Abstract

Commercial disposable facemasks have lower breathability and may cause discomfort after hours of wearing them. Graphene oxide (GO) nanoparticles offer a significant opportunity to improve the breathability of facemask materials. Hence, the current study aimed to investigate the feasibility of incorporating GO in facemask materials. The GO was synthesized from recovered carbon of waste carbon tyre. In this study, two concentrations of GO (0.01 and 0.02%) were used to enhance the comfort properties of the polypropylene (PP) facemask fabric. The GO-coated PP facemask fabrics were characterized for scanning electron microscopy, energy dispersive X-ray, and Raman spectroscopy. The comfort properties were determined using air permeability, water vapour permeability, and moisture management test. Raman analysis revealed distinctive peaks corresponding to GO at approximately 1,300 and 1,500 cm−1. The GO displayed bumping pieces of particles and a textured surface, with a diameter ranging from 30 to 80 nm. The result of mercury porosimetry shows that the PP fabric coated with 0.02% of GO provided a higher pore diameter and porosity at approximately 21.31 µm and 82.79%, respectively. Due to its high pore diameter and porosity, the PP filter facemask fabric coated with 0.02% GO demonstrated enhanced air permeability, water vapour permeability, and moisture management. These results suggested that the sample possesses favourable breathability properties as compared to the sample without GO. By undertaking this study, GO synthesized from the waste carbon tyre was developed, which can enhance the breathability of fabric materials.

1 Introduction

Coronavirus disease 2019, known as COVID-19, is a pneumonia disease confirmed by the World Health Organization on 12 January 2020 before an outbreak in all countries. COVID-19 is caused by the severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2) that infects the respiratory tract, which can cause human death [1]. It also negatively affected the economy of all countries due to the emergency lockdown in most countries to minimize the disease from spreading quickly to any human being.

Malaysia also had the highest cases of COVID-19 among Southeast Asians [2]. Since COVID-19 is known as a contagious disease, the frontliners, such as doctors and nurses, use personal protective equipment (PPE) to prevent any infectious diseases from the patients. Facemasks are used to control the transmission of droplets by the wearer [3]. Facemasks can be reusable or disposable based on the type of the mask material. The disposable facemask is mainly made of hydrophobic polymers, such as polypropylene (PP). According to several authors, the three-ply facemask consists of three essential layers, which are the outer layer, filter layer, and innermost layer [4,5]. In Figure 1, the outer layer is waterproof, and it prevents fluids, such as mucosalivary droplets that are produced from respiratory activities, such as sneezing and coughing. Meanwhile, the filter layer or the centre layer is a melt-blown nonwoven fabric. It prevents particles or germs larger than the filter layer from entering either direction. Finally, the innermost layer comprises absorbent materials that capture mucosalivary droplets from the user. The filter layer exhibits a crucial component of a facemask. Hence, the current study aimed to enhance the filter layer of the facemask.

Illustration of three layers of face masks.

Most of the facemasks are not comfortable when worn by the wearer due to the discomfort caused by facial heat, especially in hot and humid weather. According to Matuschek et al., one of the main arguments against wearing a mask is that breathing can cause the mask to become damp. When there is a lot of moisture, the masks become airtight. As a result, unfiltered air is inhaled and exhaled around the edges, reducing the protective effect for both the wearer and the environment [5]. One alternative way to improve the mask material’s comfort property is by incorporating it with graphene oxide (GO). Carbon black is found to be a good source for GO production.

Approximately 57,391 tonnes of waste tyres were produced annually in Malaysia [6]. Aside from carbon waste tyres, various studies have found that agricultural waste may be efficiently employed to generate a value-added product with improved performance attributes [7]. This waste has great potential to substitute carbon-based resources such as GO. Hence, the current study synthesized the GO from waste carbon tyres using a modified Hummers’ method.

The GO demonstrates excellent filler for thermally conductive materials that can be easily coupled with fabrics to produce textiles and clothing with improved thermal comfort. In addition, Alen et al. reported that GO could increase the permeability of membrane materials. This is due to the gas particles’ capability to pass through GO surfaces [8]. This statement shows the feasibility of incorporating GO in the facemask, which can enhance the air and water vapour permeabilities of the facemask. In addition, several studies have explored the thermal comfort properties of textile-based materials [9,10].

In the current study, GO was incorporated in the filter layer of a facemask material. The PP filter facemask fabric was sonicated in a dispersed GO suspension. The GO-coated PP filter facemask fabrics were tested for comfort properties, such as air permeability, water vapour permeability, and moisture management test (MMT). By undertaking the study, the comfort properties of the GO-coated facemask materials could be determined. Hence, enhanced properties of PP filter facemask fabric were developed, which will benefit those who wear facemasks.

2 Experimental

2.1 Materials

The materials used in this research were a single layer of PP melt-blown filter facemask fabric (Fibertex Personal Care Sdn. Bhd.) and GO. The average fabric weight obtained from ten measurements taken at various locations on the fabric was approximately 142.86 g/m2. The GO was synthesized by the modified Hummers’ method, as described earlier in previous work [11]. Prior to the coating process, the GO was dispersed in distilled water to form a GO suspension. This GO dispersion contributes to achieving a uniform coating on the fabric.

2.2 Preparation of GO suspension

The GO suspension was prepared by combining 0.1 and 0.2 g GO nanoparticles with 1,000 ml distilled water to produce two concentrations, which were 0.01 and 0.02%, respectively. The suspension was sonicated for 60 min at 40°C using a sonicate ultrasonic bath (Elma Ultrasonic S10H, Germany) to generate a homogeneous dispersion of the GO nanoparticles in distilled water.

2.3 Formation of the GO-coated PP filter facemask fabric

The PP melt-blown filter facemask was immersed into the dispersed 0.01 and 0.02% GO suspension for 30 min under 30 amplitude sonication and later was dried at 80°C for 2 h. The GO-coated PP filter facemask was then rinsed with deionized water and ethanol to remove any unfixed GO from the filter facemask. Finally, the GO incorporated with the PP melt-blown filter facemask was oven-dried overnight in a vacuum oven at 35°C. The GO-coated PP filter facemask and uncoated PP filter facemask are illustrated in Figure 2.

Photographs of the GO-coated PP filter facemask and uncoated PP filter facemask.

2.4 Characterization of the GO-coated PP filter facemask fabric using scanning electron microscopy (SEM), energy-dispersive X-ray (EDX), and Raman spectroscopy

The presence of GO from recovered carbon was tested using Raman spectroscopy (Horiba Jobin Yvon, HR800, Japan). Meanwhile, the morphological structures of the GO particles and GO-coated PP filter facemask were characterized using SEM (Hitachi TM3000 Tabletop SEM, USA). The GO-coated PP filter facemasks were cut into 1 cm × 1 cm size dimensions followed by gold coating for 60 s before observation to increase the conductivity of the samples. The magnifications used were 500× and 10,000× with a constant acceleration voltage of 5 kV. The elemental analysis of the samples was tested using the EDX analysis.

2.5 Pore diameter and porosity analysis

The pore diameter and porosity of the GO-coated PP filter facemask fabric and uncoated PP filter facemask fabric were tested using a mercury porosimeter (AutoPore V-Micromeritics). The mercury porosimeter employs a pressurized chamber (up to 60,000 psi) to force mercury to intrude into the voids of the fabrics. As the pressure is applied, mercury fills the larger pores, followed by smaller pores. The pore diameter of the GO-coated PP filter facemask fabric and uncoated filter facemask fabric was determined automatically by the porosimeter using the Washburn equation [1]:

where D is the pore diameter (µm), γ is the surface tension of mercury (485 mN/m or 485 dynes/cm), θ is the contact angle of mercury (approximately 130°), and P is the applied pressure (psi).

2.6 Air permeability, water vapour permeability, and MMT

The air permeability test was conducted using Mesdan Air Tronic 3240B (Italy) based on ASTM D737-18 in metres per second (m/s) and the air volume at about 10 l. The test area was 10 cm2, with a pressure value of about 100 Pa. For water vapour permeability (WVP), the test was conducted using the WVP tester (SDL Atlas, M261, USA) based on the ISO 8096 standard method, and the WVP of the samples was calculated using the following equation [2]:

where M is the water vapour loss (g) in the expose time period t (h), and A is the area of the uncovered specimen (m2).

The MMT was conducted based on the American Textile and Colorists Association standard test methods 195-2009 using an MMT (SDL Atlas, USA). The MMT aims to measure the transfer of liquid solutions and the distribution in a sample. The size of each sample was 80 mm × 80 mm. The top and bottom sensors were placed on the sample. The saline solution was pumped onto the upper surface of the fabric to simulate a drop of liquid sweat. The MMT software determined the moisture management properties of the sample.

3 Results and discussion

3.1 Characterization of GO from recovered carbon of waste carbon tyre using Raman spectroscopy

Raman spectroscopy explains the conversion of recovered carbon to GO. Raman analyses are essentially identical to the characteristic peak of GO by two peaks at around 1,300 and 1,500 cm−1 (D band and G band) [12].

Based on Figure 3, the Raman spectra of the obtained GO display two peaks at 1,367 and 1,593 cm−1, corresponding to the D-band and G-band. The results show that GO was successfully synthesized from the recovered carbon of waste tyre. I D/I G ratios can be determined by the heights or areas of the peak. The widening of peak D is related to the distribution of agglomerates with different orders and dimensions; thus, the information about the aromatic rings is less distorted in the maximum intensity than in width, which depends on the disorder [13].

The Raman spectra of GO from carbon waste tyre and GO on the PP filter facemask fabric.

Figure 3 shows the same pattern of Raman peak for GO onto the PP filter facemask fabric. The D band and G band peaks of Raman spectroscopy from the fabric sample successfully proved the attachment of GO. It shows that oxygen on the GO structure helps to improve the compatibility of the GO and PP fabric.

In this work, the values of the I D/I G ratios were calculated using intensity values as listed in Table 1. The I D/I G ratio measures the degree of disorder and is inversely proportional to the mean size of the sp2 clusters present in the material. Thus, the higher the I D/I G ratio in carbon materials, the greater the structural disorder. The GO reduction process can be expressed in the Raman spectra by changing the relative intensity of the D and G bands. As shown in Table 1, the I D/I G ratio of GO from recovered carbon waste is higher than that of the GO-coated PP filter facemask fabric, suggesting that new (or more) graphite domains were formed, and the number of sp2 clusters increased during the reduction. This indicates an efficient reduction, collaborating with the results obtained by the surface energy characterizations. The value of I D/I G indicates the GO with a higher degree of graphitization and less defect is produced [14,15]. From this analysis, the GO-coated PP filter facemask fabric was further investigated for comfort properties at different GO concentrations.

Raman spectroscopy of GO from recovered carbon waste and GO-coated PP filter facemask fabric

| Samples | D Peak (cm−1) | G Peak (cm−1) | I D/I G Ratio |

|---|---|---|---|

| GO from recovered carbon waste | 1367.37 | 1598.78 | 0.92 |

| GO-coated PP filter facemask fabric | 1326.87 | 1594.93 | 0.71 |

3.2 Morphological structure and elementary contents of GO and GO-coated PP filter facemask

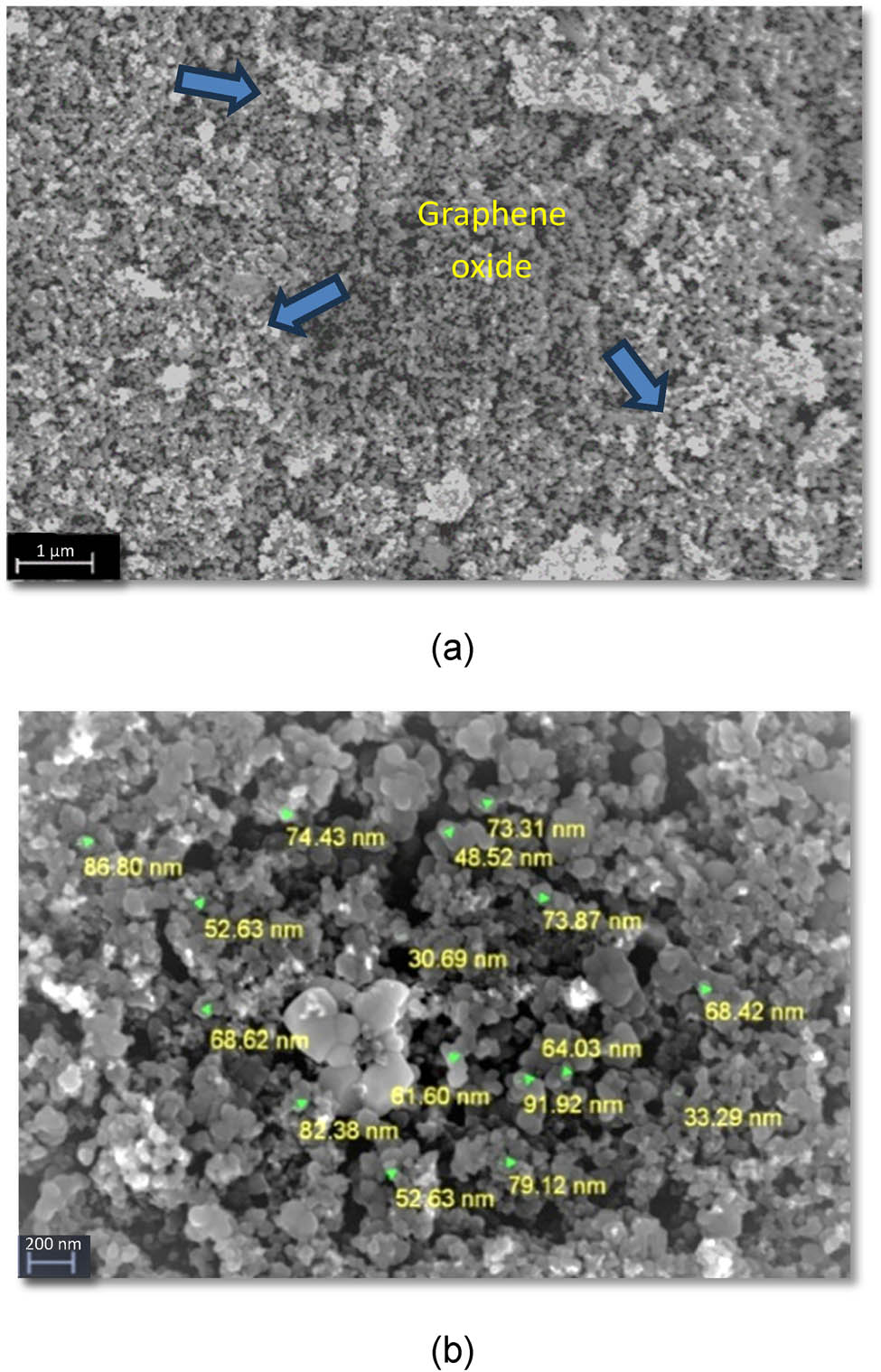

Figure 4a and b depicts our synthesized GO powder made from the recovered carbon of waste carbon tyre. As shown in Figure 4b, the image of GO reveals a circular structure trailed together on its surface. Additionally, it exhibits bumping pieces of particles and a rough surface with a diameter of between 30 and 80 nm.

(a) The SEM micrograph of GO obtained at 10,000× magnification and (b) size of GO under 30,000× magnification.

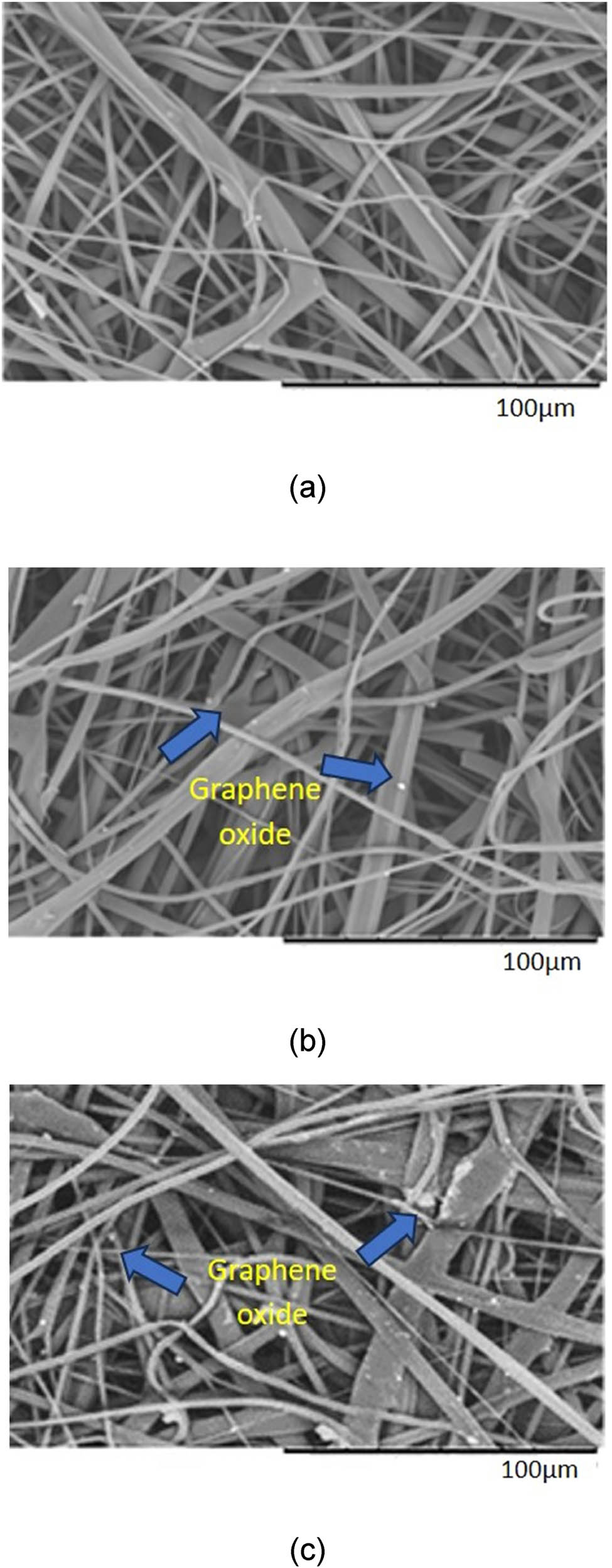

Figure 5 illustrates the SEM pictures of the uncoated, 0.01% GO-coated PP filter facemask fabric, and 0.02% GO-coated PP filter facemask fabric, revealing that the GO had effectively adhered to the filter fabric. The increasing percentage of GO indicates that the GO is increasingly attached to the fabric. Consequently, GO exhibited superior compatibility with nonwoven materials, which led to good air permeability, water vapour permeability, and moisture management.

SEM images of (a) uncoated samples, (b) 0.01% GO-coated PP filter facemask fabric, and (c) 0.02% GO-coated PP filter facemask fabric.

The EDX analysis was performed to analyse the elementary composition of GO on the fabric. Figure 6a shows the presence of carbon with a percentage of 100% in the uncoated PP filter fabric. Figure 6b reveals that the GO-coated PP filter facemask fabrics have carbon and oxygen percentages of 94.21 and 5.79%, respectively. Meanwhile, the carbon and oxygen percentages in Figure 6c are 93.7 and 6.25%, respectively, suggesting the presence of GO in the fabric. The existence of oxygen and carbon in GO was also reported by Han et al. [16].

EDX analysis of (a) uncoated samples, (b) 0.01% GO-coated PP filter facemask fabric, and (c) 0.02% GO-coated PP filter facemask fabric.

As stated by Bonnia et al., the elemental composition of carbon (C) is higher than the oxygen (O) element, which shows an excellent composition of GO. A similar finding was observed in the current study where the elemental composition of carbon (C) was also higher than oxygen (O). As shown in Figure 6b and c, the percentages of GO are as follows: 0.01% of GO exhibits 94.21% of carbon (C) and 5.79% of oxygen (O). Meanwhile, 0.02% GO provides 93.75% carbon (C) and 6.25% oxygen (O), respectively.

The EDX analysis shows that oxygen element appears for the coated sample, proving that GO was successfully attached to the fabric. Increasing the oxygen content along with an increasing percentage of GO applied to the fabric may enhance the moisture management of the PP filter facemask material. Goswami et al. also stated that GO gives good air permeability to the filter facemask, leading to good breathability of the material [17]. Hence, an extensive study on air permeability, water vapour, and moisture management was conducted in the current research work.

3.3 Pore diameter and porosity

According to Moa and Russell, the pore structure can be defined by the total pore volume (porosity) and pore connectivity [18]. In the current study, GO was found to enhance the porosity and pore diameter of the PP filter facemask fabric. Based on Figure 7a, incorporating GO in PP filter facemask fabric increases the fabric porosity by 79.59–82.79%. Meanwhile, the fabric pore diameter increased from 15.9 to 21.3 µm (Figure 7b). The presence of GO particles may result in partial embedding within the PP filter facemask fabric, which can modify the fabric’s structure, ultimately resulting in larger pores. In other words, the GO can enhance the breathability of the PP filter fabric, which is in line with Du et al. According to Du et al., a facemask with a larger porosity enables air in and out, increasing breathability. They added that the surgical mask has an intermediate porosity of 77%, while the N95 mask has the lowest porosity of 65% [19]. The authors also reported that the reusable mask has the most oversized pore diameter with approximately 46 µm, whereas the N95 mask has the finest pore diameter, 28 µm [19]. In the current study, GO-coated PP filter pore diameter is in a range of 16–21 µm. From this analysis, the results show that the GO-coated PP filter facemask fabrics have the potential to be used in one of the layers of N95 facemask materials.

(a) Porosity and (b) average pore diameter size of uncoated PP filter facemask fabric, 0.01% GO-coated PP filter facemask fabrics, and 0.02% GO-coated PP filter facemask fabric, respectively.

3.4 Air permeability

The uncoated and GO-coated PP filter facemask fabrics were tested for air permeability, and the results are presented in Figure 8. From the analysis, the air permeability of GO-coated PP filter facemask fabrics (0.01 and 0.02%) is 7% higher than that of the uncoated one. In Figure 8, the air permeability of the uncoated, 0.01% GO, and 0.02% GO are 195.28, 210.12, and 209.6 mm/s, respectively. Due to the high porosity of the GO-coated PP filter facemask fabrics as stated in Figure 7a, air was able to penetrate through the fabric samples at a higher rate than that of the uncoated fabric samples.

The air permeability of uncoated PP filter facemask fabric, 0.01% GO-coated PP filter facemask fabric, and 0.02% GO-coated PP filter facemask fabric.

The current analysis agrees with a study conducted by Li et al. The authors observed that the presence of GO resulted in enhanced air permeability and water vapour permeability in their samples [20]. Considering this, the GO-coated PP filter facemask fabric has the potential to be used as a filter layer in facemask materials. As emphasized by Patanaik and Anandjiwala, air permeability plays a crucial role in the effectiveness of nonwovens in various applications, including filters, breathable liners, protective garments, and hygiene clothes [21].

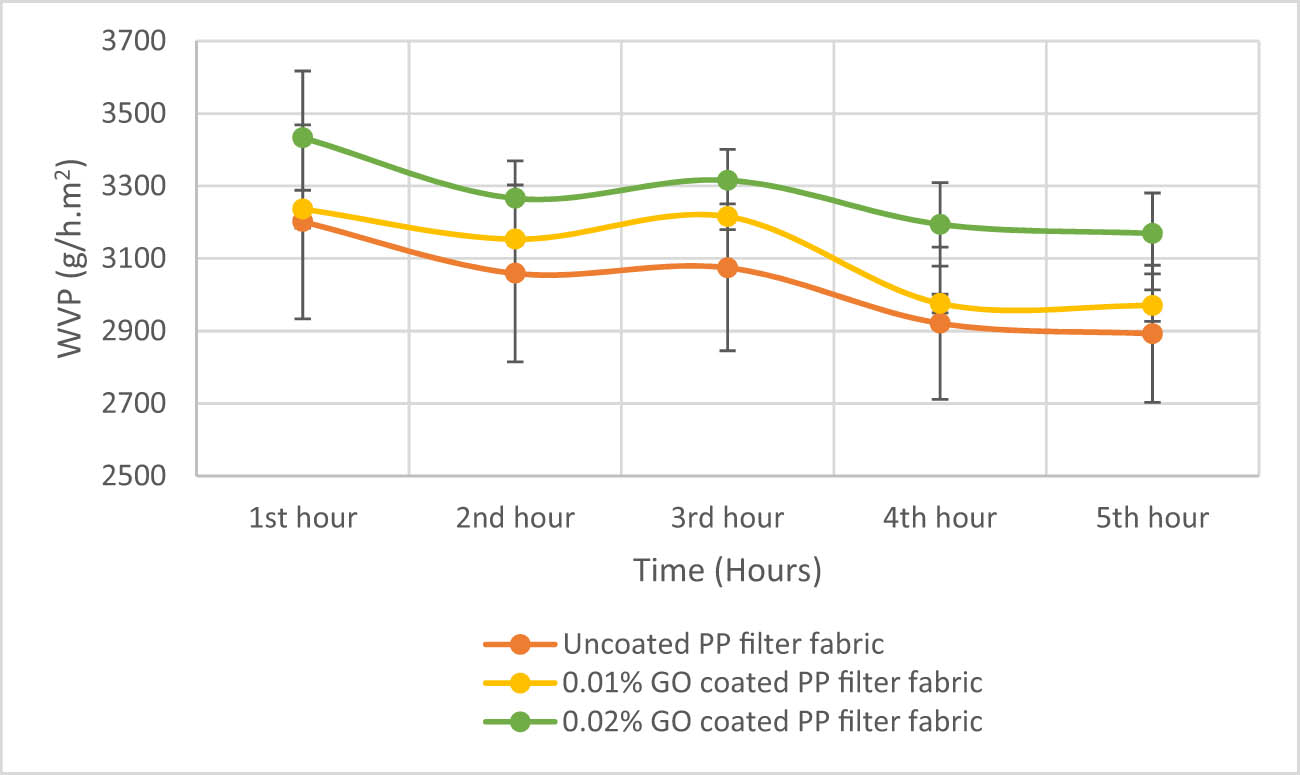

3.5 Water vapour permeability

Breathing comfort is critical while using a facemask. It is also affected by the rate of moisture transport through the filter. To understand the breathing comfort properties, the water vapour and MMTs were conducted on the uncoated PP and GO-coated PP filter facemask fabrics. In Figure 9, the uncoated PP and GO-coated PP filter facemask fabrics show a reduction from the first hour to the fifth hour. The WVP of the uncoated PP filter fabric was reduced from 3201.33 to 2892.29 g/h m2. Meanwhile, the 0.01% GO-coated PP filter facemask fabric was reduced from 3236.15 to 2970.01 g/h m2 and the 0.02% GO-coated PP filter fabric was reduced from 3432.88 to 3168.95 g/h m2.

The WVP of uncoated PP filter facemask fabric, 0.01% GO-coated PP filter facemask fabric, and 0.02% GO-coated PP filter facemask fabric.

The results presented in Figure 9 also show that the 0.02% GO-coated PP filter facemask fabric exhibits the highest WVP, followed by 0.01% GO and uncoated PP fabric samples. The high amount of GO was expected to enhance the WVP of the samples. This improvement was attributed to the transfer of water molecules either across GO or through openings created by surface imperfections in GO. Facemasks incorporated with thermally conductive materials, such as GO, are believed to offer excellent WVP, contributing to enhanced comfort during wear. This is because these conductive materials facilitate the transmission of moisture and heat into the environment [6,22].

According to Huang, water vapour is vital in determining thermal comfort [23]. From the experimental study, it can be concluded that GO can help to improve the breathability and comfort properties of the facemask materials.

3.6 MMT

Moisture control is one of the most crucial performance criteria in the textile industry today. Hence, it has significantly affected the thermophysiological comfort of the human body. The microclimate between the skin and clothes should be thermally stable through moisture management [24]. Furthermore, the overall moisture management capacity (OMMC) is an index that indicates the ability to transport liquid moisture through a sample. As shown in Table 2, the OMMC characteristics of the PP filter facemask fabric had been enhanced with the assistance of GO. The uncoated PP fabric demonstrates the lowest scale of OMMC, which is 3.5 (good to very good rating). The 0.01% GO-coated PP fabric exhibits the second-highest scale, which is 4 (very good rating), and the 0.02% GO-coated fabric shows the highest scale, which is 5 (excellent rating) of OMMC. Due to the hydrophobicity character of the PP, it enables moisture wicking at a low absorption rate and spreading speed [24]. The presence of GO in the PP filter facemask fabric increases the pore volume (voids), resulting in better fabric moisture control with promising moisture management properties.

OMMC of uncoated PP filter facemask, 0.01% GO coated PP filter facemask fabrics, and 0.02% GO coated PP filter facemasks fabrics

| Samples | Grade | Description |

|---|---|---|

| Uncoated PP filter facemask fabric | 3.5 | Good to very good |

| 0.01% GO-coated PP filter facemask fabric | 4 | Very good |

| 0.02% GO-coated PP filter facemask fabric. | 5 | Excellent |

4 Conclusions

The current study successfully incorporated GO on PP filter facemask fabric. The SEM analysis shows the bumping pieces, coarse, and chunky of sharp GO for 0.01 and 0.02% GO-coated PP filter facemask fabrics. Meanwhile, the EDX result analysis also proves the presence of GO in the fabric. Air permeability, WVP, and moisture management determine the comfort properties of the fabric samples. It can be seen that the comfort properties of the PP filter facemask have significantly improved with an additional GO in the fabric. The presence of GO in the PP filter facemask fabric transports moisture into the environment, reducing the accumulation of moisture on the fabric surfaces. Based on the results of the tests, the 0.02% GO-coated PP filter facemask fabric gives an optimal comfort property and breathability due to its high air permeability, WVP, and excellent overall moisture management rate. The current study demonstrates the feasibility of the GO-coated PP filter facemask fabric to be employed as a filter layer in facemask materials. In addition, it was expected that the GO would gradually leach out over time. Consequently, the study proposes conducting further experiments to investigate the adherence of GO to the PP filter facemask.

-

Funding information: The research study was funded by the Ministry of Higher Education, Malaysia, under the Fundamental Research Grant Scheme (Grant Project Number: FRGS/1/2019/STG07/UITM/03/2) and ERASMUS + SMARTEX Project (No. 610465-EPP-1-2019-1-EL-EPPKA2-CBHE-JP).

-

Conflict of interest: The authors state no funding.

References

[1] Shah, A. U. M. (2020). COVID-19 outbreak in Malaysia: Actions taken by the Malaysian government. International Journal of Infectious Diseases, 97, 108–116.10.1016/j.ijid.2020.05.093Search in Google Scholar PubMed PubMed Central

[2] Lip, H. T. C., Huei, T. J., Mohamad, Y., Alwi, R. I., Mat, T. T. N. A. (2020). Critical adjustments and trauma surgery trends in adaptation to COVID-19 pandemic in Malaysia. Chinese Journal of Traumatology, 23(4), 207–210.10.1016/j.cjtee.2020.05.007Search in Google Scholar PubMed PubMed Central

[3] Zhong, H. H., Zhu, Z., Lin, J., Cheung, C. F., Lu, V. L., Yan, F., et al. (2020). Reusable and recyclable graphene masks with outstanding superhydrophobic and photothermal performances. American Chemical Society Nano, 14, 6213–6221.10.1021/acsnano.0c02250Search in Google Scholar PubMed

[4] Chua, M. H., Cheng, W., Goh, S. S., Kong, J., Li, B., Lim, J. Y. C., et al. (2020). Face masks in the new COVID-19 normal: Materials, testing, and perspectives. Science Partner Journals, 2020, 7286735. 10.34133/2020/7286735.Search in Google Scholar PubMed PubMed Central

[5] Matuschek, C., Moll, F., Fangerau, H., Fischer, J. C., Zänker, K., van Griensven, M., et al. (2020). Face masks: Benefits and risks during the COVID 19 crisis. European Journal of Medical Research, 25(1), 1–8.10.1186/s40001-020-00430-5Search in Google Scholar PubMed PubMed Central

[6] Amin, M. A. M., Zuki, M. S. S., Shahidan, S., Ghadzali, N. S., Nazri, M. F., Rahim, A. M., et al. (2022). Mechanical behaviour of concrete containing crumb rubber as partial fine aggregates replacement. IOP Conference Series: Earth and Environmental Science, 1022(2022), 012043.10.1088/1755-1315/1022/1/012043Search in Google Scholar

[7] Shaker, K., Umair, M., Shahid, S., Jabbar, M., Ullah Khan, R. M. W., Zeeshan, M., et al. (2020). Cellulosic fillers extracted from argyreia speciose waste: A potential reinforcement for composites to enhance properties. Journal of Natural Fibers, 19, 1–13.10.1080/15440478.2020.1856271Search in Google Scholar

[8] Alen, S. K., Nam, S., Dastgheib, S. A. (2019). Recent advances in graphene oxide membranes for gas separation applications. International Journal of Molecular Sciences, 20(22), 1–20.10.3390/ijms20225609Search in Google Scholar PubMed PubMed Central

[9] Khan, R. M. W. U., Hussain, M., Nawab, Y, Umair, M., (2023). Influence of tetrahedral architectures on fluid transmission and heat retention behaviors of auxetic weaves. Thermal Science and Engineering Progress, 42, 101946.10.1016/j.tsep.2023.101946Search in Google Scholar

[10] Iftekhar, H., Khan, R. M. W. U., Asghar, M. A., Qadeer, A., Umair, M., Nawab, Y., et al. (2019). Study of comfort performance of novel car seat design for long drive. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 234(2), 1–7.10.1177/0954407019852279Search in Google Scholar

[11] Bonnia, N. N., Zanuri, A. Z., Affendi, N. D. N., Samsulrizal, N. (2021). Raman analysis of polypropylene fabric filled Hummers method graphene oxide from regenerate carbon of waste tyre. Proceedings of the 2nd Physics and Materials Science International Symposium (PhyMaS 2.0) (pp. 1–8).10.1063/5.0058040Search in Google Scholar

[12] Sujiono, E. H. Z, Zabrian, D., Dahlan, M. Y., Amin, B. D., Agus, S. J., (2020) Graphene oxide based coconut shell waste: synthesis by modified Hummers method and characterization. Heliyon, 6(8), 4568.10.1016/j.heliyon.2020.e04568Search in Google Scholar PubMed PubMed Central

[13] Kim, S.-K., Park, O.-K., Lee, J. H., Ku, B.-C. (2013). Layer-by-layer assembled graphene oxide films and barrier properties of thermally reduced graphene oxide membranes. Carbon Letters, 14(4), 247–250.10.5714/CL.2013.14.4.247Search in Google Scholar

[14] Jiao, X., Qiu, Y., Zhang, L., Zhang, X. (2017). Comparison of the characteristic properties of reduced graphene oxides synthesized from natural graphites with different graphitization degrees. RSC Advances, 7, 52337–52344.10.1039/C7RA10809ESearch in Google Scholar

[15] Julia, L. S., Gascho, S. F., Costa, A. A., Recco, C., Pezzin, S. H. (2019). Graphene oxide films obtained by vacuum filtration: X-ray diffraction evidence of crystalline reorganization. Journal of Nanomaterials, 2019, 1–12.10.1155/2019/5963148Search in Google Scholar

[16] Han, Y., Knightes, C. D., Bouchard, D., Zepp, R., Avant, B., Hsieh, H.-S., et al. (2019). Simulating graphene oxide nanomaterial phototransformation and transport in surface water. Environmental Science: Nano, 6(1), 180–194.10.1039/C8EN01088ASearch in Google Scholar PubMed PubMed Central

[17] Goswami, M., Yadav, A. K., Chauhan, V., Singh, N., Kumar, S., Das, A., et al. (2021). Facile development of graphene-based air filters mounted on a 3D printed mask for COVID-19. Journal of Science, 6(3), 407–414.10.1016/j.jsamd.2021.05.003Search in Google Scholar

[18] Mao, N., Russell, S. J. (2015). Fibre to Fabric. In: Sinclair, R. (Ed.). (1st ed.). Textiles and fashion materials, design and technology. Elsevier Science, Cambridge.10.1016/B978-1-84569-931-4.00013-1Search in Google Scholar

[19] Du, W., Iacoviello, F., Fernandez, T., Loureiro, R., Brett, D. J., Shearing, P. R. (2021). Microstructure analysis and image-based modelling of face masks for COVID-19 virus protection. Communications Materials, 2, 1–10.10.1038/s43246-021-00160-zSearch in Google Scholar

[20] Li, Y., Tang, Z., Wang, W., Huang, X., Lv, Y., Qian, F., et al. (2020). Improving air barrier, water vapor permeability properties of cellulose paper by layer-by-layer assembly of graphene oxide. Carbohydrate Polymers, 253, 1–33.10.1016/j.carbpol.2020.117227Search in Google Scholar PubMed

[21] Patanaik, A., Anandjiwala, R. D. (2011). Modelling nonwovens using artificial neural networks. In: Majumdar, A. (Ed.). (1st ed.). Soft Computing in textile engineering. Woodhead Publishing, Cambridge.10.1533/9780857090812.3.246Search in Google Scholar

[22] Lee, K.-P., Yip, J., Kan, C.-W, Chiou, J.-C., Yung, K.-F. (2020). Reusable face masks as alternative for disposable medical masks: Factors that affect their wear-comfort. Environmental Research and Public Health, 17(18), 6623.10.3390/ijerph17186623Search in Google Scholar PubMed PubMed Central

[23] Huang, J. (2008). Prediction of air temperature for thermal comfort of people using sleeping bags: A review. International Journal of Biometeorology, 52, 717–723.10.1007/s00484-008-0180-5Search in Google Scholar PubMed

[24] Jain, R. K., Sinha, K., Das, A. (2019). Studies on the moisture management characteristics of spunlace nonwoven fabric. Tekstilec, 62(1), 54–73.10.14502/Tekstilec2019.62.54-73Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry