Abstract

As a kind of dress combining traditional and modern design, pleated cheongsam is becoming increasingly popular among Chinese users. However, the current design of pleated cheongsam has the problem of mismatch with users’ modern aesthetics and demands, which causes serious homogenization of pleated cheongsam and low sales volume. Therefore, the optimal design of pleated cheongsam was discussed from three aspects:consumer demands, design features, and comprehensive evaluation. The Kano model was used to sort out 12 user demands in three aspects: functionality, usability, and emotion. The House Of Quality (HOQ) method was used to establish the mapping matrix of “user demand-design requirement,” and the priority of 11 design requirements was determined. Finally, the best optimization proposal was screened and evaluated by the Pugh matrix and the live streaming data of pleated cheongsam brand. The experimental results demonstrate that the Kano–HOQ–Pugh model provides a scientific and engineered attribute framework for improving the acceptability and attractiveness of pleated cheongsam and provides a theoretical basis for brands to develop pleated cheongsams with ethnicity, modernity, and differentiation.

1 Introduction

The cheongsam is a one-piece garment closely associated with Chinese traditional clothing, featuring with slim fit, right-side fastening, stand-up collar, frog buttons, side slits, single-piece fabric, and integrated sleeves, making it one of the symbolic representations of the Chinese female image [1]. With the development of Chinese traditional clothing culture, the Neo-Chinese style garments have attracted extensive attention from female users, including the Neo-Chinese style cheongsam, which is particularly favored by women born in the 70s and 80s [2]. Under the influence of the Neo-Chinese style cheongsam consumption trend and to meet the unity of traditional clothing culture and modern aesthetics, a creative modified cheongsam with pleated fabric as its distinctive feature has been created. The fabric is heat-pressed, folded, kneaded, stacked, and compressed in a certain pattern to create a neat or casual texture, thus earning the name “pleated cheongsam” [3]. The pleated cheongsam, with its flexible and elastic pleated fabric, exhibits an improved level of fashion, softness, and comfort compared to traditional cheongsams. The smooth and concise lines of the pleated cheongsam outline the female bone structure and proportions, showcasing women’s self-awareness and spirit. Symbolizing China’s personalized, differentiated aesthetic taste, and cultural quality in clothing, the pleated cheongsam represents a unique and cultural identity [4].

Given the significance of the cheongsam in Chinese traditional clothing culture, there have been some studies on improving its design to cater to modern aesthetics. For example, Yang and Chang [5] explored the three-dimensional design features of the cheongsam culture, including the outer layer, middle layer, and inner layer. They demonstrated the social, economic, technological, and fashion values of the Chinese cheongsam, providing a research foundation for the modernization of traditional Chinese clothing. Lin [6] proposed a cheongsam customization model based on a parametric model and knowledge-driven digitization to address the problems of high periodicity and poor fit of traditional cheongsam generation methods. Cheng et al. [7] proposed a fast generation method of the cheongsam pattern based on the fuzzy affiliation function for fit quantification according to human body shape characteristics.

From the above analysis, it can be observed that currently research on cheongsam improvements focuses on historical culture, manufacturing techniques, and optimization design. However, there is limited research addressing the mismatch between cheongsam improvement processes, aesthetic concepts, and user demands. Therefore, in this article, Neo-Chinese style clothing category – pleated cheongsam – was taken as a research object to be explored from three aspects: consumer demand, design features, and comprehensive evaluation. The Kano model and Pugh selection matrix were introduced into the House Of Quality (HOQ) method, and the optimal design model of pleated cheongsam was proposed to satisfy the demands of user groups; improve the market acceptance, attractiveness, and competitiveness of the product; avoid homogeneous design and over-design; and find a solution that highlights the characteristics of the category and optimizes the design.

2 Literature review

2.1 Cheongsams and pleated cheongsams

The design of traditional cheongsams focuses on appearance and aesthetics but faces issues such as body size limitations, fabric constraints, restricted movement, and not being compatible with modern women’s lifestyles [8]. Currently, scholars have conducted research on the improvement of traditional cheongsams, including innovations in fabrics, styles, patterns, and designs. Lin et al. [9] improved the compositional form of cheongsam motifs by constructing metaphors and illusions and using positional distortion design techniques with surreal expression techniques and mise-en-scene painting techniques. Meng et al. [10] explored the improvement effect of silk patterns on cheongsam in the Song Dynasty and came to the conclusion that the arrangement of silk geometric patterns, line thickness, and pattern density have a significant influence on the style of cheongsam. Feng [8] explored the versatile boundaries between Western style and cheongsam style with recycled cotton denim, recycled polyester wadding, rivets, and other techniques, enriching the modified cheongsam styles under punk style. Van and Minh [11] adapted cheongsam styles and patterns by testing the elongation and stretch of fabrics to create improved cheongsams that fit well and allow freedom of movement. Roy et al. [12] used handmade Khadi fabrics from Bangladesh to create the cheongsams, modernizing traditional cheongsams with modern, sustainable cheongsam fabrics and distinctive patterns to suit different cultural trends.

Machine-pleated or hand-pleated fabrics are used as the main innovation of the modified cheongsam. Compared with traditional cheongsam, there are four advantages: first, the pleated fabric has the characteristics of resilience, deformability, breathability, and softness, which makes the cheongsam flexibly adapt to the body curves and movement and enhances the wearing experience [9]. Second, the diversified pleated texture adds a three-dimensional creative effect to the appearance of cheongsam, which makes cheongsam more dynamic and increases the visual appeal and sense of fashion [3]. Third, the wrinkle-resistant nature of the pleated fabric makes the cheongsam have good shape retention, which can reduce the difficulty of preservation, washing, and maintenance of the cheongsam and reduce the space occupied when transporting and storing garments, thus lowering the logistics cost and carbon emission [13]. Fourth, the production of pleated cheongsams can simplify the measurement steps of human body circumference and avoid the complicated process of garment cutting, sewing, and ironing, thus reducing the production cost and error rate as well as improving the production efficiency [14].

2.2 User’s demand-driven optimization design

The user’s demands and expectations are used as dominant factors in the design which can ensure that the final product or solution meets the actual demands and expectations of the user [15]. In the field of fashion, demand-driven optimization design research mainly focuses on five aspects. First, in the context of garment comfort optimization, Liu et al. [16] proposed a fit assessment model based on BP-ANNs to rapidly and automatically predict garment fit by utilizing digital garment pressures measured by virtual fitting, which improved the efficiency of the garment design and manufacturing process. Second, in the context of intelligent technology optimization, Sun [17] used 3D scanning technology to collect human body data, generated human body contour lines through interpolation algorithms and corner detection method, and used global optimization to adaptively adjust the garment to form a virtual garment design solution that meets users’ demands. Third, in the context of optimizing fashion aesthetics, Zhang et al. [18] used a mixed ethnographic approach to investigate the dress requirements, clothing preferences, and clothing consumption behavior of Chinese elderly female consumers and proposed guidelines for fashion design and apparel product development that satisfy consumers’ specific aesthetic needs. Fourth, in the context of multifunctionality optimization, Luo and Hu [19] discussed the ergonomics-based design features of courier workwear and proposed design optimization principles and methods that take into account the clothing and working environment as well as the physiological and psychological needs of couriers. Fifth, in the context of sustainability optimization, Li and Liu [13] proposed a design method for upcycling discarded clothing and daily objects for personal protective equipment from the perspectives of functional protection, detachability, and modular design.

2.3 Research gap

Upon reviewing the literature, we can identify the following research gaps:

First, there is an issue of mismatch between the modification techniques and aesthetic concepts of pleated cheongsam and user demands at the current stage. Literature indicates a lack of comprehensive theoretical analysis and methodological exploration from the perspective of user demands, particularly in terms of women’s attitudes, preferences, and requirements toward modified pleated cheongsams.

Second, there is a lack of comprehensive and optimal design research on fashion design elements such as pleated cheongsam styles, colors, patterns, and fabric materials.

Third, the Kano model has the benefit of demand sorting, the HOQ method has the benefit of planning design requirements, and the Pugh matrix has the benefit of comprehensive evaluation and advantageous selection. Currently, the research on the above theories is relatively perfect, but the model formed by the combination of the three has not yet been applied to solve the optimal design problem of pleated cheongsams.

3 Methods

In this article, the Kano–HOQ–PUGH model was used for the optimal design of pleated cheongsam. First, the Kano model was used to analyze the demand information of the female user group of pleated cheongsams to determine the importance of the demand. Second, a matrix of “user needs – design requirements” was established based on the HOQ method to determine the importance of design requirements. Finally, the proposals were evaluated and optimized according to the Pugh matrix selection method, and the final solution was determined.

3.1 Kano model

The Kano model is a requirement parsing model that enables qualitative analysis and attributes categorization of requirements and is often used to investigate the personalized needs of users [15]. The model can be used in product design, interaction design, service design, and other fields and has the advantage of clarifying the relationship between requirements and user satisfaction.

Acquisition of user demands: The semi-structured interview method was used in this study to enable secondary questioning of respondents’ answers, to obtain user demands more directly and effectively, and to guide respondents to propose innovative ideas and suggestive comments on the product. The user interview framework proposed by Alan Cooper was used as a benchmark to collect users’ demand for pleated cheongsams and to understand the overall situation of users in terms of relatively stable attribute dimensions such as age, income, and occupation, and unpredictable behavioral dimensions such as values, lifestyles, and characteristics, respectively [20].

User demands collation: Different interviewees’ demands for pleated cheongsams may have similar, contained, or intersecting relationships. Therefore, after the interviews were completed, the acquired needs were collated using the three levels of functional, usability, and emotional, as proposed by Jordan from low to high level [21].

User demands attribution: Positive and negative questions formed the user demands importance questionnaire, which allowed for a quick prioritization of the demands. The user satisfaction level is categorized into five levels: very satisfied, deserved, indifferent, barely acceptable, and dissatisfied. Based on the attitude of user feedback, the user demands are categorized into five types of attributes according to the relationship between the degree of realization and user satisfaction, which are M (Must-be Quality), O (One-dimensional Quality), A (Attractive Quality), I (Indifferent Quality), and R (Reverse Quality).

Calculation of demand importance: Some demands belong to more than one attribute simultaneously, thus the problem of inaccurate categorization of user demands emerged. Therefore, the Better–Worse coefficient was introduced as a reference to correct the Kano demand results and determine the weight of each demand for prioritization. F i is the better coefficient, which represents the positive influence index of user satisfaction, and D i is the Worse coefficient, which represents the negative influence index of user satisfaction, as shown in equations (1) and (2). The calculation of user satisfaction index T i is shown in equation (3)

In order to more precisely determine the importance of female users’ demand for pleated cheongsams, an adjustment coefficient k is introduced, taking the values of 0, 0.5, 1, and 1.5, corresponding to I, M, O, and A, respectively. A five-point Likert scale is used for the scoring of the current demand satisfaction (S i ), the target demand satisfaction (S 0), and the demand weighting (H i ). The score ranges from 1 to 5; 1 means the least satisfactory and the least important, and 5 means the most satisfactory and the most important. Target improvement rate V i , demand adjustment improvement rate IR i , and demand importance LR i are shown in equations (4)–(6)

3.2 HOQ method

HOQ method is one of the most important matrices of Quality Function Deployment (QFD), which is a quantitative method to transform the products or services required by the users into relevant engineering characteristic models [22]. The combination of Kano–HOQ can systematically determine the category and sort of users’ demand for pleated cheongsams, provide guidance and reference for the design team, reduce the design risk, improve the design success rate, make pleated cheongsams perform better in terms of functionality, aesthetics, and emotion, increase the value and recognition of the product, satisfy the real demands of the users, and make them have higher satisfaction and loyalty. Therefore, how to effectively and accurately translate user demands into design requirements is an important work.

Construction of the HOQ matrix: Women’s demands for pleated cheongsams were transformed into design requirements, which were filled into a quality function matrix to determine the correlation between design requirements and demands γ ij . ▲, ●, and □ symbols are used to represent the strong, medium, and weak relationships in turn, which are recorded as 9, 5, and 1 points, respectively, for the calculation.

Calculate the importance of design requirements: γ ij and LR i are combined with equation (7) to obtain W j , which is the importance of the design requirements of the pleated cheongsam, and then sort according to the size of the value to determine the key design requirements

3.3 Pugh selection matrix

Pugh is a design decision-making method that integrates various criteria to quickly conceptually score, rank, and merit multiple design alternatives to meet demand metrics [23]. Therefore, the Pugh method was used as a decision-making method to select the optimal design proposal for the Kano–HOQ pleated cheongsam.

Design proposal generation: The HOQ matrix is used to determine the importance of design requirements. Higher scores indicate that the specific requirements for improving female user satisfaction with pleated cheongsams are more important. The design requirements ranked in the top 5 in terms of importance were used as the primary design direction, with the others used as supporting elements to propose design proposals.

Proposal evaluation and optimization: The Pugh method is used to compare each design proposal with the reference proposal and evaluate the strengths and weaknesses of each proposal by adding or subtracting points to select the best proposal. The score is set from 1 to 5; 1 means much worse than the reference proposal, 3 means the same as the reference proposal, and 5 means much better than the reference proposal, which is combined with the importance of the design requirements W j to calculate the proposal score Z i , as shown in equation (8). z ij denotes the raw score of the proposal j on the ith criterion.

4 Experiments and results

Shanghai JANET WEAR pleated women’s clothing brand with nearly three decades of design experience was taken as the practical object of this article to carry out the research on users’ demand for a pleated cheongsam in order to solve the problem of mismatch between the brand’s cheongsam improvement process and the users’ demand, to improve the acceptability, attractiveness, and market competitiveness of the product, and to put forward the optimized design proposals to meet the users’ demand and design requirements.

4.1 Kano demands research for pleated cheongsams

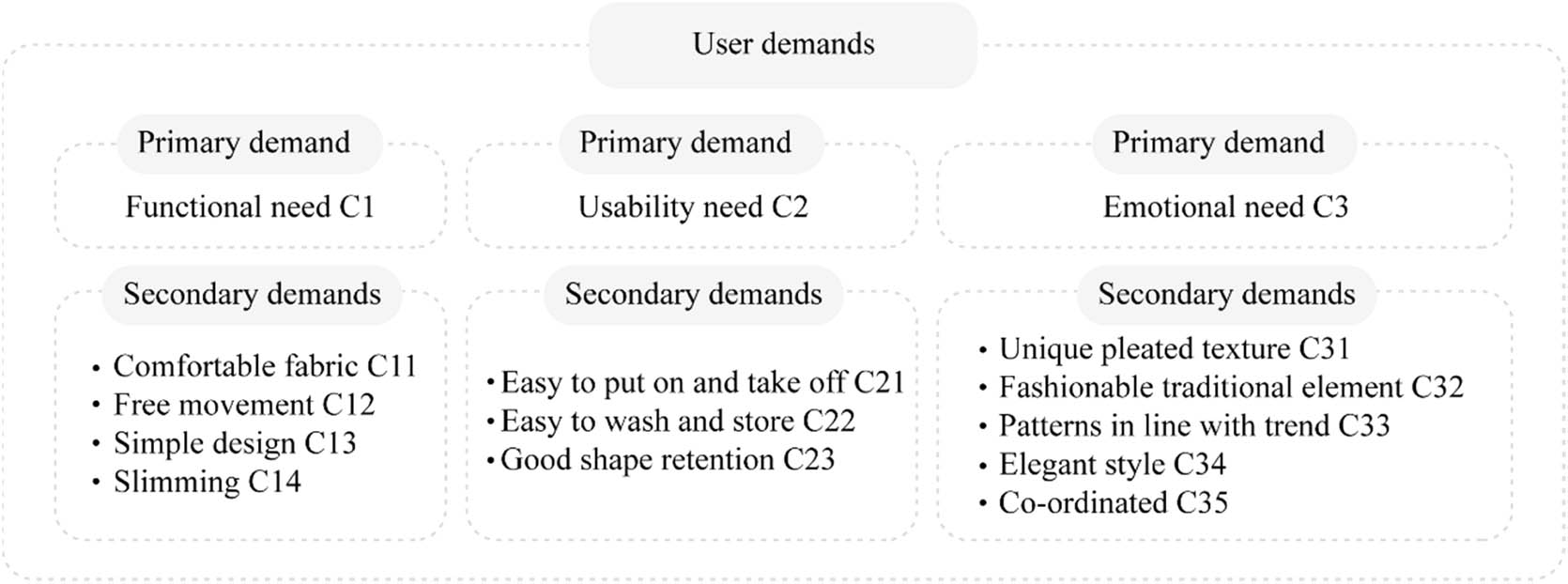

User demands interview and collation: In order to obtain as comprehensive a picture as possible of user demand for pleated cheongsams, respondent characteristics should not be homogenous. Therefore, a total of eight respondents with different occupations, including industry personnel, users, and potential users, were selected for interviews in this practice. Based on the interviews, the hierarchical grouping of demands proposed by Jordan was adopted, and 3 first-level indicators, namely C1 (Functional needs), C2 (Usability needs), and C3 (Emotional needs), and 12 second-level indicators were obtained, as shown in Figure 1.

User demands for pleated cheongsams.

Attribution and importance calculation of user demands: The demand questionnaire for pleated cheongsams was divided into three parts. The first part was personal information such as age, gender, and occupation. The second part was set up the pleated cheongsam Kano model questionnaire corresponding to the positive and negative questions of 12 demands. The third part was a Likert scale questionnaire of demand importance, current satisfaction, and target satisfaction. The questionnaires were distributed from November 20, 2022, to December 08, 2022, through the form of links in the brand’s fan communication groups and social media platforms. A total of 157 questionnaires were filled out, and 7 questionnaires that had no reference value and took too little time were excluded, resulting in 150 questionnaires with a valid recovery rate of 95.5%. The questionnaire results were used to calculate the Kano attribution of the demands against the Kano model demand result classification table. According to equations (1)–(6), Better–Worse coefficient, User satisfaction index T i , Target improvement rate V i , Requirement adjustment improvement rate IR i , and Requirement importance LR i were calculated, as shown in Table 1.

Final importance of user demands for pleated cheongsam (LR i )

| Demands | Type | T i | F i | D i | H i | S i | S 0 | V i | IR i | LR i |

|---|---|---|---|---|---|---|---|---|---|---|

| C11 | I | 0.48 | 0.48 | 0.44 | 3.77 | 3.63 | 3.86 | 1.063 | 1.063 | 4.009 |

| C12 | O | 0.72 | 0.7 | 0.72 | 3.58 | 3.65 | 3.67 | 1.005 | 1.729 | 6.191 |

| C13 | O | 0.76 | 0.72 | 0.76 | 3.77 | 3.91 | 3.6 | 0.921 | 1.620 | 6.109 |

| C14 | A | 0.8 | 0.8 | 0.52 | 3.81 | 3.72 | 3.81 | 1.024 | 2.473 | 9.424 |

| C21 | M | 0.7 | 0.54 | 0.7 | 3.65 | 3.58 | 3.91 | 1.092 | 1.424 | 5.198 |

| C22 | O | 0.66 | 0.64 | 0.66 | 3.74 | 3.76 | 3.77 | 1.003 | 1.664 | 6.225 |

| C23 | A | 0.49 | 0.49 | 0.3 | 3.75 | 3.77 | 3.88 | 1.029 | 1.872 | 7.019 |

| C31 | A | 0.7 | 0.7 | 0.53 | 3.72 | 3.74 | 3.79 | 1.013 | 2.246 | 8.356 |

| C32 | A | 0.59 | 0.59 | 0.47 | 3.77 | 3.7 | 3.84 | 1.038 | 2.081 | 7.845 |

| C33 | M | 0.69 | 0.48 | 0.69 | 3.93 | 3.72 | 3.78 | 1.016 | 1.321 | 5.191 |

| C34 | O | 0.74 | 0.72 | 0.74 | 3.84 | 3.81 | 3.87 | 1.016 | 1.340 | 5.145 |

| C35 | M | 0.8 | 0.37 | 0.8 | 3.91 | 3.8 | 3.82 | 1.005 | 1.349 | 5.273 |

Based on the classification of Kano attribute dimensions, three Must-be Quality attributes were identified, including C21 (Easy to put on and take off), C33 (Patterns in line with trend), and C35 (Co-ordinated). Additionally, there were four One-dimensional Quality attributes, namely C12 (Free movement), C13 (Simple design), C22 (Easy to wash and store), and C34 (Elegant style). Furthermore, four Attractive Quality attributes were found, which are C14 (Slimming), C23 (Good shape retention), C31 (Unique pleated texture), and C32 (Fashionable traditional element). Finally, one attribute was categorized as Indifferent Quality, represented by C11 (Comfortable fabric). The top three rankings of the importance of demands were C14, C31, and C32, indicating that female users highly value the reasonable cut and design that can showcase their more slender and fashionable appearance. They also placed great emphasis on personalized details of the pleated texture decorations, reflecting their knowledge of and appreciation for the cultural value and historical heritage of the pleated cheongsam. Understanding the significance of users’ demands for pleated cheongsam holds vital guidance for design and marketing. Brands can innovate and promote their products according to users’ preferences, satisfying their purchasing desires, and ultimately enhancing brand value.

4.2 Design requirements of pleated cheongsam based on Kano–HOQ modeling

Construction of the HOQ matrix: Fifteen pleated product designers were invited and asked to refine the design requirements based on their professional knowledge, relevant product research, and competitive product analysis. The design features with 80% common recognition were retained, and 3 first-level design requirements were obtained as D1 (Visual design), D2 (Comfort design), and D3 (Convenience design), and 11 second-level design requirements, as shown in Figure 2.

Pleated cheongsam design requirements.

The “left wall” and “roof” of the HOQ matrix conveyed the demands and design requirements of female users for the pleated cheongsam. A scoring panel consisting of pleated apparel users with more than 2 years of purchasing experience, apparel designers, and industry experts scored the relevance of the demand and design elements, as shown in Table 2.

Relationship matrix between design requirements and user demands of pleated cheongsams

| Consumer demands | Design requirements | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LR i | D11 | D12 | D13 | D14 | D15 | D16 | D21 | D22 | D23 | D31 | D32 | |

| C1 | 4.009 | ▲ | ||||||||||

| C2 | 6.191 | ● | ▲ | ● | ▲ | ● | ▲ | |||||

| C3 | 6.109 | ▲ | □ | ● | ● | ● | □ | ● | ||||

| C4 | 9.424 | ● | ▲ | □ | □ | □ | ● | □ | ● | □ | ||

| C5 | 5.198 | □ | ● | □ | ▲ | ▲ | ||||||

| C6 | 6.225 | □ | ▲ | |||||||||

| C7 | 7.019 | □ | ▲ | |||||||||

| C8 | 8.356 | □ | ▲ | ● | ||||||||

| C9 | 7.845 | □ | ● | ▲ | ▲ | ● | □ | |||||

| C10 | 5.191 | ▲ | ● | ▲ | ||||||||

| C11 | 5.145 | ● | ● | ▲ | ● | ● | □ | □ | ● | |||

| C12 | 5.273 | ▲ | ▲ | ● | ▲ | ● | ● | □ | ● | ● | ||

| γ ij | 2.50 | 2.42 | 1.83 | 2.83 | 3.17 | 3.00 | 3.08 | 0.92 | 1.42 | 3.25 | 1.67 | |

Note: ▲ indicates strong, ● indicates medium, □ indicates weak.

Calculate the importance of design requirements: The importance of the design requirements of the pleated cheongsam, in descending order of numerical size were D31 (Collar-placket design), D15 (Innovative pleat texture), D21 (Superior fabric), D16 (Modern design), D14 (Pattern co-ordination), D11 (Coherent silhouette), D12 (Harmonized style proportions), D13 (Simple decorative craft), D32 (Functional design), D23 (Suitable slits), and D22 (Multi-size fit), as shown in Table 3.

Pleated cheongsam design requirements in order of importance

| Design requirements | D11 | D12 | D13 | D14 | D15 | D16 | D21 | D22 | D23 | D31 | D32 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| W j | 190.0 | 183.6 | 139.3 | 215.3 | 240.6 | 228.0 | 234.3 | 69.7 | 107.6 | 247.0 | 126.6 |

| W j Order | 6 | 7 | 8 | 5 | 2 | 4 | 3 | 11 | 10 | 1 | 9 |

4.3 Optimized design proposal for pleated cheongsam based on the Pugh method

Generation and screening of design proposals: Through semi-structured interviews, the design style of pleated cheongsam was determined to be elegant, romantic, and classical, and the design of pleated cheongsam was carried out in combination with the brand’s tone and the thematic trends of Digital Smudge and Soft-Focus Flowers of WGSN 2023 S/S. The five design requirements of D31, D15, D21, D16, and D14 were identified as the main design direction, with the others as auxiliary elements. TikTok’s top-selling pleated cheongsam was used as the benchmark proposal to compare three brand-new design proposals, as shown in Figure 3. The following are the Pugh selection matrix of the design proposals and the weighted proposal scores.

Optimized design proposals for pleated cheongsam based on the Kano–HOQ–Pugh model.

The reference sequence for the benchmark proposal was z i0 = 3,3,3,3,3,3,3,3,3, with a benchmark value of Z 0 = 540.55. Proposal A received a weighted score of Z A = 791.54, followed by Proposal C with a weighted score of Z C = 674.68. The lowest score was obtained by Proposal B, with a weighted total score of Z B = 597.55. Based on the results of the weighted proposal scores, all three proposals outperformed the benchmark proposal, with Proposal A showing a significant advantage. Therefore, further development and evaluation of the pleated cheongsam was carried out based on Proposal A.

Optimization of design proposals and data evaluation: Proposal A demonstrated significant advantages in pattern matching, pleat texture innovation, modern design, collar-placket design, pattern, and slit position compared to Proposals B and C. However, there was still room for improvement in silhouette curves and decorative processes. Considering the feasibility of the manufacturing process and production cost, Proposal A was further optimized by incorporating the strengths of Proposals B and C in these aspects.

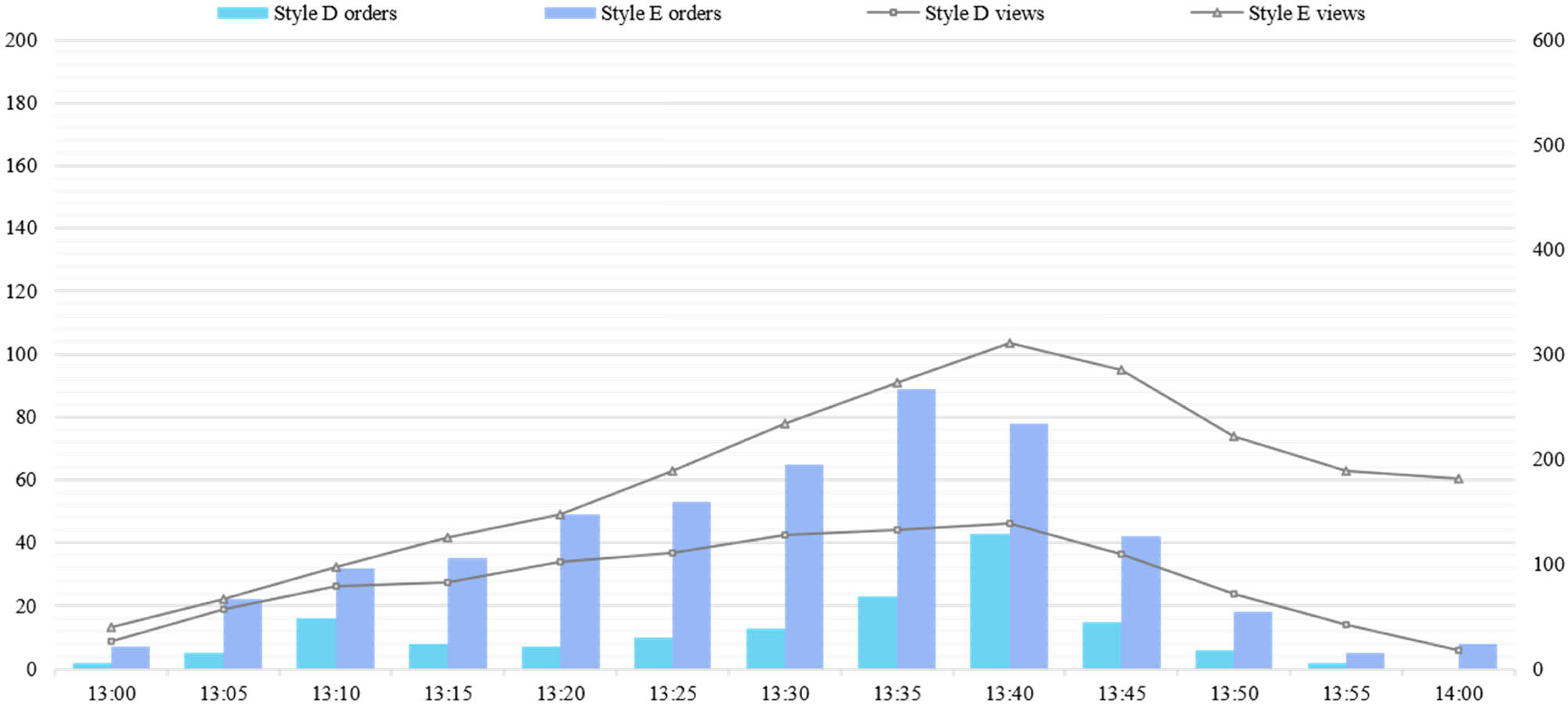

In order to objectively test whether the improved effect of pleated cheongsam based on the Kano–HOQ–Pugh model can meet user demand and improve the acceptability and attractiveness of the product, this article adopted TikTok, the purchasing channel with the highest percentage in the interview data (62.5%), as the sales channel of the modified cheongsam. During the period of 13:00–13:45 on July 28 and July 30, 2023, the live broadcast sales of the traditional cheongsam (Style D) and the modified cheongsam (Style E) were carried out. By comparing the attraction data of two cheongsam live broadcasts, including six indicators: Airplay, Completion rate, Comments, Interaction rate, Highest online number, and New fans, as well as the cheongsam’s single-item data from live sales, including three indicators: Page views, Orders, and Conversion rate, it can be determined whether the modified cheongsam is beneficial for enhancing users’ purchasing power and appeal. The background data of the two cheongsams are shown in Table 4.

TikTok live streaming data for pleated cheongsams

| Live streaming attraction data | Live streaming sales data | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Style name | Airplay | Completion rate (%) | Comments | Interaction rate (%) | Highest online number | New fans | Page views | Orders | Conversion rate (%) |

| D | 14,318 | 31.70 | 377 | 24.20 | 2,050 | 27 | 1,095 | 150 | 13.70 |

| E | 19,773 | 71.80 | 792 | 38.60 | 3,015 | 175 | 2,357 | 503 | 21.34 |

In addition, the browsing and order volume indicators were extracted, and the combination chart was drawn with the change data every 5 min to show more intuitively the sales change of the two cheongsams and the effect of the live broadcast in 60 min, as shown in Figure 4.

Pleated cheongsam views and orders change volume.

The results showed that under the premise of fixed live streaming duration and frequency, Style E’s live broadcast attraction and sales were better than Style D. Among them, the completion rate increased by 40.1%, the number of new fans was 175, the highest number of views of a single product on the same day reached 310, the number of orders was 503, and the conversion rate of the users’ orders increased by 7.64%. The folding line of Style D showed slower fluctuation, and the overall trend was low and flat. The folding line of Style E showed a sharp upward trend, with a gentle decline after the top turn, and still 181 views after the end of the live broadcast. Style E’s orders all exceeded Style D. A whopping 89 orders were placed between 13:35 and 13:40, exceeding Style D’s highest order volume of 46 orders.

The scores of the 11 design indicators for Style E and the TikTok live streaming data together demonstrated that the optimization proposal based on the Kano–HOQ–Pugh model met the design expectations and approached the ideal proposal. Simultaneously, it aligned with user demands and design requirements, effectively addressing the issue of mismatch between the pleated cheongsam’s improvement process and aesthetic concepts and user preferences. This significantly increased the product’s acceptability, appeal, and market competitiveness.

5 Conclusion

In order to solve the problem of mismatch between the improvement process of pleated cheongsam and users’ demands, three aspects of consumers’ demands, design features, and comprehensive evaluation were explored, and the Kano model and Pugh selection matrix were introduced into HOQ, so as to an optimal design model of pleated cheongsam was proposed, which was guided by users’ demand and precise mapping between the demand and the design requirements, and the model was verified based on the practical object of JANET WEAR Pleated Women’s Clothing Brand.

The results showed that the 3 primary indicators (Functional, Usability, and Emotional) and 12 secondary indicators (Comfortable fabric, Free movement, Simple design, Slimming, Easy to put on and take off, Easy to wash and store, Good shape retention, Unique pleated texture, Fashionable traditional element, Patterns in line with trend, Elegant style, and Co-ordinated) extracted from the Kano model can better characterize user demands, the 11 design requirements (Coherent silhouette, Harmonised style proportions, Simple decorative craft, Pattern co-ordination, Innovative pleat texture, Modern design, Superior fabric, Multi-size fit, Suitable slits, Collar-placket design, and Functional design) extracted from the HOQ method can be used to guide the optimal design of the pleated cheongsam, the optimal design of the pleated cheongsam based on the Pugh model was significantly improved compared with the traditional cheongsam style in the 9 indicators of the 2 live dimensions.

The experimental and theoretical results proved that the Kano–HOQ–Pugh-based model can be used for the design optimization of pleated cheongsams with cultural, ethnic, and modern characteristics, while improving the product feasibility and market acceptance, reducing the consumption of time and human resources, expanding the content of user-oriented optimal design in the field of clothing, and solving the gaps that existed in the methodology.

However, this article still has certain deficiencies. It should be more detailed in the acquisition of user demand; for example, it can be semantically interpreted through the comments of live broadcasting room, product feedback on social media, and fan messages of the brand official account in order to acquire the demand of target user groups in large quantities. This issue will be addressed in further research.

Acknowledgement

The authors wish to acknowledge the experts and scholars for their assistance in the experiments. The work described in this article was supported by the College of Fashion and Design of Donghua University.

-

Funding information: The work described in the article was funded by the Ministry of Education Social Science Major Research Project (21JZD048) and the Shanghai Science and Technology Commission “Science and Technology Innovation Action Plan” “The Belt and Road” International Cooperation Project (21130750100).

-

Conflict of interest: The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

References

[1] Chew, M. M.-T. (2022). The instrumental consumption of ethnic culture: Assessing two economically driven ways of consuming the Cheongsam in China. SAGE Open, 12(2), 21582440221097928.10.1177/21582440221097928Search in Google Scholar

[2] Yan, L., Song, J. (2021). Shanghai women’s preference and demand for Qipao. In International Conference on Business, Economics, Management Science.Search in Google Scholar

[3] Mengchao, Z., Lei, F., Xubing, X. (2021). Innovative design of pleated cheongsam for aging women. Fashion Practice, 13(1), 165–169.10.1080/17569370.2021.1873523Search in Google Scholar

[4] Liu, Z. (2018). The cultural meaning and aesthetic implication of Chinese cheongsam. In 4th International Conference on Arts, Design and Contemporary Education (ICADCE 2018). Atlantis Press.10.2991/icadce-18.2018.69Search in Google Scholar

[5] Yang, B., Chang, J. (2021). A study on characteristics analysis of Chinese Qipao design in the perspective of cultural level. The Journal of the Korea Contents Association, 21(5), 905–917.Search in Google Scholar

[6] Lin, M. (2022). A brief introduction to body-oriented parametric design for 3D-printed fashion and textiles. Textile, 20(1), 55–73.10.1080/14759756.2021.1955582Search in Google Scholar

[7] Cheng, B., Liu, Z., Chen, G., Zou, F. (2020). Generating cheongsam custom pattern based on fuzzy set theory. International Journal of Clothing Science and Technology, 32(5), 725–741.10.1108/IJCST-06-2019-0086Search in Google Scholar

[8] Feng, Q. (2013). Spicy Qipao: When Chinese dress meets punk. California State University, Los Angeles.Search in Google Scholar

[9] Lin, Y., Zhang, H., Lee, Y. (2020). Development of Qipao design applied with surrealistic expression techniques. The Research Journal of the Costume Culture, 28(5), 573–590.10.29049/rjcc.2020.28.5.573Search in Google Scholar

[10] Meng, Y., Chi, L., Yifei, C. (2022). Perceptual design of Song dynasty silk geometric patterns on cheongsam. Wool Textile Journal, 50(7), 57.Search in Google Scholar

[11] Van, N. T., Minh, T. T. (2023). Study on the elastic elongation property of fabrics silk when design the costume for cheongsam. UTEHY Journal of Science and Technology, 37, 85–90.Search in Google Scholar

[12] Roy, N. C., Luo, R., Halim, A. F., Arpan, C. (2019). Design and development of the fashionable Qipao by infliction of hand made khadi fabric. Art and Design Review, 8(1), 49–60.10.4236/adr.2020.81004Search in Google Scholar

[13] Li, J., Liu, X. (2021). The study of sustainable strategy in design of protective clothing and accessories after coronavirus (COVID-19) outbreak. Journal of Physics: Conference Series. IOP Publishing.10.1088/1742-6596/1790/1/012027Search in Google Scholar

[14] Matthews, J., Kavanagh, T., Tyrer, J. (2009). Laser assisted design for three-dimensional pleated structures. International Laser Safety Conference. AIP Publishing.10.2351/1.5061588Search in Google Scholar

[15] Xu, Q., Jiao, R. J., Yang, X., Helander, M., Khalid, H. M., Opperud, A. (2009). An analytical Kano model for customer need analysis. Design Studies, 30(1), 87–110.10.1016/j.destud.2008.07.001Search in Google Scholar

[16] Liu, K., Wu, H., Zhu, C., Wang, J., Zeng, X., Tao, X., et al. (2022). An evaluation of garment fit to improve customer body fit of fashion design clothing. The International Journal of Advanced Manufacturing Technology, 120(3–4), 2685–2699.10.1007/s00170-022-08965-zSearch in Google Scholar

[17] Sun, Y. (2023). Interactive clothing optimization design model based on 3D printing. Wireless Communications and Mobile Computing, 2023, 1–8.10.1155/2023/1319959Search in Google Scholar

[18] Zhang, M., Gill, S., Andrew, S. (2022). A design ethnography approach to developing apparel design guidelines for older women in China. Fashion Practice, 14(1), 49–78.10.1080/17569370.2021.1938819Search in Google Scholar

[19] Luo, L., Hu, X. (2020). Research on human factors engineering for the innovative design of work clothes for couriers. In Advances in Design for Inclusion: Proceedings of the AHFE 2019 International Conference on Design for Inclusion and the AHFE 2019 International Conference on Human Factors for Apparel and Textile Engineering, July 24–28, 2019, Washington DC, USA 10. Springer.Search in Google Scholar

[20] Banerjee, P. (2004). About Face 2.0: The essentials of interaction design: Alan Cooper and Robert Reimann published by John Wiley & Sons, 2003 (p. 576). SAGE Publications Sage UK, London, England.10.1057/palgrave.ivs.9500066Search in Google Scholar

[21] Jordan, P. W. (2000). Designing pleasurable products: An introduction to the new human factors. CRC press, London10.1201/9780203305683Search in Google Scholar

[22] Carnevalli, J. A., Miguel, P. C. (2008). Review, analysis and classification of the literature on QFD—Types of research, difficulties and benefits. International Journal of Production Economics, 114(2), 737–754.10.1016/j.ijpe.2008.03.006Search in Google Scholar

[23] Guler, K., Petrisor, D. M. (2021). A Pugh Matrix based product development model for increased small design team efficiency. Cogent Engineering, 8(1), 1923383.10.1080/23311916.2021.1923383Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry