Abstract

The flame-retardant cotton fabric used for welding protective clothing in the market exhibits insufficient melt hole resistance. We evaluated the stainless steel filament fabric for flame retardancy and melt hole resistance and found that it lacked sufficient comfort. A stainless steel filament and a cotton yarn were plied and twisted together and then woven following a set of specifications. The fabric was finished with a flame retardant, and its performance and flame retardancy were determined. The results indicate that the twist direction during ply twisting affects the fabric performance. Relative to the pure cotton fabric, the stainless steel filament/cotton composite fabric exhibits reduced comfort properties, such as moisture permeability and air permeability, but the mechanical properties and flame retardancy are improved. Ply twisting a stainless steel filament and a pure cotton yarn with an S twist presents certain advantages in enhancing the comprehensive performance of the fabric and exhibits potential for advancements in welding protective clothing.

1 Introduction

Numerous electric welding sparks can easily form during electric welding. These sparks, which are essentially droplets of molten metal from a welding rod, can harm the human body mostly through burns from the molten metal [1]. These high-temperature metal droplets can also ignite clothes worn by welders and flammable materials in the surrounding environment, potentially causing burns to the human body or even starting a fire [2]. Regular clothes cannot be worn by welders performing arc welding. Specially designed protective clothing that protects against these hazards should be worn [3]. Therefore, the primary considerations for welding protective clothing materials for welders are flame resistance and high-temperature stability [4]. Currently, not many fabrics can withstand temperatures of 500–700°C, which is required to shield welder protective clothing against welding spatter [5].

Owing to their lack of high-temperature resistance, commonly available flame-retardant cotton, thick cowhide, and aramid fabrics for welding clothing fail to adequately provide safety for welders, hence the need to develop new materials for protective clothing that can be used by welders to resist welding spatter [6]. As a high-quality high-temperature-resistant material, stainless steel fiber fabric has a melting point of 1,350°C and can be used continuously at an ambient temperature reaching 600°C in an oxidizing atmosphere [7]. Preliminary tests indicate that a fabric composed solely of stainless steel filament exhibits good flame resistance and resistance to melt holes caused by welding spatter [8]. However, the fabric made solely from stainless steel filament entails high costs and provides relatively limited comfort.

To enhance the flame resistance and resistance against melting holes in flame-retardant cotton fabric, improve the comfort provided by fabric made entirely from stainless steel, and reduce costs, stainless steel filaments may be integrated into a comfortable pure cotton flame-retardant fabric. Stainless steel fibers are used in manufacturing antistatic clothing because of their excellent conductivity, allowing the elimination of static charges generated through friction [9]. Stainless steel fiber exhibits low resistance and is an excellent conductor, rendering it outstanding as a conductive fiber [10]. Notably, the higher the content of stainless steel fiber, the greater the amount of fuzz generated in the resulting fabric [11]. Owing to its poor cohesion, stainless steel fiber is typically blended with other fibers [12]. The excellent mechanical and electrical properties of stainless steel fiber allow its application in manufacturing smart textiles, which can be used in motion detection, medical hygiene, electronic communication, personal protection, and industrial development for intelligent fabric sensors [13]. This material can also be a valuable tool for monitoring heart rate, blood pressure, and exercise intensity among doctors or athletes [14].

Stainless steel fibers blended with cotton fibers can be used to make electromagnetic protection clothing, which provides effective electromagnetic shielding and maintains such effect even after repeated washing [15]. In addition, these materials exhibit high durability. Moreover, the softness and moisture absorption, as well as the breathability of cotton fibers, endow this electromagnetic protective clothing with superior softness, moisture absorption, and perspiration control, in addition to its capability for direct contact with the human skin [16,17]. The content of stainless steel fiber incorporated into the fabric directly affects the electromagnetic protection provided by the fabric [18].

A stainless steel metal fiber can be used to manufacture stainless steel fiber sintered felt [19]. This material, which is based on 316L stainless steel, demonstrates exceptional corrosion resistance and serves as a vital porous metal material in numerous industrial applications [20]. It is extensively used in filtering involving corrosive media [21]. The thermal stability of a stainless steel fiber is considerably high, and the thermogravimetric analysis results from 25 to 900°C show that the weight loss rate of a stainless steel fiber tends to stabilize within this temperature range, indicating excellent high-temperature resistance [22,23]. Stability under high-temperature conditions is also an important property that enables the use of stainless steel fibers as insulation and filtration materials in high-temperature environments [24]. Stainless steel fibers have an irregular cross section, connected tortuous voids, and a rough surface. As such, they can change the linearity of sound. The viscous flow weakens the energy of the sound, creating sound-absorbing and sound-insulating effects [25]. This attribute renders stainless steel fibers more effective than ordinary sound-absorbing materials [26]. Thus, they are widely used as a silencing material in airplanes and cars, specifically to reduce engine exhaust noise [27]. Stainless steel fibers possess inherent antibacterial properties, with research and development efforts commencing in the late 1990s [28]. Antibacterial stainless steel possesses inherent properties that can be used in structural materials similar to ordinary stainless steel [29]. In addition to its decorative and beautifying functions, antibacterial stainless steel also exhibits potent antibacterial properties. A stainless steel filament is used to develop electric heating elements, which are used for bending heaters, medical heating, and defrosting [30].

In this experiment, stainless steel filament and pure cotton yarn were processed by twisting and plying to create the required yarns. Three sets of yarns were produced: one with a stainless steel filament and an S-twisted pure cotton yarn twisted in an S direction, another with a stainless steel filament and an S-twisted pure cotton yarn twisted in a Z direction, and a third set with two stainless steel filaments and an S-twisted pure cotton yarn twisted in an S direction. The three distinct yarn sets were woven into fabrics, using the same yarn for both the warp and weft, with a consistent three-up, three-down twill weave pattern. The woven fabric samples were subjected to flame-retardant finishing using phosphorous–nitrogen flame retardants by using a pad–dry–cure method. The postflame-retardant finishing characteristics of the fabrics were evaluated, including thickness, air permeability, moisture permeability, stiffness, tensile strength, and flame-retardant functionality. This article introduces fresh perspectives and methods in material selection, processing techniques, and performance testing, leading to the exploration of new research directions and application potential in the welding protective clothing field. This study evaluates the effects of modifying the process parameters used in combined twisting on the comfort and flame-retardant properties of the fabric.

2 Experiment

2.1 Materials and equipment

The 100tex pure cotton yarn used in this study was purchased from Fujian Xinhua Textile Group Co., Ltd. The 304 stainless steel filament with a diameter of 0.036 mm was purchased from Wuxi Kunxu Metal Wire Mesh Co., Ltd. A green and efficient flame retardant from the phosphorus–nitrogen series was supplied by Jiangxi Baichuan Fire Protection Technology Consulting Co., Ltd.

The DSDw-01-2 digital small sample doubling machine and the DSDt-01-4 digital small sample doubling machine were purchased from Tianjin Jiacheng Electromechanical Equipment Co., Ltd. The SGA598 automatic rapier sample loom was purchased from Jiangyin Tongyuan Textile Machinery Co., Ltd. The P-A0 vertical small rolling machine was supplied by Foshan Xiqiang Metal Manufacturing Co., Ltd. The DHG-9420A electric hot air oven was provided by Shanghai Yiheng Scientific Instrument Co., Ltd.

The YG(B)141D digital fabric thickness meter, YG(B)461X fabric air permeability tester, and YG 022 automatic fabric stiffness tester were purchased from Wenzhou Darong Textile Instrument Co., Ltd. The YG(B) 502 fabric pilling and fuzzing tester was supplied by Wenzhou Jigao Testing Instrument Co., Ltd. The YG(B)216-II fabric moisture permeability tester was provided by Wenzhou Ruibo Testing Instrument Co., Ltd. The AX224ZH electronic balance and the YG815A-III fabric flame retardancy tester were purchased from Aohaus Instrument Co., Ltd. and Wenzhou Fangyuan Instrument Co., Ltd., respectively.

2.2 Doubling and twisting of stainless steel filament and pure cotton yarn

In this experiment, the required yarn was produced by doubling and twisting the stainless steel filament and pure cotton yarn, with the pure cotton yarn as the blank control group. In evaluating the effect of modifying the doubling proportions of stainless steel filaments and varying the directions of twisting on the performance of the finished fabric, three groups of yarn were produced: one stainless steel filament and one S-twist pure cotton yarn, doubled and twisted in the S direction; one stainless steel filament and one S-twist pure cotton yarn, doubled and twisted in the Z direction; and two stainless steel filaments and one S-twist pure cotton yarn, doubled and twisted in the S direction. Testing operation: The digital small sample doubling machine was used to double the pure cotton yarn and stainless steel filament at a doubling speed of 300 m/min to obtain the doubled yarn. The digital small sample doubling machine was employed to twist the yarn after doubling on the doubling machine; the twist degree was adjusted to 15T/10 cm; the bobbin speed was set to 4,000 rpm; and the compound yarn was obtained.

2.3 Weaving samples

Sample weaving adopts a stable woven technique, resulting in a woven fabric structure that shows stability and a flat cloth surface. The woven fabric produced is highly suitable for weaving welding labor protection fabric. Each group of yarns is woven into samples measuring 150 cm × 25 cm by using a loom sample machine. The warp and weft used are the same yarn; during weaving, the warp density is set to 141 threads/10 cm, and the weft density is set to 260 threads/10 cm. The fabric structure is uniformly woven in a three-over-three-under right twill pattern. For the specific weaving process, a number 14 steel heddle is used for threading. One-to-one heddle threading is used, considering that the yarn has a large diameter and can easily unwind and entangle. Once the yarn is threaded through the heddle, the steel buckle and the harness frame are transferred to the rapier sample loom. All necessary parameters are configured, and weaving is initiated.

2.4 Flame-retardant finishing

Ordinary cotton yarn lacks inherent flame-retardant properties. Each fabric sample needs to undergo flame-retardant finishing to achieve the flame-retardant properties required for welding labor protection clothing. Specifically, the flame-retardant finishing process involves the application of the dip-rolling and baking method. A phosphorus–nitrogen flame retardant is then used. The finishing solution is prepared by mixing the flame retardant and water in a 1:1 ratio, and the prepared finishing solution and the sample fabric are soaked in the same container for 1 h. The soaked fabric is taken out, wrung dry, and placed on the rolling machine for dry rolling. The liquid carry-over rate is set to 53.12%, and the rolled fabric is placed in the oven for 2 h, based at 80°C. Subsequently, the fabric is rinsed with clean water and then allowed to dry.

2.5 Performance testing

The thickness of the fabric was measured using the YG(B)141D digital fabric thickness gauge from Wenzhou Darong Textile Instrument Co., Ltd. in accordance with the ISO5084:1996 standard for determining the thickness of textiles and textile products. The resistance of the fabric to pilling and hairiness was tested using the circular trajectory method with reference to the ISO 12945-2 standard for determining the pilling and hairiness of textile fabrics; the equipment used was the YG(B)502 fabric pilling balloon instrument supplied by Wenzhou Jigao Testing Instrument Co., Ltd. The air permeability of the fabric was measured using the equal pressure method with reference to the ISO 9237-1995 standard for determining the air permeability of textile fabrics; the equipment used was the YG(B)461X fabric air permeability tester supplied by Wenzhou Darong Textile Instrument Co., Ltd. The moisture permeability of the fabric was evaluated using the moisture absorption method with reference to the ISO 11092 standard for testing the moisture permeability of textile fabrics; the instrument used was the YG(B) 216-II fabric moisture permeability meter supplied by Wenzhou Ruibo Testing Instrument Co., Ltd. With reference to the ISO9073-7:1995 standard for determining the bending length of textile fabrics, the stiffness of the fabric was measured using the inclined plane method. The YG 022 automatic fabric stiffness tester from Wenzhou Darong Textile Instrument Co., Ltd. was used. The mechanical properties of the yarn and fabric were evaluated using the 3365 universal material testing machine from INSTRON in accordance with the ISO 13934-1:2013 standard for determining the tensile properties of fabrics. According to the test standard ISO 15025 for determining the burning performance of textiles, specifically the damaged length, afterburn, and afterglow time in the vertical direction. The flame resistance of the fabric was determined using the YG815A-III fabric flame resistance performance tester from Wenzhou Fangyuan Instrument Co., Ltd.

3 Results and analysis

3.1 Analysis of the single-stretch breaking mechanical properties of yarn

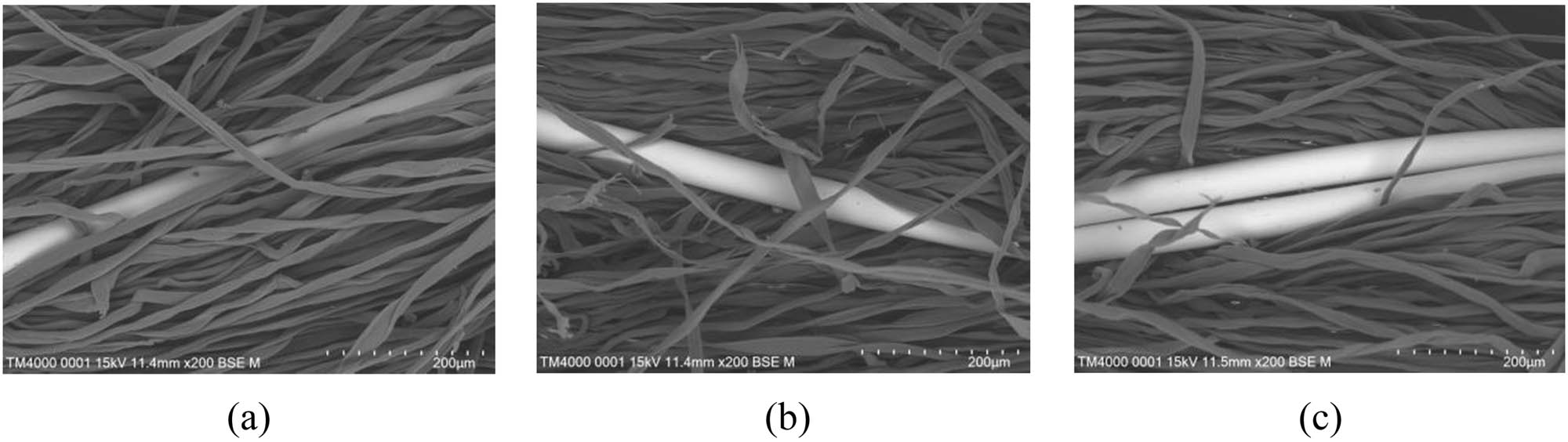

The pure cotton in Table 1 refers to the woven fabric sample woven with the S-twisted pure cotton yarn and is assigned as the control group in the experiment. As shown in Table 1, the breaking strength of the composite yarn is increased after the stainless steel long filament is twisted and combined. Compared with that of the pure cotton yarn, the breaking strength of the composite yarn increases as the number of twisted and combined stainless steel long filaments increases. The reason is that after being twisted and combined, the stainless steel long filament shares the tensile force with the pure cotton yarn, increasing the breaking strength. A scanning electron microscope (SEM) image of the composite yarn after twisting and combining is presented in Figure 1. Specifically, Figure 1a shows a stainless steel long filament combined with S-twisted pure cotton yarn and then S-twisted in the same direction (1:1 S-twisted). Figure 1b presents a stainless steel long filament combined with S-twisted pure cotton yarn and then Z-twisted in the opposite direction (1:1 Z-twisted); in addition, the twisting direction of the stainless steel long filament varies from that shown in Figure 1a. In Figure 1c, two stainless steel long filaments are combined with S-twisted pure cotton yarn and then S-twisted (2:1 S-twisted). The breaking strength of the 1:1 S-twisted composite yarn is higher than that of the 1:1 Z-twisted composite yarn. The reason is that the pure cotton yarn is S-twisted, and after the stainless steel long filament is twisted in the same direction, the twist of the pure cotton yarn increases, whereas that of the pure cotton yarn decreases. This observation is attributed to the untwisting phenomenon after the stainless steel long filament is twisted in the opposite direction. When the twist decreases, the breaking strength of the yarn decreases. Under the condition that other conditions have not changed, the tension that the pure cotton yarn and the stainless steel long filament can withstand at the same time is expected to decrease. Therefore, the breaking strength of the composite yarn is higher after the stainless steel long filament is twisted in the same direction than in the opposite direction. When the pure cotton yarn untwists during opposite twisting, the uniformity of the yarn structure decreases. Therefore, the standard deviation of the breaking strength of the composite yarn after opposite twisting increases, indicating that the strength unevenness of the composite yarn increases.

Yarn breaking strength

| Name | Breaking strength (cN/tex) | Standard deviation | Coefficient of variation | Elongation at break (%) | Standard deviation | Coefficient of variation |

|---|---|---|---|---|---|---|

| Pure cotton | 13.3 | 0.80 | 6.02 | 6.55 | 0.39 | 5.95 |

| 1:1 S-twisted | 15.3 | 0.79 | 5.27 | 7.87 | 0.49 | 6.25 |

| 1:1 Z-twisted | 14.8 | 1.13 | 7.64 | 8.67 | 0.51 | 5.88 |

| 2:1 S-twisted | 15.8 | 1.02 | 6.46 | 8.13 | 0.59 | 7.24 |

SEM image of composite yarn after parallel twisting. (a) 1:1 S-twisted, (b) 1:1 Z-twisted, and (c) 2:1 S-twisted.

The breaking elongation of the composite yarn twisted with a stainless steel long filament also increases relative to that of the pure cotton yarn. Similarly, as the metallic fiber content increases, the electromagnetic shielding effectiveness of the fabric exhibits a rising trend [31]. When the stainless steel long filament and the pure cotton yarn share the tensile force, once the pure cotton yarn gradually stretches and disintegrates, the stainless steel long filament twisted outside the pure cotton yarn will untwist and continue to share the tensile force with the pure cotton yarn. Consequently, the breaking elongation of the composite yarn increases. This difference in breaking elongation between the yarn twisted in the opposite direction and the yarn twisted in the same direction may be attributed to the untwisting of the yarn caused by twisting in the opposite direction. This untwisting leads to a decrease in the cohesion force between fibers. Under tensile force, the fiber requires more slippage distance to cause yarn breakage, hence the increase in breaking elongation.

3.2 Fabric thickness analysis

As shown in Table 2, the thickness of the prepared fabric differs despite the use of the same weaving process. The thickness of the fabric made from the composite yarn twisted with a stainless steel long filament is greater than that of the fabric made from pure cotton yarn. The greater the number of stainless steel long filaments used, the thicker the fabric. The reason is that the higher the content of the stainless steel long filament, the larger the diameter of the composite yarn, and the greater the diameter of the raw material, the thicker the fabric.

Fabric thickness

| Name | Fabric thickness (mm) | Standard deviation | Coefficient of variation (%) |

|---|---|---|---|

| Pure cotton | 1.64 | 0.14 | 7.56 |

| 1:1 S-twisted | 1.69 | 0.11 | 6.51 |

| 1:1 Z-twisted | 1.84 | 0.17 | 9.23 |

| 2:1 S-twisted | 1.86 | 0.15 | 8.06 |

Table 2 shows that for fabrics made from composite yarn twisted with one stainless steel long filament and one cotton yarn, the thickness of the fabric varies when the direction of twisting varies. Fabrics made from yarns twisted in the same direction are thinner than those twisted in the opposite direction. The yarn diameter is one of the factors affecting fabric thickness and is directly proportional to it when other conditions remain the same; thus, the yarn twisted in the opposite direction causes the cotton yarn to untwist and become fluffy, increasing the diameter of the composite yarn. Twisting in the same direction increases the twist of the cotton yarn, further tightening the yarn and reducing the diameter of the composite yarn. Therefore, the fabric obtained from the 1:1 Z-twisted composite yarn is thicker.

3.3 Analysis of fabric tensile break strength

In this experiment, we adopted a weaving method in which the weft density exceeds the warp density. As shown in Table 3, the breaking strength in the weft direction of the fabric is always greater than that in the warp direction, whereas the elongation at break in the weft direction is less than that in the warp direction. The reason is that the weft density of the fabric is higher than the warp density; more yarns carry the tensile breaking force in the weft direction, leading to a higher break strength. The weft density is greater than the warp density; thus, the bending of the weft yarn is less than that of the warp yarn. This difference leads to a smaller elongation at break in the weft direction.

Mechanical properties of fabrics

| Name | Breaking strength (MPa) | Standard deviation | Coefficient of variation (%) | |||

|---|---|---|---|---|---|---|

| Weft | Warp | Weft | Warp | Weft | Warp | |

| Pure cotton | 13.21 | 10.47 | 0.81 | 0.97 | 6.13 | 9.26 |

| 1:1 S-twisted | 15.52 | 12.33 | 1.41 | 1.13 | 5.38 | 4.53 |

| 1:1 Z-twisted | 14.69 | 11.38 | 1.39 | 0.92 | 9.46 | 8.08 |

| 2:1 S-twisted | 16.58 | 13.74 | 0.93 | 1.22 | 5.61 | 8.88 |

| Name | Breaking elongation (%) | Standard deviation | Coefficient of variation (%) | |||

|---|---|---|---|---|---|---|

| Weft | Warp | Weft | Warp | Weft | Warp | |

| Pure cotton | 3.31 | 5.35 | 0.14 | 0.28 | 4.21 | 5.32 |

| 1:1 S-twisted | 6.92 | 8.36 | 0.43 | 0.47 | 6.25 | 5.66 |

| 1:1 Z-twisted | 7.49 | 8.72 | 0.41 | 0.34 | 5.49 | 3.91 |

| 2:1 S-twisted | 7.35 | 8.33 | 0.25 | 0.31 | 3.39 | 4.84 |

The breaking strength of fabrics containing stainless steel filaments is higher than that of pure cotton fabrics. This difference is caused by the greater breaking strength of the composite yarns prepared by twisting stainless steel filaments and cotton yarn than that of pure cotton yarn. Similarly, fabrics made from composite yarns twisted in the same direction exhibit slightly higher breaking strength than those produced from yarns twisted in opposite directions.

Under the same weaving process and parameter settings, the performance of the fabric depends on the performance of the raw yarn. As analyzed in Section 2.1, the elongation at break of the composite yarn twisted with stainless steel filaments and cotton yarn is greater than that of the pure cotton yarn. However, the elongation at break of the composite yarn twisted in the same direction is lower than that of the yarn twisted in opposite directions. Therefore, the data in Table 3 indicate that the elongation at break of fabrics containing stainless steel filaments exceeds that of pure cotton fabric, and the elongation at break of fabrics made from yarns twisted in the same direction is lower than that of fabrics made from yarns twisted in opposite directions. Stainless-steel fiber yarns have higher friction coefficients, less breaking elongation, and greater hairiness. Special attention should be directed toward yarn unwinding, positive yarn feeding, and loop formation in fabric manufacturing because they pose relatively greater challenges when yarns are being processed into fabrics [32]. Compared with stainless steel fiber yarn, the stainless steel filament twisted composite yarn in the current study has a lower friction coefficient and less yarn hairiness, rendering it easier to process into fabrics.

3.4 Analysis of sample air permeability

As shown in Table 4, the air permeability rates of all fabrics exceed 50 mm/s, meeting the air permeability requirements for thermal protective clothing. Pure cotton fabric exhibits the best air permeability, and as the content of the stainless steel filament in the yarn increases, the air permeability of the woven fabric decreases more significantly. The size of the pores in the fabric is a major factor affecting its air permeability, with smaller pores leading to poorer air permeability. As more stainless steel filaments are added during the twisting process, the diameter of the composite yarn increases. Under the same weaving process and parameter conditions, the larger the yarn diameter, the smaller the pores in the finished fabric, and the poorer the air permeability. Therefore, the air permeability of the pure cotton fabric is optimal, whereas that of the 2:1 S twisted fabric is the worst. The air permeability of the fabrics using yarns twisted in the same direction is slightly higher because as the twist of the cotton yarn increases, the diameter of the yarn decreases, and the pores in the fabric increase. Consequently, their breathability and moisture permeability are far superior to those of bamboo charcoal/stainless steel/thermoplastic polyurethane composite fabrics formed by laminating a thermoplastic polyurethane film after fabric production [33].

Air permeability of fabrics

| Name | Air permeability (mm/s) | Standard deviation | Coefficient of variation (%) |

|---|---|---|---|

| Pure cotton | 62.72 | 3.70 | 9.57 |

| 1:1 S-twisted | 55.70 | 5.79 | 10.39 |

| 1:1 Z-twisted | 54.60 | 6.83 | 12.51 |

| 2:1 S-twisted | 51.59 | 5.07 | 9.83 |

3.5 Analysis of sample moisture permeability

The effective fabric area for this experiment is 0.00283 m2. The moisture permeability of the fabric is calculated using formula (1) [34]. The mean, standard deviation, and coefficient of variation are also calculated.

where WVT is the moisture permeability rate (in g/(m2 h)); m is the difference between two weighings of the same experimental combination (in g); m′ is the difference between two weighings of the same experimental combination for a blank sample (in g); A is the effective test area (in m²); and t is the effective testing time (in h).

As shown in Table 5, compared with fabrics made from pure cotton yarn, those made using twisted composite yarn with stainless steel filaments have significantly reduced moisture permeability rates. Twisting stainless steel filaments into pure cotton yarn leads to a decrease in the moisture permeability of the fabric produced. Moreover, as the content of the stainless steel filament in the yarn used for the fabric increases, the moisture permeability rate of the finished fabric decreases. The conclusion drawn from a comparison of the moisture permeability rates of fabrics produced using yarns with the same twist ratio but different twisting directions is that yarns twisted in the same direction exhibit a slightly increased moisture permeability. The reason is that the size of the pores in the fabric affects its moisture permeability performance. After stainless steel filaments are twisted and added to the yarn, some pores in the finished fabric are occupied by stainless steel filaments, causing the pores in the fabric to shrink and the moisture permeability of the finished fabric to decrease. The common factor affecting moisture permeability and air permeability is the size of the pores in the fabric. In addition to the pore size, moisture permeability is also related to the moisture absorption of the fabric materials. In this experiment, the moisture-absorbing material in the fabric is cotton fiber, and the amount of cotton yarn used in the weaving process remains essentially unchanged – that is, the moisture absorption of the fabric material remains consistent. Thus, the size of the fabric pores becomes the decisive factor in this experiment. The moisture permeability of fabrics made from yarns twisted in the same direction is slightly higher because the twist of the cotton yarn twisted in the same direction is greater, the diameter of the yarn is smaller, and the pores between the yarns are larger.

Moisture permeability of fabrics

| Name | Moisture permeability (g/(m2 h)) | Standard deviation | Coefficient of variation (%) |

|---|---|---|---|

| Pure cotton | 165.47 | 12.01 | 7.26 |

| 1:1 S-twisted | 156.61 | 6.61 | 4.22 |

| 1:1 Z-twisted | 155.32 | 11.32 | 7.29 |

| 2:1 S-twisted | 151.97 | 7.80 | 5.13 |

3.6 Analysis of sample stiffness

As shown in Table 6, fabrics using twisted composite yarns with stainless steel filaments as raw materials exhibit significantly improved extension length, bending resistance length, and bending stiffness relative to those using pure cotton yarn as raw materials. This difference is caused by the considerable rigidity of stainless steel filaments. The rigidity of composite yarns twisted with stainless steel filaments can be significantly enhanced, improving the stiffness of the fabric prepared and reducing its softness. A comparison of the extension length, bending resistance length, and bending stiffness of the fabrics prepared from composite yarns with the same twist ratio but different twisting directions reveals that the stiffness of the samples twisted in the same direction is slightly higher than that of the samples twisted in different directions; however, the difference is not significant. Twisting in the same direction leads to a greater twist in the cotton yarn within the composite yarn than in the yarn twisted in different directions. As the twist of the yarn increases, the rigidity of the yarn also increases. Consequently, the stiffness of fabrics made from composite yarns twisted in the same direction is slightly higher than that of fabrics twisted in different directions.

Stiffness of fabrics

| Name | Extension length (mm) | Bending length (mm) | Bending rigidity (mg cm) | |||

|---|---|---|---|---|---|---|

| Weft | Warp | Weft | Warp | Weft | Warp | |

| Pure cotton | 80.4 | 42.4 | 40.2 | 21.2 | 3910.9 | 573.6 |

| 1:1 S-twisted | 124.4 | 55.6 | 62.2 | 27.8 | 21860.0 | 1951.70 |

| 1:1 Z-twisted | 123.2 | 55.3 | 61.6 | 27.6 | 21009.0 | 1889.7 |

| 2:1 S-twisted | 126.9 | 69.8 | 63.5 | 34.9 | 23359.2 | 3878.1 |

A comparison of the fabrics with different twist ratios indicates that as the content of stainless steel increases, no significant changes in the extension length, bending resistance length, and bending stiffness of the fabric in the weft direction are observed; by contrast, the extension length, bending resistance length, and bending stiffness in the warp direction of the fabric change significantly. Moreover, the stiffness in the warp direction of the fabric increases significantly with an increase in the number of stainless steel filaments twisted into the composite yarns. With an increase in the number of stainless steel filaments, no significant change in stiffness occurs in the weft direction. This observation can be attributed to the close arrangement of the yarns in the weft direction of the fabric. The fabrics maintain a consistent degree of tightness, limiting the available space for significant increases in stiffness. By contrast, the yarns in the warp direction are relatively sparse. Under similar circumstances, the increase in stainless steel filaments more significantly affects the tightness of the fabric in the warp direction, causing a significant increase in the stiffness of the fabric in the warp direction as the content of stainless steel increases. Similarly, the use of SS wire-based yarns in fabrics significantly increased the flexural rigidity of hybrid fabrics [35].

3.7 Flame retardancy test of samples

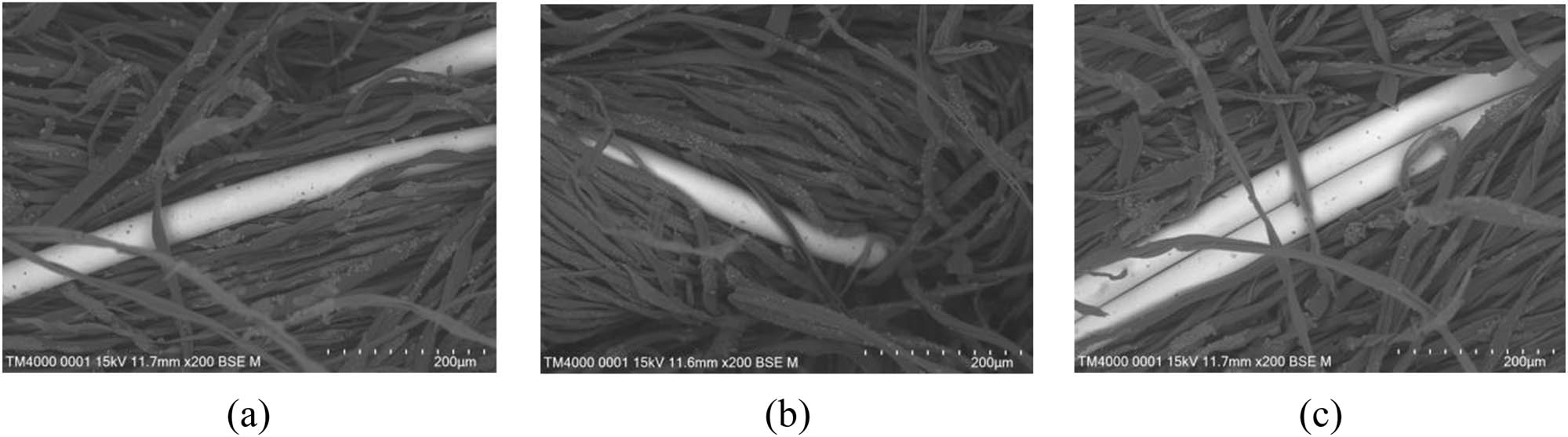

Fabrics with thermal protection performance should meet the flame retardant criteria: afterflame time ≤2 s, afterglow time ≤4 s, and damaged length ≤100 mm [36]. As shown in Table 7, all fabrics, after undergoing flame-retardant finishing, exhibit an afterflame and afterglow time of 0 and char length less than 100 mm, meeting the criteria for flame retardants. Thus, all fabrics have desirable flame-retardant properties. In the SEM images of the composite yarn fabric (Figure 2a–c), a layer of material is clearly visible on the surface of the fibers. This material is a nitrogen–phosphorus flame-retardant additive, which endows the fabric with flame-retardant properties. A comparison of the SEM images after finishing with those of untreated cotton and stainless steel fibers reveals that the surfaces of the untreated fibers appear clean (Figure 1a–c), without any adhered particulate matter. This observation indicates that the particulate matter adhered to the fibers only after the functional finishing process. A comparison of the char lengths of different samples in Table 7 indicates that fabrics made from composite yarns with twisted stainless steel filaments have significantly shorter char lengths compared with the pure cotton control group. Therefore, adding twisted stainless steel filaments to pure cotton yarn can enhance the flame retardancy of the resulting fabric to a certain degree.

Flame retardancy of fabrics

| Name | Afterflame time (s) | Afterglow time (s) | Damaged length (mm) | Melting, dripping | ||||

|---|---|---|---|---|---|---|---|---|

| Weft | Warp | Weft | Warp | Weft | Warp | Weft | Warp | |

| Pure cotton | 0 | 0 | 0 | 0 | 8 | 11 | No | No |

| 1:1 S-twisted | 0 | 0 | 0 | 0 | 3 | 2 | No | No |

| 1:1 Z-twisted | 0 | 0 | 0 | 0 | 3 | 3 | No | No |

| 2:1 S-twisted | 0 | 0 | 0 | 0 | 1 | 3 | No | No |

SEM image of fabric made from twisted composite yarn. (a) 1:1 S-twisted, (b) 1:1 Z-twisted, and (c) 2:1 S-twisted.

A comparison of the char lengths of fabrics made from composite yarns with the same twist ratio but different twisting directions is presented in Table 7. No significant change is observed in the flame-retardant properties of fabrics made from composite yarns with different twisting directions. A comparison of the flame-retardant performance data of woven fabrics with different stainless steel filament contents reveals that as the quantity of stainless steel filaments added to the twisted yarns increases, the flame retardancy of the fabric slightly improves. The flame-retardant properties of the raw materials used in the fabric significantly influence the flame-retardant performance of the fabric. Stainless steel filaments exhibit good flame retardancy, and the addition of stainless steel filaments improves the flame-retardant performance of the fabric. Therefore, the addition of stainless steel filaments positively correlates with the flame retardancy of the fabric. However, in this experiment, as the quantity of stainless steel filaments added during the processing of the twisted yarns increases, no significant improvement in the flame-retardant performance of the fabric is observed.

This lack of improvement may be attributed to the effect of post-flame-retardant finishing on the overall flame retardancy of the fabric in this experiment. The post-flame-retardant finishing process and parameters in this experiment are essentially the same, leading to a minimal change in the overall flame-retardant performance of the fabric as the quantity of stainless steel filaments increases. Applying a flame-retardant coating to cotton fabrics can significantly enhance flame retardancy and char formation. Moreover, the char formed in C3 exhibits sufficient thermal stability, limiting further degradation and starving the fire by eliminating the fuel supply. In the study by Guo, the pure cotton fabric sample was found to rapidly spread flames, without leaving a char residue. However, after flame-retardant treatment, the fabric with the best flame-retardant effect exhibits self-extinguishing properties, with a char length reaching 71 mm [37]. The flame-retardant fabrics prepared in the current study provide certain advantages and demonstrate improved flame-retardant performance. The limiting oxygen index of pure cotton fabric is 18%, and the minimum limiting oxygen index for self-extinguishing is 26%. In the study by Liu, the limiting oxygen index was 29%, consistent with the test results in the present study, confirming self-extinguishing properties [38]. Therefore, the minimum limiting oxygen index in this study is 26%.

4 Conclusions

In this experiment, composite yarns were obtained by twisting stainless steel filaments and pure cotton yarns together with varying blending ratios and twisting directions through the parallel twisting method. These composite yarns were used to prepare woven fabrics treated with a flame retardant. The greater the number of stainless steel filaments used during parallel twisting, the thicker the fabric. Varying the twisting direction during the parallel twisting of composite yarns also affects the thickness of the fabric. The fabrication of a woven fabric after stainless steel filaments and cotton yarns are twisted together leads to a decrease in the breathability and moisture permeability of the fabric. This trend intensifies as the number of stainless steel filaments increases. The twisting direction during the parallel twisting of composite yarns also slightly influences the breathability and moisture permeability of the fabric.

The addition of stainless steel filaments significantly improves the stiffness of the fabric. Variations in twisting direction during the parallel twisting of composite yarns also influence the stiffness of the fabric. The strength and elongation at the break of the yarn increase after stainless steel filaments are twisted with cotton yarns. When further prepared into fabrics, the yarn with stainless steel filaments exhibits enhanced breaking strength. The breaking strength of the fabric also improves as the number of stainless steel filaments increases. Variations in twisting direction during the parallel twisting of composite yarns also affect the primary mechanical properties of the yarn and the fabric.

The flame-retardant effect of the stainless steel filament/pure cotton woven fabric prepared after posttreatment meets expectations. Compared with the pure cotton woven fabric, the stainless steel filament/pure cotton woven fabric shows better flame-retardant performance, which slightly improves as the content of stainless steel filaments increases. The mechanical properties and thermal–moisture comfort of the fabric made from yarns twisted in the same direction are slightly better than those produced from yarns twisted in different directions. Compared with pure cotton fabric, the fabric incorporated with stainless steel filaments exhibits enhanced mechanical properties, theoretically enhancing its durability. Comfort decreases to a certain extent, but this reduction falls within an acceptable range. Owing to the limitations of the experimental conditions, this study did not evaluate the actual limiting oxygen index. In future research, equipment that can measure the limiting oxygen index will be integrated to allow for more comprehensive scientific investigations.

The use of one stainless steel filament twisted together with one pure cotton S-twisted yarn in the same S-twisted direction is recommended, considering the appropriate thermal–moisture comfort of the fabric and the improved mechanical properties and flame retardancy relative to those of pure cotton fabric. The composite yarn prepared with these parameters should be used to produce a flame-retardant fabric. This fabric may be used in the future for the upgrade and replacement of welding labor protection clothing that requires antimolten hole properties, flame retardancy, and thermal–moisture comfort.

-

Funding information: This work was generously supported by multiple grants. The China Scholarship Council provided funding under grant number 202008350058. The Fujian Science and Technology Project Guidance Project also contributed under grant number 2022H0049. The Open Project Program of the Key Lab for Sport Shoes Upper Materials of Fujian Province granted us support under grant number SSUM2202. Further support came from the Fuzhou Science and Technology Major Project (grant number 2021-Z-3) and Major Science and Technology Project of Jiebang Guashuai (grant number 2022-ZD-007). In addition, the Minjiang University Teaching Reform Project (grant number MJU2020KC315) and Minjiang University Science and Technology Project (grant number MJY21022) were instrumental to our research.

-

Author contributions: All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Taohai Yan, Yajing Shi, Jiankun Zheng, Yinneng Chu, Luming Huang, and Chaowang Lin. The first draft of the manuscript was written by Taohai Yan, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

-

Conflict of interest: The authors declare that they have no competing financial interests.

-

Ethics approval and consent to participate: Not applicable.

-

Consent for publication: All authors approved the final manuscript and the submission to this journal.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are publicly available.

References

[1] Fernandez-Pello, A. C., Lautenberger, C., Rich, D., Zak, C., Urban, J., Hadden, R., et al. (2015). Spot fire ignition of natural fuel beds by hot metal particles, embers, and sparks. Combustion Science and Technology, 187(1–2), 269–295.10.1080/00102202.2014.973953Search in Google Scholar

[2] Mobarak, Y., Alshehri, A. (2016). Perspectives of safe work practices: Improving personal electrical safety of low-voltage systems from electrical hazards. Engineering, Technology & Applied Science Research, 6(6), 1307–1315.10.48084/etasr.993Search in Google Scholar

[3] Asmita, K. B., Panduragan, S. L., Nambiar, N., Yahya, F. (2022). Occupational hazards, the use of PPE, and health impacts among welders in Sumedang, West Java, Indonesia. Malaysian Journal of Medicine & Health Sciences, 18, 243–249.10.1063/5.0168459Search in Google Scholar

[4] Venkataraman, D., Shabani, E., Park, J. H. (2023). Advancement of nonwoven fabrics in personal protective equipment. Materials, 16(11), 3964.10.3390/ma16113964Search in Google Scholar PubMed PubMed Central

[5] Leonov, V. P., Mikhaylov, V. I. (2020). Protection of welded joints from oxidation at welding of titanium alloys. Inorganic Materials: Applied Research, 11(6), 1423–1427.10.1134/S2075113320060155Search in Google Scholar

[6] Egerland, S. A., Wiesinger, M., Sharma, R., Ebert, B. (2023). Experimental study of measures preventing welders from fume exposure. Welding in the World, 67(1), 1–20.10.1007/s40194-022-01395-1Search in Google Scholar

[7] AHSSI, M. A. M. (2023). The effect of Ni on the microstructure, wear and corrosion behaviors of microalloyed steels produced by powder metallurgy. Doctoral dissertation, Karabuk University, Karabük, Turkey.Search in Google Scholar

[8] Liu, J., Xu, Y., Ge, Y., Hou, Z., Chen, S. (2020). Wire and arc additive manufacturing of metal components: A review of recent research developments. The International Journal of Advanced Manufacturing Technology, 111, 149–198.10.1007/s00170-020-05966-8Search in Google Scholar

[9] Akhil, M. G., Arsha, A. G., Manoj, V., Rajan, T. P. D., Pai, B. C., Huber, P., et al. (2021). Metal fiber reinforced composites. In Fiber reinforced composites (pp. 479–513). Woodhead Publishing, Sawston, Cambridge, United Kingdom.10.1016/B978-0-12-821090-1.00024-7Search in Google Scholar

[10] Chung, D. D. L. (2023). A critical review of electrical-resistance-based self-sensing in conductive cement-based materials. Carbon, 203, 311–325.10.1016/j.carbon.2022.11.076Search in Google Scholar

[11] Xie, Z. (2022). Study of the viability for production of conductive nonwoven reinforcement from technical textile waste. Master's thesis. Universitat Politècnica de Catalunya, Barcelona, Spain.Search in Google Scholar

[12] Rodiouchkina, M., Lind, J., Pelcastre, L., Berglund, K., Rudolphi, Å. K., Hardell, J. (2021). Tribological behaviour and transfer layer development of self-lubricating polymer composite bearing materials under long duration dry sliding against stainless steel. Wear, 484, 204027.10.1016/j.wear.2021.204027Search in Google Scholar

[13] Jiang, D., Lian, M., Xu, M., Sun, Q., Xu, B. B., Thabet, H. K., et al. (2023). Advances in triboelectric nanogenerator technology – applications in self-powered sensors, internet of things, biomedicine, and blue energy. Advanced Composites and Hybrid Materials, 6(2), 57.10.1007/s42114-023-00632-5Search in Google Scholar

[14] Muhammad Sayem, A. S., Hon Teay, S., Shahariar, H., Luise Fink, P., Albarbar, A. (2020). Review on smart electro-clothing systems (SeCSs). Sensors, 20(3), 587.10.3390/s20030587Search in Google Scholar PubMed PubMed Central

[15] Liu, Z., He, S., Wang, H., Wang, X. (2022). Improvement of the electromagnetic properties of blended electromagnetic shielding fabric of cotton/stainless steel/polyester based on multi-layer MXenes. Textile Research Journal, 92(9–10), 1495–1505.10.1177/00405175211062352Search in Google Scholar

[16] He, B., Hou, X., Liu, Y., Hu, J., Song, L., Tong, Z., et al. (2023). Design of fluorine-free waterborne fabric coating with robust hydrophobicity, water-resistant and breathability. Separation and Purification Technology, 311, 123308.10.1016/j.seppur.2023.123308Search in Google Scholar

[17] Chen, G., Xiao, X., Zhao, X., Tat, T., Bick, M., Chen, J. (2021). Electronic textiles for wearable point-of-care systems. Chemical Reviews, 122(3), 3259–3291.10.1021/acs.chemrev.1c00502Search in Google Scholar PubMed

[18] Tunakova, V., Tunak, M., Tesinova, P., Seidlova, M., Prochazka, J. (2020). Fashion clothing with electromagnetic radiation protection: Aesthetic properties and performance. Textile Research Journal, 90(21–22), 2504–2521.10.1177/0040517520923047Search in Google Scholar

[19] Zhu, S., Duan, G., Chang, C., Chen, Y., Sun, Y., Tang, Y., et al. (2020). Fast electrodeposited nickle–iron hydroxide nanosheets on sintered stainless steel felt as bifunctional electrocatalysts for overall water splitting. ACS Sustainable Chemistry & Engineering, 8(26), 9885–9895.10.1021/acssuschemeng.0c03017Search in Google Scholar

[20] Aliyu, A. A. A., Panwisawas, C., Shinjo, J., Puncreobutr, C., Reed, R. C., Poungsiri, K., et al. (2023). Laser-based additive manufacturing of bulk metallic glasses: Recent advances and future perspectives for biomedical applications. Journal of Materials Research and Technology, 23, 2956–2990.10.1016/j.jmrt.2023.01.184Search in Google Scholar

[21] Asfia, M. P., Rezaei, M. (2021). A study on localized corrosion behavior of 304 stainless steel in the presence of Allium sativum extract inhibitor using electrochemical noise analysis. Materials Chemistry and Physics, 274, 125158.10.1016/j.matchemphys.2021.125158Search in Google Scholar

[22] Bareiro, W. G., de Andrade Silva, F., Sotelino, E. D. (2020). Thermo-mechanical behavior of stainless steel fiber reinforced refractory concrete: Experimental and numerical analysis. Construction and Building Materials, 240, 117881.10.1016/j.conbuildmat.2019.117881Search in Google Scholar

[23] Kiew, L. V., Chang, C. Y., Huang, S. Y., Wang, P. W., Heh, C. H., Liu, C. T., et al. (2021). Comparative studies on microstructure evolution and corrosion resistance of 304 and a newly developed high Mn and N austenitic stainless steel welded joints. Corrosion Science, 183, 109338.10.1016/j.corsci.2021.109338Search in Google Scholar

[24] Li, H., Zhu, Y. J. (2021). Nanowires: Synthesis and energy/environmental applications. Energy & Environmental Materials, 4(4), 544–561.10.1002/eem2.12158Search in Google Scholar

[25] Amran, M., Fediuk, R., Murali, G., Vatin, N., Al-Fakih, A. (2021). Sound-absorbing acoustic concretes: A review. Sustainability, 13(19), 10712.10.3390/su131910712Search in Google Scholar

[26] Li, Z., Zhai, W., Li, X., Yu, X., Guo, Z., Wang, Z. (2022). Additively manufactured dual-functional metamaterials with customisable mechanical and sound-absorbing properties. Virtual and Physical Prototyping, 17(4), 864–880.10.1080/17452759.2022.2085119Search in Google Scholar

[27] Mohamad, B., Jalics, K., Kermani, M. (2019). Exhaust system muffler volume optimization of light commercial passenger car using transfer matrix method. International Journal of Engineering and Management Sciences, 4(1), 132–138.10.21791/IJEMS.2019.1.16.Search in Google Scholar

[28] Speranzini, E., Agnetti, S., Tomassini, E. (2022). Theoretical analysis of the adhesion law of stainless steel FRCM strengthening systems. Construction and Building Materials, 355, 129039.10.1016/j.conbuildmat.2022.129039Search in Google Scholar

[29] Zhao, G., Li, J., Zhang, R., Li, H., Li, J., Ma, L. (2023). Wear behavior of copper containing antibacterial stainless steel in different environmental media and EBSD analysis of its sub surface structure. Materials Characterization, 197, 112690.10.1016/j.matchar.2023.112690Search in Google Scholar

[30] Hu, Z., Zhou, J., Fu, Q. (2021). Design and construction of deformable heaters: Materials, structure, and applications. Advanced Electronic Materials, 7(11), 2100452.10.1002/aelm.202100459Search in Google Scholar

[31] Xue, W., Cheng, L., Li, A., Jiao, N. N., Chen, B. W., Zhang, T. H. (2013). Research on electromagnetic shielding effectiveness of composite fabrics made by stainless steel fiber. Advanced Materials Research, 821, 888–893.10.4028/www.scientific.net/AMR.821-822.888Search in Google Scholar

[32] Sun, Y. C., Cheng, Z. (2014). Property analysis of stainless steel fiber (Yarn) and its effect on knitting process. Advanced Materials Research, 1053, 93–96.10.4028/www.scientific.net/AMR.1053.93Search in Google Scholar

[33] Lou, C. W., Lin, J. H. (2011). Evaluation of bamboo charcoal/stainless steel/TPU composite woven fabrics. Fibers and Polymers, 12, 514–520.10.1007/s12221-011-0514-5Search in Google Scholar

[34] A, X., Li, Z., Luo, W., Chai, J. (2020). A study on artemisia argyi oil/sodium alginate/PVA nanofibrous membranes: Micro-structure, breathability, moisture permeability, and antibacterial efficacy. Journal of Materials Research and Technology, 9(6), 13450–13458.10.1016/j.jmrt.2020.09.075Search in Google Scholar

[35] Bedeloglu, A. (2013). Investigation of electrical, electromagnetic shielding, and usage properties of woven fabrics made from different hybrid yarns containing stainless steel wires. The Journal of The Textile Institute, 104(12), 1359–1373.10.1080/00405000.2013.806049Search in Google Scholar

[36] Jiang, X. C., Li, P., Liu, Y., Wang, J. S. (2023). Flame-retardant ramie fabrics with APP: Flame retardancy, flame-retardant mechanism and mechanical properties. Cellulose, 30(2), 1321–1334.10.1007/s10570-022-04962-3Search in Google Scholar

[37] Guo, W., Wang, X., Huang, J., Zhou, Y., Cai, W., Wang, J., et al. (2020). Construction of durable flame-retardant and robust superhydrophobic coatings on cotton fabrics for water-oil separation application. Chemical Engineering Journal, 398, 125661.10.1016/j.cej.2020.125661Search in Google Scholar

[38] Liu, Y., Wang, Q. Q., Jiang, Z. M., Zhang, C. J., Li, Z. F., Chen, H. Q., et al. (2018). Effect of chitosan on the fire retardancy and thermal degradation properties of coated cotton fabrics with sodium phytate and APTES by LBL assembly. Journal of Analytical and Applied Pyrolysis, 135, 289–298.10.1016/j.jaap.2018.08.024Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry