Abstract

The cluster of small- and medium-scale garment industries in Aba and Onitsha positioned Nigeria to meet her garment needs. Regrettably, the production process is encumbered with manufacturing waste, which hinders competitiveness with their international counterparts. This study identified manufacturing waste in the garment production process in the garment industries in Aba and Onitsha with the view of improving the production performance. A survey research design with the use of a closed-ended questionnaire was used for data collection. In total, 372 questionnaires were administered, and 324 were completed and returned, representing 87% response rate. Descriptive statistics such as mean weighted scores was used to analyze the data for this study with the Statistical Package for Social Sciences, version 16. The result of the investigation revealed that unnecessary motion, overprocessing, inventory, waiting, and defects constitute major lean manufacturing wastes in the garment production process. Therefore, concerted efforts must be intensified by the garment industry to eliminate the identified waste with a view of ensuring the garments are competitive with foreign garments.

1 Introduction

Value and waste are terms that play a significant role in the competitiveness of products. Value is an action or process that customers are willing to pay for their satisfaction. On the other hand, waste is any activity in the production process that consumes resources without adding value to the final product [1]. Every manufacturing industry faces a particular type of waste that occurs in day-to-day production activities [2]. These wastes could be due to transportation, inventory, movement, waiting, overproduction, overprocessing, defects, and underutilization of skills. It affects the productivity of the industry in terms of production efficiency and quality of work, as well as increasing production lead time and cost [3]. There is no gainsay about the fact that lean did not only affect the productivity, but it is the bane of the inability of Nigerian garments not to be competitive in the market.

The Nigerian garment industries are mostly confronted with wastes in their production line. This is so because the garment industry still sticks to traditional methods of production that accommodate waste. The manner of handling of machines, materials, and other supporting tools for production by people are responsible for the waste experienced by the garment industry [4]. Some of the common scenes in the Nigerian garment industries are an unorganized workplace, inefficient machinery, poor supervision, unnecessary movement, a lack of standardization and working ethics, a lack of regular training of workers, and many others. Obviously, the resultant effects are high cost of production, poor quality product, slow delivery time, long production lead time, and low production capacity. One method for addressing this issue is to eliminate waste in the production process through advanced manufacturing techniques.

Lean manufacturing (LM) is one of the advance manufacturing philosophies today. It implies the identification and elimination of waste in all the processes involved in production. These LM tools that perform these functions are value stream mapping (VSM) (makes obvious areas of improvement in the production process), 5S (helps to maintain an organized workplace), work standardization (helps to standardize the work flow), total productive maintenance (ensures the machines are in good condition for efficiency), etc. The implementation of these tools has helped many industries produce high-quality products at a low cost, with higher efficiency, greater flexibility, and a shorter lead time (shorter delivery time). Most garment industries in Bangladesh, India, Pakistan, and Sri Lanka that are export-driven have started to embrace LM techniques in their production processes to guarantee continuous improvement and elimination waste in their production line. The existing study in Nigeria dwelt on lean waste reduction in the milk company [5] and chiller refurbishing company [6]. Interestingly, the outcome of the study has made continuous improvement attainable in those industries. However, despite the fact that the garment industry is a lucrative, popular, and fast growing business among Nigerians, there is a dearth of literature on the implementation of LM techniques in her garment industries.

The foregoing studies indicated the negative impacts of waste in the manufacturing industry. In this manner, possible lean tools that could minimize or eliminate the effects have been exhaustively discussed. It is against this background this study attempts to identify the manufacturing waste in the Nigerian garment industry, with the view of increasing the awareness of industrial owners about the need to embrace advance manufacturing techniques. It is through this method that their garment products could become competitive in the markets. Mohibullah [7] has proposed that to sustain global competition, industries must strive to reduce waste, production time, and overall product costs using various lean tools and techniques. Therefore, garment industries in Nigeria need to minimize lean waste in the garment production process in order to have a fair market share.

2 Literature review

A waste is anything that does not add value but add only cost to the final product [1]. In the garment manufacturing industry, there are lots of wastes that serve as a clog to industrial productivity. These wastes reduce the production efficiency, quality of work, as well as increase the production lead time [3]. Waste comprises two types. Waste type I includes activities that add no value to the production but necessary or unavoidable for production, such as notching and inspection. Type II comprises activities that do not add value and are not necessary. Waste happens in eight forms (TIMWOODS). However, Shigeo Shingo identified “seven” forms of waste (plus one, the eighth waste, under-utilization of people). Numerous authors and researchers have contemplated and consented to eight waste types depicted in Figure 1.

LM waste. Source: Researcher’s work (2024).

LM waste in any manufacturing industry encompasses eight key areas (Figure 1): over-production, excessive waiting time, over-transportation, excess inventory, over-processing, excess motion, and defects [8]. These wastes contribute to increased production costs and reduced productivity. Some lean concepts, such as teamwork and just-in-time supply, are being practiced in South West Nigeria’s garment industry, but there is a lack of understanding on how to fully implement lean practices [9]. Most of the previous research studies on the Nigerian manufacturing industry focus on the awareness and implementation of LM techniques in the small- and medium-scale manufacturing industry [6,10,11], without any particular research on the garment industry in Nigeria. A recent study [9] on the garment industry in Nigeria was limited to South West Nigeria, and the investigation focused on the awareness and implementation of lean tools in the industry. In addition, a painstaking study and interrogation of literature showed that the stakeholders in the Nigerian garment industry do not pay attention to the LM waste in garment production. Regrettably, these factors underpin the increased cost of production, low quality garment, delay in delivery, and high production lead time stemming from the manufacturing. It is against this background that this study attempts to investigate the lean waste in the garment industry in Aba and Onitsha with the view of boosting the competitiveness of the Nigerian-made-garments in the local and international markets.

3 Methods

3.1 Research design

This study employed a descriptive research design approach to identify waste in the production lines of garment industries in Aba and Onitsha through the shopfloor workers. The choice of Aba and Onitsha in Nigeria was determined by the purposive sampling technique because these two towns host clusters of garment industries and possess an unequal capacity to mass-produce garments with a technological base. Equally, purposive sampling was used to determine the shopfloor workers. The sample size was determined in accordance with the studies of Bernard and Seidler [12,13], stating that there is no limit to the number of respondents in the purposive sampling technique.

The total number of shopfloor workers in Aba and Onitsha was 374. There were 251 shopfloor workers in Aba and 123 shopfloor workers in Onitsha. The wide margin in numbers of shopfloor workers in Aba and Onitsha is because the former hosts more clusters of ready-to-wear garment industries than the latter. Since the numbers of workers in the industries are countable, the study adopted the count-all procedure (census). These samples were obtained from 19 technologically based garment industries in Aba and Onitsha (Source: Abia and Anambra State Ministries of Commerce and Industries). The technological-based industries in Aba and Onitsha were visited with the help of two research assistants who were postgraduate students. The researcher sought permission from the managers, and 90% of the managers of the industry granted the author’s request to address the shopfloor workers about the significance of the study. Thereafter, all 372 questionnaires were distributed through a face-to-face method to the shopfloor workers to avoid delay. The questionnaires allotted to each respondent were filled out immediately and collected personally by the researcher and research assistant. This approach was to ensure a higher rate of response and return of the questionnaires. In Aba, 251 questionnaires were provided to the shopfloor workers, and 219 were completed and returned, while in Onitsha, 121 questionnaires were provided, and all 121 were completed and returned. In total, 372 questionnaires were provided, and 324 were completed and returned, representing 87% response rate.

3.2 Data collection and analysis

The instrument used for the collection of primary data was a questionnaire. The questionnaire was divided into two sections. Section A measured the demographics of shopfloor workers, while Section B contained nine questions to measure the lean waste in the garment production line in Aba and Onitsha. A five-point Likert-type scale (1 = strongly disagree, 2 = disagree, 3 = neutral, 4 = agree, and 5 = strongly agree) was used to solicit answers to the research questions. Descriptive statistics and mean weighted scores were used to analyze the data for this study using Statistical Package for Social Sciences, version 16. Also, the Mann–Whitney U test was adopted to test the significance difference between the LM waste in Aba and Onitsha garment industries.

4 Results and discussion

The findings and data analysis are presented in two parts. The first part took care of the demographic data of the shopfloor workers. On the other hand, the second part identified the LM waste in the garment production process in the garment industry in Aba and Onitsha, Nigeria.

4.1 Background of respondents

4.1.1 Gender of shopfloor workers

The analysis by gender (Table 1) shows that among the shopfloor workers in Aba, 73 (33.3%) were males and 146 (66.7%) were females. In the city of Onitsha, 42 were males, representing 40.0%, and 63 were females, representing 60%. From the findings, it could be deduced that there was female dominance on the shopfloor in this industry. This is a testament to the fact that women are driven to acquire hands-on skills in tailoring, especially for those who could not further their education due to reasons of a lack of sponsorship, religious bias, teenage pregnancy, and other societal discrimination against women that are prevalent in Nigeria. Hence, the continuous growth of the garment industry will create employment opportunities for women.

Gender of shopfloor workers

| Variable | Response category | Aba, Abia State | Onitsha, Anambra State | ||||

|---|---|---|---|---|---|---|---|

| Shopfloor workers | Shopfloor workers | ||||||

| Frequency | Percentage | Mode | Frequency | Percentage | Mode | ||

| Gender | Male | 73 | 33.3 | 42 | 40 | ||

| Female | 146 | 66.7 | 2 | 63 | 60 | 2 | |

| Total | 219 | 100 | 105 | 100 | |||

Source: Researcher’s fieldwork, 2023.

4.1.2 Age of shopfloor workers

Table 2 shows that in Aba, Abia State, 26 (11.9%) operators were between 14 and 20 years of age, 117 (53.4%) operators were between 21 and 30 years old, 66 (30.1%) operators were between 31 and 40 years old, 10 (4.6%) operators were between 41 and 50 years old, and none of the operators is more than 50 years old. While in Onitsha, six (5.7%) operators were between 14 and 20 years old, 59 (56.2%) operators were between 21 and 30 years old, 29 (27.6%) operators were between 31 and 40 years old, 11 (10.5%) operators were between 41 and 50 years old, and there was no operator on the shopfloor above 50 years. It can be deduced that the majority of the operators in Aba and Onitsha were between 21 and 30 years old. The presence of young people suggests that this age group is capable of embracing new techniques to rapidly improve the production techniques of ready-to-wear garments.

Age of shopfloor workers

| Variable | Age | Aba, Abia State | Onitsha, Anambra State | ||||

|---|---|---|---|---|---|---|---|

| Shopfloor workers | Shopfloor workers | ||||||

| Frequency | Percentage | Mode | Frequency | Percentage | Mode | ||

| Age | 14–20 | 26 | 11.9 | 6 | 5.7 | ||

| 21–30 | 117 | 53.4 | 2 | 59 | 56.2 | 2 | |

| 31–40 | 66 | 30.1 | 29 | 27.6 | |||

| 41–50 | 10 | 4.6 | 11 | 10.5 | |||

| >50 | 0 | 0 | 0 | 0 | |||

| Total | 219 | 100 | 105 | 100 | |||

Source: Author’s fieldwork, 2023.

4.1.3 Educational qualification of shopfloor workers

Table 3 indicates that in Aba, 106 (48.4%) had a primary six school leaving certificate, 91 (41.6%) possessed a senior school certificate (SSCE), 11 (5.0%) possessed an NCE, 9 (4.1%) had an ordinary diploma, and 2 (0.9%) possessed a Bachelor’s degree. In Onitsha, 43 (41.0%) had a primary six school leaving certificate, 44 (41.9%) possessed an SSCE, 10 (9.5%) possessed an NCE, 6 (5.7%) had an ordinary diploma, and 2 (1.9%) possessed a Bachelor’s degree. From the result, it could be deduced that in both cities, the highest academic attainment among operators on the shopfloor is the primary six school leaving certificate and SSCE. This result suggests that higher education is rarely needed for the operators to produce quality ready-to-wear garments. This is attributable to the very low engagement of people with higher education in the industry.

Educational qualification of shopfloor workers

| Variable | Response category | Aba, Abia State | Onitsha, Anambra State | ||||

|---|---|---|---|---|---|---|---|

| Shopfloor workers | Shopfloor workers | ||||||

| Frequency | Percentage | Mode | Frequency | Percentage | Mode | ||

| Qualification | Primary six leaving certificate | 106 | 48.4 | 2 | 43 | 41 | |

| SSCE | 91 | 41.6 | 44 | 41.9 | 2 | ||

| NCE | 11 | 5 | 10 | 9.5 | |||

| Diploma | 9 | 4.1 | 6 | 5.7 | |||

| BSc. | 2 | 0.9 | 2 | 1.9 | |||

| MSc. | 0 | 0 | 0 | 0 | |||

| Total | 219 | 100 | 105 | 100 | |||

Source: Author’s fieldwork, 2023.

4.1.4 Professional experience of shopfloor workers

Table 4 shows that in Aba, 113 (51.6%) of the operators have been working for 1–5 years, 92 (42.0%) of the operators had been working for 6–10 years, 11 (5.0%) had been working for 11–15 years, 2 (0.9%) had been working for 16–20 years, and only 1 (0.5%) had been working for more than 21 years. In Onitsha, 62 (59.0%) of the operators had been working for 1–5 years, 38 (36.2%) of the operators had been working for 6–10 years, and 5 (4.8%) operators had been working for 11–15 years. From the results, it could be deduced that the majority of the operators have been working for 1–10 years. This suggests that the majority of the operators have substantial years of experience in producing ready-to-wear garments.

Professional experience of shopfloor workers

| Variable | Response category | Aba, Abia State | Onitsha, Anambra State | ||||

|---|---|---|---|---|---|---|---|

| Shopfloor workers | Shopfloor workers | ||||||

| Frequency | Percentage | Mode | Frequency | Percentage | Mode | ||

| Professional experience | 1–5 years | 113 | 51.6 | 1 | 62 | 59 | 1 |

| 6–10 years | 92 | 42 | 38 | 36.2 | |||

| 11–15 years | 11 | 5 | 5 | 4.8 | |||

| 16–20 years | 2 | 0.9 | 0 | 0 | |||

| 21 years and above | 1 | 0.5 | 0 | 0 | |||

| Total | 219 | 100 | 105 | 100 | |||

Source: Author’s fieldwork, 2023.

4.2 Analysis of LM waste

4.2.1 LM waste in the ready-to-wear garment production in Aba and Onitsha, Nigeria

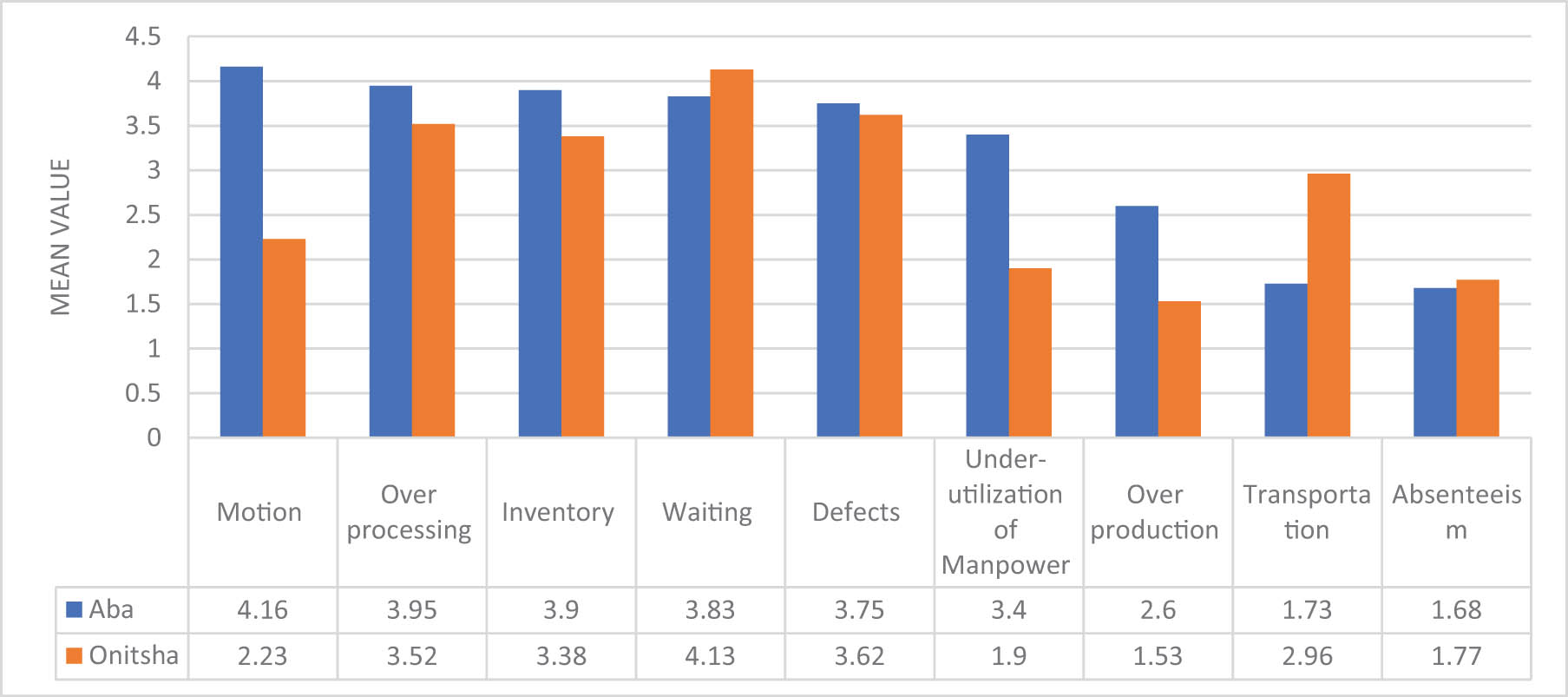

The results relating to findings from this study are presented in Figure 2. The study revealed that motion, over-processing, inventory, waiting, and defects are the major LM waste in the garment industry in Aba and Onitsha. These LM wastes have a mean score that range between 3.41 and 5.00. The results suggest that all the respondents agreed that these lean wastes are present in the garment manufacturing industry in Aba and Onitsha, Nigeria.

Graphical representation of LM waste in Aba and Onitsha, Nigeria.

4.2.2 LM waste in the garment production line

In Figure 2, motion was rated the highest with a mean value of 4.15 in Aba, while it was rated fifth in Onitsha with a mean value of 3.51. In both locations, the shopfloor workers agreed that motion constitutes a major waste in the garment industry. The slight difference in the mean value of the responses could be linked to the fact that the garment industry in Aba is bigger in size and has considerable number of workers than that of Aba. Hence, it was easier for supervisors in the Onitsha garment industry to monitor their shopfloor workers with limited number when compared with those of Aba. From the result, it was obvious that unnecessary motion was common in the garment production process in Aba and Onitsha. The findings of Arunagiria and Gnanavelbabub [2] also corroborate this result that excess motion is a major LM in the garment industry. Some of the factors that fostered the observable lean waste in the garment industry are the search for sewing thread and cleaning tools, bending, stretching, walking, lifting, and reaching out to pick up garment pieces in the course of production. According to the study of Suhardi et al. [14], these unnecessary wastes are mostly caused by process delay, badly designed cell, inadequate training, poor workstation layout, lack of standard operating system, and habit of working in traditional ways. It is therefore recommended that to avoid excess motion in the garment manufacturing industry, the manufacturing process must be simplified. A similar study carried out by Bamisaye et al. [9] on the lean waste in the garment production process in South West Nigeria rated unnecessary motion third with a mean value of 2.96. Equally, the results of the study indicated that unnecessary motion constituted one of the lean wastes in the garment manufacturing industry. In a similar manner, unnecessary motion constituted one of the major lean wastes in the garment industry in Ethiopia and Bangladesh [9,15]. Most of the unnecessary wastes witnessed in the garment production process are fostered by waiting and movement in the industry.

As shown in Figure 2, overprocessing was rated second with a mean value of 3.95 by the shopfloor workers in Aba, while in Onitsha, overprocessing was rated third with the mean value of 3.52 among the lean waste in the production process. The mean value of waste due to overprocessing in Aba and Onitsha is between the mean value of 3.41–4.21. This implies that the shopfloor workers in Aba and Onitsha agreed that overprocessing constituted one of the major wastes in the garment production process in the two locations. However, Bamisaye et al. [9] rated overprocessing low as the mean value is between 2.61 and 3.40. This suggests that the respondents are undecided on whether overprocessing constitutes a core lean waste in the selected garment manufacturing industry in South West Nigeria. The implication of this result is that the manufacturing waste varies from one region to another in Nigeria. This means that while overprocessing accounts for one of the major wastes in Aba and Onitsha, South East Nigeria, the shopfloor workers in the South West Nigeria are undecided whether overprocessing constitutes any clog to the performance in the industry. Moreover, the outcome of the result of overprocessing as one of the major wastes in Aba and Onitsha corresponded to what is obtainable in the Bangladesh garment production line. According to the study of Mazumdar [8], there is on average 15–20% overprocessing in the selected garment industry in Bangladesh. The effects of more processing are that it declined the productivity of the production line and increased the manufacturing cost. Some of the root causes of overprocessing are matching garment parts with one another, slippery of the fabrics from the machine, straightening and alignment of fabrics before sewing, notching of fabrics etc. [16]. According to the study of Uddin [17], overprocessing occurred when a revision or redoing of the procedure happens because it was not correct at the first time or taking unneeded steps to process the parts, inefficiently processing due to the poor tool and product design, causing unnecessary motion and defects. This is mostly caused by human activity rather than materials and machine related [4]. It may occur due to out of date standards, attitude to work, not understanding the process, and a lack of standard operation procedures.

Nabi and Aman [4] described inventories as those items which are either in the process of manufacturing or idle resources (material) of a factory or materials in stock. It was reported by the shopfloor workers that inventory is one of the major lean wastes in the garment industry in Aba with a mean value of 3.9, while the shopfloor workers in Onitsha are undecided with a mean value of 3.38, as shown in Figure 2. This result indicates that there is excess inventory found between operators, fabric and trim stores, cutting racks, etc. in Aba when compared to the Onitsha industry. The implication of excess inventory on the Aba garment industry is that it decreases their profit maximization and hides errors in the garment production process. Hence, there is likely to be more of defects in the garments produced in Aba when compared with the one produced in Onitsha.

Waiting most times occurs whenever work has to stop because the next person in line is overwhelmed, something broke down (machine, power supply, etc.), operators waiting for approval of materials, or they have run out of something. This kind of waste was acknowledged by the shopfloor workers as one of the lean wastes in the garment manufacturing industry in Aba and Onitsha, Nigeria. Lean waste due to waiting was ranked fourth and first in Aba and Onitsha with mean values of 3.83 and 4.13, respectively. These mean values are between 3.41 and 4.21, which suggests that the shopfloor workers in both locations agreed that the waiting experienced in the industrial environment constitute a clog to the production process. The differences in ranking is not surprising because small- and medium-scale garment industries in Aba are more compact and technologically driven than those of Onitsha. This finding is in consonance with the study of Arunagiria and Gnanavelbabub [2] who identified waiting as a core lean waste that affects the production in the industrial environment. It can be deduced from the study that there was obvious waiting in the garment production process, as indicated in Figure 2. This kind of waste is found in all processes of garment production, except in the industry where LM tools have been employed to address this particular waste. However, Bamisaye et al. [9] revealed that the shopfloors in the garment industry in South West Nigeria are undecided on whether waiting is a major waste in the production process with a mean value of 3.08. On the other hand, Mazumdar [8] reported that waiting and bottleneck were found to be mostly common in the sewing section of the garment industry in Bangladesh. Waste due to waiting become inevitable when shopfloor workers need to wait for raw materials and instruction, breakdown of sewing machines, and inadequate production layout. This waste calls for advance manufacturing techniques to address the waste in the Nigerian garment industry.

The ready-to-wear garments produced in Aba and Onitsha are considered to be of poor quality because of the defects that are prevalent in the Nigerian garment industry. It is a core challenge bedeviling the quality of garment in Nigeria. Lean waste due to defects in the garment industry in Aba and Onitsha were rated fifth and second with mean values of 3.75 and 3.62, respectively. Apparently, the mean value of each industry is between 3.41 and 4.21. This implies that the shopfloor workers in the garment industry in Aba and Onitsha agreed that defects are core manufacturing waste in the selected garment industry. Arunagiria and Gnanavelbabub [2] posited that defects arise out of processes that are poorly controlled. The root causes of the defects can be traced to variations in raw materials, changes to machine setups, wear and tear on equipment, improper maintenance, poor training of shopfloor workers, and workers’ error. On the other hand, the study of Bamisaye et al. [9] on the lean waste in the garment industry in South West Nigeria revealed that the respondents rated defects low with a mean value of 2.83, which suggests that the respondents are undecided on whether defects were major waste in the production process that lead to rework and additional cost of production. In Bangladesh, defects are recurring decimal in their garment manufacturing [8]. By inference, it could be concluded that the larger the size of the garment industry, the higher the likelihood of the defects occurrence. According to previous studies [4,8,16], some of the defects observed which often lead to rejection of the garments are fabric defects (oil spot, dust mark, fabric holes, wrong placement of embroidery design, dirty spot, color spot, fabric shading, unwanted spots, and uneven shade), sewing defects (needle hole, open stitch, missing stitch, body mismatch, bar take missing, uneven hems, misaligned buttons, slipped stitch, incorrect stitch density, wrong fusing, skipped stitch, zigzag stitch, bar take missing, sewing line displacement, wrong placement of zipper, and inaccurate shapes), finishing defects (uncut thread, improper ironing, missing of care label, and hang tag), embroidery defects, uneven lob, uneven notch, raw edge out, check match uneven, high-low, uneven pocket alignment, etc. It can be deduced from this study that the manpower, machine, and materials are primarily responsible for these defects in the Nigerian garment industry which require money and time to fix before handling to the customer or buyers.

On the other hand, the shopfloor workers rated waste due to absenteeism, overproduction, and transportation as the least rated LM wastes with mean values of 1.68, 1.73, and 1.68, respectively, in the garment manufacturing industry in Aba. In a similar manner, the shopfloor workers rated waste due to absenteeism, overproduction, and transportation low with mean values of 1.77, 1.53, and 2.96, respectively, in the garment industry in Onitsha. It is apparent that the mean values of overproduction and absenteeism are between 1.0 and 2.6 in both locations. The interpretation of this is that the respondents strongly disagreed and disagreed that the aforementioned LM wastes are common wastes in the garment production lines of the garment industries. It can be assumed that the production of garments in both locations is based on moderate order from the customers which often guide against excess production. Moreover, the result is in agreement with the findings of Arunagiria and Gnanavelbabub [2] who identified overproduction as one of the manufacturing wastes that do not portend major waste in the manufacturing industry.

For instance, in Bangladesh, there are incidences of overproduction in their industry. According to the study of Mazumdar [8], overproduction is recorded as a strategy to circumvent the likelihood of showing a shortfall in the quantity of garment due to rejection of defective pieces during the inspection process. It can be inferred that the higher the quantity of garment produced, the more likely that garments can be overproduced. Hence, overproduction generated wastes and minimized the profit of the industries. Apparently, the quantity of garments produced in Nigeria is relatively small when compared to that of Bangladesh. As a result, the small- and medium-scale Nigerian garment industry were able to produce based on customer orders when compared to larger industries that overproduced like the Bangladesh garment industry. Also, absenteeism, which is one of the lean wastes in the industry, is not common in the garment industry in Aba and Onitsha. It is evident that the operators or shopfloor workers in the garment industry in Aba and Onitsha are punctual to duty. This may not be unconnected to the unemployment rate in the country. The shopfloor workers depend solely on this job as their means of livelihood; therefore, they do not joke with jobs.

4.2.3 Difference in the LM waste in garment-making industries in Aba and Onitsha

Table 5 shows that there is statistically significant difference in the opinions of the shopfloor workers on the LM wastes in Aba and Onitsha except for absenteeism (p value = 0.253). These are significant at a p value less than 0.05. This implies that all the types of wastes differ across different industries, and therefore making LM waste a local issue than regional.

Mann–Whitney U test of difference in the LM waste in garment-making industries in Aba and Onitsha

| LM waste | Mann–Whitney U | Wilcoxon W | Z | Asymp. Sig. (two-tailed) |

|---|---|---|---|---|

| Transportation | 5810.0 | 29900.0 | −7.695 | 0.000 |

| Inventory | 8488.0 | 14053.0 | −3.999 | 0.000 |

| Motion | 2920.0 | 8485.0 | −11.312 | 0.000 |

| Waiting | 2523.5 | 8088.5 | −11.855 | 0.000 |

| Overproduction | 5494.5 | 29584.5 | −7.810 | 0.000 |

| Overprocessing | 9132.5 | 14697.5 | −3.165 | 0.002 |

| Defects | 9976.5 | 15541.5 | −2.057 | 0.040 |

| Under-utilization of manpower | 5831.0 | 11396.0 | −7.666 | 0.000 |

| Absenteeism | 10731.5 | 34821.5 | −1.142 | 0.253 |

5 Conclusions

The Nigerian ready-to-wear garment industry has continued to face the challenge of very low competitiveness of its products in terms of quality, price, delivery time, and long production lead time. An evaluation of possible and likely factors that could be responsible revealed that there are a couple of LM wastes in the garment production process. The result of the investigation revealed that unnecessary motion, overprocessing, inventory, waiting, and defects constitute major LM wastes in the garment manufacturing process in the Nigerian garment industry. On the other hand, among the eight known LM wastes in any manufacturing industry, overproduction and absenteeism do not constitute any waste to the garment industry. Consequently, efforts must be intensified to minimize or eliminate the five identified manufacturing wastes with the view of making the Nigerian garments competitive both in the local and international markets. Therefore, the industry should anticipate continuous improvement in the production process in order to eliminate the waste.

6 Recommendations

The stakeholders in the garment industry should endeavor to incorporate lean techniques in their production technique. This requires that professional training be organized for the workers about lean philosophy.

It is thus recommended that VSM should be applied to various production lines in the industry with the view of identifying the LM waste and suggesting suitable LM tools for its elimination.

Considering the major waste bedeviling the Nigerian garment industry, it should start with the implementation of lean tools such as 5S, cellular manufacturing, and line balancing to address the common waste in the Nigerian garment industry.

The proprietors of the garment industries in Aba and Onitsha should prioritize training of their workers on the practice of LM techniques in their respective industries.

The supervisors at the shopfloor should closely monitor the activities of the shopfloor workers during the production process with the view of improving the production.

Acknowledgements

The author would like to thank Dr. Emeka Ezeokoli for his helpful comments on previous versions of this paper. The author also deeply appreciates the support of Prof. Elijah A. Ayolabi, Vice-Chancellor of Mountain Top University, and the Centre for Research, Innovations, and Collaborations (CRIC) for their assistance in securing publication funding from the Chancellor of the University, Prof. D. K. Olukoya.

-

Funding information: The research was financially supported by Vice-Chancellor of MountainTop University, and the Centre for Research, Innovations, and Collaborations (CRIC).

-

Author contribution: The author confirms the sole responsibility for the conception of the study, presented results, and manuscript preparation.

-

Conflict of interest: The author states no conflict of interest.

-

Ethical approval: The research related to animal use complied with all the relevant national regulations and institutional policies for the care and use of animals.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Gebeyehu, S. G., Abebe, M., Gochel, A. (2022). Production lead time improvement through lean manufacturing. Cogent Engineering, 9(2034255), 1–14. 10.1080/23311916.2022.2034255.Search in Google Scholar

[2] Arunagiria, P., Gnanavelbabub, A. (2014). Identification of major lean production waste in automobile industries using weighted average method. Procedia Engineering, 97, 2167–2175. 10.1016/j.proeng.2014.12.460.Search in Google Scholar

[3] Paneru, N. (2011). Implementation of lean manufacturing tools in garment manufacturing process focusing sewing section of Men’s Shirts. Master’s thesis, Industrial Management, Oulu University of Applied Sciences, Oulu, Finland.Search in Google Scholar

[4] Nabi, R. M. N., Aman, A. (2020). Study of 7 wastes of Lean in Garment Industry. International Journal of Multidisciplinary Informative Research and Review, 1, 49–60. 10.5281/zenodo.4309663.Search in Google Scholar

[5] Onifade, M. K., Oroye, O. A. (2021) Application of lean manufacturing technology in a milk manufacturing company. Jurnal Sistem dan Manajemen Industri, 5(2), 87–97. 10.30656/jsmi.v5i2.3736.Search in Google Scholar

[6] Abioye, T. E., Awopetu, O. O., Ojebode, S. A. (2018). Evaluation of the production flow of a Nigerian medium scale manufacturing company using value stream mapping. Progress in Industrial Ecology: An International Journal, 12(4), 385–400.10.1504/PIE.2018.10018311Search in Google Scholar

[7] Mohibullah, A. T. M. (2006). A sewing layout which is enlarged with a part of finishing can be more effective to cost reduction of Apparel Industry. International Journal of Scientific and Engineering Research, 7(4), 1131–1137.Search in Google Scholar

[8] Mazumder, S. (2015). Lean wastes and its consequences for readymade garments manufacturing. Global Journal of Researches in Engineering: G Industrial Engineering, 15(1), 13–19.Search in Google Scholar

[9] Bamisaye, O. S., Oroye, O. A., Farayibi, P. K., Adeitan, A. D., Agbo, O. (2023). Assessment of lean practices in small and medium garment manufacturing companies in South-Western. Journal of Applied Research in Technology & Engineering, 4(2), 87–96. 10.4995/jarte.2023.18999.Search in Google Scholar

[10] Abioye, T. E., Bello, E. I. (2012). A review of awareness and implementation of lean manufacturing within Nigeria Small-Scale Manufacturing companies. Journal of Mechanics Engineering and Automation, 2, 374–380.Search in Google Scholar

[11] Ogedengbe, T. I., Abioye, T. E., Apalowo, R. K. (2017). Level of lean practices among large scale manufacturing companies in South-Western Nigeria. Progress of Industrial Ecology, An International Journal (PIE), 11(2), 195–211.10.1504/PIE.2017.10009843Search in Google Scholar

[12] Bernard, H. R. (2002). Research methods in anthropology: Qualitative and quantitative methods. 3rd ed. AltaMira Press, Walnut Creek, California.Search in Google Scholar

[13] Seidler, J. (1974). On using informants: A technique for collecting quantitative data and controlling measurement error in organization analysis. American Sociological Review, 39, 819–831. 10.2307/2094155.Search in Google Scholar

[14] Suhardi, B., Putri, M. H., Jauhari, W. A. (2020). Implementation of value stream mapping to reduce waste in a textile products industry. Cogent Engineering, 7(1), 1–25. 10.1080/23311916.2020.1842148.Search in Google Scholar

[15] Mezgebe, T. T., Asgedom, H. B., Desta, A. (2013). Economic analysis of lean wastes: case studies of textile and garment industries in Ethiopia. International Journal of Academic Research in Business and Social Sciences, 3(8), 101–127. 10.6007/IJARBSS/v3-i8/123.Search in Google Scholar

[16] Ahmed, S., Chowdhury, M. S. I. (2018). Increase the efficiency and productivity of sewing section through low performing operators improvement by using eight wastes of lean methodology. Global Journal of Researches Engineering, 18(2), 42–60.Search in Google Scholar

[17] Uddin, M. M. (2015). Productivity improvement of cutting, sewing and finishing section of garment factory through value stream mapping: a case study. B. Tech thesis, Department of Industrial and Production Engineering, Bangladesh University of Engineering and Technology, Bangladesh.Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry