Abstract

Optimization of fabric’s mechanical properties, such as strength and bagging deformation of worsted fabrics, is considered one of the most important cases in relation to the use of stenter machine. Because, in this machine, for providing fabric’s dimensional stability with drying and stretching operations, fundamental changes would occur in these properties. Therefore, in the present study, the mechanical properties of the fabric in stenter machine were optimized through simulation of laboratory conditions as well as simulation by the finite element method. First, using laboratory stenter, the experiments were performed on six common worsted fabric samples by the Design Expert software through changing temperature, percentage of fibers, and weight of the fabric, which were considered as the most effective factors. Then, the changed conditions were determined by the central composite design for optimization. For performing the finite element simulation, the initial design was first created using TexGen software and then, the strength and bagging deformation model was investigated by Abaqus software. The results of the simulation showed a statistically acceptable relationship between actual and practical conditions.

1 Introduction

Stenter machine is one of the most expensive and important machines used for finishing worsted fabric. Besides drying the sample, the dimensional stability of the fabric sample is also provided. In stenter machine, in addition to dimensional stability, properties of the fabric, such as appearance and handle of the fabric, can be changed by adding various complementary materials. The two models of needle and clip stenter machines stroke the fabric during the process by changing the fabric’s movement speed for heavy (about 10 m/min) and light fabrics (about 100 m/min) under different effects of temperature and tension. Of course, in the meantime, the distance between the two sides of the machine clip changes so that the fabric achieves the desired and fixed width [1]. The chemical effects of stabilizing properties of wool/polyester, such as changes in hydrogen and disulfide bonds in wool fibers, and non-polar bonds and dipolar effects on polyester’s ester groups are observed in macromolecules. Of course, polyester fibers can be plasticized under the influence of heat and have easier forms to change [2]. All these structural changes are effective on the fabric’s handle and proper presentation of fabric’s properties. In the stenter process, removing internal stresses of the fabric surface caused during spinning and weaving processes will influence the properties of the fabric, such as thickness, density, and fabric’s cover surface and also mechanical properties, such as fabric strength [3]. Optimization of these properties is very important regarding the high variable costs of stenter machine, calculated in kilocalories per kilogram of steamed water. In the stenter machine, hot air flow usually moves in the opposite direction of the fabric surface and reduces the moisture content of the fabric to the desired level, and as shown in various studies, the useful energy used by this machine is equal to 31%, which can be increased up to 45% [4,5,6,7,8]. Significant advances have been made in the investigation of the physical properties of the fabric, in most of which the physical–mechanical behavior of textiles can be estimated using mathematical models and software [9,10,11,12,13,14,15]. One of the most widely used tools in this regard is finite element software, such as Abaqus. These simulations are performed using a numerical solution by the finite element method (FEM) [16,17,18,19,20,21,22,23]. According to a review of the literature, no previous study was found that simulated the effects of stenter machine on the fabric. In the FEM, a complex mechanical structure will try to study the forces, such as stresses in each part, critical conditions, and deformation with division into smaller parts (meso) and then matrix summation of these factors (in macro dimensions) [24,25,26,27,28,29,30,31,32]. Given that mechanical properties are very important in worsted fabrics, the main objective of this study is to pay attention to the strength of the stentered fabric in the warp direction and also in the direction outside the surface of the fabric (or bagging deformation) direction of the fabric surface. The most suitable fabric strength and bagging deformation can be achieved by optimizing stenter conditions and providing the best conditions. Given that using mechanical simulations can make predictions easier without testing, in this regard, finite element simulation was also used by Abaqus software.

2 Experimental

2.1 Materials and methods

In this study, six samples of worsted fabric were produced based on specifications (Table 1). Then, different conditions of the stenter machine, including temperature, material, and fabric weight were selected to limit the number of tests to obtain the results in a wider range by screening the design of tests. Based on the screened conditions, 27 different test conditions were obtained, which were tested in a laboratory stenter machine based on different conditions. For investigating the accuracy of laboratory conditions, several conditions were also tested in the production line of stenter conditions (Montex5000), which did not differ significantly from laboratory conditions. Mechanical parameters of the fabric were obtained by performing strength and bagging deformation tests on the obtained samples, and the results were optimized using Design Expert software by the central composite design (CCD) [33,34,35,36,37,38,39]. Then, for simulation, the finite element and TexGen software were used to provide the initial element and then using Abaqus software and shell elements of planner type, strength and bagging deformation properties were simulated [40,41,42,43,44].

Worsted fabrics produced based on specifications

| Sample | Material | Weight (g/m2) | Density weft | Density warp | Yarn count | Fabric worsted (pol/w) |

|---|---|---|---|---|---|---|

| A | A | 375 | 22 | 20 | 2/45 | 90/10 |

| B | 365 | 21 | 21 | 2/45 | 90/10 | |

| C | B | 375 | 22 | 20 | 2/46 | 80/20 |

| D | 365 | 21 | 21 | 2/46 | 80/20 | |

| E | C | 380 | 22 | 20 | 2/56 | 55/45 |

| F | 360 | 21 | 21 | 2/56 | 55/45 |

Dry Stenter: Woven fabrics in the weaving section are washed before finishing to remove contaminants in the weaving stage. After washing, they are passed through a dry stenter (at low temperature) for preliminary drying.

Fixed Stenter: This stenter is used to create dimensional stability, which is used with higher temperature, elasticity, and suitable speed of the fabric.

Soft Stenter: After fixing the dimensions of the fabrics, these stenter conditions are used to create a suitable draft so that, the temperature of this stenter is similar to that of the dry stenter, and the only difference is that the fabric passes through the softener.

The number of samples under each test condition was randomly determined using G × POWER software (d = 0.2, α = 0.05, power (1 – β) = 0.8). To provide conditions similar to the finishing process, first, the samples were washed and dried before entering the laboratory stenter machine made by Tsujii Dyeing Machine Mfg Co. Ltd, according to Figure 1. In this machine, using clips, the samples were subjected to stenter conditions at different temperatures and speeds.

Laboratory stenter machine.

2.2 Experimental design and test results

After screening, stenter conditions were performed based on the changes in stenter machine temperature, fabric material, and design weight according to strength and bagging deformation tests applied on the worsted fabrics using surface design response. The testing design surfaces were used, as shown in Table 2a for both dry and soft states and fixed state, according to Table 2b.

Independent variables of stenter machine effective on physical and mechanical properties and their studied surfaces in (a) dry and soft and (b) fix states

| Component (a) | Unit | Symbol | Level | ||||

|---|---|---|---|---|---|---|---|

| −α | −1 | 0 | 1 | α | |||

| Temperature | °C | A | 136 | 140 | 147 | 155 | 159 |

| Weight | g/m2 | B | 362 | 365 | 370 | 375 | 377 |

| Materials | C | A | B | C | |||

| Component (b) | Unit | Symbol | Level | ||||

|---|---|---|---|---|---|---|---|

| −α | −1 | 0 | 1 | α | |||

| Temperature | °C | A | 171 | 175 | 182 | 190 | 193 |

| Weight | g/m2 | B | 362 | 365 | 370 | 375 | 377 |

| Materials | C | A | B | C | |||

After determining the desired surfaces, including 26 states, the strength tests were performed according to the ASTM-D5035 standard and bagging deformation was assessed based on the tests introduced by Zhang. The test results for dry and soft conditions are given in Tables 3 and 4 for fixed conditions.

Tests designed to optimize the condition of the stenter machine to investigate physical–mechanical properties of worsted fabrics passed through the stenter machine during dry and soft states

| No. | Temp. | Weight | Materials | Stenter dry | Stenter soft | ||

|---|---|---|---|---|---|---|---|

| Strength | Bagging deformation | Strength | Bagging deformation | ||||

| 1 | 1 | 1 | B | 931.65 | 392.12 | 715.7 | 328.74 |

| 2 | 0 | α | A | 860.48 | 693.29 | 776.15 | 497.04 |

| 3 | −1 | 1 | C | 396.21 | 286.12 | 386.23 | 271.27 |

| 4 | 0 | −α | A | 831.09 | 680.34 | 770.78 | 490.61 |

| 5 | α | 0 | B | 897.09 | 345.16 | 663.87 | 297.96 |

| 6 | −1 | −1 | C | 386.41 | 276.43 | 366.69 | 259.26 |

| 7 | −1 | −1 | A | 799.32 | 642.91 | 748.04 | 467.45 |

| 8 | 0 | 0 | B | 973.26 | 471.15 | 773.28 | 375.11 |

| 9 | 0 | 0 | A | 848.97 | 686.73 | 773.92 | 494.85 |

| 10 | 0 | 0 | C | 409.11 | 307.82 | 428.32 | 295.06 |

| 11 | 0 | −α | C | 395.91 | 304.31 | 395.91 | 291.91 |

| 12 | 1 | 1 | C | 371.27 | 263.27 | 342.05 | 258.04 |

| 13 | 0 | α | B | 1017.44 | 484.71 | 778.69 | 381.03 |

| 14 | 0 | −α | B | 965.46 | 457.54 | 773.28 | 369.62 |

| 15 | 1 | −1 | A | 790.24 | 591.32 | 705.9 | 439.82 |

| 16 | α | 0 | A | 786.73 | 559.11 | 698.26 | 395.43 |

| 17 | 1 | −1 | B | 924.42 | 370.67 | 709.96 | 310.45 |

| 18 | −α | 0 | A | 795.84 | 576.48 | 702.09 | 407.35 |

| 19 | −α | 0 | C | 346.44 | 234.91 | 765.54 | 479.14 |

| 20 | −1 | 1 | A | 806.48 | 672.08 | 317.24 | 215.22 |

| 21 | α | 0 | C | 306.71 | 209.76 | 728.37 | 337.44 |

| 22 | −1 | −1 | B | 941.53 | 407.5 | 695.17 | 303.18 |

| 23 | −α | 0 | B | 911.76 | 359.83 | 446.1 | 298.36 |

| 24 | 0 | α | C | 416.37 | 309.71 | 741.51 | 352.75 |

| 25 | −1 | 1 | B | 948.02 | 431.49 | 736.01 | 452.18 |

| 26 | 1 | 1 | A | 798.6 | 611.72 | 329.27 | 241.26 |

Tests designed to optimize the condition of the stenter machine to investigate the physical–mechanical properties of worsted fabrics passed through the stenter machine during fix states

| No. | Temp. | Weight | Materials | Strength | Bagging deformation |

|---|---|---|---|---|---|

| 1 | 1 | −1 | B | 572.54 | 581.84 |

| 2 | 0 | α | B | 661.11 | 689.61 |

| 3 | 0 | 0 | B | 657.87 | 618.49 |

| 4 | 1 | −1 | A | 597.24 | 600.09 |

| 5 | −1 | −1 | B | 659.44 | 597.63 |

| 6 | 0 | α | C | 442.73 | 437.71 |

| 7 | α | 0 | A | 600.67 | 375.78 |

| 8 | α | 0 | A | 600.67 | 365.78 |

| 9 | 1 | 1 | A | 602.48 | 664.07 |

| 10 | 1 | 1 | C | 365.6 | 397.82 |

| 11 | 0 | α | A | 671.34 | 764.13 |

| 12 | −α | 0 | B | 674.38 | 638.63 |

| 13 | −1 | 1 | C | 476.09 | 411.21 |

| 14 | 0 | 0 | A | 664.41 | 687.57 |

| 15 | α | 0 | B | 578.08 | 586.2 |

| 16 | −1 | 1 | B | 679.04 | 648.44 |

| 17 | 0 | −α | B | 648.28 | 596.39 |

| 18 | −1 | 1 | A | 690.19 | 739.12 |

| 19 | 0 | 0 | C | 425.38 | 365.93 |

| 20 | −α | 0 | C | 457.47 | 419.14 |

| 21 | 0 | −α | C | 397.26 | 365.12 |

| 22 | −1 | −1 | C | 440.11 | 369.16 |

| 23 | 1 | −1 | C | 348.18 | 311.21 |

| 24 | −α | 0 | A | 681.55 | 716.82 |

| 25 | 1 | 1 | B | 583.34 | 587.91 |

| 26 | 0 | −α | A | 656.49 | 681.19 |

2.3 Optimization of stenter machine’s conditions according to bagging deformation and narrow fabric strength

Laboratory results under screening conditions for testing bagging deformation and narrow fabric strength were entered into the software and analysis of variance (ANOVA) was done through surface design response. The results of testing bagging deformation and narrow fabric strength are given in Tables 5 and 6 for dry, fixed, and soft stenter states. p-value of <0.05 in the ANOVA table indicates the effect of screening factors on the strength of the fabric.

Results of ANOVA by the experimental CCD to measure narrow fabric strength under the influence of stenter machine’s temperature, fabric weight, and percentage of fibers in dry, fixed, and soft states of stenter machine

| Source | df | Strength dry stenter | Strength fix stenter | Strength soft stenter | |||

|---|---|---|---|---|---|---|---|

| Value | p-value | F | p-value | F | p-value | ||

| Model | 11 | 870.76 | <0.0001 | 222.00 | <0.0001 | 338.04 | <0.0001 |

| A-Temp | 1 | 10.10 | 0.0067 | 274.49 | <0.0001 | 9.21 | 0.0089 |

| B-Weight | 1 | 11.32 | 0.0046 | 14.01 | 0.0022 | 7.06 | 0.0188 |

| C-Material | 2 | 4653.38 | <0.0001 | 1145.47 | <0.0001 | 1829.60 | <0.0001 |

| R-square | Linear | 0.9821 | 0.9791 | 0.9475 | |||

| 2FI | 0.9772 | 0.9771 | 0.9329 | ||||

| Quadratic | 0.9974 | 0.9898 | 0.9933 | ||||

| Cubic | 0.9962 | 0.9889 | 0.9953 | ||||

Results of ANOVA by the experimental CCD to measure narrow fabric bagging under the influence of stenter machine’s temperature, fabric weight, and percentage of fibers in dry, fixed, and soft states of stenter machine

| Source | df | Bagging deformation dry stenter | Bagging deformation fix stenter | Bagging deformation soft stenter | |||

|---|---|---|---|---|---|---|---|

| Value | p-value | F | p-value | F | p-value | ||

| Model | 11 | 223.12 | <0.0001 | 13.08 | <0.0001 | 209.17 | <0.0001 |

| A-Temp | 1 | 15.00 | 0.0017 | 19.95 | 0.0005 | 8.85 | 0.0100 |

| B-Weight | 1 | 4.98 | 0.0424 | 4.72 | 0.0475 | 7.57 | 0.0156 |

| C-Material | 2 | 1124.40 | <0.0001 | 56.22 | <0.0001 | 1055.19 | <0.0001 |

| R-square | Linear | 0.9119 | 0.7261 | 0.8443 | |||

| 2FI | 0.8855 | 0.7690 | 0.8042 | ||||

| Quadratic | 0.9899 | 0.8416 | 0.9892 | ||||

| Cubic | 0.9967 | 0.8916 | 0.9904 | ||||

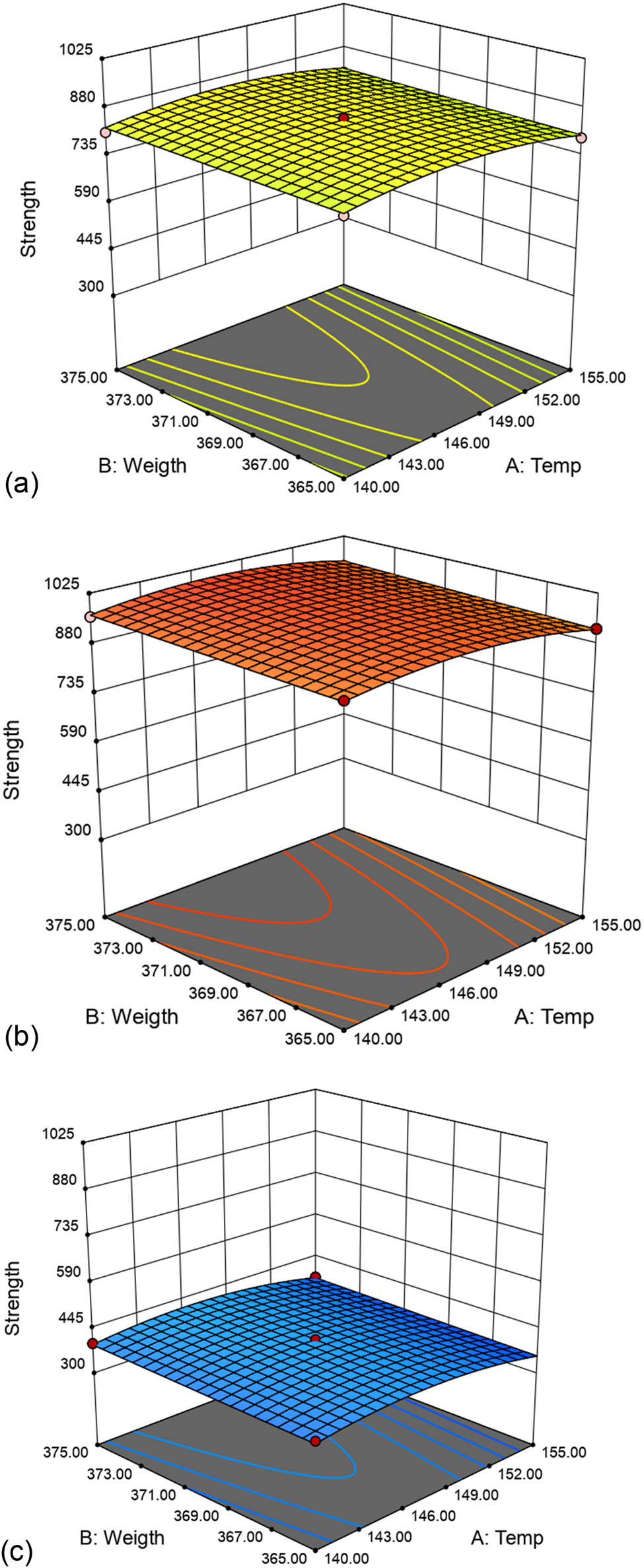

F-values for each variable showed that the coded parameters of temperature, weight, and material are the factors influencing narrow fabric strength (Figures 2–4). To predict the variable of strength under the influence of the three mentioned independent variables, the prediction equations including equations (1)–(3) for three types of material (a, b, c) and equation (4) for the average of three dry stenters and equations (5)–(7) for three types of material and equation (8) for average fixed stenter and equations (9)–(11) for three types of material and equation (12) for average soft stenter along with response level charts have been provided (A, B, and C based on Table 1). Optimal values for each condition are shown in Table 7.

Changes in fabric strength concerning stenter machine’s temperature, fabric weight, and percentage of 3D fibers (dry stenter). (a) PET/wool, 90/10, (b) PET/wool, 80/20, and (c) PET/wool, 55/45.

Changes in fabric strength concerning stenter machine’s temperature, fabric weight, and percentage of 3D fibers (fix stenter). (a) PET/wool, 90/10, (b) PET/wool, 80/20, and (c) PET/wool, 55/45.

Changes in fabric strength concerning stenter machine’s temperature, fabric weight, and percentage of 3D fibers (soft stenter). (a) PET/wool, 90/10, (b) PET/wool, 80/20, and (c) PET/wool, 55/45.

Optimal conditions based on analysis of the response procedure method

| Material | Weight of fabric (g/m2) | Optimize temp. | Optimize tensile strength | Optimize bagging deformation force | Desirability | |

|---|---|---|---|---|---|---|

| Dry stenter | 10w.90poly(A) | 375 | 146.72 | 978.214 | 691.261 | 0.860 |

| Fix stenter | 10w.90poly(A) | 375 | 175 | 688.836 | 775.712 | 0.990 |

| Soft stenter | 10w.90poly | 374.35 | 147.07 | 790.754 | 497.8 | 1.000 |

2.3.1 Final equations in terms of the actual factor

2.3.2 Final equation in terms of the actual factor

2.3.3 Final equation in terms of the actual factor

2.3.4 Final equation in terms of the actual factor

2.3.5 Final equation in terms of the actual factor

2.3.6 Final equation in terms of the actual factor

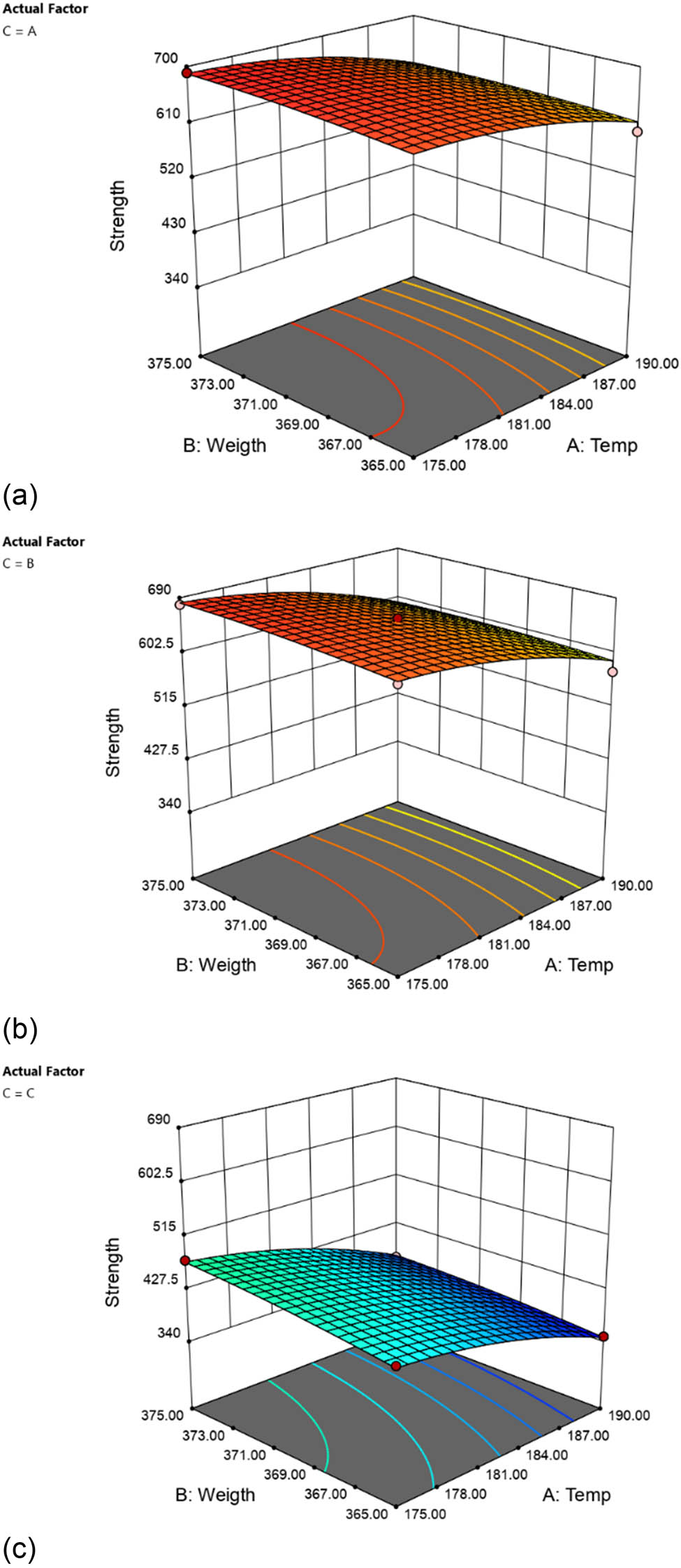

F-values for each variable showed that the coded parameters of temperature, weight, and material are the factors influencing narrow fabric bagging (Figures 5–7). To predict the variable of bagging under the influence of the three mentioned independent variables, the prediction equations including equations (13)–(15) for three types of material (a, b, c) and equation (16) for the average of three dry stenters and equations (17)–(19) for three types of materials and equation (20) for average fixed stenter and equations (21)–(23) for three types of materials and equation (24) for average soft stenter along with response level charts have been provided (A, B, and C based on Table 1). Optimal values for each condition are shown in Table 7.

Changes in fabric bagging concerning stenter machine’s temperature, fabric weight, and percentage of 3D fibers (dry stenter). (a) PET/wool, 90/10, (b) PET/wool, 80/20, and (c) PET/wool, 55/45.

Changes in fabric bagging concerning stenter machine’s temperature, fabric weight, and percentage of 3D fibers (fix stenter). (a) PET/wool, 90/10, (b) PET/wool, 80/20, and (c) PET/wool, 55/45.

Changes in fabric bagging concerning stenter machine’s temperature, fabric weight, and percentage of 3D fibers (soft stenter). (a) PET/wool, 90/10, (b) PET/wool, 80/20, and (c) PET/wool, 55/45.

2.3.7 Final equation in terms of the actual factor

2.3.8 Final equation in terms of the actual factor

2.3.9 Final equation in terms of the actual factor

2.3.10 Final equation in terms of the actual factor

2.3.11 Final equation in terms of the actual factor

2.3.12 Final equation in terms of the actual factor

2.4 FEM for stenter machine’s temperature for simulation of strength and bagging deformation of fabric

For modeling the fabric structure, it was first necessary to design a serge fabric weaving unit as a meso unit using TexGen software (Figure 8).

The constituent unit cell in the TexGen software.

Then, the model based on the contact properties and geometry of the fibers was entered into the Abaqus software. A three-dimensional C3D8R type of element was used in Abaqus software for meshing. Separate modeling was performed in Abaqus software to simulate the strength and bagging deformation of the fabric. In modeling, dimensional properties of yarn and fabric structure, such as modulus of elasticity, Poisson’s ratio, and yarn friction coefficient at different temperatures, were considered and boundary conditions were applied according to narrow fabric strength and bagging deformation figure (Figures 9 and 10).

(a) Model designed for strength in ANSYS. (b) Model designed for bagging deformation in ANSYS.

Results of simulation of (a) strength and (b) bagging deformation.

3 Relationship between simulation and laboratory results

The experimental results of simulation and actual testing of bagging deformation and strength were investigated by SPSS software for three dry, fixed, and soft states of stenter machine by linear regression as shown in Table 8 (sig. < 0.001, all equations showed R² acceptable prediction for stenter machine). The diagrams of statistical results for all states are given in Figure 11.

Results of the regression model of bagging deformation in stenter machine for experimental conditions and simulation by finite element

| Model | Strength | Bagging | ||||

|---|---|---|---|---|---|---|

| R Square | F | Sig. | R Square | F | Sig. | |

| Dry stenter | 0.992 | 488.266 | 0.000 | 0.930 | 53.207 | 0.002 |

| Fix stenter | 0.988 | 341.273 | 0.000 | 0.875 | 27.997 | 0.006 |

| Soft stenter | 0.994 | 361.454 | 0.000 | 0.951 | 77.789 | 0.001 |

Regression model for experimental values and finite element simulation of (a) narrow fabric strength and (b) fabric’s bagging deformation.

4 Result

Stenter is one of the most expensive machines, both in terms of fixed and variable capital, which has the greatest effect on the cost of products. Hence, optimizing conditions of fabric properties with the least tests was one of the objectives of this study. Using the response surface method, optimization was performed for the tested fabrics and optimal conditions were predicted by finite element simulation. The results showed that strength and bagging deformation of the fabric in the stenter machine had acceptable R² (under different conditions), through which structural properties and different temperatures of the stenter machine can be predicted.

-

Funding information: Authors state no funding is involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript. Dr. Ramin abghari and Miss. Tavangar designed the experiments and Dr. Mirjalili carried them out. Dr. Amiri developed the model code and performed the simulations. Dr. Abghari prepared the manuscript with contributions from all co-authors.

-

Conflict of interest: Authors state no conflict of interest.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Roy, A. K. (2017). The textile institute book series, principles of textile finishing. Woodhead Publishing.Search in Google Scholar

[2] De Boos, A. G., Harrigan, F. J., Wemyss, A. M. (1986). Hydrothermal setting of wool-polyester blend fabrics. Textile Research Journal, 56(4), 261–269.10.1177/004051758605600406Search in Google Scholar

[3] Naujokaitytė, L., Strazdienė, E. (2007). The effect of finishing upon textile mechanical properties at low loading. Materials Science (Medžiagotyra), 13, 249–254.Search in Google Scholar

[4] Bona, M. (1994). An introduction to wool fabric finishing. Textile Institute.Search in Google Scholar

[5] Cottle, D., Baxter, B. P. (2015). Wool metrology research and development to date. Textile Progress, 47, 163–315.10.1080/00405167.2015.1108543Search in Google Scholar

[6] Akyol, U., Akan, A. E., Durak, A. (2014). Simulation and thermodynamic analysis of a hot-air textile drying process. Journal of the Textile Institute, 106, 260–274. 10.1080/00405000.2014.916062.Search in Google Scholar

[7] Liao, Q., Brady, P. R. (2010). A study on dimensional properties of wool fabric treated at 120°C. Textile Research Journal, 80, 1958–1964. 10.1177/0040517510369404.Search in Google Scholar

[8] Hamdani, S. T. A., Potluri, P., Fernando, A. (2013). Thermo-mechanical behavior of textile heating fabric based on silver coated polymeric yarn. Materials, 6, 1072–1089. 10.3390/ma6031072.Search in Google Scholar PubMed PubMed Central

[9] Dixit, A., Mali, H. S. (2013). Modeling techniques for predicting the mechanical properties of woven-fabric textile composites: a review. Mechanical of Composite Materials, 49, 1–20.10.1007/s11029-013-9316-8Search in Google Scholar

[10] Ramić, M., Zrno, A., Husika, A. (2016). Energy flow analysis of stenter type artos babcock driven by textile producer prevent fabrics. 16th World Textile Conference Autex, Ljubljana, Slovenia.Search in Google Scholar

[11] Sabir, E. C., Uçak, F. (2016). Energy saving of the stenter in a selected textile mill, 16th World Textile Conference Autex, Ljubljana, Slovenia.Search in Google Scholar

[12] Tarakcıoglu, I., Karaaslan, M. A., Cay, A. (2008). An experimental study on the heat recovery from the exhaust air of stenters with a packed bed column. International Journal of Energy Research, 328, 648–654. ORG/10.1002/Er.1382.Search in Google Scholar

[13] Hasanbeigi, A., Hasanabadi, A., Abdorrazaghi, M. (2011). Energy efficiency technologies and comparing the energy intensity in the textile industry. Proceedings of the American Council for an Energy-Efficient Economy's 2011 Summer Study on Energy Efficiency in Industry, held in Niagara Falls, New York, USA.Search in Google Scholar

[14] Fiaschi, D., Manfrida, G., Russo, L., Talluri, L., (2017). Improvement of waste heat recuperation on an industrial textile dryer: Redesign of heat exchangers network and component. Energy Conversion and Management, 150, 924–940.10.1016/j.enconman.2017.05.053Search in Google Scholar

[15] Şekkeli, M., Keçecioğlu, F. O. (2012). SCADA based an energy saving approach to operation of stenter machine in a textile plant using waste heat recovery system. Tekstil ve konfeksiyon, 3, 248–257.Search in Google Scholar

[16] Dar, H. F., Meakin, J. R., Aspden, R. M. (2002). Statistical methods in finite element analysis. Journal of Biomechanics, 35, 1155–1161.10.1016/S0021-9290(02)00085-4Search in Google Scholar PubMed

[17] Sze, K. Y., Liu, X. H. (2007). Fabric drape simulation by solid-shell finite element method. Finite Elements in Analysis and Design, 43, 819–838.10.1016/j.finel.2007.05.007Search in Google Scholar

[18] Nilakantan, G., Keefe, M., Bogetti, T. A., Adkinson, R., Gillespie, J. W. (2010). On the finite element analysis of woven fabric impact using multiscale modeling techniques. International Journal of Solids and Structures, 47, 2300–2315.10.1016/j.ijsolstr.2010.04.029Search in Google Scholar

[19] Shahkarami, A., Vaziri, R. (2007). A continuum shell finite element model for impact simulation of woven fabrics. International Journal of Impact Engineering, 34, 104–119.10.1016/j.ijimpeng.2006.06.010Search in Google Scholar

[20] Durville, D. (2007). Finite element simulation of textile materials at mesoscopic scale, materials science. Saint Petersbourg, Russia.Search in Google Scholar

[21] Senem, K., Bahadir, F., Kalaoglu, F., Simona, J., Eryuruk, S. H., Saricam, C. (2015). Use of artificial neural networks for modelling the drape behaviour of woollen fabrics treated with dry finishing processes. Fibers and Textiles in Eastern Europe, 23, 90–99.Search in Google Scholar

[22] Kumar, R., Tewari, P. C., Khanduja, D. (2016). Performance modeling and availability analysis of the fabric finishing system of a textile industry. Journal of Mechanical Engineering, 6, 2563–2567.Search in Google Scholar

[23] Cimilli, S., Nergis, F. B. U., Candan, C. (2008). Modeling of heat transfer measurement unit for cotton plain knitted fabric using a finite element method. Textile Research Journal, 78, 53–59. 10.1177/0040517507082186.Search in Google Scholar

[24] Xie, H., Li, Z., Qiao, Z. (2011). A Finite element method for elasticity interface with locally modified triangulations. International Journal of Numerical Analysis and Modeling, 8, 189–200.Search in Google Scholar

[25] Xu, H. Y., Jiang, J., Chen, N. L., Lin, F., Shao, H. (2018). Finite element modeling for the uni-axial tensile behavior of metallic warp-knitted fabric. Fibers & Textile in Eastern Europe, 26, 49–54. 10.5604/01.3001.0011.5738.Search in Google Scholar

[26] Sharma, S. B., Sutcliffe, M. P. F. (2004). A simplified finite element model for draping of woven material. Composites: Part A: Applied Science and Manufacturing, 35, 637–643.10.1016/j.compositesa.2004.02.013Search in Google Scholar

[27] Chichani, S., Guha, A. (2015). A method of modeling fabric shear using finite element analysis. Journal of the Institution of Engineer (India), 96, 1–7.10.1007/s40034-014-0051-zSearch in Google Scholar

[28] Sun, B., Wang, Y., Wang, P., Hu, H., Gu, B. (2011). Investigations of puncture behaviors of woven fabrics from finite element analyses and experimental tests. Textile Research Journal, 81, 992–1007. 10.1177/0040517510395999.Search in Google Scholar

[29] Wang, P., Ma, Q., Sun, B., Hu, H., Gu, B. (2011). Finite element modeling of woven fabric tearing damage. Textile Research Journal, 81, 1273–1286.10.1177/0040517510397578Search in Google Scholar

[30] Lin, H., Clifford, M. J., Long, A. C., Lee, K., Guo, N. (2012). A finite element approach to the modelling of fabric mechanics and its application to virtual fabric design and testing. The Journal of Textile Institute, 103, 1063–1076. 10.1080/00405000.2012.660755.Search in Google Scholar

[31] Abghary, M. J., Nedoushan, R. J., Hasani, H. (2016). Simulation of the spherical deformation of biaxial weft-knitted fabrics using meso and macro models. Fibers and Polymer, 17, 1702–1708.10.1007/s12221-016-6511-ySearch in Google Scholar

[32] Lin, H., Clifford, M. J., Long, A. C., Sherburn, M. (2009). Finite element modelling of fabric shear. Modeling and Simulation in Materials Science and Engineering, 17, 1–16.10.1088/0965-0393/17/1/015008Search in Google Scholar

[33] Harianto, R. A. (2018). Optimization of woven fabric production in textile industry of pt. argo pantes tangerang. International Journal of Advanced Scientific Research & Development, 5, 70–76.10.26836/ijasrd/2018/v5/i4/50412Search in Google Scholar

[34] Wani, T. A., Ahmad, A., Zargar, S., Khalil, N. Y., Darwish, I. A. (2012). Use of response surface methodology for development of new microwell-based spectrophotometric method for determination of atorvastatin calcium in Tablets. Chemistry Central Journal, 6(1), 134. 10.1186/1752-153X-6-134.Search in Google Scholar PubMed PubMed Central

[35] Arbabi, M., Mayahi, B., Mohammadi, M. F., Sedehi, M., Hemati, S. (2017). Removal of acid bleu 113 by UV/H2O2/Fe3O4 process: optimization of treatment conditions using experimental design. Journal of Shahrekord University of Medical Sciences, 19, 13–25.Search in Google Scholar

[36] Ahmad, N., Kamal, S., Zulfiqar, A. R., Tanveer, H. (2017). Multi-objective optimization in the development of oil and water repellent cellulose fabric based on response surface methodology and the desirability function. Materials Research Express, 4, 035302. 10.1088/2053-1591/aa5f6a.Search in Google Scholar

[37] Zhang, S., Fu, L., Yang, Z., Jing, M., Zhang, Z., Xiang, S., et al. (2021). Response surface methodology for optimizing the preparation process of cellulose acetate/polylactic acid nonwoven surgical gown material. Fibers and Polymers, 22, 928–935.10.1007/s12221-021-0274-9Search in Google Scholar

[38] Ayed, L., Ksibi, I., Cheref, A. A., Bakhrouf, A. (2012). Response surface methodology for optimization of the treatment of textile wastewater by a novel bacterial consortium: Enzymes and metabolites characterization. Academic Journal Expand Your Knowledge, 59, 12339–12355.Search in Google Scholar

[39] Rezić, I., Kiš., A. (2020). Design of experiment approach to optimize hydrophobic fabric treatments, Polymers, 12(9), 2131. 10.3390/polym12092131.Search in Google Scholar PubMed PubMed Central

[40] Hua, L., Andrew, L., Louise, P. B. (2011). Modelling and simulating textile structures using Texgen. Advanced Materials Research, 331, 44–47.10.4028/www.scientific.net/AMR.331.44Search in Google Scholar

[41] Yardan, K., Francois, B. (2021). Advanced weaving technology. Springer International Publishing. 10.1007/978-3-030-91515-5.Search in Google Scholar

[42] Louise, P. B., Xuesen, Z., Andrew, C., Long, I., Arthur, J., (2013), Recent Developments in the realistic geometric modelling of textile structures using Texgen. International Conference on Digital Technologies for the Textile Industries.Search in Google Scholar

[43] Matthew, T., Louise, B., Kishen, R., Nick, W. (2022). Texgen – Geometrical modeling of biaxial braided fabrics. Composites Meet Sustainability – Proceeding of the 20th European Conference on Composite Materials, pp. 26–30.Search in Google Scholar

[44] Lin, H., Long, A. C., Sherburn, M., Clifford, M. J. Modelling of mechanical behavior for women fabrics under combined loading. International Journal of Material Forming, 1, 899–902.10.1007/s12289-008-0241-7Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry