/product/passive-washable-pps-rfid-laundry-tag-for-textile-tracking/.Suche in Google Scholar

[23] RAIN Flexible Thin RFID Tag for Clothing Easy Tracking. Retrieved 05.15, 2024. https://huayuansh.com/product/ultra-thin-washable-rfid-tag-for-apparel-management/.Suche in Google Scholar

[24] Textile UHF RFID Laundry Tag for Linen and Clothing Tracking. Retrieved 05.15, 2024. https://huayuansh.com/product/fabric-textile-washable-uhf-rfid-laundry-tag/.Suche in Google Scholar

[25] Circlolink is not just a DPP it’s a circular economy game plan. Retrieved 05.15, 2024. https://www.circlolink.com/, https://www.circlolink.com/technology/rfid-threads.Suche in Google Scholar

[26] NEAR FIELD COMMUNICATION. About Near Field Communication. Retrieved 05.15, 2024. http://nearfieldcommunication.org/about-nfc.html [Accessed 2023-08-29].Suche in Google Scholar

[27] CNBC-TV18. Explained: What are NFC tags and how to use them. June 23, 2022. Retrieved 05.15, 2024. https://www.cnbctv18.com/technology/explained-what-are-nfc-tags-and-how-to-use-them-13917422.html.Suche in Google Scholar

[28] The Ultimate Guide to Using NFC Garment Tags for Clothing. Retrieved 05.15, 2024. https://seritag.com/learn/using-nfc/garment-nfc-tags-in-clothing.Suche in Google Scholar

[29] LINQS® – Laundry NFC Tag Button, Retrieved 05.15, 2024. https://shop.linqs.in/LINQS-Laundry-NFC-Tag-NTAG213-2.Suche in Google Scholar

[30] Wang, J., Zhang, J., Li, K., Pan, C., Majidi, C., Kumar, S. (2023). Locating everyday objects using NFC textiles. Communications of the ACM, 66, 107–114. 10.1145/3615450.Suche in Google Scholar

[31] Heat sealable NFC Tags for fabrics. Retrieved 05.15, 2024. https://www.shopnfc.com/en/wearable-nfc-tags/568-1030-heat-sealable-nfc-tags-for-fabrics-hotmelt-adhesive-ntag213-ntag424.html.Suche in Google Scholar

[32] Lin, R., Kim, H. J., Achavananthadith, S., Kurt, S. A., Tan, S. C., Yao, H., et al. (2020), Wireless battery-free body sensor networks using near-field-enabled clothing. Nature Communications, 11(444), 1–8. 10.1038/s41467-020-14311-2.Suche in Google Scholar PubMed PubMed Central

[33] Désirée | Innovative Textile Nfc Label, Retrieved 05.15, 2024. https://www.desiree.com/fr/news/innovative-textile-nfc-labelSuche in Google Scholar

[34] Hajiaghajani, A., Afandizadeh Zargari, A. H., Dautta, M., Jimenez, A., Kurdahi, F., Tseng, P. (2021). Textile-integrated metamaterials for near-field multibody area networks. Nature Electronics, 4, 808–817. 10.1038/s41928-021-00663-0.Suche in Google Scholar

[35] LEDGER INSIGHTS, A sustainable future: Using blockchain for digital product passports. Retrieved 05.15, 2024. https://www.ledgerinsights.com/sustainable-blockchain-digital-product-passports/.Suche in Google Scholar

[36] Tan, B., Yan, J., Chen, S., Liu, X. (2018). The impact of blockchain on food supply chain: the case of Walmart. In: Qiu, M. (ed.) Smart Blockchain. SmartBlock 2018. Lecture Notes in Computer Science, vol. 11373, Springer, Cham. 10.1007/978-3-030-05764-0_18.Suche in Google Scholar

[37] Cozzio, C., Viglia, G., Lemarie, L., Cerutti, S. (2023). Toward an integration of blockchain technology in the food supply chain. Journal of Business Research, 162, 1–11. 10.1016/j.jbusres.2023.113909.Suche in Google Scholar

[38] Rotunno, R., Cesarotti, V., Bellman, A., Introna, V., Benedetti, M. (2014). Impact of track and trace integration on pharmaceutical production systems. International Journal of Engineering Business Management, 6, 1–11. 10.5772/58934.Suche in Google Scholar

[39] Tripathi, G., Tripathi Nautiyal, V., Ahad, M. A., Feroz, N. (2021), Blockchain Technology and Fashion Industry-Opportunities and Challenges. In Panda, S. K., Jena, A. K., Swain, S. K., Satapathy, S. C. (eds.) Blockchain Technology: Applications and Challenges, Intelligent Systems Reference Library, vol. 203, Springer, Cham. 10.1007/978-3-030-69395-4_12.Suche in Google Scholar

[40] Melinda, S., Teresa, D. (2022). Integrating LCA and blockchain technology to promote circular fashion – A case study of leather handbags. Journal of Cleaner Production, 373, 133557. 10.1016/j.jclepro.2022.133557.Suche in Google Scholar

[41] Bernardino, C. (2021). Blockchain technology in the fashion industry: opportunities, applications and challenges. Blockchain Technology: Applications and Challenges, Springer Cham, Cham, Switzerland. p. 201–220. 10.1007/978-3-030-69395-4_12.Suche in Google Scholar

[42] Andon, C. H., Pham, H. T. Patent No WO2021231911A1 (France), 05.14. 2020.Suche in Google Scholar

[43] Nelson Jr, K. (2018). Nike takes big step into connected tech by testing it in limited-edition sneakers. Retrieved 05.15, 2024. https://www.digitaltrends.com/outdoors/nike-af1-nikeconnect-nfc-news/.Suche in Google Scholar

[44] Schlemmer, Z. (2015). Marshawn Lynch Teams Up With GREATS for the Beastmode 2.0 Royale Chukka. Retrieved 05.15, 2024. https://sneakernews.com/2015/11/23/marshawn-lynch-teams-up-with-greats-for-the-beastmode-2-0-royale-chukka/.Suche in Google Scholar

[45] Auraconsortium. A Revolution in the Luxury Industry. Retrieved 05.15, 2024. https://auraconsortium.com/.Suche in Google Scholar

[46] Moraru, A., Corneliu, U., Elena H. (2020), A new washable UHF RFID tag: design, fabrication, and assessment. Sensors, 20(12), 3451. 10.3390/s20123451.Suche in Google Scholar PubMed PubMed Central

[47] University of Borås, New system ensures traceability in the textile industry (2019). Retrieved 05.15, 2024. https://phys.org/news/2019-07-traceability-textile-industry.html.Suche in Google Scholar

[48] Han, J., Wang, G., Sidén, J. (2015). Fragment‐type uhf rfid tag embedded in QR barcode label. Electronics Letters, 51(4), 313–315, 10.1049/el.2014.4355.Suche in Google Scholar

[49] Mangla, S. K., Luthra, S., Mishra, N., Singh, A., Rana, N. P., Dora, M., et al. (2018). Barriers to effective circular supply chain management in a developing country context. Production Planning & Control, 29(6), 551–569. 10.1080/09537287.2018.1449265.Suche in Google Scholar

[50] Fu, J., Shiyuan, Y., Lujie, C., Xiaowei, C. (2020). The circular economy in the textile and apparel industry: A systematic literature review. Journal of Cleaner Production, 259, 120728. 10.1016/j.jclepro.2020.120728.Suche in Google Scholar

[51] Consciously Crafted App. (2020). Retrieved 05.15, 2024. https://www.ltpgroup.com/cases/consciously-crafted-app.Suche in Google Scholar

[52] European Commission. (2022, March). Proposal for a Regulation of the European Parliament and of the Council Establishing a Framework for Setting Ecodesign Requirements for Sustainable Products and Repealing Directive. Retrieved 05.15, 2024. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=circulareconomyLEX:52022PC0142.Suche in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Artikel in diesem Heft

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry