Polymer-based nanocarriers for biomedical and environmental applications

-

Dahir Sagir Idris

, Soumya Pandit

Abstract

Polymer-based nanocarriers are created from natural or synthetic polymers that are modified to form submicroscopic particles. The polymer matrix can be customized to provide specific properties, such as surface chemistry and flexibility. This allows the particles to be designed and used in different fields. They are promising nanomaterials that are used as therapeutic and diagnostic agents, and they have potential biomedical and environmental applications. These nanocarriers are polymers that can be engineered with other types of nanomaterials with different sizes, shapes, and compositions. They can deliver drugs or their cargo to a specific site with precisely controlled release. They have many advantages compared to traditional drug delivery carriers, including improved biocompatibility, reduced toxicity, and increased efficacy. In biomedical applications, polymer nanocarriers have been used as drug delivery carriers, cancer therapy, and gene therapy. In environmental applications, polymer nanocarriers are able to remove heavy metals and other contaminants from air and water bodies. In this review, a summary of recent fabrication, design, synthesis, characterisation, and various applications in the biomedical and environmental fields has been provided. The review also highlights the current challenges and prospects of evolving polymer nanocarriers.

1 Introduction

In recent years, the use of nanotechnology aimed at developing cancer drugs and nanocarriers has increased rapidly. Nanotechnology has a very wide range of applications and also has the potential to make a significant impact in biotechnology, healthcare, drug delivery, electronics, storage systems, and industries (1). However, the history of nanotechnology dates back as far back as 1959 when the physicist Richard P. Feynman once said “There is plenty of room at the bottom” in a lecture, forecasting that materials can be reduced to the nanoscale level. He suggested that shrinking materials to the nanoscale level and building them back up is the key to future technological advancement (2). Nanomaterials are considered to be in the range of 1–100 nm which allow these particles to communicate or interact with the surface of a cell in such a way that the physiological and biochemical properties of the cell can be decoded. Nanoparticles can be incorporated into a form of composites with improved properties, strength, toughness, or thermal conductivity. Of course, sometimes we cannot deny the fact that the newly formed composite possesses an unknown property that is not known to the parent constituent material (3). For example, in nanomedicine, there is an increasing research interest in the development of various systems, such as nanocarriers for drug delivery to targeted cells such as cancer cells or infections/neurodegenerative disorders (4,5,6). Among the various types of nanomaterials, polymer-based nanocarriers and colloids have attracted more attention because they have interesting properties such as flexibility, diversity, and unique composition, and also easy to functionalise with specific ligands that are intended to be recognised by a particular cell receptor, thus paving the way for active targeting (6). Subject to the type, nature, ligand involved, and coupling reaction of the selected polymer, nanocarriers can be designed to possess the ability to load drugs in them and deliver them to cells of specific site in a biological system (7). Subsequently, polymeric nanomaterials used for the delivery of agrochemicals such as pesticides, antibiotics, growth promoters, and other essential nutrients, considering the impact of biodegradability and biocompatibility of polymeric nanomaterials, have gained great interest in research from many researchers (8). They contribute to less environmental impact and higher efficiency for their use (8). Some of these polymeric nanocarriers are designed to act as smart systems in the sense that they respond or react to certain stimuli such as light, sound, temperature, pH, or even potential differences in triggers and release the drug or cargo content at the preferred location or destination (9). This review will examine the latest trend in polymer-based nanocarriers, their types, synthesis approach, characterisation, and biomedical and environmental applications among others.

2 Types of nanomaterials

Nanomaterials are of different types depending on their size, shape, and functional group, or physical, chemical, biological, and optical properties. These types include carbon-based, metal-based, polymer-based, ceramic-based, semiconductor-based, dendrimers, and nanocomposites (Figure 1).

Types of nanomaterials.

2.1 Carbon-based nanoparticles

Carbon is one of the most abundant elements in the universe that is allotropic in nature. It can assume different forms based on how the atoms are arranged. Diamonds, fullerenes, graphene, and graphite are considered to be four allotropes of pure carbon. In nanotechnology, carbon nanostructures are making a significant contribution in different research fields (10). They have been used as catalysts or support for catalysts, additives, sensors or substrates for sensors, adsorbents, filtering media, active materials in energy systems (i.e. supercapacitors, batteries, and energy), additives for metals and their alloys, glass, ceramics, polymer textiles, and composite nanomaterials (11). Nanocomposites of carbon derivatives may exhibit superior performance, like electrical and mechanical properties, which are useful for various applications. There are other forms of carbon nanomaterials as well.

2.2 Metal-based nanomaterials

Metal-based nanomaterials are submicrometre nanomaterials that are synthesised from pure metal salts or precursor of pure metals. Their synthesis approach is usually classified under the bottom-up technique of synthesising nanoparticles. Almost all of the metal-based nanoparticles available can be synthesised from their respective metal salts/precursors. Gold, silver, platinum, palladium, zinc, iron, nickel, copper, cobalt, aluminium, lead, cadmium, and manganese salts/precursors have all been used in fabricating various metallic nanoparticles. These nanoparticles are known to possess unique properties such as biocompatibility, crystallinity, pore size, electrical conductivity, optoelectrical characteristics, high surface area, and sensitivity (12,13,14,15). To precisely tailor the unique size, shape, and other properties of nanoparticles, some synthesis constraints need to be adjusted accordingly. These constraints include the pH of the reaction chamber, concentration, and temperature. Furthermore, metal oxide has also been exploited and found its application in many fields, including sensors, super-strong materials, antimicrobial activity, catalysts, tissue engineering, and electrochemical detection of biomolecules (16,17,18,19).

2.3 Ceramic nanoparticles

Ceramic nanoparticles are made of tiny particles that are primarily of ceramic materials such as oxides, nitrides, carbides, and carbonates of metals and metalloids such as silicon, titanium, and calcium. Ceramic nanomaterials possess some characteristics and properties such as increased surface area, increased reactivity, high heat resistance, chemical inertness, and improved mechanical strength (20). They have been used for different applications in many fields including biomedicine, electronics, catalysis, energy storage, and environmental remediation (21,22,23). For example, ceramic nanoparticles can be used in electronics as conductive fillers in polymer composites to improve their electrical conductivity (24). Another example is their use in the fabrication of electrodes for lithium ion batteries to improve their energy storage capacity and density (22). In the case of catalysis, they are used to increase the efficacy of chemical reactions (25,26). Ceramic nanocarriers also found their use in the field of biomedicine as nanocarriers to enhance targeted cargo release at the required site (20). However, the synthesis and processing can be challenging due to their very small size and their tendency to aggregate or even form unwanted structures (27). Therefore, a thorough understanding of the synthesis methods and behaviour of ceramic nanoparticles is crucial for their successful application in various fields.

2.4 Semiconductor nanoparticles

Semiconductor nanoparticles are fluorescent materials that are generally metal compounds with non-metallic properties (28). These nanomaterials are made from different compounds, such as II–VI semiconductor nanocrystals. III–V and IV–VI semiconductor nanocrystals have been used (29). Although these nanomaterials are still in the early stage of research, they have promising application in many fields, including light-emitting diodes, laser technology, solar cells, waveguides, nanoscale electronic devices, chemicals, and biosensors (30). With the advancement of nanotechnology, the semiconductor industry may witness a significant breakthrough in the near future.

2.5 Nanocomposites

Nanocomposites, as the name implies, are heterogeneous/hybrid complexes that are made up of two or more different materials combined to blend their properties, in which at least one of these materials is in the dimension of 10−9 m. Nanocomposites usually consist of one or more discontinuous phases (reinforcements; e.g., metals, clay) distributed along a continuous phase (matrix; e.g., polymer). They can be polymer base (biocomposites base [e.g., elastin-collagen], polymer–polymer base [e.g., poly(p-phenylene oxide)], polymer-layered silica base [e.g., nylon-6], polymer–ceramics base [e.g., barium titanate], inorganic–organic polymer base [e.g., nanofibers], inorganic–organic hybrid base [e.g., nanocrystals]), or non-polymer base (metal–metal nanocomposites; either in the form of alloy or shell [e.g., Pt-Ru], metal–ceramics nanocomposites; either in the form of nanotubes or complicated nanostructures [e.g., polysiloxane/polysiloxane], ceramic–ceramic nanocomposite; alloy or ceramics [e.g., zirconia]) (31,32,33,34,35).

2.6 Polymer-based nanoparticles

Polymer-based nanoparticles are an exciting field of study in nanotechnology. The development of these particles has the potential to revolutionise many industries, from medical applications to energy production/storage to the automobile industry. Polymer-based nanoparticles are created from natural or synthetic polymers that are modified to form submicroscopic particles. The polymer matrix can be customized to provide specific properties, such as surface chemistry and flexibility. This allows the particles to be designed and used in different fields. For example, polymeric nanoparticles have been used to deliver drugs or genes to a specific site and are also used in tissue engineering (36). Biodegradable and low-toxic poly(lactic acid) (PLA), chitosan, and poly(ethylene glycol) (PEG) are the common polymers used in the synthesis process of polymeric nanocarriers. PEG-based nanoparticles are especially advantageous because they can be easily modified and are hydrophilic in nature, thereby, making them ideal for drug delivery (37,38). PLA-based nanoparticles are preferred for nanofabrication due to their excellent optical properties and their ability to form stable complexes with other materials (39). The main advantages of using polymer-based nanoparticles are their versatility and biocompatibility, which means that they can be safely used in medical applications. However, polymer-based nanoparticles in terms of cost and complexity. The synthesis of these particles requires sophisticated equipment, and the cost can be prohibitive for some applications (40). Furthermore, the particles need to be carefully characterised to ensure that their properties match the desired specifications.

3 Types of polymeric nanomaterials

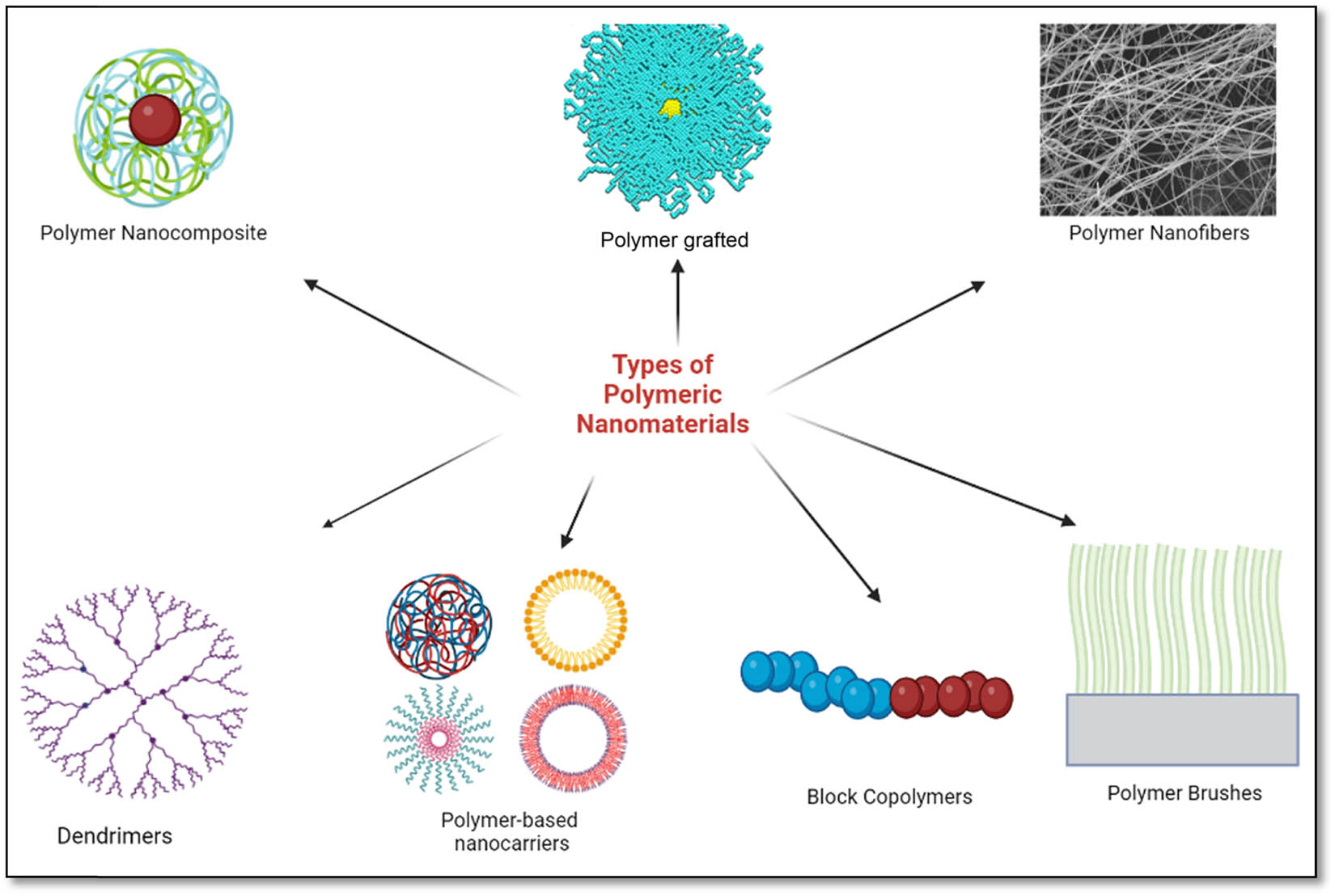

Biocompatible and biodegradable polymer-based nanomaterials are becoming increasingly popular because of their remarkable properties, such as their small size and their ease of incorporation into various materials. They are designed to be used for different applications in fields such as biomedical imaging, drug delivery, catalytic activities, and sensing. They are usually designed to have a very large surface area and a high degree of accessibility, and can also be tailored to exhibit various biological, mechanical, and optical properties (41,42). There are several types of polymeric nanomaterials (Figure 2).

Types of polymeric nanomaterials.

3.1 Polymer nanocomposites

Polymer nanocomposites are materials that consist of two distinct components: a polymer matrix, which is a continuous phase combined with nanofillers, which is a discontinuous phase or reinforcement (in the form of nanoparticles, such as ceramics, metals/metal oxide, or carbon-based nanoparticles). The addition of these nanofillers creates unique structures with advanced characteristics and properties such as mechanical, electrical, thermal, and chemical properties of the nanocomposite (43). For example, polymers that are reinforced with carbon nanotubes have been shown to have increased tensile strength and stiffness compared to traditional polymeric material (44). Polymer nanocomposite also shows excellent barrier properties that make them suitable for application in food packaging, coatings, and medical devices (45,46). Among the promising applications of polymer nanocomposites, polymer nanocarriers that are used to encapsulate and deliver drugs have gained more attention due to the increased efficacy of drug loading/encapsulation (47). They have also been used for biomedical imaging applications (48).

3.2 Polymer nanofibers

These are a class of nanomaterials composed of nanofibrils that have properties and characteristics that make them ideal for applications in many fields. They are made from a combination of polymers and nanotechnology and possess some remarkable properties that are not found in conventional materials. These nanofibers with a diameter in the nanoscale range (1–100 nm) can be synthesised using different synthesis methods to create fibres of various shapes, sizes, and compositions. They can be made by spinning polymer solutions or melting through a nozzle or spinneret (49). The unique properties of the polymer nanofiber, such as its flexibility, lightweight, high strength, and corrosion resistance, make them suitable for application in many industries ranging from biomedical to automotive. For example, polymer nanofibers have been used as scaffolds (50), wound dressings (51,52), and delivering of drugs (53) in the biomedical field. They are also used in lithium-ion recovery (54) which is very useful for battery-related industries, filtration systems such as water and air purification systems (55,56), and also used in the production of fuel cells (57). They can be used to create conductive materials, as well as to store and transport liquids, gases, and biological molecules (54). Furthermore, they can be used to create flexible and transparent displays, as well as to create nanosensors for use in different industries (58,59). The automotive industry has also taken advantage of the unique characteristics of polymer nanofibers, using them to create lightweight, fuel-efficient vehicle components (60). With further research, the potential for polymer nanofibers is sure to expand and provide new and exciting opportunities for researchers and engineers.

3.3 Polymer-grafted nanoparticles

These are nanoparticles that are a relatively recent addition to the field of materials science, and their potential for technological development is immense. Polymer-grafted nanoparticles are nanomaterials that have been coated/attached with a thin layer of polymer on their surface which can improve their stability and compatibility with other materials (61). This concept of polymers attached to nanoparticles has been studied extensively and has resulted in many potential applications. The most impressive applications of polymer-grafted nanoparticles are in drug delivery systems. By having polymers and nanoparticles attached, the loading capacity of the drug can be increased by up to five times, allowing for more drugs to be administered effectively and efficiently (62,63). This impressive and amazing phenomenon has the potential to revolutionise the way drugs are administered and distributed, as many drugs can now be efficiently tested and administered without having to worry about being wasted or lost. Polymer-grafted nanoparticles have also been used in other fields, such as tissue engineering and sensors (64,65). The hybrid combination of nanoparticles attached to the surface of polymers can make them more resistant to mechanical and chemical damage, and they can also interact more effectively and efficiently with biological cells and other molecules. This can be used to create better tissue scaffolds or better biosensors, leading to better and more reliable medical treatments. Moreover, the application of polymer-grafted nanoparticles in dielectric capacitors has also been exploited (66). With more research, polymer-grafted nanoparticles could be used in a variety of ways and revolutionise the field of materials science.

3.4 Dendrimers

These are a type of specialised nanomaterial with a highly branched 3-dimensional structure, and a well-defined molecular architecture that are usually used as nanocarriers (67), imaging agents (69), sensors (70), for water purification (68), and to deliver drugs (71) in a biological system because of their unique size, shape, functional groups, and chemical functionalities. They consist of a central core that is characterised by a highly branched tree-like structure with many functional groups. This unique structure gives dendrimers a special opportunity to engage in a multivalent reaction. Dendrimers are made of polymers with a repeating structure and they can be several nanometres in size. They are generally synthesised through a step-by-step iterative approach known as the divergent or convergent approach. In the divergent approach, dendrimer formation grows outwards from the multifunctional core molecule, which serves as the central scaffold for dendrimer growth. The core molecule is functionalised with a branching unit containing one reactive site and two dormant groups. The core molecule reacts with these branching units to form the first-generation dendrimers. The new periphery of the molecules is then reactivated for a new reaction with monomers, thereby forming the second-generation dendrimers, and the iteration keeps repeating itself, forming multiple generations. As for the convergence approach, the synthesis/formation starts from the exterior, starting with a single unit that eventually becomes the outermost structure of the final dendrimer. Once the desired generation is achieved, dendrimer growth is terminated by attaching specific functional groups which are very useful for different applications such as biomedical imaging, drug encapsulation, or targeting ligands (72). Each dendrimer is made up of many branches of polymer, forming a spherical structure with several functional groups spread along the surface. These functional groups can be designed to interact with different molecules, and can also contain drug molecules or other materials (73). Dendrimers have a high degree of solubility due to their highly branched structure and surface area, which enables them to be applied in a field of study. For example, the dendrimer surface can be decorated with functional groups to target specific cells or organs in the body (74). They can also be used to transport other materials, such as drugs, genes, or proteins (75).

3.5 Polymer brushes

When thin layers of polymer are grafted onto the surface of another core layer, they form a structure known as a polymer brush. They are usually composed of a core layer of polymers, which are densely packed together, and surrounded by an outer layer of polymers, which are loosely packed together. This combination creates a brush like structure that is flexible, strong, and biocompatible (76). Polymer brushes have been used in different fields, from materials science to medical implants. In materials science, for example, they can be used to increase surface tension or modify surface energy. These modifications allow for improved adhesion of coatings and improved wear resistance (77). In medical applications, polymer brushes can be used as an antibacterial coating, hip and knee joint replacement coating, or implant coatings such as orthopaedic implants and dental implants. The brush like structure increases the surface area of the implant, thereby allowing for a more secure attachment to the bone or other tissues (78,79,80). In addition, its unique properties can provide a barrier to bacterial adhesion, thus reducing the risk of infection. Polymer brushes are also used in the pharmaceutical industry as nanocarriers that can be tailored to specific needs. Brushes can be designed to release the drug at a programmed rate or to shield and protect the drug from degradation or premature release as a result of external forces such as light or heat, or enzymes (81). As such, the properties of polymer brushes are attractive for many different applications.

3.6 Block copolymers

These are polymers that are made up of two or more polymeric chains that are chemically distinct but covalently bonded together. They can self-assemble into nanoscale structures. Block copolymers, in general, comprise two distinct types of blocks. The first type is the “hard” block, which is made of molecules that are not as flexible or as easily deformable as the “soft” block molecules. The second type is the “soft” block, which is made of molecules that are more flexible and deformable. The combination of the two types of blocks allows the formation of a variety of structures such as cylindrical or spherical depending on the ratios and proportions of the two blocks (82). Block copolymers have had multiple applications in medicine and in the automotive industry. In medical applications, block copolymers are often used to create medical microspheres, which are small vehicles that are used for drug delivery purposes (83). They have also been used for nanolithography (84). In industrial applications, they are used to create some kind of hybrid materials that have unique properties, such as the ability to resist heat or chemical degradation (85). In addition, block copolymers can also be used to create biodegradable materials, such as plastics and composites (86). The biodegradable materials created by block copolymers can be used in the food and construction industries. Block copolymers are also used in the production of additives (87), biosensors (88,89), pharmaceuticals, and cosmetics (90).

3.7 Polymer-based nanocarriers

Polymeric nanocarriers are a unique, novel, and fascinating type of nanocarriers that possess the potential to transform medicine. These nanocarriers are extremely small vehicles that can transport drugs, vaccines, and other molecules to a specific area or cell in the body. Depending on their application, these nanocarriers consist of different types of materials, including lipids, proteins, and polymers. Among these, polymer-based nanocarriers are considered a better option due to their flexibility, biocompatibility, and ease of synthesis (91). Polymeric nanocarriers are made up of biocompatible polymers, which are materials that do not cause harm to living tissues. They have many advantages over traditional drug delivery systems. First, they can deliver drugs to a specific target, bypassing the need to administer high doses of a drug to the entire body. This can result in fewer side effects and better efficacy. For instance, a study designed a nanocarrier using luteinizing hormone-releasing hormone peptide with specific targeting ligands for cancer cells to minimise the effect of chemotherapy drugs on healthy cells while simultaneously enhancing drug inflow and retention of the drug in cancer cells (92). Second, the nanocarriers can protect drugs/cargo from the body’s natural metabolic processes, thus, increasing the drug’s shelf life and decreasing the need for continuous administration of the drug to the entire body. Afrouz et al. (93) designed a fluorescence correlation spectroscopy (FCS) method to track and monitor the circulation time, stability, and premature release of drugs from the nanocarrier in a highly dense and complex environment in the body. Third, the design and targeting of specific types of cells, such as cancer cells, can be achieved through modification of the surface of the nanocarrier surface with the help of ligands, which can be effective in delivering drugs directly to the diseased cells (92). This implies that the drugs can be programmed to be released over a certain period, thus allowing a lower overall dose of the drug to be administered to the whole body. This has the potential and possibility of decreasing the cost of treatment and also improving patient compliance. In addition, polymer-based nanocarriers are also being explored for other applications in the field of tissue engineering and gene therapy. For example, they could be used to deliver genes to a specific tissue, allowing the expression of desired proteins in the target tissue (94). Polymer-based nanocarriers are a promising technology that could revolutionise the field of medicine. They offer a more targeted and cost-effective form of drug delivery, with the potential to improve patient outcomes. They could also be used in a variety of other applications, such as energy conversions, making them an exciting technology for the future.

4 Design, fabrication, and characterisation of polymer-based nanocarriers

4.1 Design of polymer-based nanocarriers

Polymer-based nanocarriers are noble, specialised, and incredibly small vehicles that are engineered to transport and deliver materials or cargo such as drugs, genes, vaccines, and other therapeutic molecules in the body. They are designed to be biocompatible and biodegradable, which means they can be used safely in vivo, and can also target specific areas of the body without causing harm to healthy tissues or cells. The design of polymer-based nanocarriers is a critical step in developing effective nanocarriers. This section will detail the most important aspect of designing polymer-based nanocarriers, including the selection of suitable polymers, the preparation of nanocarriers, surface modification, loading of cargo (drug or genes), and cargo release kinetics.

4.1.1 Selection of the appropriate material

The first and most important step in the fabrication and design of polymer-based nanocarriers is selecting the best material. Selecting the polymer is based on the intended properties that the nanocarrier should possess. These properties can be biocompatibility, biodegradability, stability, drug loading capacity, nanocarrier release kinetics, or ability/properties that enable them to interact with and deliver their cargo to targeted sites (91). They also provide the nanocarrier with its structural and functional properties. Natural polymers are known to be biocompatible, less toxic, and biodegradable. Chitosan, alginate, and hyaluronic acid have been used in the fabrication of polymer nanocarriers for various types of drugs and biomolecules, including proteins, peptides, and genes. For example, chitosan, which is derived from chitin, is a biopolymer that is known to possess good mucoadhesive properties (95). Mucoadhesion is the ability of a substance to attach to mucosal surfaces, such as those found in the gastrointestinal tract, respiratory tract, and urinary tract. So, fabricating a chitosan-based nanocarrier to target respiratory or gastrointestinal tract infection will prove to be more effective than a traditional nanocarrier. Lee and Mooney (96) fabricated a chitosan nanocarrier that is functionalised with graphene oxide (GO) and used for the delivery of genes and water-soluble anticancer drugs. The nanocarrier shows a higher loading capacity and remarkably high cytotoxicity in Hela cells and HepG2 cells. The same functionalised chitosan graphene nanocarrier was able to contract plasmid DNA into a stable nanosized complex. Alginate is a biocompatible, inexpensive, and low-toxic type of biopolymer derived from brown seaweed that is known for its excellent gel-forming properties. They are used as drug carriers and have been applied in tissue engineering to support the growth of cells (97,98). One of the advantages of natural polymers is their unique ability to interact with biological systems, but the physical and chemical characteristics of the polymer might be challenging to control, which might limit their applications in certain fields.

Poly(lactic-co-glycolic acid) (PLGA), polyethyleneimine (PEI), and PEG are considered as synthetic polymers that are biocompatible, biodegradable, and have great tunability and control over their physicochemical properties. PLGA is a copolymer of glycolic and lactic acid that is used extensively in drug delivery applications (4). It can also be produced with varying molecular weights and monomer ratios, which can affect the efficiency of loading drugs, as well as the release kinetics of the nanocarrier. Similarly, PEI is a type of synthetic polymer that has found its use as a gene delivery vehicle due to its unique ability to encapsulate and protect the content of its cargo like DNA (94). PEG is also another example of a synthetic polymer used as a nanocarrier. It helps to increase the circulation time of nanocarriers by reducing their recognition and uptake by the body’s immune system (99). However, synthetic polymers can have high toxicity and immunogenicity, which can limit their use in certain applications (100).

A hybrid polymer from natural and synthetic polymers can be formed that has the properties and advantages of both natural and synthetic polymers. For example, the combination of chitosan and PLGA can enhance the biocompatibility and drug release kinetics of the nanocarrier (101). Hybrid polymers fabricated with varying ratios of natural and synthetic polymers can have an impact on the physicochemical properties and drug release kinetics of the nanocarrier to a great length. Once the polymer has been selected, the next step is to modify the polymer so that it has the desired properties. For example, Lee et al. (102) fabricated a chitosan gold nanocarrier functionalised with PLGA to improve oral insulin uptake. The nanocarrier was found to be a highly effective vehicle for the loading and release of insulin at various pH levels.

4.1.2 Preparation of the nanocarriers

The preparation of polymer-based nanocarriers involves several steps, including polymer synthesis, nanoparticle formation, and drug/cargo loading. There are various techniques available for the preparation of polymer-based nanocarriers with specific physicochemical properties. Most of them are explained in Section 4.2.

4.1.3 Nanocarrier surface modification for active targeting

Surface modification is the process of changing the surface properties and characteristics of a material to improve its performance or functionality. In terms of polymer-based nanocarriers, modifying their surface can improve their stability, biocompatibility, and targeting capabilities. Modification can be done by attaching ligands or other types of macromolecules and functional groups to the polymer surface or coating the surface with a layer of another material thereby changing the surface properties (103). An example of this is a lipid-based nanocarrier that is coated with a thin layer of PEG to enhance the circulation time of the nanocarrier in the bloodstream while reducing the possibility of its clearance by the immune system (104). A common method of surface modification techniques used in polymer-based nanocarriers is the attachment of ligands that can interact with specific receptors that are found on the surface of cells for active targeting. Active targeting is achieved through the process of molecular recognition of the target tissue or cell via different molecular signatures that are overexpressed at the affected site either through antigen–antibody interaction, targeting with the help of aptamers, or through the ligand–receptor interaction. Ligands employed for active targeting include carbohydrates (such as galactose, mannose, hyaluronan, glycyrrhizin, and lactose), small molecules (such as vitamin B7 and B9, biotin, selegiline, alendronate, selectin, and curcumin), peptides and proteins (such as octapeptide octreotide, lectin, glutathione, cysteine and glycine, tripeptide Arg-Gly-Asp (RGD) with their derivatives, cell-penetrating peptides, epidermal growth factor receptor, A665, A666, Tet1, hNgf EE, and transferrin), mini aptamers, and antibodies (91). These ligands have been used to target brain, breast, lung, and ovarian cancer cells. The modification mechanism includes physical adsorption, covalent binding, and encapsulation. Physical adsorption involves the noncovalent surface binding of molecules to the nanocarrier through electrostatic, hydrophobic, or van der Waals force of attraction. Covalent binding involves a chemical bond in between the surface of the polymeric nanocarrier and the modified functional group or ligand. Encapsulation involves the entrapment of the functional group or ligand within the nanocarrier matrix. Ligands can be decorated on the surface of the nanocarrier through physical adsorption or covalent binding (105,106,107). Ligands can be used to improve the targeting capabilities of the nanocarrier, enabling it to precisely deliver drugs to specific cells. Furthermore, the nanocarriers should possess specific physicochemical properties that enable them to evade immune surveillance and prolong their circulation in the body.

4.1.4 Loading of cargo/drug

After nanoparticle formation, the drug is loaded into the nanocarrier and must be chosen on its solubility and stability in the chosen polymer matrix. There are various mechanisms for loading drugs into the nanocarrier, including physical entrapment, chemical conjugation, and electrostatic interactions.

4.1.4.1 Physical entrapment/encapsulation

Physical entrapment is a relatively simple, versatile, and reproducible method used to load drugs into polymer-based nanocarriers that are employed for active targeted drug delivery applications. The physical entrapment/encapsulation method involves physically trapping the drug molecules or cargo within the polymer matrix of the nanocarriers during the synthesis process. This is usually done through a non-covalent interaction and can be used for both hydrophilic and hydrophobic loading of drugs (108). The physical entrapment method is known for its simplicity. The process of loading drugs into nanocarriers through physical entrapment is relatively straightforward and does not require complex chemical reactions or expensive equipment. This makes it a cost-effective method for drug loading. For instance, Trofymchuk et al. (109) incorporated an anticancer drug (adriamycin – ADR) into polymeric micelles, thus forming a block copolymer nanocarrier. The structural stability of the block copolymer was found to depend on the physical entrapment of the anticancer drug and the anti-tumour activity was also found to be high against the C 26 tumour. Similarly, ADR entrapment in the AB block copolymer was also investigated by Park and Na (110). Fluorescence spectroscopy and gel permeation chromatography were used to determine the successful entrapment of the ADR. However, there are also some limitations associated with the physical entrapment. One of the main limitations is the potential for drug leakage from the nanocarrier, especially during storage or transportation (111). This can be addressed by modifying the polymer matrix to improve its stability and prevent drug leakage. Another limitation is the potential for premature drug release from the nanocarrier, which can lead to suboptimal drug discharge at the target site. However, this problem can be addressed by controlling the release kinetics of the nanocarrier using methods like modifying the polymer matrix or incorporating stimuli-responsive components (112,113).

4.1.4.2 Chemical conjugation

In this method, drug molecules or the cargo of the nanocarrier are covalently attached to the polymer matrix of the nanocarrier through chemical reactions (109). Chemical conjugation offers several advantages over other drug loading, including high drug loading efficacy, specificity, controlled drug release kinetics, and improved stability of the drug (114). One of the main benefits of chemical conjugation is its high drug loading efficiency. Since the cargo is covalently attached to the polymer matrix, a high degree of drug loading can be achieved, which can result in a more efficient drug delivery system (114). Furthermore, the controlled chemical conjugation of drugs to the polymer matrix allows for precise control over the number of drug molecules attached to each nanocarrier, resulting in a more uniform drug distribution. For instance, Sharp and Honig (115) synthesised a polyN-(2-hydroxypropyl)methacrylamide (HPMA) nanocarrier functionalised with polyclonal and monoclonal antibodies to deliver anticancer drug doxorubicin. Another advantage of chemical conjugation is the ability to control the release kinetics. This is achieved through modification of the chemical structure of the drug molecule and/or polymer matrix, which can affect the strength and stability of the covalent bonds. When the strength and stability of these bonds are controlled, the release of the drug from the nanocarrier can be tailored to specific conditions, such as pH or temperature. A study tested the hypothesis of the pharmacokinetics of poly(2-oxazoline) drug conjugate nanocarriers with drugs like tetrahydrocannabinol, cannabigerol, buprenorphine, cannabidiol, dronabinol, and rotigotine attached to the nanocarrier through releasable linkages (116). Evidence supports the hypothesis and demonstrated how it can be used to tune drug release kinetics. Chemical conjugation also offers improved stability of the drug, as the covalent bonds between the drug and the polymer matrix prevent the drug from being released prematurely. This can be particularly important for drugs that are unstable or rapidly degraded in the body. However, there are some limitations associated with chemical conjugation. One of the main limitations is the potential toxicity and reduced bioactivity of the drug after conjugation. Chemical conjugation can alter the chemical structure of the drug, which can affect its bioactivity and reduce its efficacy. This can be addressed by optimising chemical conjugation conditions to minimise the impact on the bioactivity of the drug (116).

4.1.4.3 Electrostatic interactions

Electrostatic interactions are a type of noncovalent interaction that can be used to load drugs into polymeric nanocarriers. In this method, drug molecules are attracted to the surface of the nanocarrier through electrostatic forces between the charged groups on the drug and the polymer matrix of the nanocarrier (117). Electrostatic interactions can be particularly useful for loading charged drugs, such as nucleic acids, proteins, and peptides, into polymer-based nanocarriers. A study proposed a perspective that uses electrostatic interaction to enhance drug penetration into cartilaginous tissues due to the inefficiency of current traditional methods, such as intra-articular drug delivery methods, to deliver adequate drugs into cartilage tissue at the desired concentration to trigger a biological response (118). An advantage of electrostatic interactions for drug loading is their simplicity and ease of use. Electrostatic interactions have been employed for loading different types of drugs into various types of nanocarriers without the need for complex chemical reactions or modifications, and they also possess the ability of controlled release kinetics. This can be achieved by modifying the charge density or pH of the surrounding environment, which can affect the strength of the electrostatic interaction between the drug and the nanocarrier. For instance, a study examines the release behaviour of the lovastatin drug from polycaprolactone (PCL) coated β-tricalcium phosphate (119). The lovastatin drug was incorporated into a water-soluble and biodegradable PCL coating where a controlled release was observed when there is a variation in the pH medium. The hydrophilic–hydrophobic interaction between the PLC and the drug was the main factor controlling the release kinetics. So, by controlling the strength of these interactions, the release of the drug from the nanocarrier can be tailored to specific conditions, such as drug release at the targeted site. However, there are also some limitations associated with electrostatic interactions. One of the main limitations is their sensitivity. Some changes in the surrounding environment such as pH or ionic strength can weaken electrostatic interactions thereby, resulting in premature release of the drug, as in the case of lovastatin drug loaded in PCL (119). Another limitation is the potential for reduced drug loading efficiency. Charge density and surface area can influence the electrostatic interactions, which ultimately limit the amount of drug that can be loaded onto the nanocarrier. This can be addressed by optimising the charge density and ionic strength, as well as the pH of the surrounding environment (120).

4.1.5 Cargo release kinetics

Drug loading and release studies are used to determine the amount of drug to be loaded and the release kinetics. The amount of drug that is to be loaded is a measure of the amount of drug that can be incorporated into the nanocarrier. The kinetics is a measure of the rate and extent to which the drug is released from the nanocarrier (121). These parameters can be affected by several characteristics, including polymer properties, nanoparticle size, and pH (122). How the nanocarrier is designed can influence the release kinetics of the nanocarrier. For example, hydrophobic groups at the surface of a nanocarrier can delay the release of hydrophilic drugs by slowing the penetration of water into the nanocarrier (123). Furthermore, stimuli-responsive polymers such as pH- or temperature-sensitive polymers can allow controlled release of cargo in response to changes in environmental conditions at the target site (119). The type of cargo that is loaded into the nanocarrier can also influence the cargo release. For example, the charge of the cargo and size can affect the rate of release from the nanocarrier. Small, highly charged molecules may be released more quickly than larger, less charged molecules (124). The environmental conditions at the target site can also influence the kinetics of cargo release kinetics. The condition of the surrounding environment, such as changes in pH or ionic strength, can affect the electrostatic interactions between the cargo and the nanocarrier, which can influence the release kinetics. For example, a decrease in pH can weaken the electrostatic interactions, leading to a faster release of cargo from the nanocarrier (122). The overall cargo release kinetics from polymer-based nanocarriers is a complex interplay between the properties of the nanocarrier, the cargo, and the target site environment. The complex design and optimisation of nanocarriers to be used as drug delivery vehicles require a thorough understanding of these factors to achieve optimal drug release kinetics and also improve the efficacy of drug delivery. After the fabrication process and drug loading are complete, the nanocarriers are tested to ensure that they possess the desired properties.

4.1.6 Biocompatibility essay

Biocompatibility, as the name implies, is the ability of a material to interact with biological systems without causing adverse effects. For polymer-based nanocarriers, biocompatibility is assessed in terms of their potential toxicity, immunogenicity, and interactions with biological barriers, such as cell membranes and the immune system, which can be done via any of the in vivo or in vitro studies. These studies are specially designed to ensure the safety and effectiveness of the nanocarrier (7). Toxicity is a major concern when designing polymer-based nanocarriers, which can result from many factors such as the size, composition, or surface modification of the nanocarriers. Toxicity is known to cause adverse side effects such as inflammation, cell death, and organ damage. To minimise toxicity, biodegradable and biocompatible polymers PLGA or PEG are commonly employed in fabricating nanocarriers (125). These polymers degrade into nontoxic by-products in the body, minimising the risk of toxicity. Additionally, purification techniques and characterisation of the nanocarriers can be used to remove impurities and ensure the biocompatibility of the nanocarrier. Immunogenicity is another factor that can affect the biocompatibility of a polymer-based nanocarrier. The presence of foreign materials in the body can trigger an immune response, leading to the clearance of the nanocarrier and to decreased efficacy of drug delivery. To minimise immunogenicity, biocompatible polymers that are less likely to elicit an immune response, such as PEG, are commonly used to coat the nanocarrier surface of the nanocarrier (126). Similarly, stimuli-responsive polymers, such as pH-sensitive or temperature-sensitive polymers, can minimise the exposure of the nanocarrier to the immune system and increase circulation time in the body (126). Interactions with biological barriers, such as cell membranes and the immune system, are also critical considerations for the biocompatibility of polymer-based nanocarriers. The surface characteristics of the nanocarrier, such as the surface charge and hydrophobicity, can affect the interaction between the nanocarrier and biological barriers. For example, hydrophobic moieties on the nanocarrier surface can facilitate interactions with cell membranes, promoting cellular uptake of the nanocarrier (127). Similarly, the surface charge of the nanocarrier can influence interactions with the immune system, with neutral or negatively charged nanocarriers less likely to elicit an immune response (128). Overall, the biocompatibility of polymer-based nanocarriers is a critical factor that must be carefully considered during their design and fabrication. Biodegradable and biocompatible polymers, purification and characterisation techniques, and surface modifications can be used to minimise the toxicity, immunogenicity, and interactions with biological barriers of the nanocarrier. When the biocompatibility of polymer-based nanocarriers is ensured, the safety and efficacy of targeted drug delivery can be improved, which will subsequently lead to better therapeutic outcomes for patients.

4.2 Fabrication of polymer-based nanocarrier

Fabrication of nanoparticles can be achieved by either breaking down of bulk material into nanoparticles or building the nanoparticles from their respective atoms. With regard to nanocarriers, the top-down approach usually employs a preprepared polymer material to synthesise the NPs. Such a technique includes emulsion diffusion/evaporation, electrospinning, salting out, and the nanoprecipitation method. Bottom-up methods, on the other hand, normally start from a monomer and build up to form a polymer. Precipitation polymerisation, chemical vapour deposition (CVD), interfacial polymerisation, thermal, and emulsion polymerisation, and solution-based techniques are the specific forms of synthesis.

4.2.1 Emulsion evaporation method

Emulsion evaporation is a process used to produce polymer nanocarriers using the emulsion polymerisation technique. This method involves the preparation of an emulsion of monomers, stabilisers, and water, followed by the initiation of the polymerisation with the help of a catalyst or initiator. The polymerisation reaction takes place within the emulsion droplets, which results in forming polymer nanoparticles. The polymer nanoparticles are obtained by evaporating the water from the emulsion during emulsion evaporation, thus leaving behind the solid nanoparticles. The nanoparticle properties such as size and shape can be affected by simply adjusting the synthesis parameters such as the concentration of the polymer, the type of organic solvent, the stirring rate, and the temperature of the evaporation process. For example, when the concentration of the polymer is increased, it can result in larger nanoparticles, while the use of a different organic solvent can affect the surface chemistry. As such, optimisation of the synthesis parameters is very necessary to obtain nanoparticles with the desired properties (129,130,131).

4.2.2 Emulsion diffusion method

Polymeric nanoparticles can be synthesised by emulsion of polymer solution in a nonsolvent, followed by the diffusion of the nonsolvent into the polymer solution, thereby inducing precipitation and formation of the polymer nanomaterial. In simpler terms, a mixture of polymer and water-immiscible organic solvent is added to an aqueous solution in a dropwise manner. The aqueous solution containing the stabiliser or surfactant is then sonicated or stirred to form an emulsion containing the dispersed polymer droplets. Then, the nonsolvent is added dropwise to the emulsion. As the nonsolvent diffuses with the polymer solution, it induces precipitation that forms the polymer nanoparticles. This method can be viewed as a variation in the solvent evaporation technique used in the solution-based synthesis of polymeric nanoparticles. Like emulsion evaporation, polymeric nanoparticle properties such as size, morphology, and surface chemistry can be regulated by adjusting the synthesis condition, such as polymer concentration, organic solvent, the type and concentration of the non-solvent, and the stirring rate (126).

4.2.3 Electrospinning method

Electrospinning is a process of fabricating nanofibers. It involves using an electric field with a melt or polymer solution. The process begins with applying a high voltage through the polymer solution or melt, which subsequently creates an electrically charged jet of polymer that is then drawn out into a fine fibre by an opposing electric field or collector plate, or rotating drum, thus forming a nonwoven mat or a fabric-like structure. The result is a continuous nanoscale fibre with a high surface area-to-volume ratio (132). The electrospinning process can be used to fabricate nanofibers using different types of synthetic and natural polymers, including polyethylene, polypropylene, nylon, polystyrene (PS), and chitosan (133,134). The properties of nanofibers, such as diameter, morphology, and surface chemistry, can be regulated by adjusting various synthesis conditions such as polymer concentration, the electric field strength, the space between the needle and the collector, and the temperature and humidity of the surrounding environment (135). This method has some advantages. First, it is a relatively simple and inexpensive process that only requires a voltage source, a syringe, and a collector plate. Second, it can create nanofibers with different diameters, from nm to mm. Third, the surface area of the electrospun nanofibers can be useful for several applications ranging from biomedical applications to engineering applications. Electrospinning has many potential applications. For example, electrospun nanofibers have been used to create scaffolds, drug delivery systems, and high-performance battery electrodes (136,137). However, there are still some challenges that need to be addressed to make electrospinning a more practical and scalable process for industrial applications, including improving the consistency and reproducibility of nanofibers and increasing the production rate (138).

4.2.4 Salting out

Fabricating a polymer nanocarrier via the salting-out method involves adding salt to a polymer solution, thereby causing it to precipitate polymer nanoparticles. The salt causes the polymer to become less soluble and to form aggregates, which then form nanoparticles. The salting process for polymeric nanomaterial synthesis typically involves the following steps: first, the dissolution of a well-suitable polymer solvent to form a clear solution. The amount of dissolved polymer can affect the size and morphology. Second, a high concentration of salt is added to the polymer solution. The salt concentration and type of salt used will depend on the specific polymer being used and the desired nanoparticle properties. Third, the polymer solution is stirred and incubated for some time, allowing the salt to interact with the polymer and induce nanoparticle formation. Then finally, the resulting nanoparticles were separated from the solution by centrifugation and washed to remove any residual salt or impurities (139,140). The salting-out method for polymeric nanoparticle synthesis has several advantages. It is quite simple and inexpensive and has the potential to produce polymer nanomaterial in large quantities (141). The salting method is suitable for synthesising different types of polymeric nanoparticles, including those made from PS, poly(methyl methacrylate), and PEG, which has potential for application in the biomedical field (142).

4.2.5 Nanoprecipitation

This method involves the rapid mixing of two immiscible liquids, typically a polymer solution and an antisolvent. The mixture of the solution results in precipitation of the polymer. It is a simple method for fabricating polymeric nanoparticles with desirable size and surface properties. The basic principle of nanoprecipitation is to use a polymer that is soluble in a solvent but not in a non-solvent, also called an antisolvent. When the antisolvent is added to the polymer solution, it becomes supersaturated, leading to the formation of nanoparticles. The nanoprecipitation process generally involves the preparation of a clear solution mixture of polymer and a suitable organic solvent. The polymer concentration can vary depending on the desired size and morphology of the nanoparticles. Then, an antisolvent is added rapidly to the polymer solution while the mixture continues to be stirred vigorously. The antisolvent causes the polymer to precipitate as a result of the decreasing solubility of the polymer. Finally, the resulting nanoparticle suspension was then collected by centrifugation or filtration and washed to remove any residual solvent or impurities. This method can be used to synthesise a variety of polymeric nanoparticles, including those made of PS, poly(methyl methacrylate), and PEG (143,144). Nanoprecipitation has potential applications in many biomedical fields, such as imaging and sensing, among others (145). This method is easy and scalable, and control of size and surface modification is achievable by adjusting the ratio of polymer to antisolvent, the concentration of the polymer, and the stirring speed (141).

4.2.5.1 CVD

CVD is a technique for depositing thin films of materials on the surface of a substrate. This process involves the reactions of highly reactive gas molecules with the surface of the substrate to form a thin film. The CVD process begins when the reactant gases enter the deposition chamber and are brought to a high temperature. At this temperature, the reactants break down into their component atoms which then react with the substrate surface. Depending on the reactants used, this reaction can result in the formation of either a single- or multiple-layer film. On the basis of the properties of the substrate, the film may be deposited as a solid, an oxide, or a combination of both. Once the layer has been deposited, the film is then subjected to post-deposition processing, such as oxidation, etching, and baking, to refine its properties (146,147). This method has been used to synthesise many polymeric nanomaterials including polymer films (148). For example, the growth of carbon nanotubes involves the catalytic decomposition of a hydrocarbon gas, such as methane or ethylene, on a metal substrate, typically iron, nickel, or cobalt. CNTs can be grown in a vertical or horizontal orientation which depends on the substrate type and growth conditions (149). Another instance is the deposition of a thin polymer film on a substrate. This process involves the use of a polymer precursor, such as a monomer or polymerizable gas, which is introduced into the reaction chamber along with a reactive gas. The reactive gas can be used to initiate the polymerisation reaction which results in the formation of a thin polymer film on the substrate (148). The properties of the resulting film can be customized by varying reaction conditions like temperature, pressure, and gas flow rate. CVD synthesis of polymeric nanomaterials has a wide range of applications, including the production of electronic devices, sensors, and biomedical materials. For example, CNTs have been used as conductive additives in composites and as electrodes in batteries and supercapacitors (150). Polymer thin films have been used as coatings to improve the biocompatibility of medical devices, antireflux, and protective coatings for electronic devices (151,152,153). CVD is often used to produce high-quality components, due to its ability to produce uniform and homogeneous films and is also used instead of wet chemical processes, as it can produce films with greater control of their physical and chemical properties (154). Furthermore, CVD is often used to produce large-scale components, such as integrated circuits and flat panel displays, due to its ability to create large-area films quickly (155). Types of CVD include thermal CVD, plasma-enhanced CVD, low-pressure CVD, and atomic layer deposition (156).

4.2.5.2 Interfacial polymerisation

Interfacial polymerisation is used to synthesise polymeric nanoparticles at an interface between two immiscible liquids. Monomer polymerisation occurs in between the two phases (usually an aqueous phase and an organic phase), thereby resulting in nanoparticle formation. The polymerisation process typically involves a monomer and initiator dissolved in one of the immiscible liquids, typically the organic phase. The choice of monomer and initiator depends on the intended characteristics of the resulting nanoparticles. Then, the immiscible liquids are brought into contact, forming an interface between them. The interface can be stabilised using a surfactant or emulsifying agent. The monomers at the interface are polymerised by adding a catalyst or by a chemical reaction triggered by heat or light. The polymerisation reaction occurs at the interface and the growing polymer chains form nanoparticles. Finally, the nanoparticles are collected by separating them from the bulk solution using centrifugation, filtration, or other methods. They are then purified to remove any unreacted monomers, surfactants, or other impurities (157,158). Interfacial polymerisation can be used to synthesise a wide range of polymeric materials such as core, nanocapsules, and nanospheres (159,160). These nanomaterials have found applications in drug delivery, catalysis, and imaging (160). They have several advantages, such as producing well-defined narrow-sized particles and control over the composition and morphology (158). However, it also has some limitations, such as the need for careful control of reaction conditions and the difficulty of scaling up the process (161).

4.2.5.3 Solution-based techniques

Solution-based synthesis of polymeric nanomaterials is a commonly used technique for producing nanoparticles with controlled size, morphology, and properties. This method involves dissolving monomers or prepolymers in a solvent, followed by the addition of a crosslinker and initiator to initiate the polymerisation reaction. The reaction proceeds in the solution, resulting in the formation of polymeric nanoparticles (162). One common approach to solution-based synthesis is known as the “solvent evaporation” method. In this method, a monomer or a prepolymer is dissolved in a solvent, and a crosslinker and initiator are added. The mixture is then stirred or sonicated to ensure homogeneity. The solution is then added dropwise to a nonsolvent or anti-solvent, which causes the polymer to precipitate out of the solution and form nanoparticles. The resulting nanoparticles are collected by filtration or centrifugation and can be further characterised and processed (163). Another solution-based synthesis method is known as “microemulsion polymerisation.” This method involves the formation of a microemulsion, which is a thermodynamically stable system consisting of droplets of a dispersed phase (i.e., monomer) surrounded by a continuous surfactant-stabilised phase (i.e., water). A cross-linker and initiator are added to the microemulsion, and the polymerisation reaction occurs within the droplets. The resulting polymeric nanoparticles are then recovered by various methods, such as filtration or centrifugation (164). Solution-based synthesis allows for the production of nanoparticles with a high degree of control over size, morphology, and composition. This technique can be used to produce a wide range of polymeric nanoparticles, including core-shell, dendrimer, and block-copolymer nanoparticles. Additionally, solution-based synthesis can be scaled up, making it suitable for large-scale production (165). However, this method typically requires the use of organic solvents, which can be hazardous to handle and dispose of. Therefore, the development of green synthesis approaches for polymeric nanoparticles is an area of active research.

4.2.5.4 Self-assembly-based approach

Self-assembly is a technique that involves the continuous formation of molecules into a specific structure without the need for external forces. This can be achieved through hydrogen bonding mechanisms and electrostatic and hydrophobic interactions. One method of a self-assembly-based approach for fabricating polymer-based nanocarriers is the use of block copolymers. Block copolymers are made up of two or more chemically distinct polymer blocks that are covalently linked together. As a result of the incompatibility between the different polymer blocks, they tend to spontaneously organise into well-defined nanostructures, such as micelles, vesicles, and nanoparticles. Self-assembly can be initiated by stimuli such as pH, temperature, and ion concentration and does not require the use of organic solvents or surfactants, making it a simple and environmentally friendly method for nanocarrier preparation (166). For example, self-assembled nanocarriers can be prepared by mixing cationic and anionic polymers in a solution, which results in the formation of nanoparticles through electrostatic interactions (167). Self-assembly can also be used to prepare nanocarriers with specific targeting properties, such as incorporating ligands that can interact with specific receptors on the surface of cells (168).

4.2.5.5 Layer-by-layer assembly (LbL)

LbL is a sequential deposition of alternating layers of oppositely charged polymers onto a substrate, creating a multilayer film or coating. The resulting nanocarrier can be customized for a variety of applications, including drug delivery, sensing, and tissue engineering (169). The LbL assembly allows for precise control over the width and composition of the multilayered film, which can be customized to optimise the properties of the nanocarrier. The process is versatile and can be used for several substrates and templates, including nanoparticles, fibres, and surfaces. Finally, LbL assembly can be performed using water-based solutions, which is advantageous for biological applications as it minimises the use of organic solvents. The process of assembly of LbL starts with the depositing of a charged polymer layer onto the substrate or template. This can be accomplished by immersing the substrate in a solution of the charged polymer or by using a spray-coating or spin-coating technique. Once the first layer has been deposited, the substrate is rinsed with a buffer solution to remove any unbound polymer. The process is repeated with a solution of the opposite charge, creating a multilayered film. The choice of polymer is critical in LbL assembly because it affects the properties of the produced nanocarrier (169). Common polymers used in LbL assembly include polyelectrolytes PEI and poly(sodium 4-styrene sulfonate), and biopolymers, such as chitosan and alginate. The charge of the polymer can be adjusted by modifying the pH or ionic strength of the solution, allowing for precise control over the deposition process (170). The properties of the resulting nanocarrier can be further tailored by incorporating functional groups or biomolecules into the multilayered film. For example, peptides, proteins, and nucleic acids can be incorporated into the nanocarrier to facilitate targeted drug delivery or gene therapy. Additionally, polymers that respond to stimuli, such as temperature-sensitive or pH-sensitive polymers, can be incorporated into the nanocarrier to facilitate triggered drug release. The assembly of LbL has been applied in biomedical applications and tissue engineering scaffolds (171,172).

4.2.5.6 Thermal and emulsion polymerisation

Emulsion polymerisation and thermal polymerisation are two common methods for synthesising polymeric nanomaterials. Emulsion polymerisation involves dispersing the monomer in an aqueous solution containing a surfactant, resulting in the formation of nanometre-sized droplets. Polymerisation is triggered within the droplets by the addition of an initiator, leading to the formation of polymeric nanoparticles. Surfactant plays an important role in stabilising the droplets and controlling the size and morphology of the resulting polymeric nanomaterials. The formation of these polymers can be easily controlled by the synthesis condition (173). The first step in emulsion polymerisation is the formation of an emulsion. The monomer is dispersed in an aqueous medium containing a surfactant, which stabilises the droplets and prevents them from coalescing. Surfactant also serves as a template for polymer particles, influencing their size, shape, and surface properties. The choice of surfactant can, therefore, have a significant impact on the properties of the resulting nanoparticles. Next a polymerisation initiator is added to the emulsion. The initiator can be water-soluble or oil-soluble and can be added in a single shot or gradually over time. The initiator generates free radicals, which initiate the polymerisation reaction and promote the growth of the polymer particles. The polymerisation reaction proceeds as the monomer droplets grow and coalesce to form larger polymer particles. The surfactant stabilises the growing particles, preventing them from sticking together, and promoting their growth in size. The reaction can be stopped at a desired point by quenching the reaction with a quenching agent. The size and morphology of nanoparticles can be characterised using techniques such as dynamic light scattering, electron microscopy, and X-ray diffraction (XRD) (174). Emulsion polymerisation is a versatile and widely used technique for synthesising polymeric nanomaterials, with applications in fields such as drug delivery, coatings, and electronics (175). The technique allows precise control over the size and morphology of the resulting nanoparticles, and the use of surfactants and other additives can further tailor the properties of the particles. It is a relatively inexpensive process.

Thermal polymerisation, on the other hand, involves the initiation of polymerisation by heating the monomer under pressure or a mixture of monomers above their melting point or glass transition temperature. The reaction is typically initiated using a thermal initiator, which generates free radicals or other reactive species that trigger the polymerisation reaction. During the process, cross-linking occurs between monomer units to create a polymer chain (176). Homopolymers, copolymers, block copolymers, and cross-linked polymers can be produced using this method. The resulting polymer properties can be controlled by varying the polymerisation conditions, like temperature, duration of the reaction, and type and concentration of initiator used to trigger the polymerisation reaction. An example of thermal polymerisation synthesis of polymeric nanomaterials is the production of PS nanoparticles. PS is a widely used polymer in many applications, including insulation, electronics, and the production of packaging materials. The thermal polymerisation process of styrene monomers using a radical initiator, such as benzoyl peroxide, produces PS nanoparticles with a narrow size distribution and a controlled morphology (177). Cross-linked polymeric nanoparticles are another example of thermal polymerisation. The process involves the polymerisation of a cross-linking monomer, such as divinylbenzene, along with a primary monomer. The resulting cross-linked polymer nanoparticles have improved mechanical strength and thermal stability compared to their linear counterparts (178). Thermal polymerisation synthesis of polymeric nanomaterials has a wide range of applications, including the production of coatings, adhesives, and composites.

One key difference between the two techniques is the reaction environment. Emulsion polymerisation is typically performed in an aqueous solution which allows for more precise control over particle size and morphology and uses surfactants and other additives to control particle properties, while thermal polymerisation is carried out in a nonaqueous environment and may result in a broader size distribution, and also relies on the choice of thermal initiator to control the properties of the resulting nanoparticles. This can have a significant impact on the properties of the resulting nanoparticles, as the presence of water can affect the stability of the polymer particles and their physical properties. Furthermore, the choice of monomers and initiators can differ between the two techniques. In emulsion polymerisation, the choice of surfactant and monomer significantly influences the properties of the resulting nanoparticles. In thermal polymerisation, the type and concentration of the thermal initiator can impact the properties of the nanoparticles.

4.2.6 Green synthesis approaches to polymeric nanomaterial synthesis

Polymeric nanomaterial synthesis via the green approach/method explores the production of nanoparticles without the use of hazardous chemicals and solvents. The increasing concern over the environmental impact of chemical synthesis methods led to the development of more sustainable approaches for the synthesis of polymeric nanoparticles. Green synthesis approaches for polymeric nanoparticle synthesis use eco-friendly, nontoxic, and renewable materials and solvents such as plant extracts. These phytochemicals are used to replace toxic chemicals and their by-products. Here are some examples of green synthesis approaches for polymeric nanoparticles.

4.2.6.1 Biopolymer-based synthesis

Biopolymer-based synthesis refers to the use of naturally occurring polymers, such as proteins, polysaccharides, and nucleic acids, as templates for the synthesis of polymeric nanomaterials. Biopolymers are eco-friendly and attractive materials for nanoparticle synthesis. There are several approaches to the biopolymer-based synthesis of polymeric nanoparticles. One method involves the use of protein-based templates for the synthesis of inorganic nanoparticles. For example, bovine serum albumin has been used to synthesise gold nanoparticles, where the protein reduced and stabilised the nanoparticles (179). Polysaccharides, such as hyaluronic acid, chitosan, and starch have also been employed as starting materials for synthesising polymer nanomaterials. Chitosan is a natural polymer derived from chitin; a biopolymer found in crustacean shells. It has been used to prepare nanoparticles through a variety of techniques, including emulsion crosslinking, ionic gelation, and polyelectrolyte complexation. Chitosan can also be used to reduce silver nitrate to produce chitosan-silver nanoparticles on linen fabric for antibacterial activity (180). Starch can be used to reduce gold ions to produce starch-gold nanoparticles (181). Hyaluronic acid is a glycosaminoglycan that is widely distributed in the human body and has been used to prepare nanoparticles for drug delivery applications (182). Another approach to biopolymer-based synthesis involves the use of nucleic acids, such as DNA and RNA, as templates for the synthesis of nanoparticles. For example, DNA has been used as a template for the synthesis of gold and silver nanoparticles, where nucleotide bases act as reducing agents, and the DNA strands provide stability to the nanoparticles (183,184). The biopolymer-based synthesis of polymeric nanoparticles offers several advantages, including the use of renewable and biodegradable materials, the potential for targeted drug delivery, and reduced toxicity compared to synthetic polymers (185). However, it also presents some challenges, such as the need for careful control of the synthesis conditions to ensure reproducibility and the potential for low yields or low drug loading capacity (186). Despite these challenges, biopolymer-based synthesis of polymeric nanoparticles is an active area of research and holds promise for a wide range of biomedical and environmental applications.

4.2.6.2 Microbial synthesis

The microorganisms are used to produce nanoparticles that are made up of biopolymers or biocompatible polymers. This method has the potential for green and sustainable synthesis to produce nanomaterials. One approach to the microbial synthesis of polymeric nanomaterials is through the use of biopolymer-producing microorganisms. For example, bacterial strains such as Acinetobacter (187), Pseudomonas (188), and Azotobacter (189) have been used for the synthesis of biopolymer nanoparticles such as polysaccharides. By the use of specific growth conditions and modifying the nutrient media, the production of biopolymers can be optimised for nanoparticle synthesis. Another approach is through the use of genetically modified microorganisms. By engineering the microorganisms to express specific enzymes or proteins, polymeric nanoparticle synthesis can be controlled and targeted toward specific applications. For example, fungus (190), Escherichia coli (191), and Bacillus subtilis (192) have been genetically modified to produce nanoparticles, such as gold and silver, with controlled size and shape. Another bacterium can be used to synthesise biodegradable polyhydroxyalkanoates, which can serve as a precursor for the synthesis of polymeric nanoparticles (193). Fungi and yeast have also been explored for the microbial synthesis of polymeric nanoparticles. For example, the Fusarium oxysporum has been used for the synthesis of chitosan nanoparticles (194), while the yeast Saccharomyces cerevisiae has been used for the production of polystyrene nanoparticles, respectively (195). Algae have also been used for the microbial synthesis of polymeric nanoparticles. For example, Chlamydomonas reinhardtii microalgae have been used for the synthesis of biocompatible polymeric nanoparticles, such as chitosan and alginate (196). One of the advantages of microbial synthesis of polymeric nanoparticles is the potential for sustainable and eco-friendly synthesis. For example, the use of biopolymer-producing microorganisms can utilise waste materials as nutrient sources, reducing the environmental impact of nanoparticle synthesis. Additionally, microbial synthesis can be easily scaled up for large-scale nanoparticle production and has great potential for sustainable and controlled synthesis of nanoparticles with unique properties (197,198). Although this method is still in its early stages, further research into the use of different microorganisms and their genetic modification can unlock the full potential of microbial synthesis for polymeric nanoparticle synthesis.

4.2.6.3 Plant extract-based synthesis

Plant extract-based polymeric nanomaterial synthesis is an emerging approach for green and sustainable nanoparticle synthesis. This method involves the use of plant extracts, which contain various phytochemicals, such as flavonoids, terpenoids, and phenolic acids, as reducing agents and stabilisers for nanoparticle synthesis (199). This approach has many advantages, including its simplicity, low cost, and absence of toxic chemicals, making it environmentally friendly and sustainable for nanoparticle synthesis. The synthesis approach using plant extracts is typically similar to that used for the synthesis of metal nanoparticles where the reduction of metal ions leads to the formation of metal nanoparticles. The plant extracts can act as reducing agents by donating electrons to the metal ions, leading to their reduction and formation of nanoparticles, and also act as stabilisers by providing a kind of protective layer on the nanoparticle surface to prevent aggregation and improve stability. Similarly, the synthesis of polymeric nanoparticles involves adding plant extract to a solution containing the monomer and initiator, and the process is allowed to proceed. For example, chitosan has been synthesised using different types of extracts from garlic, ginger, and basil (200,201). Chitosan is commonly used for biomedical applications because of its biodegradability and biocompatibility. The resulting polymeric nanoparticles can have enhanced bioactivity due to the presence of phytochemicals.

The main advantage of plant extract-based synthesis is its low-cost and scalable production. Plant extracts used in the synthesis are often readily available and can be easily extracted using simple methods, making this approach a cost-effective alternative to traditional chemical methods (202). Plant extract-based synthesis also offers the potential for numerous applications due to the variable biomolecule compositions in the plant extract. When the plant extract composition and extraction method are modified, the properties of the synthesised nanoparticles can be tuned to specific applications. Polymeric nanomaterials synthesis based on plant extracts is a promising approach for green and sustainable nanoparticle synthesis (203).

4.2.6.4 Supercritical fluid-based synthesis