Abstract

In the ready-to-wear industry, bias tape is one of the many factors that affect the efficiency of the manufacturing process. In particular, the bias tape change period slows down production. The purpose of this study is to identify the effect of fabric length on the time of changing bias tape rolls. At most manufacturers, the bias tape is made by cutting an average of 1 m from the product’s own fabric. In this study, the effect of bias tape fabrics cut into three different lengths on the manufacturing process was compared with three models. By producing bias tape for each model, the time spent on cutting the fabric, sewing, and changing the roll in the bias holder that feeds the lockstitch machine was calculated. It was revealed that the difference in fabric length affects the efficiency of the sewing process. Namely, it was found that the time spent on changing the bias tape roll decreased between 4.31 and 8.98%. Based on these findings, it can be said that the time efficiency can be increased by increasing the length of the fabric of the bias tape roll to be produced, and thus the production process could be accelerated.

1 Introduction

One of the main tasks of the industry is to reduce production costs, including the efficient use of resources and materials [1,2,3]. An important output of production indicators is the improvement of technical information, the application of modern scientific knowledge, the restructuring of technological processes, and process automation [4,5].

Today, the increasing competitive conditions in the ready-made garment industry force companies to produce their products faster and at lower costs [6,7]. It is important to solve the optimisation problems in which the garment industry is engaged in, to increase the efficiency of the company, and to reduce the time of application and the amount of consumption [8,9].

Factors that directly affect the calculation of the amount of fabric required for the production of a garment are the type of fabric, the model of the product, the dimensions of the product, etc. When all these parameters are taken into account, it becomes difficult to make accurate calculations and objectively determine the amount of the fabric [10]. Understanding fabric consumption is the most important factor in terms of production efficiency [11,12,13]. Fabric consumption is influenced by width and length dimensions. Hence, it should be estimated using mathematical calculations prior to actual marker making consumption [14]. Paşayev, in his study on reducing fabric waste in the production of ready-made garments, investigated the effect of production planning and marker planning on the cost of fabric [15]. Erdogan et al. found that when planning production in terms of fabric waste in garment production, determining the appropriate fabric width and length can significantly reduce fabric waste [16]. Pamuk and Yıldız, in their studies on the effectiveness of the marker planning, showed that the correct choice of fabric size in various outer garments ensures high production efficiency [17]. Yeşilpınar (2012) investigated the impact of different assortment plans on the number of units in the production of classic denim trousers, and showed that the size of the fabric used is important [18].

Although it is challenging to define a clear standard time for production processes, precision in measurements at each stage of production is essential to reduce costs and increase efficiency. Companies that plan, constantly review, and manage their production processes are more successful in increasing production efficiency [19]. Kurtul’s research highlights the central role of planning in improving production speed, efficiency, and product quality in the ready-made garment industry, emphasising the indispensability of proactive planning initiatives [20].

In the field of garment production, Yücel and Güner conducted a study to elucidate the factors influencing sewing time. Their analysis included various operational variables such as reach distance, take-off distance, garment area, sewing length, sewing shape, number of sewing steps, fabric weight, and sewing machine rotation, culminating in the development of a unit sewing time equation. This equation serves as a valuable tool for more effective management and control of sewing times [21]. In addition, Upendra et al. developed a methodology for calculating laying and cutting times in the cutting departments of garment manufacturers. Using data collected on woven trouser patterns, they created a basic database of the laying and cutting processes, along with an analysis of time variations due to influential parameters. The resulting system facilitates the calculation of fabric cutting time based on parameters such as fabric type, layer height, and pattern shape, thereby improving operational efficiency [22].

Bias tape is of considerable importance in the garment industry, serving a variety of practical purposes such as edge reinforcement, aesthetic enhancement, and deformation prevention. Cutting bias tape is a critical step in the garment manufacturing process, typically involving pieces of fabric approximately 100 cm long that are sewn together to form a tubular structure before undergoing bias tape preparation using a cutting device [23]. The length of the resulting bias tape roll depends on the dimensions of the fabric used and the width of the bias tape produced. However, the frequent need to change bias tape rolls during the sewing process consumes valuable time and reduces workflow efficiency. Lengthening the bias tape rolls could potentially reduce the need for frequent roll changes, thereby reducing time wastage. To the author’s knowledge, there is no empirical research in the literature on the time efficiency of bias sewing. Therefore, the primary objective of this study is to investigate the effect of the length of fabric used in the bias tape rolls on the efficiency of the manufacturing process.

2 Materials and method

2.1 Materials

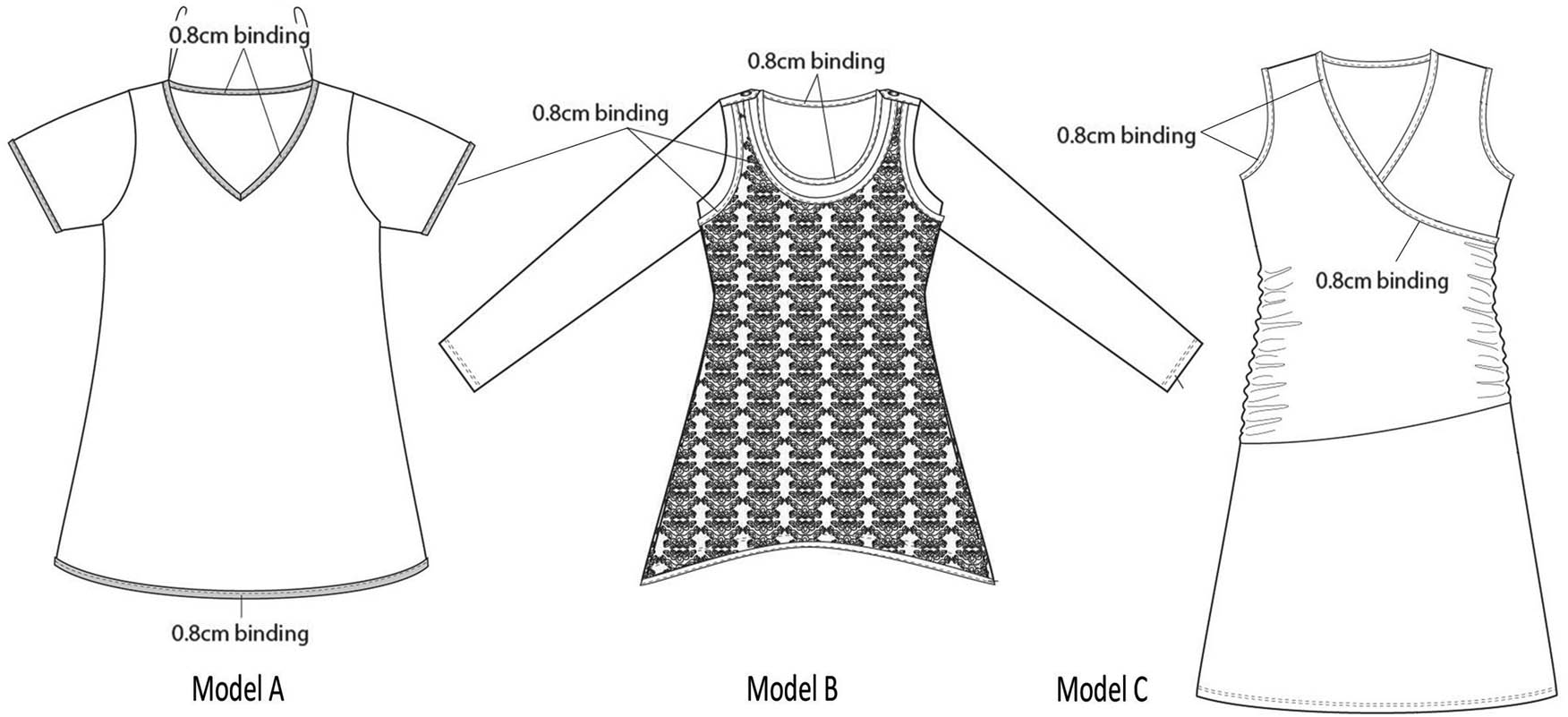

In this study, cutting schedules were developed for different fabric lengths on three different models. The fabric was cut into different sizes and converted into bias rolls. The data collected were then analysed to determine the relationship between fabric length and time savings, providing comparative insights. As shown in Figure 1, different models were selected in terms of the shape and amount of bias tape. The bias is used on the collar, sleeve, and hem of the models. A cut order plan was used to more reliably determine the relationship between the data for the front, back, sleeve, and bias pattern markings that make up the model. The lengths and widths of the bias tapes for each model are given in Table 1.

Technical drawing and markers of sample models.

Lengths and widths of the bias tapes for each model

| Models | Model A | Model B | Model C |

|---|---|---|---|

| Bias tape lengths (cm) | 278 | 241 | 156 |

| Bias tape width (cm) | 3 | 3 | 3 |

2.2 Method

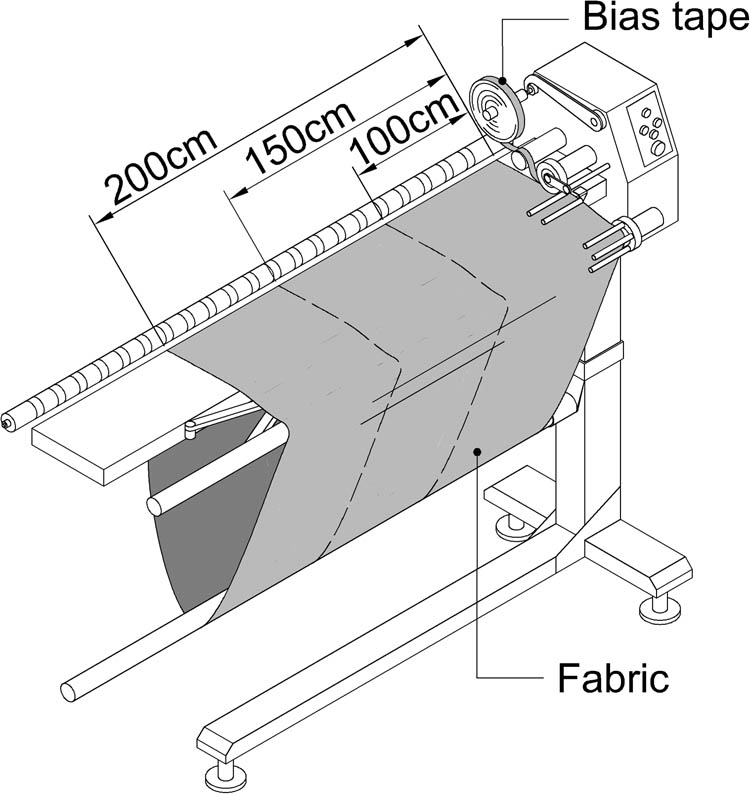

Tools, cutting equipment, and software play an important role in garment production. The role of the cutting equipment is to cut the material according to the shape quickly, efficiently, and accurately. In this study, the Lectra Modaris system was used in the process of pattern preparation and installation of the selected model (Figure 1). The pattern distribution process is carried out using the Lectra Diamino programme. In this respect, the pattern and assortment plan of the dress model was taken into account in the CAD programme of the design and pattern department. The first stage in the calculation of the model was to determine the initial data, such as the size composition and the number of products. The bias tape is not included in the pattern plan, its production is carried out on the cutting machine (Figure 2).

Fabrics of various lengths placed in a bias tape cutting machine.

In this study, the bias tape was cut to three different lengths for each model. In order to accurately compare the effects of fabric length on different models, the same fabric width (150 cm) was used for all models.

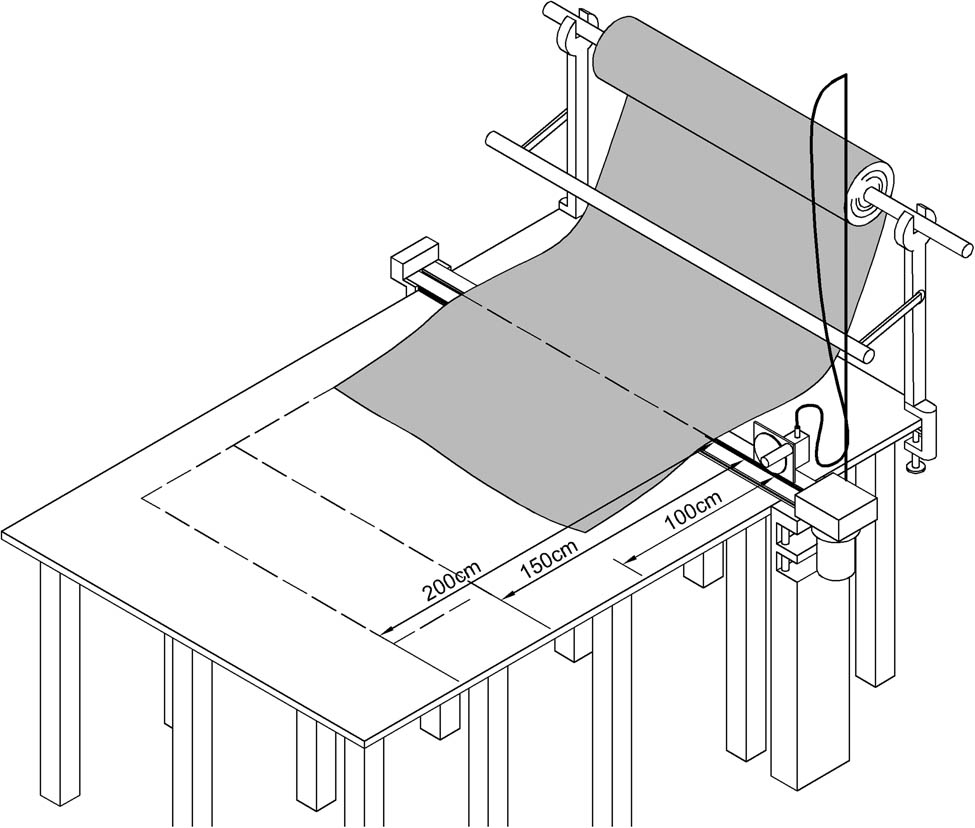

To make bias tape, fabric of the desired length and quantity is prepared on a table for spreading and cutting (Figure 3) and converted into tubes by sewing on a lockstitch sewing machine.

Fabric cutting in three different lengths (100, 150, and 200 cm).

The tubular fabric fed into the bias cutting machine is cut by a circular knife and automatically wound into a special bias roll. Bias tape cutting machines are used to cut strips of a specific width, ranging from 1 to 12 cm. The width used in the study is 3 cm.

From each piece of fabric, the length of the bias tape roll after processing on a cutting machine is calculated according to the following equation:

where B is the width of the fabric (in cm); L is the length of the fabric (in cm) (Figure 3); and b is the bias tape width (in cm). In this study, the bias tape width is b = 3 cm.

The results of equation (1) calculations are given in Table 2.

Bias tape roll lengths after the post-processing on a cutting machine

| Model | Fabric width (cm) | Bias tape roll lengths | ||

|---|---|---|---|---|

| Fabric length 100 (l 100) (cm) | Fabric length 150 (l 150) (cm) | Fabric length 200 (l 200) (cm) | ||

| Model A | 150 | 4,512 | 6,912 | 9,312 |

| Model B | 150 | 4,700 | 7,200 | 9,700 |

| Model C | 150 | 4,575 | 7,008 | 9,441 |

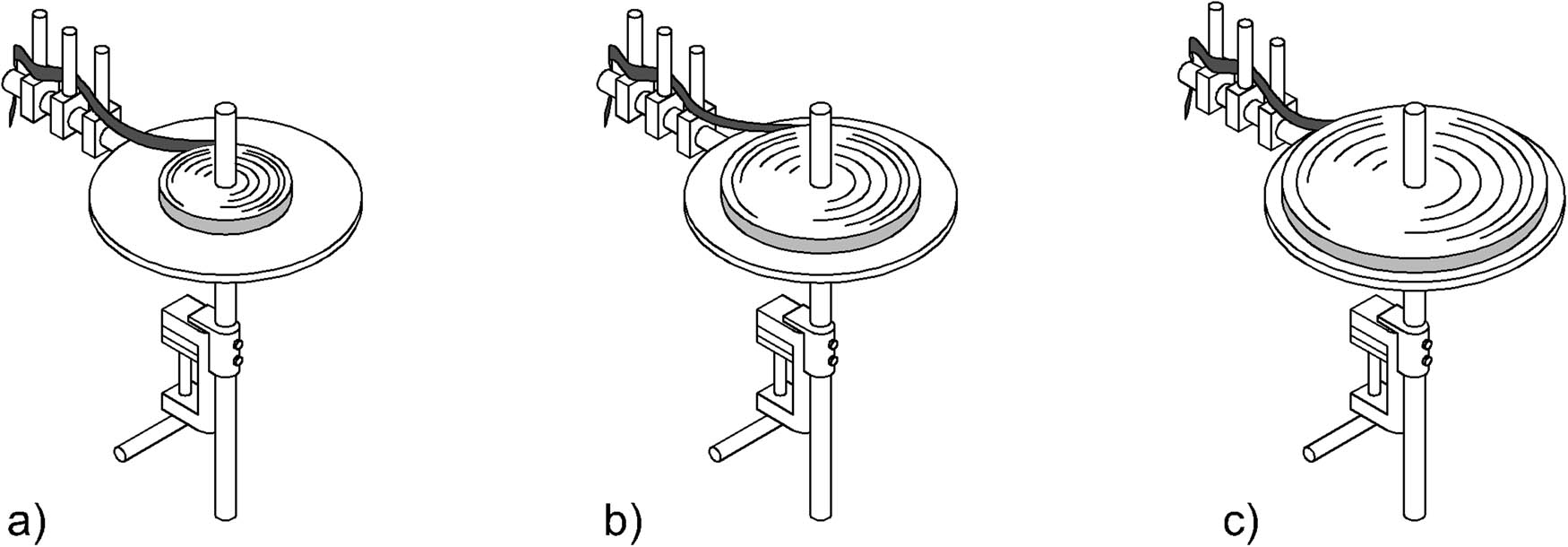

After the bias tape was sewn, the obtained bias tape rolls were placed on the holders and the bias tape sewing operations were started. Figure 4 shows an example of three levels of bias tape roll placement:

Bias tape roll placed on holder for lockstitch machine: (a) length 100 cm; (b) length 150 cm; and (c) length 200 cm.

Losses and wastage that occur during the production and sewing of bias tapes are taken into account in the calculation of the cut order plan. In textile factories, the gaps between successive embroidery markers should not exceed 5 cm (Figure 5). This parameter is also taken into account in the calculations.

Sewing bias tape on the sleeves one after the other.

According to the fabric length L used in the production of bias tape, the number of rolls of bias tape to be used in the production of a batch of products can be calculated with using equation (2).

where N is the production amount of the model (Table 3); l av is the average length of the sleeves, collars, and hems for all sizes to be produced (in cm) (Table 4); l w is the bias tape waste between the parts sewn one after the other (in cm) (Figure 5); and l is the bias tape roll length (in cm) (Table 2). Accordingly, as the length of the bias tape roll increases, the amount of bias tape rolls decreases.

Bias tape plan for the model

| Model | Fabric width (cm) | Product amount (N) | Total bias tape length to be sewn on a product (cm) |

|---|---|---|---|

| Model A | 150 | 207 | 274 |

| Model B | 150 | 180 | 271 |

| Model C | 150 | 264 | 202 |

Dimensions of the areas where the bias tape will be applied in the models (cm)

| Model | Size | XS | S | M | L | XL | XXL | XXXL | Average l av |

|---|---|---|---|---|---|---|---|---|---|

| Model A | Armhole | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 37 |

| Collar length | 67 | 67 | 67 | 67 | 67 | 67.5 | 67.5 | 67.14 | |

| Hem | 120 | 126 | 132 | 138 | 144 | 150 | 156 | 138 | |

| Model B | Armhole | 28.75 | 30 | 31.25 | 32.5 | 33.75 | 35 | 36.25 | 32.5 |

| Collar length | 121.6 | 125 | 128.4 | 131.8 | 135.2 | 138.6 | 142 | 131.8 | |

| Model C | Armhole | 43.75 | 46 | 48.25 | 50.5 | 52.75 | 55 | 57.25 | 50.5 |

| Collar length | 105.3 | 110 | 114.7 | 119.4 | 124.1 | 128.8 | 133.5 | 119.4 |

As a result of the calculations made using equation (2), the number of rolls of bias tape used in the production of the models is given in Table 5.

Number of rolls of bias tape used in the production of the models as a result of the calculations made

| Model | Fabric length L (cm) | Amount of bias tape rolls n (piece) | Total amount of bias tape rolls n tot (piece) | ||

|---|---|---|---|---|---|

| Armhole | Collar length | Hem | |||

| Model A | 100 | 3.85 | 3.31 | 6.56 |

|

| 150 | 2.52 | 2.16 | 4.28 |

|

|

| 200 | 1.9 | 1.6 | 3.2 |

|

|

| Model B | 100 | 3.3 | 6.02 | — |

|

| 150 | 216 | 3.93 | — |

|

|

| 200 | 1.6 | 2.92 | — |

|

|

| Model C | 100 | 5.02 | 5.63 | — |

|

| 150 | 3.28 | 3.67 | — |

|

|

| 200 | 2.43 | 2.73 | — |

|

|

During the production in the factory, observations were made and time was recorded for each model produced. From the time measurements taken during the production of models A, B, and C, it was observed that the cutting (Figure 3), sewing, and positioning (Figure 2) process of each fabric used in the production of bias tapes took an average of

and the total bias sewing time for a batch of products can be determined using the following equation:

where

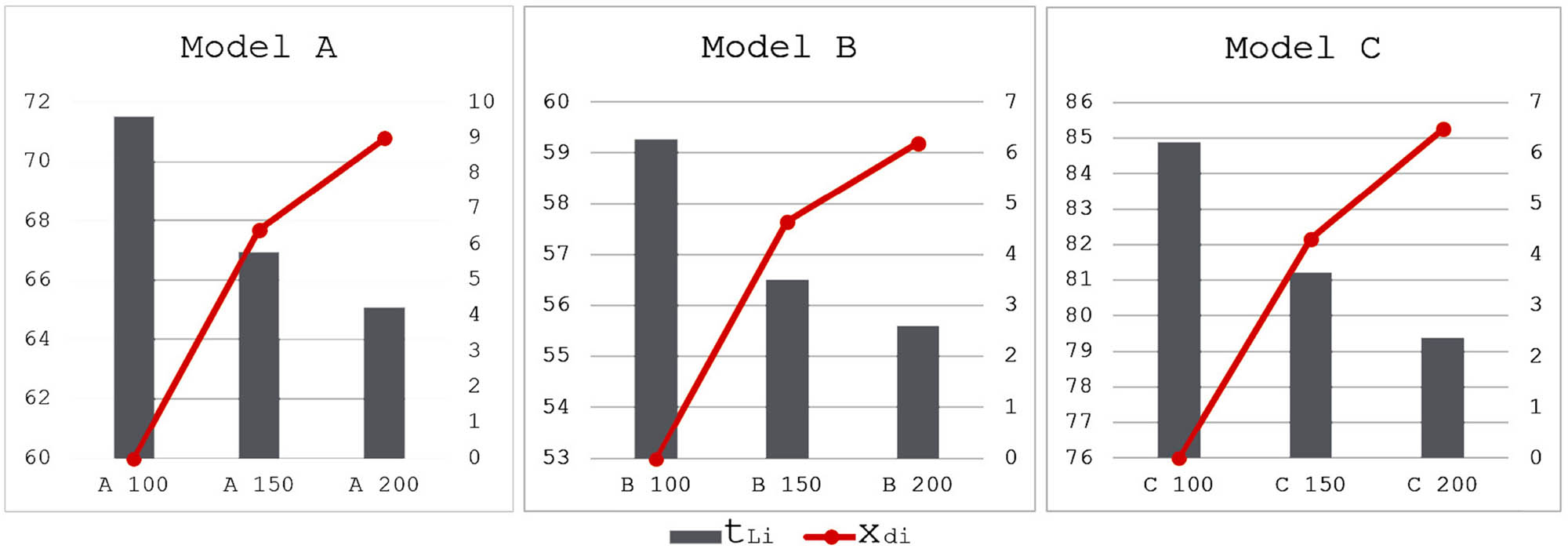

Percentage of decrease in the amount of changes according to the results obtained in the study

| Model | Fabric length L (cm) | Total bias sewing time of a batch of products t Li (min) | Change efficiency percentage of the bias tape rolls x di (%) |

|---|---|---|---|

| Model A | 100 | 71.48 | 0 |

| 150 | 66.9 | 6.41 | |

| 200 | 65.06 | 8.98 | |

| Model B | 100 | 59.25 | 0 |

| 150 | 56.5 | 4.64 | |

| 200 | 55.58 | 6.19 | |

| Model C | 100 | 84.88 | 0 |

| 150 | 81.22 | 4.31 | |

| 200 | 79.38 | 6.48 |

Based on these data, the relationship between fabric lengths and time savings and the change efficiency percentage of the bias tape rolls in the production process is clearly shown in Figure 6.

Comparing fabric lengths to total sewing time and the change efficiency percentage of bias tape rolls in production.

3 Result and discussion

In this study, the effect of the length of fabric used in the bias tape rolls in the textile industry on the productivity of the manufacturing process was investigated. To address it, a comparative analysis of three different garment models was carried out. The time required to change a roll of bias tape is one of the many factors affecting the production process. Also, it is known that the process of attaching the bias tape rolls to the machines slows down the assembly process of the markers. Therefore, the process of forming and using of the bias tape sewn from the fabric of the model to be made was comparatively studied on three different models, taking into account the different lengths of the fabric. To do this, first of all, fabrics of 100 cm length were used to make bias tapes of three different models, and measurements were made for sewing these fabrics from the edges and placing them in the edging machine. Then, the number of change bias tape rolls in the holder feeding the lockstitch machine was calculated according to the different lengths of the fabric (i.e. 100, 150, and 200 cm), and their effect on this time was studied.

As shown in Table 6, there is a clear correlation between fabric length and productivity percentage. From the results of this study, it can be seen that if the fabric length is 150 cm instead of 100 cm, time savings of between 4.31 and 6.41% can be achieved, and if 200 cm is chosen, time savings of between 6.19 and 8.98% can be achieved. This improvement means a noticeable increase in production efficiency throughout the manufacturing process. In addition, longer bias rolls allow smoother transitions between production runs, improving overall operational agility. The study showed that significant time savings can be achieved by extending the length of the bias tape roll during the garment manufacturing process. This also ensures that once the production of one model is completed, it can be quickly switched to the production of another model.

4 Conclusion

This study showed that the choice of fabric length when sewing bias tape affects the efficiency of the production process. As a result, as the length of the fabric increases, the length of the roll will increase, and therefore the number of rolls required for production will decrease. Thus, the time spent on changing rolls will be reduced and the continuity of the work process on the belt will continue more efficiently.

The findings underline the importance of optimising fabric length in bias tape preparation to improve manufacturing efficiency. By minimising the frequency of roll changes, manufacturers can reduce workflow disruptions and streamline production processes. By incorporating longer fabric lengths into production strategies, manufacturers can achieve tangible improvements in efficiency without compromising quality standards.

In conclusion, this study provides valuable insights into the relationship between fabric length and production efficiency in bias tape preparation, and emphasises the need for empirical research in this area. It is hoped that this research will contribute to a broader discourse on sourcing and production optimisation in the apparel industry.

Acknowledgements

I would like to thank the officials and staff of Minaz Textile Manufacturing Industry and Trade Ltd STI, who made it possible to collect the necessary data for the realisation of this study.

-

Author contribution: The author confirms the sole responsibility for the conception of the study, presented results and manuscript preparation.

-

Conflict of interest: The author states no conflict of interest.

References

[1] Özdemir, S., Yeşil, E., Utkun, E. (2015). An application study to create a mobile-based cost calculation software regarding woven fabric manufacturing in small-scale textile businesses. Textile and Apparel, 25(3), 183–193.Search in Google Scholar

[2] Utkun, E. (2016). A study on effects of model and marker plan differences on fabric productivity: case of bathrobe. Journal of Textiles and Engineer, 23, 271–276.10.7216/1300759920162310404Search in Google Scholar

[3] Akansel, M., Yagmahan, B., Emel, E. (2017). Determination of standard times for process improvement: a case study. Global Journal of Business Economics and Management, Current Issues 7(1), 62.10.18844/gjbem.v7i1.1400Search in Google Scholar

[4] Koroleva, L. A., Podshivalova, A. V., Streltsov, I. P., Sheromova, I. A. (2011). Automation of the process of confectioning materials in clothing design (Vol. 2, Issue 11). Publishing House of Vladivostok State University of Economics and Service, Territory of New Opportunities, Russian Federation.Search in Google Scholar

[5] Patnaik, S., Patnaik, A. (2018). Advancements in production planning and control. In: Nayak, R., Padhye, R. (Eds.). Automation in Garment Manufacturing, The Textile Institute Book Series, Woodhead Publishing, United Kingdom (pp. 291–310).10.1016/B978-0-08-101211-6.00012-4Search in Google Scholar

[6] Doğan, S., Pamuk, O. (2014). Calculating the amount of sewing thread consumption for different types of fabrics and stitch types. Textile and Apparel, 24(3), 317–323.Search in Google Scholar

[7] Deste, M., Berber, G. (2018). A literature review on process improvement applications. International Journal of Economics, Business and Politics, 2(2), 213–230. http://dergipark.gov.tr/ueip.10.29216/ueip.462265Search in Google Scholar

[8] Shenxun, Y. (2012). Prevention of waste from textile in Sweden. Digital Scientific Archive, TRITA-IM 2012:03.Search in Google Scholar

[9] Khedher, F., Jaouachi, B. (2015). Waste factor evaluation using theoretical and experimental jean pants consumptions. The Journal of the Textile Institute, 106(4), 402–408.10.1080/00405000.2014.924225Search in Google Scholar

[10] Artamoshina, M. N. (2010). Information technologies in garment production (p. 176). Publishing Center Academy, Russian Federation.Search in Google Scholar

[11] Kothari, V. R. (2014). Fabric and Trim consumption for fashion merchandising. https://www.textiletoday.com.bd/fabric-and-trim-consumption-for-fashion-merchandising/(accessed 25.11.2022).Search in Google Scholar

[12] Bilgiç, H., Baykal, P. D. (2016). The effects of width of the fabric, fabric and model type on the efficiency of marker plan in terms of apparel. Textile and Apparel, 26(3), 314–320.Search in Google Scholar

[13] Kalkancı, M., Özer, İ. (2018). Developing a software calculating fabric consumption of various bathrobe models. İndustria Textila, 69(4), 406–411.10.35530/IT.069.05.1550Search in Google Scholar

[14] Islam, M., Saha, P. K., Islam, Md. N., Saha, S. K., Kısa, S. K. B. (2019). Impact of sleeve types on marker efficiency and fabric consumption. Global Journal of Researches in Engineering: J General Engineering, 19(4), Version 1.0.Search in Google Scholar

[15] Paşayev, N. (2010). Investigating the effects of production planning on fabric costs in confection production. Textile and Apparel, 3, 262–270.Search in Google Scholar

[16] Erdogan, M. C., Sen, G. A., Yuecel, O. (2007). Determining the product cost using the transportation method in clothing production. Textile and Apparel, 17(2), 132–139.Search in Google Scholar

[17] Pamuk, O., Yıldız, E. Z. (2016). A study about parameters affecting the marker plan efficiency. Textile and Apparel, 26(4), 430–435.Search in Google Scholar

[18] Yeşilpınar, S. (2012). Research on determining the optimum fabric width in the production of denim pants. Journal of Textiles and Engineer, 58, 3–9.Search in Google Scholar

[19] Şener, T., Kilinç, N. (2013). Improvisation of production processes in ready-made clothing enterprises by means of comparisons. The Journal of Social and Economic Research, 25, 445–464. Selçuk University Faculty of Economics and Administrative Sciences.Search in Google Scholar

[20] Kurtul, Z. (2020). The planning of cloth production with regard to management process and the Iskur case. Pamukkale University Journal of Social Sciences Institute, 38, 249–261.Search in Google Scholar

[21] Yücel, Ö., Güner, M. (2008). Analyzing the factors affecting garment sewing times. Textile and Apparel, 1, 41–48.Search in Google Scholar

[22] Upendra, R. A. S., Kaluarrachchi, P., Weerasekara, K. M. R. D., Ratnayake, V. S. (2013). Developing a system to calculate cutting process time of garments. National Engineering Conference 2013, 19th Eru Symposium, Faculty of Engineering, University of Moratuwa, Sri Lanka (pp. 26–32).Search in Google Scholar

[23] Minaz Textile Manufacturing Industry and Trade LTD. ŞTİ. (2022). Ready-To-Wear Garment Manufacturer, Antalya.Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry