Abstract

In the present work, seven different weave-structured jute fabrics were treated using an organophosphorus-based flame-retardant (FR) chemical (ITOFLAM CPN) along with a cross-linking agent (KNITTEX CHN) by the pad–dry–cure method. The flammability properties were determined by vertical and horizontal flammability tests and limiting oxygen index (LOI). The flame-spread and after-glow time in the vertical flammability test were calculated to be zero seconds on the FR-treated fabrics while the untreated fabrics were completely burnt. The burn rate in the horizontal flammability test is also measured at zero seconds on the FR-treated fabrics. The highest LOI (43.33) is found in the Twill-3/1 and 4-ends Irregular Satin fabrics, while other fabrics had similar LOI (40) results after FR treatment. The maximum char length (71 and 74 mm) was determined in the warp and weft directions of the Plain-1/1 fabric, while an average minimum char length was found for Twill-2/2 fabrics. Despite the significant improvement in FR performance, it strongly affects the tensile properties of FR-treated fabrics. A substantial loss of tensile strength loss was measured in all treated fabrics; however, the highest loss (77%) was examined for the Plain-1/1 fabric, and the lowest loss of strength (60%) was in the Basket weave (Matt)-4/4 fabric.

1 Introduction

The structure and chemical compositions of cellulosic and lignocellulosic fibers have a significant impact on their thermal behavior. Jute is a lignocellulosic fiber made up of 24% hemicellulose, 60% α-cellulose, and 14% lignin. It serves as a natural fiber with applications in technical textiles due to its unique composition. Due to chemical variations, the thermal behaviors of various components should differ [1]. Previous studies [2,3] have explored the thermal behavior and fire-retardant coatings. The studies focused on understanding the properties of materials in relation to flame resistance. Specifically, they investigated the effects of fire-retardant treatments on various substrates. To minimize fatalities and injuries resulting from fires, fire-resistant properties have been incorporated into jute carpet backing, decorative jute furnishing fabrics, and brattice cloth for mines. Flame-retardant (FR) jute fabrics have extensive applications across a variety of products, including industrial ventilation, floor coverings, mats, carpets, military uniforms, hospital furnishings, and hospital curtains. These treated jute fabrics not only enhance fire safety but also serve practical purposes in diverse settings [4]. Key challenges in enhancing the fire resistance of jute fabrics involve the need for a higher chemical application, a significant decrease in the material’s tensile strength, and a tendency to turn yellow. Moreover, a large quantity of specific chemicals is often essential in these FR compositions, which results in them being either not long-lasting or only partially durable [5]. An essential quality of textile materials is flame retardancy, which helps protect wearers from dangerous clothing. Floor coverings, furniture, and curtains must be flame-resistant when used in public facilities, especially for firefighters and emergency personnel. There are also numerous fire retardancy requirements in the aviation and military sectors [6,7].

Currently, one of the major challenges that researchers are facing is the durability of the flame retardancy of Jute-based products. Several types of fire-resistant treatments have been experimented with on jute-based products for potential use in mining environments, vehicle seat covers, and home fabrics. This is particularly important for protective kitchen wear like aprons and gloves, as well as hangings and curtains in communal areas, given their susceptibility to catching fire. Various durable and non-durable FRs can be applied to make cellulosic materials FR for various purposes. Nonetheless, standardizing the FR finish recipe and application method is important for ligno-cellulosics, especially for jute and jute-blended textiles [8]. In general, jute along with various other fibers derived from plants tends to be extremely susceptible to combustion. Jute is a bast and cellulosic fiber and the main difference from cotton is that jute contains a significant amount of lignin (14%) and hemicellulose (24%) in its chemical constituents [9].

There have not been many studies done on natural fibers except cotton, however, Yusuf [10] studied linen, hemp, silk, and wool, while Mehta and Hoque [11] investigated the FR of Jute. The study by Dorez et al. focused on analyzing the impact that the components cellulose, hemicellulose, and lignin have on the processes of pyrolysis and combustion in natural fibers [12]. Prior investigations have utilized a range of organophosphates, such as sodium metasilicate nonahydrate, ortho-phosphoric acid, diammonium hydrogen phosphate, ammonium sulfamate, borax, thiourea, and urea, in addition to other compounds, in the treatment of jute [1,13,14,15,16,17,18]. Recent investigations conducted by Samanta et al. have effectively analyzed how nano-zinc oxide serves as an FR coating on jute textiles [19], and the FR properties of jute by employing chitosan and sodium alginate were explored by Li et al. [20]. Roy et al. also reported long-lasting flame-retardance in jute [9].

Significant research has been conducted on the flame-retardance performance of cotton knitted fabrics, while very few studies are focused on the flame-retardance woven jute fabrics. It was found that a longer loop length of the knit structure caused greater air permeability and therefore resulted in a shorter burning time and vice versa [21]. Similarly, thicker fabrics and higher porosity of fabrics are associated with the high flammability of knitted fabrics [22]. Investigations have assessed the possibility of enhancing the comfort level and mechanical features of cotton fabrics through the application of a softener and wetting agent amidst FR processing [23]. Further studies were conducted to evaluate the flammability, comfort, and mechanical properties of plant-structured cotton fabrics. According to the findings, the study claimed that plant structures based on twill, Matt, and plain weave showed superior performance. The twill-based plant structure exhibited greater flame-retardance compared to conventional fabric structures, attributed to stronger chemical bonding with the fabric surface due to its larger surface area. Conversely, the plant-structured fabrics with matte and plain weave designs retained superior wettability, higher thermal conductivity, air permeability, and fabric hand [24]. Previous studies also claimed that heavier and denser fabrics resist ignition more than lighter and thinner fabrics; on the other hand, the pile length of fabrics inversely affects the flammability of fabrics [25].

The hypothesis of the present research work for FR finish of jute-based fabrics of different woven construction may be postulated as follows: on changes of woven construction, the following dimensions and properties will change, i.e., GSM, thickness, shrinkage, tensile strength, and elongation behavior, tear strength, bending and flexural rigidity, etc., assuming a higher cover with a higher density of warp or weft ends, all these properties may lead. However, these changes are expected to be in favor of improving some functional properties, assuming to show higher softness and better fabric hand value for twill weave than plain weave jute fabric with also higher abrasion resistance for twill weave than plain weave jute fabrics, while water repellence or fire retardancy effect may not be dependent on changes on type of weave, but will improve with number of warp and weft ends per inch and also increased twist level in the yarn up to a limit. With this hypothesis, the present work is proceeded further.

In this article, we applied the FR treatment (ITOFLAM CPN) along with a crosslinking agent (KNITTEX CHN) on seven different weaves designed pure Jute fabrics, and the flame-retardance performance was investigated. The flammability of untreated and FR-treated jute fabrics was determined by vertical and horizontal flammability tests and limiting oxygen index (LOI) test. This study extends the FR analysis on seven weave-structured jute fabrics and evaluates the influence of weave on the flame-retardance performance among them as no such studies are reported at the present time.

2 Experimental

2.1 Materials

All experimental works were executed utilizing 100% Jute with seven different structurally designed woven fabrics. Detailed specifications are summarized in Table 1. The jute fabrics were manufactured at Janata Jute Company, Dhaka, Bangladesh.

Fabric specifications

| Sample ID | Weave structure | Fabric sett on loom (yarn/cm) | Yarn linear density (Tex) | ||

|---|---|---|---|---|---|

| Warp | Weft | Warp | Weft | ||

| D1 | Weft Rib: 2/2 | 26 | 20 | 210.54 | 210.54 |

| D2 | Warp Rib: 2/2 | 26 | 20 | 210.54 | 210.54 |

| D3 | Basket weave (Matt): 4/4 | 26 | 20 | 210.54 | 210.54 |

| D4 | Twill 3/1 | 26 | 20 | 210.54 | 210.54 |

| D5 | Twill 2/2 | 26 | 20 | 210.54 | 210.54 |

| D6 | Plain 1/1 | 26 | 20 | 210.54 | 210.54 |

| D7 | 4 ends Irregular Satin | 26 | 20 | 210.54 | 210.54 |

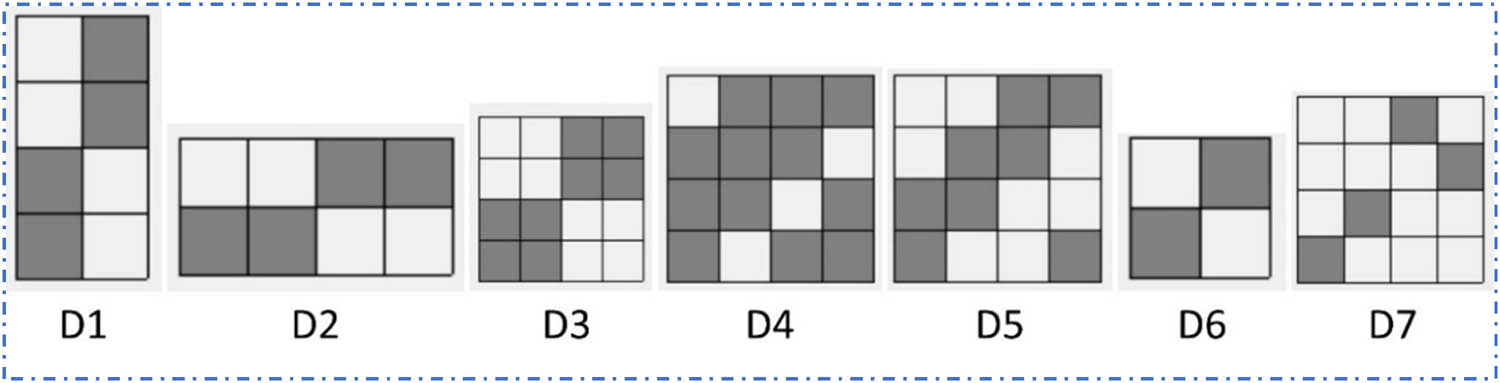

Table 1 describes the specifications of the Jute fabric that has been used throughout the experiments in this study. There are seven different weave structured fabrics used in this study, such as 2/2 Weft Rib, 2/2 Warp Rib, 4/4 Basket weave (Matt), 3/1 Twill, 2/2 Twill, 1/1 Plain, and 4 ends Irregular Satin. In this study, the jute fabrics are designated as D1 through D7, and following the FR treatment, they are referred to as FRD1 through FRD7, respectively. The weave structures are presented in Figure 1.

Fabric weave structures.

2.2 Chemicals and reagents

An organophosphorus-based commercial FR chemical, ITOFLAM CPN, a melamine resin (crosslinking agent) KNITTEX CHN, and phosphoric acid were supplied by a textile factory in India. All chemicals were utilized in their original form.

2.3 Pretreatment of jute fabrics

Prior to implementing the FR treatment, all fabrics were subjected to traditional de-sizing and scouring processes by using SCOUTEX SLC (Detergent) 1 g/L, MASQUOIL (Sequestering agent) 1 g/L, Na2CO3 2 g/L at 90°C for 40 min; the process was applied for four cycles on a Jigger machine. The fabrics were then neutralized with acetic acid 0.5 g/L at 50°C for 20 min, two cycles, and dried at 110°C in the flat-bed dryer.

2.4 Preparation of FR jute fabrics

ITOFLAM CPN was applied on jute fabrics along with a crosslinking agent like melamine resin (KNITTEX CHN) by the pad-dry-cure (2-dip-2-nip) method followed by a laboratory-scale vertical padder. Details of the FR treatment process are described in Table 2. The samples underwent 1 min of drying at 120°C, followed by 2 min of curing at 170°C on a laboratory-scale stenter machine (Mathis, CH-8156, Switzerland).

FR finish treatment process

| Chemicals names | Commercial name of the chemicals | Amount in the recipe (g/L) |

|---|---|---|

| FR chemical | ITOFLAM CPN | 400 |

| Crosslinking agent | KNITTEX CHN | 50 |

| Catalyst | Phosphoric acid (80%) | 20 |

| Pick-up % | — | 75 |

2.5 Assessment of flammability

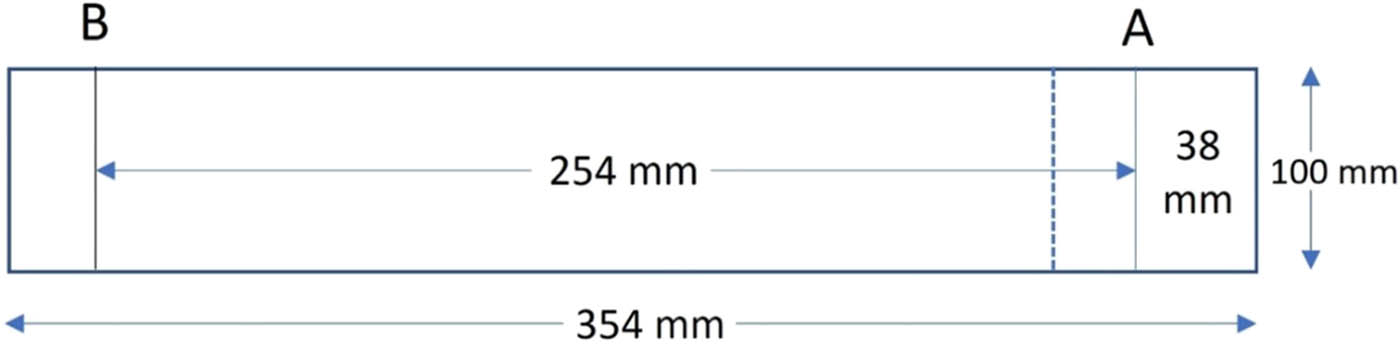

A vertical flammability test method (ASTM D6413) was utilized to evaluate the untreated and FR-treated jute fabrics. The specimen, measuring 305 mm × 70 mm ignited for 12 s at a 90° vertical angle using a gas hob; the flame source was then withdrawn and allowed to continue burning. Subsequently, the flame spread time, afterglow duration, and char length were measured. The char length was measured by folding the specimen in half lengthwise and puncturing with a hook approximately ¼ inch or 6.35 mm from the side and bottom of the specimen and then hanging a 200 g weight on the hook to generate adequate tearing force. The sample is gripped by the corner opposite the hook and weights and then smoothly and steadily lifted until the specimen fully supports the weight. Examine any tears within the burned fabric area and ascertain the distance of the tear as the length of the charring. In accordance with the standard FMVSS 302, the horizontal flammability test was conducted. The dimensions of the sample were 354 mm × 100 mm, and the test measurement was followed according to Figure 2. The horizontal burning test was determined by calculating the burn rate according to equation (1). LOI was determined by following the standard IS 13501, and specimen size was 140 mm × 53 mm. All tests were repeated five times.

Sample specification of horizontal flammability test.

2.6 Analysis of physio-mechanical properties

The tensile strength test and elongation at break were employed to evaluate how the FR finish influenced the physical and mechanical properties of the treated fabrics. The grab method (EN ISO 13934-2; Zwick MTS 1475) was utilized to determine the maximum force in both the tensile strength test and the elongation at the break. All tests were repeated three times, and the error bars were adopted based on standard error calculated on a standard deviation of mean values. The increase in weight of the samples was assessed through equation (2) and represented as a percentage.

where W 1 and W 2 denote the oven-dry weight of the fabric samples prior to and following FR treatments, respectively.

3 Results and discussions

3.1 Determination of flammability

The Jute fabrics listed above were subjected to FR treatment and measured the flame-retardance performance by the vertical and horizontal flammability test and the LOI test.

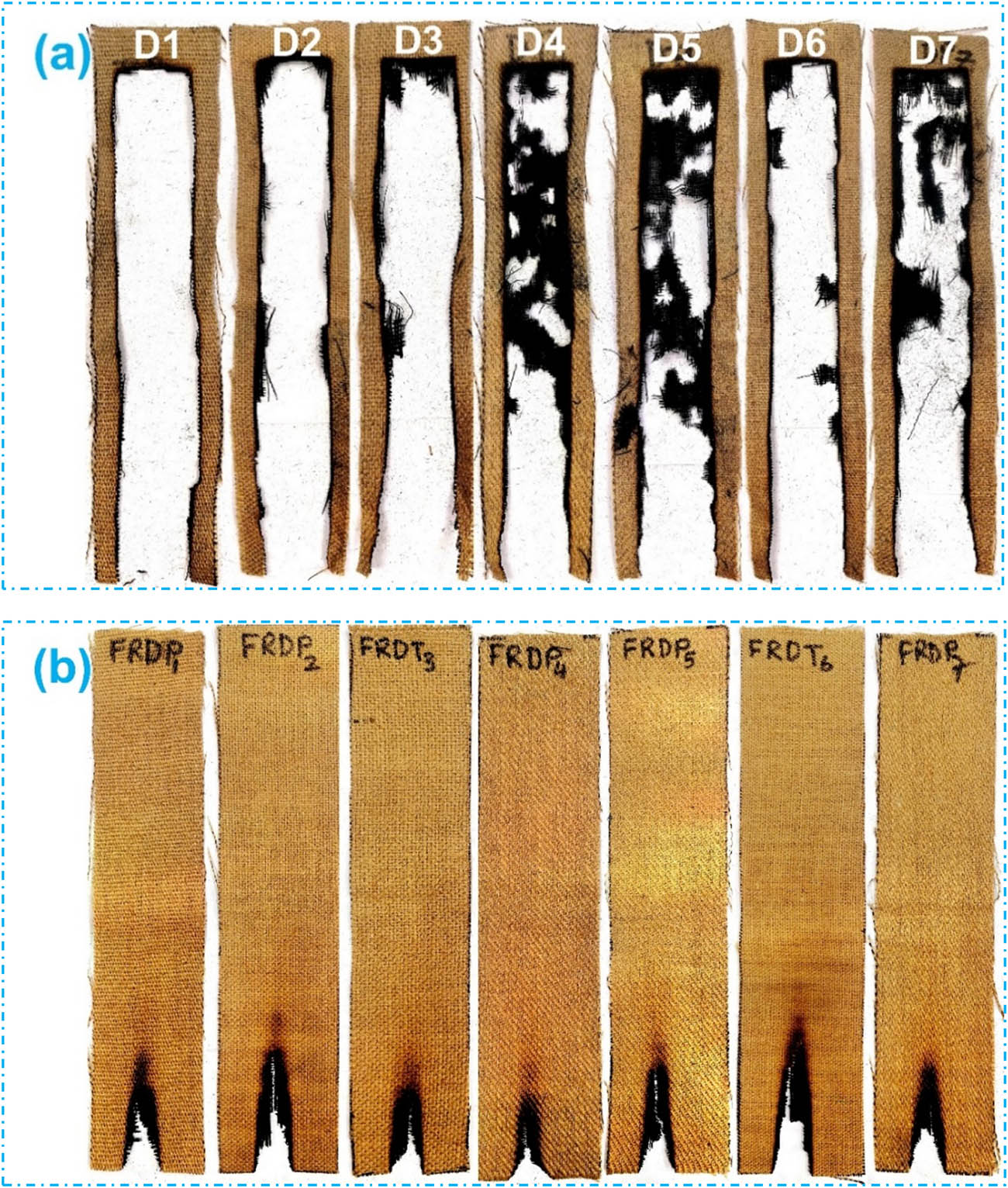

Table 3 displays the findings from the vertical flame test conducted on both untreated and FR-treated jute fabrics. Based on the findings outlined in this table, the untreated fabrics (D1–D7) were completely burnt. The flame-spread time shows a slight difference among the various structured fabrics; however, the highest was found for D7 fabric in both warp and weft directions. The FR-treated fabrics demonstrated effective flame retardancy in regard to flame-spread duration, after-glow duration, and the length of char. After the ignition time, the FR-treated samples showed retardation of the fire and resulted in zero seconds of after-flame and after-glow time and resulted in some char. The least char length of 40 mm was found in the warp direction of the FRD4 fabric, while the maximum was 71 mm for the FRD6 fabric. Similarly, the longest char length (74 mm) in the weft direction was observed in FRD6 fabrics and the lowest (51 mm) in FRD5 fabrics. Images of untreated and FR-treated jute fabric samples after the vertical burning test are shown in Figure 3. These results demonstrate a substantial enhancement in the FR properties of the jute-based materials investigated in this study, satisfying the criteria for the FR capability of decorative fabrics (B1 rating, ≤5 s), thereby corroborating earlier observations [20,26].

Vertical flame test results

| Sample no. | After flame time (s) | Char length (mm) | ||

|---|---|---|---|---|

| Warp | Weft | Warp | Weft | |

| D-1 | 35 | 34 | 305 | 305 |

| FR-D-1 | 0 | 0 | 49 | 53 |

| D-2 | 37 | 35 | 305 | 305 |

| FR-D-2 | 0 | 0 | 61 | 58 |

| D-3 | 35 | 39 | 305 | 305 |

| FR-D-3 | 0 | 0 | 51 | 53 |

| D-4 | 40 | 41 | 305 | 305 |

| FR-D-4 | 0 | 0 | 40 | 59 |

| D-5 | 40 | 41 | 305 | 305 |

| FR-D-5 | 0 | 0 | 53 | 51 |

| D-6 | 37 | 37 | 305 | 305 |

| FR-D-6 | 0 | 0 | 71 | 74 |

| D-7 | 42 | 40 | 305 | 305 |

| FR-D-7 | 0 | 0 | 57 | 63 |

Samples after vertical burning test: (a) untreated and (b) FR-treated jute fabrics.

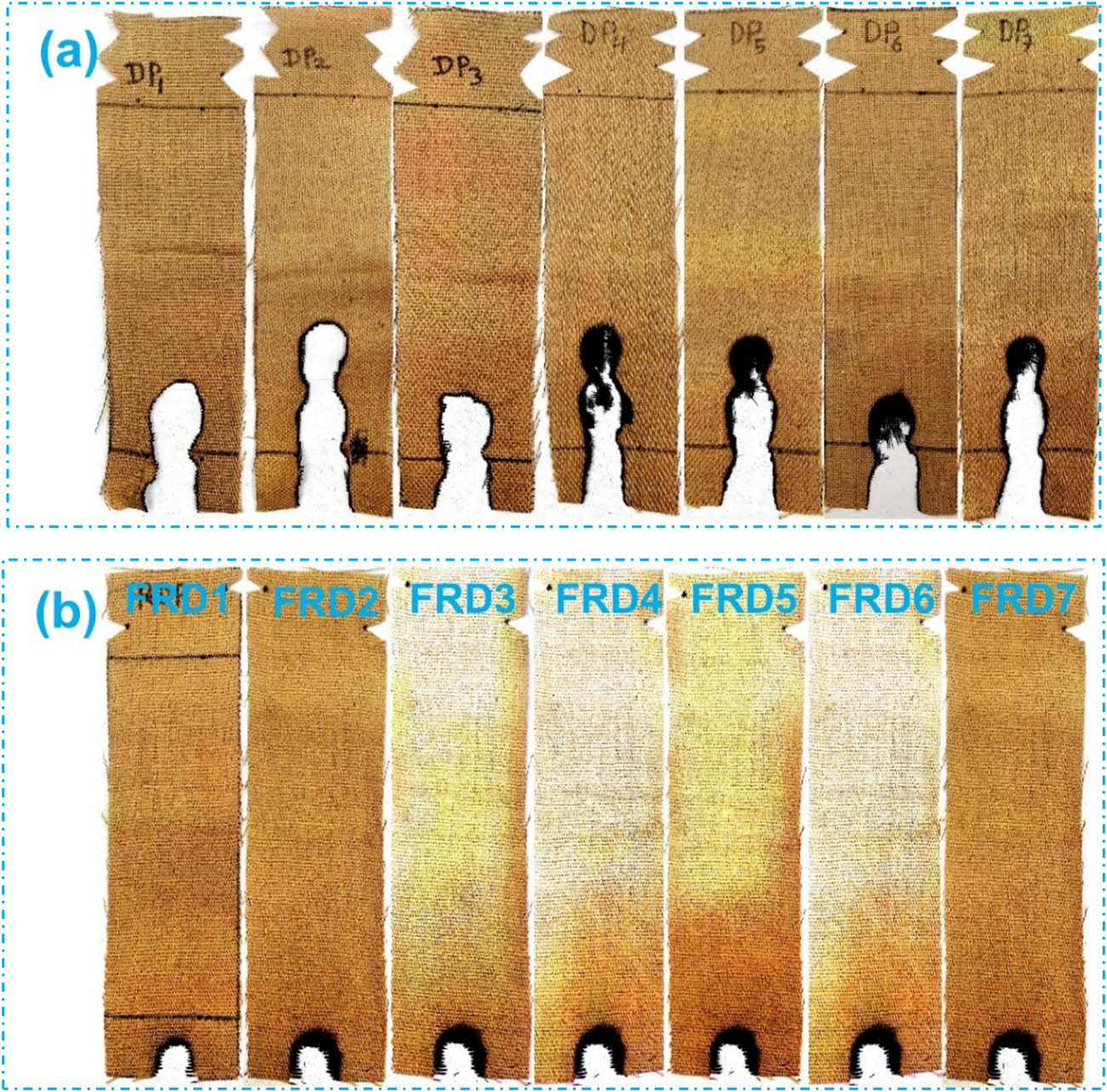

The horizontal burning test is determined by the burn rate (mm/min) of the fabrics after the flame source is removed, and the test results are presented in Table 4. Among the untreated fabrics, the lowest burn rate was reported for the D1 fabric, while the maximum was reported for the D6 fabric. On the other hand, the burn rate was zero on the FR-treated samples. Similarly, the samples after the horizontal burning test for untreated and FR-treated jute fabrics are shown in Figure 4.

Horizontal burning test results

| Sample no. | Burn rate (mm/min) | |

|---|---|---|

| Warp | Weft | |

| D-1 | 37 | 43 |

| FR-D-1 | 0 | 0 |

| D-2 | 56 | 43 |

| FR-D-2 | 0 | 0 |

| D-3 | 46 | 42 |

| FR-D-3 | 0 | 0 |

| D-4 | 40 | 49 |

| FR-D-4 | 0 | 0 |

| D-5 | 56 | 51 |

| FR-D-5 | 0 | 0 |

| D-6 | 65 | 51 |

| FR-D-6 | 0 | 0 |

| D-7 | 41 | 35 |

| FR-D-7 | 0 | 0 |

Samples after horizontal burning test: (a) untreated and (b) FR-treated jute fabrics.

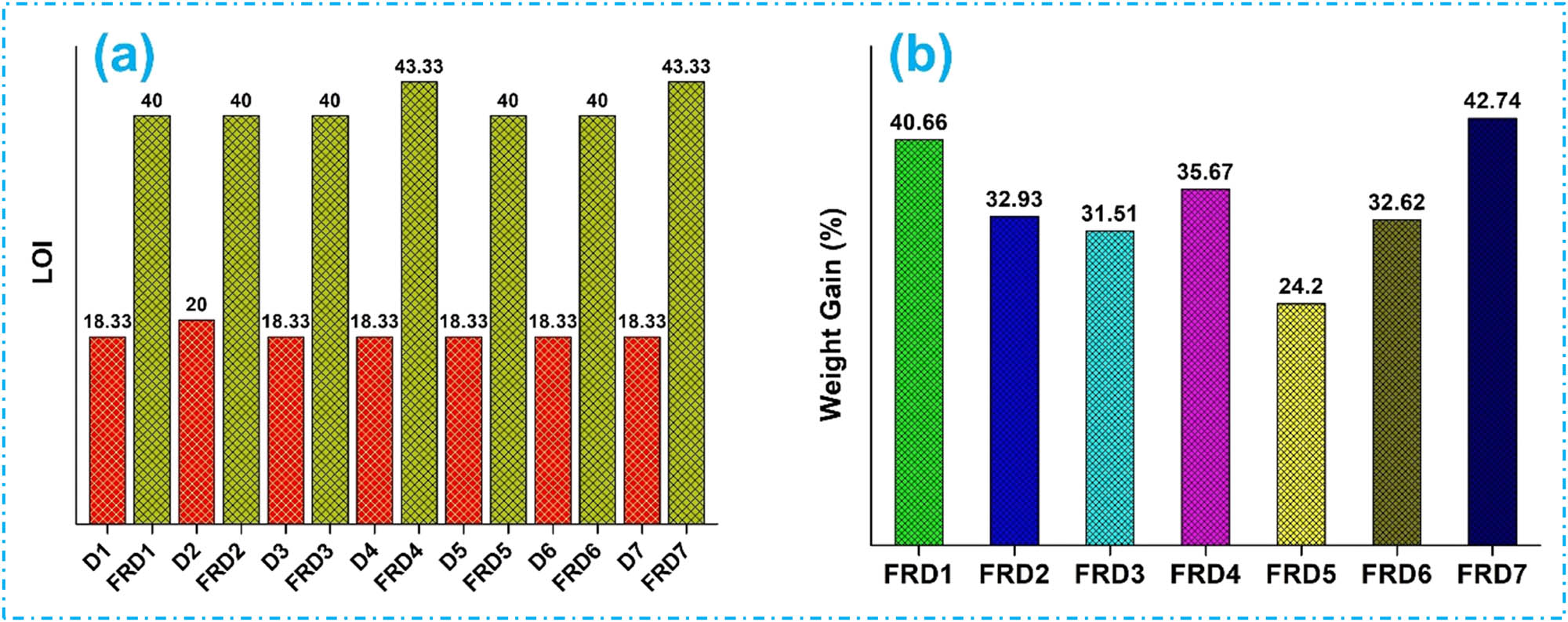

The LOI is an important indicator for determining the flame-retardance property of the fabric samples. Any sample that shows LOI greater than 27 indicates high flame-retardance performance and vice versa. In this study, the LOI and the weight gain percentage after FR treatment on the jute fabrics are shown in Figure 5. The substantial increase in LOI is evident in the samples treated with FR. All samples resulted in LOI 40, and the highest was for FRD4 and FRD7 fabrics. A notable weight gain percentage was also reported after FR treatment for all fabrics; however, the maximum weight gain was 42.74% and the minimum was 24.2% reported for the FRD7 and FRD5 fabrics, respectively. The weight gain variances between the fabrics may be due to the thickness, porosity, compactness, and weave differences of the Jute fabrics. The weight gain parameter is a great indication of increased LOI and improved flame-retardance properties.

(a) LOI and (b) weight gain% of the untreated and FR-treated jute fabrics.

3.2 Physico-mechanical properties analysis

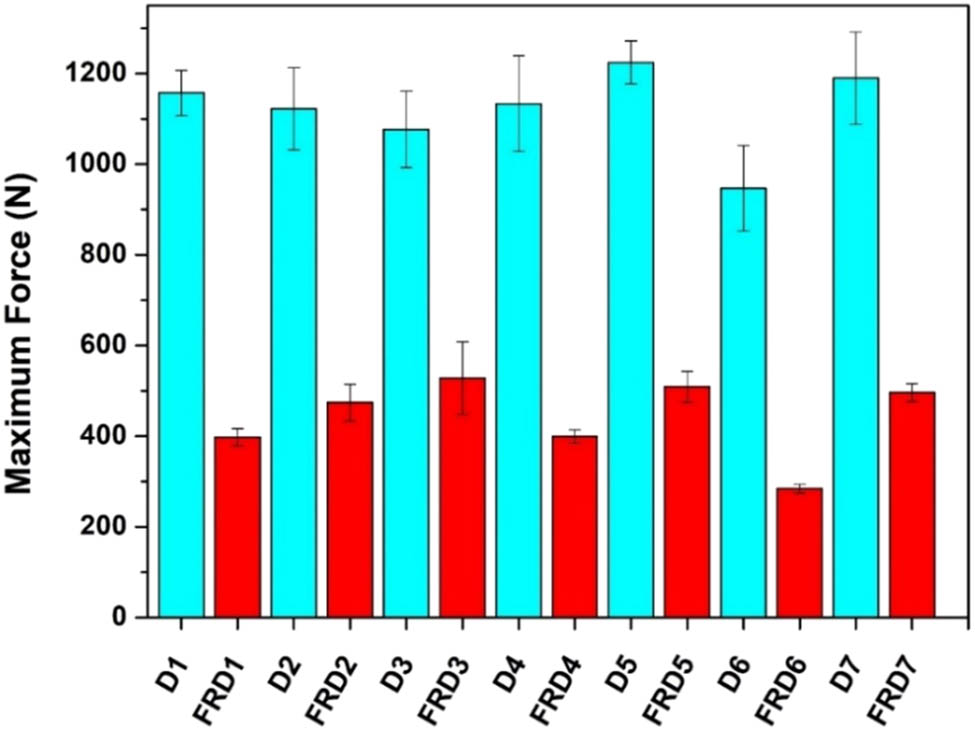

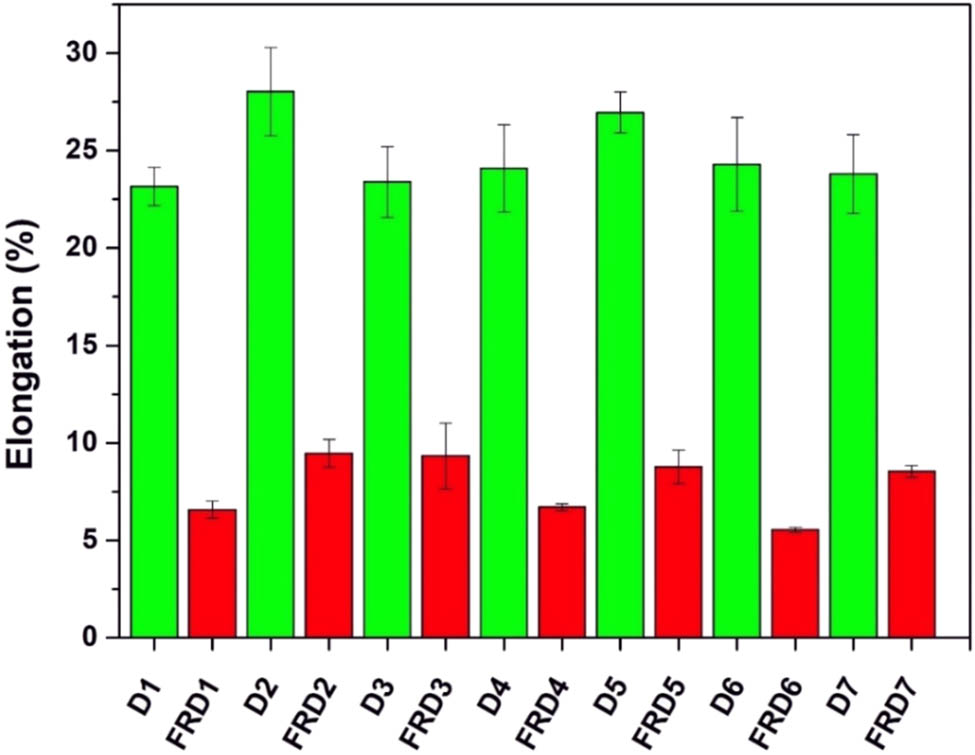

The physico-mechanical properties were determined by means of tensile tests on the untreated and FR-treated jute fabrics. Figure 6 depicts the outcomes of the tensile test. It is evident that there was a substantial reduction in strength following the FR treatment in all samples compared to untreated fabrics. The maximum strength loss of 70% was determined in the FRD6 fabric, and the second highest strength loss of 65% was found in the FRD1 fabric while the least was found at 50% in FRD3 and followed by 57, 58, 58, and 64% in the FRD2, FRD5, FRD7, and FRD4 fabrics, respectively. The elongation at maximum force is illustrated in Figure 7. The elongation percentage at maximum force is also rapidly dropped on the FR-treated fabrics as compared to the untreated samples. The highest loss of elongation was reported at 77% in FRD6 fabrics, while the largest loss was 60% in FRD3, and an almost similar loss was found at 64, 66, 67, and 71% in FRD7, FRD2, FRD5, and FRD1 fabrics, respectively. Compared to untreated fabrics, the earlier study also supports the aforementioned observations regarding the decline in physiological and mechanical properties [23]. This reduction in tensile strength and percentage of elongation can be attributed to the inclusion of a crosslinking agent in the FR treatment. Such findings coincide with previous research [23,27]. This occurs because the yarns stick together as a result of the cross-linking agent in the FR finish, restricting the mobility of yarns and consequently decreasing their tensile strength [28]. The reduction in elongation observed in the FR-treated fabrics may be due to the uneven crimp in each yarn set resulting from the dense weave structures used in jute fabrics. Moreover, enhanced cohesion between fibers and yarns can lead to reduced elongation in FR-treated fabrics, which aligns with findings from prior research [23].

Tensile strength of untreated and FR-treated fabrics.

Elongation% of control and FR-treated fabrics.

4 Conclusion

This research aims to explore the potential for enhancing the FR properties of jute fabric by employing an organophosphorus FR chemical. It was observed that upon removal of the flame source, the Jute fabrics extinguished themselves without exhibiting flame spread or after-glow. Significant improvement in the thermal stability and FR ability of the jute fabrics was achieved despite a substantial loss of mechanical strength. The char-forming ability of the FR-treated fabrics improved as found during the thermal degradation and combustion stage. Among the fabric weaves used in this study, the FR performance was achieved almost the same in all fabrics except D6 plain weave fabric. According to the specified findings such as the char length after the vertical flammability test and the loss of tensile strength, the FRD6 fabric leads to the worst performance. Approximately equivalent findings of the above results were observed on FRD3 and FRD5 fabrics with a relatively low loss of mechanical strength. It is assumed that the use of melamine-based cross-linking agents with the FR chemical leads to poor physico-mechanical properties and high free-formaldehyde content on the FR-treated fabrics. It has the capability to establish bonds between the FR agent and cellulose; on the other hand, it makes the FR-treated fabric stiffer and promotes poor mechanical and hand properties. These substances affect the pyrolysis process by inhibiting the formation of levoglucosan and flammable vapors, enhancing char production and thereby functioning as FRs for cellulose [29].

To conclude the observation, based on the results of the flammability test, all weave designs in this study show negligible differences. It is observed that fire retardant performance for different weave structures of jute fabrics does not vary widely and no major changes are indicated. According to the observation in this work, FR properties or LOI value or char length, etc. are not truly much dependent on differences in the weave structure of jute-based fabric. Propagation of fire is more of a chemical functionality depending on its composition, finishes, coating that affects its thermal degradation and decomposition, oxidative combustion, etc., having a minor dependency on physical structure. However, among the weaves applied in this study, FRD6 (plain weave) fabrics, the performance is poor, while FRD3 (matt weave) and FRD5 (2/2 twill weave) fabrics have better performances. This may also be correlated with the thickness of the fabric and the percentage of weight gained after FR treatment. Thus, this kind of FR chemical finish can be used for applications where mechanical properties are not the main concern but FR functions. Matt weave and 2/2 twill are suggested to be used for fabric manufacturing as they present better properties than other types of weaves.

Acknowledgments

We would like to thank the Janata Jute Mills Ltd., Bangladesh for their support in manufacturing the jute fabrics.

-

Funding information: The authors state no funding is involved.

-

Author contributions: All authors contributed to the study conception and design. Material preparation was performed by Most. Setara Begum, Ayub Nabi Khan, and Rimvydas Milašius; data collection, and analysis were performed by Most. Setara Begum, Michael Hummel, Manjeet Singh Parmar, and Rimvydas Milašius. The first draft of the manuscript was written by Most Setara Begum, reviewed and supervised by Michael Hummel and Rimvydas Milašius. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data sets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Basak, R. K., Saha, S. G., Sarkar, A. K., Saha, M., Das, N. N., Mukherjee, A. K. (1993). Thermal properties of jute constituents and flame retardant jute fabrics. Textile Research Journal, 63(11), 656–666.10.1177/004051759306301107Search in Google Scholar

[2] Samanta, A. K., Biswas, S. K., Bagchi, A., Bhattacharjee, R. (2011). Semi-durable fire retardant finishing of jute fabric and its thermal behaviour. Journal of the Institution of Engineers, 91(1), 18–20.Search in Google Scholar

[3] Samanta, A. K., Bagchi, A., Biswas, S. K. (2011). Fire retardant finishing of jute fabric and its thermal behaviour using phosphorous and nitrogen based compound. Journal of Polymer Materials, 28(2), 149–169.Search in Google Scholar

[4] Weil, E. D., Levchik, S. V. (2008). Flame retardants in commercial use or development for textiles. Journal of Fire Sciences, 26(3), 243–281.10.1177/0734904108089485Search in Google Scholar

[5] Samanta, A. K. (1995). Chemical finishing of jute and jute blended textiles. Colourage, 42, 37–42.Search in Google Scholar

[6] Schindler, W. D., Hauser, P. J. (2004). Chemical finishing of textiles. Elsevier, CRC Press, Boca Raton, FL, USA.10.1201/9781439823477Search in Google Scholar

[7] Roy Choudhury, A. K. (2017). Flame- and fire-retardant finishes. Principles of textile finishing, Woodhead Publishing, Elsevier, United Kingdom, pp. 195–244. 10.1016/B978-0-08-100646-7.00008-4Search in Google Scholar

[8] Pandey, S. N., Day, A., Mathew, M. D. (1993). Thermal analysis of chemically treated jute fibers. Textile Research Journal, 63(3), 143–150.10.1177/004051759306300303Search in Google Scholar

[9] Roy, P. K., Mukhopadhyay, S., Butola, B. S. (2018). A study on durable flame retardancy of jute. Journal of Natural Fibers, 15(4), 483–495.10.1080/15440478.2015.1029190Search in Google Scholar

[10] Yusuf, M. (2018). A review on flame retardant textile finishing: current and future trends. Current Smart Materials, 3(2), 99–108.10.2174/2405465803666180703110858Search in Google Scholar

[11] Mehta, R. D., Hoque, A. M. (1982). Flammability of metal-cation-exchanged jute fabrics. Textile Research Journal, 52(9), 607–608.10.1177/004051758205200909Search in Google Scholar

[12] Dorez, G., Ferry, L., Sonnier, R., Taguet, A., Lopez-Cuesta, J. M. (2014). Effect of cellulose, hemicellulose and lignin contents on pyrolysis and combustion of natural fibers. Journal of Analytical and Applied Pyrolysis, 107, 323–331.10.1016/j.jaap.2014.03.017Search in Google Scholar

[13] Reddy, K. M., Feris, K., Bell, J., Wingett, D. G., Hanley, C., Punnoose, A. (2007). Selective toxicity of zinc oxide nanoparticles to prokaryotic and eukaryotic systems. Applied Physics Letters, 90(21), 213902.10.1063/1.2742324Search in Google Scholar PubMed PubMed Central

[14] Begum, M. S., Kader, A., Milašius, R. (2023). Flame-retardance functionalization of jute and jute-cotton fabrics. Polymers (Basel), 15(11), 2563.10.3390/polym15112563Search in Google Scholar PubMed PubMed Central

[15] Begum, S., Kader, A., Milašius, R. (2022). The effect of flame-retardant finish on jute and jute-cotton fabrics. AUTEX 2022 Conference Proceedings (21st World Textile Conference) (pp. 20–24).Search in Google Scholar

[16] Basak, S., Samanta, K. K., Chattopadhyay, S. K., Das, S., Narkar, R., Dsouza, C., et al. (2014). Flame retardant and antimicrobial jute textile using sodium metasilicate nonahydrate. Polish Journal of Chemical Technology, 16(2), 106–113.10.2478/pjct-2014-0039Search in Google Scholar

[17] Samanta, A. K., Bhattacharya, K. (2015). Simultaneous dyeing and fire-retardant finishing of jute fabric using an acid dye and selective F - R finishing chemicals. Textiles and Light Industrial Science and Technology, 4(1), 1–16.10.12783/tlist.2015.0401.01Search in Google Scholar

[18] Repon, M. R., Siddiquee, N. A., Jalil, M. A., Mikučionienė, D., Karim, M. R., Islam, T. (2021). Flame retardancy enhancement of jute fabric using chemical treatment. Tekstilec, 64(1), 70–80.10.14502/Tekstilec2021.64.70-80Search in Google Scholar

[19] Samanta, A. K., Bhattacharyya, R., Jose, S., Basu, G., Chowdhury, R. (2017). Fire retardant finish of jute fabric with nano zinc oxide. Cellulose, 24(2), 1143–1157.10.1007/s10570-016-1171-zSearch in Google Scholar

[20] Li, S. Q., Tang, R. C., Yu, C. B. (2022). Flame retardant treatment of jute fabric with chitosan and sodium alginate. Polymer Degradation and Stability, 196(109826), 1–6.10.1016/j.polymdegradstab.2022.109826Search in Google Scholar

[21] Mikučionienė, D., Milašiūtė, L., Milašius, R. (2014). Influence of knits structure on flammability and comfortability. Autex Research Journal, 14(4), 226–232.10.2478/aut-2014-0022Search in Google Scholar

[22] Mishra, R., Jamshaid, H., Basra, S. A., Jiang, G., Gao, Z., Ma, P., et al. (2020). Effect of stitch characteristics on flammability and thermo-physiological comfort properties of knitted fabrics. Fibers and Polymers, 21(11), 2652–2663.10.1007/s12221-020-1381-8Search in Google Scholar

[23] Tang, K. P. M., Kan, C. W., Fan, J. T., Tso, S. L. (2017). Effect of softener and wetting agent on improving the flammability, comfort, and mechanical properties of flame-retardant finished cotton fabric. Cellulose, 24(6), 2619–2634.10.1007/s10570-017-1268-zSearch in Google Scholar

[24] Tang, K. P. M., Kan, C. W., Fan, J. T., Sarkar, M. K., Tso, S. L. (2017). Flammability, comfort and mechanical properties of a novel fabric structure: plant-structured fabric. Cellulose, 24(9), 4017–4031.10.1007/s10570-017-1372-0Search in Google Scholar

[25] Hawas, H. S. (2017). Effect of some construction elements on the flammability of upholstery fabrics. International Design Journal, 7(4), 77–83.10.12816/0044478Search in Google Scholar

[26] GB/T 17591–2006. (2006). Flame retardant fabrics, China’s General Administration of Quality Supervision, Inspection and Quarantine and Standardization Administration of China, Beijing.Search in Google Scholar

[27] Lam, Y. L., Kan, C. W., Yuen, C. W. M. (2011). Effect of titanium dioxide on the flame-retardant finishing of cotton fabric. Journal of Applied Polymer Science, 121(1), 267–278.10.1002/app.33618Search in Google Scholar

[28] Saville, B. P. (1999). Physical testing of textiles, Woodhead Publishing, Cambridge, United Kingdom.10.1533/9781845690151Search in Google Scholar

[29] Gaan, S., Sun, G. (2009). Effect of nitrogen additives on thermal decomposition of cotton. Journal of Analytical and Applied Pyrolysis, 84(1), 108–115.10.1016/j.jaap.2008.12.004Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry