Abstract

Fabric strength plays a crucial role in determining and influencing all other performance attributes of textiles. Therefore, considering the strength of the fabric becomes essential when choosing the appropriate textile for a specific purpose. This article presents an experimental study that focusses on the properties of 100% polyester fabrics. To conduct this study, we created ten fabrics with different weave structures, resulting in a total of 200 samples for tensile strength testing. Moving on to the second phase, we analysed the physical and constructional characteristics of the fabrics, including the number of warp and weft threads, warp and weft density, and weight. This analysis was carried out based on the weave structures. Additionally, we performed tensile strength tests in both warp and weft directions to examine the mechanical properties of the fabrics. Finally, a statistical analysis was performed to determine the impact of the weave structures on the tensile strength of the fabrics.

1 Introduction

Fabrics are becoming an indispensable part of daily life. Contrary to past centuries, when textiles were merely used for clothing, today they are used for several purposes. Textiles should generally meet standards for strength, colour fastness, beauty, and other qualities. These characteristics are essential for daily use.

Fabric is assessed based on six primary criteria, which include the materials used for warp and weft, the count of warp and weft threads, the density of warp and weft, the type of weave used, the adjustment of the tension of warp and weft threads on the loom, treatments and finishes [1,2,3,4,5], the research conducted in these articles offers valuable insights into the intricate relationships between weave parameters, fabric structure, and the mechanical properties of woven fabrics. By investigating factors such as tear strength, drapeability, shear characteristics, and compressional properties, these studies contribute to a deeper understanding of how design choices in fabric production impact performance attributes. The findings not only provide guidance for optimising fabric properties based on specific requirements, but also pave the way for innovative advancements in textile engineering and product development. These parameters play a significant role in determining the fabric structure. Numerous researchers have examined the assessment of weaving fabric properties, such as air permeability [6,7,8,9], the collective findings of these research articles delve into the critical interplay between woven fabric structure and key performance attributes such as air permeability, moisture management, and structural parameters· Through experimental and theoretical investigations, the studies shed light on how specific constructional parameters influence air and water vapour permeability, thereby impacting the fabric’s breathability and comfort properties. By predicting structural parameters and their correlation with air permeability in cotton woven fabrics, these studies provide valuable insights for enhancing fabric functionality and performance in various applications, contributing to advancements in textile science and design. These research articles collectively contribute to a comprehensive understanding of how various factors influence the mechanical properties of woven fabrics [10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35]. By exploring the effects of weave types, densities, yarn, constructions, and fabric structures on the tearing strength, puncture strength, bursting strength, and tensile strength, as well as investigating the dependence of yarn and fabric strength on structural parameters, and elongation [36,37,38,39], the research described in these articles investigates the complex relationships between fabric properties and structural parameters, highlighting how fabric structure and filament fineness influence the mechanical characteristics of fabrics. By exploring the effects of structural parameters on elongation, these studies provide valuable insights into optimising fabric performance. In addition, studies of the influence of fabric structure on fabric fracture characteristics contribute to a better understanding of how design choices influence the mechanical behaviour of textiles, providing valuable knowledge for fabric development and engineering applications.

To our knowledge, several studies have worked with a practical approach to predict different types of strength: the ability of a material to withstand applied forces without breaking or tearing, tearing strength, which measures the resistance of a textile to tearing when subjected to a force that causes a material to rip apart [18,19,20,21,22,23,24]; puncture strength, which refers to the ability of a material to resist penetration by a sharp object without tearing or rupturing [25,26,27,28,29]; bursting strength, which refers to the ability of a material to withstand pressure without rupturing or bursting [30,31,32,33,34,35]; and finally, tensile strength, the maximum tensile (pulling) force that a material can withstand without breaking [10,11,12,13,14,15,16,17]. Our study focuses only on the tensile strength of 2D.

In 2007, Ünal and Taskin [10] conducted a study to investigate the impact of weave patterns and densities on the tensile strength of fabrics made entirely of polyester. Various types of fabrics were generated, incorporating different warp and weft densities, with focus particularly on plain and twill weaves. However, certain limitations were acknowledged, including the absence of specific sample sizes and concerns about the representativeness of the fabric samples. Furthermore, the measurements were made after the fabrics went through a washing process, which could influence the recorded tensile strength values.

In 2008, Oğulata and Kadem [11] developed an empirical equation to forecast the tensile strength of fabrics composed entirely of cotton. This equation considered factors such as thread count and weave structures. However, the study was limited to plain and twill weaves and did not account for immediate measurements after the weaving process. It was proposed that measurements be conducted after the fabrics went through a double-sided burning process on a cooled cylinder, followed by incineration in a desiccant tank. This approach would enhance comprehension of the fabric’s properties.

Similarly, in the same year, a report from Teli et al. [12] focused on the experimental design and testing of fabrics utilising various yarns, fabric manufacturing techniques, and pick densities. However, the article had certain limitations, as it concentrated exclusively on specific types of yarns and had restricted ranges of warp and weft counts, which affected the precision of strength prognostics.

In 2008, Cernoša and Dimitrovski [13] conducted a study to investigate the influence of weft characteristics, weave patterns, and perpendicular threads on the breaking strength and elongation of woven fabrics. The study revealed that the utilisation of doubled weft yarns increased the breaking strength and elongation in the warp direction. However, limitations were observed, including a confined range of weaves and the intricacy of accurately estimating the effects attributed to less dense structures. In 2010, Sekerden and Celik [14] examined the influence of weft density, weft count, and weave type on the physical and mechanical characteristics of the fabric. However, the investigation mainly focused on the tensile strength of fabric wefts after washing and sanforising, thus disregarding the impact on warp yarns.

In 2011, Malik et al. [15] constructed models to predict the tensile strength of cotton woven fabrics. However, these models were solely validated for plain and twill weaves, thus restricting their applicability to alternative weave structures.

In 2013, Özdemir and Mert [16] carried out a comparative analysis that examined the tensile, bursting, and impact strengths of cell-woven fabrics in contrast to plain-woven fabric. The analysis focused primarily on specific fabric structural parameters and did not investigate other potential factors or variations in yarn materials.

In 2016, Nasrun et al. [17] investigated the impact of weft density on yarn crimps and the tensile strength of 3D angle interlocking woven fabric. However, the study did not specify how many fabric samples were evaluated, which would have increased the statistical significance of the results.

In 2017, Jahan [18] conducted research to find out how various weave configurations affected the mechanical characteristics of woven cotton textiles. Research found certain yarn kinds and weave patterns that improved tear strength, but statistical analysis lacked to determine the significance of the changes detected.

In 2020, Mebrate et al. [19] investigated how loom tension affected the mechanical characteristics of the plain cotton fabric produced. The study’s shortcomings were a small sample size and a tight emphasis on tension, and it was limited to one type of cloth. Ultimately, in 2021, an experimental investigation on the performance characteristics of 100% cotton terry textiles was carried out by Ala [20]. Although the study looked at different fabric structures, it did not examine how different finishing techniques and treatments affected the performance of the fabric, which may have revealed important information for enhancing the fabric’s longevity and quality.

Table 1 presents the review of the various cases carried out by various authors regarding the effect of the six variables indicated in the above table on the tensile strength of the fabric. By examining this table, we can conclude that in all the cases studied, most authors used more than one variable, two, three, or four, depending on the objective of the study. As for current research, we will fix five variables and only change one variable, the structure of the fabrics, the number of structures in this study is 14 in Table 2, consisting of plain, twill, sateen, and some derivatives.

Summary of different studies from 2007

|

Weave patterns used in the experiment

| Fabric code | Weave structures | Weave structures | Weave interlacing coefficient | Average float length thread/intersection |

|---|---|---|---|---|

| 1 | Plain |

|

1.000 | 1.00 |

| 2 | Basket 2-2 |

|

0.500 | 2.00 |

| 3 | Warp-faced twill 3 × 1 right hand |

|

0.625 | 2.00 |

| 4 | Twill 2 × 2 right hand |

|

0.62500 | 2.00 |

| 5 | Warp-faced twill 7 × 1 right hand |

|

0.34375 | 4.00 |

| 6 | Twill 4 × 4 right hand |

|

0.34375 | 4.00 |

| 7 | Warp-faced twill 6 × 2 right hand |

|

0.34375 | 4.00 |

| 8 | 4-end sateen |

|

0.625 | 2.00 |

| 9 | Warp-faced sateen de 8 |

|

0.34375 | 4.00 |

| 10 | Warp-faced sateen de 8 |

|

0.34375 | 4.00 |

2 Methods

Before starting the production of the samples to be used in this study, we adjusted the tension on the VAMATEX weaving machine which turns at a speed of 440 ppm and selected the parameters that will remain unchanged. Raw material: warp yarn lighter colour polyester (300/72) denier and weft yarn yellow colour polyester (300/72) denier, warp density = 26 (threads/cm), weft density = 19 (picks/cm). The fabrics produced will not be subjected to any treatments or finishes. Throughout the study, we manufactured ten types of fabrics, each measuring around 4 m, with various weave structures. All types of weave structures used in this research are shown in Table 2. To establish the impact of the number of intersections between warp and weft threads on the tensile strength of the textile, it is essential to quantify these intersections. To achieve this, the Ashenhurst and Ashenhurst equations will be used to assign numerical values corresponding to the intersections between warp and weft threads. Fabric samples were classified according to their weave pattern in Table 2. The numerical values assigned to the fabric codes indicate the weave type. All weave patterns consist of square unit weaves, ensuring an equal number of interlacing between each warp and weft yarn. This results in the average interlacing of the yarn being equivalent to the number of interlacing. Moreover, the average length of the floats in the warp yarn matches that of the weft yarn.

The average float length F has been calculated according to Ashenhurst’s rule, which proposed the thread-spacing theory enabling us to calculate the average float length for any draught in any yarn using equation (1) [40].

where R 2 (1) is the repeat weft (2) or warp (1), and t 1 (2) is the number of warp or weft intersections in the repeat weave. Subscripts 1 and 2 are used throughout to denote warp and weft, respectively. The weave interlacing coefficient, defined by Galcerán [40], was calculated using equation (2).

where i is the number of interlacing points in the weave repeat, w 1 is the number of ends in the weave repeat, and w 2 is the number of picks in the weave repeat.

After producing different fabrics, we condition them in a standard test atmosphere (temperature T = 20°C ± 2°C and humidity Hr = 65% ± 2%) for 24 h at the ESITH-LEC Expertise and Control Laboratory. Subsequently, we organised, prepared, and cut the necessary test specimens for inspection and analysis.

To better understand the influence of weave structures on fabric tensile strength, we initiated the study by examining changes in the fabric’s physical properties, such as warp and weft densities, mass per m2, warp and weft shrinkage, width (cm), and warp and weft shrinkage.

Once the different samples were produced, we measured the physical and structural properties of the fabrics according to the following standards: Count yarn of the warp and weft: [ISO 2060, November 1994], fabric warp and weft counts: [NF NE 1049-April 1994], fabric mass per m2: [NF G 07 157 NF G 07 150 September 1984], where EN is the European Norm and NF is Norm francaise. From the various fabric analysis carried out and the mean values obtained, we can see that the constitution characteristics of warp and weft densities and mass per m2 vary according to the weave structure in Table 3.

Physical and constructional characteristics mean value of the fabrics

| Weave structures | Count warp yarn (denier) | Count weft yarn (denier) | Warp densities (yarn /cm) | Weft densities (picks/cm) | Weight (g/m²) |

|---|---|---|---|---|---|

| Plain | 300 | 300 | 26.00 | 19.00 | 184.92 |

| Basket 2-2 | 300 | 300 | 26.64 | 19.84 | 188.66 |

| Warp-faced twill 3 × 1 right hand | 300 | 300 | 26.64 | 19.88 | 190.32 |

| Twill 2 × 2 right hand | 300 | 300 | 26.8 | 20.2 | 192.58 |

| Warp-faced twill 7 × 1 right hand | 300 | 300 | 27.00 | 21.2 | 196.76 |

| Twill 4 × 4 right hand | 300 | 300 | 27.6 | 21.4 | 202.34 |

| Warp-faced twill 6 × 2 right hand | 300 | 300 | 27.32 | 21.32 | 199.06 |

| 4-end sateen | 300 | 300 | 26.8 | 19.92 | 190.78 |

| Warp-faced sateen de 8 | 300 | 300 | 27.00 | 21.04 | 195.78 |

| Warp-faced sateen de 8 | 300 | 300 | 27.00 | 21.04 | 195.76 |

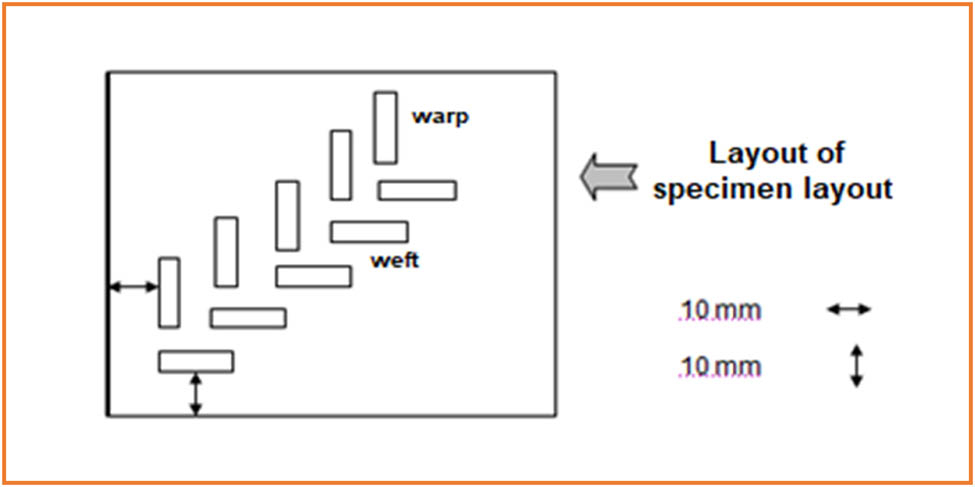

Once the physical properties have been determined, the mechanical properties will be determined using a tensile test in the warp and weft direction. In our study, we measured the tensile strength of the warp and weft yarns incorporated into the fabrics, as well as those extracted from the fabrics, in both the warp and weft directions. The purpose of these measurements was to demonstrate the relationship between fabric tensile strength and weave structures. In the first part, we prepared a total of 200 samples, 100 samples in the warp directions and 100 samples in the weft directions, each measuring 50 mm wide and 300 mm long.

The warp sample locations are distributed across the width of the fabric to avoid having two samples containing the same yarns in both the warp and weft directions.

To prepare the warp thread strips (the warp threads extracted from the fabric), we removed all the weft threads along various samples. Similarly, for the weft thread strips (the weft threads extracted from the fabric), we removed all the warp threads along various samples (Figure 1).

Specimen preparation method.

Second, for determining the tensile properties, we made various adjustments to the dynamometer, including setting the force scale to 500 N, the elongation scale to 100 mm, the speed to 1,000 mm/min, the reference length to 200 mm, and the preload to 5 N. These parameters enabled us to obtain consistent and reliable test measurements.

In the final stage of the experiment, the break tensile strength and elongation at the break were evaluated according to the standard: [ISO 13934-1:2013]. For each weave structure, we conducted five tests on warp yarn strips (warps extracted from fabric) (Figure 2) and five tests on fabric strips (warps embedded from fabric) (Figure 3) in the warp direction. Similarly, we performed five tests on weft yarn strips (weft extracted from fabric) and five tests on fabric strips (weft embedded from fabric in the weft direction under standard test conditions (100 mm fixation length and 1,000 mm/min extension rate) for each weave structure.

Warps and weft extracted from fabric.

Warp and weft not extracted from fabric.

The measurements were statistically analysed (mean value, coefficient of variation) and the results of the mechanical properties of all samples embedded or extracted from the fabrics in the warp and weft directions are summarised in Table 4.

Average value of the warp and weft direction tensile tests

| Warps extracted from fabric | Warps embedded in the fabric | Weft extracted from fabric | Weft embedded in the fabric | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weave structures | Mean value of the breaking force (N) | Mean value of the elongation at break (%) | Coefficient of variation (%) of the breaking force | Coefficient of variation (%) of the elongation at break | Mean value of the breaking force (N) | Mean value of the elongation at break (%) | Coefficient of variation (%) of the breaking force | Coefficient of variation (%) of the elongation at break | Mean value of the breaking force (N) | Mean value of the elongation at break (%) | Coefficient of variation (%) of the breaking force | Coefficient of variation (%) of the elongation at break | Mean value of the breaking force (N) | Mean value of the elongation at break (%) | Coefficient of variation (%) of the breaking force | Coefficient of variation (%) of the elongation at break |

| Plain | 1051.00 | 20.31 | 3.31 | 2.51 | 1165.00 | 23.4 | 3.929 | 3.01 | 764.00 | 20.42 | 0.638 | 2.66 | 840.00 | 24.8 | 1.642 | 2.66 |

| Basket 2-2 | 1062.00 | 19.88 | 1.807 | 2.8 | 1171.00 | 23.93 | 2.466 | 2.7 | 798.00 | 20.04 | 3.84 | 2.91 | 878.00 | 22.12 | 2.57 | 2.91 |

| Warp-faced twill 3 × 1 right hand | 1077.00 | 20.96 | 4.068 | 3.01 | 1175.00 | 23.77 | 3.637 | 1.16 | 807.00 | 22.95 | 4.03 | 3.97 | 887.00 | 22.01 | 3.863 | 3.97 |

| Twill 2 × 2 right hand | 1088.00 | 20.4 | 3.705 | 2.7 | 1186.00 | 23.00 | 3.312 | 3.312 | 818.00 | 20.36 | 3.595 | 2.56 | 899.00 | 20.96 | 4.85 | 2.56 |

| Warp-faced twill 7 × 1 right hand | 1110.00 | 19.91 | 1.43 | 1.67 | 1197.00 | 22.18 | 3.02 | 3.67 | 860.00 | 21.43 | 4.8 | 4.76 | 946.00 | 20.34 | 4.29 | 2.45 |

| Twill 4 × 4 right hand | 1170.00 | 20.79 | 1.263 | 3.15 | 1220.00 | 20.21 | 3.934 | 2.44 | 870.00 | 21.94 | 3.449 | 2.45 | 957.00 | 20.14 | 3.55 | 2.4 |

| Warp-faced twill 6 × 2 right hand | 1112.00 | 20.81 | 1.824 | 2.44 | 1201.00 | 21.63 | 3.705 | 2.51 | 865.00 | 19.8 | 1.776 | 2.7 | 952.00 | 20.14 | 3.705 | 3.705 |

| 4-end sateen | 1080.00 | 20.48 | 1.566 | 2.00 | 1178.00 | 23.66 | 2.696 | 2.89 | 809.00 | 22.52 | 1.959 | 2.2 | 890.00 | 21.52 | 3.85 | 1.89 |

| Warp-faced sateen de 8 | 1106.00 | 21.69 | 2.487 | 2.487 | 1192.00 | 22.5 | 3.664 | 3.14 | 849.00 | 22.29 | 1.917 | 2.88 | 933.00 | 20.54 | 4.172 | 2.45 |

| Warp-faced sateen de 8 | 1108.00 | 19.78 | 2.113 | 3.17 | 1196.00 | 22.33 | 2.693 | 2.65 | 850.00 | 19.07 | 1.472 | 1.3 | 935.00 | 20.5 | 4.71 | 2.5 |

Before analysing and studying the experimental results, we will explain why there is a difference in the resistance of the yarns extracted from the fabric. According to the values obtained experimentally, there is a difference in the strengths of the yarns extracted from the fabric (Table 4). To understand why this difference exists, we need to compare plain weave and twill 4 × 4 weave. In the case of plain weave, the mean value of the breaking force is 1,051 N, while in the case of twill 4 × 4 weave, the mean value of the breaking force (N) is 1,170 N.

During the plain weave weaving process, the warp threads are subjected to significant stress due to the repeated extensions they undergo each time the weft threads are inserted. These repeated lifting and slackening movements affect the strength of the warp yarns. On the other hand, these repeated stresses lead to material fatigue, which may eventually reduce the strength of the warp threads in the long term.

In the case of twill weave 4, warp and weft wires are crossed alternately, reducing direct tensile stress on the warp wires compared to plain weave. Repeated stretching of the warp threads is less pronounced in a twill weave of 4, as the warp threads pass over several weft threads before changing position. This reduction in direct tensile stress influences the strength of the warp threads. Although the warp threads in a twill weave of 4 are also subjected to stresses during the weaving process, these are generally less severe than those encountered in a plain weave.

The same observation can be applied to the different weaving modes, in warp or weft direction.

3 Analysis and study of experimental results

To gain a better understanding of the influence of weaves on fabric tensile strength, we first studied changes in the fabric’s physical characteristics of the fabric, such as warp and weft densities, mass per m2. Additionally, we examined the evolution of strength tensile as a mechanical characteristic, in order to establish a relationship between changes in physical and mechanical properties. After arranging the textiles by their thread density, weight, interlacing coefficient of the weave, and average float length of the thread, Table 5 was generated. From this table, it can be deduced that the physical characteristics of the textile composition (yarn and weft densities, weight mass) vary based on the interlacing coefficient of the weave and the average float length of the thread intersection.

Upon examination of Table 5, it can be deduced that there exists an inverse correlation between the weave interlacing coefficient and the average float length thread in woven fabrics. This indicates that an increase in the float length will lead to a decrease in the number of intersections. The addition of intersections could potentially diminish the spatial capacity for warp and weft threads. If the desired density of warp or weft threads has already been attained, or if the available space is restricted, enhancing the number of warps per unit length may prove unfeasible.

Physical properties according to the weave structure

| Code fabric after categorising | Weave structures | Weave interlacing coefficient | Average float length thread | Warp density (yarn/cm) | Weft density (picks/cm) | Weight (g/m²) |

|---|---|---|---|---|---|---|

| 6 | Twill 4 × 4 right hand | 0.34375 | 4.00 | 27.6 | 21.4 | 202.34 |

| 7 | Warp-faced twill 6 × 2 right hand | 0.34375 | 4.01 | 27.3 | 21.32 | 199.06 |

| 5 | Warp-faced twill 7 × 1 right hand | 0.34375 | 4.02 | 27.00 | 21.2 | 196.76 |

| 10 | Warp-faced sateen de 8 | 0.34375 | 4.03 | 27.00 | 21.04 | 195.78 |

| 9 | Warp-faced sateen de 8 | 0.34375 | 4.04 | 27.00 | 21.04 | 195.76 |

| 4 | Twill 2 × 2 right Hand | 0.625 | 2.00 | 26.8 | 20.2 | 191.00 |

| 8 | 4-end sateen | 0.625 | 2.01 | 26.8 | 19.92 | 190.78 |

| 3 | Warp-faced twill 3 × 1 right hand | 0.625 | 2.02 | 26.6 | 19.88 | 190.3 |

| 2 | Basket 2-2 | 0.50 | 2.03 | 26.6 | 19.84 | 188.66 |

| 1 | Plain | 1.00 | 1.00 | 26.0 | 19.00 | 184.92 |

To elucidate the impact of weave structures on the physical properties under investigation, the influence of the weave interlacing coefficient, and the average float length thread will be expounded upon approximately plain, 4-end sateen, and twill 4/4 weave structures, which encompass the three primary categories of weave structures.

For plain weave, a weave interlacing coefficient of 1 denotes that all threads in the fabric are fully interlaced, without any gaps or spaces between them. This results in a dense and tightly woven fabric structure where both warp and weft threads are fully interlaced with no gaps. Similarly, an average float length thread of 1 indicates that there are no uninterrupted sections of warp or weft threads without interlacing. Each thread interlaces with its adjacent threads at every intersection point, creating a consistent and uniform interlacement pattern in which all warp and weft threads fully interlace without any gaps. The value of these two factors led to obtaining the lowest value for warp and weft densities 26 yarn/cm and 19 picks/cm. Consequently, the warp and weft thread densities on the fabric closely match the mechanical warp and weft thread counts.

In the case of the 4-end sateen weave, the weave interlacing coefficient is determined to be 0.5000, which signifies a lower density of thread interlacing in the fabric when compared to the plain weave. A weave interlacing coefficient of 0.5000 implies that only half of the threads are interlaced, while the remaining half float above multiple warp or weft threads without intertwining. This particularity results in a unique pattern in which the threads exhibit longer floats or uninterrupted segments without interlacement. The average float length of 2 indicates that there are typically longer uninterrupted segments of warp or weft threads without interlacing in the 4-end sateen weave.

Consequently, this leads to a more prominent and conspicuous float effect in the fabric, with extended floating segments in contrast to the plain weave.

Due to these characteristics, the 4-end sateen weave exhibits a different fabric structure compared to the plain weave. The value of these two factors led to the acquisition of the medium value for the warp and weft densities 26.80 yarn/cm and 19.92 picks/cm.

In the case of the twill 4/4 weave, the weave interlacing coefficient is 0.34375, and the average floating length of the thread is 4. A weave interlacing coefficient of 0.34375 means that only a portion of the warp and weft threads are interlaced in the fabric, with most threads potentially floating over multiple adjacent threads without interlacing. This results in longer float segments and wider gaps between the interlaced threads, leading to a fabric structure that is more open and denser compared to a fabric with a higher interlacing coefficient.

The average length of the float in a thread (4) indicates the presence of continuous segments of warp or weft threads without intertwining. A single thread can extend over several neighbouring threads before intertwining. Consequently, this leads to extended floating segments and wider spaces between the interwoven threads. As a result of these two factors, the highest warp and weft densities of 27.60 yarn/cm and 21.40 picks/cm were achieved.

Consequently, it can be deduced that the configuration of a woven structure plays a significant role in determining the densities of warp and weft, which is influenced by the frequency of interlacing and the length of floating threads within the repeat of the weave patterns. An escalation in either warp or weft counts signifies a greater number of respective threads per unit length within the fabric. This, in turn, results in a higher concentration of threads in the fabric, potentially leading to an increase in the overall mass of the material. We analyse the mechanical properties following the analysis of the physical properties. After classifying weaves made according to warp and weft strength embedded or extracted from fabric in the warp and weft direction, we drew up Table 6 for the tensile test in warp directions and Table 7 for tensile test in weft directions.

Average tensile strength values in the warp direction according to the weave structure

| Mean value of the breaking force (N) of warp embedded in the fabric | Mean value of the breaking force (N) of warp extracted from fabric | Difference % | ||

|---|---|---|---|---|

| 6 | Twill 4 × 4 right hand | 1,220 | 1,110 | 9.02 |

| 7 | Warp-faced twill 6 × 2 right hand | 1,201 | 1,093 | 8.99 |

| 5 | Warp-faced twill 7 × 1 right hand | 1,197 | 1,088 | 9.11 |

| 10 | Warp-faced sateen de 8 | 1,196 | 1,084 | 9.36 |

| 9 | Warp-faced sateen de 8 | 1,192 | 1,083 | 9.14 |

| 4 | twill 2 × 2 right hand | 1,186 | 1,077 | 9.19 |

| 8 | 4 end sateen | 1,178 | 1,068 | 9.34 |

| 3 | Warp-faced twill 3 × 1 right hand | 1,175 | 1,068 | 9.11 |

| 2 | Basket 2-2 | 1,171 | 1,064 | 9.14 |

| 1 | Plain | 1,165 | 1,059 | 9.10 |

| Mean value | 9.15 | |||

Measurement of warp yarn resistance before weaving revealed an average resistance value of 10.89 N. To compare the resistance values of the warp yarns before and after weaving, we calculated the resistance of different samples by multiplying the value obtained by the number of warp yarns per 5 cm, as detailed in Table 6. When comparing the resistance values of the warp yarn strips before weaving with those of the warps extracted from the fabric, the resistance values of the yarns are higher than those of the yarns present in the fabric. This is due to the damage suffered by the warp threads during the weaving and warping operations.

During warping and weaving, the warp threads are subjected to various stresses, including friction with the various components of the weaving and warping machines. During warping, this includes cup tensioners, thread guides, thread breakers, the spanning reed, and the weaving reed. During weaving, there is rubbing with the thread-breakers, heddles, and reed, as well as repeated extensions during shed formation and settling of the pick in weaving.

We compare the values between the warp strength still present in the fabric and the strength of the warps removed from the fabric as illustrated in the graph.

From Figure 3, it can be inferred that the average breaking strength of the warp fibres that remain embedded in the fabric exceeds the average strength of the extracted warp fibres. The disparity between these two values is approximately 9%.

This discrepancy is probably due to the intertwining of the weft and warp yarns within the fabric composition. When the warp yarns are retained within the fabric structure, they are closely interwoven with the weft yarns, offering added reinforcement and stability to the warp fibres. This intertwining aids in evenly spreading tension and load across the warp yarns, leading to increased breaking strength.

When the warp yarns are removed from the fabric, they lose the support and reinforcement provided by their interlacing with the weft yarns. Consequently, the breaking strength of the extracted warp yarns is slightly decreased compared to that of those still within the fabric. The difference of approximately 9% in breaking strength between the two scenarios demonstrates the impact of fabric structure on the mechanical properties of warp yarns. This discovery underscores the importance of considering the interlacing pattern and fabric construction when evaluating the strength attributes of woven fabrics.

Measurement of the resistance of the weft wires before weaving resulted in an average resistance value of 8.2 N. To compare the resistance values of the weft wires before and after weaving, we calculated the resistance of the different samples by multiplying the value obtained by the number of weft threads per 5 cm strip, as shown in Table 7.

Average tensile strength values in the weft direction according to the weave structure

| WEFT | Strength per 1 weft yarn thread | Coefficient of variation (%) of theelongation at break | Mean value of theelongation at break (%) | Coefficient of variation (%) of the elongation at break | Weft densities (weft/cm) | Number of weft yarn per 5 cm strip | Mean value of the breaking force (N) weft strip before weaving | Mean value of the breaking force (N) weft embedded in the fabric | Mean value of the breaking force (N) of weft extracted from fabric | The difference % | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | Twill 4 × 4 right hand | 8.20 | 3.09 | 21.75 | 14.37 | 21.40 | 107.00 | 877.4 | 957 | 870 | 9.00 |

| 7 | Warp-faced twill 6 × 2 right hand | 8.30 | 3.1 | 21.75 | 14.37 | 21.32 | 106.50 | 873.3 | 952 | 865 | 9.13 |

| 5 | Warp-faced twill 7 × 1 right hand | 8.40 | 3.11 | 21.75 | 14.37 | 21.20 | 106.00 | 869.2 | 946 | 860 | 9.09 |

| 10 | Warp-faced sateen de 8 | 8.50 | 3.12 | 21.75 | 14.37 | 21.04 | 105.20 | 862.64 | 935 | 850 | 9.09 |

| 9 | Warp-faced sateen de 8 | 8.60 | 3.13 | 21.75 | 14.37 | 21.04 | 103.20 | 850.75 | 933 | 849 | 9.00 |

| 4 | Twill 2 × 2 right hand | 8.70 | 3.14 | 21.75 | 14.37 | 20.20 | 101.00 | 828.2 | 899 | 818 | 9.01 |

| 8 | 4-end sateen | 8.80 | 3.15 | 21.75 | 14.37 | 19.92 | 99.80 | 890 | 890 | 809 | 9.10 |

| 3 | Warp-faced twill 3 × 1 right hand | 8.90 | 3.16 | 21.75 | 14.37 | 19.88 | 99.50 | 887 | 887 | 807 | 9.01 |

| 2 | Basket 2-2 | 8.10 | 3.17 | 21.75 | 14.37 | 19.84 | 99.30 | 846 | 878 | 798 | 9.11 |

| 1 | Plain | 8.11 | 3.18 | 21.75 | 14.37 | 19.00 | 95.00 | 840.00 | 840 | 764 | 9.04 |

| Mean value | 9.7 | ||||||||||

When resistance values are compared between the wefts yarn before weaving operation and the wefts extracted from the fabric after weaving operation, the resistance values of the yarns are slightly higher than those of the yarns extracted from the fabric. This observation can be explained by slight damage sustained by the weft yarns during the weaving operations at the pre-feeder, weft selector, and insertion system.

If we compare the values between the weft strength that remains embedded in the fabric and the strength of the wefts that have been extracted from the fabric, as shown in the graph, it indicates that the mean breaking strength value of the weft still embedded in the fabric exceeds the mean value of the extracted weft. This observed 9% difference in values can be ascribed to the intricate interlacing mechanism between the weft yarns and the warp yarns within the fabric structure. The weft yarns, while still embedded in the fabric, are closely interlaced with the warp yarns, thus offering enhanced support and stability to the weft fibres. This interlacing process aids in the uniform distribution of stress and load across the weft yarns, leading to an increase in breaking strength.

The removal of weft yarns from the fabric results in a reduction in the support and reinforcement they receive from their interlacing with the warp yarns. Consequently, the break strength of these extracted weft yarns is marginally lower in comparison to that of those that remain integrated within the fabric.

The disparity of around 9% in break strength between these two scenarios signifies the impact of fabric structure on the mechanical attributes of weft yarns. This discovery underscores the need to consider the interlacing arrangement and fabric composition when evaluating the strength properties of woven textiles.

4 Discussion

After studying the physical properties, the results obtained reveal significant variations in terms of the densities of the warp yarn and the weft yarn. The densities of the warp yarn vary from 26.0 to 27.6 yarns/cm, while those of the weft yarn range from 19.0 to 21.4 wefts/cm. These variations have allowed us to classify the weave structures in the order illustrated in Table 5.

Similarly, in the study of mechanical properties, the results obtained reveal significant variations in terms of tensile strength in both warp and weft directions. Tensile strengths in the warp direction vary from 1,165 to 1,220 N, while those in the weft direction vary from 840 to 957 N. These variations have allowed us to have the same ranking of weave structures illustrated in Tables 6 and 7.

These observed differences in densities and tensile strengths led us to classify the weave structures in a consistent and similar manner in Tables 5–7. The results of our study highlight the critical importance of the weaving mode in determining the tensile strength of fabrics, providing valuable information for the selection and design of fabrics to meet the specific needs of a variety of applications.

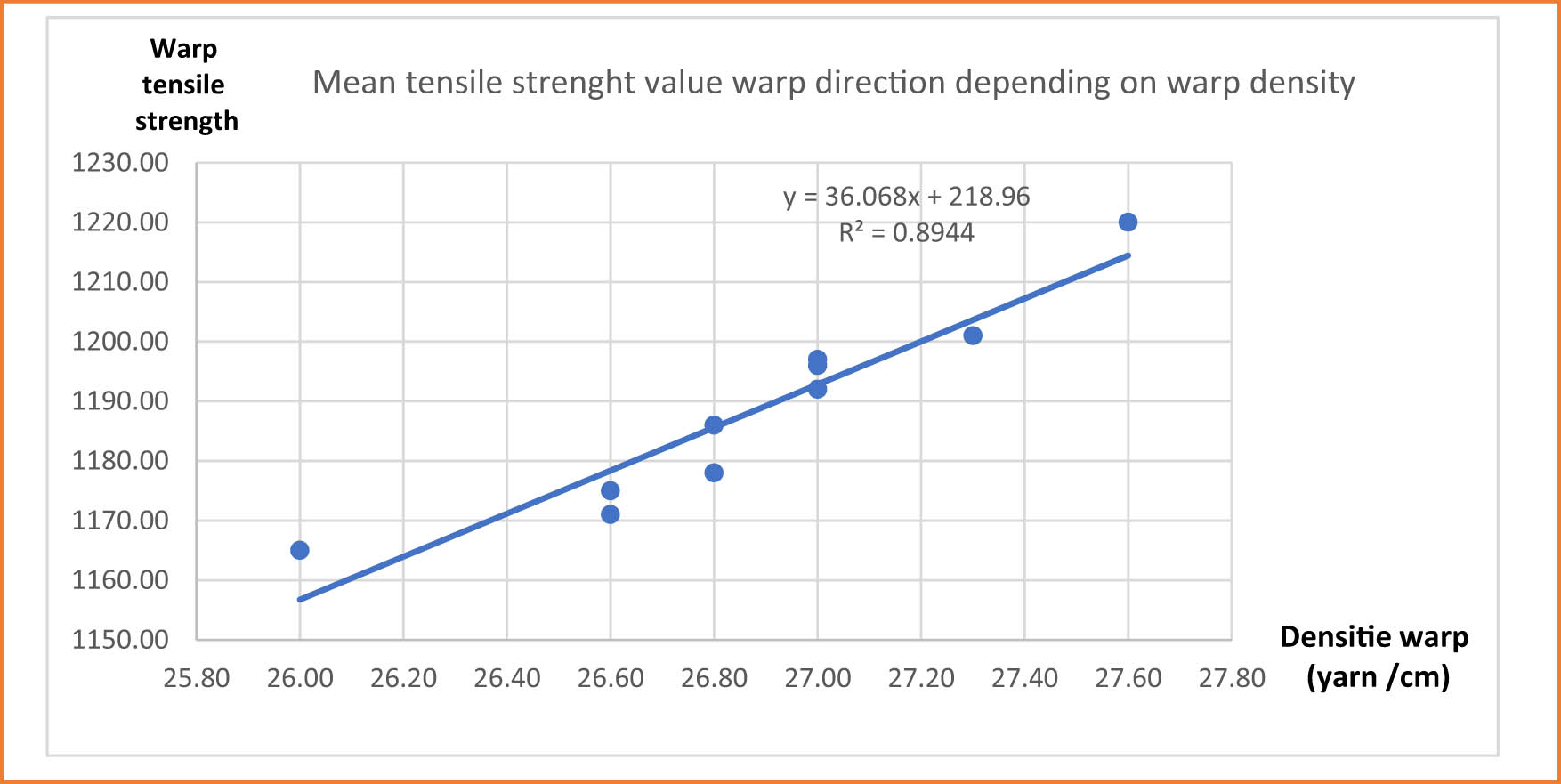

4.1 Mean tensile strength value warp direction depending on warp density

The data we have collected, including a correlation coefficient of 0.8944 and a linear regression equation of y = 36.068x + 218.96, offer insight into the association between thread count and tensile strength within the dataset. A correlation coefficient of 0.8944 signifies a robust positive correlation between thread count and tensile strength. The linear regression equation y = 36.068x + 218.96 suggests that with each incremental increase in thread count, the tensile strength sees an average increase of 36.068 units. These findings highlight a substantial positive connection between thread count and tensile strength, as observed in the specific data set at hand (Figure 4).

Mean tensile strength value warp direction depending on warp density.

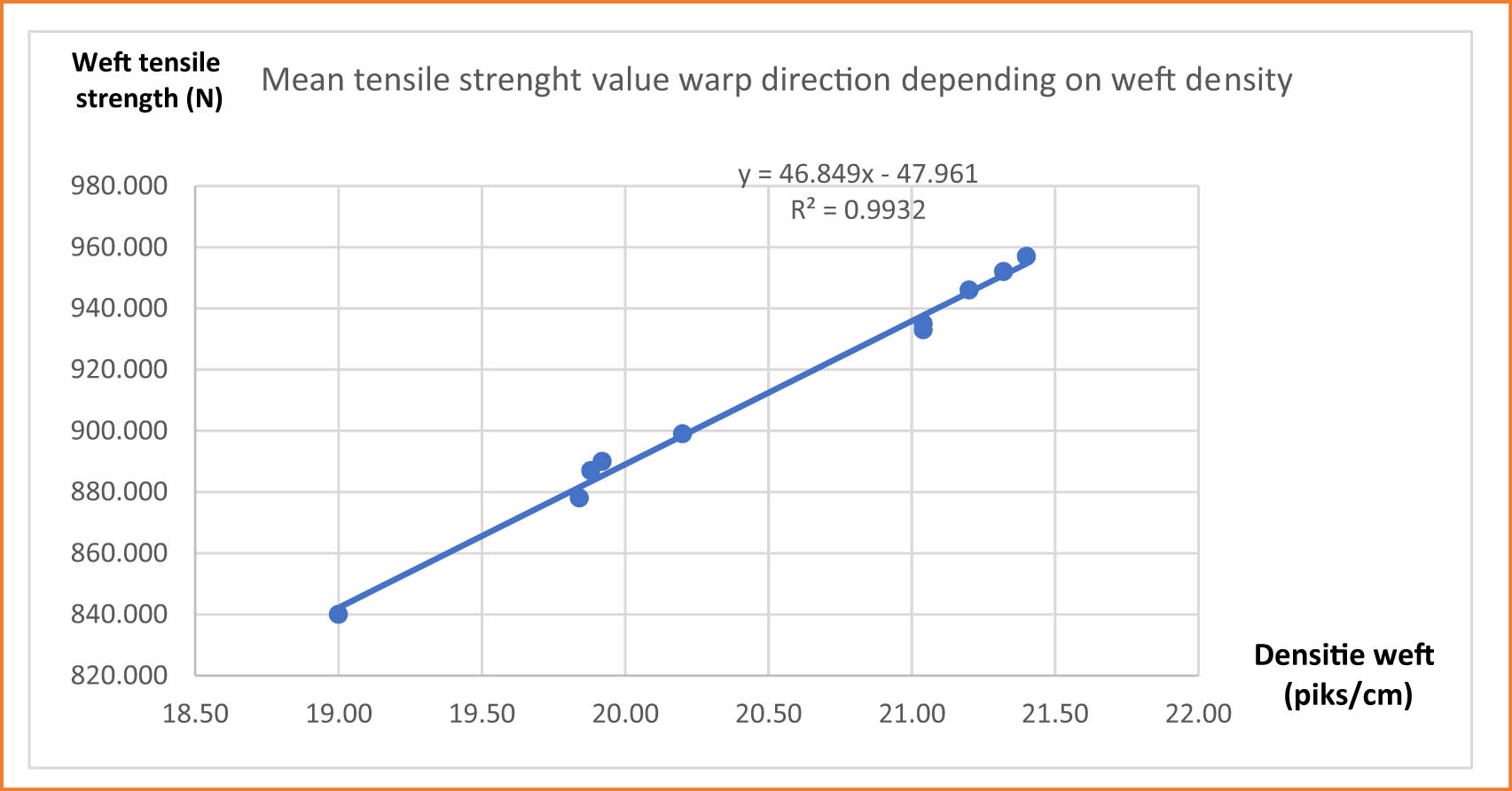

4.2 Mean weft tensile strength value depending on warp density

The values obtained, with a correlation coefficient of 0.9932 and a linear regression equation y = 46.849x–47.961, offer valuable insights into the correlation between thread count and tensile strength in the dataset. The correlation coefficient of 0.9932 suggests a highly positive correlation between thread count and tensile strength. This indicates that as the thread count increases, the tensile strength also tends to increase significantly. A correlation coefficient closer to 1 signifies a stronger relationship between the variables. The linear regression equation y = 46.849x – 47.961 further elucidates this association by stating that for each unit increase in thread count (x), the tensile strength (y) increases by an average of 46.849 units (Figure 5).

Variation in the physical properties according to the weave structure.

Using the values presented, one can infer that a strong and positive relationship exists between thread count and tensile strength within the dataset under consideration. As the thread count increases, there is a corresponding increase in tensile strength. However, it is crucial to bear in mind that these observations pertain solely to the given dataset, and broad generalisations should be approached judiciously in the absence of additional statistical scrutiny and a more extensive sample size.

5 Synthesis and conclusion of the study

To study the impact of weave structures on the tensile strength of fabrics, a total of 200 fabric samples with different weaves were produced. These samples were carefully designed and manufactured under identical production conditions.

When examining the tensile strength, the results of our research on fabrics confirm that the weave structure plays a significant role in determining the warp and weft densities, which are influenced by the number of interlacing points and the length of float sections within the repeat of the weave pattern. When the warp and/or weft count increases, the warp and weft strength also tend to increase. This difference can be attributed to the effect of increased pick density, which leads to a greater number of interlacements in the fabric. These interlacements contribute to the overall strength of the fabric by creating greater mutual pressure on the yarn and resulting in a better binding effect.

To comprehend the progression of tensile strength, we have employed the weave interlacing coefficient and the average float length. These factors quantify the level of interlacing between the warp and weft yarns. For fabrics with identical production parameters, such as warp and weft thread count and interlacing, these factors provide information on the evolution of yarns in fabrics and offer valuable information on the development of tensile strength.

The research we carried out may have several significant implications for managers. Enhancing product quality: Managers can improve the quality of final products by understanding the impact of various binding methods on the tensile strength, enabling them to make more informed decisions. Using the utilisation of suitable binding techniques to meet tensile strength requirements, the overall quality of the products can be elevated. Optimisation of production processes: The results of our study can also aid in optimising production processes. When identifying the most efficient binding methods to increase the tensile strength, managers can adjust manufacturing practices to optimise product quality while reducing costs and waste. Competitive differentiation: Managers can leverage their understanding of how binding techniques affect fabric tensile strength to differentiate themselves from competitors. For example, if a company can ensure superior tensile strength through specific binding methods, it can establish a substantial competitive edge.

The future study might focus on the following topics, to name a few.

Future research can examine how weave structures affect other fabric attributes, such as air permeability, abrasion resistance, and dimensional stability. This work focused on the link between fabric tensile strength and weave structures. Choosing and designing fabrics can greatly benefit from an understanding of these interactions. The study specifically looked at textiles made of 100% polyester. The study can be expanded in the future to examine other types of fibres, such as cotton, wool, or synthetic mixes, to see if the correlation between fabric tensile strength and weave topologies is consistent with various materials.

Although plain, twill, sateen, and derivative weaves were addressed in the study, many different weave structures can be investigated. Future studies can examine how various weave structures, yarn counts and densities, and weave patterns affect the tensile strength of fabrics.

In this study, the impact of weaving techniques on the tensile strength was discussed. The effects of additional production procedures, such as yarn spinning methods, finishing touches, and dyeing procedures, on the tensile strength of woven textiles can be further investigated in future studies. A thorough understanding of fabric performance may be obtained by understanding the combined impact of these processes.

-

Funding information: Authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results and approved the final version of the manuscript. Conceptualisation – Redouane Messnaoui, Mhammed El Bakkali, Mustapha Elkhaoudi; Data Curation – Redouane Messnaoui; Formal Analysis – Redouane Messnaoui, Mohammed El Bakkali, Mustapha Elkhaoudi; Research – Redouane Messnaoui; Methodology – Redouane Messnaoui, Mhammed El Bakkali, Mustapha Elkhaoudi; Supervision – Omar Cherkaoui, Aziz Soulhi; Validation – Aziz Soulhi; Original Drawing and Editing – Redouane Messnaoui, Mohammed El Bakkali, Mustapha Elkhaoudi; Writing, Proofreading and Editing – Redouane Messnaoui, Aziz Soulhi.

-

Conflict of interest: Authors state no conflict of interest.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Thanikai Vimal, J., Prakash, C., Jebastin Rajwin, A. (2018). Effect of weave parameters on the tear strength of woven fabrics. The Journal of Natural Fibres, 17, 9.Search in Google Scholar

[2] Matusiak, M. (2017). Influence of the structural parameters of woven fabrics on their drapability. The Journal of Fibres & Textiles in Eastern Europe, 25, 1.10.5604/12303666.1227883Search in Google Scholar

[3] Jahan, I., Jahan, I. (2018). Effect of fabric structure on the mechanical properties of woven fabrics. The Journal of Research in Textile Engineering, 2, 2.Search in Google Scholar

[4] Shanbeh, M., Safar Johari, M., Zarrebini, M., Barburski, M., Komisarczyk, A. (2019). Analysis of the shear characteristics of woven fabrics and their interaction with integrated structural factors. The Journal of Engineered Fibers and Fabrics, 14, 15.10.1177/1558925019867520Search in Google Scholar

[5] Asayesh, A., Mirgoli, F., Gholamhosseini, A. (2017). An investigation into the effect of fabric structure on the compressional properties of woven fabrics. The Journal of The Textile Institute, 109, 1.10.1080/00405000.2017.1320817Search in Google Scholar

[6] Havlová, M. (2013). Air permeability and constructional parameters of woven fabrics. The Journal of Fibres & Textiles in Eastern Europe, 21, 2.Search in Google Scholar

[7] Umair, M., Hussain, T., Shaker, K., Nawab, Y., Maqsood, M., Jabbar, M. (2016). Effect of the structure of the woven fabric on the air permeability and moisture management properties. The Journal of The Textile Institute,107, 5.10.1080/00405000.2015.1054124Search in Google Scholar

[8] Zhu, G., Fang, Y., Zhao, L., Wang, J., Chen, W. (2018). Prediction of structural parameters and air permeability of cotton woven fabric. The Journal of Textile Research Journal, 88,14.10.1177/0040517517705632Search in Google Scholar

[9] Marie, H. (2018). Air permeability, water vapor permeability and selected structural parameters of woven fabrics. The Journal of Fibres and Textiles, 1, 3.Search in Google Scholar

[10] Ünal P. G., Taşkin, C. (2007). The effect of weave and densities on tensile strength of 100% polyester fabrics. The Journal of Textile and Apparel, 17, 2.Search in Google Scholar

[11] Oğulata, R., Kadem, F. D. (2008). Prediction of regression analyses of fabric tensile strength of 100% cotton fabrics with dyed yarn in different constructions. The Journal of Tekstil ve konfeksiyon, 18, 3.Search in Google Scholar

[12] Teli, M. D., Khare, A. R., Chakrabarti, R. (2008). Dependence of yarn and fabric strength on structural parameters. The Journal of Autex Research Journal, 8(3), 63–67.10.1515/aut-2008-080301Search in Google Scholar

[13] Cernoša, H. E., Dimitrovski, K. (2008). Influence of weave and weft characteristics on the tensile properties of fabrics. The Journal of Research and Development, 16, 45–51.Search in Google Scholar

[14] Sekerden, F., Celik, N. (2010). Weft elastane weaving and fabric characteristics. The Journal of Tekstil ve Konfeksiyon, 20, 120–129.Search in Google Scholar

[15] Malik, Z., Malik, M., Hussain, T., Ahmed, F. (2011). Development of models to predict tensile strength of cotton woven fabrics. The Journal of Engineered Fibres and Fabrics, 6, 46–53.10.1177/155892501100600407Search in Google Scholar

[16] Özdemir, H., Mert, E. (2013). The effects of fabric structural parameters on the tensile, bursting, and impact strengths of cellular woven fabrics. The Journal of The Textile Institute, 104(3), 330–338.10.1080/00405000.2012.725521Search in Google Scholar

[17] Nasrun, F. M. Z., Yahya, M. F., Ghani, S. A., Ahmad, M. R. (2016). Effect of weft density and yarn crimps towards tensile strength of 3D angle interlock woven fabric. AIP Conference Proceedings, 1774(1), 020003.10.1063/1.4965051Search in Google Scholar

[18] Jahan. (2017). Effect of the fabric structure on the mechanical properties of woven fabrics. The Journal of Advance Research in Textile Engineering, 2, 2.10.26420/advrestexteng.2017.1018Search in Google Scholar

[19] Mebrate, M., Gessesse, N., Zinabu, N. (2020). Effect of lean tension on mechanical properties of plain-woven cotton fabric. The Journal of Fibres & Textiles in Eastern Europe, 19, 4.10.1080/15440478.2020.1776663Search in Google Scholar

[20] Ala, M. (2021). An experimental study on selected performance properties of 100% cotton terry fabrics. The Journal of Textile and Apparel, 31, 1.10.32710/tekstilvekonfeksiyon.713344Search in Google Scholar

[21] Eltayib, H. E., Ali, A. H. M., Ishag, I. A. (2016). The prediction of tear strength of plain weave fabric using linear regression models. The Journal of Advanced Engineering Research and Science, 3(11), 236921.10.22161/ijaers/3.11.25Search in Google Scholar

[22] Chen, J., Chen, W., Zhou, H., Zhao, B., Wang, M., Sun, W., et al. (2018). Fracture failure analysis and bias tearing strength criterion for a laminated fabric. The Journal of Industrial Textiles, 47, 7.10.1177/1528083717695839Search in Google Scholar

[23] Milašius, R., Legaudienė, B., Laureckienė, G. (2018). Influence of weave parameters on woven fabric tear strength. The Journal of Fibres & Textiles in Eastern Europe, 26(4), 48–51.10.5604/01.3001.0012.1312Search in Google Scholar

[24] Thanikai Vimal, J., Prakash, C., Jebastin Rajwin, A. (2020). Effect of weave parameters on the tear strength of woven fabrics. The Journal of Natural Fibers, 17(9), 1239–1248.10.1080/15440478.2018.1558155Search in Google Scholar

[25] Chen, F., Wang, G., Li, L., Cheng, H. (2011). Mechanical properties of a woven ramie fabric under multidimensional loadings. The Journal of Textile Research Journal, 81(12), 1226–1233.10.1177/0040517511398947Search in Google Scholar

[26] Hossain, M., Datta, E., Rahman, S. (2016). A review on different factors of woven fabrics’ strength prediction. The Journal of Science Research, 4, 88–97.10.11648/j.sr.20160403.13Search in Google Scholar

[27] Ali, M., Zeeshan, M., Qadir, M. B., Riaz, R., Ahmad, S., Nawab, Y., et al. (2018). Development and mechanical characterisation of weave design based 2D woven auxetic fabrics based on weave design for protective textiles. The Journal of Fibres Polymer, 19(11), 2431–2438.10.1007/s12221-018-8627-8Search in Google Scholar

[28] Thiruchitrambalam, M., Veerapandiyan, K., Suresh, A. G., Praveen, R. (2020). Effect of weaving architecture on the mechanical properties of a polyester/eco-friendly lyocell composite. AIP Conference Proceedings, 2426(1), 020023.10.1063/5.0112498Search in Google Scholar

[29] Messnaoui, R., El Bakkali, M., Soulhi, A., Cherkaoui, O. (2023). Application of fuzzy logic in weaving process: A systematic literature review. The Journal of Theoretical and Applied Information Technology, 101, 23.Search in Google Scholar

[30] Tabiei, A., Nilakantan, G. (2008). Ballistic impact of dry woven fabric composites: A review. The Journal of Applied Mechanics Reviews, 61, 010801.10.1115/1.2821711Search in Google Scholar

[31] Li, T-T., Wang, R., Lou, C. W., Lin, J-H. (2013). Evaluation of high-modulus, puncture-resistance composite nonwoven fabrics by response surface methodology. The Journal of Industrial Textile, 43, 2.10.1177/1528083712452900Search in Google Scholar

[32] Baztech-Yadda. (2014). Effect of weaving structure and hybridization on the low velocity impact behavior of woven carbon-epoxy composites. The Journal of Fibres & Textiles in Eastern Europe, 22, 3.Search in Google Scholar

[33] Wang, Q.-S., Sun, R.-J., Tian, X., Yao, M., Feng, Y. (2016). Quasi-static puncture resistance behaviors of high-strength polyester fabric for soft body armour. The Journal of Results in Physics, 6, 554-560.10.1016/j.rinp.2016.08.018Search in Google Scholar

[34] Bilisik, K. (2017). Two-dimensional (2D) fabrics and three-dimensional (3D) preforms for ballistic and stabbing protection: A review. The Journal of Textile Research Journal, 87, 18.10.1177/0040517516669075Search in Google Scholar

[35] Lin, T. R., Lin, Y.-Y., Lin, T. A., Jhang, J.-C., Lou, C.-W., Lin, J.-H. (2020). Effects of heat treatments on puncture resistant properties of nonwoven fabrics based on polyamine and polyamide. The Journal of Fibers Polymer, 21(9), 2118–2124.10.1007/s12221-020-1048-5Search in Google Scholar

[36] Kumpikaitė, E. (2007). Analysis of the dependencies of the breaking force and elongation of the woven fabric on its structure parameters. The Journal of Fibres & Textiles in Eastern Europe, 15, 1.Search in Google Scholar

[37] Kumpikaitė, E. (2008). Influence of fabric structure on the character of fabric breakage. The Journal of Fibers and Textiles in Eastern Europe, 16(3), 68.Search in Google Scholar

[38] Kaynak, H. K., Babaarslan, O. (2015). Breaking strength and elongation properties of polyester woven fabrics based on filament fineness. The Journal of Engineered Fibres and Fabrics, 10, 4.10.1177/155892501501000416Search in Google Scholar

[39] Klevaityte, R., Masteikaite, V. (2008). Anisotropy of woven fabric deformation after stretching. The Journal of Fibres and Textiles in Eastern Europe, 16, 52–56.Search in Google Scholar

[40] Özdemir, H. (2013). The effects of fabric structural parameters on the breaking, bursting, and impact strengths of diced woven fabrics kumas. The Journal of Tekstil ve konfeksiyon, 23, 2.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry