Abstract

With dry weather and low humidity in autumn and winter, human skin is usually prone to dryness, even leading to itchy skin and other problems, so it is important to do a good job of skin moisturizing. The fabrics produced by using protein fiber have a certain moisturizing effect on human skin. Five types of yarn including collagen fiber, cheese protein fiber, silkworm pupa protein fiber, cashmere protein fiber, and viscose are chosen as veil materials, while nylon/spandex composite fiber is chosen as inner yarn material. Three fabric structures including the weft plain stitch, 1 + 1 mock rib, and 1 + 3 mock rib are selected for the study. Based on the full factorial experimental design method, 15 samples of seamless knitted fabrics are produced using a circular knitting machine. In order to investigate the effects of different veil materials and fabric structure of seamless knitted fabric on skin moisturizing performance, the skin moisture content test and the trans-epidermal water loss test were carried out before and after the fabric samples were wrapped around the skin of 20 participants. The results show that both the veil materials and the fabric structure have significant effects on the skin moisture content. The use of collagen yarn as the veil material and 1 + 1 mock rib as the fabric structure results in better moisturizing effects on human skin. In terms of the trans-epidermal water loss test, the fabric structure has significant effects on the results, while the veil material has no significant effect on it. However, the value of trans-epidermal water loss of the fabric with protein yarn is smaller than that of the fabric with ordinary viscose. Therefore, using cheese protein yarn as the veil material and 1 + 1 mock rib as the fabric structure results in a smaller trans-epidermal water loss value.

1 Introduction

Skincare textiles contain substances that are released over time on the human skin [1] and have certain skincare or cosmetic effects [2]. Generally, the textiles that can be used for skin care and moisturizing must ensure that they are natural, healthy, and non-irritating to the skin. Therefore, the raw materials of skincare textiles should be sourced from pure natural raw materials or extractions of natural raw materials as far as possible, so as to ensure that they are mild to the skin and safe for the human body and the natural environment [3].

Protein fiber has a shorter production cycle than chemical fiber. It is recyclable, environmentally friendly, and also can reduce energy consumption. Because of the preparation process through blending modification technology, protein fiber has some excellent performance characteristics that other natural fibers do not have. Therefore, it is also widely used in the field of textile and clothing.

Nowadays, a series of moisturizing fiber and textiles with cosmetic and skincare functions have been developed [4,5], contributing to a certain richness and innovation of textile industry products. Some researchers found that vitamin E-textiles have moisturizing effects on the skin. The reason was that when proteases were destroyed, the skin tissue in contact with the fabric would produce a large amount of active ingredients, which could allow vitamin E to enter the skin and exert its effects [6].

Therefore, it is of great application value to design and develop protein seamless knitting products with a good moisturizing effect by combining seamless knitting technology with protein fiber. This study is based on the moisturizing effect of protein fiber on human skin, analyzes the influence of the fabric structure and raw materials of protein fiber seamless knitted fabrics on the moisturizing performance of human skin, and proposes a reference theoretical basis and test method of the moisturizing performance of protein fiber seamless knitted products.

2 Experimental

2.1 Materials

2.1.1 Selection of yarn scheme

This study mainly researches the effect of protein fiber seamless knitted fabric on the moisturizing performance of human skin. 11.81 tex (50 s) collagen yarn, 11.81 tex (50 s) cheese protein yarn, 11.81 tex (50 s) silkworm pupa protein yarn, 11.81 tex (50 s) cashmere protein yarn, and 11.81 tex (50 s) viscose yarn are chosen as veil materials, while 2.22 tex/3.33 tex (20D/30D) nylon/spandex composite yarn is chosen as the inner yarn material, and the front coil as the face yarn and the back coil as the inner yarn. The specific face yarn specifications are shown in Table 1.

Face yarn raw materials and specifications

| Yarn raw materials | Fiber blending ratio |

|---|---|

| 11.81 tex (50 s) collagen yarn | 70% viscose + 30% collagen fiber |

| 11.81 tex (50 s) cheese protein yarn | 70% viscose + 30% silkworm pupa protein fiber |

| 11.81 tex (50 s) silkworm pupa protein yarn | 40% Lanzing Modal + 30% acrylic + 30% cheese protein fiber |

| 11.81 tex (50 s) cashmere protein yarn | 40% Jasel + 30% acrylic + 30% cashmere protein fiber |

| 11.81 tex (50 s) viscose | 100% viscose |

The cheese protein yarn, silkworm pupa protein yarn, and cashmere protein yarn were purchased from Sichuan Yibin Huimei Fiber New Material Co., Ltd, collagen yarn was purchased from Qingdao Bonte Fiber Co., LTD., and viscose yarn and nylon/spandex composite yarn were purchased from Yiwu Huading Nylon Co., Ltd. The four protein fiber raw materials are obtained by adding extracted protein solutions to the spinning solution and then spinning. Due to the limited yarn available in the market, the four types of protein yarn selected in this study are blended with protein fibers and other types of fibers. The blending ratios of collagen yarn and silkworm pupa protein yarn were 70% viscose + 30% collagen fiber and 70% viscose + 30% silkworm pupa protein fiber. The blending ratio of cheese protein yarn is 40% Lanzing Modal + 30% acrylic + 30% cheese protein fiber, in which Lanzing Modal fiber is a cellulose regenerated fiber with high moisture modulus viscose fiber. The blending ratio of cashmere protein yarn is 40% Jasel + 30% acrylic + 30% cashmere protein fiber, in which Jasel fiber is a viscose staple fiber. The blending proportion of protein fiber in the four protein yarns is 30%.

2.1.2 Fabric structure design

Fabric structure design has a certain impact on the appearance and performance of seamless knitted fabrics. This study mainly focuses on seamless knitted products for autumn and winter. Therefore, based on the actual production characteristics and the wearing needs of winter knitted fabrics, three commonly used structures of seamless knitted products in autumn and winter were selected, namely weft plain stitch, 1 + 1 mock rib, and 1 + 3 mock rib [7].

2.1.3 Establishment of sample scheme

In this study, the veil raw materials and fabric structure are taken as experimental factors. There are five levels of raw materials, namely collagen yarn, cheese protein yarn, silkworm pupa protein yarn, cashmere protein yarn and viscose yarn. There are three levels of fabric structure, namely weft plain stitch, 1 + 1 mock rib stitch and 1 + 3 mock rib stitch. The specific factor levels are shown in Table 2. The full-factor experimental design method is used to design the sample scheme, so as to find the performance differences of protein fiber seamless knitted fabrics with different raw materials and fiber structure of veil yarn. The specific sample scheme is shown in Table 3.

Factor level sheet

| Number | Factors | |

|---|---|---|

| A (Raw materials) | B (Fiber structure) | |

| 1 | Collagen yarn | Weft plain stitch |

| 2 | Cheese protein yarn | 1 + 1 mock rib |

| 3 | Silkworm pupa protein yarn | 1 + 3 mock rib |

| 4 | Cashmere protein yarn | — |

| 5 | Viscose yarn | — |

Sample scheme sheet

| Number | Raw materials (face yarn) | Raw materials (inner yarn) | Fiber structure |

|---|---|---|---|

| 1# | Collagen yarn | Nylon/spandex composite yarn | Weft plain stitch |

| 2# | Collagen yarn | Nylon/spandex composite yarn | 1 + 1 mock rib |

| 3# | Collagen yarn | Nylon/spandex composite yarn | 1 + 3 mock rib |

| 4# | Cheese protein yarn | Nylon/spandex composite yarn | Weft plain stitch |

| 5# | Cheese protein yarn | Nylon/spandex composite yarn | 1 + 1 mock rib |

| 6# | Cheese protein yarn | Nylon/spandex composite yarn | 1 + 3 mock rib |

| 7# | Silkworm pupa protein yarn | Nylon/spandex composite yarn | Weft plain stitch |

| 8# | Silkworm pupa protein yarn | Nylon/spandex composite yarn | 1 + 1 mock rib |

| 9# | Silkworm pupa protein yarn | Nylon/spandex composite yarn | 1 + 3 mock rib |

| 10# | Cashmere protein yarn | Nylon/spandex composite yarn | Weft plain stitch |

| 11# | Cashmere protein yarn | Nylon/spandex composite yarn | 1 + 1 mock rib |

| 12# | Cashmere protein yarn | Nylon/spandex composite yarn | 1 + 3 mock rib |

| 13# | Viscose yarn | Nylon/spandex composite yarn | Weft plain stitch |

| 14# | Viscose yarn | Nylon/spandex composite yarn | 1 + 1 mock rib |

| 15# | Viscose Yarn | Nylon/spandex composite yarn | 1 + 3 mock rib |

The 15 fabric samples in this study were woven by Saint-Tony SM8-TOP2 MP seamless circular knitting machine, as shown in Figure 1. This machine has an 8-loop system, each loop system has eight nozzles. During weaving, each loop system threads a veil and an inner yarn, with a ratio of 1:1 between the veil and the inner yarn. All seamless knitted samples were woven with the same weaving parameters: machine number, 28 stitches/inch; barrel diameter, 14 inches; needle number, 1,248 stitches; and the height position of the loop triangle was the same. Due to the influence of factors such as the raw material and organizational structure of the veil, the density, square meter weight, and thickness of each sample may vary after being removed from the machine.

Saint-Tony SM8-TOP2 MP seamless circular knitting machine.

The horizontal and longitudinal density test results of 15 seamless knitted fabrics in this article are shown in Table 4. Among them, horizontal density refers to the number of coils within 5 cm along the horizontal direction of the knitted fabric, and longitudinal density refers to the number of coils within 5 cm along the longitudinal direction of the loops. According to the experimental standards and steps, 15 seamless knitted fabrics were tested and calculated, and the results of the square meter weight and thickness tests are shown in Table 5.

Horizontal and longitudinal density

| Number | Horizontal density | Longitudinal density |

|---|---|---|

| 1# | 75 | 116 |

| 2# | 82 | 142 |

| 3# | 90 | 152 |

| 4# | 74 | 114 |

| 5# | 90 | 143 |

| 6# | 108 | 156 |

| 7# | 75 | 110 |

| 8# | 93 | 138 |

| 9# | 112 | 148 |

| 10# | 70 | 118 |

| 11# | 92 | 144 |

| 12# | 106 | 156 |

| 13# | 71 | 137 |

| 14# | 78 | 141 |

| 15# | 80 | 146 |

Square meter weight and thickness

| Number | Square meter weight (g·m−2) | Thickness (mm) |

|---|---|---|

| 1# | 229.77 | 0.747 |

| 2# | 271.17 | 0.977 |

| 3# | 366.56 | 1.477 |

| 4# | 248.75 | 0.727 |

| 5# | 297.21 | 0.996 |

| 6# | 432.86 | 1.710 |

| 7# | 244.16 | 0.683 |

| 8# | 287.26 | 0.923 |

| 9# | 381.82 | 1.434 |

| 10# | 248.90 | 0.710 |

| 11# | 301.85 | 0.970 |

| 12# | 409.93 | 1.697 |

| 13# | 238.90 | 0.693 |

| 14# | 288.38 | 0.950 |

| 15# | 368.92 | 1.443 |

2.2 Methods

2.2.1 Skin moisture content test

The skin moisture content in this study refers to the water content of the skin stratum corneum. The capacitance test for testing skin moisture content is used in this study. The principle of the capacitance test is designed based on the significant difference between the dielectric constant of water and other substances. The dielectric constant of water is 81, while the dielectric constant of other tissue components in the skin is less than 7 [8]. As a capacitor, the Corneometer CM 825 skin moisture test probe measures different dielectric constants when the probe comes into contact with different substances. Thus, the change of water content of the stratum corneum can be measured and calculated. The advantage of the capacitance test is that there is no unnatural contact between the tested skin and the probe, the skin will not be harmed, the test process is not affected by external electric fields, and the test results are more accurate. In addition, the water content of the stratum corneum of the skin can be measured quickly because the probe and the moisture in the skin establish a balance process very quickly.

Experimental instruments: MPA6 multi-probe test system and Corneometer CM 825 skin moisture test probe, as shown in Figure 2.

MPA6 multi-probe test system and Corneometer CM 825 skin moisture test probe.

Reference standard: QB/T 4256-2011 “Guidelines for Evaluation of Moisturizing Effect of Cosmetics.”

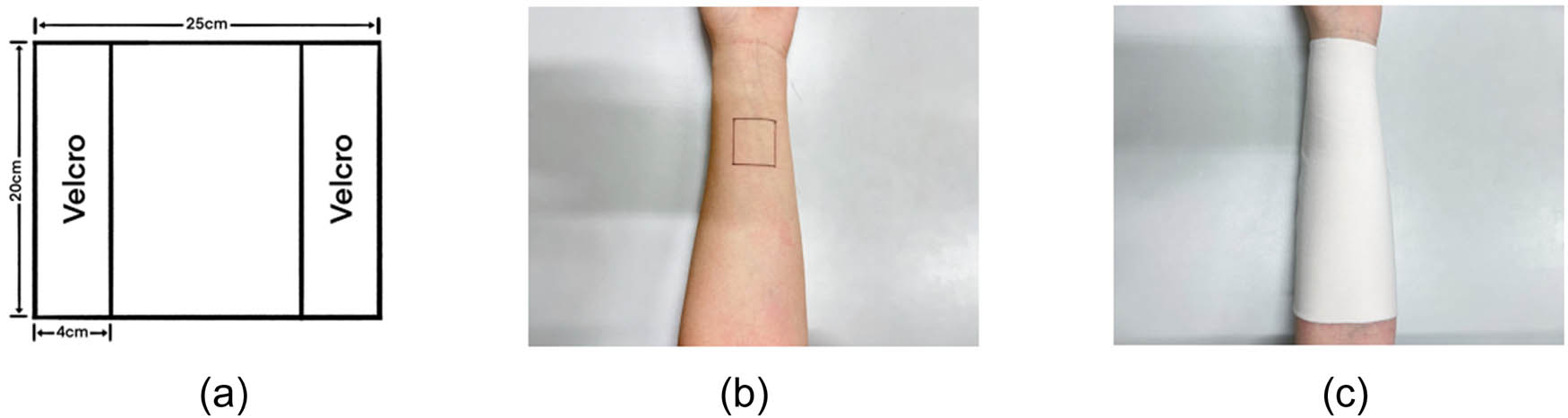

Test sample: The reasonable size of the sample size is 25 cm in length and 20 cm in width. Velcro tapes with a length of 20 cm and a width of 4 cm are set on both sides of the sample for convenient measurement, which can not only ensure that the sample completely wraps around the forearm but also adjust according to the circumference of the forearm of different participants. The specification of the fabric sample is shown in Figure 3(a).The test area is 5 cm from the inner forearm to the palm, with an area is 3 cm × 3 cm. The marking of the test area is shown in Figure 3(b), and the coating state of the sample is shown in Figure 3(c).

(a) Sample specification diagram, (b) marking area diagram, and (c) coating area diagram.

Conditions for participants: Participants are non-highly sensitive and have no immune system defects or autoimmune diseases. The test site cannot accept skin treatments that may cause inaccurate test results. They have not used hormone drugs or immunosuppressants within the past month.

Test environment: Room with ambient temperature of 20–22°C and humidity of 40–60% in line with test standards.

Pre experiment: After the fabric contacts the skin for a period of time, the moisturizing effect brought by the fabric will no longer change the skin moisture content, so it is necessary to conduct a pre-experiment. The instrument was calibrated according to the instructions, and the test was performed after making sure that the instrument is in normal condition. The time gradient set in this experiment was to test skin moisture content 30 min, 1 h, and 2 h after the fabric sample was covered. The results show that the test results of the sample 1 h after wrapping around the forearm are basically consistent with those of the sample 2 h, indicating that the skin moisture content reaches a balanced state after 1 h of wrapping around the forearm. Therefore, it is reasonable to determine the sample covering time of 1 h.

Formal test steps: After the participants sit for 30 min, the initial value T 0 is tested, as shown in Figure 4. During the experiment, different locations in the test area are selected to test five times and take the average value. After the initial value T 0 is tested, the fabric sample is wrapped around the forearm, and the above formal test steps are repeated for testing to obtain T 1.

Test status diagram of testing skin moisture content.

2.2.2 Trans-epidermal water loss test

The higher the value of trans-epidermal water loss, the more water is lost through the skin per unit time, and the more serious the damage to the skin’s stratum corneum function. Conversely, it means that the stratum corneum gradually recovers [9]. Therefore, trans-epidermal water loss is an indispensable parameter. The relatively stable testing environment formed by the Tewameter TM Hex skin moisture loss test probe on the skin surface is due to the specially designed cylindrical cavity with open ends, which measures the trace water evaporation on the skin surface through temperature and humidity sensors, and then obtains the amount of water lost through the epidermis.

Experimental instruments: MPA6 multi-probe test system and the Tewameter TM Hex skin moisture loss test probe, as shown in Figure 5.

MPA6 multi-probe test system and the Tewameter TM Hex skin moisture loss test probe.

Reference standard: QB/T 4256-2011 “Guidelines for Evaluation of Moisturizing Effect of Cosmetics.”

Test sample: Same as the skin moisture content test.

Conditions for participants: Same as the skin moisture content test.

Test environment: Same as the skin moisture content test.

Test steps: After completing the skin moisture content test, in order to avoid the loss of water in the skin when the forearm is exposed to the air after the sample is taken off, a trans-epidermal water loss test should be conducted immediately. During the test, the probe and the participant’s forearm are naturally fitted at 90°, and the probe should not be excessively pressed, as shown in Figure 6.

Test status diagram of testing trans-epidermal water loss.

3 Results and discussion

3.1 Test results and analysis of skin moisture content

The skin moisture content corresponding to 15 samples was calculated according to formula (1), and the test results of the skin moisture content change rate were obtained by taking the average value.

Change rate of skin moisture content (%):

where R is the change rate of skin moisture content in the test area covered by the sample, %; T 1 is the skin moisture content of the test area after 1 h of sample covering, %; T 0 is the skin moisture content of the test area before the sample covering, %.

The results of the average skin moisture content change rate of the participants are shown in Table 6.

Skin moisture content change rate

| Sample number | Skin moisture content change rate (%) | Sample number | Skin moisture content change rate (%) |

|---|---|---|---|

| 1# | 5.67 | 9# | 4.85 |

| 2# | 6.76 | 10# | 4.58 |

| 3# | 5.14 | 11# | 5.19 |

| 4# | 3.98 | 12# | 4.37 |

| 5# | 5.42 | 13# | 1.24 |

| 6# | 4.05 | 14# | 1.34 |

| 7# | 4.96 | 15# | 1.97 |

| 8# | 6.33 |

The data measured through SPSS were consistent with normal distribution, and further exploration was conducted on the relationship between the veil raw materials and fabric structure and the influence of fabrics on the skin moisture content change rate using two-factor ANOVA. The variance analysis results of the skin moisture content change rate of the fabric are shown in Table 7. It can be seen from the table that these two factors have significant effects on the skin moisture content change rate, in which the change of the veil raw material has a greater impact on the skin moisture content change rate. It has statistical significance.

Variance analysis of skin moisture content change rate

| Source | Sum of squares | Freedom | Mean square | F | Significance |

|---|---|---|---|---|---|

| Veil raw materials | 34.674 | 4 | 8.669 | 36.454 | <0.001 |

| Fabric structure | 2.828 | 2 | 1.414 | 5.946 | 0.026 |

| Error | 1.902 | 8 | 0.238 | ||

| Total | 39.404 | 14 |

Duncan method was used to further compare the differences between different levels within veil raw materials and fabric structure. The veil raw materials and fabric structure were set as fixed factors, and the skin moisture content change rate was set as the dependent variable. The horizontal differences among subsets were analyzed in detail through the results of different subsets output by the Duncan method. The results are shown in Tables 8 and 9. It can be seen from these tables that:

In terms of veil raw materials, collagen fiber and silkworm pupa protein fiber occupy the same subset, indicating that there is no significant difference between the two types of veils; Silkworm pupa protein fiber, cashmere protein fiber, and cheese protein fiber account for a subset, indicating that there is no significant difference among them; viscose accounts for a subset alone, indicating that viscose fabric and the other four kinds of protein yarn fabrics have significant differences in the influence of skin moisture content change rate. The skin moisturizing effect of four kinds of protein yarn fabrics is obviously better than that of viscose fabric. By analyzing the blending ratios of different fibers in the veil raw materials, it can be seen that the fiber blending ratios of collagen yarn and silkworm pupa protein yarn are 70% viscose and 30% protein fiber. The skin moisturizing effect of these two fabrics is better than that of ordinary viscose fabric, indicating that protein fiber plays a certain role in skin moisturizing. The blending ratios of cashmere protein yarn and cheese protein yarn both contain 30% acrylic fiber, which have poor moisture absorption. However, the skin moisturizing effect of these two fabrics is also better than that of ordinary viscose fabric, indicating that the addition of protein fiber improves the skin moisturizing performance of the fabric.

In terms of fabric structure, 1 + 3 mock rib and weft plain stitch occupy the same subset, indicating that the difference between them is not significant; 1 + 1 mock rib accounts for a subset alone, indicating that 1 + 1 mock rib and the other two kinds of fabric structure have obvious differences in moisturizing performance. Although the structural characteristics of 1 + 1 mock rib and 1 + 3 mock rib make the fabric thicker and have obvious lines on the surface, the thickness of 1 + 1 mock rib fabric is smaller than 1 + 3 mock rib, so the protein fiber in the fabric has a larger contact area with the skin. Therefore, the moisturizing effect of 1 + 1 mock rib fabric is better than 1 + 3 mock rib fabric. Compared to weft knitted fabric, 1 + 1 mock rib fabric is thicker and warmer, which prevents the loss of moisture on the surface of the human skin and also provides a moisturizing effect. In summary, 1 + 1 mock rib has the highest value of skin moisture content change rate and the best moisturizing effect.

Multiple comparisons of different levels of veil types

| Veil raw materials | N | Subset | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

| Viscose | 3 | 1.5067 | ||

| Cheese protein | 3 | 4.4833 | ||

| cashmere protein | 3 | 4.7133 | ||

| Silkworm pupa protein | 3 | 5.3800 | 5.3800 | |

| Collagen protein | 3 | 5.8567 | ||

Multiple comparisons of different levels of fabric structure

| Fabric structure | N | Subset | |

|---|---|---|---|

| 1 | 2 | ||

| 1 + 3 mock rib | 5 | 4.0760 | |

| Weft plain stitch | 5 | 4.0860 | |

| 1 + 1 mock rib | 5 | 5.0020 | |

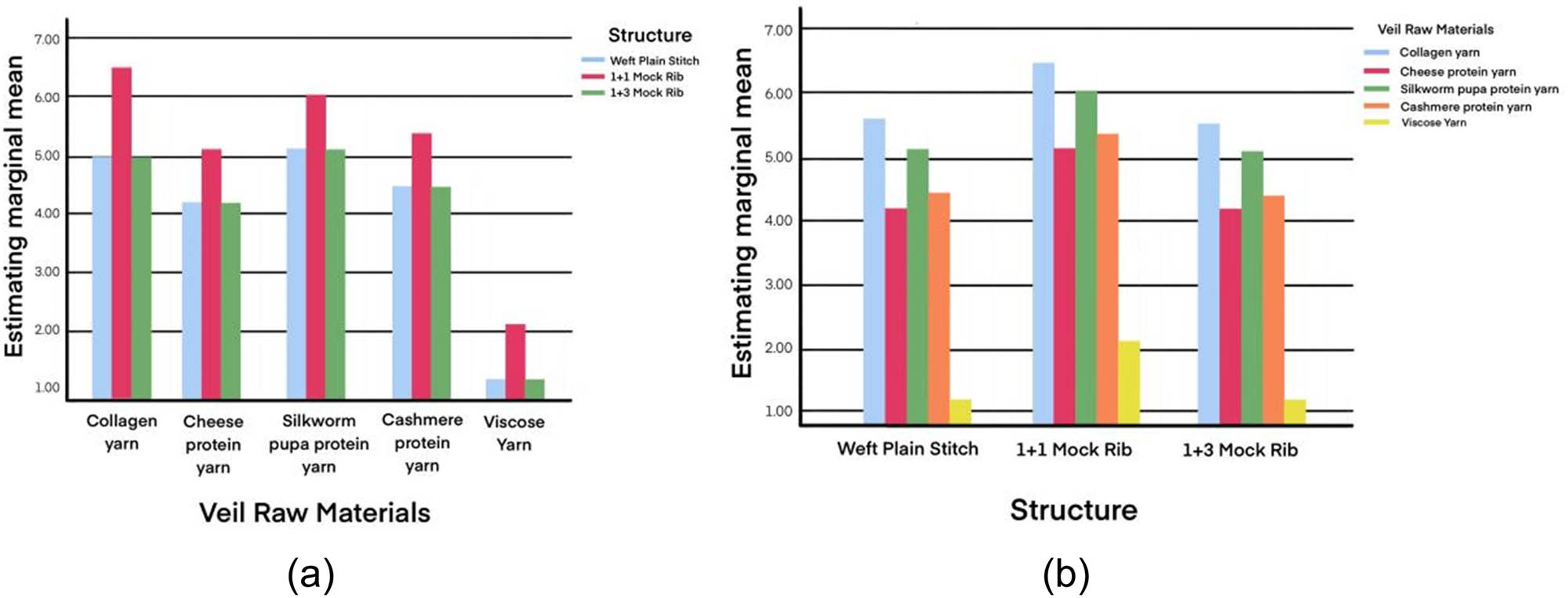

The marginal average value is an estimate calculated based on the sample situation to compare the average values of each level when controlling for the influence caused by other factors under the premise of existing models [10]. The contour diagram of the estimated marginal average value of the skin moisture content change rate is shown in Figure 7. According to the variance analysis of the skin moisture content change rate mentioned earlier, both the veil raw material and fabric structure have a significant influence on the skin moisture content change rate. It can be seen from the figure that when the independent variable is the veil raw material, there is a significant difference in the estimated marginal value of different fabric structures. The value of 1 + 1 mock rib fabric is the highest, which has the best skin moisturizing effect. The following is the fabric with weft plain stitch and 1 + 3 mock rib, the difference is not obvious, and the effect of the fabric sample is poor. When the independent variable is the fabric structure, there is also a significant difference in the estimated marginal value of different veil raw materials. The value of collagen yarn fabric is the highest, which has the best skin moisturizing effect, followed by silkworm pupa protein yarn fabric, cashmere protein yarn fabric, and cheese protein yarn fabric, and viscose yarn fabric has the worst skin moisturizing effect.

Estimated marginal average of skin moisture content change rate: (a) independent variable is veil materials, (b) independent variable is fabric structure.

3.2 Test results and analysis of trans-epidermal water loss

The change rate of trans-epidermal water loss corresponding to 15 samples was calculated according to formula (2), and the test results of trans-epidermal water loss change rate were obtained by taking the average value.

Change rate of trans-epidermal water loss (%):

where R is the change rate of trans-epidermal water loss in the test area covered by the sample, %; T 1 is the trans-epidermal water loss of the test area after 1 h of sample coating, %; T 0 is the trans-epidermal water loss of the test area before the sample coating, %.

The results of the average trans-epidermal water loss change rate of the participants are shown in Table 10.

Change rate of trans-epidermal water loss

| Sample number | Change rate of trans-epidermal water loss (%) | Sample number | Change rate of trans-epidermal water loss (%) |

|---|---|---|---|

| 1# | −2.20 | 9# | −5.13 |

| 2# | −3.71 | 10# | −2.35 |

| 3# | −3.54 | 11# | −4.27 |

| 4# | −2.25 | 12# | −3.04 |

| 5# | −5.83 | 13# | −1.07 |

| 6# | −4.11 | 14# | −2.39 |

| 7# | −2.85 | 15# | −2.61 |

| 8# | −3.36 |

The data measured through SPSS were consistent with normal distribution, and further exploration was conducted on the relationship between the veil raw materials and fabric structure and the influence of fabrics on the trans-epidermal water loss change rate corneum using two-factor ANOVA. The variance analysis results of the change rate of trans-epidermal water loss of the fabric are shown in Table 11. It can be seen from the table that the raw materials of veil have no significant effect on the trans-epidermal water loss rate of skin, while the fabric structure has a significant effect on the trans-epidermal water loss change rate of skin.

Variance analysis of change rate of trans-epidermal water loss

| Source | Sum of squares | Freedom | Mean square | F | Significance |

|---|---|---|---|---|---|

| Veil raw material | 7.374 | 4 | 1.843 | 3.161 | 0.078 |

| Fabric structure | 9.258 | 2 | 4.629 | 7.938 | 0.013 |

| Error | 4.665 | 8 | 0.583 | ||

| Total | 21.297 | 14 |

In order to compare the differences among different levels of fabric structure, the fabric structure was set as a fixed factor, and the change rate of trans-epidermal water loss was set as a dependent variable. Duncan method was used to further analyze the differences among different subsets, and the results are shown in Table 12. It can be seen from the table that the weft plain stitch occupies a subset alone, and the 1 + 3 mock rib and 1 + 1 mock rib occupy the same subset, indicating that the 1 + 1 mock rib has a better effect on reducing the water loss through the epidermis.

Multiple comparisons of different levels of fabric structure

| Fabric structure | N | Subset | |

|---|---|---|---|

| 1 | 2 | ||

| Weft plain stitch | 5 | 2.1440 | |

| 1 + 3 mock rib | 5 | 3.6860 | |

| 1 + 1 mock rib | 5 | 3.9120 | |

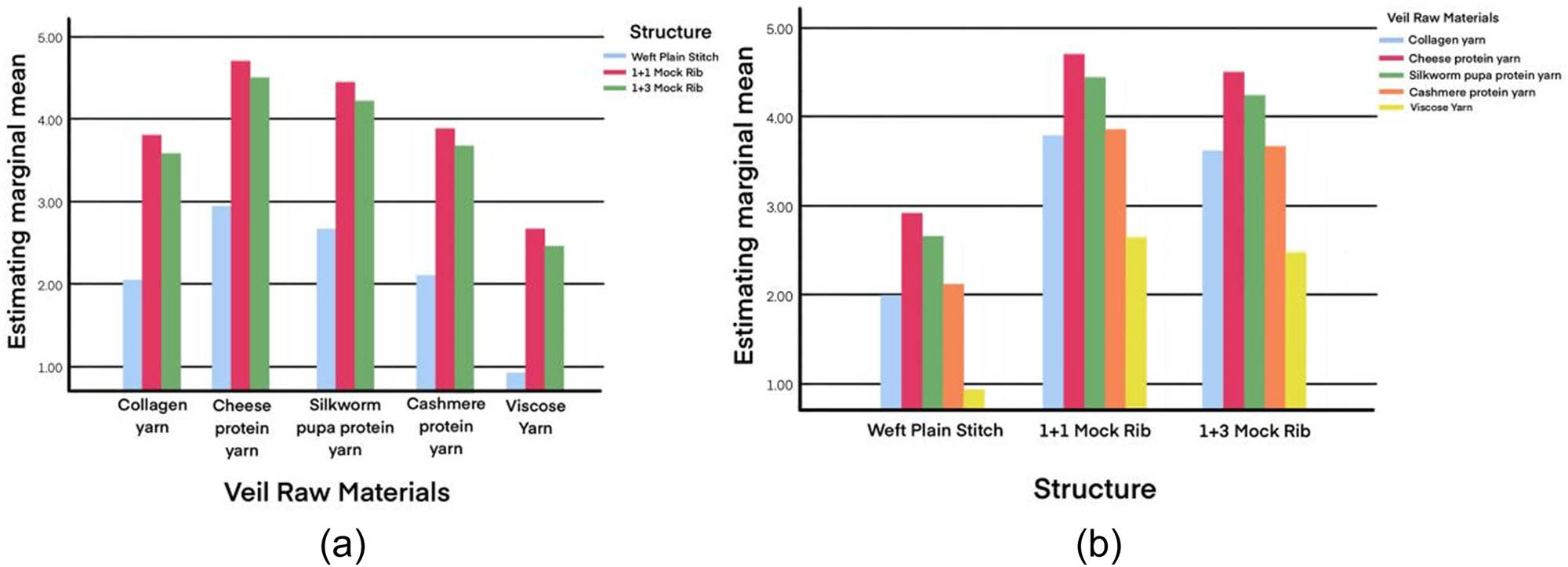

The contour diagram of the estimated marginal average value of the change rate of trans-epidermal water loss is shown in Figure 8. According to the variance analysis of the change rate of trans-epidermal water loss mentioned above, fabric structure has a significant influence on the change rate of trans-epidermal water loss. It can be seen from the figure that when the independent variable is the veil raw material, there is a significant difference in the estimated marginal value of different fabric structures. The value of 1 + 1 mock rib fabric is the highest, which has the best effect of the change rate of trans-epidermal water loss. Followed by the 1 + 3 mock rib fabric, the estimated marginal value of the weft plain stitch fabric is the lowest, and the moisture effect of the fabric sample is poor. When the independent variable is the fabric structure, it can be seen from the diagram that the estimated marginal average of the change rate of trans-epidermal water loss of the cheese protein yarn fabric is the highest, indicating that the effect of reducing skin epidermal water loss is the most obvious after coating the sample. It means that the fabric has a relatively good moisturizing effect. The second is silkworm pupa protein yarn fabric, and cashmere protein yarn fabric and collagen protein yarn fabric are close to each other, indicating that the effect of the fabric on the trans-epidermal water loss after covering the arm is not significant. The change of viscose yarn fabric is the least obvious, and the moisture retention of the fabric is relatively the worst.

Estimated marginal average of the change rate of trans-epidermal water loss: (a) independent variable is veil materials and (b) independent variable is fabric structure.

4 Conclusions

In this study, 15 kinds of knitted samples were tested for skin moisture content and trans-epidermal water loss in 20 participants. The change rates of skin moisture content and trans-epidermal water loss were obtained according to the calculation. Based on the test results, it was analyzed as follows:

In the skin moisture content change rate test:

In terms of veil raw materials, the order of influence of fabric samples on the moisturizing performance of skin is collagen protein yarn fabric > cheese protein yarn fabric > silkworm pupa protein yarn fabric > cashmere protein yarn fabric > viscose fabric.

In terms of fabric structure, the order of influence of fabric samples on the moisturizing performance of skin is 1 + 1 mock rib fabric > weft plain stitch fabric > 1 + 3 mock rib fabric.

Overall, when the fabric structure uses 1 + 1 mock rib, the veil raw material uses collagen protein yarn, and skin moisture change rate is the highest, which has the best moisturizing effect on human skin.

In the test of trans-epidermal water loss change rate, the veil material used in the fabric sample had no significant effect on trans-epidermal water loss, possibly because the protein yarn fabric could not significantly change the trans-epidermal water loss in a short period of time, and the skin barrier did not change significantly due to the coating of the protein yarn fabric sample. It may also be because the content of protein fiber in the fabric is not high enough, and the moisture content in the yarn cannot cause changes in the index. The change rate of trans-epidermal water loss was significantly affected by fabric structure, and the change rate of trans-epidermal water loss of 1 + 1 mock rib fabric was the highest, indicating that 1 + 1 mock rib fabric played a good role in reducing skin moisture loss. However, the change rate of trans-epidermal water loss after covering the sample of protein yarn is smaller than that after covering the sample of viscose fabric, indicating that the moisture retention ability of protein yarn fabric is better than that of ordinary viscose fabric.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Jamal, Z., Rani, S., Zeba, C., Hd, J. P., Scholars, R. (2018). Cosmetotextiles: A wearable skin care. International Journal of Home Science, 4(3), 31–35.Search in Google Scholar

[2] Wei, Z., Yuanlin, R. (2007). The development trend of new skin care fibers and textiles. Proceedings of the 7th Symposium on Functional Textiles and Nanotechnology Applications (pp. 257–259).Search in Google Scholar

[3] Yingying, H., Haiyang, Z., Yujing, T., Qi, H. (2020). Development and research status of skin care textiles. Textile Testing and Standards, 6(5), 10–12.Search in Google Scholar

[4] Xu, P. (2002). New progress of functional textile materials in Japan. Foreign Textile Technology, 1, 1–9.Search in Google Scholar

[5] Shanghai Jierun Silk Textile Industry Co., LTD. (2009). Multifunctional skin care aromatic textile material and its manufacturing method: Shanghai, 03141745.6.Search in Google Scholar

[6] Ghaheh, F. S., Khoddami, A., Alihosseini, F., Jing, S., Ribeiro, A., Cavaco-Paulo, A., et al. (2017). Antioxidant cosmetotextiles: Cotton coating with nanoparticles containing vitamin E. Process Biochemistry, 59, 46–51.10.1016/j.procbio.2017.04.020Search in Google Scholar

[7] Hai-yan, W. (2015). Reconstruction and application about weft plain stitch in the knitting sweater design. Wool Textile Journal, 43, 21–27.Search in Google Scholar

[8] Qiu, D. (2019). Research and design of intelligent skin health detection system. Electronic Testing, 424(19), 38–40.Search in Google Scholar

[9] Peng, W., Ruoxi, G., Shaojun, H., Lei, Z. (2021). Test method for human evaluation of moisturizing effect of cosmetics. Journal of Daily Use Chemicals, 44(7), 66–69.Search in Google Scholar

[10] Carneiro, P., Heckman, J., Vytlacil, E. (2010). Evaluating marginal policy changes and the average effect of treatment for individuals at the margin. Econometrica, 78(1), 377–394.10.3982/ECTA7089Search in Google Scholar PubMed PubMed Central

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry