Abstract

The helmet shell material featuring a gradient in bending is urgently required for the next-generation integrated helmet system. However, achieving a bending gradient design for orthogonal woven composites on a 3D shell surface is a significant challenge. Here, nonorthogonal woven composites at 30°, 45°, and 60° were fabricated, and their bending properties are discussed. Furthermore, their bending properties are compared to those of plain off-axis woven composites, which indicates that the bending linearity trend of nonorthogonal woven composites is evident. Notably, the bending strength of the 30° and 60° nonorthogonal woven composites is 66.9 and 67.4% higher, respectively, than that of the plain off-axis woven composites, and the bending modulus is 169.8 and 196.9% higher, respectively. Finally, a finite element analysis of the bending properties of nonorthogonal woven composites was conducted, and a stress analysis of the inner layers was also conducted. This work paves the way for designing gradient materials for helmet shells.

1 Introduction

Helmet skeleton material is essential personal protective equipment for the human body in aerospace, architectural engineering, sporting event, fire rescue, and explosion-proof filed [1,2,3,4,5,6]. Therefore, people are trying to develop special materials for high-performance helmet shells. Among them, composite materials are favored because of their high stiffness, high strength, light-weight, high-temperature resistance, fatigue resistance, corrosion resistance, vibration reduction, high designability, and a range of other advantages [7,8]. The research of helmet skeleton materials focuses on the design of potential textile structure composites to meet the informatization and functionalization needs of helmets with complex shell structure and multiple functions. However, the helmet shell with complex curvature causes the plain off-axis woven material to wrinkle in the process of helmet body laying [9]. So, the plain off-axis woven materials must be cut to adapt to the complex curved surface of the shell [10,11], which results in stress concentration [12] of the helmet shell and the decline of protective performance. To solve this issue, researchers turned to nonorthogonal woven materials to improve the integrity of the helmet shell and achieve the variable stiffness design in the shell area. The research on woven composites has important engineering and academic value, but it is limited to the weaving process of woven materials. There are few reports on the preparation of nonorthogonal woven fabrics and the mechanical properties of nonorthogonal woven fabric-reinforced composites.

In view of the special use of nonorthogonal woven fabrics in aerospace and weapon equipment, it was mainly focused on the technological design and preparation in the early stage. Dayin [5] first put forward the viewpoint of developing nonorthogonal woven fabrics based on the development of aerospace technology and national defense technology, even the successful development and utilization of high-modulus carbon fiber, but the disadvantages of narrow width, unstable structure, and complex production process were revealed. The special structure and industrial application of nonorthogonal woven fabrics make it develop rapidly in the field of industrial textiles. Based on the complex weaving process constraints of nonorthogonal woven fabrics, Liu et al. [13] fabricated the nonorthogonal woven fabrics on the dobby loom machine and tested its basic properties. The off-axis tensile strength and tear resistance of nonorthogonal woven fabrics are stronger than the orthogonal plain weave fabrics under the same conditions. Due to the special fiber orientation of nonorthogonal woven fabrics, the outer layer used for driving the V-belt can greatly improve the wear resistance and reverse bending fatigue resistance of the belt body. Lvliang et al. [14] developed a wide-angle woven fabric for polyester cotton-blended V-belt. Through many tests, it is found that the polyester cotton-blended fabric has good heat resistance and wear resistance and can overcome problems such as the decline of wear resistance caused by too thick canvas. At present, the main method of producing nonorthogonal woven fabrics is realized through secondary processing. Its production process and production equipment [15,16] are relatively complex, resulting in an increase in production cost. To optimize the production process of nonorthogonal woven fabrics, Yanqin et al. [17] proposed and designed a special rapier loom for wide-angle woven fabric, which makes it form an angle of 120° or 60° with the warp through off-axis weft insertion, which greatly improves the production efficiency of nonorthogonal woven fabrics.

With the continuous expansion of nonorthogonal woven fabrics, the performance of this type of fabric has been widely concerned. Yao et al. [18] not only used the air jet loom to weave the nonorthogonal woven fabrics by using the water jet to guide the weft diagonally but also initially explored the tensile properties of polyester wide-angle woven fabrics. As a result, the tensile properties of the wide-angle fabric that own the 60° warp and weft yarn angle showed that the breaking strength of the fabric was large and the breaking elongation was small when the wide-angle fabric was loaded along the warp direction. Differently, when subjected to the load along the weft direction, the breaking strength and elongation at break of the fabrics are both large. Through research, we come to the conclusion that wide-angle fabrics are better than plain fabrics in terms of mechanical properties and have broad application prospects. Zhang et al. [19] proposed a method of wide-angle fabric preparation with a warp-weft yarn angle of 120° and deeply studied the mechanical properties of this fabric. The results show the elongation at break and the elastic modulus in the warp and weft directions exhibit varying degrees, compared with conventional woven fabrics, indicating that the nonorthogonal woven fabric has excellent strength and deformation characteristics.

Considering the superior mechanical properties of nonorthogonal structure, it has great potential in helmet shell materials. Therefore, 30°, 45°, and 60° nonorthogonal woven composites were prepared and the bending properties of the materials were explored in this work. Ideally, the linear characteristics of this type of composite are evident. Furthermore, the bending characteristics of nonorthogonal woven composites were studied, revealing that both their bending strength and bending modulus were higher than those of the plain off-axis composites. In addition, numerical simulations of the bending properties were carried out by using the finite element software ABAQUS, and the results of the finite element simulations were compared with the experimental results, which is to further carry out the stress analysis of the inner layer in the specimen. Therefore, using a nonorthogonal structure, helmet shell composites with superior bending performance can be prepared. Consequently, the shell material combines excellent bending properties with the gradient design features of the helmet shell. The feasible study proposed in this work could offer a promising strategy for the development of new-generation helmet shell materials with enhanced bending properties and a design oriented toward gradients.

2 Materials and methods

2.1 Materials

The warp and weft yarns of woven fabrics and nonorthogonal woven fabrics were both made of aramid 1414 that was provided by Yantai Tayho Advanced Materials Co., Ltd. The yarn density was 1,100 dtex, single strand, and both warp and weft densities were 110 bunch/(10 cm). The fabrics were prepared at the National Experimental Center for Fabrics of Tiangong University. The Q-301 epoxy resin was supplied by Suzhou Colorless Stone Chemical Co., Ltd. The epoxy resin and its related accelerator are of analytical grade and used without further purification.

2.2 Fabric preparation

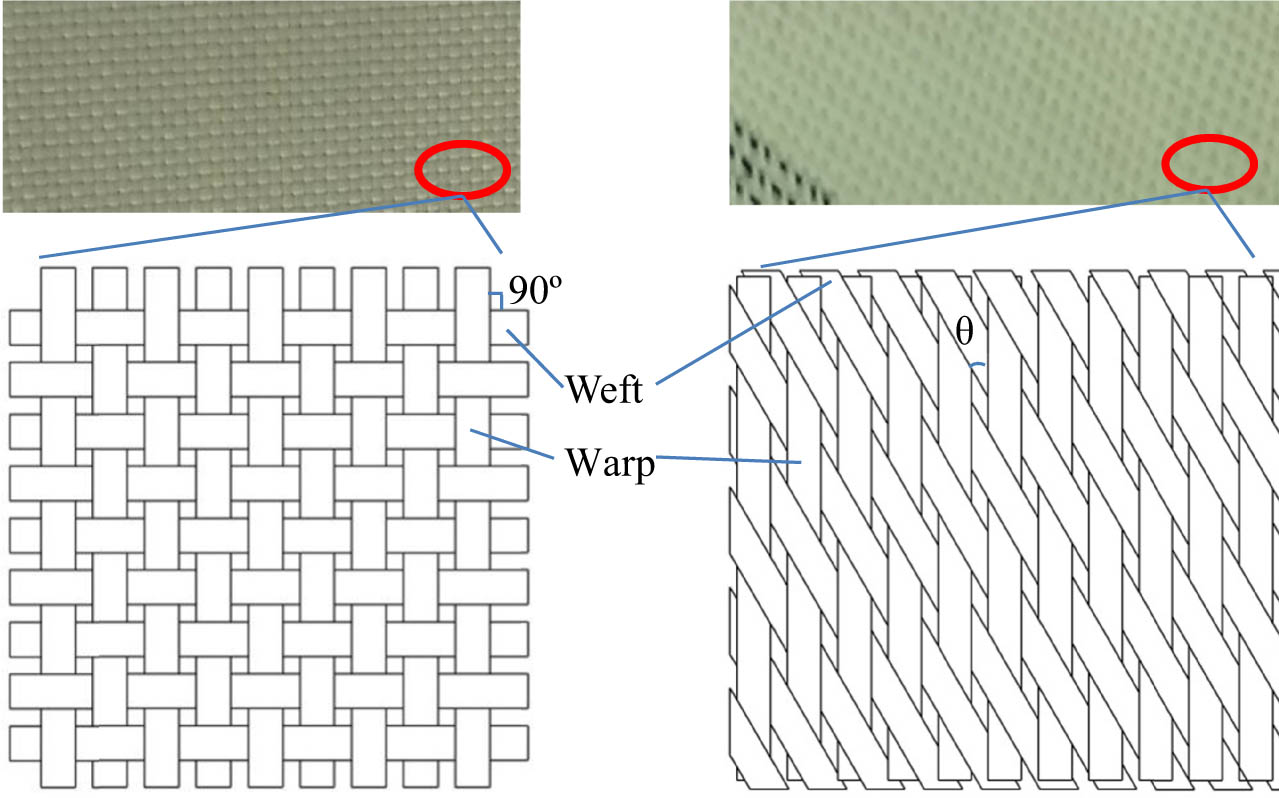

The plain off-axis woven fabrics and nonorthogonal woven fabrics are shown in Figure 1. Aramid 1414 filament bundles are used for both warp and weft yarns, and plain off-axis woven fabrics and nonorthogonal woven fabrics are woven on a small sample loom. The nonorthogonal woven fabrics are realized by a special warp edge design, an edge locking design, and a special weft-triggering mechanism design. The warp and weft yarn angle “θ” can be varied from 30° to 150°.

Schematic diagram of the structure of plain off-axis woven fabrics and nonorthogonal woven fabrics.

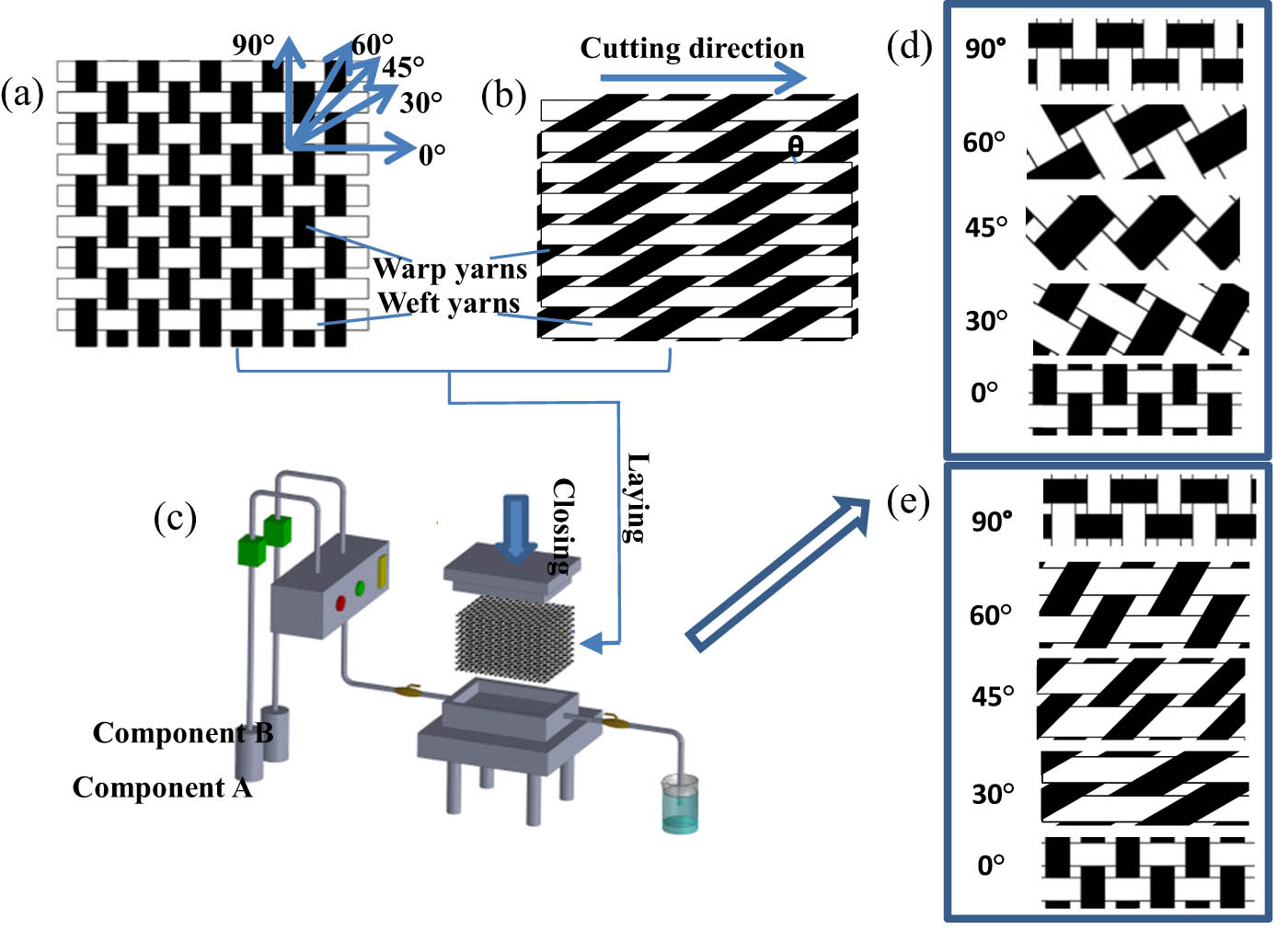

2.3 Composite specimen preparation

Plain off-axis woven composites and nonorthogonal woven composites were prepared using the resin transfer molding (RTM) process. The composite specimens measured 130 mm × 15 mm × 3 mm, in accordance with GB/T 1449-2005 “Bending Performance Test Method for Fiber Reinforced Plastics” (year) [20]. The off-axis woven composite specimens included angles of 0°, 30°, 45°, 60°, and 90°, with the weft direction at 0° and the warp direction at 90°. Correspondingly, the angles of warp and weft yarn include 30°, 45°, and 60° in the nonorthogonal woven composite specimens. Both types of samples are defined through the cutting direction along the weft direction. The cutting schematics of plain and nonorthogonal woven fabrics are given in Figure 2(a) and (b), respectively. Figure 2(a) is the schematic diagram of off-axis cutting of plain off-axis woven specimens. Different angles were divided according to counterclockwise; Figure 2(b) is the schematic diagram of nonorthogonal woven fabrics, where the specimens are cut along the weft direction. The fabric was cut to the size required by the RTM mold for curing and laid into the mold using the 0°-layering method for preparing woven composites via the RTM process. The preparation process is shown in Figure 2(c). The fiber orientation of the formed composites is shown in Figure 2(d) and (e).

Schematic diagram of composite material preparation and fiber orientation (a) Cutting schematics of plain woven fabrics; (b) Cutting schematics of nonorthogonal woven fabrics; (c) Curing process of composite materials; (d) Fiber orientation of plain woven composite materials; (e) Fiber orientation of nonorthogonal woven composite materials.

2.4 Test methods and devices

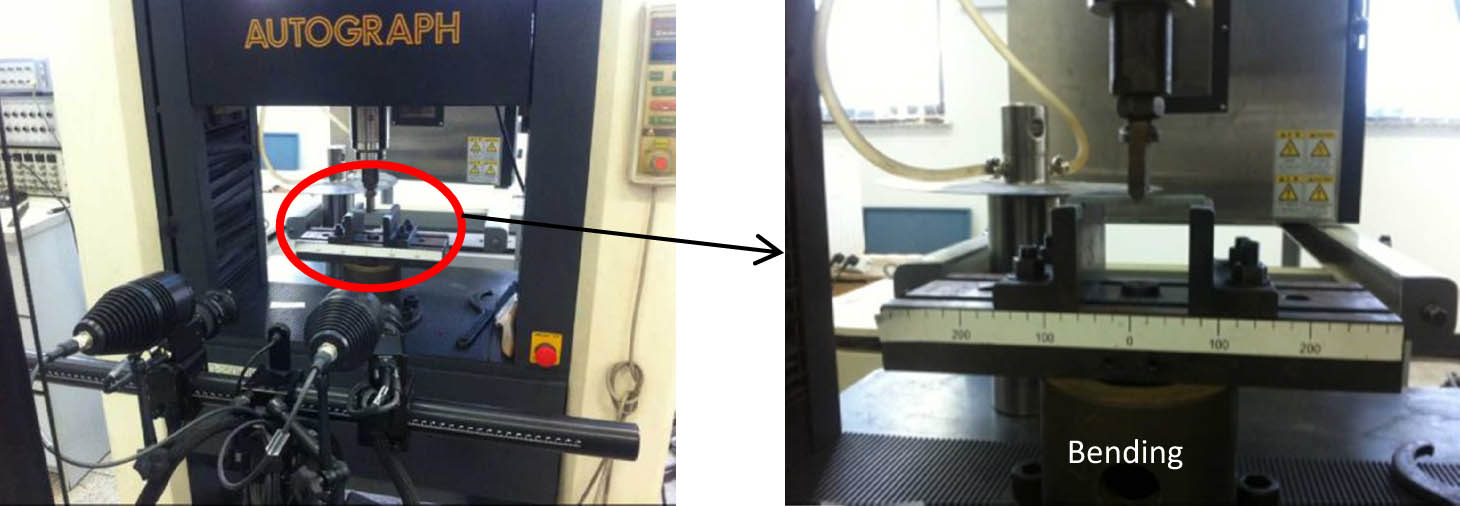

The three-point bending test in accordance with the standard GB1449-2005 “fiber-reinforced plastic bending performance test method” for testing, the span-thickness ratio is 32:1, the radius of the indenter and the radius of the support are 5 mm, and the loading speed is 2 mm/min. The Shimadzu AG-250KNE universal material testing machine was used for testing, as shown in Figure 3.

Three-point bending test.

3 Results and discussion

3.1 Bending characteristics analysis

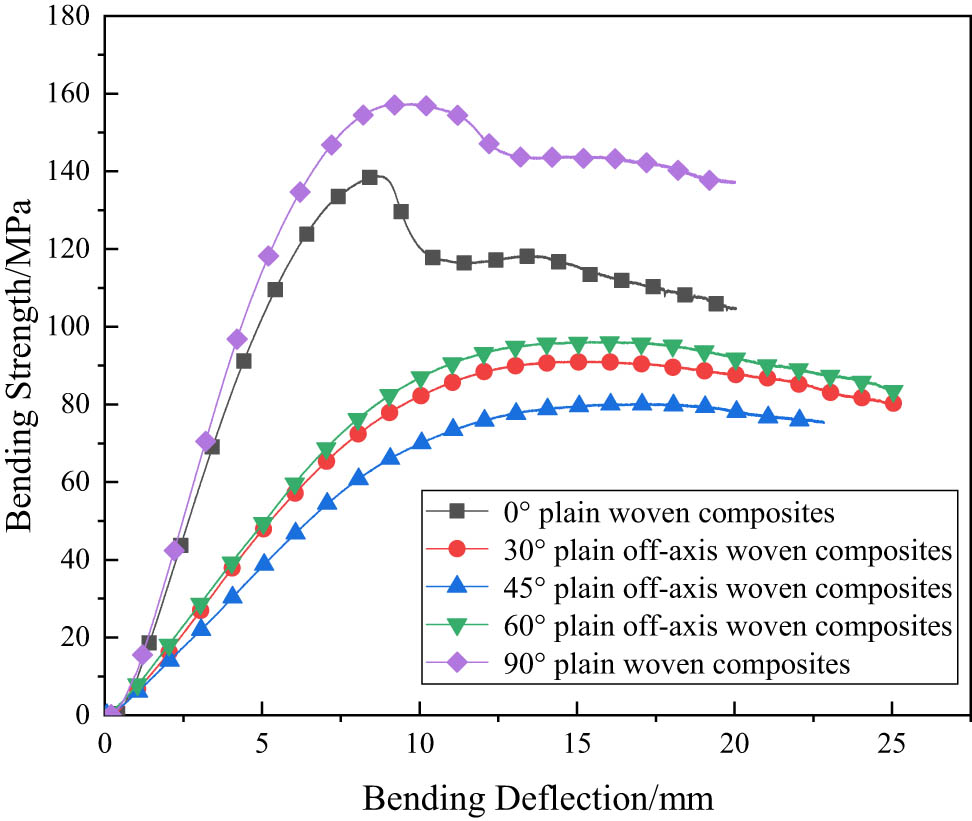

The three-point bending test was performed to study the ultimate bending strength, bending stiffness, and the bending characteristics analysis of the material, which was loaded until the specimen failure. As shown in Figure 4, the bending characteristics are clearly displayed under different off-axis cutting angles 0°, 30°, 45°, 60°, and 90°, respectively. It can be seen that the bending strength–deflection curves of 30°, 45°, and 60° off-axis woven composites show nonlinear trends with the change in off-axis cutting angles. Differently, the 0° and 90° woven composites showed approximately linear trend, which also indicated that the common woven fabrics had the important off-axis effect. The bending strength–deflection curves of 0° and 90° specimens increase approximately linearly until the maximum bending strength, after which there was the clear failure characteristic. The explanation was that the fibers along the axial direction own faster mechanical response when bearing the external load for the 0° and 90° specimens. When the failure load is reached, the fibers fracture or withdraw, which results in a sharp decline. For 30°, 45°, and 60° specimens, the bending strength–deflection curve showed a linear increase in the first stage, and then, the non-linear trend near the failure load happened in the second stage with the large bending deflection and lower bending strength. Due to the similar fiber orientation of warp and weft yarns, the fiber bearing capacity of the composite under external load was similar, which led to the similar bending characteristics of 30° and 60° off-axis cutting specimens. Most surprisingly, the bending strength of 45° off-axis cutting specimens was the smallest, which was completely different from the theoretical value. In this case, the 45° off-axis structure caused the extremely unstable fiber statement, which was highly susceptible to deformation and failure when the composites were subjected to an external load.

Bending strength–deflection curves of plain off-axis woven composites.

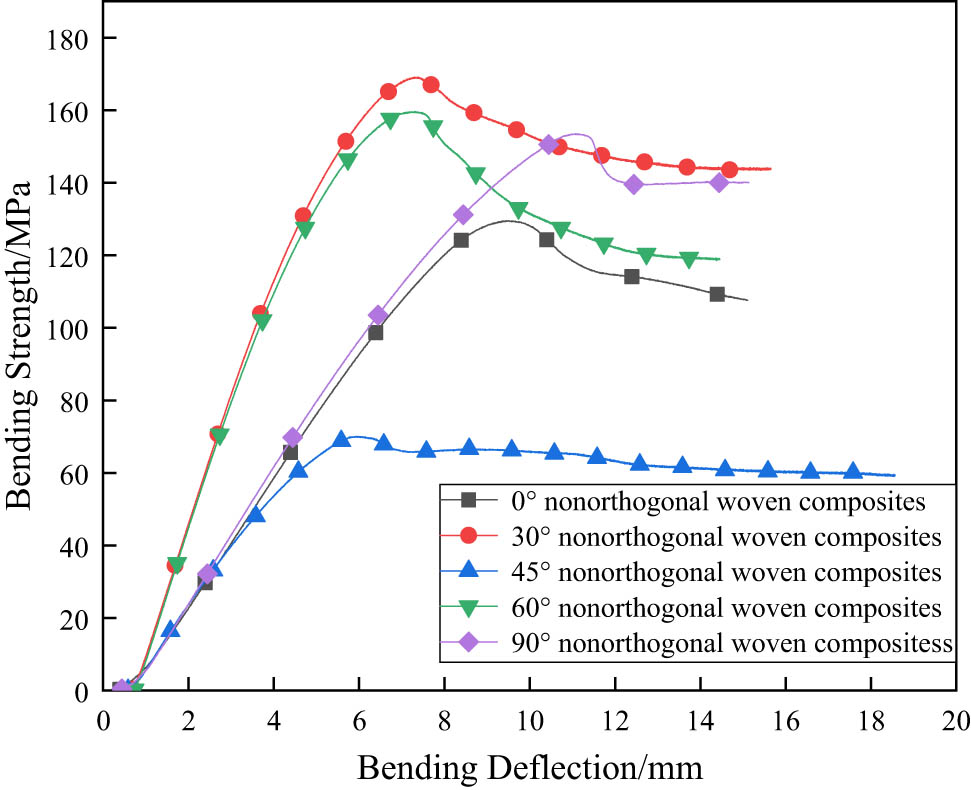

Figure 5 shows the bending characteristic curves of nonorthogonal woven composites, which gave the bending characteristics of the composites at 0°, 30°, 45°, 60°, and 90° warp-weft orientation angles, respectively. Obviously, the bending strength–deflection curves of the nonorthogonal woven composites increased linearly with the change of fiber angle, which was highly related to the fiber orientation in the composites. In the preparation process of nonorthogonal woven composites, the fabrics were cut along the weft direction, which made the weft yarn always along the length of the composite, and the warp yarn is the twill yarn. Therefore, when the composites received an external bending load, the twill yarn only affected the bending resistance of the composites at different degrees, but it did not change the bending characteristics of the composites. Although the bending strength changed, its bending characteristics did not change. As shown in Figure 5, the 30° specimen owns the largest bending strength, which was mainly dependent on the largest warp yarn partition force in the length direction; thus, it can be involved in the resistance of the external bending load. Notably, the bending strength of the 45° specimen was the smallest, but the theoretical value of the 45° specimen should be lower than that of the 30° specimen and higher than that of the other specimens. However, this was not the case; the 45° fiber angle caused the instability of the composite structure, which can easily lead to deformation and failure of the composites. Therefore, the bending strength of the composites with the 45° nonorthogonal woven fabric in the experiment was the smallest.

Bending strength–deflection curves of nonorthogonal woven composites.

3.2 Bending results and discussion

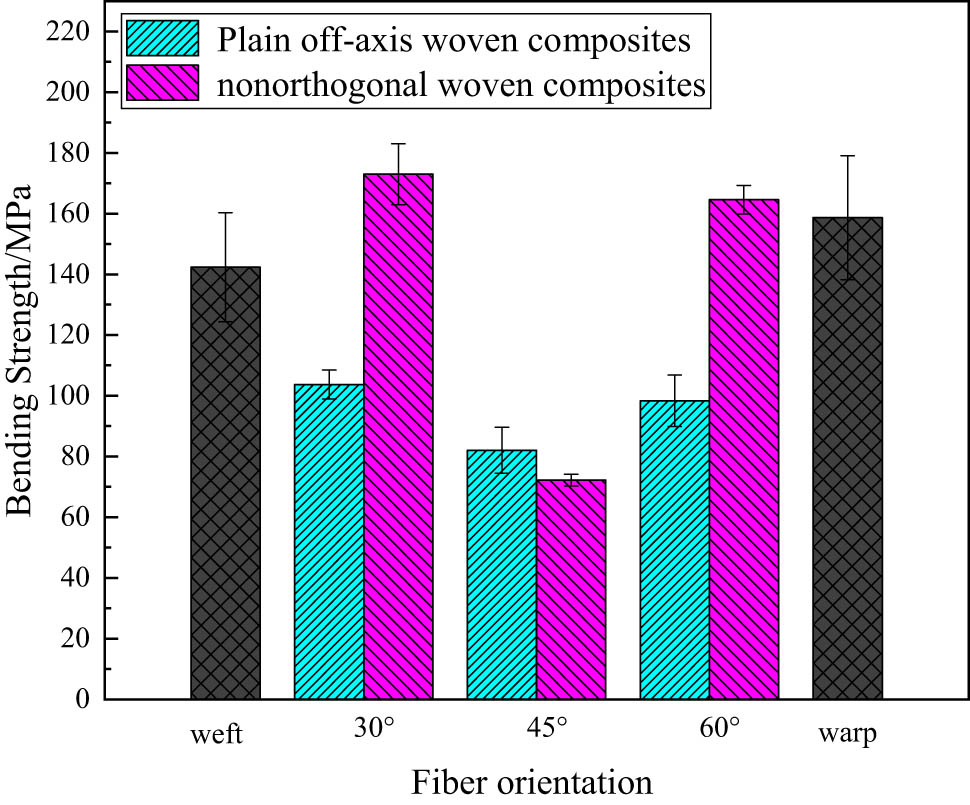

The comparative results of bending strength of plain off-axis woven and nonorthogonal woven composites with different angles are clearly displayed in Figure 6. The result from Figure 6 pointed out that the bending strengths of 30° and 60° nonorthogonal woven composites were 66.9 and 67.4% higher than those of plain off-axis woven composites, respectively, and even 21.5 and 9.0% higher than those of warp-oriented and weft-oriented woven composites, which showed that the nonorthogonal woven composites owned very good bending performance. The bending strength of 45° plain off-axis woven composites and 45° nonorthogonal woven composites was the smallest, evenly smaller than that of the other composites, which was mainly due to the unstable reinforcement structure that aramid fibers 45° arrangement. In addition, the bending strengths of 30° and 60° plain off-axis woven composites are basically the same, which is mainly due to the fact that the warp and weft orientations of 30° and 60° are basically the same, and thus, their bending strength values are basically the same.

Comparative analysis of bending strength.

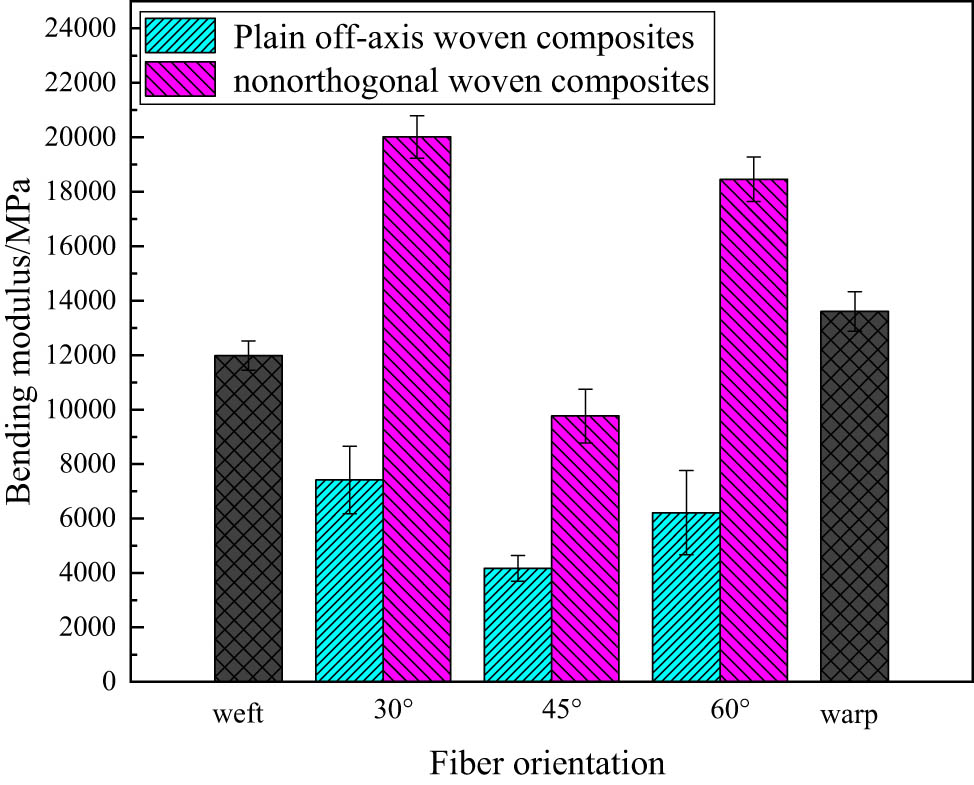

The comparative results of the bending modulus of plain off-axis woven and nonorthogonal woven composites with different angles are clearly displayed in Figure 7. Apparently, the bending modulus of 30°, 45°, and 60°nonorthogonal woven composites is 169.8, 134.1, and 196.9% higher than that of plain off-axis woven composites, respectively, while the bending modulus of 30° and 60° nonorthogonal woven composites is 67.0 and 47.1% higher than that of 30° and 60° plain off-axis woven composites, which prominently showed that the nonorthogonal woven composites owned the excellent bending stiffness. This is mainly related to the different warp-weft interweaving angles, which is consistent with the results of the above-bending strength–deflection curve analysis.

Comparative analysis of bending modulus.

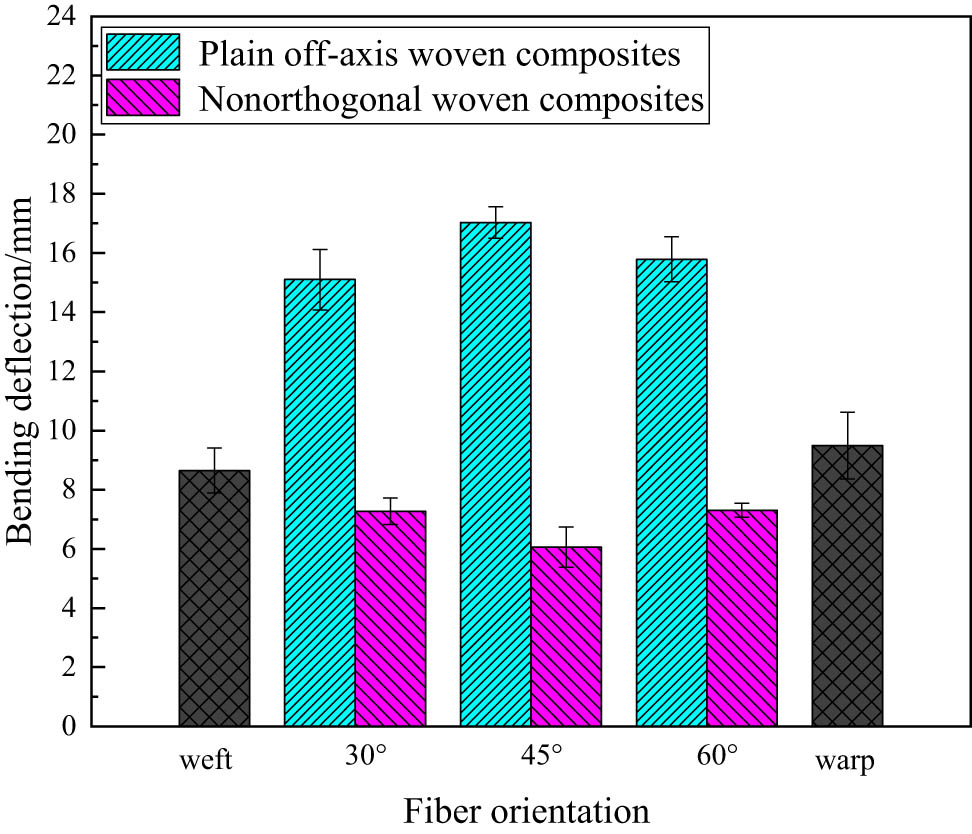

The comparative results of bending deflection of plain off-axis woven and nonorthogonal woven composites with different angles are clearly displayed in Figure 8. The maximum bending deflection of nonorthogonal woven composites was smaller than that of plain off-axis woven composites, which is mainly due to the different fiber orientations along the length of the composites. The above analysis showed that the nonorthogonal woven composites have greater bending stiffness and resist bending deformation compared with the twill-cut woven composites.

Comparative analysis of material bending deflection.

4 Finite element numerical analysis

4.1 Finite element model

In this work, the bending properties of plain off-axis woven and nonorthogonal woven composites were numerically simulated by using the commercial software ABAQUS 6.13. Considering the nonorthogonal layup of these composites, the internal layers experienced complex and variable forces under external loads. Therefore, the model was configured with all layers in the [010] orientation [21,22]. The basic parameters of the internal layers were defined by setting the real constants, as shown in Table 1. The Hashin failure criterion for the composite damage model was chosen, and the model parameters were determined by defining the material anisotropy parameters. “Rigid Model” that was determined by defining the density, elastic modulus, and Poisson’s ratio was selected for the loading head.

Elastic parameters of composite single-layer panels

| Sample | E 1 | E 2 | v 12 | G 12 | G 13 | G 23 |

|---|---|---|---|---|---|---|

| 0-A | 22 | 22 | 0.25 | 0.77 | 5.34 | 5.34 |

| 1.0-A | 22 | 22 | 0.25 | 0.77 | 5.34 | 5.34 |

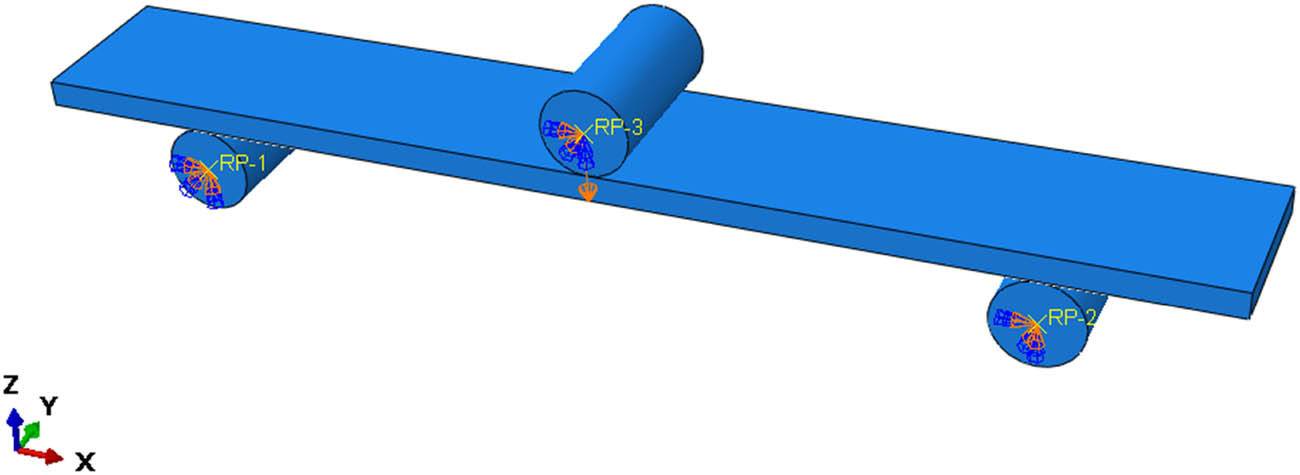

Regarding the bending model, the laminate was placed on two fixed supports with a distance of 96 mm between them; the loading head speed was set at 2 mm/min. The model’s middle part is subjected to a downward displacement. The mesh of the laminate consisted of ordinary shell cells (S4R) using the “Hashin-2D criterion.” The simulation process included the deletion of all failed cells, which was computationally managed using the ABAQUS/Explicit solver, and the results were post-processed. The geometric modeling and boundary conditions are depicted in Figure 9.

Schematic diagram of the finite element model for quasi-static three-point bending simulation.

4.2 Finite element simulation results of three-point bending test

Three-point bending loading finite element simulations were carried out for plain off-axis woven composites and nonorthogonal woven composites, respectively, for a total of 0° (weft), 30°, 45°, 60°, and 90° (warp) of plain off-axis woven composites and 0° (weft), 30°, 45°, 60°, and 90° (warp) of nonorthogonal woven composites. A total of ten types of specimens were planned to be used to examine their bending characteristics and bending stress distribution. The finite element simulation results were compared with the experimental results. The finite element simulation results were compared with experimental data. The bending modulus comparison between these simulations and tests is detailed in Table 2. Table 2 indicates a significant discrepancy for the 0° (weft) and 90° (warp) woven composites, whereas the nonorthogonal woven composites showed good agreement between simulation and experiment. The primary reason is that while the simulation process accounted for the overall performance of individual plies in the laminate, it did not fully consider the coupling effects within the plies, excluding axial stress, due to the significant deformation of the fibers. Therefore, a very large error had been generated for the plain off-axis woven composite.

Comparison results of bending modulus between finite element simulation and test

| Sample | Bending modulus of plain off-axis woven composites (MPa) | Bending modulus of nonorthogonal woven composites (MPa) | ||||

|---|---|---|---|---|---|---|

| Finite element results | Experimental results | Relative error (%) | Finite element results (MPa) | Experimental results | Relative error (%) | |

| 0° | 11982.82 | 12,473 | 4.1 | 11982.82 | 12,473 | 4.1 |

| 30° | 7416.47 | 10,301 | 38.9 | 20012.61 | 20,683 | 3.3 |

| 45° | 4169.37 | 18,898 | 353.2 | 9761.80 | 18,853 | 93.1 |

| 60° | 6215.87 | 10,301 | 65.7 | 18456.77 | 18,814 | 1.9 |

| 90° | 13605.91 | 12,473 | 8.3 | 13605.91 | 12,473 | 8.3 |

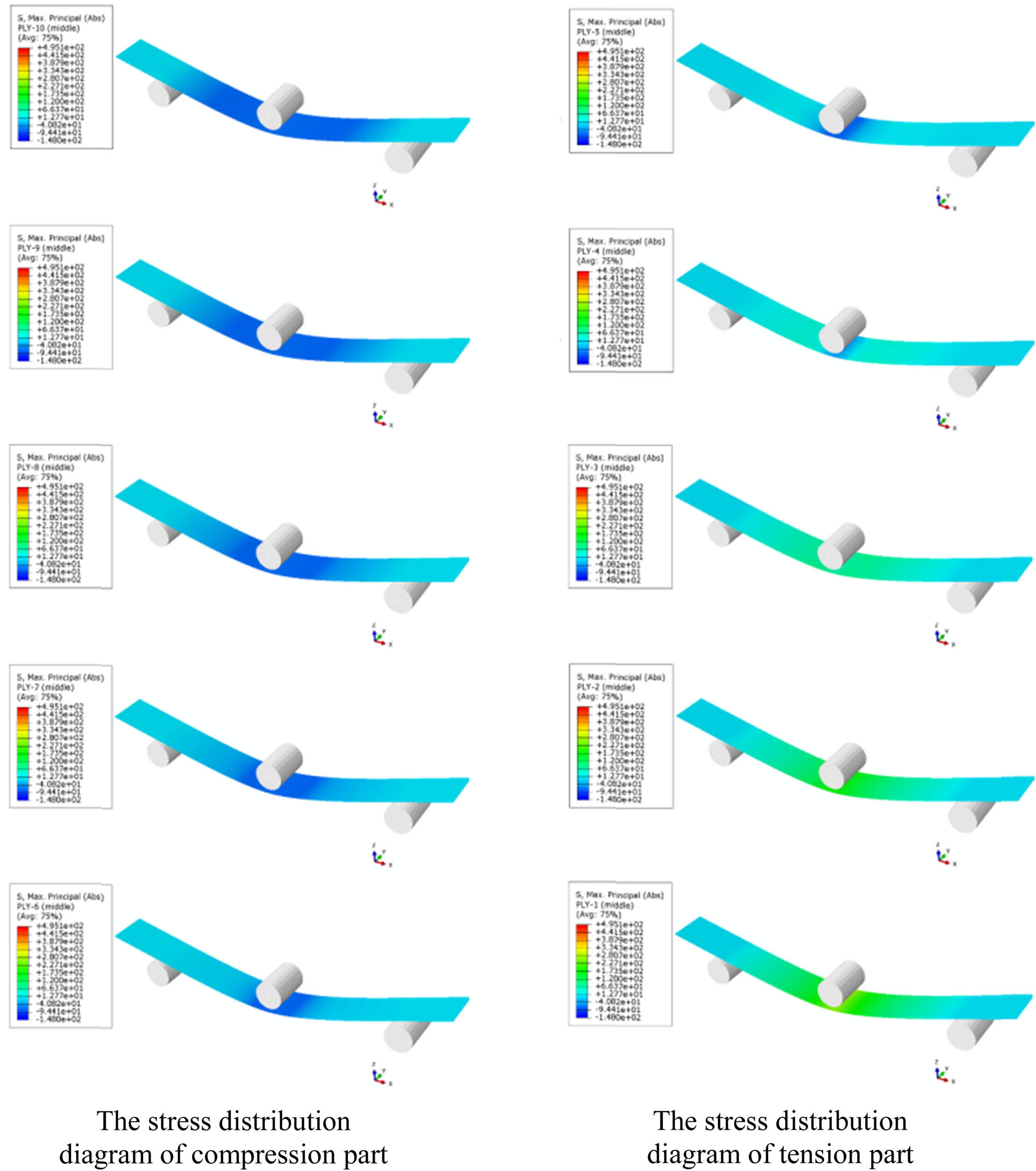

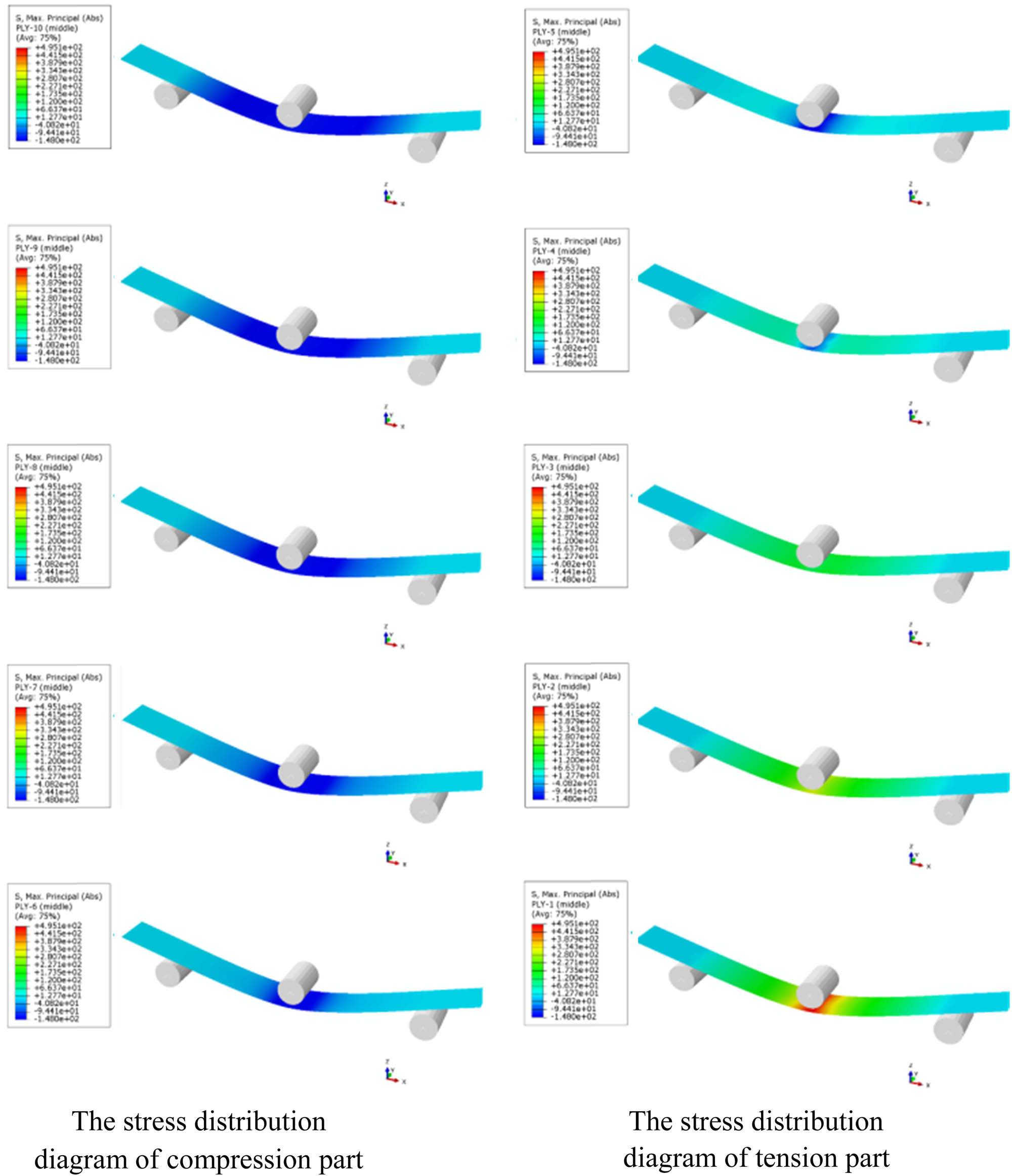

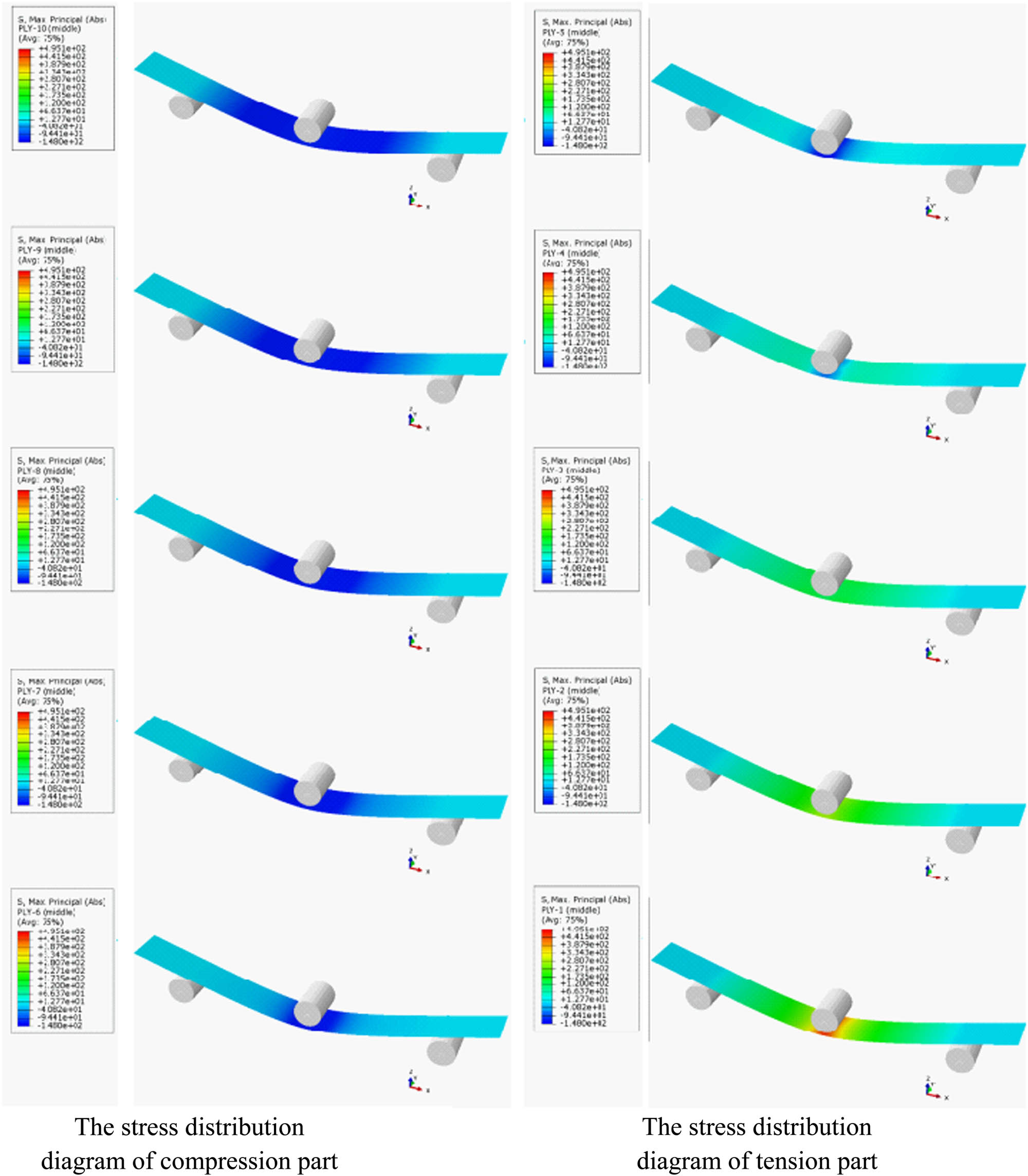

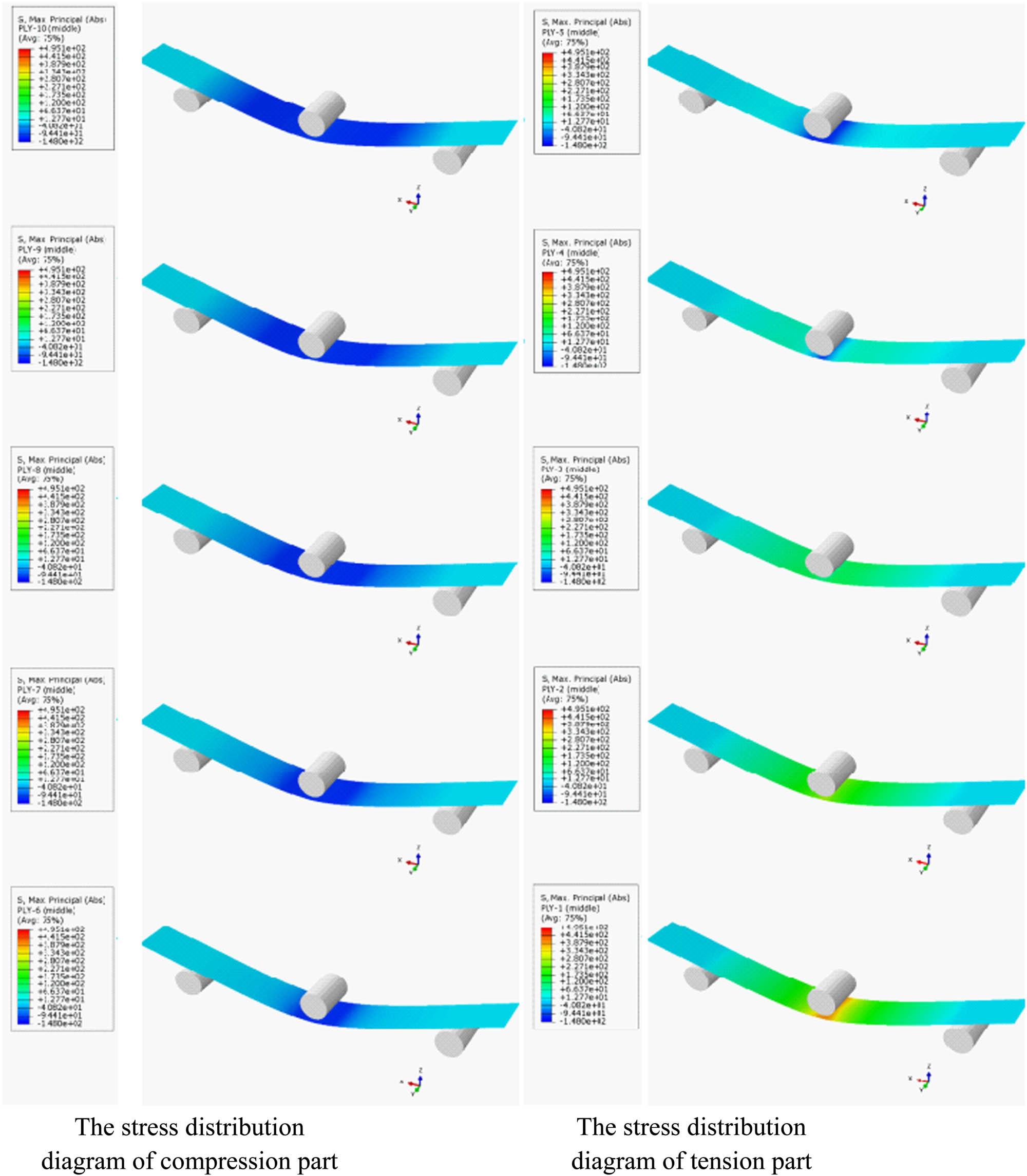

Figures 10–13 show the stress distribution in nonorthogonal woven composites when subjected to an external bending load, with the diagram illustrating the stress from the compression surface to the tension surface. The stress situations of each layer in the composites were shown clearly through the stress distribution diagram. Similarly, 30°, 45°, and 60° nonorthogonal woven composites owned a similar stress distribution state with the 0° and 90° woven composites, which indicated that 30°, 45°, and 60° nonorthogonal woven composites owned the basic characteristics compared with laminated composites. The stress states of the corresponding layers are basically the same, and there was no obvious coupling effect between layers. Even, the first five layers mainly bear compressive stress and the last five layers mainly bear tensile stress from the compression surface to the tension surface. The stress distribution diagram clearly reflects the stress distribution of the composites under external load and provides data support for the internal stress of the composites under external load.

The stress distribution of 0° and 90° woven composites under external bending load.

The stress distribution of 30° woven composites under external bending load.

The stress distribution of 45° woven composites under external bending load.

The stress distribution of 60° woven composites under external bending load.

5 Conclusions

In this work, 30°, 45°, and 60° nonorthogonal woven composites were successfully prepared and the bending characteristics of the materials were investigated. Through the analysis of test results, their linear characteristics were obvious. The bending characteristics of nonorthogonal woven composites were compared with those of plain off-axis woven composites, revealing that both the bending strength and modulus of the nonorthogonal composites were higher. In detail, the bending strengths of 30° and 60° nonorthogonal woven composites were much higher than those of plain off-axis woven composites by 66.9 and 67.4%, and the bending modulus was higher by 169.8 and 196.9%, respectively, which showed that the nonorthogonal woven composites owned good bending properties. In addition, an in-depth finite element analysis of the bending performance of nonorthogonal woven composites was conducted, followed by a detailed stress analysis of the internal plies of the specimens. The numerical results were comparable and, in some aspects, superior to the experimental outcomes. The feasibility study and the remarkable results presented in this article offer a promising strategy for developing new-generation helmet shell materials characterized by high bending properties and a gradient-based design.

-

Funding information: This research was funded by “Tianjin Municipal Education Commission Research Plan Project Achievements: Research on the Construction of Lacquer Art Curriculum System and Talent Cultivation Mode in Arts and Crafts Major (Grant No: 2019SK010).”

-

Author contributions: Yong Zheng: Conceptualization, Funding Acquisition, Supervision; Yexiong Qi: Writing-Original Draft, Writing-Review & Editing, Methodology, Formal Analysis; Xiaoling Qi: Validation, Resources; Ning Sun: Visualization; Runze Shao: Numerical analysis; Miao Li: Investigation; Shiwang Gao: Experimentation.

-

Conflict of interest: Authors state no conflict of interest.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Zahid, B., Jamshaid, H., Waqar Rajput, A, Chen X. (2021). Impact properties of continuously textile reinforced double fabric layered riot-police-helmet-shells. Industria Textila,72,485–490.Search in Google Scholar

[2] Bower, D., Herbert, E., Breedlove, K. M., Lacy, A., Casa, D., Bowman, T. G. (2020). Mechanical characterization of athletic helmet shells. Sports Biomechanics, 23, 241–252. 10.1080/14763141.2020.1837926.Search in Google Scholar

[3] Palomar, M., Belda, R., Giner, E. (2019). Effect of different helmet shell configurations on the protection against head trauma. The Journal of Strain Analysis for Engineering Design, 54, 408–415.Search in Google Scholar

[4] Wu, J. Z., Pan, C. S., Wimer, B. M., Rosen, C. L. (2017). Finite element simulations of the head-brain responses to the top impacts of a construction helmet: Effects of the neck and body mass. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, 231, 58–68.Search in Google Scholar

[5] Dayin, H. (1996). Development of oblique weft. Technical Textiles, 14, 15–16 + 14.Search in Google Scholar

[6] Salman, S. D., Leman, Z., Sultan, M, Ishak, M., Cardona, F. (2017). Effect of kenaf fibers on trauma penetration depth and ballistic impact resistance for laminated composites. Textile Research Journal, 87, 2051–2065.Search in Google Scholar

[7] Rajak, D. K., Pagar, D. D., Menezes, P. L, Linul, E. (2019). Fiber-reinforced polymer composites: manufacturing, properties, and applications. Polymers, 11, 37.Search in Google Scholar

[8] Edwards, C. A., Ogin, S. L., Jesson, D. A., Oldfield, M., Livesey, R. L., James, B. J., et al. (2021). Characterization and ballistic performance of thin pre-damaged resin-starved aramid-fiber composite panels. Textile Research Journal, 91, 2846–2858.Search in Google Scholar

[9] Ahn, H., Kuuttila, N. E., Pourboghrat, F. (2021). Effects of pressure, boundary conditions, and cutting reliefs on thermo-hydroforming of fiber-reinforced thermoplastic composite helmet based on numerical optimization. Journal of Thermoplastic Composite Materials, 34,181–202.Search in Google Scholar

[10] Salman, S. D., Leman, Z., Sultan, M. T. H, Ishak, M. R., Cardona, F. (2016). Ballistic impact resistance of plain woven kenaf/aramid reinforced polyvinyl butyral laminated hybrid composite. BioResources, 11, 7282–7295.Search in Google Scholar

[11] Liang, Y. Z., Chen, X. G., Soutis, C. (2021). Review on manufacture of military composite helmet. Applied Composite Materials, 29, 305–323. 10.1007/s10443-021-09944-5.Search in Google Scholar

[12] Yang, M., Chen, X. (2018). Mouldability analysis and impact performance of 3D aramid angle-interlock fabric panels for ballistic helmets. Journal of Industrial Textiles, 51, 6134S–6152S. 10.1177/15280837211051951.Search in Google Scholar

[13] Li, J. Q., Liang, Y. J., Chen, X. Y. (2000). A primary study on property of the oblique weft fabric and weaving. Journal of Wuhan Textile University, 13, 33–36 + 41.Search in Google Scholar

[14] Lvliang, J., Shusheng, Z., Lihua, L. (2002). Development of wide-angle canvas for transmission V-belt. Rubber Industry, 737–739.Search in Google Scholar

[15] Zhang, B., Tang, C. M. (2019). A method for defect detection of yarn-dyed fabric based on frequency domain filtering and similarity measurement. Autex Research Journal, 19, 257–262.Search in Google Scholar

[16] Guo, W., Zheng, X., Zhang, W., Chen, M., Wang, Z., Hao, C., et al. (2018). Fabric defect detection using salience metric for color dissimilarity and positional aggregation. IEEE Access, 6, 49170–49181.Search in Google Scholar

[17] Yanqin, Z., Yuxiu, C., Yueqing, Q. (2014). Patent No. CN104005156A, (China). Special rapier loom for wide angle cloth.Search in Google Scholar

[18] Yao, G. X., Zhou, H. T., Zhao, L., Qu, C. X., Kuai, D. W. (2017). Study on the tensile properties of wide angle fabric. Cotton Textile Technology, 45(545), 9–11.Search in Google Scholar

[19] Zhang, Z. H., Zhang, D. T., Qian, K., Xu, Y., Lu, J. (2020). Weaving process of wide-angle woven fabrics and their off-axis tensile mechanical properties. Journal of Textiles, 41(413), 27–31 + 44.Search in Google Scholar

[20] GB/T 1449-2005. (2005). Bending performance test method for fiber reinforced plastics. Standards Press of China, Beijing, China.Search in Google Scholar

[21] Karahan, M., Lomov, S. V., Bogdanovich, A. E., Mungalov, D., Verpoest, I. (2010). Internal geometry evaluation of non-crimp 3D orthogonal woven carbon fabric composite. Composites Part A-Applied Science and Manufacturing, 41(9),1301–1311.Search in Google Scholar

[22] Umair, M., Hamdani, S. T. A., Asghar, M. A., Hussain, T., Karahan, M., Nawab, Y., et al. (2018). Study of influence of interlocking patterns on the mechanical performance of 3D multilayer woven composites. Journal of Reinforced Plastics and Composites, 37(7), 429–440.Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry