Abstract

Bio-based polyamide 56 (PA56) has significant advantages in reducing oil dependence and reducing carbon emissions. This study compared the physical properties of bio-based PA56 and conventional polyamide 66 (PA66) fibers and their fabrics. The results showed that due to the odd arrangement structure of carbon atoms in PA56 fiber molecules, its crystallinity and orientation were lower than those of PA66. At the same time, PA56 had a higher degradation rate and coloring rate due to its smaller crystallinity and higher moisture content and gave PA56 fabrics better instantaneous cooling and moisture absorption and drying properties. In addition, the molecular structure characteristics of PA56 also lead to a lower stiffness and soft feel of the fabric, which is beneficial for improving the curling phenomenon of the fabric. Overall, bio-based PA56 fibers can meet the applications in the textile and clothing field and can largely replace PA66, which is worthy of further research and utilization.

1 Introduction

Polyamide (PA), also known as nylon, has long been a chemical product made from petroleum. With the increasing awareness of environmental protection, many enterprises and research institutions have started the research and development of bio-based PA products [1]. Polyamide 11 (PA11) is the earliest industrialized bio-based PA, which was first successfully synthesized in the laboratory by Carothers [2]. At present, companies in China, France, and Germany have developed bio-based PA1010, PA1012, and PA610 using castor oil as a raw material [3,4,5,6,7]. However, the development cost is relatively high and is often used in special engineering plastics. And PA is more widely used in the field of clothing fibers [8]. Based on PA66, a bio-based polyamide 56 (PA56) was successfully developed. As a newly developed bio-based PA, PA56 has great potential in the field of fibers and textiles due to its high strength, high moisture absorption, and easy dyeing [9]. PA56 is composed of two monomers, pentane diamine and adipic acid [10]. Although using biological fermentation to extract adipic acid and pentane diamine is a mature technology, due to the low efficiency of biological extraction, it has not yet been industrialized in the field of clothing fiber.

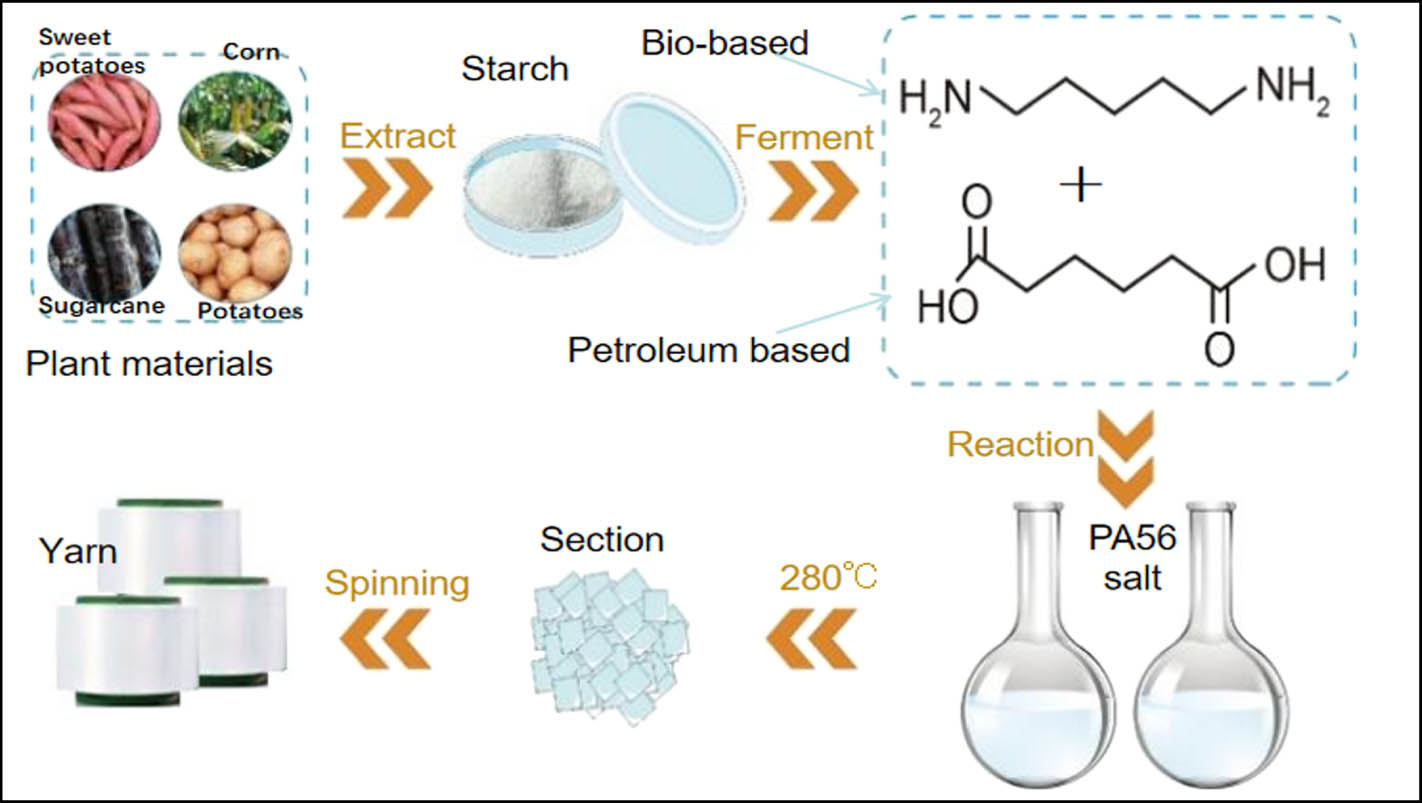

At present, the industrial preparation of bio-based PA56 is based on the preparation of bio-based pentane diamine from plants and the extraction of petroleum-based adipic acid from petroleum. Among them, biogenic pentane diamine can be obtained through microbial fermentation, or a whole-cell Escherichia coli system can be constructed to directly convert lysine into pentane diamine. Chen et al. successfully used genetic engineering to increase the efficiency of the key amino acid decarboxylase in microbial strains by 100 times, thereby greatly reducing costs [11]. At present, the whole-cell catalytic method is used in commercial production, which uses lysine decarboxylase to convert l-lysine into pentane diamine [12]. The production process of bio-based PA56 is shown in Figure 1. Starch is first obtained from plant raw materials, such as corn and potatoes, and then fermented into glucose. The starch is then fermented by Corynebacterium glutamicum to obtain lysine. Then, lysine is further fermented to produce pentane diamine. After purification, the concentration of pentane diamine reached 99.9%, and then, it reacted with adipic acid to form PA56 salt. After copolymerization of PA56 salt at 280°C, slices are generated and then spun on a spinning machine [13].

Schematic diagram of the production process of bio-based PA56.

In recent years, researchers have conducted some studies on the processing methods and physicochemical properties of PA56 fibers. For example, Haixia et al. analyzed the hygrothermal properties of PA fibers during weaving, dyeing, and finishing processes. The results showed that the temperature of PA fibers should be controlled below 370°C, and the cooling, moisture absorption, and release properties of PA fibers were superior to those of ordinary PA fibers [14]. Chen et al. analyzed the effects of different process parameters on the crystallization behavior of PA56 fibers using X-ray diffraction and differential scanning calorimetry. The results showed that compared with PA6 and PA66, the crystallinity and orientation of the crystalline zone of the bio-based PA56 fiber were the lowest, at 49.56 and 76.78%, respectively [15]. Yongfeng et al. compared the moisture absorption, desorption, and drying properties of bio-based PA56 fibers with different cross-sectional shapes. The results showed that the moisture absorption, desorption, and moisture content of PA56 with irregular cross-section were 5.18, 5.45, and 5.46%, respectively, which were higher than those of PA56 with circular cross-section [16]. In response to the problem of poor hydrophilicity of polyester, Tengfei et al. used a biologically based PA56 oligomer to copolymerize and modify polyester, preparing a new type of PA ester copolymer. It was found that the fiber moisture regain was 265% of the pre-modified polyester fiber [17] and gradually increased with the addition of PA56.

Due to the widespread application of PA56 fibers in clothing fabrics, there is currently limited research on the relationship between the microstructure and macroscopic properties of PA56 fibers. Therefore, it is necessary to study these properties of PA56 fibers. This article compares and studies the hydrophilicity and crystallization behavior of PA56 fibers and characterizes the related properties of fibers and fabrics at the molecular level. We selected 78dtex/48F FDY filaments from PA56 and PA66, respectively; analyzed their crystallization, orientation, and degradation properties; and compared their hot water shrinkage rate with the weaving process. We then studied the dyeing behavior, moisture absorption and quick drying performance, and anti-curling performance of the two fabrics. This can provide reference for the promotion and application of PA56 in the field of clothing.

2 Material preparation

Two types of PA semi-gloss chips, PA56 and PA66, were used as raw materials for spinning on a DY66 spinning machine and spun into 78dtex/48F FDY yarn. After repeated experimentation and testing of the boiling water shrinkage, strength, and knitting indicators of the yarn, the final spinning parameters used are shown in Table 1.

Spinning process parameters of PA56 and PA66 fibers

| Spinning | Temperature (℃) | Spinning speed (m/s) | Winding speed (m/s) | Traction ratio | Hot roller temperature (℃) |

|---|---|---|---|---|---|

| PA56 | 275 | 4,500 | 0.7 | 1.48 | 160 |

| PA66 | 285 | 4,500 | 0.6 | 1.26 | 160 |

Using Karl Mayer 28 Gauge, diameter 34-inch weft knitted single jersey knitting machine, PA56 and PA66 yarns were paired with 20D Lycra elastic fibers to produce plain knit fabrics, and then, post-processing was carried out to test and analyze the finished fabric. The fabric specifications are shown in Table 2, and after dyeing and shaping, parallel comparisons of various properties are made. In the table, CPC represents the courses per center, while WPC represents the walls per center.

Fabric specifications for PA56 and PA66

| Knitting | Yarn fineness (dtex) | Loop length (mm) | CPC(cm−1) | WPC (cm−1) | Gram weight (g/m2) |

|---|---|---|---|---|---|

| PA56 | 83.3 | 2.37 | 21.1 | 35.6 | 162.3 |

| PA66 | 83.1 | 2.35 | 20.8 | 36.1 | 160.7 |

3 Results and discussion

3.1 Crystallinity analysis

Using a Dmax Rapid II X-ray diffractometer with a fiber bundle length of 40 mm, the fiber was sandwiched into a fiber testing platform for testing. The crystallinity and orientation of the fibers were calculated using MID Jade 5 software. The X-ray generator is a copper target, with a test voltage of 40 kV and a current of 300 mA. The scanning angle range is 0–90°, and the exposure time is 1,500 s. Table 3 shows the physical properties of PA56 and PA66 yarns. The difference in fineness between the two yarns is significant because there is a significant difference in hot water shrinkage between the two yarns. The crystallinity and breaking strength of PA56 are relatively small, while the moisture regain and boiling water shrinkage are relatively large, and the orientation and elongation at break are close.

Physical indicators of PA56 and PA66 fibers

| Yarn | Fineness (dtex) | Crystallinity | Orientation | Moisture regains (%) | Boiling water shrinkage rate (%) | Breaking strength (cN/dtex) | Elongation at break (%) |

|---|---|---|---|---|---|---|---|

| PA56 | 74.6 | 45.7 | 81.2 | 5.6 | 11.2 | 4.15 | 24.69 |

| PA66 | 78.1 | 51.4 | 84.9 | 4.0 | 6.2 | 4.49 | 23.81 |

From Figure 2(a) and (b), it is found that the heating and cooling curves of PA56 and PA66 are similar, both of which are single peak curves. When heating up, the melting point of PA56 is 253°C, the melting point of PA66 is 264°C, and the melting point of PA56 is 11°C lower than that of PA66. When cooling, the crystallization peak temperature of PA56 is 224°C, and the crystallization peak temperature of PA66 is 234°C, which is about 10°C higher than the former. Since the melting point can be regarded as the temperature required for molecular chain motion, it can be seen from Figure 2 that the temperature of PA66 molecular chain motion is higher, proving that the internal structure of PA66 molecules is more regular than PA56, and the molecular chain orientation is better [18]. In Figure 2, it can also be observed that the peak strengths of the melting and crystallization curves of PA56 are greater than those of PA66. The analysis is due to the unique carbon effect of PA56, the flexibility of the molecular chain, and the large heat absorption and release during the melting and crystallization process. This proves that its thermal stability is lower than PA66, and the reaction activity is high, resulting in a high peak value [19,20].

Differential scanning calorimetry and XRD curves of PA56 and PA66: (a) melting curve, (b) crystallization curve, and (c) XRD curve.

From the X-ray diffraction (XRD) curve in Figure 2(c), the curve characteristics of PA56 and PA66 are similar, with a bimodal phenomenon of characteristic peaks appearing near 20.8° and 23.6°, respectively. This is due to the inconsistent orientation of crystal cells, resulting in the diffraction spot positions of two similar crystal planes being relatively close, resulting in two diffraction peaks with similar positions [21].

Figure 3 shows a schematic diagram of the molecular structures of PA56 and PA66. The carbon atoms of PA56 are arranged in odd and even numbers. In an ideal state, the repeating unit formed by PA56 crystal is 26 chain links, while the repeating unit of PA66 crystal is 14. In fact, PA56 cannot achieve this ideal state. There is a gravitational force between the 10th and 16th positions of macromolecule (a) and the 8th and 14th positions of macromolecule (b), which results in the molecular chain not being completely straightened and even producing a certain degree of bending. The internal structural characteristics of the molecule affect the crystallinity and orientation of PA56. Furthermore, the crystallinity is low, and there are many unbound groups within the molecules, resulting in a low breaking strength of PA56 fibers. The low degree of orientation affects the boiling water shrinkage rate [18,21]. However, the large number of unbonded groups makes it easier for PA56 fibers to bind to water molecules in the atmosphere, resulting in a higher moisture regain of 5.6%.

Molecular schematic diagram: (a) PA56 molecular schematic diagram and (b) PA66 molecular schematic diagram.

3.2 Biodegradability

Pseudomonas aeruginosa was cultivated twice and then transplanted it into a conical flask containing 500 ml of culture medium and samples for degradation experiments. PA56 and PA66 were the only nitrogen sources in the culture medium, respectively. Figure 4 shows the biodegradation of two types of PA fibers at different stages. It can be observed that in the initial stage, both PA56 and PA66 fiber surfaces showed uneven protrusions. Starting from week 8, the surface of PA56 fiber gradually peeled off, and obvious degradation was observed. At this time, the surface of PA66 fiber became smoother, but there was no significant peeling. As the degradation progressed, by the 16th week, degradation was also observed on the surface of PA66 fibers, and at this time, PA56 fibers were more significantly degraded. This is mainly because PA56 has a higher proportion of amorphous regions than PA66, and the gaps within the molecules facilitate the entry of water molecules and fungal reproduction, thus exhibiting faster biodegradability [22].

Degradation diagram of PA56 and PA66 fibers.

3.3 Dyeing performance

78dtex/48F PA56 and PA66 DTY fiber fabrics, respectively, were prepared, and coloring was observed at different temperatures. The dye used was acidic dye NHFS, with a dye concentration of 4%. Six temperature gradients were set, namely, 50, 60, 70, 80, 90, and 98°C. The slow dyeing agent was acetic acid, with a dyeing bath ratio of 1:20 and a pH value of 5.5. The temperature was raised from room temperature at 1.0°C/min to the target temperature, kept at a constant temperature for 30 min. After dyeing, the temperature was lowered to below 40°C at 2°C/min, followed by cold water washing, hot water washing at 60°C, drying, and coloring of samples.

From Figure 5(a), it can be observed that the fabric colors of PA56 and PA66 fabrics are very similar. From (b), the dyeing residual dye liquor of PA56 and (c) the dyeing residual dye liquor of PA66, it shows that from 50 to 90°C, the residual dye liquor color of PA56 was lighter. At 98°C, the dyeing residual dye liquor colors of PA56 and PA66 are very close. This phenomenon is attributed to the difference in crystallinity between the two. The crystallinity of PA56 is relatively low, and at lower temperatures, dye molecules are more likely to enter the interior of the fiber and combine with PA56, resulting in a darker color of the fabric. When the temperature rises to 90 to 98°C, dye molecules can relatively freely enter and exit between PA56 and PA66 fibers, so the problem of color uptake caused by crystallinity is no longer obvious, so the adsorption of dyes by the two tends to be consistent [23,24].

Dyeing status of two types of fabrics at different temperatures: (a) color comparison between PA56 and PA66 fabrics, (b) residues after dyeing PA56 fabrics, and (c) residues after dyeing PA66 fabrics.

3.4 Moisture absorption and quick drying capacity

According to the AATCC79-2010 testing method, 0.2 ml of distilled water is dropped onto the back of the fabric at a height of 1 cm using a dropper, and the time when the liquid on the fabric no longer reflects light is observed to evaluate its moisture absorption performance. According to the Chinese standard GB 21655, 0.2 ml of distilled water is dropped onto the back of the fabric at a height of 1 cm, and the fabric weight is recorded within 0–30 min at intervals of 5 min. The quick drying performance is calculated according to the following equation:

The structure, material, and moisture content have a significant impact on the coolness of the fabric. When the organizational structure is the same, the coolness mainly depends on the material and moisture content, and usually, the influence of moisture on the coolness of the fabric is greater than the thermal conductivity of the fibers [25,26]. Table 4 shows the instantaneous cooling test and rapid drying test results of these two fabrics. The instantaneous cooling sensation of PA56 fabric is significantly higher than that of PA66 fabric because the moisture regain of PA56 is 5.6%, and the moisture regain of PA66 is 4.0%. The presence of water molecules accelerates the conduction of heat.

Instantaneous cooling sensation and rapid drying test of PA56 and PA66 fabrics

| Fabric | Instantaneous cooling sensation (J/(cm2 s)) | Dripping time (s) | Quick drying (g/h) |

|---|---|---|---|

| PA56 | 0.36 | 0.7 | 0.28 |

| PA66 | 0.25 | 0.9 | 0.24 |

Due to the higher moisture regain of PA56 fiber compared to PA66 fiber, PA56 fiber has higher hydrophilicity. In the drip test, the moisture absorption and quick drying properties of PA56 are slightly better than those of PA66, with a full absorption effect achieved in 0.7 s, while PA66 requires 0.9 s. PA56 absorbs and disperses water faster, increasing the evaporation area, resulting in a rate of 0.28 g/h in rapid drying tests, while PA66 fabric has a rate of 0.24 g/h. The performance of PA56 enables it to be applied in the field of clothing that requires quick drying.

3.5 Curling performance

Curling is a very common phenomenon in knitted fabrics. In the operation of automated clothing production equipment, curling has become a significant factor affecting efficiency. Reducing or avoiding curling is conducive to the smooth production process. One factor affecting curling is the bending stiffness of the yarn. Fabrics with low bending stiffness are more likely to avoid curling [27,28]. Balance for 24 h under standard atmosphere, a temperature of 21 ± 1℃, a relative humidity of 65 ± 2%, and use KES-F tester to conduct bending test on the fabric. Record the bending stiffness B and average bending stiffness (cN cm2/cm), and the width of the test sample is 20.0 cm. Calculate the following formula:

Figure 6(a) and (b) shows the bending stiffness of PA56 and PA66 fabrics. As the knitting and finishing processes of the two fabrics are identical, the density and weight of the finished product are also very similar, so the difference in bending stiffness is mainly caused by the material itself. From Figure 6, the bending stiffness of PA56 is relatively low in both warp and weft directions. The average bending stiffness of the two types of fabrics in the warp direction is 0.0608 and 0.0849 gf cm2/cm, while the average bending stiffness in the weft direction is 0.0199 and 0.0338 gf cm2/cm. This is also caused by the microstructure of PA56. As mentioned earlier, in the schematic diagram of PA56 molecule in Figure 3, there is a gravitational force between the 10th and 16th positions of macromolecule (a) and the 8th and 14th positions of macromolecule (b), respectively. This causes the molecular chain to not be completely straightened, resulting in a certain degree of bending. The long curved chain segments help to form a soft feel [18,21].

Fabric bending stiffness and curling condition: (a) meridian bending stiffness, (b) weft bending stiffness, (c) PA56 fabric, and (d) PA66 fabric.

The low bending stiffness of PA56 makes it very suitable for producing knitted underwear fabrics and can effectively reduce the problem of fabric curling. As shown in Figure 6(c) and (d), PA56 fabric produced using the same process has almost no curling phenomenon compared to PA66 single jersey fabric.

4 Conclusion

This article compares the crystallinity and degradation performance of FDY fibers of PA56 and PA66, as well as the dyeing performance, instantaneous cooling sensation, and moisture absorption and quick drying ability of their weft-knitted jersey fabrics. The thermodynamic curves of PA56 and PA66 fibers are similar, but the crystallinity and orientation of PA56 fibers are lower than those of PA66 fibers. There are many unbound charged groups within the PA56 molecule, and the interaction forces between charged groups between different molecules can cause distortion of the molecular chain, affecting crystallization and orientation.

Compared with PA66 fabric, PA56 has a lower crystallinity and higher moisture content, making it easier for fungi to enter the fibers and reproduce, accelerating the degradation of PA56. Low crystallinity also makes it easier for dyes to enter the interior of the fiber, resulting in a higher coloring rate of PA56 compared to PA66. Compared with PA66 fabric, the molecular structure characteristics of PA56 result in a lower stiffness of PA56 fabric. The macroscopic performance is that PA56 has a softer hand feel and is beneficial for improving curling.

-

Funding information: This work was supported by the Science and Technology Commission of Shanghai Municipality (No. 20015800200).

-

Author contributions: Methodology, software, data calculation, K.Z.; writing – original draft, S.C.; writing – review and editing, G.X. All authors have read and agreed to the published version of the manuscript.

-

Conflict of interest: The authors declare no competing financial interest.

-

Data availability statement: The authors declare that the data supporting the findings of this study are available within the article. Should any raw data files be needed in another format, they are available from the corresponding authors (S. Cao; G. Xu) upon reasonable request.

References

[1] Eltahir, Y. A., Saeed, H. A. M., Xia, Y. M., Wang, Y.-M. (2014). Preparation of polyamide 5,6 (PA56) fibers and its mechanical properties. Advanced Materials Research, 937, 86–91.10.4028/www.scientific.net/AMR.937.86Search in Google Scholar

[2] Salazar, A., Rico, A., Rodríguez, J., Escudero, J. S., Seltzer, R., de la Escalera Cutillas, F. M. (2014). Monotonic loading and fatigue response of a bio-based polyamide pa11 and a petrol-based polyamide PA12 manufactured by selective laser sintering. European Polymer Journal, 59, 36–45.10.1016/j.eurpolymj.2014.07.016Search in Google Scholar

[3] Francis, P., Slim, S., Brigitte, R., Martine, T., Alain, F. (2008). Unsaturated polyamides from bio-based z-octadec-9-enedioic acid. Macromolecular Chemistry and Physics, 209(1), 64–74.10.1002/macp.200700319Search in Google Scholar

[4] Huang, Z. Q., Cui, Z., Zhang, H. M., Fu, P., Zhao, Q. X., Ying, M., et al. (2013). Progress in bio-based polyamides. Chinese Journal of Bioprocess Engineering, 32(6), 761–774.Search in Google Scholar

[5] Samhan, A., Meshal, M., Yussuf, A., Jacob, A. (2017). A comparison of the polymer matrix behavior and mechanical properties of the glass reinforced plastics and glass reinforced epoxy pipes under different oil field chemicals. Key Engineering Materials, 748, 55–61.10.4028/www.scientific.net/KEM.748.55Search in Google Scholar

[6] Hablot, E., Donnio, B., Bouquey, M., Averous, L. (2010). Dimer acid-based thermoplastic bio-polyamides: reaction kinetics, properties and structure. Polymer, 51(25), 5895–5902.10.1016/j.polymer.2010.10.026Search in Google Scholar

[7] Jasinska, L., Dudenko, D., Rozanski, A., Thiyagarajan, S., Sowinski, P., Van Es, D., et al. (2012). Structure and molecular dynamics in renewable polyamides from dideoxy-diamino isohexide. Macromolecules, 45(14), 5653–5666.10.1021/ma301091aSearch in Google Scholar

[8] Zhang, X.-S., Buzinkai, J., Quinn, E., Rhoades, A. (2022). Key insights into the differences between bimodal crystallization kinetics of polyamide 66 and polyamide 6. Polymer, 55(20), 9220–9231.10.1021/acs.macromol.2c01059Search in Google Scholar

[9] Yang, T.-T., Gao, Y.-B., Liu, X. C., Wang, X. L., Ma, B. M., He, Y. (2022). Flame-retardant polyamide 56 with high fire safety and good thermal performance. Polymer Advanced Technology, 33(9), 2807–2819.10.1002/pat.5734Search in Google Scholar

[10] Stefanie, K., Steffi, N., Judith, B., Motonori, M., Martin, V., Gregory, A., et al. (2014). From zero to hero-production of bio-based nylon from renewable resources using engineered corynebacterium glutamicum. Metabolic Engineering, 25, 113–123.10.1016/j.ymben.2014.05.007Search in Google Scholar PubMed

[11] Chen, J., Ma, H., Cheng, X., Xu, Y. (2021). Research progress on bio based PA56. Synthetic Fiber Industry, 44, 53–56.Search in Google Scholar

[12] Ma, X., Xu, X., Chen, Y. (2019). Performance and application of bio based chemical fiber PA56. Textile Guide, 8, 43–46.Search in Google Scholar

[13] Zhang, S. Y., Ma, J. H. (2019). Tailored process for spinning fine denier bio-based polyamide 56 fibers. Journal of Biobased Materials and Bioenergy,13(1), 102–108.10.1166/jbmb.2019.1822Search in Google Scholar

[14] Zhang. H.-X., Zhang, X.-C. (2016). Heat-moisture performance of cool polyamide fibers. Textile Research Journal, 37(7), 39–43.Search in Google Scholar

[15] Chen, M.-Y., Sun, Y., Chen, R.-J., Xin, C., Zhang, H. (2017). Crystallization behavior of bio-based polyamide 56 fibers. Journal Textile Research, 38(12), 38–43.Search in Google Scholar

[16] Wang, J.-M., Li, Y.-F., Hao, X.-M., Yang, J.-L., Qiao, R.-R., Wang, M. H. (2021). Study on structure and moisture absorption and liberation properties of bio-based polyamide 56 and polyamide 66. Journal Textile Research, 42(8), 1–7.Search in Google Scholar

[17] Zhang, T. F., Shi, L. D., Hu, H. M., Wang, Y., Xue, X. L., Yu, J. Y. (2019). Synthesis and characterization of bio-based polyamide 56 oligomer modified polyester. Journal Textile Research, 40(6), 43474.Search in Google Scholar

[18] Wang, Y., Zhang. Y. H., Zhang, Y. H., Xu, X. C., Liu, W., Guo, H. (2021). Research on compatibility and surface of high impact bio-based polyamide. High Performance Polymer, 33(8), 960–968.10.1177/09540083211005511Search in Google Scholar

[19] Liu, B. W., Zhang, S. C., Wang, X. L., Yu, J. Y., Ding, B. (2015). Efficient and reusable polyamide-56 nanofiber/nets membrane with bimodal structures for air filtration. Journal Colloid Interface Science, 457, 203–211.10.1016/j.jcis.2015.07.019Search in Google Scholar PubMed

[20] Wang, Y., Kang, H. L., Wang, R., Liu, R. G., Hao, X. M. (2018). Crystallization of polyamide 56/polyamide 66 blends: Non-isothermal crystallization kinetics. Journal of Applied Polymer Science, 135(26), 46409.10.1002/app.46409Search in Google Scholar

[21] Yang, T.-T., Gao, Y.-B., Wang, X.-L., Ma, B.-M., He, Y. (2021). Hydrogen bonding and crystalline structure of bio-based PA56. Polymer, 237, 124356.10.1016/j.polymer.2021.124356Search in Google Scholar

[22] Luo, K.-M., Liu, J.-X., Abbay, K., Mei, Y.-J., Guo, X.-W., Song, Y.-H., et al. (2023). The relationships between the structure and properties of PA56 and PA66 and their fibers. Polymer, 15(13), 2877.10.3390/polym15132877Search in Google Scholar PubMed PubMed Central

[23] Wei, B., Chen, Q.-Y., Tang, R.-C., Chen, G.-Q. (2011). Dyeing properties of lac dyes for wool, silk and nylon. Advanced. Materials Research, 233, 817–820.10.4028/www.scientific.net/AMR.233-235.817Search in Google Scholar

[24] Nadarajah, V., Han, X.-X. (2003). Effect of polymer micro-structure on the dye diffusion in polyamide66 fibers. Journal Applied Polymer Science, 89(12), 3803–3807.10.1002/app.12533Search in Google Scholar

[25] Kan, C. W., Yam, L. Y., Ng, S. P. (2013). The effect of stretching on ultraviolet protection of cotton and cotton/coolmax-blended weft knitted fabric in a dry state. Mater, 6(11), 4985–4999.10.3390/ma6114985Search in Google Scholar PubMed PubMed Central

[26] Li, H.-Y., Wang, H.-B., Fu, J.-J., Wang, W.-C. (2019). Effect of pretreatment on comfortability and coolness modification of pet fabric by microcapsule finishing. Chemical Industry and Engineering Progress, 38(10), 4651–4658.Search in Google Scholar

[27] Mozafary, V., Payvandy, P., Rezaeian, M. (2018). A novel approach for simulation of curling behavior of knitted fabric based on mass spring model. Journal of the Textile Institute, 109(12), 1620–1641.10.1080/00405000.2018.1453635Search in Google Scholar

[28] Araujo, M., Fangueiro, R., Hong, H. (2004). Modelling and simulation of the mechanical behavior of weft knitted fabrics for technical applications. Autex Research Journal, 3(4), 166–172.10.1515/aut-2003-030403Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry