Abstract

In this study, ultrasound energy was applied to assist the alkali hydrolysis of polyethylene terephthalate (PET) fabric, and then, the results were compared with those of the mechanical oscillating method, which was used as the control. The effects of various factors such as the sodium hydroxide concentration, the dosage of dodecyl dimethyl benzyl ammonium chloride (DDBAC), and the frequency on the weight loss of the PET fabrics were systematically investigated. The surface appearance and microstructures of the treated fibers with different methods were analyzed using a scanning electron microscope and X-ray diffraction, respectively. The results showed that DDBAC played a prominent accelerating role in the hydrolysis of the PET polymer, and the frequency had a great influence on the weight loss of the PET fabric. Ultrasound with a frequency of 60 kHz showed a similar decomposition rate as the control, resulting in similar weight loss, which was the highest value among the three frequencies (20, 60, and 80 kHz). In addition, the application of ultrasonic energy led to more pits on the fiber surface, a smaller average grain size, and decreased crystallinity of the treated fibers, while the mechanical oscillating method resulted in slightly increased crystallinity. By comparing the K/S value of the dyed fabrics with two commercial disperse dyes, we found that the treatment method had no obvious correlation with the color depth of the treated fabric.

1 Introduction

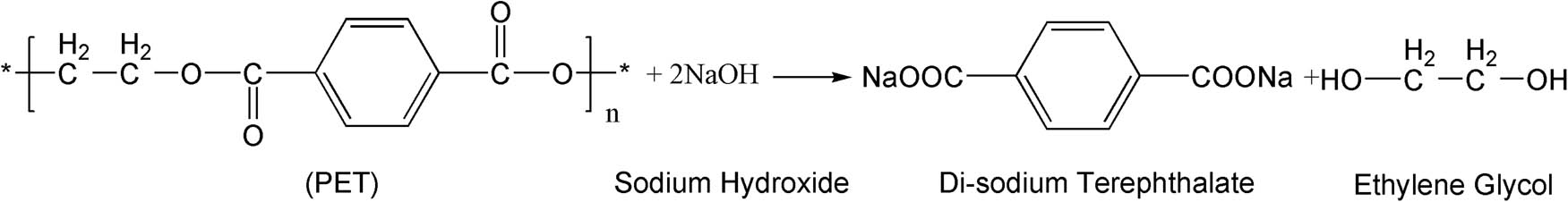

Alkali treatment of polyester fabric will cause the reaction between the hydroxyl ions in solution and the electron-deficient carbonyl carbon in the polymer chain, resulting in the hydrolysis of the ester groups into the carboxyl and hydroxyl end-groups (Scheme 1). As a result, the weight of the fiber is lost, the diameter of the fibers is reduced, and the surface and properties of the fiber are also modified. It is universally acknowledged that the undesirable characteristics of polyethylene terephthalate (PET), such as its hydrophobicity, the optical effects of its smooth surface, and its rigid handle, will be improved, giving it good drapability, luster, and soil release properties [1,2,3]. Therefore, the alkaline treatment of polyester fabric has often been referred to as silk-like finishing, which has been widely adopted in the textile industry. Reports have shown that the static charge generation and pilling tendency will be reduced, particularly when the degree of weight loss is controlled between 15 and 25% [4].

Alkaline hydrolysis reaction of PET fiber.

Numerous studies regarding the alkali hydrolysis of polyester fibers have been published, which have mainly focused on the changes in structure and properties of PET fibers, mechanism, kinetics, and the effect of conditions and additives [5,6,7,8,9,10,11]. In addition, by activating the surface of the PET fabrics through alkali hydrolysis, polyester fibers have been simultaneously subjected to various functional finishing treatments such as antimicrobial and UV protection with TiO2 nanoparticles and silk-fibroin coatings for increased hydrophilic properties [12,13]. Lee [14] and Cho and Kim [15] constructed a superhydrophobic surface by introducing nano-roughness to the surface of the polyester fabric by using alkaline hydrolysis. Yang et al. found that alkali-treated PET nanofibers, which are negatively charged due to the carboxyl end groups, can have remarkable antibacterial properties [16]. Recently, the alkaline hydrolysis method has gained increasing attention in the field of chemical recycling of PET fabrics because of the freedom of organic solvents and tolerance for PET mixed waste streams including copolymers [17,18].

In order to reduce the concentration of alkali, treating time and temperature, the phase transfer agent (PTA) was applied to facilitate PET alkaline hydrolysis in milder reaction conditions with temperatures between 70 and 95°C and atmospheric pressure. Kosmidis et al. used trioctylmethylammonium bromide as a PTA in alkaline hydrolysis [19]. Subsequently, other PTAs including quaternary phosphonium, ammonium salts, and tetrabutyl ammonium iodide were reported for PET alkaline hydrolysis [20,21,22]. Besides, ultrasound has been reported as alternative energy for PET alkaline hydrolysis, which could enhance the diffusion of water into the PET matrix by causing PET structural relaxation, resulting in higher reaction rates than those exhibited for traditional heating process alone [23]. The kinetic characteristics of alkali hydrolysis between with and without ultrasound were compared with each other [24,25,26]. The results indicated that the ultrasound did not alter the intrinsic mechanism and activation energy of the alkaline hydrolysis reaction, and the enhancement of reaction rate was attributed to the increased number of collisions between PET and the alkali molecules produced by the ultrasound-generated cavitation.

Until now, no detailed investigation has been conducted on the effect of ultrasonic application on the microstructure and properties of treated polyester fibers. In this study, PET fabrics were subjected to ultrasound-assisted alkaline treatment with varied frequencies. We then explored the effect of alkali concentration and ultrasonic frequency on the weight loss of the PET fabric in the presence of varied concentrations of dodecyl dimethyl benzyl ammonium chloride (DDBAC). Under a chosen condition, the weight loss of ultrasound-assisted PET fibers treated with different frequencies was compared with that of the mechanical oscillation method, which was used as the control treatment. In addition, the appearance of the fiber surface, the bulk microstructure, and the dyeing properties of PET treated using different methods were investigated and compared.

2 Experimental

2.1 Chemicals and material

About 100% PET woven fabric with a warp and weft density of 21 × 16 yarns/cm was used in this article and the fabric weight of 205 g/m2. The warp was of the same type of set textured yarn (96 filament/300 Denier) as the weft. The PET fabric was stabilized with hot air.

Two commercial disperse dyes, C.I. Disperse Blue 79 (200%) and C.I. Disperse Red 167 (100%), were provided by Zhejiang Runtu Chemical Co., Ltd. (Shaoxing, Zhejiang, China). A cationic surfactant, DDBAC used as the accelerating agent (52% active ingredient), was provided by Jiangsu Haian Petroleum Chemical Factory (Haian, Jiangsu, China). Sodium hydroxide and acetic acid were purchased from Aladdin Reagent Co., Ltd (Shanghai, China) and were of analytical reagent grade.

2.2 Alkali treatment process

Precisely weighted polyester fabric (±0.1 mg) was placed in a bath containing a certain concentration of sodium hydroxide with and without the addition of an accelerating agent (DDBAC) under a liquor ratio of 30:1. This alkali treatment was performed using an SCQ-9201-type numerical control ultrasonic cleaning machine (Shanghai Shengyan Ultrasonic Instrument Co., Ltd., Shanghai, China) or an L-12C/L-24A-1 mechanical oscillating dyeing machine (Xiamen Rapid Precision Machinery Co., Ltd., Xiamen, China). When the temperature was increased to 95°C, the PET fabric was placed in the bath and treated for a predetermined period at a constant temperature. The treated samples were immediately and thoroughly washed with water for complete alkali removal. The final washings were assessed with pH paper until neutral. Finally, the samples were dried.

2.3 Measurement of percentage weight loss

The treated PET samples were dried in an oven at 140°C for 30 min and then cooled in a P2O5 desiccator to room temperature. Then, the dried sample was accurately weighed. The weight loss of PET fabric was calculated according to the following formula:

where W 1 and W 2 denote the weights of the control and treated samples, respectively.

2.4 Dyeing procedure

The PET fabrics was dyed in the dyebath containing 1% (o.w.f) disperse dyes and 1 mL/L acetic acid with a liquor ratio of 30:1. Dyeing was carried out in a laboratory dyeing machine (Rapid, China), and the temperature of dyebath was raised from 70 to 130°C at a rate of 1°C/min and held for 45 min, and then reduced to 80°C. The dyed polyester fabrics were cleaned with an aqueous solution containing sodium hydroxide (2 g/L) and disodium hydrosulfite (4 g/L) at 85°C using a liquor ratio of 30:1 for 15 min, and then rinsed [27].

2.5 Measurement of the color depth

The reflectance of the dyed PET fabric was recorded on a Datacolor SF 600 spectrophotometer (Datacolor Corporation, Lawrenceville, NJ, USA) under illuminant D65 via a 10° standard observer. The color depth of dyed fabric (K/S value) was calculated according to the Kubelka‒Munk equation:

where R is the decimal fraction of the reflectance of dyed fabric, K is the absorption coefficient, and S is the scattering coefficient.

2.6 Surface observations of the treated fiber

The fibers were attached to the sample table and subjected to gold spray treatment for 140 s. The surface appearance of the alkali-treated fibers was observed by an SU 3800 scanning electron microscope (SEM [Hitachi Production Co., Ltd, Tokyo, Japan]) at a scanning voltage of 10 kV, a temperature of 25°C, and a relative humidity of 65%.

2.7 X-Ray diffraction (XRD) determination

The warp yarn was taken from the alkali-treated fabric and cut into a powder. The XRD patterns of the fiber powder were collected on Rigaku D/max 2550 VB/PC X-ray diffractometer (Rigaku Company, Tokyo, Japan) under Ni-filtered Cu‒Kα (40 kV, 40 mA) radiation at a scanning speed of 5°/min with a step width 2θ of 0.026° and a scanning angle of 5–70°.

3 Results and discussion

3.1 Effect of treatment conditions

By varying the concentrations of the alkali and the accelerating agent (DDBAC), ultrasound-assisted alkali treatment was performed under 60 kHz at 95°C for 45 min, and the weight loss of the PET fabrics was measured, as shown in Figure 1. The results demonstrated that the weight loss of the PET fabrics was linearly proportional to the alkali dosage, which was consistent with the quantitative relationship in the reaction between PET and sodium hydroxide. With increasing concentration of accelerating agent (DDBAC), the slope of the linear function between weight loss and alkali dosage was enhanced. As the concentration increased to 3 g/L, the promotion of the decomposition rate became prominent, after which the degree of increase started to decrease. Therefore, 25 g/L of NaOH and 3 g/L of DDBAC were chosen to perform the subsequent studies.

The effect of alkali dosage on the weight loss of the PET fabric at different concentrations of accelerating agent.

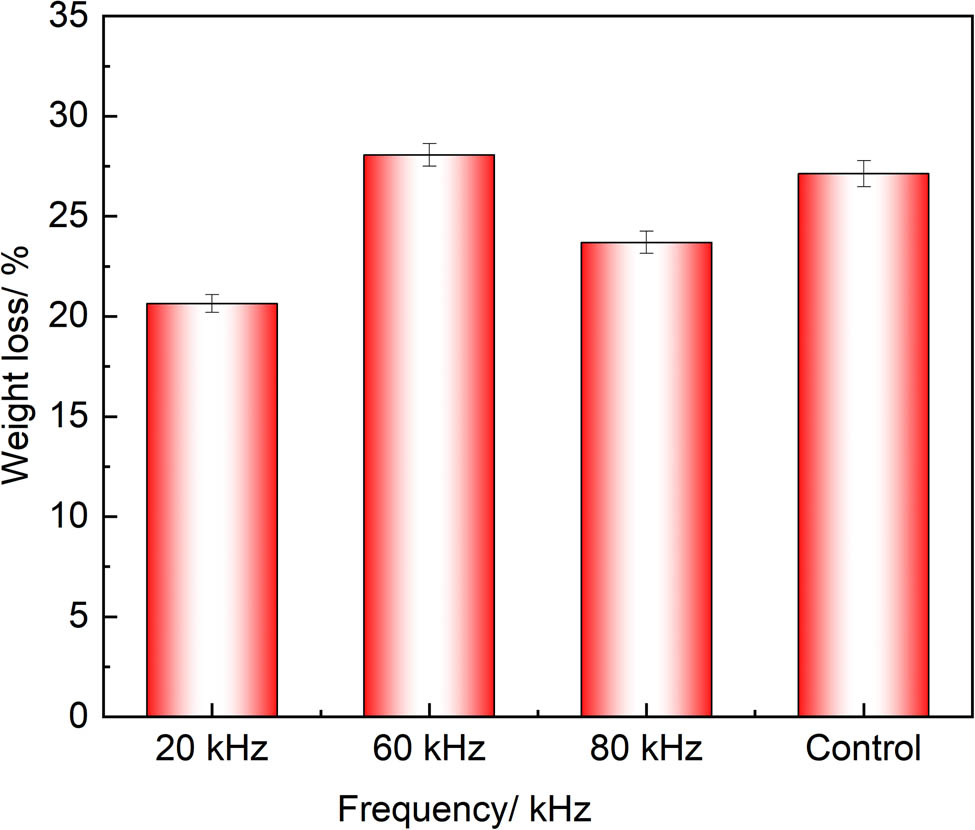

Ultrasound-generated transient cavitation will vary with the frequency, which tends to affect the alkaline hydrolysis of PET. At the same temperature as above (95°C), ultrasound-assisted alkali treatment of the PET fabric was performed for 45 min under different frequencies, and the results were compared with the control treatment, as shown in Figure 2.

Weight loss values of the PET fabrics resulting from different frequencies and the control treatment.

The results showed that the ultrasound frequency had a great effect on the hydrolysis rate of PET fibers, and the weight loss of the PET fabrics decreased in the following order of 60 kHz > 80 kHz > 20 kHz, with values of 28.07, 23.70, and 20.63%, respectively. Generally, the higher the ultrasonic frequency, the greater the cavitation threshold. Low-frequency ultrasound often produces a small number of large bubbles, as well as a strong blasting force. By contrast, high-frequency ultrasound will generate a greater number of smaller holes, resulting in a reduced blasting force and better permeability. While Paliwal et al. [23] demonstrated that the application of ultrasound was not able to alter the hydrolysis mechanism or reaction activation energy of PET polymer, the enhancement of the decomposition rate was found to originate from the increase in the number of collisions between PET and alkali molecules, which was caused by ultrasonic cavitation. The above results indicated that a moderate ultrasound frequency was more effective for increasing collisions between PET and alkali molecules, resulting in a greater PET polymer decomposition rate than under other ultrasound frequencies. This could be attributed to there being a reasonable number of bubbles, as well as a suitable blasting force and permeability as using a moderate ultrasound frequency. By using the control method, a similar weight loss (27.13%) as for the 60 kHz condition was obtained. Hence, an additional investigation was performed to determine the dependence of hydrolysis of the PET polymer on time during ultrasound-assisted and mechanical oscillating treatments, and the results are presented in Figure 3.

Dependence of weight loss of the polyester fabric on the treatment time.

With increasing time, the weight loss values of the two treatment methods almost grew in parallel with each other. This indicated that ultrasound-assisted alkali treatment under 60 kHz produced a similar frequency of collisions between PET chain and alkali molecules as the control, resulting in a similar PET polymer decomposition rate.

3.2 Surface appearance of the PET fibers

An SEM was used to observe the surface appearance of the treated PET fibers with different ultrasound frequencies, which were then compared with the control and untreated PET fibers, and the results are presented in Figure 4. Except for the frequency, the other conditions were the same (i.e., 95°C, 45 min, 25 g/L of NaOH, and 3 g/L of DDBAC).

SEM images of the PET fibers: (a) untreated, (b) control, (c) 20 kHz, (d) 60 kHz, and (e) 80 kHz.

It was found that the untreated PET fibers have a smooth surface and a cylindrical shape, as shown in Figure 4(a). After hydrolysis, many pits with varied sizes were observed on the PET fiber surfaces, and the diameter of fibers became obviously smaller. The appearance of pits was caused by the different decomposition rates of the PET chains within the crystal and amorphous regions of fibers. By comparing the SEM graphs of treated fibers by the different methods, a slight difference in the surface appearance of the PET fibers was found. The number of pits in the ultrasound-assisted treated fibers was slightly greater than that in the control. This was possibly attributed to the higher diffusion of alkali into the amorphous regions of the PET fiber under the application of ultrasound, compared with the mechanical oscillating method. With increasing frequency, the density of pits on the fiber surface appeared to increase, which derived from the enhancement of penetration abilities of alkali, where the ultrasound at 80 kHz had the highest permeability and produced the greatest density of pits.

3.3 XRD analysis

Figure 5 shows the XRD analysis results for the untreated and treated PET fibers by the different methods under the same conditions (25 g/L of NaOH and 3 g/L of DDBAC at 95°C for 45 min).

XRD curves for the untreated and treated PET fibers.

Figure 5 shows that the treatment method had no effect on the crystal structure of the PET fibers, and each treated fiber presented diffraction peaks at the same positions as the untreated fibers, at 17.60°, 22.62°, and 25.69°. Using the multi-peak fitting method, the parameters of the crystal structures of the PET fibers were calculated, which are listed in Table 1. We found that the alkaline treatment method affected the crystallinity of the fibers. Compared with the untreated fibers, the application of ultrasound produced a slight decrease in crystallinity and average grain size, while the control method resulted in a slight increase in crystallinity and average grain size. The result regarding the change of crystallinity after ultrasonic treatment was consistent with that revealed by Peng et al. and Wang et al in studies on the ultrasonic treatment of wool and cellulose, respectively [28,29]. It was illustrated that the ultrasonic energy disrupted the orderly arrangement of polymer chains, and relatively low frequencies such as 20 and 60 kHz led to lower crystallinity than 80 kHz, due to a stronger blasting force. The phenomenon that the crystallinity of the PET fibers was enhanced by the mechanical oscillation method was similar to the results obtained by Tavanai and Niu using a regular shaking bath. This was due to the faster decomposition of the polymer in the amorphous region of the PET fibers than in the crystal region [1,5].

Crystallization parameters of the PET fibers

| Treating methods | Peak parameters | Peak height (S−1) | Half-peak width (°) | Integrated intensity | Grain size (Å) | Crystallinity (%) |

|---|---|---|---|---|---|---|

| Untreated fibers | 010 | 2,380 | 2.07 | 268,719 | 39 | 49.78 |

| 110 | 1,322 | 1.94 | 139,992 | 42 | ||

| 100 | 2,189 | 1.90 | 188,249 | 44 | ||

| Control | 010 | 2,322 | 2.62 | 309,357 | 31 | 52.51 |

| 110 | 463 | 1.26 | 23,679 | 66 | ||

| 100 | 2,261 | 1.98 | 181,742 | 42 | ||

| 20 kHz | 010 | 1,196 | 1.56 | 75,925 | 52 | 44.46 |

| 110 | 1,232 | 3.14 | 157,133 | 26 | ||

| 100 | 2,097 | 2.34 | 224,400 | 35 | ||

| 60 kHz | 010 | 984 | 1.69 | 94,808 | 48 | 43.78 |

| 110 | 1,090 | 2.75 | 173,895 | 30 | ||

| 100 | 1,607 | 2.50 | 234,762 | 33 | ||

| 80 kHz | 010 | 1,108 | 2.26 | 122,547 | 36 | 46.47 |

| 110 | 698 | 2.05 | 74,810 | 40 | ||

| 100 | 1,017 | 2.54 | 151,910 | 32 |

3.4 Comparison of color depth after dyeing

Two commercial disperse dyes, namely, C.I. Disperse Red 167 (100%) and C.I. Disperse Blue 79 (200%), were used to dye the treated PET fabrics in a bath containing 25 g/L of NaOH and 3 g/L of DDBAC at 95°C for 45 min. The absorption spectral curves reflecting the relationship between the K/S value of the dyed fabrics and the wavelength are shown in Figure 6.

Absorption spectral curves of the dyed fabric in terms of K/S values: (a) C.I. Disperse Red 167 and (b) C.I. Disperse Blue 79.

For each of the dyes, the K/S values of the dyed PET fabric varied slightly with the treatment method, but no obvious correlation was found between the color yield and the treatment method. Generally, the crystallinity of the fibers will affect dye uptake because dyes will always diffuse into the amorphous regions in fibers. The above results demonstrated that the microstructure changes resulting from the treatment methods had no prominent effect on the color yield of the dyed fabric. In the case of red dye, the ultrasound-assisted treated fibers at 60 kHz obtained the highest K/S value, while the control had the lowest value. However, for the blue dye, the control had a similar color depth as the fibers treated at 80 kHz, which was the highest value among the three ultrasound-assisted treated fibers. This was possibly because other than crystallinity, other factors such as weight loss, orientation degree of the polymer, and surface appearance possibly influenced the color depth.

4 Conclusions

The ultrasound-assisted alkali treatment of PET fabric was investigated in terms of weight loss of PET fabric, by varying the concentration of alkali, dosage of DDBAC, frequency, and treatment time, with the mechanical oscillating method used as the control. The results showed that DDBAC had a great accelerating effect on the hydrolysis of the PET polymer, and the weight loss varied with changes in frequency. The ultrasound-assisted treatment with a frequency of 60 kHz showed a similar hydrolysis rate as the control, resulting in similar weight loss, which was the highest value among the three frequencies (20, 60, and 80 kHz). Both SEM and XRD analyses indicated that more pits on the fiber surface, a smaller average grain size, and decreased crystallinity of the PET fibers were produced by the application of ultrasonic energy. The dyeing of the treated fabrics with two commercial dyes demonstrated that there was no obvious correlation between the treatment method and the color depth of the dyed fabric.

Acknowledgments

We are grateful to Science Compass, a large Chinese scientific research service institution, for its support in XRD data analysis.

-

Conflict of interest: Authors state no conflict of interest.

References

[1] Tavanai, H. (2009). A new look at the modification of polyethylene terephthalate by sodium hydroxide. Journal of the Textile Institute, 100(7), 633–639.10.1080/00405000802128489Search in Google Scholar

[2] Valipour, P. (2023). Preparation of multifunctional polyester fabrics using zinc stannate nanoparticles. Indian Journal of Fibre & Textile Research, 48(2),190–197.10.56042/ijftr.v48i2.56296Search in Google Scholar

[3] Siva Jagadish Kumar, M., Ramesh Naidu, M., Hayavadana, J. (2020). Effect of alkaline hydrolysis of jute/polyester union fabrics on low-stress mechanical properties. Journal of Fiber Science and Technology, 26(72), 412–421.10.2115/fiberst.2020-0044Search in Google Scholar

[4] Shukla, S. R., Mathur, M. R. (2000). Action of alkali on polybutylene terephthalate and polyethylene terephthalate polyesters. Journal of Applied Polymer Science, 75(9), 1097–1102.10.1002/(SICI)1097-4628(20000228)75:9<1097::AID-APP2>3.0.CO;2-7Search in Google Scholar

[5] Grancaric, A. M., Kallay, N. (1993). Kinetics of polyester fiber alkaline hydrolysis: effect of temperature and cationic surfactants. Journal of Applied Polymer Science, 49(1), 175–181.10.1002/app.1993.070490121Search in Google Scholar

[6] Yoo, H. J., Choi, J. M., Lee, H. J. (1996). Effects of alkali treatment on physical properties of PET fabrics. Journal of the Korean Society of Dyers and Finishers, 20(4), 609–619.Search in Google Scholar

[7] Seo, E. D. (2003). Effects of Ar-plasma treatment in alkali-decomposition of poly(ethylene terephthalate). Macromolecular Research, 11(5), 387–392.10.1007/BF03218381Search in Google Scholar

[8] Barani, H., Peyvandi, S. (2012). Enhanced deep coloring of micro polyester fabric. Materials Science, 16(2), 138–143.Search in Google Scholar

[9] Gupta, D.,Chaudhary, H., Gupta, C. (2015). Topographical changes in polyester after chemical, physical and enzymatic hydrolysis. The Journal of The Textile Institute, 106(7), 690–698.10.1080/00405000.2014.934046Search in Google Scholar

[10] Musale, R. M., Shukla, S. R. (2017). Measurement of anofilament-fabric optical properties. Textile Science and Engineering, 52, 325–330.10.12772/TSE.2015.52.325Search in Google Scholar

[11] Čorak, I., Tarbuk, A., Đorđević, D, Višić K., Botteri L. (2022). Sustainable alkaline hydrolysis of polyester fabric at low temperature. Materials, 15(4),1530.10.3390/ma15041530Search in Google Scholar

[12] Wei, Z. H., Gu, Z. Y. (2001). A Study of one-bath alkali-amine hydrolysis and silk fibroin finishing of polyester microfiber crepe fabric. Journal of Applied Polymer Science, 81(6), 1467–1473.10.1002/app.1573Search in Google Scholar

[13] Al-Balakocy, N. G., Hassan, T., Khalil, S., El-Salam, S. A. (2021). Simultaneous chemical modifification and functional finishing of polyester textiles. Research Journal of Textile and Appare, 25(3), 257–273.Search in Google Scholar

[14] Lee, S. (2022). Superhydrophobicity and conductivity of polyester-conductive fabrics using alkaline hydrolysis. Royal Society of Chemistry, 12(35), 22911–22921.10.1039/D2RA03996FSearch in Google Scholar

[15] Cho, Y. K., Kim, S. M. (2023). Prediction of optimum alkaline hydrolysis conditions for imparting superhydrophobicity to large-area fabrics using three-dimensional modeling. Textile Research Journal, 93(15–16), 3703–3716.10.1177/00405175231165334Search in Google Scholar

[16] Yang, X., Wang, Y., Huang, Q., Zeng Y., Lu W., Qin X. (2023). Constructing antibacterial surfaces with alkali treatment on polyethylene terephthalate nanofibers. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 675, 132096.10.1016/j.colsurfa.2023.132096Search in Google Scholar

[17] Abedsoltan, H. (2023). A focused review on recycling and hydrolysis techniques of polyethylene terephthalate. Polymer Engineering and Science, 63(9), 2651–2674.10.1002/pen.26406Search in Google Scholar

[18] Kirstein, M., Lücking, C., Biermann L., Brepohl E., Salikov V., Eichert C., et al. (2023). Monomer recycling and repolymerization of post-consumer polyester textiles. Chemie Ingenieur Technik, 95(8), 1290–1296.10.1002/cite.202200197Search in Google Scholar

[19] Kosmidis, V. A., Achilias, D. S., Karayannidis, G. P. (2001). Poly (ethyleneterephthalate) recycling and recovery of pure terephthalic acid. Kinetics of a phase transfer catalyzed alkaline hydrolysis. Macromolecular Materials and Engineering, 286(10),640–647.10.1002/1439-2054(20011001)286:10<640::AID-MAME640>3.0.CO;2-1Search in Google Scholar

[20] López-Fonseca, R., González-Marcos M. P., González-Velasco J. R. (2009). A kinetic study of the depolymerisation of poly(ethylene terephthalate) by phase transfer catalysed alkaline hydrolysis. Journal of Chemical Technology and Biotechnolog, 84(1), 92–99.10.1002/jctb.2011Search in Google Scholar

[21] López-Fonseca, R., González-Velasco J. R., Gutiérrez-Ortiz, J. I. (2009). A shrinking core model for the alkaline hydrolysis of PET assisted by tributylhexadecylphosphonium bromide. Chemical Engineering Journal, 146(2), 287–292.10.1016/j.cej.2008.09.039Search in Google Scholar

[22] Musale, R. M., Shukla, S. R.(2017). Weight reduction of polyester fabric using sodium hydroxide solutions with additives cetyltrimethylammonium bromide and [BMIM]Cl. Journal of the Textile Institute, 108(4), 467–471.10.1080/00405000.2016.1171029Search in Google Scholar

[23] Paliwal, N. R., Mungray, A. K. (2013). Ultrasound assisted alkaline hydrolysis of poly (ethylene terephthalate) in presence of phase transfer catalyst. Polymer Degradation Stability, 98(10), 2094–2101.10.1016/j.polymdegradstab.2013.06.030Search in Google Scholar

[24] Seo, M. Y., Cho, H. H., Kim, S. S., Jeon, J. W., Lee, S. G. (2002). A study on the alkali hydrolysis of PET fabrics with ultrasonic application(I)-decomposition rate constant and activation energy. Textile Coloration and Finishing, 14(4), 214–222.Search in Google Scholar

[25] Kimt, S. S., Seo, M. Y., Park, S. W., Yoon, T. H., Lee, S. G., Huh, M. W. (2002). A study on the alkali hydrolysis of PET fabrics with ultrasonic application(Ⅱ)- surface porosity and oligomer analysis. Textile Coloration and Finishing, 14, 305–312.Search in Google Scholar

[26] Bhogle, C. S., Pandit, A. B. (2018). Ultrasound-assisted alkaline hydrolysis of waste poly(ethylene terephthalate) in aqueous and non-aqueous media at low temperature. Indian Chemical Engineer, 60(2),122–140.10.1080/00194506.2017.1310634Search in Google Scholar

[27] Qian, L., Fang, S., Song, X., Qian H. (2023). An alternative strategy for the synthesis of disazo disperse dyes and their application on polyester fabric. Dyes and Pigments, 2014(suppl C), 111188.10.1016/j.dyepig.2023.111188Search in Google Scholar

[28] Wang, L., Jiang, Z. X., Yan, J. E. (2006). Effect of ultrasonic treatment on the structure and properties of cotton fibers. Journal of Textile Research, 27(10), 77–79.Search in Google Scholar

[29] Peng, F., Chen, X., Huang, X. B. (2011). Effects of ultrasonic treatment on surface morphology and inner crystalline of wool. Journal of Donghua University Natural Science, 37(6), 693–697.Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry