Abstract

As a material that can release infrared rays, volcanic rock polymer fibers can be used in textiles to improve human microcirculation, which is helpful to relieve chronic inflammatory diseases such as perishoulder arthritis. In this article, there are two different kinds of exterior yarns. Volcanic rock blended polyester, volcanic rock blended polyamide, polyester and polyamide are chosen as the material type of exterior yarn Ⅰ, whereas the material type of exterior yarn II is conductive polyamide yarn. The exterior yarn feed ratio of exterior yarn Ⅰ and exterior yarn II is designed as 8:0, 7:1 and 6:2 when weft plain stitch, 1 + 1 mock rib and 1 + 3 mock rib are used as the knitted structure of the fabric. According to the three-factor four-level orthogonal experimental design method, the sample protocol was established, and 16 knitted sample fabrics were produced. Then, the promotion multiple of blood flow velocity on human epidermal microcirculation of each sample was tested and analyzed. The results show that the promotion multiple of blood flow velocity on human epidermal microcirculation of the fabrics woven by volcanic rock polymer fibers is better than that of the blank control group, and the difference between fabrics with different volcanic rock polymer fibers is small. The higher the proportion of exterior yarn Ⅰ is, the better the promotion multiple of blood flow velocity on human epidermal microcirculation of fabric will be. The effect of knitted structure on the promotion multiple of blood flow velocity on human epidermal microcirculation of fabrics is not obvious. This study provides reference for the design of medical or health textiles for chronic inflammatory diseases.

1 Introduction

At present, the proportion of people with various chronic diseases and subhealth is increasing [1]. As a chronic inflammatory disease [2], the most common treatment of periarthritis of shoulder is taking medicine internally at present, but the curative effect is not good. On the contrary, using external treatment can strike the pathogeny with a better curative effect [3]. Currently, many controlled experimental studies and clinical applications use conventional infrared therapy as well as integrated infrared therapy as external treatment methods [4]. Zhao [5] had treated 96 cases of periarthritis of shoulder with traditional Chinese medicine by using an LD-AF digital low- and medium-frequency far-infrared heating machine which achieved a satisfactory curative effect. Wang et al. [6] cured 67 cases of periarthritis of shoulder with acupuncture plus multi-functional far-infrared local irradiation and functional exercise and got satisfactory results. Vatansever and Hamblin [7] concluded that technological progress has provided a new technology for transmitting far-infrared radiation to the human body. It is safe, effective and widely used to employ professional lamps and sauna providing pure far-infrared radiation as a light source for producing therapeutic effects.

Because of the presence of volcanic rock composite powder, volcanic rock polymer fibers not only can make the fibers store more heat and remain warm [8] but also can release far-infrared radiation beneficial to the human body to improve human microcirculation [9]. Most of the conventional external treatment methods for periarthritis of shoulder are not wearable clothes [10], so the research and development of fabrics with far-infrared property are of great significance in meeting the needs of consumers in medical and healthcare textiles.

At present, most studies on volcanic rock fibers are limited to the mechanical properties of volcanic rock fibers. The studies on far-infrared and thermal storage functions are mostly limited to the far-infrared emissivity and far-infrared radiation temperature rise of fabrics, but the promotion multiple of blood flow velocity on human epidermal microcirculation is relatively lacking. There is also no research on the differentiation of different volcanic rock polymer fibers. In this article, volcanic rock blended polyester fibers and volcanic rock blended polyamide fibers are selected as materials that can release far-infrared rays. Aiming at the requirements of autumn and winter clothing, volcanic rock polymer yarn and conductive polyamide yarn are combined by the seamless knitting technology to weave the samples, and the promotion multiple of blood flow velocity on human epidermal microcirculation of the samples is tested and analyzed. It provides a theoretical basis for the application of volcanic rock polymer fibers on far-infrared seamless knitted clothing in traditional infrared therapy and integrated infrared therapy.

2 Materials and methods

2.1 Sample protocol establishment

This article mainly investigates the influences of different yarn materials, exterior yarn feed ratio and knitted structure of the sample fabrics on the promotion multiple of blood flow velocity on human epidermal microcirculation, so three fabric factors (Factors A, B and C) were established first. Combined with the basic performance requirements of autumn and winter clothing like warmth and antistatic, 77.8 dtex (70 D) volcanic rock blended polyester, volcanic rock blended polyamide, polyester and polyamide fibers are respectively used as exterior yarn I, 22.2 dtex (20 D) carbon black polyamide/77.8 dtex (70 D) semi-gloss polyamide blended with conductive polyamide yarn were used as exterior yarn II, and 22.2 dtex (20 D) polyamide/55.6 dtex (50 D) polyurethane wrapped yarn were used as the inner yarn; the specifications of yarn are presented in Table 1. In addition, polyester and polyamide fibers are chosen for the exterior yarn Ⅰ as a blank control.

Materials and specifications of yarn materials

| Type of yarn | Fineness | Supplier |

|---|---|---|

| Volcanic rock polyester filament | 77.8 dtex (70 D) | Taicang Kekai Textile Technology Co., Ltd. (Taicang, China) |

| Volcanic rock polyamide filament | 77.8 dtex (70 D) | Taicang Kekai Textile Technology Co., Ltd. (Taicang, China) |

| Polyester filament | 77.8 dtex (70 D) | Yiwu Huading Polyamide Co., Ltd. (Yiwu, China) |

| Polyamide filament | 77.8 dtex (70 D) | Yiwu Huading Polyamide Co., Ltd. (Yiwu, China) |

| Conductive polyamide yarn | 22.2 dtex (20 D)/77.8 dtex (70 D) | Taicang Kekai Textile Technology Co., Ltd. (Taicang, China) |

| Polyamide/polyurethane wrapped yarn | 22.2 dtex (20 D)/55.6 dtex (50 D) | Yiwu Huading Polyamide Co., Ltd. (Yiwu, China) |

The knitted structure of fabric affects the surface texture and mechanical properties of the fabrics as well as wear properties of the textiles. Because the sample fabrics will eventually be used in the clothing products which will be in direct contact with the skin, the weft plain stitch whose appearance is smooth and soft to touch is selected as one of the knitted structures. Considering that autumn and winter clothing have certain requirements for fabric thickness, 1 + 1 mock rib and 1 + 3 mock rib are added as the knitted structure of the sample protocol.

In order to comprehensively analyze the effects of different fabric factors, the fabric factors are set as follows: factor A is different material types of exterior yarn Ⅰ, composed of four levels (volcanic rock blended polyester, volcanic rock blended polyamide, polyester and polyamide). Factor B is the exterior yarn feed ratio of exterior yarn Ⅰ and exterior yarn II, composed of three levels (8:0, 7:1 and 6:2). Factor C is a knitted structure of the fabric, composed of three levels (weft plain stitch, 1 + 1 mock rib and 1 + 3 mock rib). The sample protocol was obtained according to the three-factor four-level orthogonal experimental design method, as shown in Table 2. Sixteen samples were knitted on a 28-needle SM8-TOP2 electronic seamless knitting machine with the same weaving parameters as follows: machine number, 28 needles/inch; cylinder diameter, 14 inches; 1,248 needles, and the same positions of the loop forming triangle.

Fabric sample protocol

| Sample number | A (material types of exterior yarn Ⅰ) | B (exterior yarn feed ratio) | C (knitted structure) |

|---|---|---|---|

| 1# | Polyamide | 8∶0 | Weft plain stitch |

| 2# | Polyamide | 8:0 | 1 + 1 mock rib |

| 3# | Polyester | 8:0 | Weft plain stitch |

| 4# | Polyester | 8:0 | 1 + 3 mock rib |

| 5# | Volcanic rock blended polyamide | 8:0 | Weft plain stitch |

| 6# | Volcanic rock blended polyamide | 8:0 | 1 + 3 mock rib |

| 7# | Volcanic rock blended polyester | 8:0 | Weft plain stitch |

| 8# | Volcanic rock blended polyester | 8:0 | 1 + 1 mock rib |

| 9# | Polyamide | 7:1 | Weft plain stitch |

| 10# | Polyester | 7:1 | 1 + 1 mock rib |

| 11# | Volcanic rock blended polyamide | 7:1 | Weft plain stitch |

| 12# | Volcanic rock blended polyester | 7:1 | 1 + 3 mock rib |

| 13# | Polyamide | 6:2 | 1 + 3 mock rib |

| 14# | Polyester | 6:2 | Weft plain stitch |

| 15# | Volcanic rock blended polyamide | 6:2 | 1 + 1 mock rib |

| 16# | Volcanic rock blended polyester | 6:2 | Weft plain stitch |

2.2 Basic specification of sample fabrics

The thickness of the fabric will directly affect the style and wear properties of the fabric, such as feeling, warmth, air permeability and stiffness. The per square meter weight of fabric can be used as a reference for the subsequent performance test and analysis. The thickness, per square meter weight and horizontal and longitudinal densities of the sample fabrics are shown in Table 3.

Basic specification of sample fabrics

| Sample number | Thickness (mm) | Per square meter weight (g m−2) | Horizontal density(coil (5 cm)−1) | Longitudinal density(coil (5 cm)−1) |

|---|---|---|---|---|

| 1# | 0.72 | 247.3 | 83.3 | 150.0 |

| 2# | 0.98 | 302.9 | 47.6 | 148.6 |

| 3# | 0.78 | 257.3 | 77.2 | 153.4 |

| 4# | 1.80 | 425.1 | 43.6 | 147.8 |

| 5# | 0.76 | 240.8 | 83.1 | 147.5 |

| 6# | 1.60 | 392.4 | 41.3 | 138.7 |

| 7# | 0.81 | 249.5 | 81.6 | 146.7 |

| 8# | 1.15 | 300.9 | 54.1 | 142.6 |

| 9# | 0.73 | 248.4 | 93.3 | 145.5 |

| 10# | 1.05 | 307.7 | 58.5 | 143.8 |

| 11# | 0.77 | 244.6 | 81.9 | 143.2 |

| 12# | 1.90 | 422.3 | 41.6 | 138.3 |

| 13# | 1.66 | 393.2 | 36.3 | 134.4 |

| 14# | 0.79 | 252.3 | 82.5 | 137.1 |

| 15# | 1.03 | 293.8 | 52.8 | 129.1 |

| 16# | 0.79 | 255.4 | 80.1 | 130.6 |

2.3 Air permeability test

As a basic index of fabric permeability, fabric air permeability has a great impact on the wearing comfort of clothing [11].

Experimental equipment: YG461E-III automatic air permeability apparatus.

Experimental procedure: Following the Chinese standard GB/T 5453-1997 [12] operating specifications, ten wrinkle-free locations were selected for each sample to test, and the sample fabric was placed on a round table. The apparatus was started, and the apparatus would automatically stop when it reached the set pressure difference, and the viewing screen would display the gas flow data. Finally, the average value was calculated.

2.4 Human epidermal microcirculation blood flow velocity test

2.4.1 Experimental equipment and principle

Laser Speckle Contrast Imaging (LSCI) is a non-contact imaging technique that utilizes the backward dynamic scatter contrast values generated by the movement of red blood cells in the blood vessels to obtain information about the blood flow velocity [13]. When the scattered particles of the observed object remain stationary, that is to say the red blood cells in the human epidermal microcirculation blood flow are in a stationary state. The scattering pattern formed by the backscattered light also remains stationary and has high contrast gray scale undulation. When red blood cells in the blood flow are in motion, the intensity distribution of the scattering pattern formed will fluctuate. It means that there exists a special correlation between the contrast of the image and the speed of movement of the scattered particles [14]. Compared with other blood flow monitoring methods, LSCI adopts a full-field optical imaging method without scanning, which is a non-scanning optical imaging technology that can detect blood flow velocity in a wide-field way. Due to its characteristics of good spatial and temporal resolution rates, rapid real-time imaging, non-direct contact, and quantitative analysis of blood flow changes, LSCI is widely used in the field of blood flow imaging detection [15].

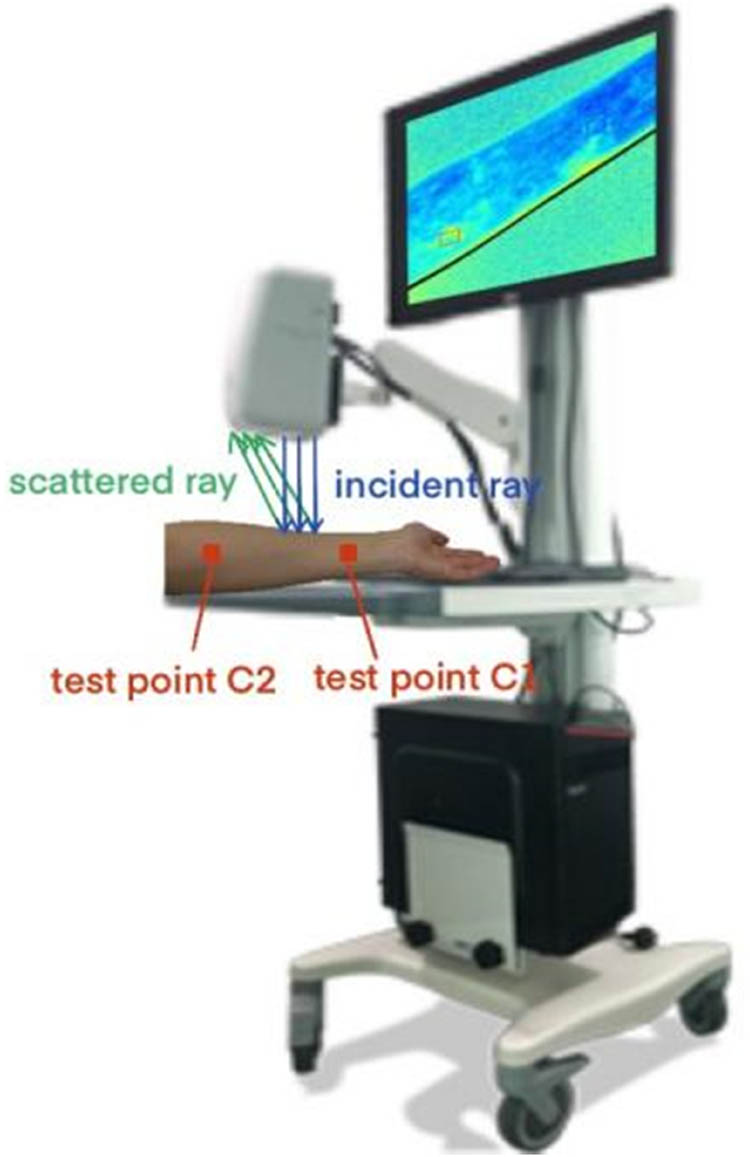

A BVI microcirculation blood flow imager (Shenzhen Shengqiang Technology Co., Ltd) was used to test the effect of sample fabrics’ promotion multiple of blood flow velocity on human epidermal microcirculation. The experimental equipment and principle are shown in Figure 1; the imager adopted the principle of LSCI. Rays were emitted by the host machine, the incident rays were exposed to the human skin, and the scattered rays generated on the skin were received by the host machine and transmitted to the computer system through an optical system for image and data analyses. Then, the scanning images, microcirculation blood flow images as well as the microcirculation blood flow velocity of the subjects were obtained [16].

BVI microcirculation blood flow imager and experimental principle.

2.4.2 Experimental materials and methods

On the basis of standard CAS 115-2005 [17] and the test sample size and test time being verified by Chen [18], the human epidermal microcirculation blood flow velocity of the sample was measured.

2.4.2.1 Subjects

The subjects were 20 healthy female graduate students aged 22–26 years old. The test position was about 1.5 cm2 in size, and the points were selected at a distance of no less than 5 cm from the wrist and no less than 2.5 cm from the elbow socket. The test points C1 and C2 are shown in Figure 1.

2.4.2.2 Experimental sample

The sample size was set as 20–25 cm in length and 10 cm in width. Velcro was sewn on both sides of the sample, and a circular hole with a diameter of about 2 cm was cut in the middle of the sample to serve as the test selection area, which corresponded to the location of the arm test point C2. The hole area was covered with the same material as the sample during the wrapping period, and the sample was removed covering the hole during the testing period to perform the test, which can avoid the error caused by removing the whole test sample. The samples were humidified for 24 h according to the Chinese standard GB/T 6529-2008 [19].

2.4.2.3 Experimental conditions

The temperature and humidity of the laboratory were controlled at 24–26°C and 40–60%, respectively, and kept free of wind, shielded from direct sunlight, and indoor lighting was used. The day before the test, the subjects should not consume functional beverages, tea, coffee and other foods that will cause excitement in the human body [20].

2.4.2.4 Experimental procedure

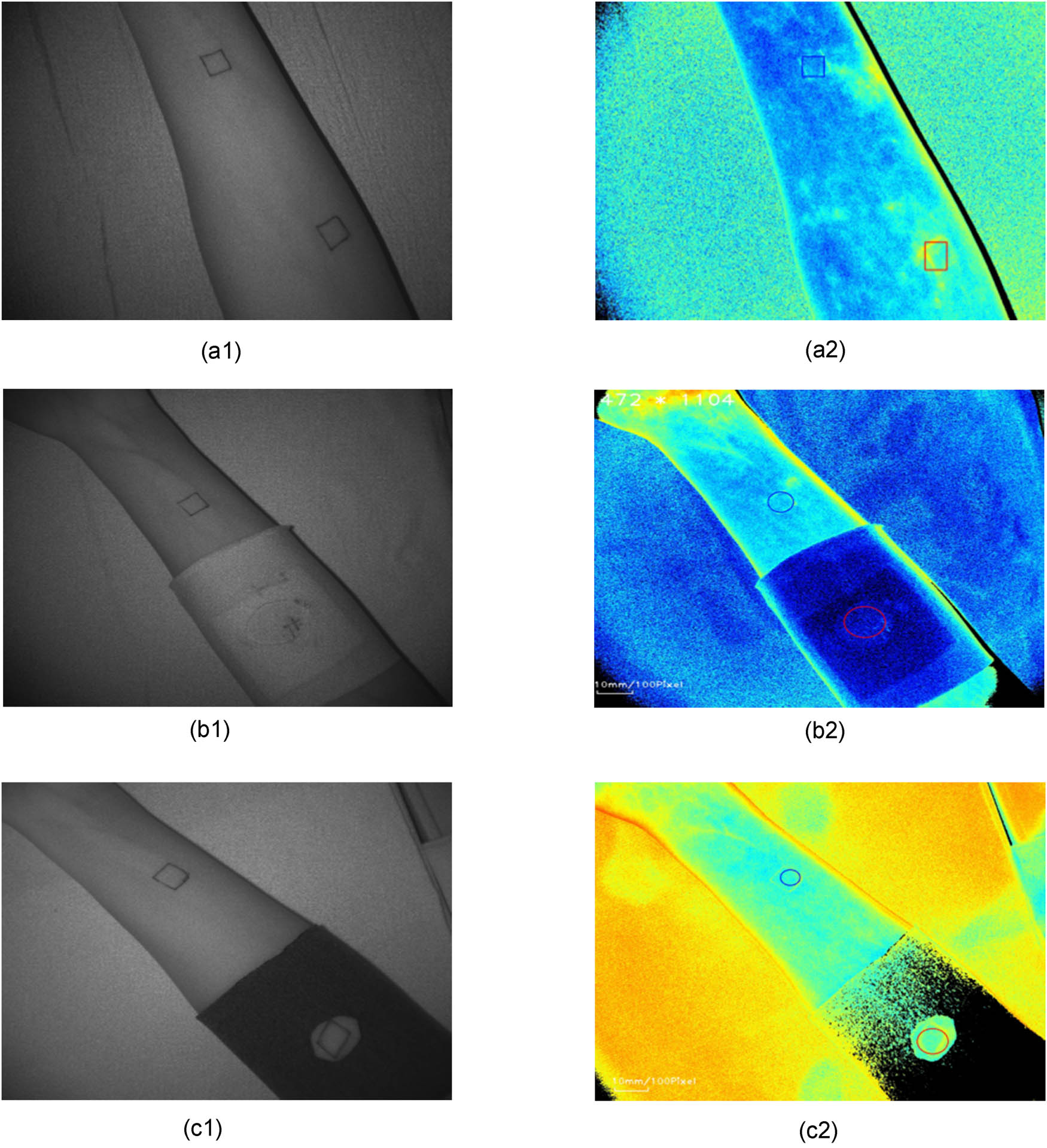

Two test points C1 and C2 were marked on the inner side of the subject’s arm. For the LSCI assay, after the blood flow velocity of the subject’s arm was relatively stable, the test point C1 was exposed as a blank control. After keeping the test point C2 exposed for 20 min, the software was used to select the test area and measure the dynamic microcirculation blood flow velocity at test points C1 and C2. When the blood flow velocity reached a relatively stable state, the blood flow velocity was taken for 5 min. The ratio of the average values of blood flow velocity at test points C1 and C2 was taken as the original ratio of the subject’s epidermal microcirculation blood flow velocity. After completing the test, the subject was required to sit still for 10 min. The scanning image and microcirculation blood flow image of the subject’s arm without covering the two test points are shown in Figure 2(a1) and (a2).

Scanning images and microcirculation blood flow images of the subject’s arm. (a1) Scanning image without covering the sample. (a2) Microcirculation blood flow image without covering the sample. (b1) Scanning image of covering sample 1#. (b2) Microcirculation blood flow image of covering sample 1#. (c1) Scanning image of covering sample 6#. (c2) Microcirculation blood flow image of covering sample 6#.

Test point C1 was continued to expose as a blank control, sample 1# at test point C2 was covered for 20 min, and the test procedure of the original ratio of blood flow velocity was repeated. The ratio of average values of blood flow velocity at test points C1 and C2 was taken as the changed ratio of microcirculation blood flow velocity acted on the subject by sample 1#. The changed ratio of the microcirculation blood flow velocity of sample 1# to the original ratio is the promotion multiple of blood flow velocity of sample 1# for the subject. After the test was completed, the subject had to sit still for 10 min. Then, the aforementioned steps were repeated to obtain the promotion multiple of blood flow velocity on human epidermal microcirculation of the subjects from the 16 samples sequentially. As shown in Figure 2(b1) and (b2), the scanning image and the microcirculation blood flow image were obtained by covering the sample 1# at test point C2 for 20 min without removing the covered sample from the test area. The scanning image and the microcirculation blood flow image were obtained after covering the sample 6# for 20 min and the covered sample at test point C2 was removed, as shown in Figure 2(c1) and (c2).

The changed ratio of the microcirculation blood flow velocity to the original ratio of all samples was calculated as the promotion multiple of blood flow velocity on human epidermal microcirculation, using the formulas shown in (1) and (2):

where

3 Results and discussion

3.1 Air permeability test results and discussion

Following the above steps, the air permeability of the sample fabrics was tested, and the results are shown in Table 4.

Air permeability of sample fabrics

| Sample number | Air permeability rate (mm s−1) | Sample number | Air permeability rate (mm s−1) |

|---|---|---|---|

| 1# | 127.08 | 9# | 131.76 |

| 2# | 119.78 | 10# | 121.30 |

| 3# | 115.08 | 11# | 158.68 |

| 4# | 138.26 | 12# | 142.56 |

| 5# | 168.92 | 13# | 153.82 |

| 6# | 167.48 | 14# | 129.46 |

| 7# | 114.42 | 15# | 148.64 |

| 8# | 119.80 | 16# | 120.42 |

SPSS software was used to analyze the air permeability results displayed in Table 4, so as to further study the influence of material types of exterior yarn Ⅰ, exterior yarn feed ratio and knitted structure on fabric air permeability. The test results of between-subjects effect are shown in Table 5. The significant P-value of factor A (0.000) and factor C (0.004) is less than 0.01, which means the material types of exterior yarn Ⅰ and knitted structure all have significant influence on the air permeability. The significant P-value of factor B (0.475) is higher than 0.05, which illustrates that the exterior yarn feed ratio has less effect on air permeability.

Results of between-subjects effects of air permeability results

| Observational variable: Air permeability rate | ||||

|---|---|---|---|---|

| Source | Class III sum of squares | Mean square | F | Sig. |

| A (material types of exterior yarn Ⅰ) | 3464.857 | 1154.952 | 23.460 | 0.000 |

| B (exterior yarn feed ratio) | 80.672 | 40.336 | 0.819 | 0.475 |

| C (knitted structure) | 1203.062 | 601.531 | 12.218 | 0.004 |

| Error | 393.851 | 49.231 | ||

| Corrected total | 5142.442 | |||

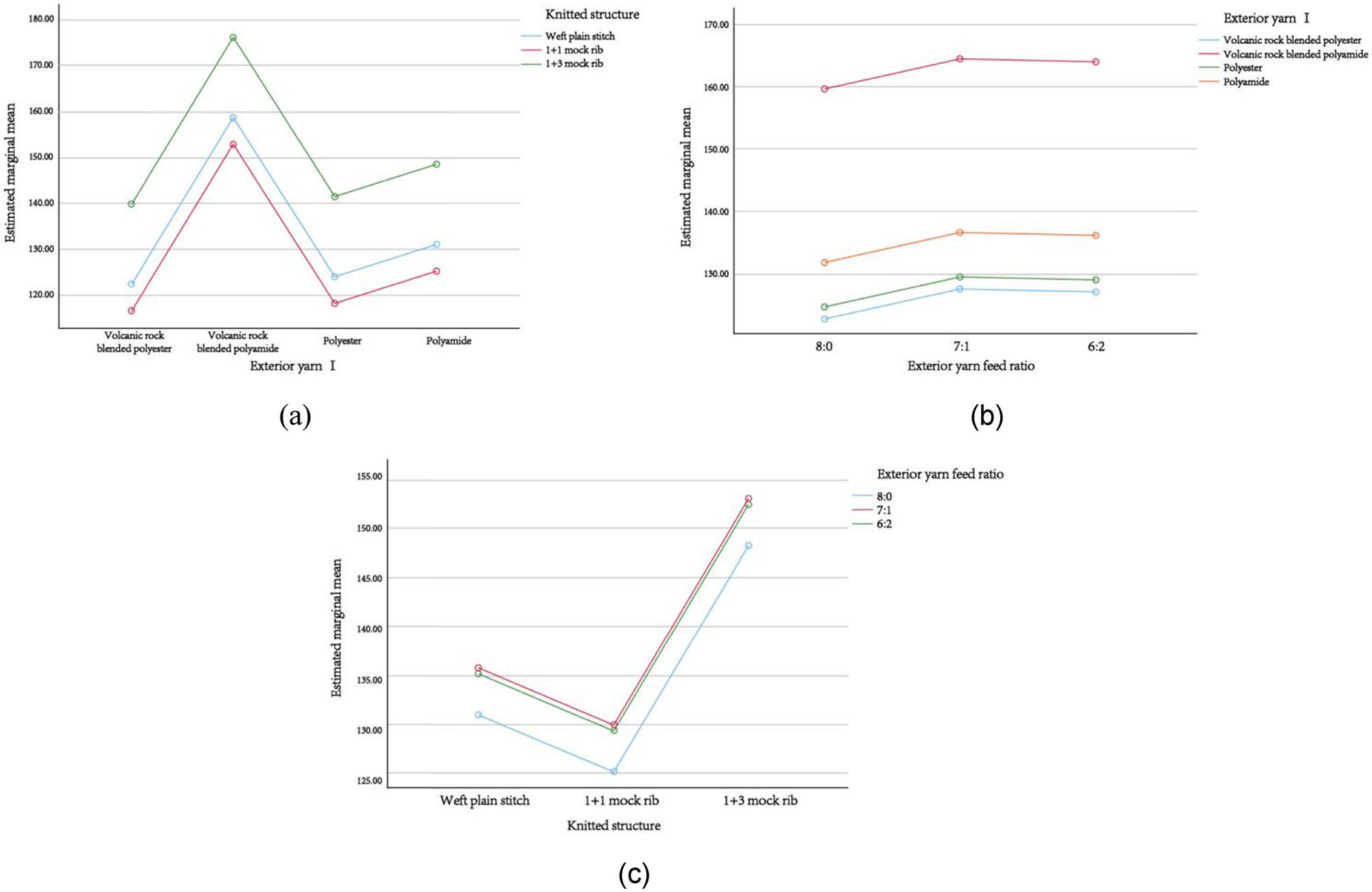

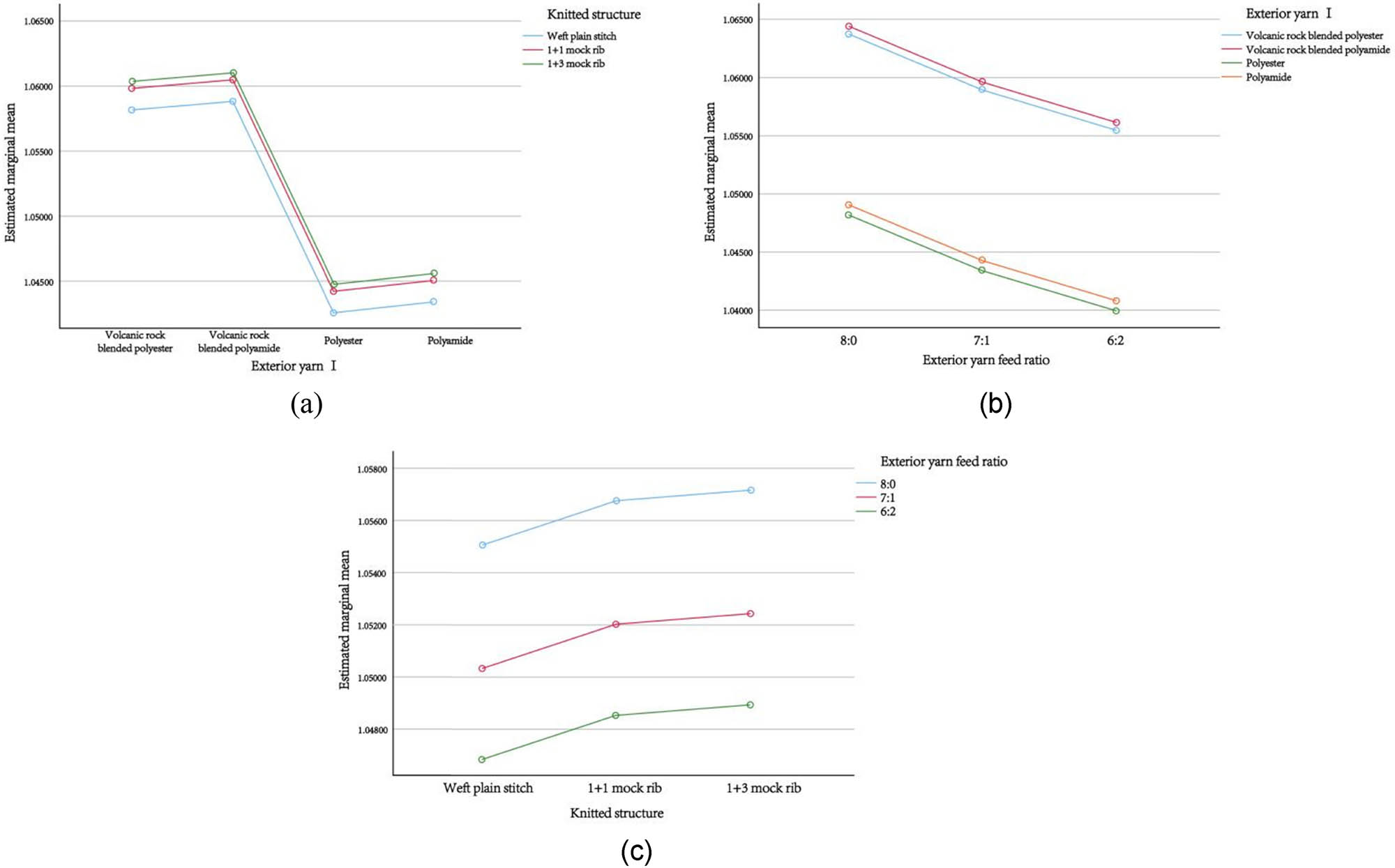

Furthermore, the marginal mean is used for intra-group comparison, and each point in the contour graph represents the marginal mean at a certain factor level corresponding to that point. The three factors are used as horizontal axes and separate lines and crossed to make a contour graph of the estimated marginal mean, as shown in Figure 3. While the independent variable is material types of exterior yarn Ⅰ, the order of fabric air permeability is as follows: volcanic rock blended polyamide > polyamide > polyester > volcanic rock blended polyester. According to the line features, the volcanic rock blended polyamide fabric is significantly higher than the other three levels, and the air permeability of volcanic rock polymer fabrics is not deteriorated by adding the volcanic rock composite powder. While the independent variable is a knitted structure, the point represents that 1 + 3 mock rib fabric is higher than the weft plain stitch and 1 + 1 mock rib. It shows that the air permeability of the fabric with different structures is different. The above analysis shows that the volcanic rock polymer fabrics have good air permeability.

Contour graphs of the estimated marginal mean of air permeability. (a) Exterior yarn I is taken as the independent variable. (b) Exterior yarn feed ratio is taken as the independent variable. (c) Knitted structure is taken as the independent variable.

3.2 Human epidermal microcirculation blood flow velocity test results and discussion

The mean value of promotion multiple of microcirculation blood flow velocity of 16 samples from 20 subjects is taken as the promotion multiple of blood flow velocity on human epidermal microcirculation of each sample, and the results are listed in Table 6. The order of promotion multiple of blood flow velocity on human epidermal microcirculation of each sample is as follows: 8# > 6# > 5# > 7# > 11# > 12# > 16# > 15# > 1# > 2# > 4# > 3# > 9# > 10# > 13# > 14#. This means that the promotion effect of sample 8# is the best, followed by sample 6#, but sample 14# performed the worst.

Promotion multiple of blood flow velocity on human epidermal microcirculation results

| Sample number | Promotion multiple of blood flow velocity on human epidermal microcirculation | Sample number | Promotion multiple of blood flow velocity on human epidermal microcirculation |

|---|---|---|---|

| 1# | 1.04709 | 9# | 1.04532 |

| 2# | 1.04634 | 10# | 1.04480 |

| 3# | 1.04537 | 11# | 1.05760 |

| 4# | 1.04546 | 12# | 1.05737 |

| 5# | 1.06378 | 13# | 1.04304 |

| 6# | 1.06978 | 14# | 1.04281 |

| 7# | 1.05938 | 15# | 1.05207 |

| 8# | 1.07077 | 16# | 1.05315 |

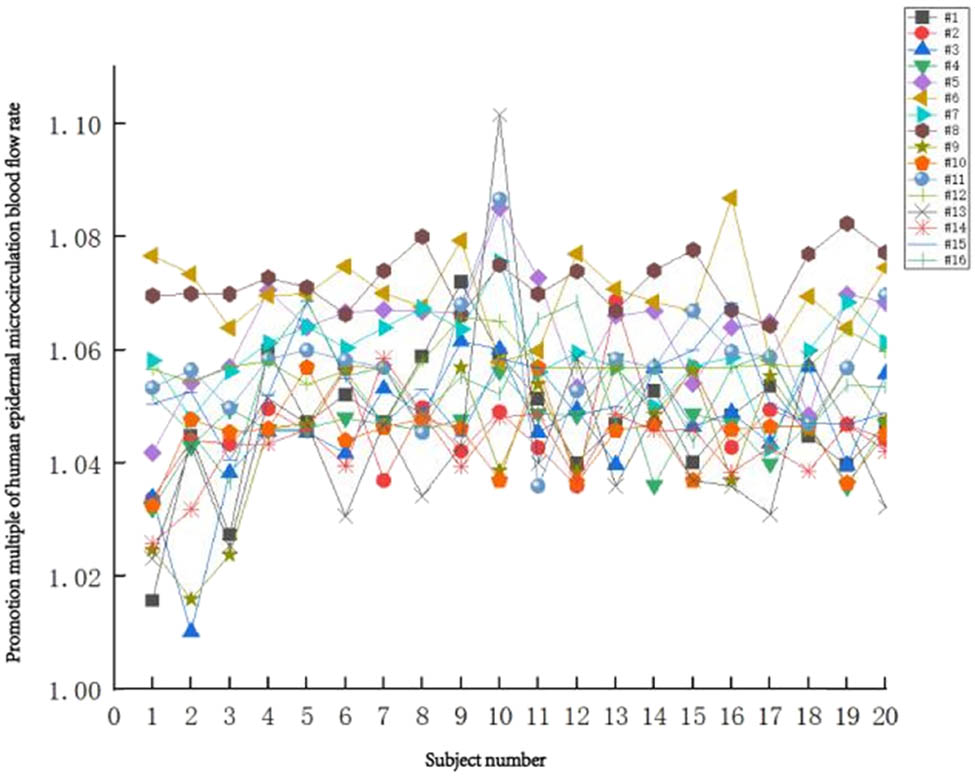

The line chart of the results of promotion multiple of blood flow velocity on human epidermal microcirculation of 16 samples is shown in Figure 4. It illustrates that 20 healthy subjects also show certain differences in promotion multiple of blood flow velocity on human epidermal microcirculation due to the individual differences.

Line chart of promotion multiple of blood flow velocity on human epidermal microcirculation.

SPSS software was used to conduct a homogeneity test on the value of promotion multiple of blood flow velocity on human epidermal microcirculation, which proved that the variance has no significant difference. The randomized group design ANOVA method was used to analyze Table 6 data, and the between-subjects effects test values are presented in Table 7. The significant P-values of factor A (0.001) and factor B (0.039) are less than 0.05, and the P-value of factor A (0.001) is less than 0.01, while the P-value of factor C (0.694) is more than 0.05. This shows that the material types of exterior yarn Ⅰ has a great difference in the microcirculation blood flow velocity, and the exterior yarn feed ratio has a bit difference, while the knitted structure has no effect.

Results of between-subjects effects of the promotion multiple of blood flow velocity on human epidermal microcirculation results

| Observational variable: promotion multiple of blood flow velocity on human epidermal microcirculation | ||||

|---|---|---|---|---|

| Source | Class III sum of squares | Mean square | F | Sig. |

| A (material types of exterior yarn Ⅰ) | 0.001 | 0.000 | 16.699 | 0.001 |

| B (exterior yarn feed ratio) | 0.000 | 9.619 × 10−5 | 5.029 | 0.039 |

| C (knitted structure) | 1.465 × 10−5 | 7.326 × 10−6 | 0.383 | 0.694 |

| Error | 0.000 | 1.913 × 10−5 | ||

| Corrected total | 0.001 | |||

The contour graph of the estimated marginal mean of the promotion multiple of blood flow velocity on human epidermal microcirculation is shown in Figure 5. The integrated analysis results are as follows: when the independent variable is material types of exterior yarn Ⅰ, the order of promotion multiple of blood flow velocity on human epidermal microcirculation of the fabrics is as follows: volcanic rock blended polyamide > volcanic rock blended polyester > polyamide > polyester. In the chart, the points representing the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fabrics are obviously higher than the others. It shows that volcanic rock composite powder is rich in metal elements, which can release far-infrared rays to improve human microcirculation and significantly enhance the blood flow promotion effect of fabric. While the independent variable is the exterior yarn feed ratio, the exterior yarn feed ratio of 8:0 has the best impact on the promotion multiple of blood flow velocity on human epidermal microcirculation, while the exterior yarn feed ratio of 7:1 has a slight influence and the exterior yarn feed ratio of 6:2 has the worst effect. The graph illustrates that the blood flow promotion effect of fabric increases when the content of volcanic rock polymer fiber is augmented. This shows that the volcanic rock composite powder added in the polymer makes a great difference in the promotion multiple of blood flow velocity. As the independent variable is a knitted structure, the order of promotion multiple of blood flow velocity on human epidermal microcirculation of the fabrics is as follows: 1 + 3 mock rib > 1 + 1 mock rib > weft plain stitch. On the basis of the fabric thickness of these three kinds of fabric structures, the weft plain stitch fabric which is relatively flat and compact has a low porosity, preventing the infrared energy from reaching the skin surface through the fabric. Therefore, the blood flow promotion effect is slightly lower than the other fabric structures. However, in accordance with the P-value of factor C in Table 5, the influence of the knitted structure can be ignored.

Contour graph of the estimated marginal mean of the promotion multiple of blood flow velocity on human epidermal microcirculation. (a) Exterior yarn I is taken as the independent variable. (b) Exterior yarn feed ratio is taken as the independent variable. (c) Knitted structure is taken as the independent variable.

4 Conclusions

This article mainly explores the influence of different material types of yarn Ⅰ, exterior yarn feed ratio and knitted structure on the air permeability and the promotion multiple of blood flow velocity on human epidermal microcirculation. A total of 16 sample fabrics were tested and analyzed. According to the air permeability experimental results, it concluded that the air permeability of the volcanic rock polymer fabrics is good and can be used in the clothing in direct contact with the skin.

The promotion multiple of blood flow velocity on the human epidermal microcirculation experiment explains the following:

With regard to material types of exterior yarn Ⅰ, the fabrics made of different volcanic rock polymer fibers have less variability in the promotion multiple of blood flow velocity on human epidermal microcirculation, and all are superior to those made of common fibers.

From the aspect of exterior yarn feed ratio, the promotion multiple of blood flow velocity on human epidermal microcirculation of fabrics becomes better with the increase of the content of exterior yarn Ⅰ. In addition, the promotion multiple of blood flow velocity on human epidermal microcirculation of fabrics with an exterior yarn feed ratio of 8:0 is significantly higher than that of 6:2.

In terms of knitted structure, the fabric with weft plain stitch has a slightly lower promotion effect on the promotion multiple of blood flow velocity on human epidermal microcirculation than the other two structures.

The experimental results show that volcanic rock polymer fibers have better promotion influence on the human epidermal microcirculation blood flow velocity due to the far-infrared emitting property of the added volcanic rock composite powder. In addition, the higher the content of the volcanic rock composite powder is, the better the promotion of the blood flow velocity will be. It means the fabric made of volcanic rock polymer fibers is beneficial to chronic inflammatory arthritis, which provides theoretical reference for the application of volcanic rock polymer fibers in the external treatment of shoulder periarthritis.

-

Funding information: This research was funded by New Products of Zhejiang Province (Grant/Award Number: 2022D60SA7012024).

-

Author contributions: Conceptualization: Z.J.; methodology: S.Q.; validation: S.Q.; formal analysis: S.Q., Y.Z. and J.J.; investigation: S.Q. and Y.S.; resources: C.F.; writing – original draft: S.Q. and Y.Z.; writing – review & editing: Z.J.; visualization: S.Q.; supervision: Z.J.; project administration: Z.J.; funding acquisition: C.Z. All authors have read and agreed to the published version of the manuscript.

-

Conflict of interest: The authors state no conflict of interest.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Zhou, J., Wu, Q., Wang, Z. C. (2021). Effect of self-employment on the sub-health status and chronic disease of rural migrants in China. BMC Public Health, 21(1), 2250. 10.1186/s12889-021-12214-5.Search in Google Scholar PubMed PubMed Central

[2] Wright, V., Haq, A. M. (1976). Periarthritis of the shoulder. I. Aetiological considerations with particular reference to personality factors. Annals of the Rheumatic Diseases, 35(3), 213–219. 10.1136/ard.35.3.213.Search in Google Scholar PubMed PubMed Central

[3] James, J. P. (1882). The treatment of a form of painful periarthritis of the shoulder. The Boston Medical and Surgical Journal, 107(22), 509–512.10.1056/NEJM188211301072202Search in Google Scholar

[4] Huang, D., Gu, Y. H., Liao, Q., Yan, X. B., Zhu, S. H., Gao, C. Q. (2012). Effects of linear-polarized near-infrared light irradiation on chronic pain. The Scientific World Journal, 2012, 567496. 10.1100/2012/567496.Search in Google Scholar PubMed PubMed Central

[5] Zhao, Z. J. (2007). 96 cases of periarthritis of shoulder treated with traditional Chinese medicine far-infrared by heating machine. Journal of Practical Chinese Internal Medicine, 1, 93. 10.13729/j.issn.1671-7813.2007.01.084.Search in Google Scholar

[6] Wang, Z. Z., Wang, Y. P., Wan, J. P. (2010). Acupuncture combined with far-infrared irradiation for treatment of 67 cases of periarthritis of shoulder. Journal of Clinical Military Medicine, 38(4), 533–542.Search in Google Scholar

[7] Vatansever, F., Hamblin, M. R. (2012). Far infrared radiation (FIR): its biological effects and medical applications. Photonics & Lasers in Medicine, 4, 255–266.10.1515/plm-2012-0034Search in Google Scholar PubMed PubMed Central

[8] Pico, D., Wilms, C., Seide, G., Tries, T. (2012). Natural volcanic fibre. International Textile Guide, 40(4), 6–8.Search in Google Scholar

[9] Strain, W. D., Adingupu, D. D., Shore, A. C. (2012). Microcirculation on a large scale: Techniques, tactics and relevance of studing the microcirculation in larger population samples. Microcirculation, 19(1), 37–46.10.1111/j.1549-8719.2011.00140.xSearch in Google Scholar PubMed

[10] Li, H. B., Shi, J. H. (2021). Research progress of external treatment of periarthritis of shoulder. Chinese Ethnic and Folk Medicine, 30(15), 65–68.Search in Google Scholar

[11] Yun, M. Y., Sas, H., Simacek, P., Advani, S. G. (2017). Characterization of 3D fabric permeability with skew terms. Composites Part A-Applied Science and Manufacturing, 97, 51–59.10.1016/j.compositesa.2016.12.030Search in Google Scholar

[12] China Textile Association. (1997). Determination of air permeability of textile fabrics: GB/T 6529-2008, pp. 1–12. Standards Press of China, Beijing.Search in Google Scholar

[13] David, J. B. (2007). Laser speckle contrast imaging for measuring blood flow. Optica Applicata, 37(1–2), 139–152.Search in Google Scholar

[14] Winship, I. R. (2014). Laser speckle contrast imaging to measure changes in cerebral blood flow, Methods in Molecular Biology (Clifton, NJ), 1135, 223–235. 10.1007/978-1-4939-0320-7_19.Search in Google Scholar PubMed

[15] Boas, D. A., Dunn, A. K. (2010). Laser speckle contrast imaging in biomedical optics. Journal of Biomedical Optics, 15(1), 011109. 10.1117/1.3285504.Search in Google Scholar PubMed PubMed Central

[16] Zieger, M., Kaatz, M., Springer, S., Riesenberg, R., Wuttig, A., Kanka, M., et al. (2020). Multi-wavelength, handheld laser speckle imaging for skin evaluation. Skin Research and Technology, 27(4), 486–493. 10.1111/srt.12959.Search in Google Scholar PubMed

[17] China Standardization Association. (2005). Health functional textiles: CAS 115-2005, pp. 2–9. Standards Press of China, Beijing.Search in Google Scholar

[18] Chen, K. Y. (2021). Study on the relationship between structure and property of magnetic polypropylene fiber seamless knitted fabric. Zhejiang Sci-Tech University, Hangzhou. 10.27786/d.cnki.gzjlg.2021.000849.Search in Google Scholar

[19] China Textile Industry Association. (2008). Standard atmosphere for humidification and testing of textiles: GB/T 6529-2008, pp. 1–2. Standards Press of China, Beijing.Search in Google Scholar

[20] Huang, Y. (2017). Application of laser Doppler flowmetry to monitor cutaneous microcirculation in a healthy Chinese population. Anhui Medical University, Hefei.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry