Abstract

Based on the current process of clothing design and development, as well as research and analysis of domestic and foreign literature, this article guides the current digitalization status of the front-end and back-end of the clothing industry and proposes the research problem of this topic. Through clothing design modeling (physical model and design of fabrics, collision detection analysis between human body and fabrics, clothing fabric rendering, and flexible 3D clothing simulation model) and dynamic virtual display of clothing, an effective method to solve the problem is constructed. It has been found that during the design phase, the real effect of clothing fabrics can be realistically restored, and the development speed can be improved, reducing labor costs. At the same time, dynamic simulation display can be used to solve the cost waste problem of sample materials. It can also improve the product selection rate and design level, and solve cost and time problems at the source.

1 Introduction

Clothing is a very important item in people’s lives; clothing, food, housing, and transportation are ranked first. China has the world’s most complete apparel industry chain foundation, from planning, design, sampling, production, logistics, and sales links, all at advanced levels. However, most of the enterprises are serving international brands and also do original equipment manufacture (OEM) services for some domestic brands, lacking the ability to actively give brand services to customers, while the design development sampling time of enterprises is at least about 10–15 days, which leads to a long time for the whole product line, and the efficiency of rapid response is very low. With the development of digital technology and the addition of artificial intelligence, the traditional apparel design method has failed to meet the needs of rapid response development of enterprises and needs to break this restriction to digitally open up the content of rapid apparel design and virtual display of products.

After the Reform and Opening Up, a large amount of information from foreign garment design flowed into the country, and through the integration and development of the domestic industry, a set of standardized garment design and development processes has been formed and applied by various large- and medium-sized enterprises [1]. With the development of digital technology, the existing set of standardized design and development processes has not adapted to the market and the needs of customers’ brand rapid response.

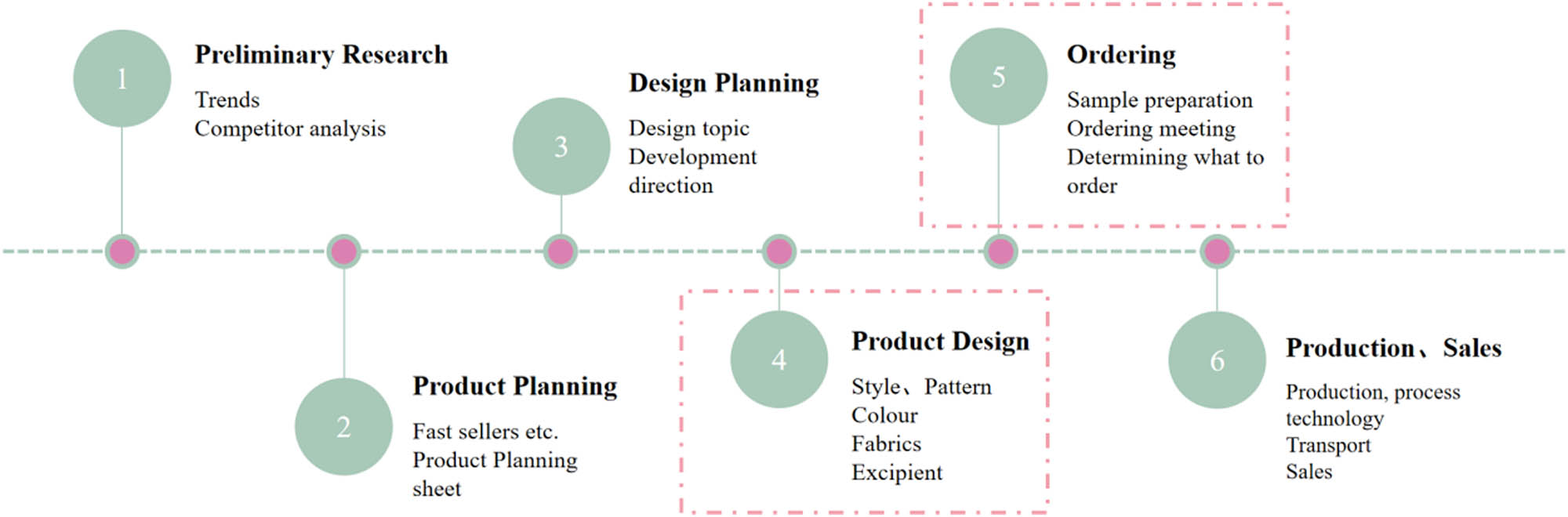

As shown in Figure 1, the current clothing design and development process mainly includes six links. The overall time from the preliminary research of the first link to the production and sales of the sixth link is about 25–30 days, especially in the design link, which takes up a lot of time. The fourth link and the fifth link (the square dotted box in the figure) are key parts of the design phase. If we optimize the time and efficiency, the service to the customer brand and the cost reduction are both great advantages. For the fourth and fifth links, from the clothing 3D simulation design, including the wearing effect, fabric simulation, rapid design, and other contents, from the clothing dynamic virtual display, according to the clothing 3D simulation design, the development of dynamic display simulating the real scene can directly replace the order meeting process and show to customers in online, electronic pictures and other forms, saving a lot of time and proofing costs.

Apparel design development process.

This article starts from the problems that appear in the design and development of the apparel industry and extends to the status quo of the front-end and back-end rapid response of the apparel industry. The specific content of this study is elaborated from two aspects: clothing design modeling and dynamic virtual display. The main objectives are to train algorithm models using SMPL models and multipose datasets to construct suitable human body model samples, simulate the physical movement of fabrics using spring particle models, utilize the advantages of hierarchical bounding boxes and hierarchical space decomposition method to improve collision detection speed and efficiency between human body models and fabrics, cooperate with various algorithms and simulation tools to render fabrics realistically, and ultimately construct 3D flexible clothing models using curve equations, pressure perception, and unity rendering engines. At the same time, a dynamic virtual display suitable for the scene is constructed, which can intuitively show the dynamic display of apparel products, fabric feeling, and samples, and can solve the efficiency of the design stage low efficiency, high cost, and long time in the design stage and indirectly improve the digital design level of enterprises.

2 Research background

2.1 Research status at home and abroad

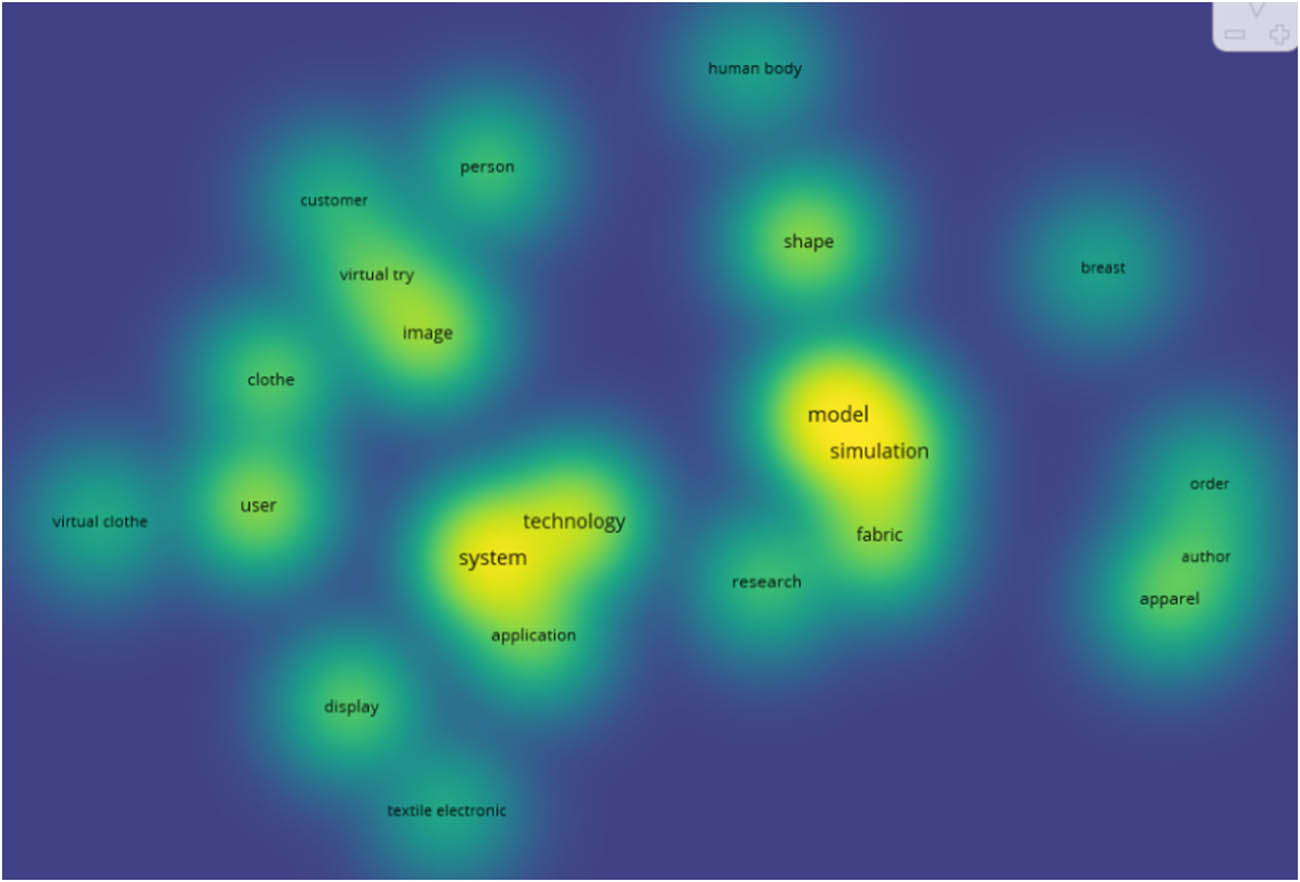

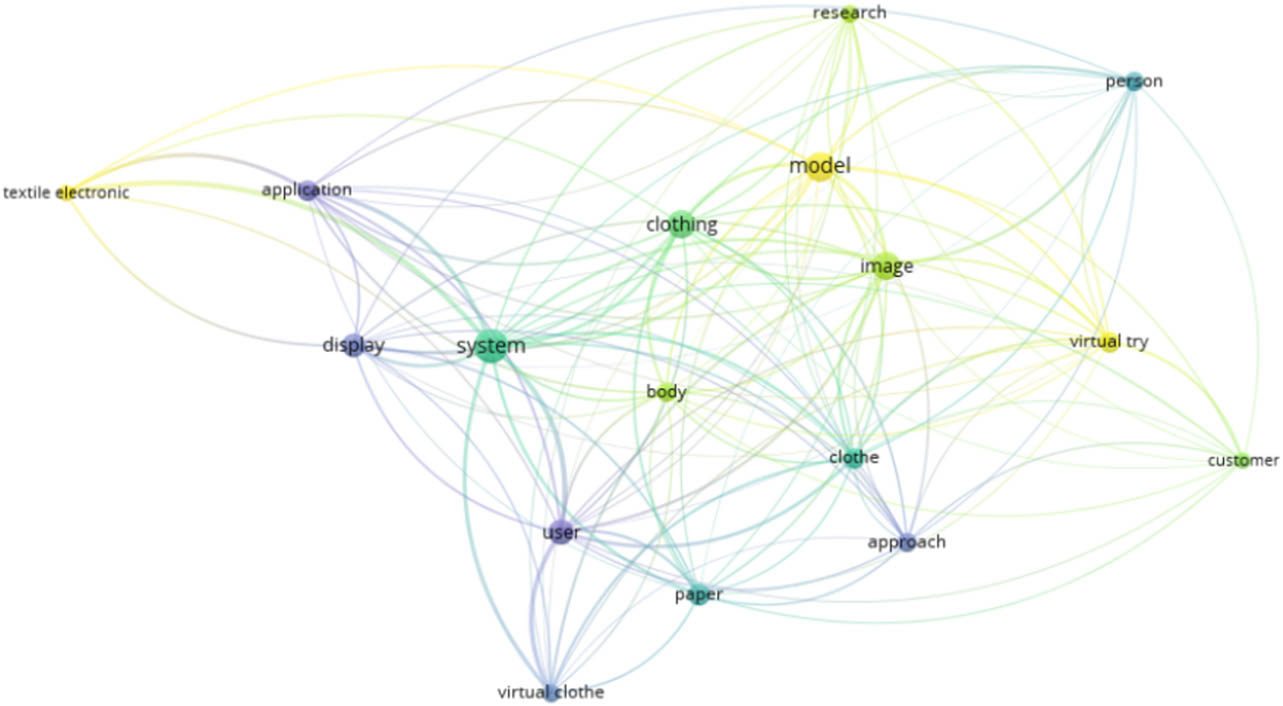

In order to better discuss the application and influence of 3D simulation design and dynamic virtual display of clothing in clothing design, researchers used visual analysis software to search and analyze the related literature in domestic and foreign databases. For the research of this topic, the researchers selected VOSviewer software as the data analysis tool. VOSviewer software is a free JAVA-based software developed by the Science and Technology Research Center of Leiden University in the Netherlands in 2009 [2]. It mainly focuses on literature data, adapts to the construction of relationships and visual analysis of literature knowledge units, and achieves the drawing of scientific knowledge graphs. Currently, Citespace software is the mainstream tool for visual data analysis software. The method of using VOSviewer software for data visualization analysis includes searching for literature in the Web Science database (confirming the search keywords), saving the retrieved valid files as plain text files (including author, title, source publication, and abstract), opening the VOSviewer software, clicking on Create, selecting the data type option, selecting Create a map based on text data, then clicking on data resources, selecting Read data from bibliographic database files, selecting the plain text file just saved, continuing to select the analysis scope (field) of the text, such as title, abstract, etc., and selecting the continuous method (default system selection under normal circumstances). Then, a threshold is set, the number of keywords is selected to analyze and retrieve, the number of keywords is confirmed, and finally, a visual analysis graph is generated. Specifically, first of all, the current status of foreign research is analyzed, as shown in Figures 2 and 3, in the Web science database with apparel 3D simulation design as the keyword, and the valid literature 27 is retrieved, using VOSviewer literature visualization software to get as shown in Figure 2, as can be seen from the figure. The brighter the color represents the higher the degree of association, and the high degree of association with clothing 3D simulation design is the system technology application, fabric (fabric) model visualization of the two general directions, and the other for the smaller degree of association of the content. The same operation as in Figure 2, 38 documents were retrieved from the web science database, and the results of the keyword co-citation analysis are shown in Figure 3, the number of common keywords is small, and the formation of a close connection between the system, image, and model centered on the clothing, which indicates that the analysis of the image is more dominant in the dynamic virtual display of the clothing.

Analysis of keyword commonness based on 3D clothing simulation design as keyword retrieval result.

Analysis of keyword commonness based on garment dynamic virtual display.

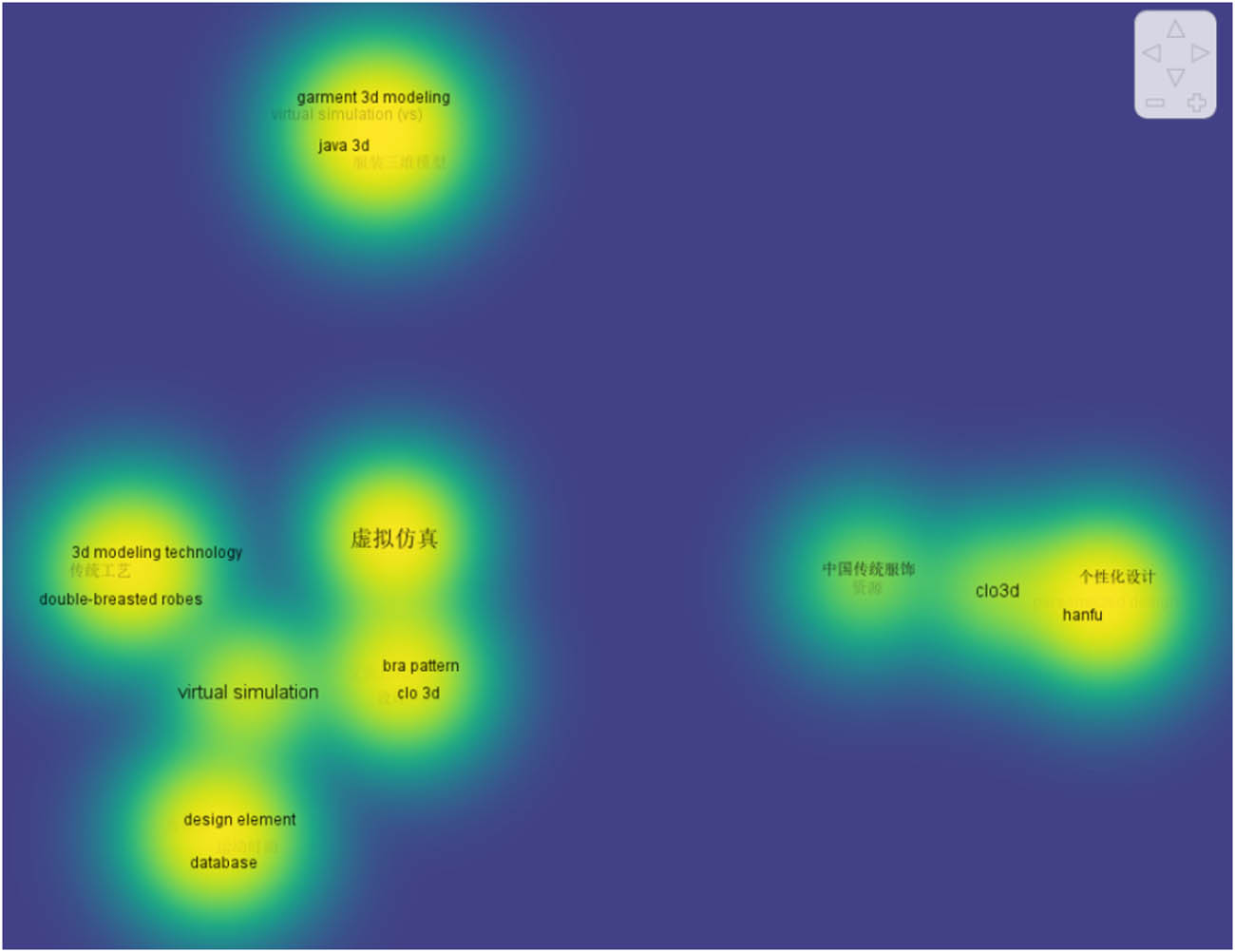

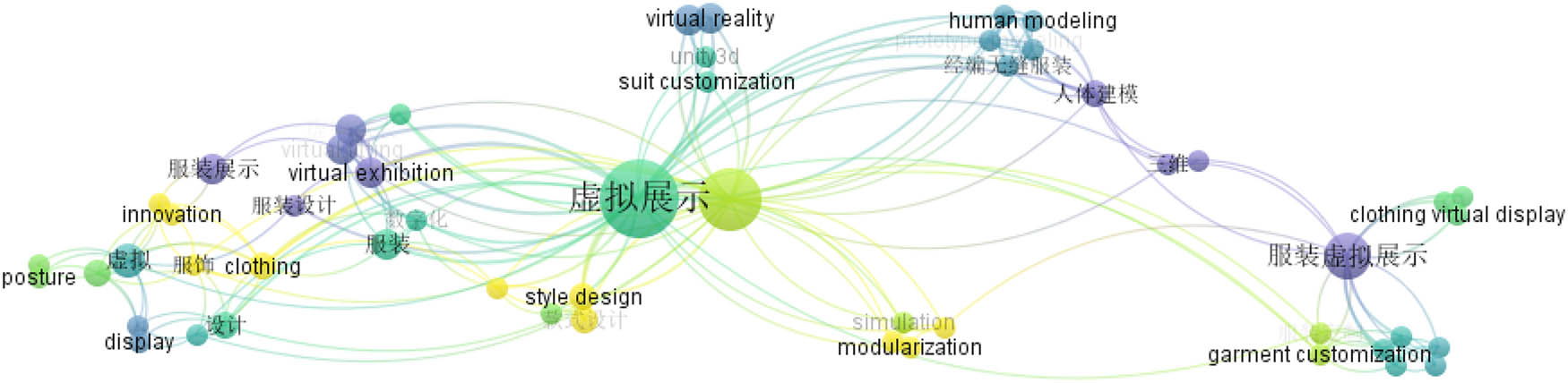

The researchers obtained the domestic research situation by searching the CNKI database. Specifically, as shown in Figures 4 and 5, 22 valid literature studies were obtained by using the 3D simulation design of clothing as the keyword. After using the VOSviewer to analyze, as shown in Figure 4, it can be found that several bright spots are the areas with the closest relationship between the keywords, among which the 3D model of clothing, 3D model technology, and personalized design element database are the most relevant to this topic. It can be found that China pays attention to the research of modularization in the theme of 3D simulation design of clothing, especially the details and aesthetics. Figure 5 shows the visual retrieval analysis with the keyword of dynamic virtual display of clothing. We can see that there are many relationship points with virtual display as the core, among which virtual reality, style design, and virtual exhibition are related to this topic. It can be found that there are few dynamic virtual displays related to clothing, and the related areas are all on the branch line.

Analysis of keyword co-citation based on 3D clothing simulation design as keyword retrieval result.

Co-citation analysis of keywords based on dynamic virtual display of clothing.

Through the analysis of the research status quo at home and abroad by the visual analysis software, we can know that although some scholars at home and abroad have done some research on 3D simulation design and dynamic virtual display, most of them prefer technical models, detailed research and more elaborate specific 3D simulation design and dynamic virtual display content from the clothing ontology with less images, and have not found any impact on the clothing design content. Therefore, the research on this topic will provide a new method and new idea for clothing design and reduce the cost and development time investment, and the impact on the clothing industry is a research of great value.

2.2 Research question – the rapid response status of the front and back ends of the clothing industry

Since the 1980s, the garment industry has experienced nearly half a century of development, at present, the front-end and back-end of the clothing industry are developing toward digitalization, presenting a development status of multiple dimensions, as follows:

First, the development of a digital supply chain is becoming a new means of competition for the entire industry. In the digital supply chain, core technology and data become key factors, and how to use digital technology to occupy the high ground of industry development is the core of clothing enterprises.

Second, digital transformation is becoming a new asset driven by innovation in the clothing industry. The “digital industrialization” led by Internet platforms, mobile Internet applications, and information technology is gradually developing into a new stage of “industrial digitalization,” in which artificial intelligence (AI), big data, and other technologies promote the in-depth transformation and upgrading of the real industry. The digitization and industrialization of industries are providing important development opportunities for China’s clothing industry.

Third, digital fashion is becoming a new form of value growth for Chinese clothing brands [3]. In the process of promoting digital fashion development in the clothing industry, the intelligence (IQ) and experience (EQ) of products will play a key role. Having a rich imagination and new skills, thinking about how to use digital technology to design, manufacture, and sell truly digital products, and deliver more personalized experiences. The real challenge lies in whether to organically adapt diverse technologies to the development genes of the enterprise and drive overall fashion change.

Based on the current development of digital technology and artificial intelligence, as well as the research direction of this topic, the author analyzes it from the following two aspects:

With the development of digital technology, the chain of front end and back end of clothing has changed. For example, in the front end of clothing, some digital software, such as 3DCLO, Marvelous Design, and other design software with great design space, have been used to improve the design quality. However, it is just a simple design, not related to the selection of accessories in front, ordering, production, and sales in the rear, At the same time, the purchase price of this digital design software (Different from traditional Photoshop, AI, and CorelDRAW) is relatively high. Most of the large brands that can afford to buy it are large brands, and small- and medium-sized brands (enterprises) will not invest so much money to buy it. Therefore, we can think of the changes in the design stage. It is still small. Most enterprises still have traditional design models, such as design, proofing, ordering, etc. This also leads to the loss of the ability and opportunities for small- and medium-sized brands to provide active services to large customers (providing innovative design products, digital design, and other content), and they will be eliminated in a long time.

At present, most domestic clothing brands still use the on-site ordering mode to provide the proofing products for key customers to choose from in the form of exhibition. This mode is limited by many factors, and the selection rate of products is very low, leading to the waste of proofing products, which increases the development cost and also prolongs the time for the entire product development. If the order mode is not improved, the development of the enterprise will be subject to many restrictions.

Therefore, the design mode and ordering mode adopted by most domestic brands at the design stage cannot adapt to the development of the digital technology era and cannot change the traditional design and ordering methods in a new way; then, the result will be worse. This is also the research problem of this article.

Based on the above analysis, there are currently two main issues in the fashion brand industry. On the one hand, the fashion industry relies on a large number of new products to drive consumption. For fashion companies, only by continuously producing new products can they retain consumers and meet their diverse needs. On the other hand, the fashion industry heavily relies on design creativity. Unique inspiration gives designers creativity, and companies often tolerate less precise design sketches because creativity is not achieved in one step and requires designers and production teams to repeatedly polish. However, if digital tools are used for clothing creative design, there will be many options for iterative updates.

2.3 Research objects – how to solve the problems of traditional fashion design method and order mode

Based on the previous analysis of relevant literature and clothing industry content, the researchers will solve the problem that the traditional clothing design methods and ordering mode cannot adapt to the development of the digital era from two directions. The details are as follows:

Fashion 3D simulation design and modeling. Different from the traditional fashion design mode, the researchers make the effect of clothing products present the simulation content in the design stage, including the rendering of fabrics and human bodies, tend to be real. The specific contents include obtaining physiological parameters of clothing body, style detail design, physical model and design of fabric, collision detection and analysis of human body and fabric, clothing fabric rendering and 3D simulation model of clothing, etc. The key step in the whole content is the effect simulation of the fabric physical model, which relates to the real style and characteristics of surface rendering.

Dynamic virtual display of clothing. The research of this content is mainly to provide customers with electronic clothing dynamic display and place it in different environments. At the same time, based on the 3D simulation effect of the front clothing, we strive to achieve the most real clothing dynamic and scene simulation, which can be directly sent to customers in the form of an online conference or email for selection, directly omitting the ordering process of clothing development, saving the cost of sample clothing, and reducing the time cost. This section uses a geometric modeling algorithm to build a three-dimensional clothing dynamic virtual display model.

3 Methods

In this topic, the clothing flexible body refers to the 3D model of the simulated clothing, which has the texture and visual sense of the real clothing, and requires a variety of algorithms and models. Therefore, this section will analyze from two directions: fashion design and modeling, and dynamic virtual display research.

3.1 Fashion design and modeling

Fashion design and modeling is the first and most basic step in this research. The key to this step is to integrate the four contents of human modeling data acquisition – clothing module database – fabric and human body collision test and fabric rendering simulation.

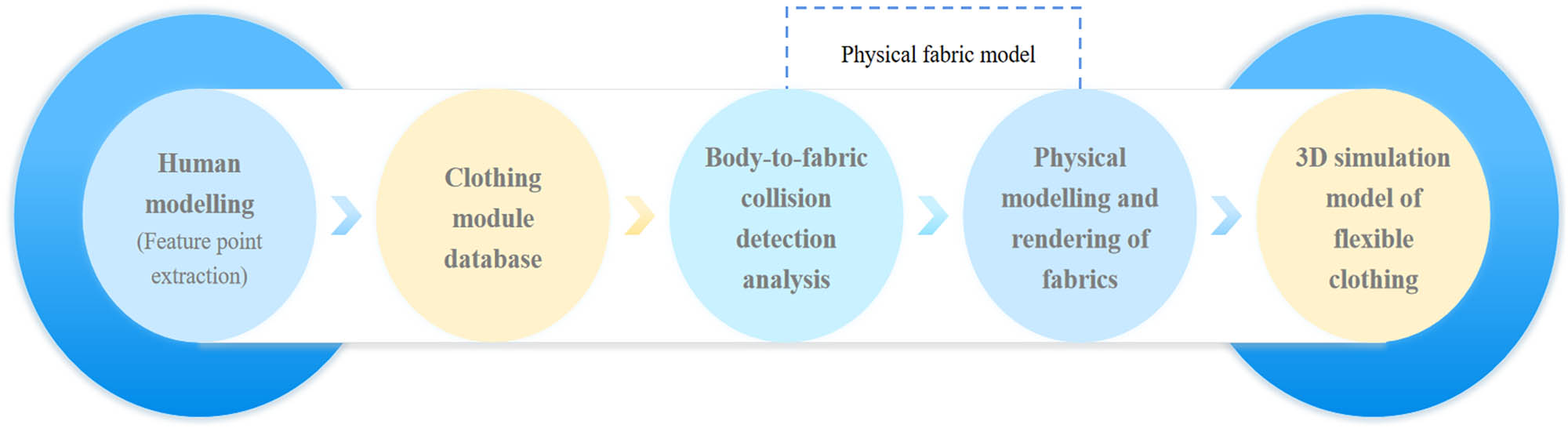

Specifically, as shown in Figure 6, clothing design and modeling includes five processes: human body modeling (feature point extraction), clothing module database, human body and fabric collision detection and analysis, fabric physical model and rendering, and flexible clothing 3D simulation model. Among them, human body and fabric collision detection and analysis, fabric physical model and rendering the use of physical fabric model algorithm for simulation, and related contents will be described later. In order to enhance the accuracy and order of this research, the researcher takes the women’s dress as the design subject, connecting the following process analysis, and will also more clearly express the content related to design modeling dynamic display.

Associated content and process of fashion design and modeling.

3.1.1 Body modeling and clothing module database

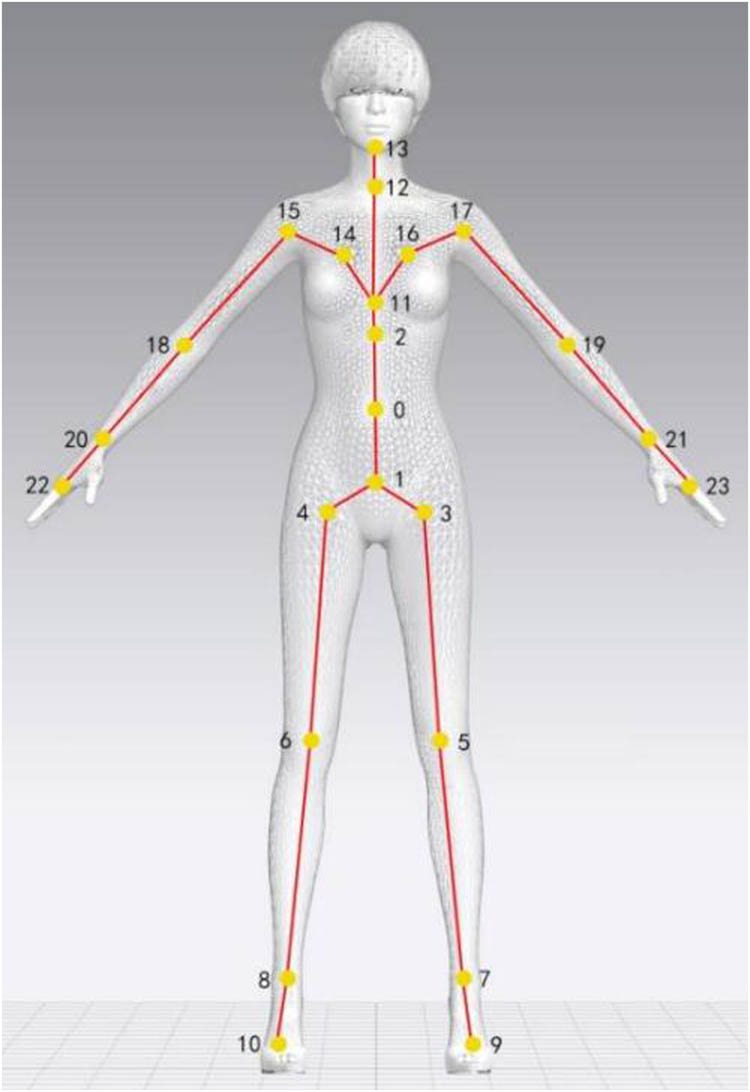

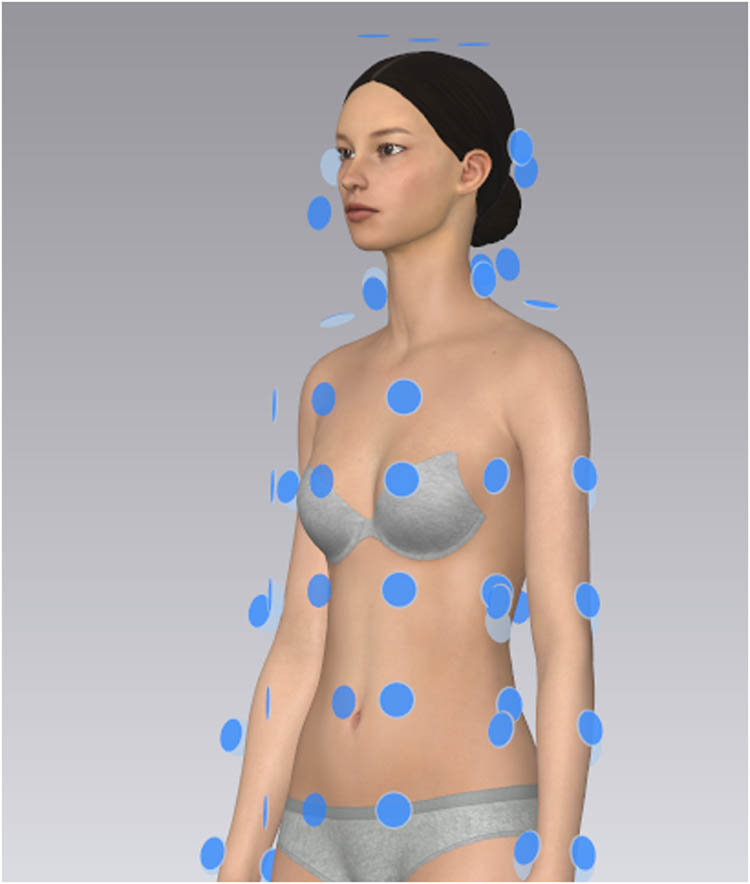

Human modeling is the basis of the garment simulation model, without the acquisition of human physiological feature points, it cannot accurately establish the human parameter model. Human modeling is to form a virtual 3D model of a real human body through parameterization. At present, there are many methods to obtain the 3D model of a human body. The common methods are as follows: the first is to capture the visual points of a human body from multiple angles with high-definition cameras in a closed space, obtain the spatial point cloud coordinates of the human body through image processing technology, and then use the splicing algorithm to form a human model. This requires high quality of environment and camera, as shown in Figure 7. The second is to use Kinect photosensitive capture camera equipment to convert scanned images into body size data using data cleaning and compression technology and use multiple algorithms such as ray casting algorithm to obtain the coordinates of spatial point cloud, and finally build a human model [4,5] as shown in Figure 8. The third method is to establish a point cloud model by acquiring data of multiple human parts and, at the same time, compare it with the existing human model database, and select a closer human model for fine-tuning reconstruction, as shown in Figure 9.

3D Human scanning room.

Kinect photosensitive capture scanner.

3DCLO design software models with data.

At present, the three methods are the best and have the highest utilization rate. In enterprises, the first and second methods are commonly used, and the third method is mostly used for college research. However, some problems have also been encountered. From this topic, the researchers believe that integrating the second and third methods to extract and model human body data is the best method with high accuracy, and can fine-tune relevant data in the later stage. Specifically, Mao and Wang [6] used the ray cast by the non-contact three-dimensional scanning equipment (photosensitive capture equipment) to the human body, used the sensor to receive the reflected ray, used the photoelectric conversion element to obtain the digital signal, and then used the image processing technology to obtain the spatial point cloud coordinates, which are converted into human body size data. According to the 24 physiological parameters of the human body obtained, different human skeleton models are constructed using the SMPL model, as shown in Figure 10. Human body shapes and features can be divided into different categories and sizes to achieve personalized and accurate customization [7].

![Figure 10

Female manikin derived from SMPL model [7].](/document/doi/10.1515/aut-2023-0042/asset/graphic/j_aut-2023-0042_fig_010.jpg)

Female manikin derived from SMPL model [7].

Among them, SMPL [8] (Skinned Multi Person Linear Model) is a naked, vertex-based three-dimensional human model, which can accurately represent different shapes and postures of the human body. The SMPL model contains N = 6,890 vertices, 13,776 patches, 24 joint points (note: 23 joint points + 1 root node), and the model parameters are determined by

T̄: R 3N , Human average network model;

W: R N×K , LBS/QBS, Hybrid Matrix;

S: R 3N×|β|, PCA base for human body shape;

J: R 3N×3K , Calculate the regression matrix for the 24 nodes;

P: R 3N×9K , PCA base for human posture.

Then, the corresponding formula of the model: M(β, θ) = W (T p (β, θ), J(β), θ, W) [9]. The calculation process consists of three steps: body parameters (vertex offset) – posture parameters (vertex offset) – skinning. The number of shape PCA-based parameters is 4.28 × 10−6, and the number of pose PCA-based parameters is 23 × 9 = 207.

Figure 11 is the schematic diagram of the joint point layout in the SMPL model, which is a normal posture. The coordinates of the human joint points are calculated by the formula

Layout of 23 joint points in SMPL model.

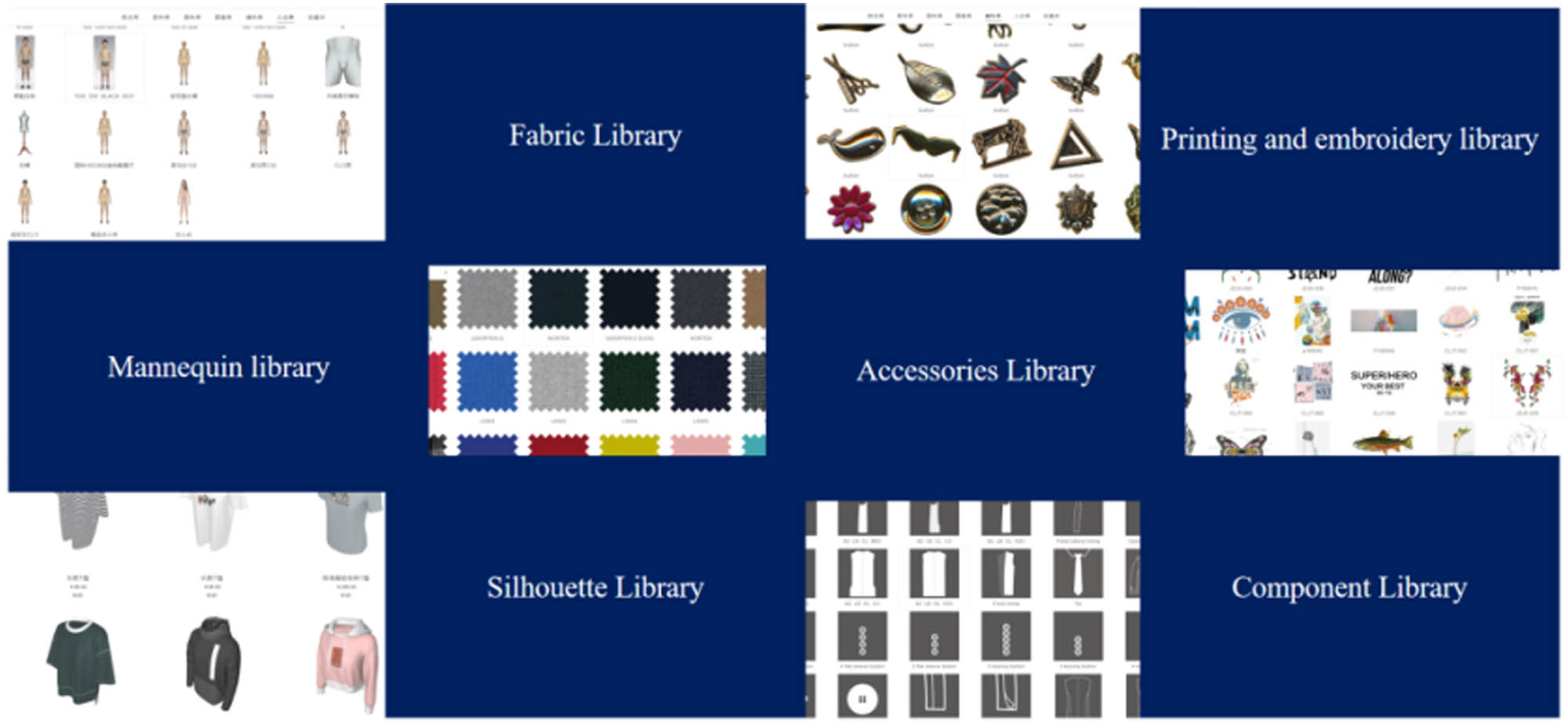

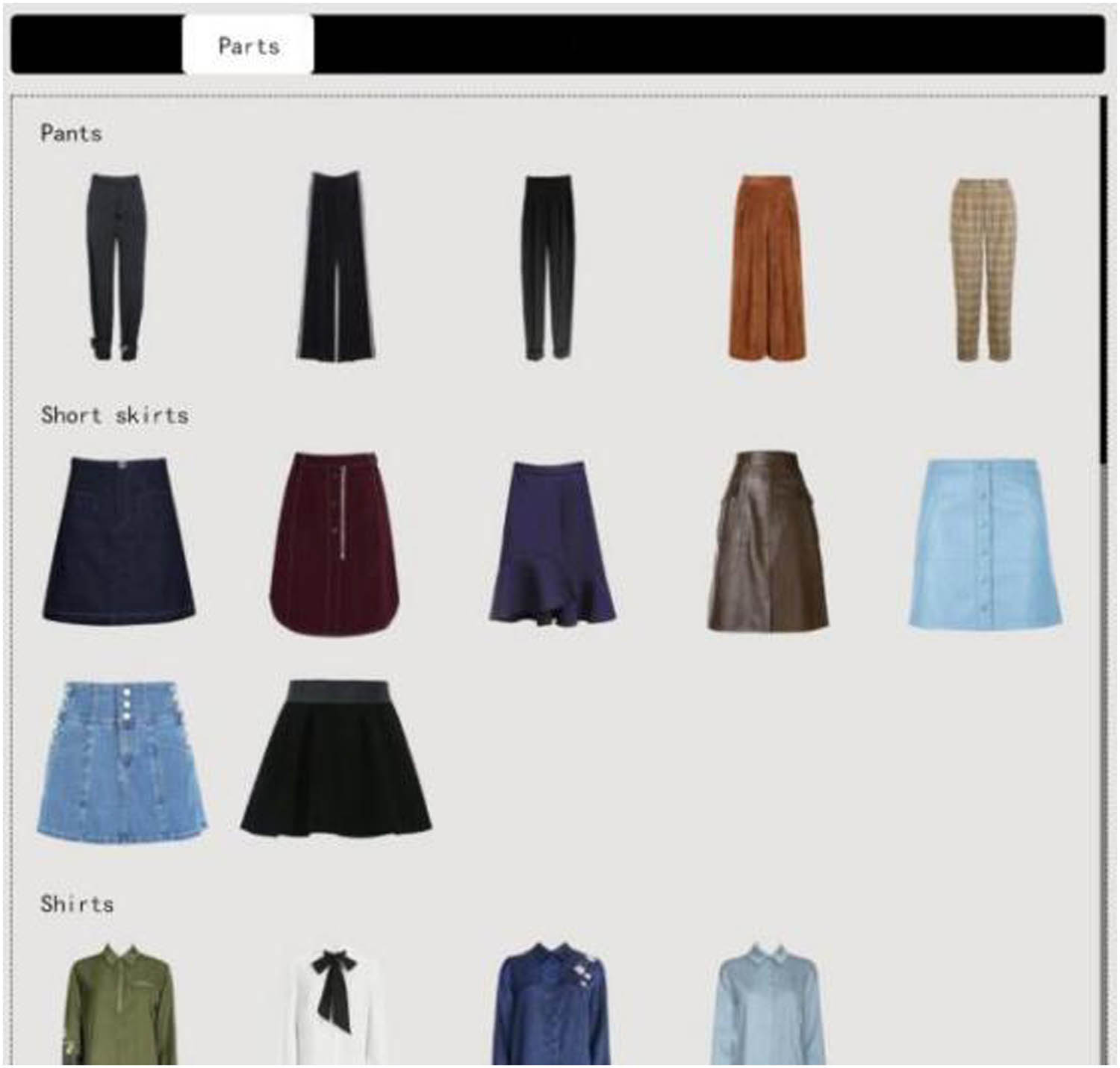

After the manikin is determined, the clothing module database can be used for a certain degree of combination design from the database, including fabric library, body library, accessories library, printing and embroidery library and parts (styles) library, as shown in Figure 12. At the same time, the content of the module database can be edited and adjusted. For the clothing modules attached to the manikin, a secondary design (combination) can be carried out according to the needs of researchers (Figure 13).

Interface design of apparel module database.

Clothing module database – part library content display.

The two contents of the human body modeling and clothing module database are separate. The clothing module database appears in the form of Web pages, and the two parts can cooperate with each other through computer input ports, JAVA architecture, links, and other tools. Specifically, after processing the mannequin, you can link to the clothing module database in an embedded way. You can click what you need to get the link, and directly edit the mannequin until you are satisfied.

3.1.2 Physical model and design of fabric

Fabric simulation is an important step in the process of 3D flexible simulation of clothing. It is also the attempt and preparation of the subsequent flexible simulation model. At present, there are three methods for fabric simulation models: physical method, geometric method, and hybrid method. The most commonly used, simplest, and most valuable method is the physical method. It takes a long time to calculate the speed and position of particles by analyzing the force of particles in the model, but the results are real. The most commonly used physical model is the spring-mass model, which is simple, effective, and easy to implement (Figure 14).

![Figure 14

Type of spring-mass model: (a) tensile spring, (b) square grid, (c) shear spring, and (d) bending spring [10].](/document/doi/10.1515/aut-2023-0042/asset/graphic/j_aut-2023-0042_fig_014.jpg)

Type of spring-mass model: (a) tensile spring, (b) square grid, (c) shear spring, and (d) bending spring [10].

The particle represents the movement track of the unit and finally forms the movement deformation route (shape) of the fabric. There are several types of specific spring particle models: a. tensile spring, b. square grid, c. shear spring, and d. bending spring; the four spring-mass models have different characteristics, which are used in physical modeling. These spring-mass models form the internal power of the fabric mechanical system and are also the cause of minor changes in the fabric, such as fabric stretching, shaking, and wrinkles.

In the process of spring-mass model simulation, the fabric is separated into many mass points, and the mass points are connected by many small springs, and the model needs to calculate their tensile force and bending coefficients and distribute the mass points reasonably, so before calculating the physical model of the spring-mass points, it is also necessary to add the physical data information to the model, these pieces of information are the basis for the movement, force, and structural bending deformation of spring particles. The associated parameters for the physical model of fabric simulation are shown in Table 1, which is based on the physical information related to the force applied to the fabric. The whole table will be divided into three parts: internal factors, external factors, and other parameters, which are all close factors affecting the four spring-plasmoid models, and a clear understanding of them is decisive for the spring-plasmoid model simulation of fabrics.

Associated parameters of physical model of fabric simulation

| Type | Explain | Factors affecting parameters |

|---|---|---|

| Internal factors | Tension/shear spring | Spring maximum elongation, stretching data, damping data |

| Bending spring | Spring initial length, tension data, damping data, collision data, dynamic friction and static friction data | |

| External factors | Human factor | Rotation, drag, tension |

| Nonhuman factor | Ambient wind, air resistance, physical gravity | |

| Other parameters | Model correlation factors | Number of model particles, model structure and model difficulty |

Specifically, external factors include human factors and non-human factors. Human factors mainly refer to the effect of other forces on the fabric, including pulling, rotating, etc. [11]. The non-human factors are mainly the wind force, air resistance, and gravity in nature. The wind factor coefficient is

Therefore, to build a spring-mass model (physical model of fabric), first of all, we need to build a mechanical system. Generally, the movement process of the mass is in accordance with Newton’s second mechanical law [10], and the formula is as follows:

The cloth is mainly affected by gravity, wind, collision force, and the performance of the fabric itself. These factors affect the calculation rate of the spring particle model, which is constantly changed in the process. Then, the velocity and position of the next particle of the cloth are calculated through Newton’s second law of mechanics, where m represents the weight of the particle, f G represents that only gravity is considered in this topic, f in represents the total internal force of the particle, and y represents the current position of the spring particle [10].

The particle is affected by wind, gravity and particle coordinates, quantity, and position. The researchers calculate the deformation force of the particle spring by using Hooke’s law [12]. The formula is as follows:

where ∆ χ is the expansion and contraction of the mass–spring.

The mass will consume energy in the process of moving or moving, and the spring-mass will vibrate in the process of consumption, affecting the running track, so the damping force is required to simulate and eliminate such vibration [9]. The formula is as follows:

where C d is the damping parameter, and υ is the motion direction of the mass-spring.

Through the above analysis, formulas (1)–(3) are converted into formula (4):

The entire physical model equation is a nonlinear differential equation. At the same time, the explicit midpoint method is used to calculate the motion and spatial coordinates of the spring particle, and the calculation is repeated iteratively; that is, the physical motion of the fabric can be simulated.

For the model system established by spring mass, during the movement process, due to the characteristics of spring structure, the spring will appear excessively stretching, which will eventually affect the effect, and even lead to distortion of cloth simulation. The researchers believe that this pain point problem can be solved by improving position correction. Specifically, by changing the speed of the particles on both sides of the spring and the position coordinates of the particles on both sides of the spring, the hardness and softness of the cloth can be reflected to achieve the desired simulation effect [10].

3.1.3 Analysis of collision detection between human body and fabric

Cloth simulation technology is a very important step in virtual clothing, so the collision and processing between human body and fabric are also the most time-consuming part of the cloth simulation process. When clothing is worn on the human body, many collision phenomena will be encountered when simulating the wearing effect, such as the crossing and collision between the mannequin and cloth, and between cloth and cloth. Therefore, collision detection is a key problem in the simulation process. The simplest method of collision detection is to pass through the basic geometric elements in the mannequin and fabric.

At present, there are two commonly used collision detection methods: spatial decomposition and hierarchical bounding box. Specifically, the spatial decomposition method is to divide the virtual space centered on the human model into multiple cells with equal volume and cross-test the crossing between cells occupying the same cell or adjacent cells. Hierarchical bounding boxes are used to divide multiple parts of the human body model by using the bounding boxes with large volumes and simple modeling to form multiple bounding boxes of different sizes. When the bounding boxes cross each other, the objects between the two bounding boxes will be cross-calculated. At the same time, the bounding boxes also have some hierarchical structures, such as bounding boxes along the coordinate axis, bounding balls, and directional bounding boxes.

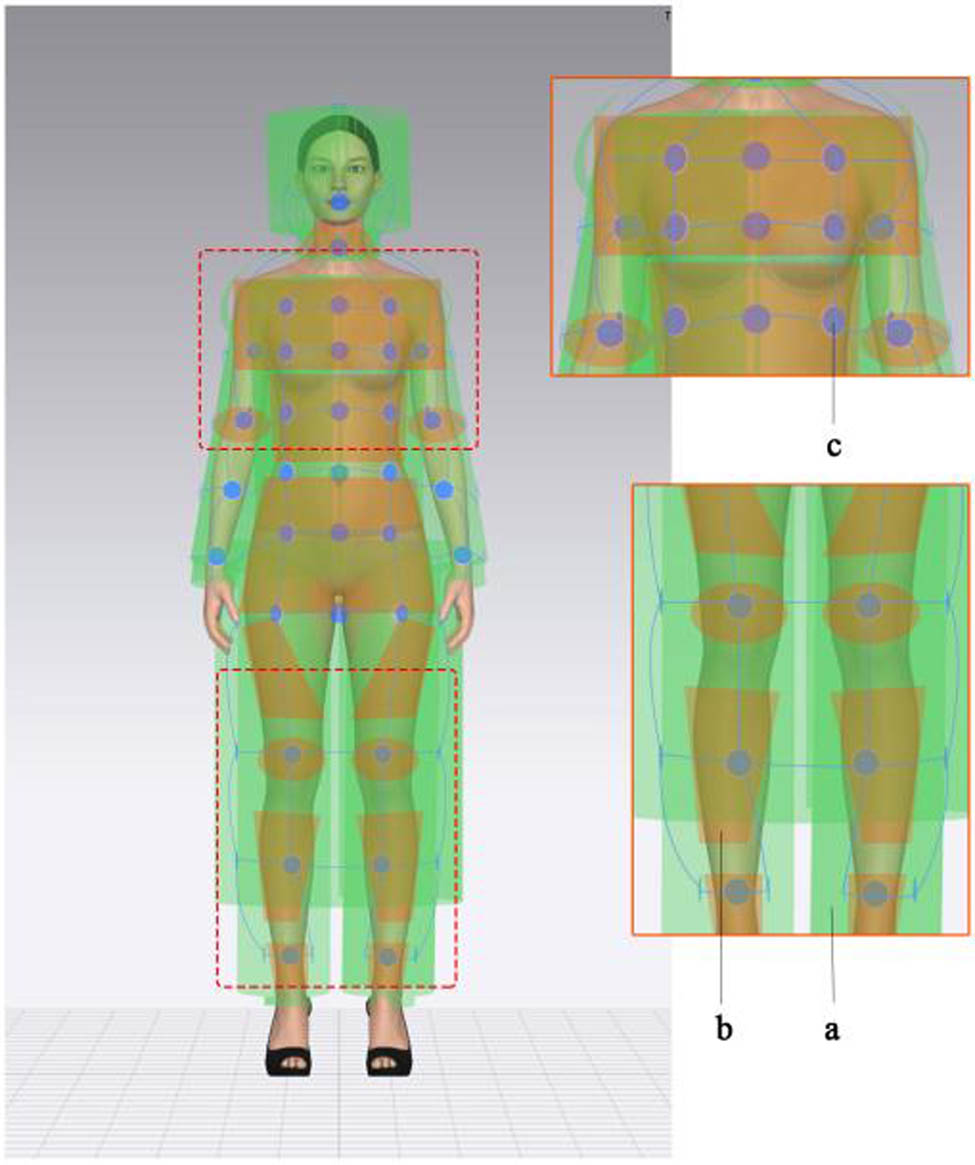

In this study, the author combines the advantages of the two methods. Aiming at the cross collision between the mannequin and the fabric, the author makes use of the advantages of hierarchical bounding boxes (two or more bounding boxes cross each other – wrapping objects <mannequin> cross calculation), and uses hierarchical spatial decomposition (spatial decomposition of multiple color cells) to improve the order, three-dimensional and flexibility between the mannequin and the fabric. It reduces the irrelevant elements in cross-testing and improves the speed and efficiency of collision detection.

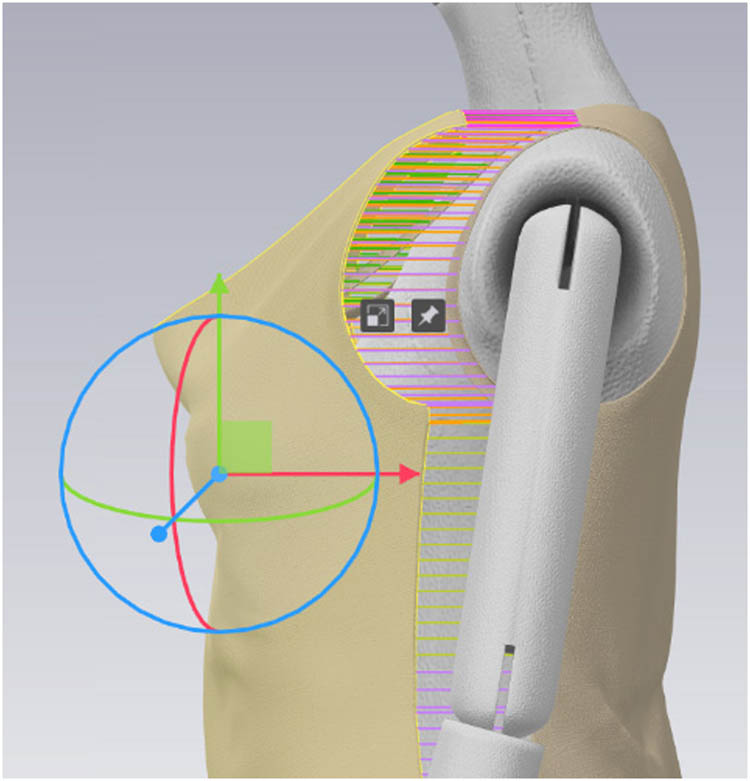

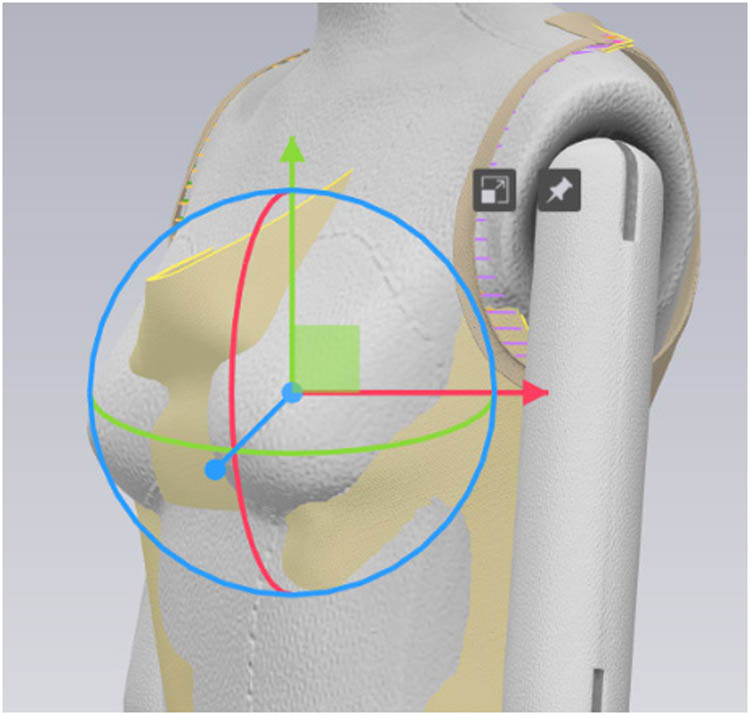

Specifically, first, the authors take the female human body model as an example and use the hierarchical enveloping box and static ellipsoid fitting to construct the static keyframe screen. In Figure 15, the schematic diagram of a hierarchical enveloping box and static ellipsoid fitting [10], the right side is the randomly selected two keyframe screens for the set of regions corresponding to the enveloping box coordinates, in which a is the ellipsoid enveloping box schematic region, indicated in green, and the regular shape is carried out to wrap the different parts of the human body; b is the interpolation region of ellipsoid fitting, when the number of keyframes of the model is small, the connection between the keyframes is not smooth, in order to reduce the interspersed fabrics and fabrics affect the cross between the human body model and fabrics, so insert linear interpolation between the two frames; c is the human body model nodes, based on the interspersed position, ellipsoidal structure to build the node coordinates around the human body model, through the node coordinates to better simulate and cross the external characteristics of the fabrics.

Schematic diagram of hierarchical bounding box and static ellipsoid fitting.

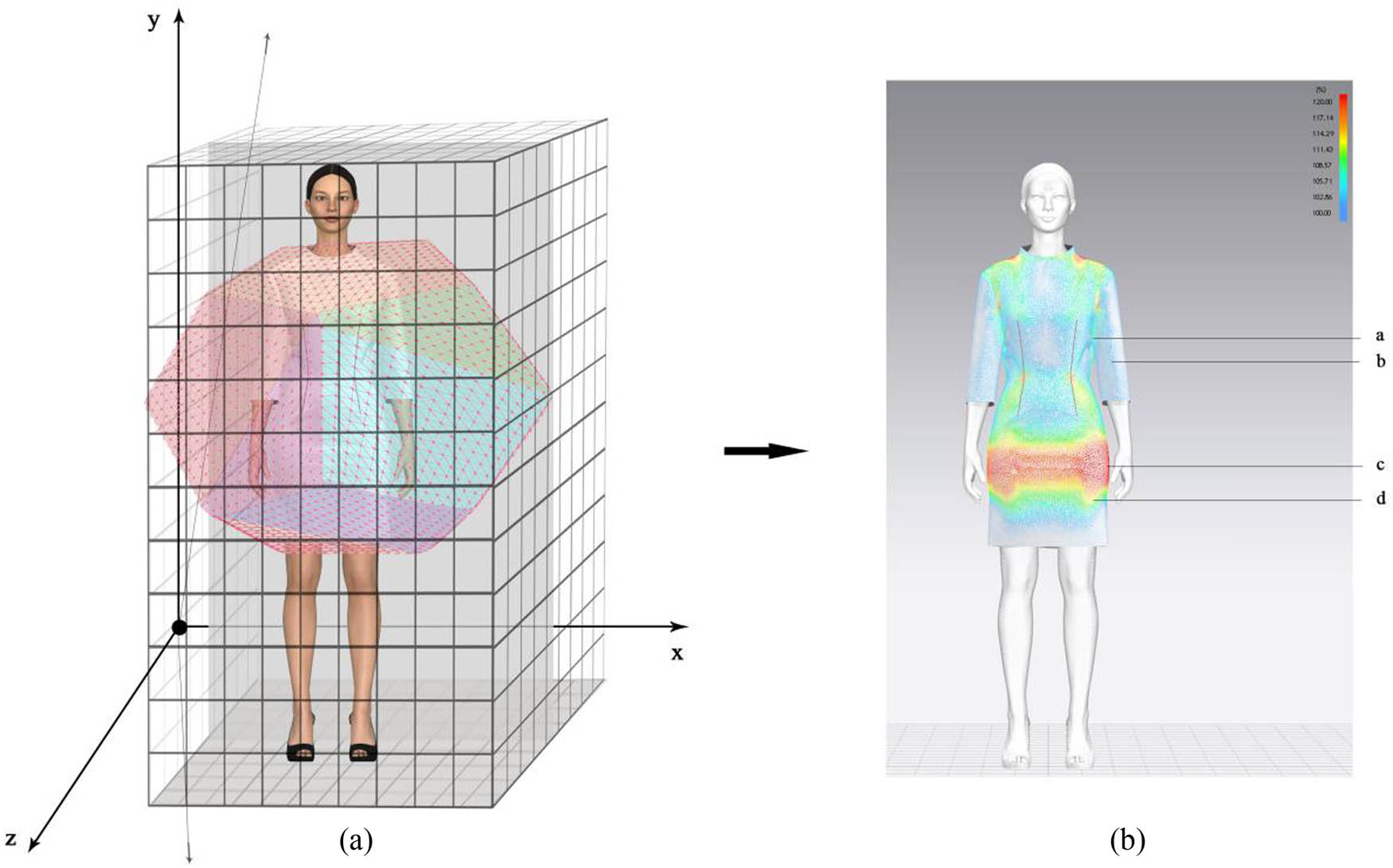

The second step uses the hierarchical space decomposition method to detect the collision between the mannequin and the fabric, which is also based on the first step of the hierarchical bounding box method. Figure 16a is the schematic diagram of the hierarchical space decomposition method of color labeling [13]. In this article, the color enclosure centered on the human body is wrapped with an irregular polygonal cube. In order to accurately calculate the contact value between the convex point of the fabric and the polygonal cube, the three-dimensional space is divided into multiple small squares with the same color and volume. Each small square has unique coordinate information unique color representation. When the mannequin is in motion, the clothing cloth and polygon color cube cross collide, and the coordinates will mark the coordinate hierarchy between the color bounding body and the human body and fabric. Specifically, the whole model coordinate diagram (Figure 16a) includes three parts: human body model coordinate, clothing cloth coordinate, and polygon color cube enclosure coordinate. Specifically, three collision forms are judged through algorithms, including the coincidence of human body model coordinate and clothing cloth coordinate, the coincidence of clothing cloth coordinate and polygon color cube enclosure coordinate, and the coincidence of human body model and polygon color cube enclosure coordinate. At the same time, there are also some self collisions between cloth, including the intersection of cloth points and faces. In the whole process, first, the Sweep and Prune algorithm is used to detect the physical method of AABB bounding box, and at the same time, the separating axis theorem algorithm is used to optimize. The intersection of the polygon cube’s face, line, and point with cloth and human body model is adjusted, and determined whether they intersect according to the overlapping shadow area.

Visualization diagram of color annotation space decomposition (a) and cross-collision pressure perception (b).

Figure 16b is the pressure perception diagram of the intersection of the garment fabric and the mannequin, which is also a reflection of the repetition of the coordinates of the two. Using different colors to indicate the size of the cross-pressure, a/b/c/d in the figure indicate the pressure value of different parts of the human body, c indicates the largest pressure value, which is orange-red, divided into the combination of crotch and fabric, the shoulder and neck points and the combination of fabric; the yellow area indicates that the pressure value is the next lowest, and the lowest pressure value is the blue area. The expression of the pressure perception map also highlights the color space, polygonal cubic enclosure, and the cross-fusion of coordinates of the human body model and multiple parts of the fabric in Figure 16a. It is the best expression in a collision detection method. Through 3D modeling and algorithms, the researcher simulated the pressure-aware visualization maps as in Figure 17 for a mannequin wearing a garment fabric, divided into four directions: front, back, and left and right sides, which provides a clear understanding of the collision-monitoring pressure values for each part.

Visualization diagram of pressure point perception.

3.1.4 Clothing fabric rendering

Cloth rendering is an important part of the 3D flexible design of clothing. Traditional cloth rendering uses machines to scan the tfabric, and secondary design and processing is carried out through AI or photoshop software to make the desired style. However, because the size proportion is often inconsistent with the actual, it consumes time and costs. Before the appearance of the digital physics engine, this method was a common method for garment enterprises to build fabric databases. Before analyzing the digital rendering of fabrics, researchers first proposed several factors affecting fabric rendering, as shown in Table 2.

Material definition and direction to be considered for fabric rendering

| Category | Content affected |

|---|---|

| Fabric appearance | Color, texture, luster, area size |

| Physical properties of fabric | Bending force, elasticity, pressure point, anti-collision force |

| Fabric data properties | Weight, composition, yarn count |

The material definition and direction to be considered in the fabric rendering shown in Table 2 are important factors that affect the digital scanning and rendering in the later stage. Before rendering, we should first understand and be familiar with the material definition of fabric, including fabric appearance, physical attributes, and data attributes. In terms of fabric appearance, we mainly focus on the color, texture, luster, and other contents of the fabric, such as silk luster, cotton texture, etc. The physical properties of fabrics include elasticity, bending, pressure, and other properties, such as the elasticity of knitted fabrics and the bending degree of wool fabrics. Fabric data attributes include composition, yarn count, etc. For example, when rendering, the appearance of the components is considered.

The researcher is familiar with the material definition and direction attribute of the fabric. Starting from this topic, the researcher proposes the relevant process of fabric rendering. The whole process includes four parts: digital fabric creation, texture mapping, texture redesign and color scheme, and realistic rendering. Specifically, the establishment of digital fabric is mainly to scan the fabric with high definition through digital scanning equipment to form a high definition base map. Second, the base map is processed by Substance Alchemist tool and AI algorithm to generate normal, yarn texture height and other contents, and impurities, shadows and other contents on the base map can be removed to finally generate texture maps. Then, relevant software is used to redesign the texture map and adjust the color matching of the fabric, such as Adobe IIIustrator, Adobe Dimension, etc. This step is related to the diversity and accuracy of the fabric. Finally, by matching the size, light, and camera pigment of the fabric, and then through PBR rendering, the conventional PBR rendering is mainly applied to fabrics such as cotton fabrics and wool fabrics, and the special PBR rendering is mainly applied to silk fabrics with shiny and high linear requirements. In the specific implementation process, relevant algorithms in the Unity Shader tool are applied to render. Figure 18 shows the silk fabric effect in the fabric rendering [14].

Fabric rendering – silk fabric effect.

3.1.5 Flexible 3D garment simulation model

The establishment of the 3D simulation model of a garment flexible body is the core content of this topic, and also an important link for garment enterprises to actively design and serve key customers. At present, there are many methods for 3D modeling of clothing. This topic adopts the point line surface trinity modeling method, which is time-saving and effective. Therefore, according to the previous chapters and the particularity of 3D modeling of clothing flexible body, the researchers propose the flow of 3D clothing simulation model of clothing flexible body suitable for this topic, which is the flow of 3D clothing simulation model of flexible body [15].

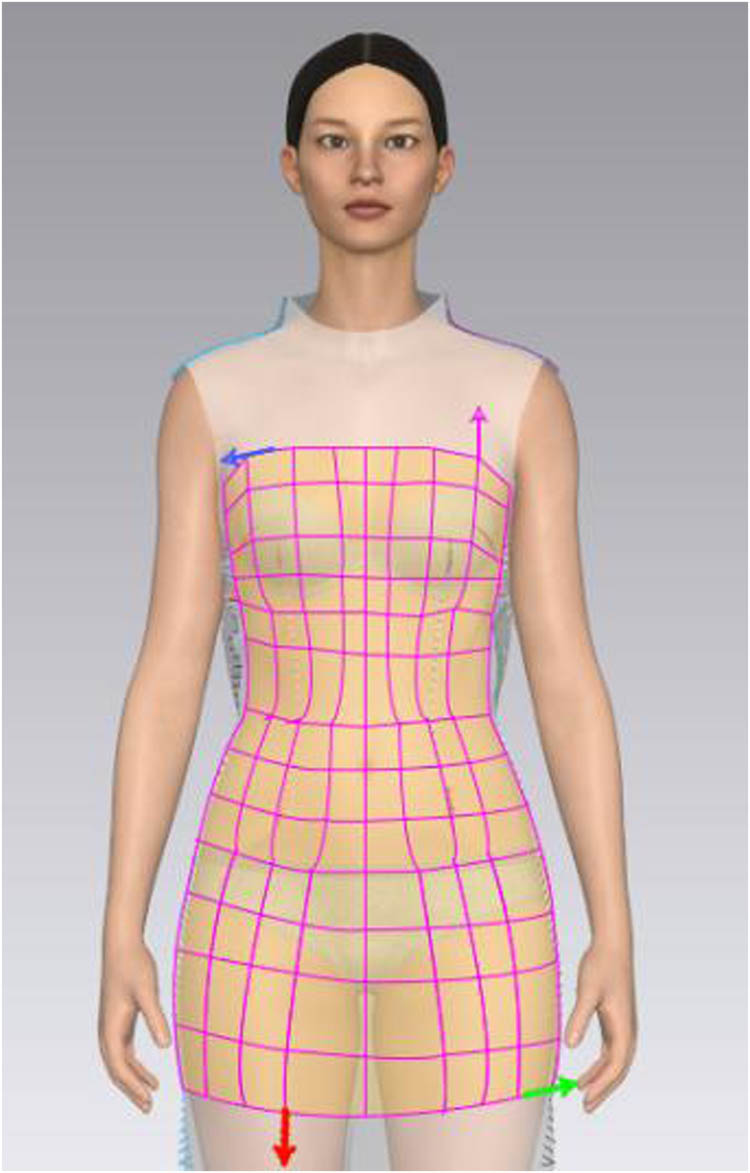

Specifically, the whole process is divided into five modules. The first module is a customized manikin. According to the manikin designed using the SMPL model method, the corresponding size of the target clothing, such as women’s 160/68 A and men’s 180/92 A, is matched. At the same time, according to the characteristics of the target clothing, the design of the manikin is customized, such as a little wider shoulder, a little more waist circumference, a little bigger chest circumference, etc. The second module is to select the data points of the clothing parts. This module exactly selects multiple data points reflecting the clothing shape according to the customized manikin and corresponding to the needs of the target clothing, as shown in Figure 19. The clothing shape is set as the women’s bodice top, and the data points of the target clothing shape are selected. The selected position points are, respectively, 10 cm below the armpit, mastoid, side waist point, belly button, and neck center. The purpose is to better control the surface modeling of the clothing form after the connection is formed and reduce the number of unnecessary surfaces. There are four surfaces in the figure, and the left and right clothing pieces are distinguished by different colors [16]. The third module is to draw the internal and external line types of clothing on the basis of selecting the data points of clothing form parts in the second part, as shown in Figure 20. It mainly uses the curve equation to calculate from point to line and constructs the structure in terms of cloth topology, wrinkle shaping, etc., to form a closed-loop internal and external line type structure of clothing. This is also the initial clothing form master. The line type parameters are obtained by calculating the XYZ axis of the curve equation and each part point connected into line type. In this module, we should consider the rationality of clothing attachment to the mannequin and the reflection of a normal state under the action of gravity. At the same time, in this step, we should also consider the characteristics of fabric, force direction, structure, pleating volume, and other factors.

Point selection of target clothing shape.

Draw the inner and outer lines of clothing.

The fourth module is to build the clothing surface model [15]. Specifically, this step is the most complex and key step in the whole model construction, mainly including fabric stress structure analysis, pressure fitting points, fabric mapping and property rendering, screen Z-axis carving, low mold foreskin, etc. The fabric stress structure and pressure fitting point are mainly carefully drawn on the clothing softness and fitting degree, so that the bending degree and hardness of the fabric can maintain a certain state of confrontation, so as not to lose the sense of support of the clothing form, as shown in Figure 21. Cloth mapping and property rendering are mainly based on the previous cloth rendering for UV mapping. According to the shape effect of the target clothing, the pre-rendered fabric map is placed in the clothing model to make it fit. The space between the human body and the cloth covered by the cloth can be replaced by the conventional shadow mapping algorithm, which can make the space between the cloth and the human body more fit and more realistic. Screen Z-axis carving cannot be clearly drawn based on the relationship between the side seam of the target clothing form, the upper edge of the clothing, and the human model. Generally, we use the XY axis direction, so we use the Z-axis view of screen coordinates for interpolation and careful drawing, as shown in Figure 22. The low mode foreskin simulates the clothing effect to a certain extent through the lighting effect and depth buffer algorithm, so that the contrast between the clothing and the front and back pixels of the human body can form a certain visual gap and enhance the stereoscopic sense.

Adjustment of fabric stress structure and fitting point.

Screen Z-axis engraving (interpenetration).

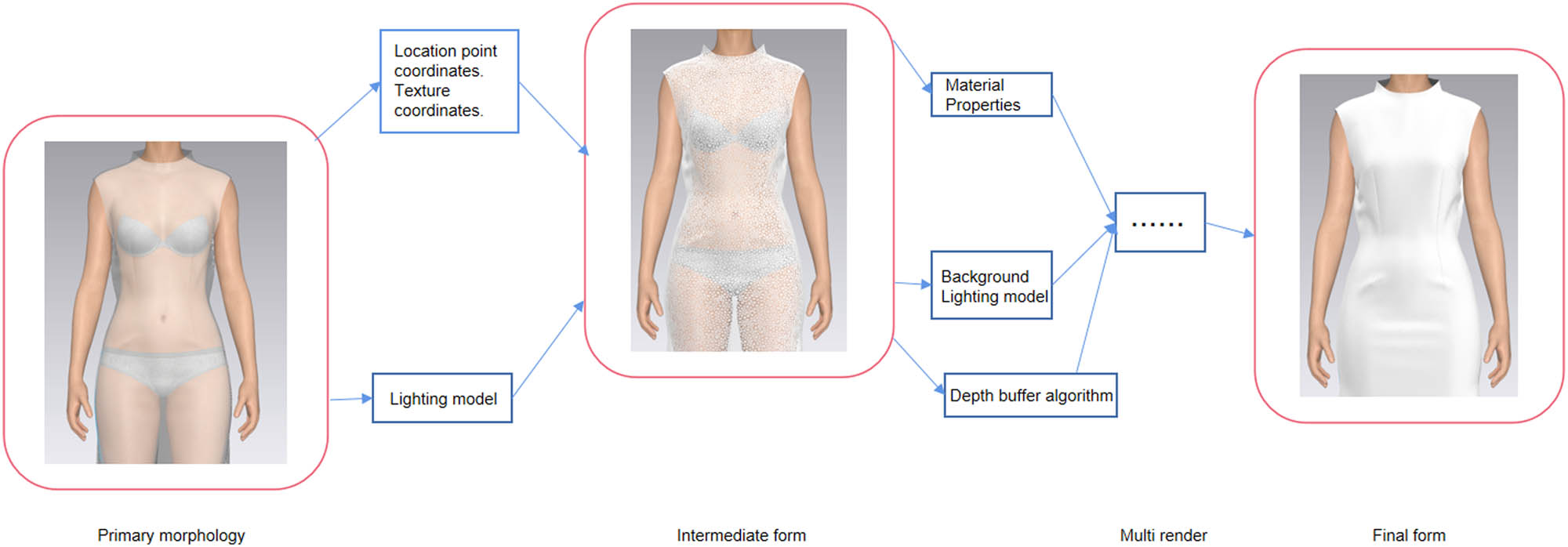

The fifth module is engine rendering, which is used to work on lighting, materials, clothing shape effects, and other aspects through the unity rendering engine. As shown in Figure 23, we have constructed the primary clothing form. Through the mapping relationship between the position point coordinates (XYZ) and the texture coordinates, as well as the calculation of the lighting model, the middle form of the clothing is formed. It can be seen that the fabric is a grid texture, which cannot meet the needs of researchers. Therefore, we render again through the material characteristics, background environment (reflective, etc.), lighting model, and depth buffer algorithm. After several rendering adjustments, the final shape of the target garment is finally constructed. The above is the specific workflow of the rendering engine. Due to the different shapes of the target clothing, there will be some differences in the workflow [17].

Garment model rendering – engine flow diagram.

3.2 Research on dynamic virtual display

According to the completion of the previous contents, the final content is to form a dynamic virtual exhibition of clothing after stitching the plates. This section studies the dynamic display of the clothing after the sewing is closed. The dynamic virtual display link can truly show the real state of the clothing before the proofing process, save costs, reduce development time, and play an important role in the whole clothing supply chain. At the same time, the saved costs can be used in the research and development link, making the product more competitive.

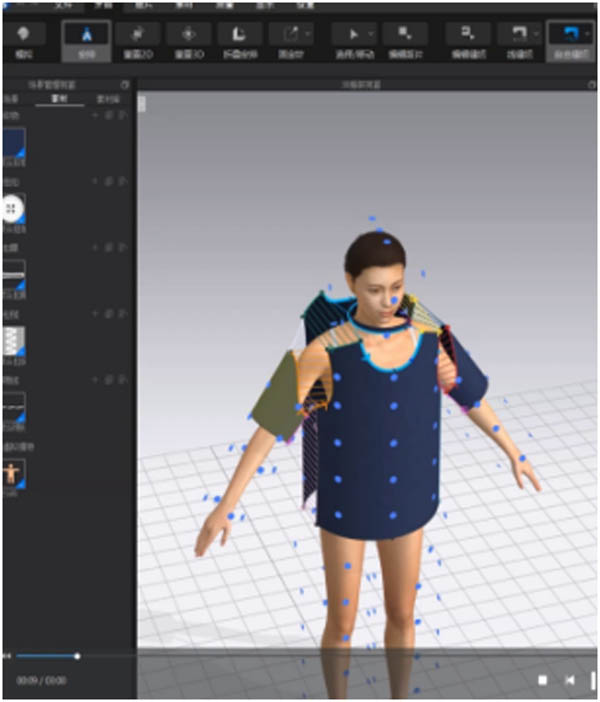

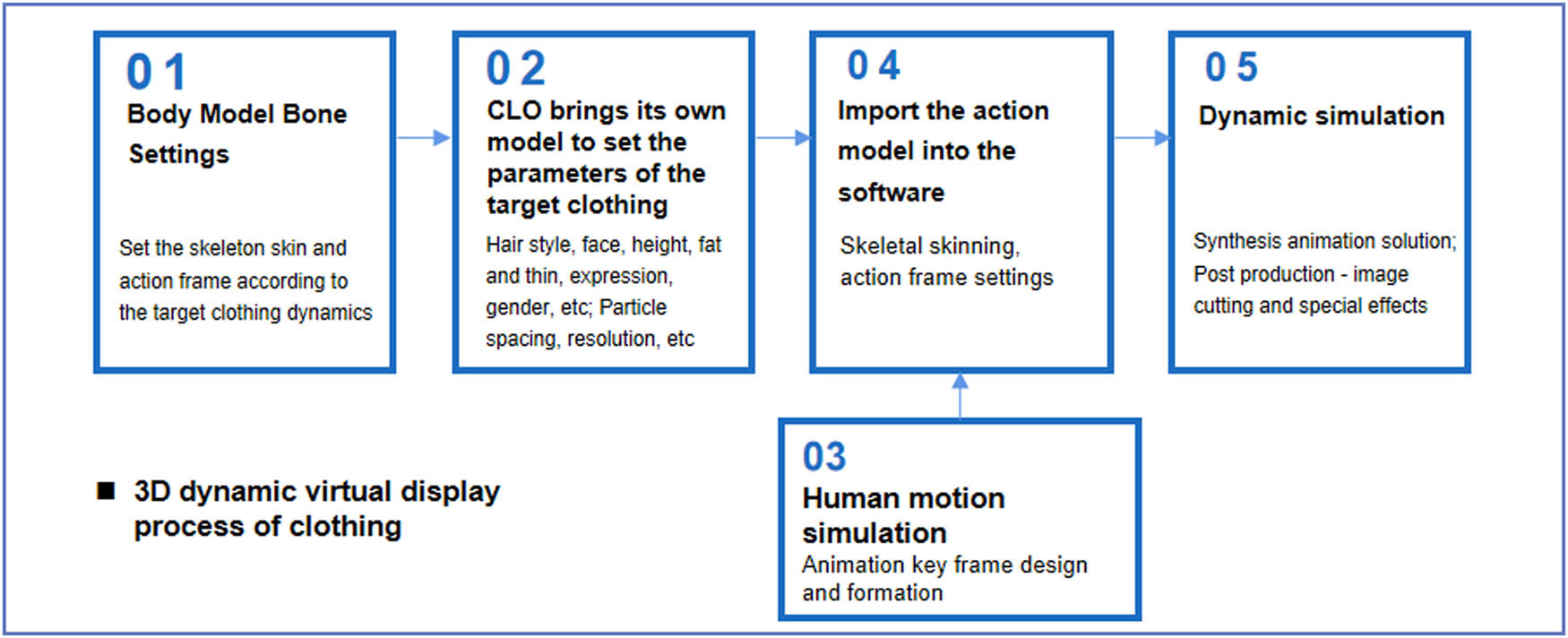

As shown in Figure 24, it is the flow chart of 3D dynamic virtual display of clothing. Specifically, the whole process is divided into five parts. The first part is the skeleton setting of the mannequin. According to the dynamics of the target clothing, the skeleton skin is constructed, including the rotation angle and radian of each part of the upper and lower limbs. At the same time, the motion direction and angle of the target dynamics are matched to confirm the shape displayed by the skeleton structure in the action frame [18]. The second part is to use the model in CLO clothing modeling software to set the parameters of the target clothing, such as hairstyle, face, height, fat and thin, expression and gender, as well as particle spacing, resolution, etc., to make basic preparations for dynamic display [19], so that it can more vividly and accurately display the characteristics of the target clothing, which can improve the probability of successful selection. The third part is human motion simulation. This part needs to achieve consistency between the actions of clothing and human bones. 3DMAX is used to establish systematic and regular forms of human walking, running, turning, and other actions as well as actions between bones to form animation keyframes. At the same time, the format is exported to Obj format and then converted to fbx format to prepare for the next step [18]. The fourth part is to import the completed action model into 3DCLO software and then select mannequins, clothing prints, sewing prints, and other links in repeated operations for dynamic simulation. The fifth part is dynamic simulation; click the animation solution button, set the solution time, and conduct animation synthesis simulation. After simulation, the whole dynamic picture may not meet the user’s requirements in terms of chroma, background, etc. Premiere software picks up the human body, renders the background, chroma, brightness, etc., and finally sets special effects and designs in the direction of unified color, lens transition, etc. [19], so as to achieve a more complete dynamic virtual display. Let the company’s target customers see a more realistic clothing design effect before making sample clothes. As shown in Figure 25, the screenshot of a dynamic virtual display of a round neck five part sleeve long skirt is derived according to the previous virtual display process. There are ten screenshots in total, and the researcher selects six screenshots here.

3D Dynamic virtual display process of clothing.

Dynamic virtual display screenshot of round neck five sleeve long skirt.

3.3 Design case analysis

This section showcases the design process of outdoor mountaineering suits through 3D design, dynamic virtual displays, and other content, as a support for effectively understanding theoretical concepts. Specifically, as shown in Figure 26.

![Figure 26

3D flexible design and virtual dynamic display of outdoor mountaineering suits (a–e) [20].](/document/doi/10.1515/aut-2023-0042/asset/graphic/j_aut-2023-0042_fig_026.jpg)

3D flexible design and virtual dynamic display of outdoor mountaineering suits (a–e) [20].

From Figure 26, it can be seen that the entire process of outdoor mountaineering suit design is divided into five parts [20]. First, the pattern is quickly drawn through the software platform, and the internal structural lines are adjusted, especially the elbow joint, shoulder joint, and other positions, with reasonable looseness. Therefore, a diagonal split line design is adopted in the structure to obtain a 2D clothing piece pattern effect of Figure 26a. The software platform is used to fit the pattern surface to obtain the effect diagram of the front and back clothing pieces, and the clothing piece pattern is further adjusted to finally form a C-surface pattern ready-to-wear model, which is also the final clothing surface unfolding diagram. Next, the generated garment samples will be used for fabric texture and color filling, followed by fabric rendering and shape rendering to generate 3D renderings. During this process, the researchers updated the software platform’s built-in fabric and replaced it with woven white cotton fabric, as well as adjusted texture properties and colors. Finally, a virtual model is used to dynamically display clothing, checking the fit of the clothing and displaying the wearing effect in all aspects, in order to provide customers with a clear understanding.

Figure 27 shows the dynamic simulation of the 3D effect of outdoor mountaineering suits in a virtual scene, with the main purpose of allowing consumers or customers to experience the feeling of wearing products in this scene, in order to achieve resonance effects. This is also a method of promotion and marketing.

Dynamic simulation display of 3D effects of outdoor mountaineering suits in virtual scenes.

4 Discussion and results

Based on the description and analysis of the two modules of clothing design modeling and clothing dynamic virtual display, the researchers can express the design process well and smoothly in the whole process, including modeling and dynamic display, and better display the two contents of clothing 3D simulation design, digital fabric effect, and dynamic environment virtual display to target customers, so as to save proofing costs, reduce research and development time, and improve the efficiency of the entire supply chain. At present, it is more suitable for small- and medium-sized clothing enterprises and some large clothing enterprises. However, there are also some problems in this process, such as the heavy workload of overall design and simulation, involving many AI problems. For example, it is difficult to capture the accuracy of physiological parameters of human models, which involves multiple human models of different shapes and ages. The 3D modeling of clothing takes a long time, involving the training of multiple algorithms. There is much interdisciplinary content knowledge, which is a variety of challenges for researchers in the direction of design.

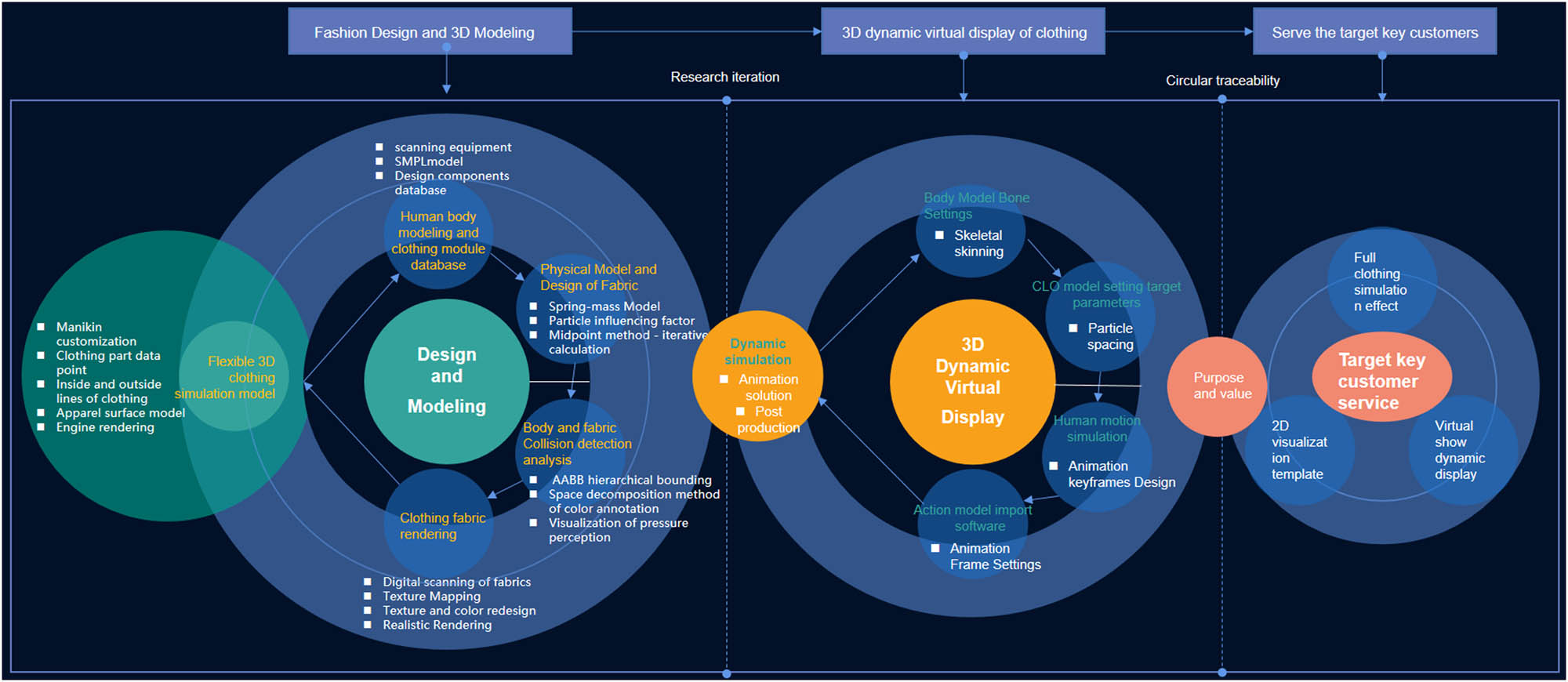

The research goal of this topic is to build a 3D model of clothing and research on the integration of dynamic virtual display. At the same time, the research terminal can provide the target customers with visual product development design and dynamic display, which shows the real effect of clothing design after proofing. This is also a way for small- and medium-sized clothing enterprises to actively promote services for target customers, which can increase customers’ trust and feelings toward the enterprise. As shown in Figure 28, it is a flow chart for 3D flexible body modeling, dynamic virtual display, and key customer service of clothing. Specifically, the whole flow chart is divided into three parts: clothing design and 3D modeling, 3D dynamic virtual display of clothing and service for target key customers. Among them, the clothing design and 3D modeling part includes human modeling and clothing module database, physical model and design of fabric, and collision detection analysis of human body and fabric The five sub-modules of garment fabric rendering and flexible 3D garment simulation model are circular and have sustainable characteristics. The second content is 3D dynamic display of clothing, including five sub-modules: skeleton setting of a mannequin, human motion simulation, etc. The five sub-modules are also circular. The first two parts have the relationship of research iteration. If one part of the content does not meet the requirements, it can be traced back to the previous part for redesign. The third part is target customer service, which is composed of three modules: complete clothing simulation effect, 2D visual template, and virtual show dynamic display. This is the purpose and value of this research. The whole process can be studied iteratively. If the target customers put forward their ideas in detail, they can go back to the first part again for redesign, which will be completed quickly and efficiently, and the whole process can be traced back to the source. This is of great value and significance to the rapid response system of many small- and medium-sized garment enterprises in China.

Flow chart of 3D flexible body modeling, dynamic virtual display, and key customer services.

The focus of this project is on clothing 3D simulation design, digital fabric effects, and dynamic environment virtual display, which can fully showcase to target customers, save sampling costs, reduce research and development time, and improve the efficiency of the entire supply chain. However, during the promotion process, it was found that the ultimate goal of clothing 3D technology modeling is a pattern, so the effect obtained by virtual technology is significantly different from the actual performance of sample clothing, such as in terms of material, color, and fabric texture. The pattern produced simultaneously is a single pattern. If a company wants to design clothes suitable for its own brand, it needs to develop customized virtual models, which requires a lot of money to develop independently and verify the fit of the clothes. In addition, in terms of fabrics, they are all scanned into images by scanners, forming machine-generated texture maps, normal maps, etc., which may have color differences, unattractive, and unrealistic effects caused by factors such as light and lighting. There are also issues such as the final fabric shrinkage that cannot be calculated. The above are the limitations of current in-depth research.

Based on the development of AI technology and various algorithms, researchers propose development directions to address the aforementioned limitations as follows:

The diversity and authenticity of virtual models need to be improved. At present, the combination of AI and algorithms can generate a variety of virtual models, using models with accurate body shapes to ensure the accuracy of pattern verification.

Optimization of virtual fabric production. Iterative fabric testing methods are updated to improve testing operability and convenience; consider new technological means to directly generate textures, patterns, gloss, etc.; do not use scanning techniques as they are time-consuming, laborious, and have poor results.

Intelligent process simulation, capable of automatically changing process details (such as curled edge sewing, handshake sewing, triangular needle edging, etc.). This operation requires a large amount of computation, and current machines and performance find it difficult to handle tasks with high computational power.

Strengthen validation simulations such as tactile sensation, pressure sensation, and weight sensation. Relying on simulation algorithms and multimodal platforms for mathematical modeling and calculation can assist in the development of some special functional clothing, such as space suits.

5 Conclusion

At present, the impact of digital technology and intelligent algorithms on many industries has been very obvious. From the perspective of clothing, both the clothing design teaching in colleges and universities and the clothing design tools in enterprises have started to expand in the digital direction. At present, the design tools used by designers in enterprises still rely on manual drawing and 2D design software. At the same time, there are not many clothing designers in small- and medium-sized enterprises, and expensive salaries will limit the number of people, which will lead to slow response in the design part. At the same time, most production and processing small- and medium-sized garment enterprises will react slowly to the big order meeting, and cannot lock this big customer for a long time, so they lack the trust and strength to let the big customer choose the enterprise.

At the same time, most small- and medium-sized garment enterprises provide OEM services for foreign brands. Therefore, quick response and active introduction of design services are an effective way to obtain long-term orders. Therefore, based on this, the researchers propose how to design flexible 3D effects of clothing, 3D dynamic virtual display, and virtual simulation of fabrics and human models from the two directions of 3D modeling of clothing flexible bodies and 3D dynamic virtual display of clothing. Through the research on this topic, the rapid reaction speed of clothing enterprises can be greatly improved, the R&D efficiency can be improved, the cost can be reduced, and the trust and reputation in front of large customers can be improved, improving order durability.

The development of digital technology enables garment enterprises to better transform and adapt to the current trend of intelligent manufacturing.

-

Funding information: This research was supported by the 2023 General Project of Philosophy and Social Science Research in Jiangsu Universities (Project No. 2023SJYB0884), 2023 Jiangsu Province Innovation and Entrepreneurship Program Technology Vice President Project (Project No. FZ20230479), and The Fundamental Research Funds for the Central Universities (Project No. JUSRP123081).

-

Author contributions: Xiangfang Ren wrote the manuscript, Methodology and Funding acquisition; Sijia NIu performed the formal analysis; Xinyi Huang performed the Data Curation.

-

Conflict of interest: The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Omwami, A., Lahti, H., Seitamaa-Hakkarainen, P. (2020). The variation of the idea development process in apparel design: a multiple case study. International Journal of Fashion Design, Technology and Education, 13(3), 341–351.10.1080/17543266.2020.1817573Search in Google Scholar

[2] Eck, N. J. V., Waltman, L. (2010). Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics, 84(2), 523.10.1007/s11192-009-0146-3Search in Google Scholar PubMed PubMed Central

[3] Noris, A., Nobile, T. H., Kalbaska, N., Cantoni, L. (2021). Digital fashion: A systematic literature review. A perspective on marketing and communication. Journal of Global Fashion Marketing, 12(1), 32–46.10.1080/20932685.2020.1835522Search in Google Scholar

[4] Izadi, S., Kim, D., Hilliges, O., Molyneaux, D., Newcombe, R., Kohli, P., et al. (2011). Kinect Fusion: real-time 3D reconstruction and interaction using a moving depth camera. Proceedings of the 24th Annual ACM Symposium on User Interface Software and Technology (pp. 559–568). ACM, New York, NY, United States.10.1145/2047196.2047270Search in Google Scholar

[5] Gao, L, Zhang, Y, Han, X. (2018). Research on 3D human modeling based on Kinect. Chinese Scientific Papers, 13(2), 196–201.Search in Google Scholar

[6] Mao, T, Wang, Z. (2005). Fast modeling method of personalized 3d human model. Journal of Computer Aided Design and Graphics, 10, 51–55.Search in Google Scholar

[7] Loper, M., Mahmood, N., Romero, J., Pons-Moll, G., Black, M. J. (2015). SMPL: a skinned multi-person linear model. ACM Trans Graph, 34, 851–866.10.1145/3596711.3596800Search in Google Scholar

[8] Hypochondria. (2022). SMPL based 3D reconstruction of human body Calculation and construction of SMPL model (3). Zhi Hu Net. https://zhuanlan.zhihu.com/p/458868557.Search in Google Scholar

[9] Python Little White. (2020). Briefly introduce the latest version of SMPL structured human body model: STAR. ZhiHuColumn. https://zhuanlan.zhihu.com/p/315014435.Search in Google Scholar

[10] Xiang, Y. (2012). Research and application of virtual human 3d clothing. Master’s thesis. Southwest Jiaotong University, China.Search in Google Scholar

[11] Xue, Y., Huang, L., Yang, R. (2016). Real time dynamic simulation of clothing with different materials. Journal of Graphics, 1, 102–109.Search in Google Scholar

[12] Zilch. (2021). Introduction to GPU cloth physical simulation. Zhi Hu Net. https://zhuanlan.zhihu.Com/p/365025737.Search in Google Scholar

[13] Yang, Y., Shi, M., Fei, G. (2006). Collision detection technology of clothing fabrics based on human color bounding volume. China Society of Image Graphics, China Association of Artificial Intelligence, Shandong University (pp. 202–205). New Progress in Intelligent CAD and Digital Entertainment, Jinan, China.Search in Google Scholar

[14] Hwan Sul, I., Kang, T. (2004). Improvement of drape simulation speed using constrained fabric collision. International Journal of Clothing Science and Technology, 16(2), 43–50.10.1108/09556220410520342Search in Google Scholar

[15] Liu, Y., Geng, Z., Wan, D. (2003). Application of Matlab in 3D human body and clothing modeling. Microcomputer and Application, 9, 38–40.Search in Google Scholar

[16] Gong, S. (2018). Research on dynamic simulation of virtual human dress based on ellipsoid fitting. Master’s thesis. Southwest Jiaotong University, China.Search in Google Scholar

[17] Audio and Video Development. (2021). Research and practice on flexible 3D rendering of costume. CSDN. https://blog.csdn.net/zhying719/article/details/119396616.Search in Google Scholar

[18] Zhang, S. (2019). Research on design and implementation of Chinese suits based on CLO3D. Master’s thesis. Xi’an University of Engineering, China.Search in Google Scholar

[19] Wang, C. (2022). Research on the technology of digital dynamic display and production of garments. Screen Printing, 5, 36–40.Search in Google Scholar

[20] Li, G., Ren, X., Shen, L. (2023). Design of rechargeable warm mountaineering clothing based on digital technology. Wool Textile Technology, 51(11), 47–53.Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry