Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

-

Malik Yonis Hassan Saty

Abstract

The lattice apron-based compact spinning system is a form of pneumatic compact spinning that employs airflow to condense fibres into a bundle, enhancing the yarn’s attributes. To explore the airflow dynamics in pneumatic compact spinning, researchers primarily employ traditional theoretical approaches, experimental measurement techniques, and computational fluid dynamics (CFD) methods. In our previous research, we utilized CFD to observe the airflow patterns in pneumatic compact spinning. In this study, we implemented experimental measurement techniques to assess the impact of a 3D-printed guiding device (B-type) on yarn properties. We tested different fibre types in the condensing zone of the compact spinning system with a lattice apron. We used three types of roving to spin the yarn: pure cotton, cotton/polyester (80/20), and polyester/viscose (65/35). The findings revealed that yarns spun using the guiding device exhibited superior strength, hairiness, and evenness compared to those spun without the device.

1 Introduction

Compact technology is a modified ring-spinning method that can be applied to both short and long staple fibres and provides unique benefits [1,2]. By expanding the capabilities of ring spinning, compact spinning improves the quality of the textiles produced [3,4,5]. This technique is widely recognized as one of the most progressive in the field of ring spinning [1,6,7,8,9,10,11,12]. Because of this, this technology has drawn a lot of interest since it was first shown to the market at ITMA-Paris in 1999. Since then, many spinning mills all around the world have adopted these tools as standard equipment [1]. The yarn formation has set new criteria by the technology of compact spinning [13,14,15,16,17,18,19]. Because of the elimination of the spinning triangle, the assembly of the yarn created by the compact technic is dissimilar from using conventional ring spinning. The novel perspectives led by the technology of compact spinning have shown their value in textile operations, from producing yarns to the ultimate steps [20,21,22,23,24,25]. The goal of compact spinning, as a new spinning mechanism, is to create outstanding yarns [26,27,28,29,30,31].

Compact spinning condenses the fibres pneumatically or mechanically. Pneumatic compact spinning is dominant nowadays due to the yarns produced from it having the best quality compared to mechanical compact spinning [32]. Pneumatic compact spinning is generally categorized into two types: roller type and lattice apron type [33]. Currently, the most popular compact spinning system is the one that uses a lattice apron; it contributes to up to 95% of the spinning market. As a result, both industry and academic research have shown a great deal of interest in and attention to compact spinning with a lattice apron [34]. Research endeavours aimed at delving deeper into the compact spinning system have concentrated on understanding the airflow domain, which is thought to be crucial in characterizing the yarn manufacturing process [26,34,35]. In order to investigate the flow field in pneumatic compact spinning, researchers mainly focus on traditional theoretical methods, experimental measurement methods, and computational fluid dynamics (CFD) methods [11,31,36]. Experimental investigations were conducted by Altas and Kadoğlu [22] to compare the physical properties of spun yarns and knitted textiles produced using both a mechanical compact spinning machine and the traditional ring spinning system. The analysis examined and compared the characteristics of yarns created through mechanical compaction, pneumatic compaction, and conventional ring spinning techniques. Based on the findings, it was determined that yarns produced by the pneumatic compact spinning method exhibited the highest quality. Yilmaz and Usal [28] conducted a study to examine the characteristics of yarns produced by various spinning methods. The study utilized traditional ring, compact, and compact jet spinning devices. The investigation revealed that yarns manufactured using the compact jet system had improved property values in comparison to those produced by the conventional ring and compact systems. Cheng and Yu [21] compared the characteristics of cotton yarns made with a traditional ring spinning machine and a Rieter ComforSpin® K40 compact spinning machine. The objective of their investigation was to comprehend the structural variations and underlying principles of the two approaches. The results showed that yarns spun with the compact spinning process were of higher quality with respect to evenness, hairiness, and tensile strength.

In current years, the use of CFD to solve flow-related problems in the textile industry is steadily increasing [37]. Previous studies have utilized CFD methods to analyse and investigate pneumatic compact spinning processes [38,39]. Han et al. [40,41] concentrated on examining the condensation impacts of three different suction slot designs: V-shaped, parallel-shaped, and obliquely parallel-shaped. Utilizing simulations, the researchers investigated the fibre trajectories and flow field within the condensing zone of a compact Siro spinning machine fitted with a lattice apron.

The findings suggested that the optimization of the slot shape could lead to a significant improvement in the possessions of compact spun yarn. Liu and Liu [42] conducted an examination of the 3D flow field characteristics across four different pneumatic compact spinning system configurations. To accomplish this, they utilized AutoCAD software to construct 3D models of the numerous condensing zones and conducted numerical simulations to evaluate the flow field within these zones. The study findings revealed that the type of roller lattice apron utilized has a principal influence on the spreading of the flow field, which in turn significantly impacts the properties of the yarn within the condensing zone. In our previous work [34], three unique guiding devices (A-type, B-type, and C-type) were created to explore the impact of guiding devices on airflow characteristics and yarn properties within the condensing zone of compact spinning using a lattice apron. Through numerical flow field simulations, the underlying concept for designing the guiding device was identified as minimizing negative pressure dispersion and enhancing the efficiency of airflow utilization. Furthermore, the utilization of a guiding device demonstrates a substantial enhancement in the condensing zone’s active range of air velocity, leading to considerable benefits in fibre condensing when compared to the absence of such a device. The analysis of airflow revealed a significant negative pressure in the air-suction flume area, while the central zone exhibited high velocity on its centreline. According to the results obtained, the B-type guide device demonstrated optimal performance in terms of achieving the best quality outcomes for tensile strength, hairiness, and yarn evenness.

The use of 3D printing to fabricate the guiding device provides several advantages over traditional manufacturing methods. The design flexibility of additive manufacturing enables highly customized geometries and material selection, allowing for an optimized form factor with a reduced size. Furthermore, the customized geometry can improve ergonomics and user comfort compared to standard designs. Depending on production volumes, 3D printing may also result in lower manufacturing costs. Additionally, the 3D-printed guiding device offers enhanced customizability, miniaturization, ergonomics, and potential cost savings over conventional approaches. In this study, we investigated the effect of a 3D-printed guiding device (B-type) on yarn properties using experimental measurement methodologies. To achieve this, diverse fibre varieties were spun within the condensing zone of a compact spinning system equipped with a lattice apron. The sections that follow describe the experimental procedures for spinning, yarn spinning, yarn testing, and yarn analysis. In conclusion, the study draws a comprehensive conclusion based on the obtained results.

2 Materials and method

2.1 Materials

The objective of this study was to determine the impact that a 3D-printed guiding device (B-type) has on yarn qualities in the condensing zone of a compact spinning frame with a lattice apron when spinning different fibre types. This was accomplished by spinning the yarn from a combination of three distinct rovings: (a) 100% cotton roving, (b) a blend of cotton and polyester fibre (80/20) roving, and (c) a blend of polyester and viscose (65/35). The linear density of the polyester/viscose blend roving was 538 tex, whereas the pure cotton and cotton/polyester fibre blend rovings weighed 535 tex.

2.2 Method

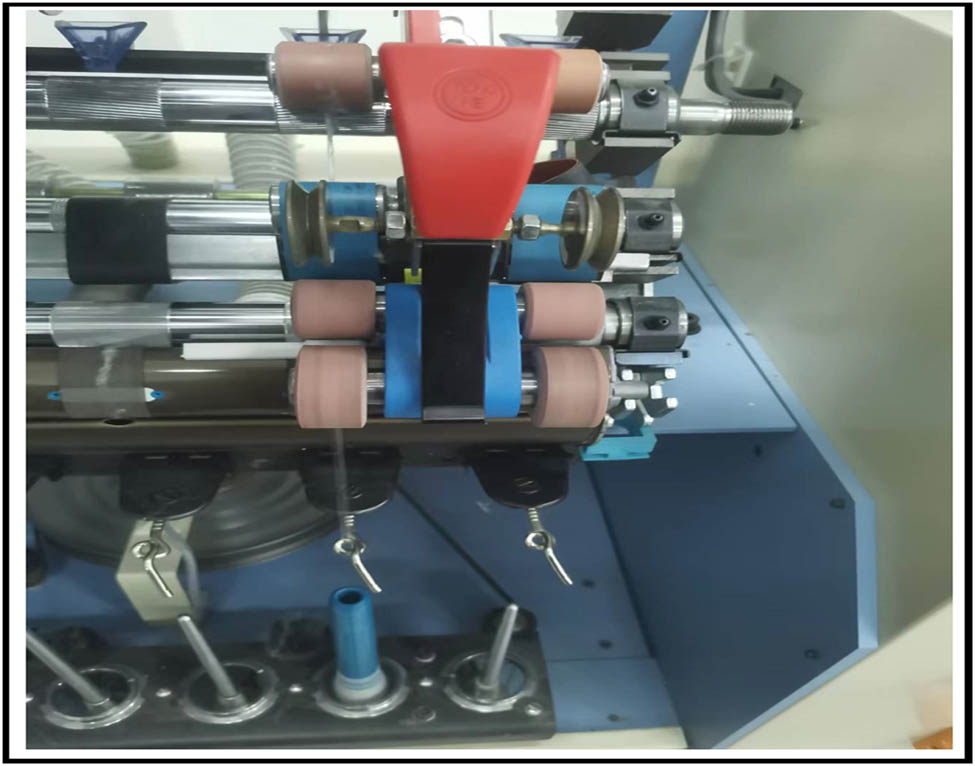

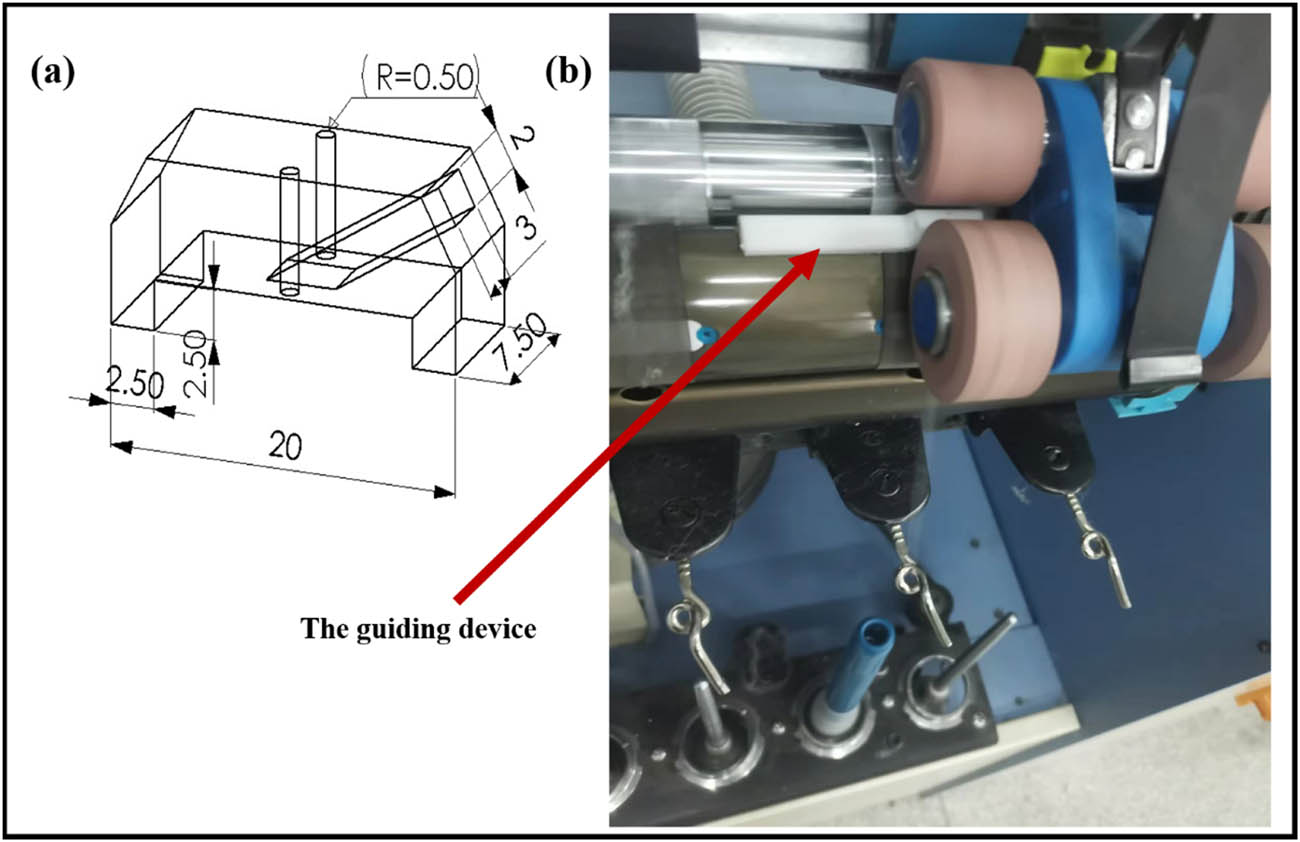

This section examines the use of a compact spinning system with a lattice apron to produce yarns, with the goal of investigating the effects of a guiding device on diverse fibre types. The top view of the drafting system for the compact spinning system with a lattice apron, which was utilized in this experimental work, is depicted in Figure 1. The specific B-type prototypes, chosen based on the simulation findings, were then 3D printed to enable further experimental evaluation, as shown in Figure 2(a) [34]. Figure 2(b) illustrates the side angle of the condensing zone with the guiding device. The specifics of the spinning parameters are presented in Table 1.

Top-down view of the drafting system in the compact spinning system equipped with a lattice apron.

(a) Guiding device, with all dimensions provided in millimetres. (b) The side perspective view of the condensing zone incorporating the guiding device.

Details the spinning procedure parameters utilized in this study

| Linear density (tex) | Spindle speed (rpm) | Negative pressure (Pa) | Twist (turn per meter) |

|---|---|---|---|

| 29.2 | 10,000 | 3,000 | 630 |

3 Results and discussion

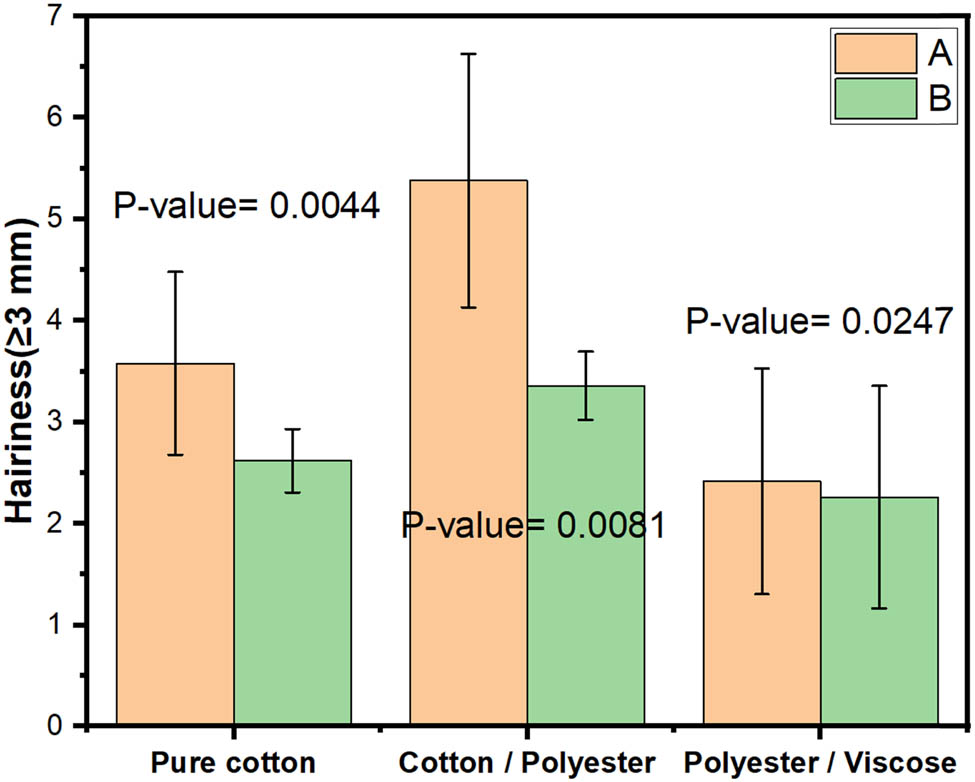

The following testing process was used to evaluate the spun yarns. To get accurate results, we conditioned five bobbins of yarn for at least 48 h under our lab’s regular conditions (65% RH and 20.2% C). Spun yarns were then evaluated based on their hairiness, evenness, and breaking strength. To maintain consistency in performance, the same spindle was used to produce all of the 29.2 tex yarns. Yarn hairiness was evaluated by taking ten measurements on each bobbin yarn sample using a YG172A hairiness tester running at a speed of 30 m/min. The hairiness for that specific bobbin yarn was calculated as the average of these ten measurements. By averaging the hairiness ratings of the five bobbin yarns, the equivalent hairiness of the spun yarn was determined; the empirical findings are presented in Figure 3. According to simulation results from our previous work [34], increasing negative pressure leads to a reduction in hairiness due to the ensuing increase in total airflow velocity, which eliminates the spinning triangle (Figure 3). In contrast, the use of a guiding device that generates a moderate level of negative pressure produces optimal hairiness outcomes. This is attributed to the guiding device’s single, angled side opening, which enables airflow from the side and increases the transverse condensing force. This, in turn, reduces fibre width. Consequently, the flow velocity component appears to be advantageous in reducing yarn hairiness.

Hairiness characteristics of the spun yarns. (A) Yarns produced without a guiding device. (B) Yarns produced using the guiding device.

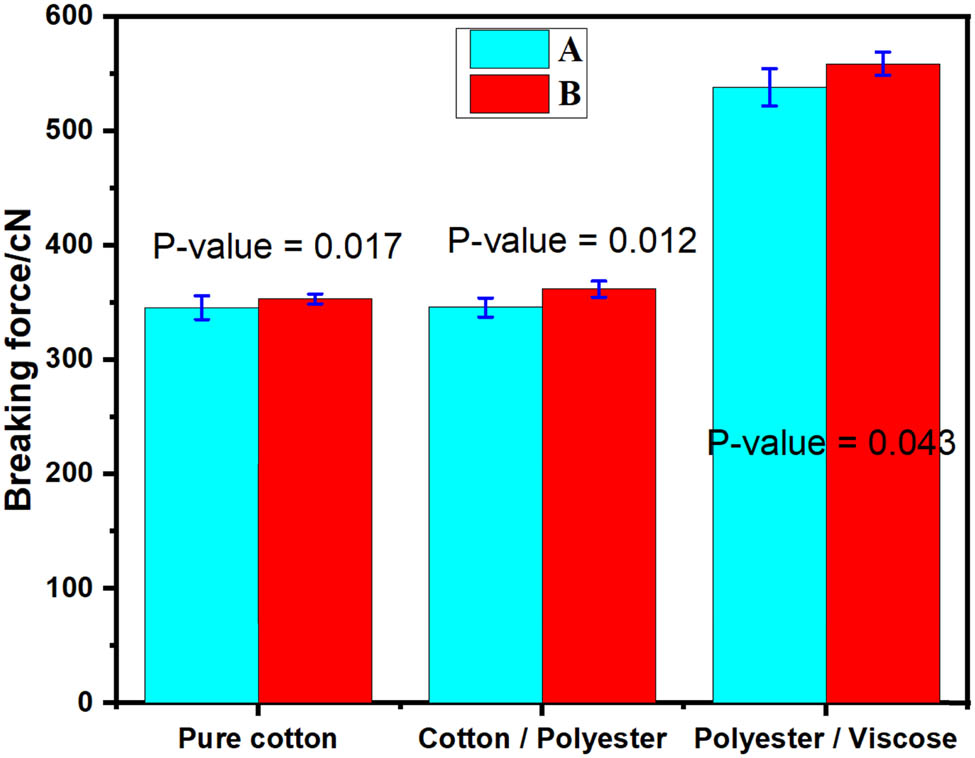

The breaking force of the yarn was calculated by running ten tests at a speed of 500 mm/min and a pre-tension of 0.5 cN on a YG020 fully automatic single yarn strength tester in line with the ASTM D2256 international standard. The breaking force for that particular bobbin yarn was calculated by taking the average of these ten measurements. Averaging the breaking force values of the five bobbin yarns yielded the matching breaking force of the spun yarn, and the empirical findings are presented in Figure 4. Figure 4 and the analysis of variance (ANOVA) result indicate that using a guiding device improves the breaking force of yarn. This is because the increased total airflow velocity eliminates the spinning triangle and twists the unbound fibres. This additional twist is created by the airflow in the condensing zone thanks to the guiding device. As a result, the yarn becomes more compact, with improved fibre configuration in the yarn’s body, resulting in improved regularity and a greater potential for increasing yarn strength.

Breaking force (in cN) of the spun yarns. (A) Yarns produced without a guiding device. (B) Yarns produced using the guiding device.

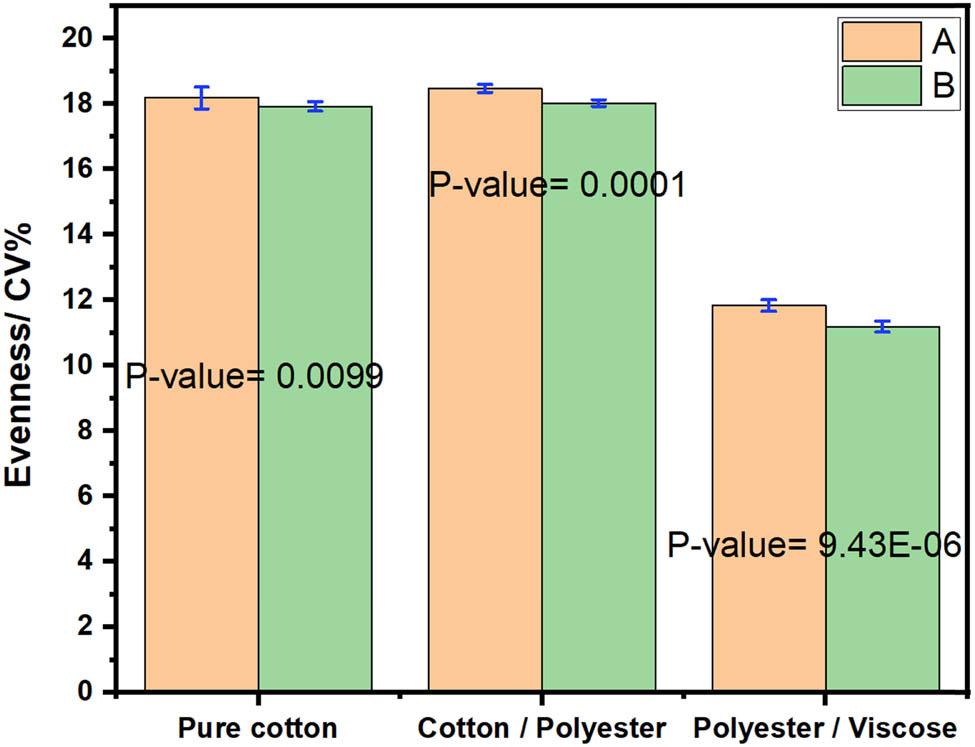

The yarn evenness was assessed using a YG136 evenness tester operating at a speed of 200 m/min, in accordance with the D1425/D1425 M-14 (ASTMD3822/D3822M-14, 2014) standards. The corresponding evenness of the spun yarn was obtained by averaging the evenness values of the five bobbin yarns, and the measured results are shown in Figure 5. Figure 5 and the ANOVA result show that utilizing the guiding device improves yarn evenness due to the increase in the overall air flow velocity, which helps to produce the additional twist. As a result of reducing border fibre transfer, the fibre distribution in the yarn body became more consistent, improving yarn evenness. The use of the guiding device facilitated the generation of additional twists, which freed up the fibres and reduced their width. This, in turn, contributed to the improved evenness.

Evenness characteristics of the spun yarns. (A) Yarns produced without a guiding device. (B) Yarns produced using the guiding device.

The yarn parameter’s ANOVA test findings (p-value). The variance is important when p-value ≤ 0.05. As observed from Figures 3–5, the p-value is less than 0.05 when using the guiding device compared to without a guiding device. To end, the data suggest that the difference is statistically significant. In other words, utilizing the guiding device can enhance the breaking force, reduce hairiness, and improve the evenness of the material.

4 Conclusions

Using an experimental measurement technique, we analysed the result of the 3D-printed guiding device (B-type) on textile properties when spinning different fibre types within the condensing zone of a compact spinning machine with a lattice apron. The use of the guiding device resulted in substantially greater measured strengths, hairiness, and evenness than those obtained without the guiding device. This is due to the fact that the guiding device helps to centralize airflow around the air vacuum flume above the surface, resulting in a more stable and constant flow field that encourages fibre condensation. Without a guiding device, airflow is diffused and less efficient for negative pressure applications. The experimental results are qualitatively consistent with previous simulation studies [34]. The incorporation of a lattice apron in conjunction with a 3D-printed guiding device represents a novel approach in this work. The lattice apron structure is designed to provide enhanced control and guidance of the yarn path, while the 3D-printed guiding device component helps to precisely direct the yarn flow through the spinning system. By integrating these two elements, this work achieves improved yarn quality and processing efficiency compared to without using guiding device methods.

Acknowledgements

This work was financially supported by Open Project Program of Anhui Engineering and Technology Research Center of Textile, Anhui Province College Key Laboratory of Textile Fabrics (2021AETKL08), Advanced Fiber Materials Engineering Research Center of Anhui Province (2023AFMC14), the Science and Technology Project of Wuhu City (2022yf59), and preparation of yarns based on different spinning systems (S022023008).

-

Author contributions: Malik Yonis Hassan Saty wrote the original draft and was responsible for conceptualization. Ibrahim Abdalla, Ahmed Elhassan, Amjad Farooq, and Bismark Sarkodie were responsible for the conceptualization, methodology, formal analysis, investigation, and data curation. Yong Wang contributed to the conceptualization, methodology, formal analysis, investigation, and data curation. Zhenzhen Xu and Jinmei Du contributed to the conceptualization, review and editing of the manuscript, and supervision. All authors played key roles throughout the research and writing process.

-

Conflict of interest: The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

References

[1] Çelik, P., Kadoglu, H. (2004). A research on the compact spinning for long staple yarns. Fibres & Textiles in Eastern Europe, 12(4), 48.Search in Google Scholar

[2] Zheng, S., Cheng, L., Liu, S. (2011). Model of the yarn twist propagation in compact spinning with a pneumatic groove. Fibres & Textiles in Eastern Europe, 19(1), 84.Search in Google Scholar

[3] Jackowski, T., Sieradzki, K. (2007). Quality of wool-type compact yarns from twisted and rubbed roving. Fibres & Textiles in Eastern Europe, 15(3), 62.Search in Google Scholar

[4] Clapp, D. (2001). Suessen elite ring spinning evaluation. In 14th EFS® System Conference North Carolina.Search in Google Scholar

[5] Khurshid, M. F., Abbas, A., Aslam, S., Ali Hamdani, T., Ali, U., Fiaz, H. (2017). Comparative analysis of siro yarn properties spun on ring and pneumatic compact spinning systems. Industria textilă, 6, 245–249.10.35530/IT.068.04.1383Search in Google Scholar

[6] Basal, G., Oxenham, W. (2006). Comparison of properties and structures of compact and conventional spun yarns. Textile Research Journal, 76(7), 567–575.10.1177/0040517506065591Search in Google Scholar

[7] Goswami, B. (1998). New technology challenges conventional spinning systems. ATI, 27(12), 69–70.Search in Google Scholar

[8] Kampen, W. (2000). The advantages of condensed spinning. Melliand Textilberichte International Textile Reports, 81(4), E 58.Search in Google Scholar

[9] Meyer, U. (2000). Compact yarns: Innovation as a sector driving force. Melliand International, 6(2), 22–25.Search in Google Scholar

[10] Krifa, M., Ethridge, D. (2003). Compact ring spun yarn: An examination of some productivity issues. Textile Topics, 2, 2–8.Search in Google Scholar

[11] Liu, X., Liu, W., Zhang, H., Su, X. (2015). Research on pneumatic compact spun yarn quality. The Journal of The Textile Institute, 106(4), 431–442.10.1080/00405000.2014.925198Search in Google Scholar

[12] Elmessiry, M., Hosny, N., Mohamed, A. (2012). Optimization of specific energy consumption for compact-spun yarns Indian Journal of Fibre & Textile Research, 37(1), 34–38.Search in Google Scholar

[13] Omeroglu, S., Ulku, S. (2007). An investigation about tensile strength, pilling and abrasion properties of woven fabrics made from conventional and compact ring-spun yarns. Fibres & Textiles in Eastern Europe, 15(1), 39–42.Search in Google Scholar

[14] Yilmaz, D., Göktepe, F., Göktepe, Ö., Kremenakova, D. (2007). Packing density of compact yarns. Textile Research Journal, 77(9), 661–667.10.1177/0040517507078796Search in Google Scholar

[15] Artzt, P. (1999). Short staple spinning on the way to new yarn structures and better raw material utilisation. International Textile Bulletin, 45(4), 16–23.Search in Google Scholar

[16] Beceren, Y., Nergis, B. U. (2008). Comparison of the effects of cotton yarns produced by new, modified and conventional spinning systems on yarn and knitted fabric performance. Textile Research Journal, 78(4), 297–303.10.1177/0040517507084434Search in Google Scholar

[17] Abou-Nassif, G. A. (2014) A comparative study between physical properties of compact and ring yarn fabrics produced from medium and coarser yarn counts. Journal of Textiles, 2014(1), 569391.10.1155/2014/569391Search in Google Scholar

[18] Haleem, N., Wang, X. (2015). Recent research and developments on yarn hairiness. Textile Research Journal, 85(2), 211–224.10.1177/0040517514538692Search in Google Scholar

[19] Yang, J. P., Fu, T., Wang, J. (2011). Analysis on the characterization of the twist insertion level and its effect of the compact and ring spun yarns. Journal of Donghua University (English Edition), 28, 252–254.Search in Google Scholar

[20] Yeşilpınar, S. (2006). Analysis of the performance of sewing threads manufactured from conventional and compact ring-spun yarns. Fibres & Textiles in Eastern Europe, 14(2), 20–23.Search in Google Scholar

[21] Cheng, K., Yu, C. (2003). A study of compact spun yarns. Textile Research Journal, 73(4), 345–349.10.1177/004051750307300412Search in Google Scholar

[22] Altas, S., Kadoğlu, H. (2012). Comparison of conventional ring, mechanical compact and pneumatic compact yarn spinning systems. Journal of Engineered Fabrics & Fibers (JEFF), 7(1), 87–100.10.1177/155892501200700110Search in Google Scholar

[23] Mavruz, S., Ogulata, R. T. (2008). Statistical investigation of properties of ring and compact yarns and knitted fabrics made of these kinds of yarns. Tekstil ve Konfeksiyon, 18(3), 197–205.Search in Google Scholar

[24] Brunk, N. (2003). Elitwist - A compact yarn for superior demands, Spinnovation, 19, 17–22.Search in Google Scholar

[25] Stalder, H. (2000). Ring-spinning advance, Textile Asia, 31(3), 43–46.Search in Google Scholar

[26] Zhuan Yong, Z., Long Di, C., Zhi Hong, H. (2009). A numerical approach to simulate fiber motion trajectory in an airflow field in compact spinning with a perforated drum. Textile Research Journal, 80(5), 395–402.10.1177/0040517509343815Search in Google Scholar

[27] Patil, N., Raichurkar, P., Mukherjee, S., Anjane, M. S., Parsi, R. (2011). To study the influence of different compact systems and non-compact system on yarn quality. www.fibre2fashion.com.Search in Google Scholar

[28] Yilmaz, D., Usal, M. R. (2011). A comparison of compact-jet, compact, and conventional ring-spun yarns. Textile Research Journal, 81(5), 459–470.10.1177/0040517510385174Search in Google Scholar

[29] Fu, T., Yang, J., Cheng, G., Chen, N., Qiu, Y. (2017). Mechanical modeling of an arc-shaped suction slot for compact spinning and analysis of additional twists. Textile Research Journal, 88(21), 2499–2505.10.1177/0040517517723029Search in Google Scholar

[30] Abdul, S., Sandip, J. (2013). Properties evaluation of cotton ring and compact spun yarns after scouring and bleaching process. Journal of Textile Science & Engineering, 3(3), 1.10.4172/2165-8064.1000139Search in Google Scholar

[31] Ma, H. C., Cheng, L. D., Yan, G. X., Xu, S. P. (2014). Studies of negative pressure and cleaning condition effects on gathering for ramie compact spinning with a suction groove. Fibres & Textiles in Eastern Europe, 3(105), 54–57.Search in Google Scholar

[32] Saty, M. Y., Akankwasa, N. T., Wang, J. (2022). Numerical simulation and analysis of airflow in the condensing zone of compact spinning with lattice apron. Autex Research Journal, 22(3), 258–263.10.2478/aut-2021-0018Search in Google Scholar

[33] Demir, M., Kilic, M., Sayin, S., Kiral, Z., Balduk, F., Denge, K. K. (2021). Design of three-strand compact spinning system and numerical flow-field simulation for different structures of air-suction guides and suction inserts. Textile Research Journal, 91(15–16), 1795–1814.10.1177/0040517520987521Search in Google Scholar

[34] Saty, M. Y. H., Akankwasa, N. T., Wang, J. (2020). Three-dimensional simulation and experimental investigation of three-dimensional printed guiding devices on lattice-apron compact spinning. Textile Research Journal, 91(11–12), 1389–1398.10.1177/0040517520982586Search in Google Scholar

[35] Zhang, X., Zou, Z., Cheng, L. (2010). Numerical study of the three-dimensional flow field in compact spinning with inspiratory groove. Textile Research Journal, 80(1), 84–92.10.1177/0040517509105601Search in Google Scholar

[36] Su, X., Liu, X., Liu, X. (2018) Numerical simulation of flow field in the pneumatic compact spinning systems using Finite Element Method. International Journal of Clothing Science and Technology, 30(3), 363–379.10.1108/IJCST-11-2017-0180Search in Google Scholar

[37] Akankwasa, N. T., Lin, H., Wang, J. (2017). Evaluation of the dual-feed rotor spinning unit based on airflow dynamics and blended yarn properties. Journal of the Textile Institute, 108(11), 1–12.10.1080/00405000.2017.1305866Search in Google Scholar

[38] Saty, M. Y. H., Akankwasa, N. T., Wang, J. (2021). A novel compact spinning with lattice apron achieved through airflow simulations. Journal of Textile Engineering, 67(4), 73–76.10.4188/jte.67.73Search in Google Scholar

[39] Fu, T., Zhang, Y., Akankwasa, N. T., Chen, N., Lin, H. (2021). Study on the model of semi-open-end twist in compact spinning with lattice apron. Textile Research Journal, 91(5–6), 467–479.10.1177/0040517520942545Search in Google Scholar

[40] Han, C., Gao, W., Chen, L. (2020). Numerical simulation of the condensing effect of different suction slots on fiber strands in a compact siro spinning machine with lattice apron. Autex Research Journal, 20(1), 1–10.10.1515/aut-2018-0058Search in Google Scholar

[41] Han, C., Wei, M., Xue, W., Cheng, L. (2015). Numerical simulation and analysis of airflow in the condensing zone of compact-siro spinning. Textile Research Journal, 85(14), 1506–1519.10.1177/0040517514561924Search in Google Scholar

[42] Liu, X., Liu, X. (2015). Numerical simulation of the three-dimensional flow field in four pneumatic compact spinning using the Finite Element Method. Textile Research Journal, 85(16), 1712–1719.10.1177/0040517514553876Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry