Abstract

Recently, there has been a sharp increase in interest in Smart clothing. This type of clothing is equipped with electronic systems connected using wires with various types of connectors. This article presents the impact of repeated current switching through contacts made of electroconductive fabrics on their electrical resistance and analyses the influence of selected parameters of these fabrics on the above phenomena. Textile contacts described in the article are one of the most important parts of the future textile electric connectors incorporated into modern Smart clothing. The article also describes tests of resistance of these fabrics to overheating caused by the current flowing through them. The present research was conducted to check the suitability of electroconductive fabrics for making electrical contacts of future textile connectors. The research presented in the article showed that electroconductive fabrics can be used as durable contacts for direct current circuits carrying currents of several amperes. The type of metal with the highest percentage among the metals used to impart electroconductivity to the tested fabrics has a statistically significant impact on the durability of electrical contacts made of these fabrics.

1 Introduction

Smart clothing that combines textiles, electronics, and information technology is constantly gaining popularity. The potential areas of these products are very diverse. Electronic elements in the form of LEDs can have decorative or warning functions in clothing for pedestrians moving in limited visibility conditions [1,2]. Another potential application area of Smart garments is health care [3,4,5,6]. Smart garments also have numerous applications in outdoor activities [2,7]. An example of this type of application is a large group of clothing with an active heating function [8,9].

In all the aforementioned application areas and others, the Smart garment should offer comfort to the wearer through its flexibility, handling, and design. This results in intensive research on solutions leading to the improvement of these parameters. One way to increase flexibility is by using flexible alternatives to traditional electronic components, cables, and connectors. Such solutions are widely described in the literature [10,11,12,13,14,15,16]. For wires and connectors, attempts are made to replace rigid conductive elements with electroconductive textiles [10,11,12,13]. Replacing conventional contacts in an electrical connector with electroconductive textile materials requires careful testing of many parameters, including their resistance to electrical discharges, which may occur during the connection and disconnection process. This is especially important in applications, e.g. in electrically heated clothing, where high current flows through the connector [6,17,18,19]. These contacts should be resistant to the flow of high currents and be able to switch this current on and off multiple times without extensive wearing.

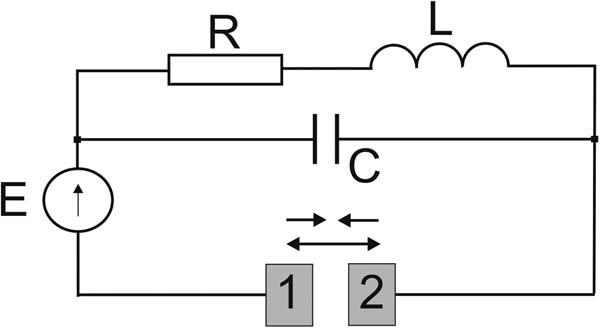

The present research aimed to check the possibility of using electroconductive fabrics as contacts in future textile electrical connectors. It focused on the resistance of fabrics to repeated disconnection and reconnection of the current flowing between two contacts made of these fabrics. The idea of the measurements is shown in Figure 1.

Idea of conducted measurements.

The proposed electrical circuit consists of a voltage source E and conventional wires connecting it with the tested textile contacts (1) and (2) in the form of fabric strips. The resistance R, inductance L, and capacitance C shown in Figure 1 are the parameters of these wires. The wires used in the measurements had a resistance of R = 0.5 ohm, an inductance of L = 3.0 µH, and a capacitance of C = 1.2 pF. These values are typical for cables over a dozen or so centimetres long. No additional inductances and capacitances were used to increase these values during the tests.

The main factor causing the degradation of the contacts of any switch is the sparking that occurs mainly when they are disconnected. Sparking depends primarily on the value of the commutated current and the values of the circuit’s R, L, and C where the current flows. In the proposed test, two contacts made of electroconductive fabrics were connected and disconnected cyclically after being connected to a voltage source E.

The second important parameter influencing the possibility of using electroconductive fabrics as contacts is their maximal current carrying capacity. This parameter is related to the heating phenomenon of electroconductive fabrics under the influence of current flowing through them. The amount of thermal energy generated by a strip of such fabric can be calculated from the formula:

where the parameter I is a current flowing through the textile strip, ρ is the resistivity of the strip’s material, t is the current flow time, and l, w, and h are the strip’s length, width, and height, respectively.

In extreme cases, heating such an electroconductive textile element by the thermal energy Q produced by the current may cause burns to the person wearing clothing with such elements. Excessive temperature can also damage them. Therefore, the article also describes tests of the resistance of selected electroconductive fabrics to the current flowing through them.

2 Materials and methods

2.1 Textile materials used

The basic parameters of 11 electroconductive fabrics used for testing are presented in Table 1. The data presented in this table are taken from the manufacturer’s datasheet.

Basic parameters of the tested electroconductive fabrics (manufacturer’s data)

| Trade name/Producer | Material | Thickness (mm) | Surface resistivity (ohm/sq) | Areal weight (g/m2) | Weave (–) | Warp density (yarns/cm) | Weft density (yarns/cm) |

|---|---|---|---|---|---|---|---|

| 3050-525/Laird | Nylon + 13% Ni + 12% Cu | 0.127 | 0.07 | 71–92 | Twill | 55 | 40 |

| Bremen RS/Shieldex | 82% Polyamide + 18% Ag | 0.09 | 0.3 | 43 | Ripstop | 48–50 | 45–49 |

| Pisa RS/Shieldex® | Polyester + 35% Cu + 20% Ni | 0.09 | 0.05 | 80 | Ripstop | 58 | 45 |

| Ponge/Soliani | Polyester + Ni | 0.15 | 0.4 | 45–75 | Plain | 26 | 18 |

| PT230/Shzhou Wanhe Electronic | 70% Polyester + 16% Cu + 14% Ni | 0.08 | 0.05 | 80 | Plain | 38 | 29 |

| Prag PW/Shieldex | 46% Polyester + 49% Cu + 5% acrylic coating | 0.08 | 0.05 | 85 | Plain | 58 | 45 |

| Zell RS CR/Shieldex | Polyamide 34% Cu + 10% Ag + 4% Sn + 9% CR coating | 0.12 | 0.02 | 81 | Ripstop | 48–50 | 45–49 |

| Berlin RS/Shieldex | 60% Polyamide + 14% Ag + 25% conductive polyurethane | 0.10 | 0.3 | 58 | Ripstop | 48–50 | 45–49 |

| Kassel RS/Shieldex | Polyamide 49% Cu + 9% Ag + 5 CR coating | 0.11 | 0.03 | 85 | Ripstop | 48–50 | 45–49 |

| Nora Dell CR/Shieldex | Polyamide + 48% Cu + 7% Ag + 4% NI + 9% CR coating | 0.125 | 0.009 | 110 | Ripstop | 48–50 | 45–49 |

| Porto PES RS/Shieldex | Polyester + 65% Cu + 4% Sn | 0.1 | 0.02 | 120 | Ripstop | 58 | 45 |

2.2 Measured parameters

All the measurements presented in the article were carried out under specific standard atmospheres at 23°C and 50% relative humidity according to standard atmospheres for conditioning and testing [20]. The research presented in the article consists of two stages. In the first stage of research, temperature measurements of electroconductive fabrics were performed as a function of the density of the current flowing through them. The tests were aimed at determining the maximum current density flowing through the cross-section of the tested fabrics, which will not result in exceeding their maximum permissible temperature. For further consideration, it was assumed that this temperature could not exceed 50°. This temperature protects the clothing user against possible burns. The results obtained at this research stage were to be used, among others, to determine the minimum width of contacts made of electroconductive fabrics used in the main studies. The measurement stand, used to carry out these tests, consists of two clamps where the tested electroconductive fabric is mounted, a DC power supply, and an FLIR ThermaCam E65 thermal cam. Before surface temperature measurements, samples of the tested fabrics were placed in an air-conditioned room to estimate their emission factor ε. Knowing this coefficient for each tested fabric enables a more accurate measurement of their surface temperature using a thermal imaging camera. After acclimatization, the fabric’s surface temperature was measured using a thermal imaging camera. If the surface temperature measured by the camera deviated from the temperature in the acclimatized room, the ε value in the camera was changed to obtain the sample surface temperature equal to the temperature in the room. After equalizing these readings, the ε obtained for the tested fabric was taken for further measurements. The process was repeated for each of the tested fabrics. The temperature in the room near the surface of fabrics was measured using a Tempmaster-100 thermometer which assures ±0.04°C basic accuracy.

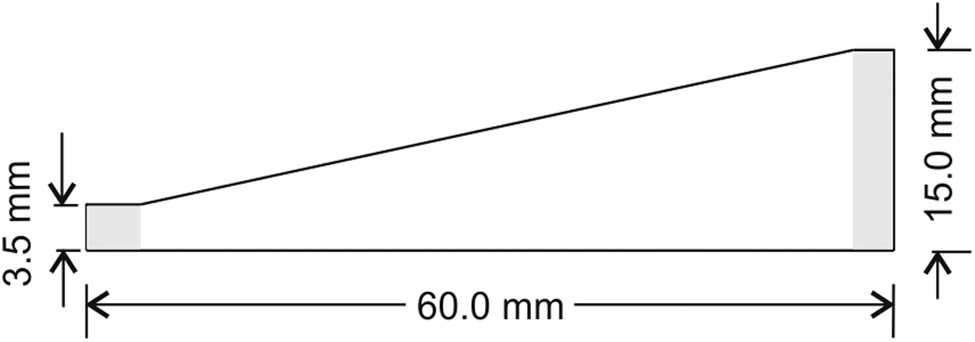

Next, samples with the shape shown in Figure 2 were cut out of the fabrics whose parameters are shown in Table 1. A laser plotter was used to cut them to increase the repeatability of their dimensions. The cut samples were clamped between the clamps shown in Figure 3. The places of fabric where the measuring clamps are attached are marked in grey in Figure 2.

Shape of the fabrics used for studying changes in temperature under the influence of a flowing current.

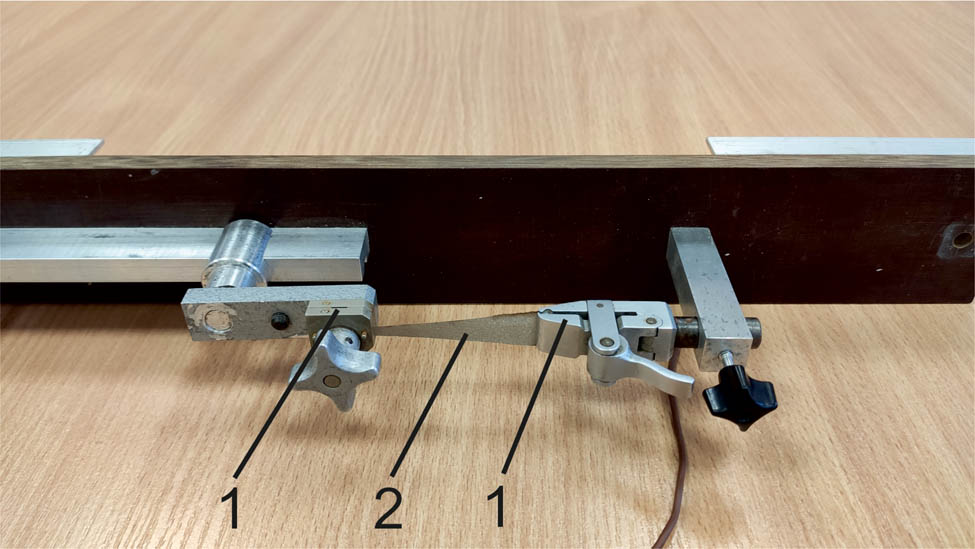

Clamps (1) with tested fabric mounted (2).

The fabric shape shown in Figure 2 causes its cross-section to change linearly. This allows us to obtain the temperature distribution on the surface of the fabric in a single image from a thermal imaging camera. This facilitated the subsequent analysis of the obtained results and enabled easy presentation (in one photo) of the dependence between the temperature and the fabric width for the assumed current flowing through it. A DC power supply was connected to the clamps (1) shown in Figure 3 to ensure current flow through the tested fabric. This current was set using the current control knob of the DC power supply and measured using a built-in ammeter.

The tested fabric (2) was positioned with its surface oriented vertically during the measurements, as shown in Figure 3. This was done to simulate the working conditions in Smart clothing, where the surface of these fabrics is typically oriented perpendicular to the Earth’s surface.

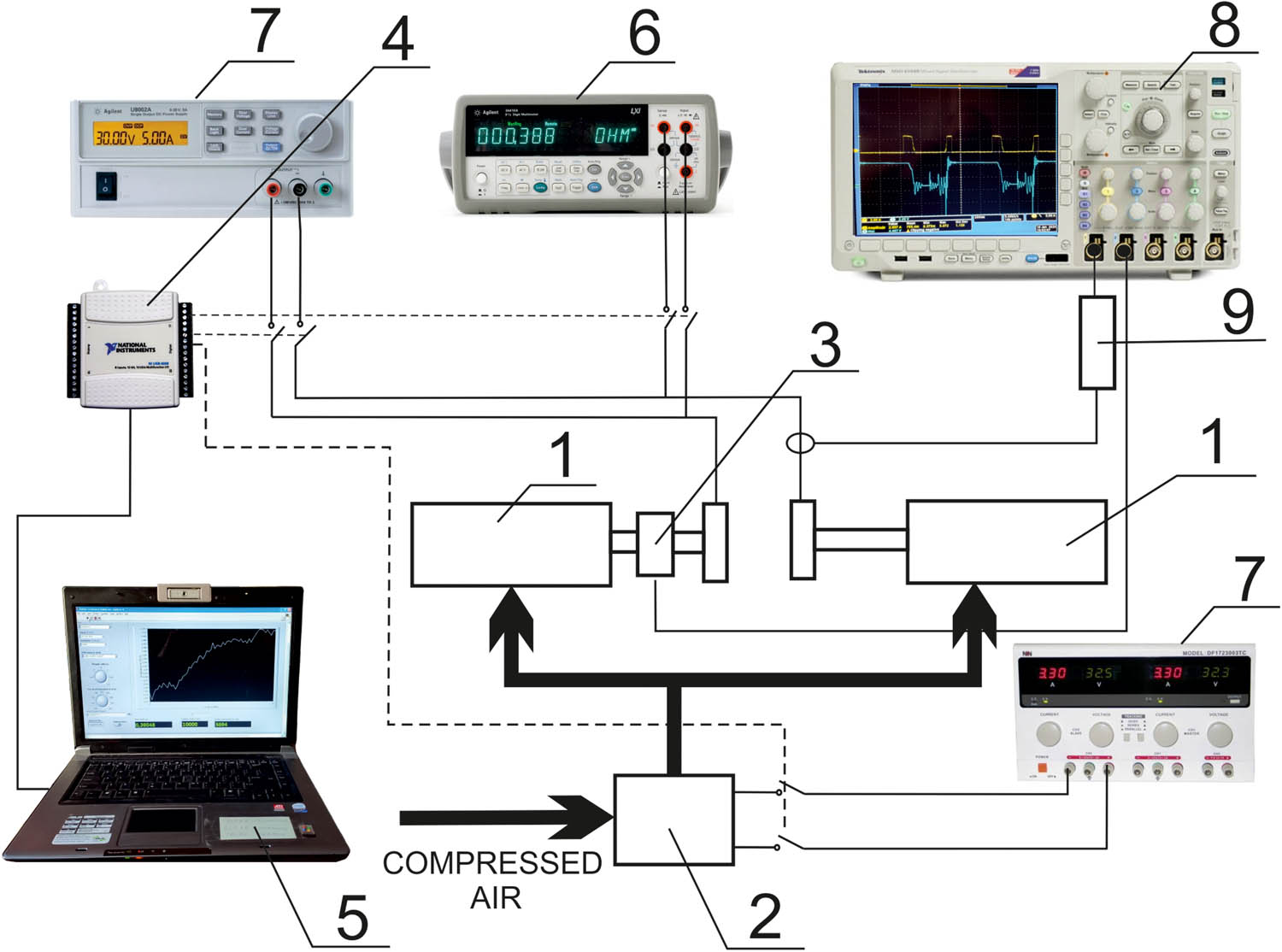

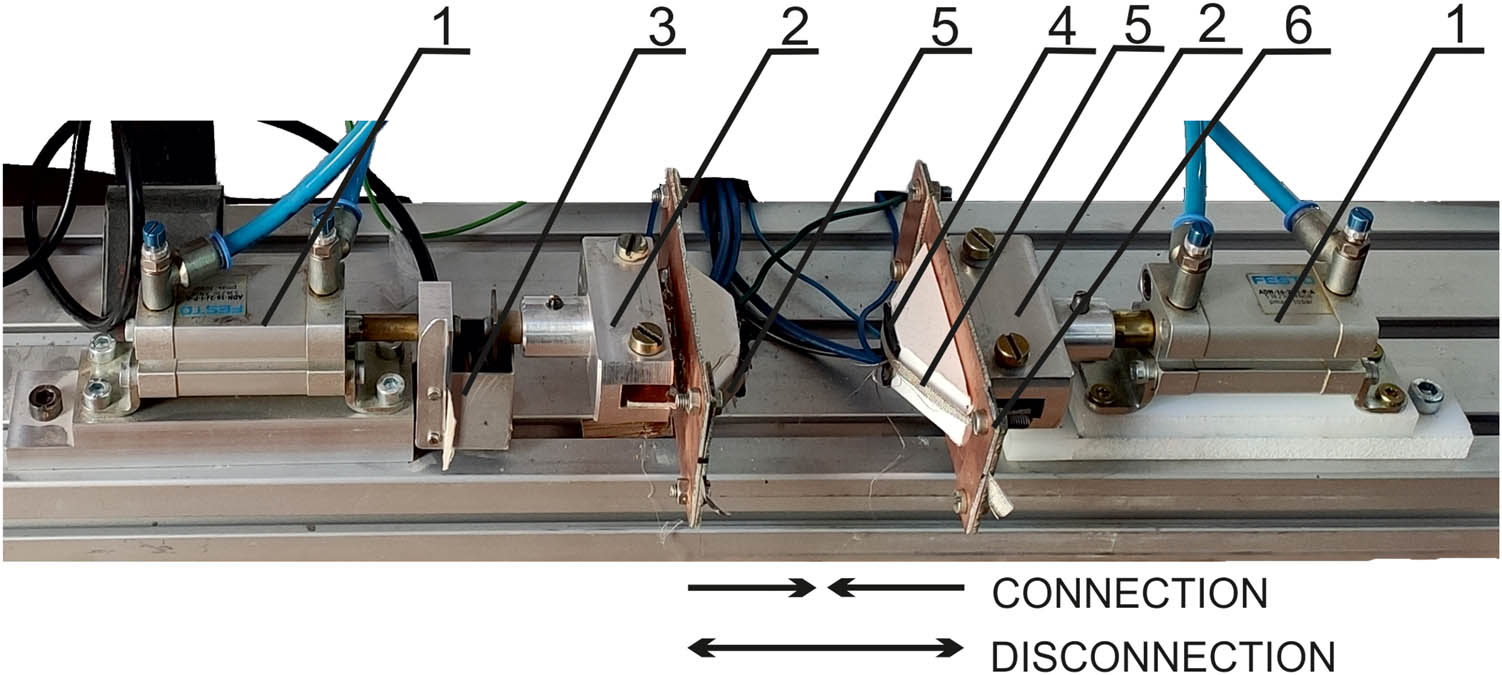

In the second part of the research, the impact of repeated disconnection of current through rectangular contacts made of electroconductive fabrics on their electrical resistance was tested. The measurement stand shown in Figure 4 was constructed to investigate this.

Measurement stand.

The stand consists of two pneumatic actuators (1), an electrovalve (2), a force sensor (3), a computer acquisition board (4), a PC (5), an Agilent 34410A multimeter (6), two DC power sources (7), and a Tektronix digital oscilloscope (8) equipped with a current probe (9). An Agilent 34410A multimeter (6) operating in 4-wire mode was used to measure the resistance between two tested textile contacts. This instrument has an accuracy of ±0.0030% of reading ±0.003 ohm of range.

The PC (5) with a LabVIEW procedure controls all measurement processes. Pneumatic actuators are controlled by an electrovalve and used to connect and disconnect the tested electroconductive fabrics. The general appearance of the sample mounting holders and pneumatic actuators is shown in Figure 5.

Sample mounting holders and pneumatic actuators.

Each of the actuator piston rods (left and right) is equipped with a clamp (2) (Figure 5) with a rectangular strip of electroconductive fabric (5) (Figure 5) on it, which constitutes the tested electrical contact.

Each tested textile contact in the form of a strip of fabric (5) is placed on flexible rubber foam (4), which improves the contact of both tested fabrics when they are connected and pressed together. The ends of each strip of fabric are mounted between two plates (6) made of copper laminate usually used to produce printed circuits. The test leads of the Agilent 34410A multimeter are connected to the left and right clamp, assuring resistance measurement. A DC power supply (7) (Figure 4) is also connected to these clamps to ensure current flow through the tested contacts. This source is automatically disconnected from the tested contacts during the measurement to ensure the correct resistance measurement. The computer (5) (Figure 4) uses a computer acquisition board (4) (Figure 4) to control the electrovalve (2) (Figure 4) to ensure cyclic movement of the actuator piston rods, causing cyclic connection and disconnection of the tested fabric contacts. The arrows shown in Figure 5 indicate the directions of this movement. When the actuator piston rods are fully extended, the surfaces of electroconductive fabric contacts mounted in the left and right clamp are connected, allowing current to flow through them. When the piston rods retract, the tested fabrics are disconnected, interrupting this current.

One of the pneumatic actuators is equipped with a force sensor (3) (Figures 4 and 5) to ensure consistent compressive force control during the measurement. The signal from the force sensor is measured by Tektronix’s digital oscilloscope (8). This oscilloscope also has a current probe (9) to measure the current flowing through tested textile contacts.

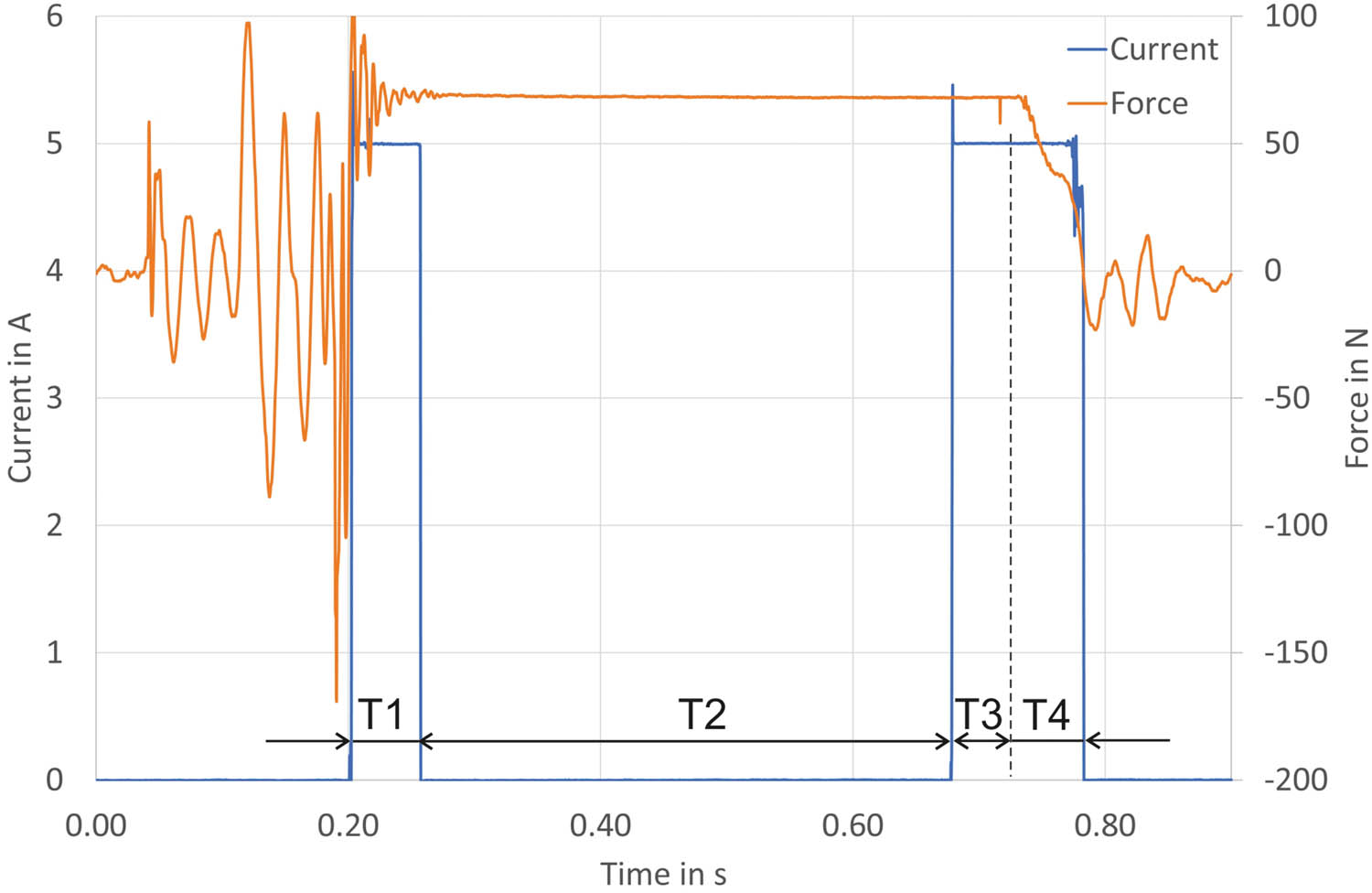

Each connection–disconnection cycle of the tested fabrics consists of four steps, as shown in Figure 6.

Connection–disconnection cycle of the tested textile contacts.

During the T1 period, the piston rods of the pneumatic actuators (1) (Figure 5) extend, causing the connection and pressure of the tested fabrics with a set force. After this (during T2) (Figure 6), the voltage is disconnected from the tested fabric contacts, and their resistance is measured using an Agilent 34410A ohmmeter. The disconnection of the voltage is necessary to measure this resistance correctly. In the next stage, the voltage is switched on to both fabric contacts again, causing current to flow through them during T3. In the last stage, T4, the piston rods retract, and the fabric contacts are separated, interrupting the current flowing through them. Then, the entire connection disconnection cycle is repeated.

The measuring stand enables the study of changes in contact resistance between surfaces of two electroconductive fabrics caused by phenomena occurring when connecting and disconnecting the current flowing through them.

The oscillations visible in the force waveform (Figure 6) are caused by vibrations generated when the piston rods of the pneumatic actuators are moved in and out. These oscillations do not affect the clamping force measurement when measuring the resistance (time T2) because, during this time, the pressure force is constant.

3 Results and discussion

3.1 Measurements of the dependence of fabric surface temperature on current density flowing through it

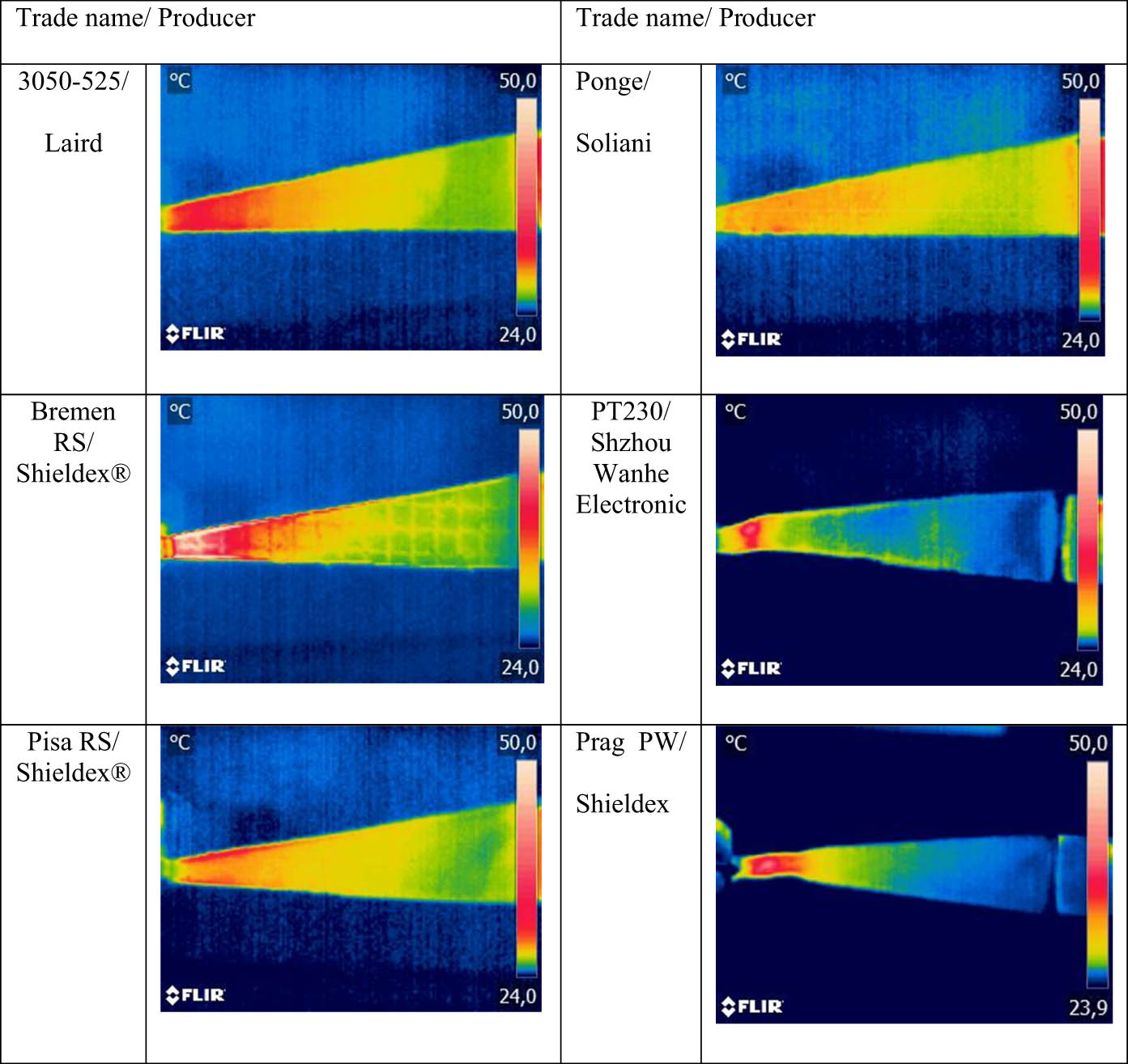

As mentioned earlier in the first stage of conducted research, the relation between the temperature of the fabric and the current flowing through it was found. Examples of results are shown in Figure 7. From Figure 7, it can be inferred that the surface temperature of the tested samples depends not only on the value of the current flowing through them but also on their geometric dimensions, especially the width. Therefore, to compare the influence of the flowing current on these temperatures, the average current density value was calculated from the formula:

where w and h are the fabric’s width and height, respectively.

Examples of the surface temperature of electroconductive fabrics carrying a current of 0.5 A.

Metallized fabric is a structure for which it is tough to determine the distribution of current flowing through its cross-section. This distribution depends on many factors, e.g. weave, metallization method, type of yarns, etc. Therefore, for simplicity, the average value of the current density calculated from equation (2) was adopted for further consideration. Surface temperatures in places of different widths were read from the thermograms, examples of which are shown in Figure 7. Then, the average current density value was calculated from equation (2).

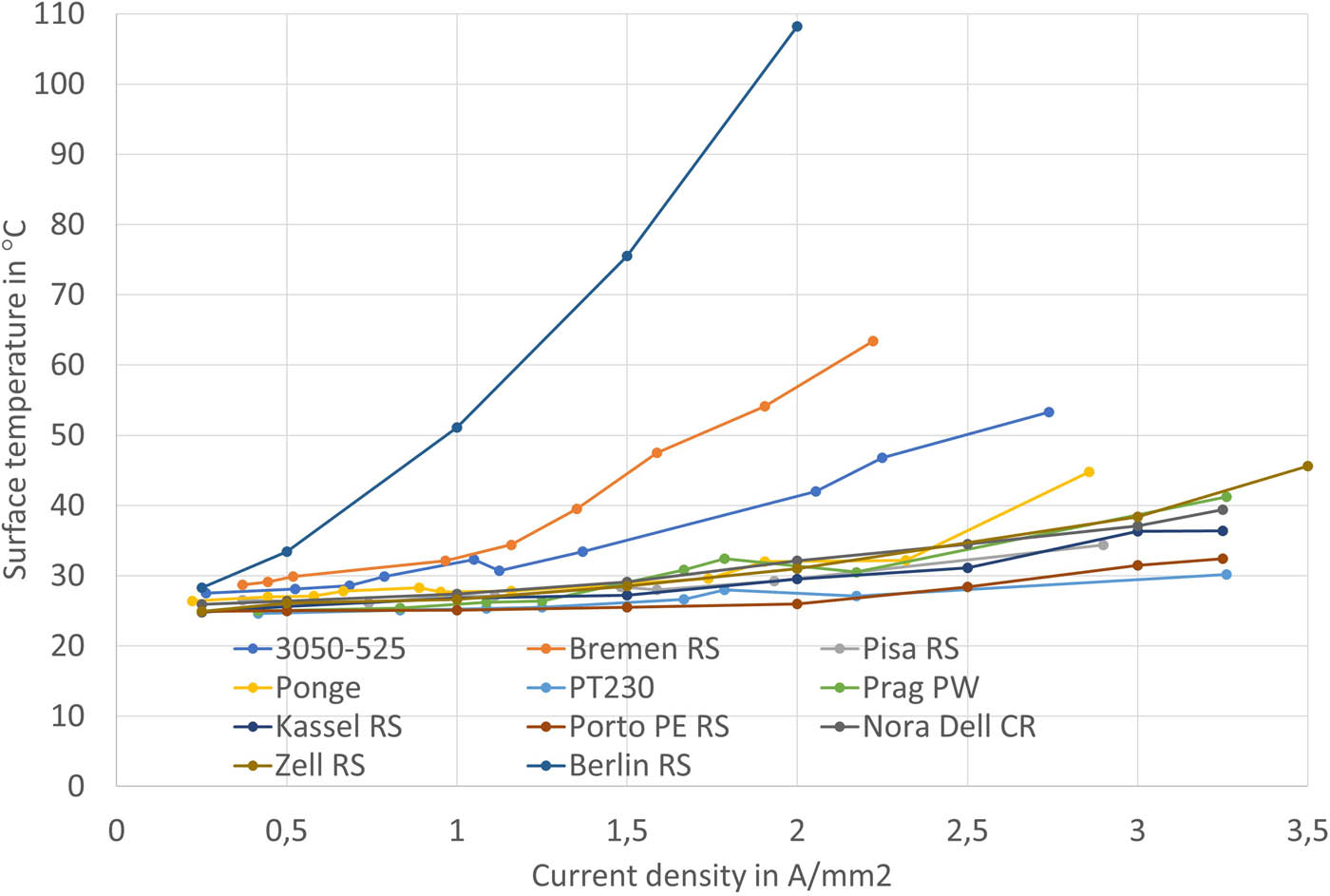

The results obtained from these measurements and calculations are presented in Figure 8. The fabrics named Berlin and Bremen showed the least resistance to the flowing current. Compared to other samples, even low current density values cause a significant increase in their surface temperature. One possible reason is their highest surface resistivity and the smallest thickness among the tested fabrics.

Surface temperature of the textile line versus current density.

3.2 Measurements of the resistance of fabric contacts to repeated connection and disconnection of current

In the first step of this part of research, contact resistance was measured by repeatedly connecting and disconnecting fabric contacts in a current-free state. This was intended to detect a situation in which the change in resistance was caused by mechanical factors such as contact friction during the connection and disconnection process. These tests showed no significant change in the resistance of all tested fabrics after 10,000 connection–disconnection cycles.

Then, the connection–disconnection test of fabric contacts with the current flowing through them was performed. The test consisted of 10,000 connection–disconnection cycles for each tested fabric using 5 A current. Tylman et al. [21] found that the required electrical power of clothing with electric heating to ensure thermal comfort reached 60 W. Assuming a 12 V battery was used to power the heaters, this power corresponds to a current flowing through the heating elements and a connector of 5 A. Therefore, this current value was adopted in the conducted tests. At the same time, the width of the tested fabric was assumed to be 15 mm. This value is a compromise between the width ensuring no excessive heating of the sample and the required width of the textile connector contacts, which should be as small as possible.

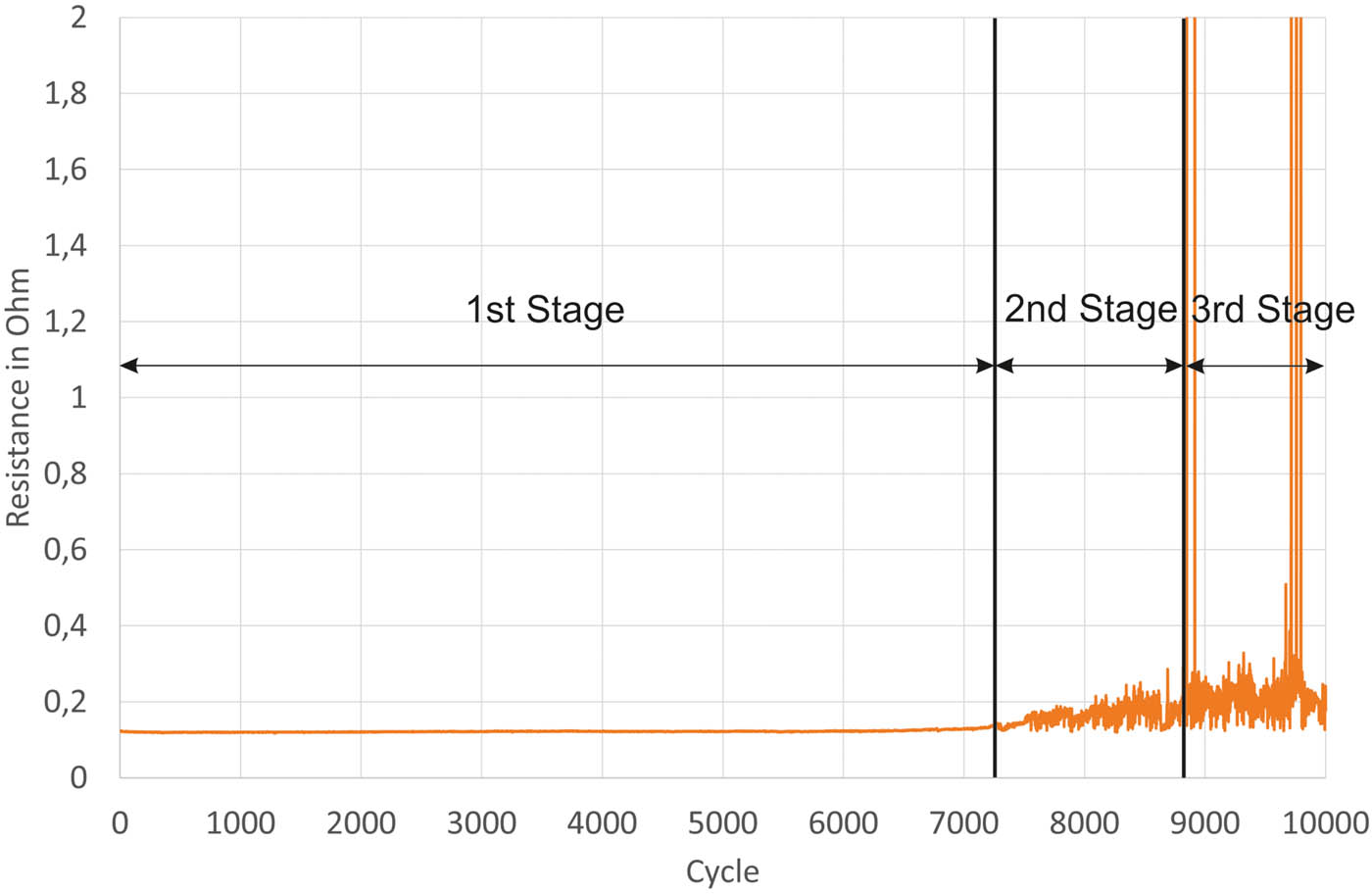

The test described above was performed three times for each tested pair of contacts. Before each test repetition, the tested contacts were replaced with new ones. An example of changes in electrical resistance as a function of the number of connection–disconnection cycles is shown in Figure 9.

An example of changes in electrical resistance as a function of the number of connection–disconnection cycles for the 3050-525/Laird fabric.

As you can see from Figure 9, three stages were observed during these measurements. During the first stage, the contact resistance does not differ substantially from its initial resistance. In the second stage, the spread of resistance values increases. The third stage starts when resistance values appear many times higher than the average resistance.

This usually means a loss of contact between the tested contacts.

Figure 9 shows that after 7,200 connection cycles, the dispersion of the contact resistance starts to increase. This indicates the first signs of contact wear. Then, in the 8,846 cycle, a high resistance value of the connected contacts appears, indicating their further degradation. From this moment, the contacts do not ensure the correct connection with 100% certainty.

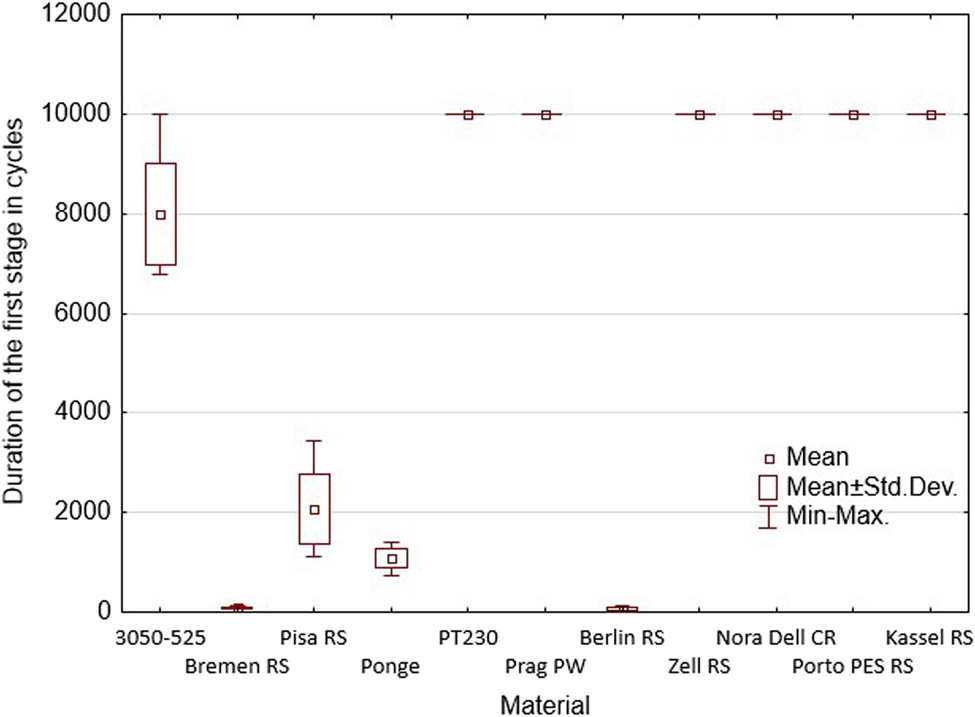

For further analysis, the length of the first stage expressed in the number of cycles was assumed. Figure 10 illustrates the duration of the first stage, i.e. the number of cycles needed for wear to be visible in the tested contacts.

Number of cycles until the first signs of tested contact wear appear (duration of the first stage).

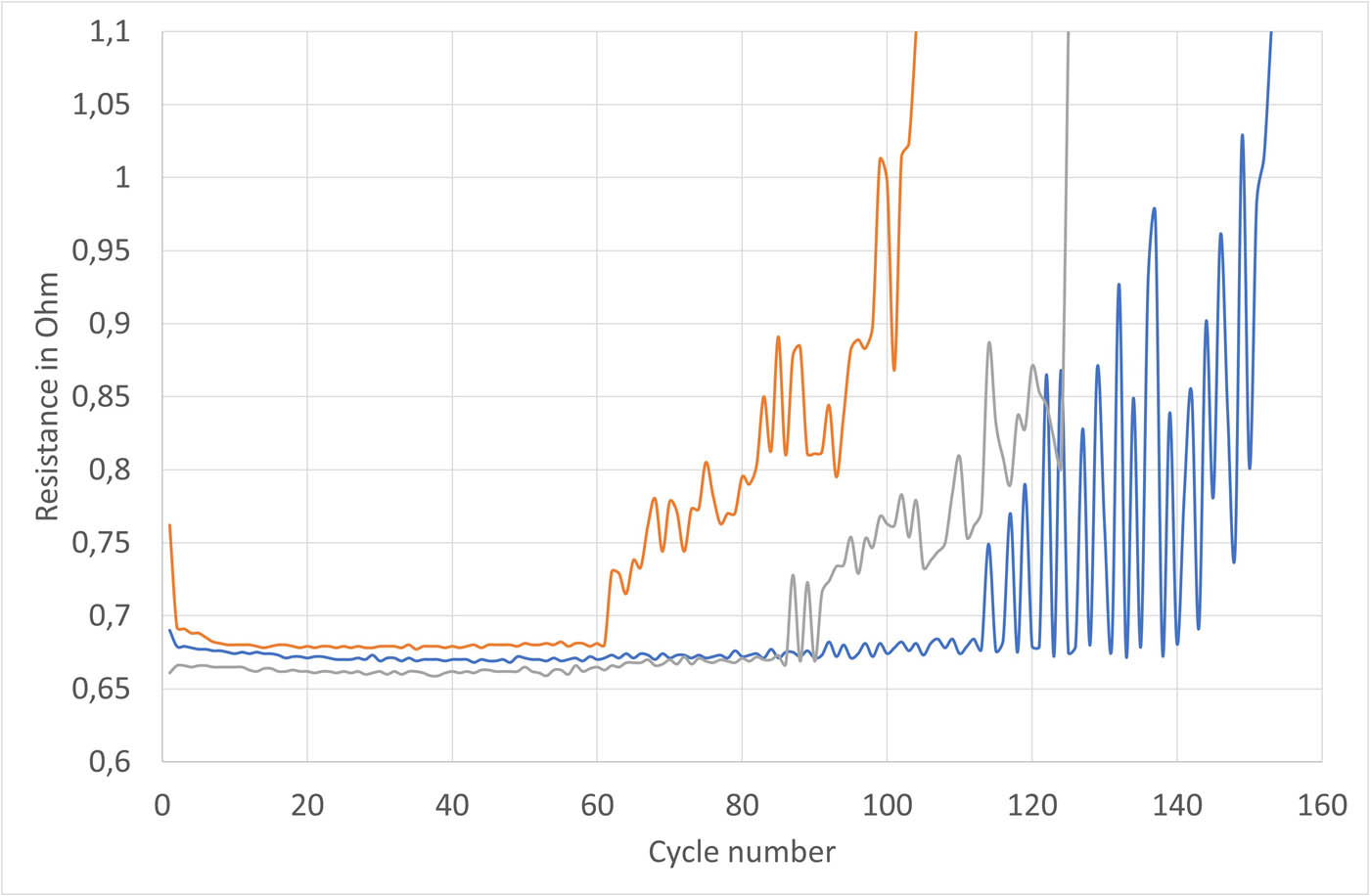

Figure 10 shows that contacts made of Bremen RS and Berlin RS fabrics indicate the lowest durability to current switching. These fabrics are also the least resistant to continuous current flow. More detailed results of resistance changes of three pairs of contacts of the Bremen RS fabric are shown in Figure 11. For this fabric, a sharp increase in electrical resistance was recorded after several dozen cycles of connecting and disconnecting a current of 5 A.

Changes in the contact resistance made of Bremen RS fabric under the influence of 5 A current commutation.

As mentioned earlier, this is due to their low electrical conductivity, which causes the generation of significant amounts of heat. At the same time, the small thickness of these fabrics causes them to heat up significantly, resulting in rapid wear.

3.3 Statistical analysis of the obtained results

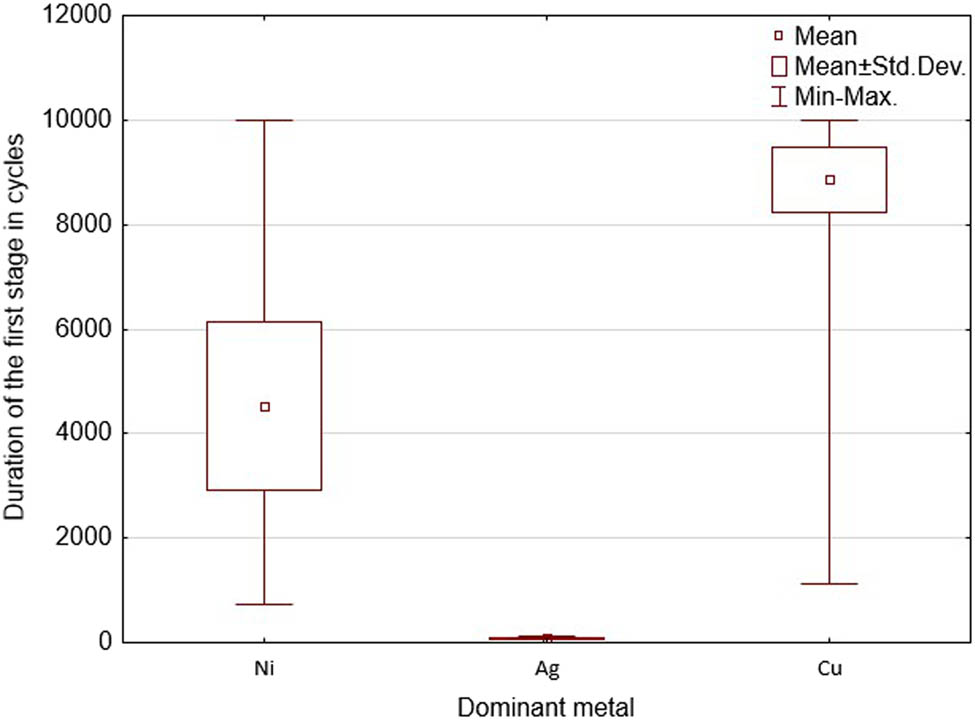

An analysis of the influence of the dominant metal on fabrics’ electrical conductivity was carried out. The term “dominant metal” refers to the metal used in the highest percentage during imparting electroconductivity of the tested fabrics. For example, the dominant metal for Zell RS fabric (Table 1) is copper (Cu). The dependence of the duration of the first stage on the type of dominant metal is shown in Figure 12.

Dependence of the duration of the first stage on the type of dominant metal.

Analysis of Figure 12 may lead to the conclusion that the dominant metal of the electroconductive fabric influences the durability of the contacts made.

To confirm this, a hypothesis H0 was assumed about the equality of the duration of the first stage for groups of fabrics characterized by different dominant metals. The non-parametric statistical Kruskal–Wallis test and Statistica software were used to verify this hypothesis. A non-parametric test was used instead of the multifactor analysis of variance due to the failure to meet the assumptions of variance analysis (lack of normality of distributions in groups determined by variables and lack of homogeneity of variance). In all tests, the significance level was assumed to be α = 0.05.

The probability p = 0.0000 obtained as a result of the test means that at the assumed α significance level, the H0 hypothesis should be rejected. Therefore, the effect of the dominant metal is statistically significant. Figure 12 shows that contacts made of fabrics with a coating containing most copper are characterized by the highest resistance to phenomena occurring during repeated switching on and off of the conducted current. In turn, fabrics with the highest silver content have low resistance to the above phenomena.

As part of the research, an analysis of the influence of other fabric parameters on the resistance to current commutation was also carried out. These parameters were thickness, surface mass, and surface resistance. The regression method was used to find a correlation between the duration of the first stage and each of these parameters. The analyses did not show any significant correlation between the duration of the first stage and the parameters of electroconductive fabrics such as thickness, surface mass, and surface resistance.

4 Conclusions

The research conducted showed the following:

Electroconductive fabrics can be used as durable contacts for direct current circuits carrying currents of several amperes.

To not exceed the tested fabrics’ temperatures of 50°C, the maximum current density conducted through the tested fabrics cannot exceed in the worst case 1 A/mm2 (assuming the vertical arrangement of the line, the temperature and relative humidity of the air surrounding the line are equal to 23° and 55%, respectively).

The type of metal with the highest percentage among the metals used to impart electroconductivity to the tested fabrics has a statistically significant impact on the change in the resistance of contacts made of these fabrics, caused by repeated connection and disconnection of the current flowing through them.

Fabric’s metallization with the highest copper content assures the highest resistance to multiple current commutations.

No relationship was found between the electrical resistance of contacts made of the tested fabrics to multiple commutations of the current flowing through them and their thickness, surface mass, and surface resistance.

Acknowledgement

These studies were partially financed by the project “Sustainable Industrial Design of Textile Structures for Composites,” which is funded by the European Union. Grant Agreement no. 101079009 Call: HORIZON-WIDERA-2021-ACCESS-03/Twinning. Acronym: SustDesignTex.

-

Funding information: The research was partially supported by the European Union. Grant Agreement no. 101079009 Call: HORIZON-WIDERA-2021-ACCESS-03/Twinning. Acronym: SustDesignTex.

-

Author contributions: The authors confirm the sole responsibility for the conception of the study, presented results, and manuscript preparation.

-

Conflict of interest: Authors state no conflict of interest.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Cheng, K. W. E., Kwok, K. W., Kwok, Y. L., Chan, K. W., Cheung, N. C., Ho, Y. K., et al. (2009). LED lighting development for intelligent clothing. 3rd International Conference on Power Electronics Systems and Applications, 1(1), 1–4.Search in Google Scholar

[2] Jiang, S., Stange, O., Bätcke, F., Sultanova, S., Sabantina, L. (2021). Applications of smart clothing – a brief overview. Communications in Development and Assembling of Textile Products, 2(2), 123–140.10.25367/cdatp.2021.2.p123-140Search in Google Scholar

[3] Cay, G., Solanki, D., Ravichandran, V., Hoffman, L., Laptook, A., Padbury, J., et al. (2021). Baby-Guard: An IoT-based neonatal monitoring system integrated with smart textiles. 2021 IEEE International Conference on Smart Computing (SMARTCOMP) (pp. 129–136).10.1109/SMARTCOMP52413.2021.00038Search in Google Scholar

[4] Hasan, M. U., Negulescu, I. (2020). Wearable technology for baby monitoring: a review. Journal of Textile Engineering & Fashion Technology, 6(4), 112–120.10.15406/jteft.2020.06.00239Search in Google Scholar

[5] Lv, T., Lu, Y., Zhu, G. (2022). Research and analysis of user needs for smart clothing for the elderly. Wearable Technology, 2(2), 101–108.10.54517/wt.v2i2.1653Search in Google Scholar

[6] Wu, Y., Wang, Z., Xiao, P., Zhang, J., He, R., Zhang, G. H., et al. (2022). Development of smart heating clothing for the elderly. The Journal of The Textile Institute, 113(11), 2358–2368.10.1080/00405000.2021.1983964Search in Google Scholar

[7] Lee, H., Baek, K. (2021). Developing a smart multifunctional outdoor jacket with wearable sensing technology for user health and safety. Multimedia Tools and Applications, 80(21), 32273–32310.10.1007/s11042-021-11166-7Search in Google Scholar

[8] Krzemińska, S., Greszta, A., Bartkowiak, G., Dąbrowska, A., Kotas, R., Pękosławski, B., et al. (2023). Evaluation of heating inserts in active protective clothing for mountain rescuers – preliminary tests. Applied Sciences, 13(8), 1–19.10.3390/app13084879Search in Google Scholar

[9] Ma, L., Li, J. (2023). A review on active heating for high-performance cold-proof clothing. International Journal of Clothing Science and Technology, 35(6), 952–970.10.1108/IJCST-03-2021-0036Search in Google Scholar

[10] Leśnikowski, J. (2015). New kind of textile transmission line with an impedance of 50 Ohms. Fibres & Textiles in Eastern Europe, 2(110), 51–54.Search in Google Scholar

[11] Atalay, O., Kalaoglu, F., Kursun Bahadir, S. (2019). Development of textile-based transmission lines using conductive yarns and ultrasonic welding technology for e-textile applications. Journal of Engineered Fibers and Fabrics, 14(8), 1–8.10.1177/1558925019856603Search in Google Scholar

[12] Bahadir, S. K., Kalaoğlu, F., Jevšnik, S. (2015). The use of hot air welding technologies for manufacturing e-textile transmission lines. Fibers and Polymers, 16(6), 1384–1394.10.1007/s12221-015-1384-zSearch in Google Scholar

[13] Daniel, I. H., Flint, J. A., Seager, R. (2017). Stitched transmission lines for wearable RF devices. Microwave and Optical Technology Letters, 59(5), 1048–1052.10.1002/mop.30461Search in Google Scholar

[14] Leśnikowski, J. (2020). Research into the textile-based signal lines made using ultrasonic welding technology. Autex Research Journal, 22(1), 1–7.10.2478/aut-2020-0025Search in Google Scholar

[15] Leśnikowski, J. (2016). Research on poppers used as electrical connectors in high speed textile transmission lines. Autex Research Journal, 16(4), 228–235.10.1515/aut-2016-0025Search in Google Scholar

[16] Stanley, J., Hunt, J. A., Kunovski, P., Wei, Y. (2022) A review of connectors and joining technologies for electronic textiles. Engineering Reports, 4(6), 1–24.10.1002/eng2.12491Search in Google Scholar

[17] Wang, F. (2010). Evaluation of the performances of electrically heated clothing. Licentiate Thesis. Lund University, Department of Design Sciences, Lund, Sweden, (pp. 1–19).Search in Google Scholar

[18] Xu, P., Wang, F., Zhao, M. (2014). Electrically heated clothing (EHC) for protection against cold stress. In: Wang, F., Gao, C. (Eds.), Protective Clothing (1), Elsevier Ltd, Amsterdam, The Netherlands.10.1533/9781782420408.2.281Search in Google Scholar

[19] Kurczewska, A., Leśnikowski, J. (2008). Variable-thermoinsulation garments with a microprocessor temperature controller. International Journal of Occupational Safety and Ergonomics, 14(1), 77–87.10.1080/10803548.2008.11076751Search in Google Scholar PubMed

[20] ISO 139. Textiles – Standard atmospheres for conditioning and testing, 2005.Search in Google Scholar

[21] Tylman, W., Kotas, R., Kamiński, M., Dąbrowska, A., Młynarczyk, M. (2022). Modeling and experimental verification of the required power for electrically heated clothing. Energies, 15(20), 1–15.10.3390/en15207713Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry