Abstract

In this article, CaCu3Ti4O12 (CCTO) and Zr-doped CaCu3Ti3.95Zr0.05O12 (CCTZO) particles were fabricated by the sol–gel combustion method, and then, CCTO/LDPE and CCTZO/LDPE composite films were prepared by the melt-blending and hot briquetting. The microstructures and dielectric properties of fillers and LDPE composites were investigated in detail. Results showed the lattice expansion of CCTZO caused by Zr doping reduced grain size, increased size uniformity, and remarkably reduced dielectric loss and conductivity. Compared with CCTO, small-size CCTZO enhanced dielectric constant of LDPE by 88.5% (∼3.45) due to enhanced interfacial polarization included by ultrahigh interfacial area (∼3.0 × 105 m2), remaining a lower loss tangent (0.013) and conductivity (2.42 × 10−13 S·cm−1) for the 10 vol% CCTZO/LDPE composite. Furthermore, finite element simulation proofed small-size and uniform CCTZO particles played a prominent role in homogenize electric field distribution in LDPE composite, which was beneficial for the use of these composites in the high voltage power cable field.

Graphical abstract

Small-size CaCu3Ti3.95Zr0.05O12 enhanced dielectric constant of LDPE by 88.5% due to enhancing interfacial polarization included by ultrahigh interfacial area (∼3.0 × 105 m2) and played a prominent role in homogenize electric field distribution in LDPE composite.

1 Introduction

Owing to rapid developments of the power transfer technology to high voltage grade, the power cable and its terminations are required to possess higher operational reliability and a longer service life compared to previous needs (1,2,3). However, the critical problem of the electric field concentration has been restricting the service life of the power cable terminations. In power cable terminations, the cutback points of the shield layer appear the phenomenon of the electric field concentration, resulting in a stressed field along the insulation surface beyond the shield layer. Unfortunately, the stressed field will be out of control to cause air breakdown if this phenomenon is not suppressed; furthermore, surface discharge will occur at the insulation layer, which will eventually lead to insulation failure, followed by cable breakdown (3). Therefore, most research has been focused on the aim to reduce the surface electric stress below the breakdown strength of air (4,5,6). Up to now, besides the structure of the power cable termination is usually designed as a stress relief cone (4), it has attracted wide attention that an electric stress control layer laid on the surface of the insulation layer in the power cable termination more efficiently homogenizes electric field (6,7,8). This electric stress control material should play a relatively high dielectric constant and a low conductivity. Simultaneously, this material shows fine dielectric compatibility with the material of the insulation layer in the cable (8). For one thing, polyethylene (PE) polymer is the most popular insulation material for cable industries. Especially, LDPE is an environmentally friendly material featuring excellent insulation characteristic, high operation temperatures, and light weight, which is widely used in DC cables as an insulation material (9,10,11,12). For another, with the rapid development of composite technology, polymer matrix composites with a high-dielectric-constant (high-k) have a potential application in the embedded planar capacitors and power cable accessories (1,13,14). Thus, the high-k polyethylene-matrix composites could be used as potential functional materials for cable accessories in electrical engineering because they could balance the electric field distribution in the cable termination to prevent the cable from failure. An efficient way to obtain high-k polymer composites is to fill high-k ceramics into the polymer matrix, such as CCTO ceramics, which is widely used as a functional filler to enhance the dielectric constant of the polymer composite due to its huge dielectric characteristic (15). Although some composites have relatively high dielectric constants, their dielectric loss is usually high, particularly under high electric fields (13), resulting in a serious electric field distortion in composites and low breakdown strength. Furthermore, the related research showed that doping Zr element could reduce the intrinsic dielectric loss of CCTO ceramics (16). In addition, Chen et al. synthesized Zr-doped CaCu3Ti4O12 ceramics and obtained high resistivity property with increase of Zr4+ doping (17). Therefore, it is a significant and valuable study to collectively control the dielectric properties and internal electric field distribution in high-k ceramic/polyethylene-matrix composites, for the development of a new dielectric material used for electric stress control layer in the power cable termination. Furthermore, the effect of element doping on the microstructure and dielectric properties of the ceramic itself and polyethylene composites is supposed to be researched in detail, which is rarely reported.

In the present work, to obtain the composites with a lowered dielectric loss and conductivity, maintaining a relatively high dielectric constant, meanwhile possessing an excellent advantage of internal homogenized electric field distribution, we chose Zr-doped CCTZO ceramics prepared by a sol–gel combustion method as fillers to synthesize the LDPE composites. In addition, the effect of the ceramic fillers before and after Zr modified on the microstructure, dielectric properties, and internal electric field distribution of the LDPE-based composites was studied in detail. It is found that the CCTZO/LDPE composites have much more excellent dielectric properties than the CCTO/LDPE composites at the same filler loading. Furthermore, the dielectric response mechanism of the LDPE-based composites was discussed, and the internal electric field distribution in the LDPE-based composites was also analyzed by the finite element simulation.

2 Experimental

2.1 Materials

Copper nitrate trihydrate (Cu(NO3)2·3H2O, ≥98%), calcium nitrate tetrahydrate (Ca(NO3)2·4H2O, ≥98%), glycol methyl ether (C3H8O2), tetrabutyl titanate (C16H36O4Ti), anhydrous ethanol (C2H6O), and low density polyethylene (LDPE, LD200GH, 0.922 g·cm−3).

2.2 Preparation of CCTO and CCTZO particles

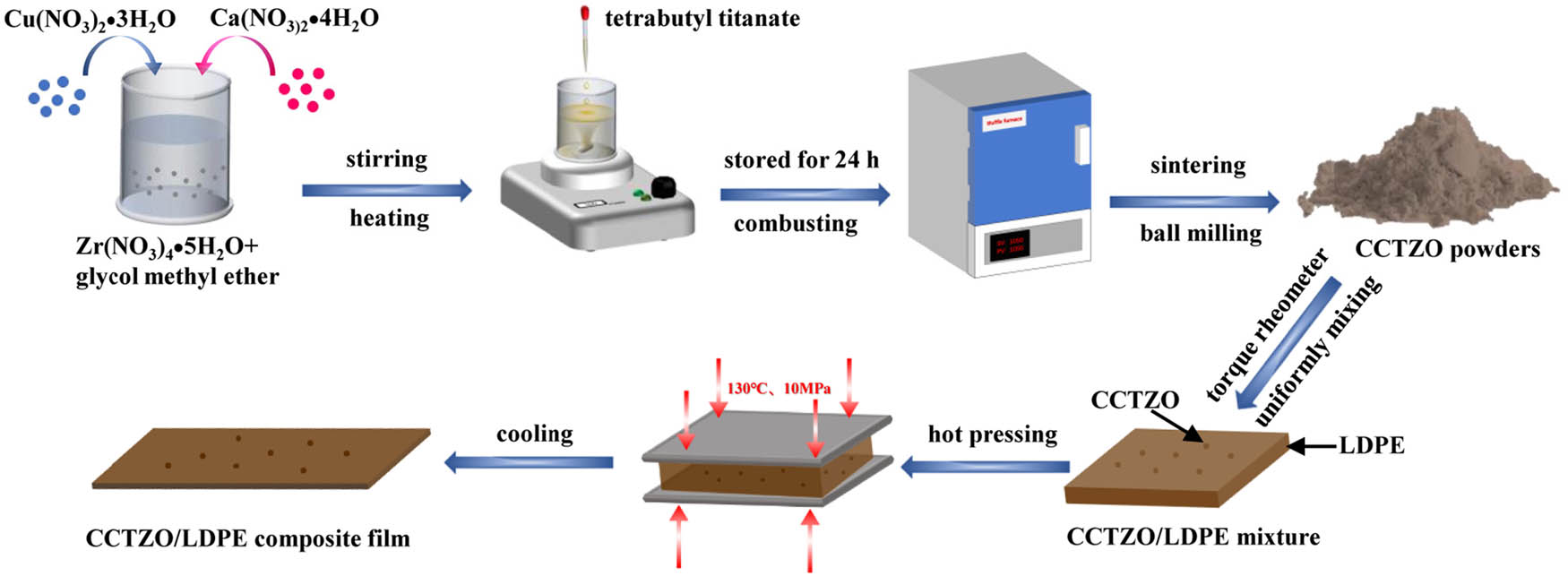

CCTO particles were prepared using a sol–gel combustion method (18,19). First, the pre-calculated amount of Cu(NO3)2·3H2O and Ca(NO3)2·4H2O was dissolved in glycol methyl ether with a heating stirring. When the solution was cooled to room temperature, tetrabutyl titanate was dropped into the above solution, continually stirring for 1 h. The resulting sol was stored for 24 h and then combusted in the open air to obtain CCTO sol powders. Prepared powders were ground carefully and sintered at 300°C for 2 h; then, part of powders was cold pressed into pieces of 10 mm in diameter and about 1 mm in thickness at a pressure of 15 MPa. These ceramic pieces and residual powders were crystallized by sintering at 800°C for 3 h and then re-sintering at 1,050°C for 6 h in the air at a heating rate of 5°C·min−1, followed by cooling to room temperature. CCTO ceramic particles were obtained by ball milling crystallized powders for 4 h, followed by drying at 80°C for 24 h. Zr-doped CaCu3Ti3.95Zr0.05O12 (CCTZO) ceramic particles were prepared using the earlier method, as shown in Scheme 1. The difference was that Zr(NO3)4·5H2O was dissolved in glycol methyl ether, together.

Schematic diagram of the preparation of CCTO, CCTZO ceramics, and LDPE composite films.

2.3 Preparation of LDPE composite films

LDPE composite films were fabricated by the typical process of melt-blending and hot briquetting (20), as shown in Scheme 1. A desired amount of CCTO or CCTZO particles were added into the torque rheometer loaded with LDPE, accompanied by mixing continuously for 30 min at 130°C. The final LDPE-based composite films with a thickness of about 80 μm were then pressed into pieces using a flat vulcanization machine at 130°C and a pressure of 10 MPa for 20 min. In addition, pure LDPE film was also prepared by the above-mentioned method as a comparison. In the previous process for fabricating LDPE-based composites, the series of volume fractions for added CCTO particles were 1, 5, and 10 vol%, corresponding to the CCTO/LDPE composite film samples marked as 1#1 vol%, 1#5 vol%, and 1#10 vol%, respectively. Similarly, a series of CCTZO/LDPE composite film samples were denoted as 2#1 vol%, 2#5 vol%, and 2#10 vol%. Pure LDPE film sample was remarked as 0#.

2.4 Characterizations

The phase compositions of CCTO, CCTZO particles, and the LDPE-based composites were analyzed using X-ray diffraction (XRD, Empyrean) under the testing condition of Cu Kα radiation, 40 kV, 40 mA, the scanning mode of θ–2θ, and the scanning angle from 15° to 75°. The microstructures of the LDPE-based composites were determined using SEM (Hitachi S-3400N) at the accelerating voltage of 30 kV. The dielectric properties of all samples, including CCTO piece, CCTZO piece, LDPE film, and LDPE-based composite films, were measured in the frequency range from 10 to 105 Hz at room temperature using a broad-band dielectric spectral instrument (Novocontrol Aloha-A). Prior to the measurements, a hybrid layer of Al paste was evaporated on both surfaces of all samples, followed by discharge treatment of evaporated samples at 80 for 24 h in a vacuum drying oven. Finite element simulation of the electric field distribution for the LDPE-based composites was carried out under an applied voltage of 6 kV and a setting thickness of 80 μm.

3 Results and discussion

3.1 Microstructure and morphologies of fillers and LDPE composite films

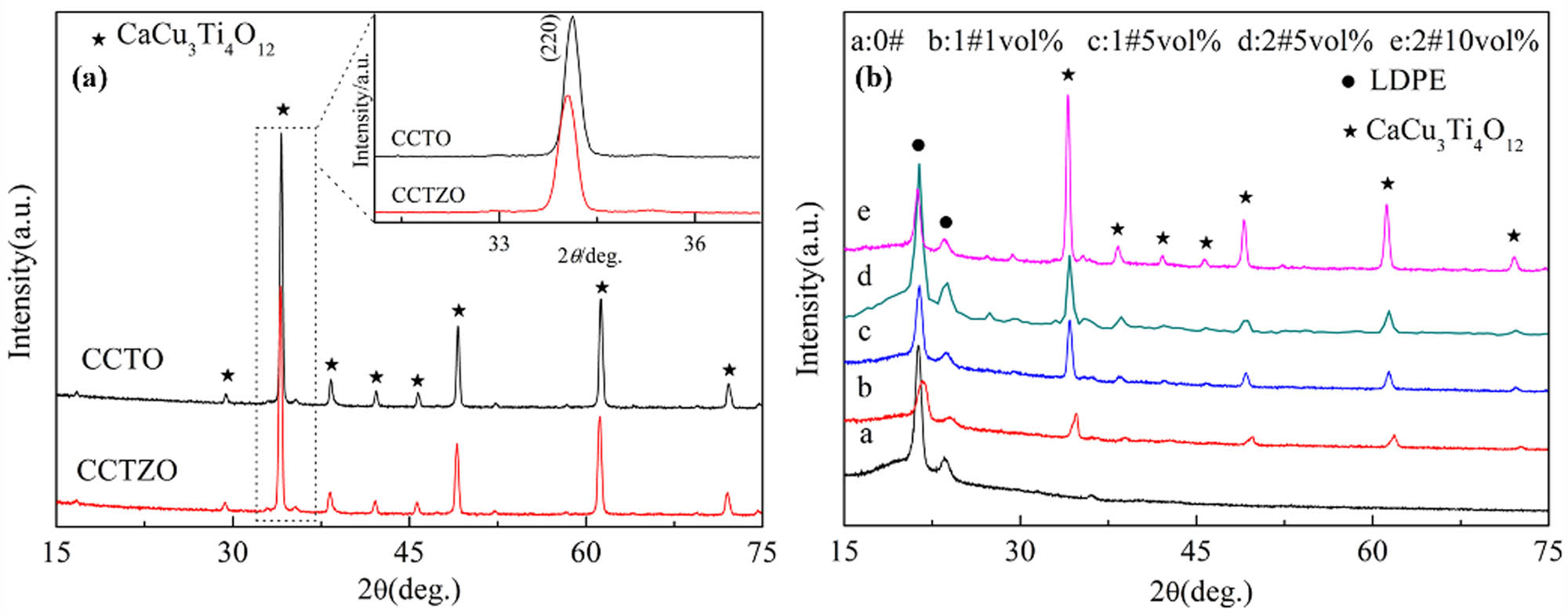

Figure 1a shows the XRD patterns of the CCTO and CCTZO ceramics. As shown in Figure 1a, the characteristic peaks of CCTO and CCTZO were clearly visible, and their main diffraction peaks were consistent with the PDF card (JCPDS No. 75-2188), which showed that the CCTO and CCTZO ceramics prepared by a sol–gel combustion method possessed the body-centered cubic perovskite crystal structure with ABO3 type (21,22). Meanwhile, CCTO and CCTZO ceramics were crystallized completely without impurity phases. These results showed that Zr ions had fully integrated into the lattice of CCTO to form a solid solution crystal. According to the related literature (23), Zr ions were likely to be deposited into the domain or grain boundary regions of the CCTO particles in the process of CCTO ceramic crystallization, and even into CCTO grains. Additionally, it was obviously different that the diffraction peaks of the CCTZO ceramic shifted to the left compared with those of the CCTO ceramics, shown in the inset in Figure 1a. According to Bragg's law in Eq. 1 (24):

where d is the distance among parallel atom plane, λ is the incident wavelength, and θ is the diffraction angle between the incident light and the crystal plane. The decrease in the diffraction angle was attributed to the increase in the distance of the crystal plane. Zr4+ ions with a large ion radius were likely to integrate into the CCTO lattices to substitute Ti4+ ions with a small ion radius, resulting in the imbalance of TiO6 octahedrons, which caused the lattice expansion of CCTZO. Besides, redundant Zr4+ ions were probably deposited into the domain or grain boundary regions of the CCTZO particles. The change in the lattice of CCTZO bound to have a profound effect on the morphology and dielectric properties of CCTZO particles.

(a) XRD patterns of the CCTO and CCTZO ceramics; the inset is image magnification. (b) XRD patterns of the CCTO/LDPE and CCTZO/LDPE composites.

Figure 1b shows the XRD spectrums of the LDPE composite samples. Typical amorphous diffractions at 2θ ≈ 21.3° and 23.6° were observed in the pattern from pure LDPE, which was consistent with the literature report (25). Comparing Figure 1a with Figure 1b, the crystal structures of CCTO and CCTZO ceramics completely existed in the LDPE matrix. As shown in Figure 1b, it can be found that the peaks of LDPE showed an evident reduction in intensity after CCTO or CCTZO fillers were incorporated into LDPE matrix. With the volume fraction of fillers increasing, the peaks of LDPE reduced gradually, while those of the CCTO or CCTZO became sharper and stronger, which indicated that the interaction between the ceramic phases and LDPE matrix strengthened. Additionally, XRD spectrums of the composites showed CCTO or CCTZO and LDPE diffraction peaks, which clearly demonstrated that CCTO or CCTZO particles filled into polymer matrix to form two phases composite system.

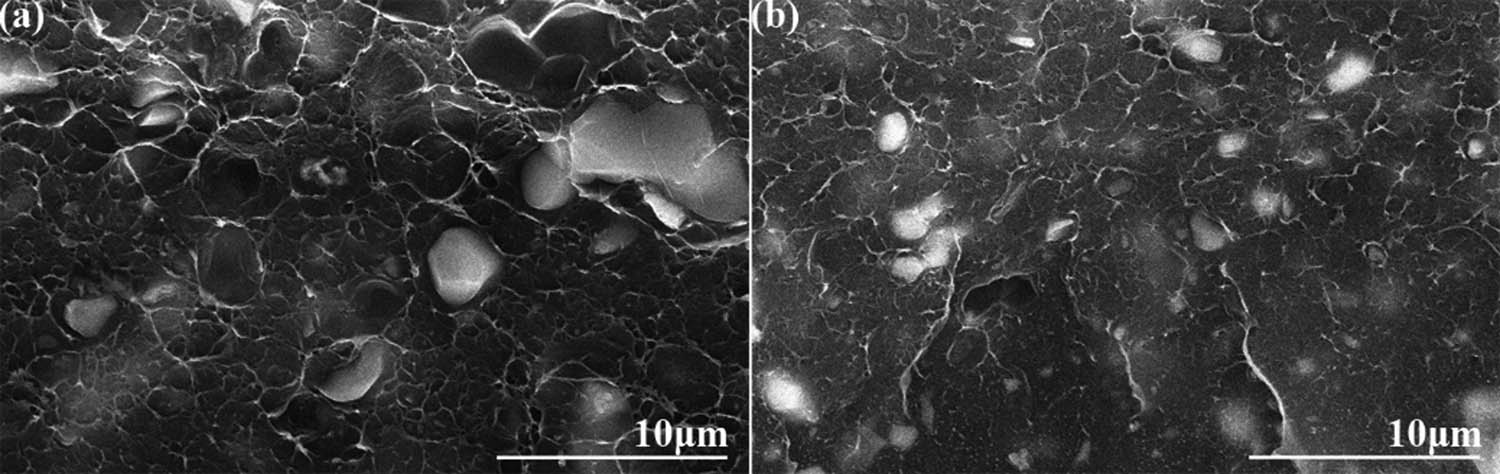

SEM morphologies of the CCTO/LDPE composite and the CCTZO/LDPE composite with a same loading of 10 vol% are shown in Figure 2a and b, respectively. It could be found from Figure 2a that CCTO particles were loosely embedded within the LDPE matrix to form a random composite with obvious agglomeration and surface pores when the CCTO filler content was 10 vol%. Additionally, particle sizes of CCTO ceramics were inhomogeneous from 5 to 10 μm. However, Figure 2b shows that the CCTZO ceramics doped with Zr possessed perfect size uniformity and its particle size reduced to an average diameter of 2 μm. Furthermore, CCTZO fillers were closely embedded within the LDPE matrix to form the CCTZO/LDPE composites with a smooth surface when CCTZO filler content was 10 vol%. The conclusion could be drawn from the above-mentioned phenomena that Zr doping could reduce the particle size, improve size uniformity, and enhance the binding force between CCTZO fillers and LDPE matrix, which attributed to the effect of Zr substituting Ti on growth inhibition of CCTZO grains and improvement electric insularity of CCTZO grain boundaries (23,26).

SEM morphologies of (a) the 10 vol% CCTO/LDPE composite and (b) the 10 vol% CCTZO/LDPE composite.

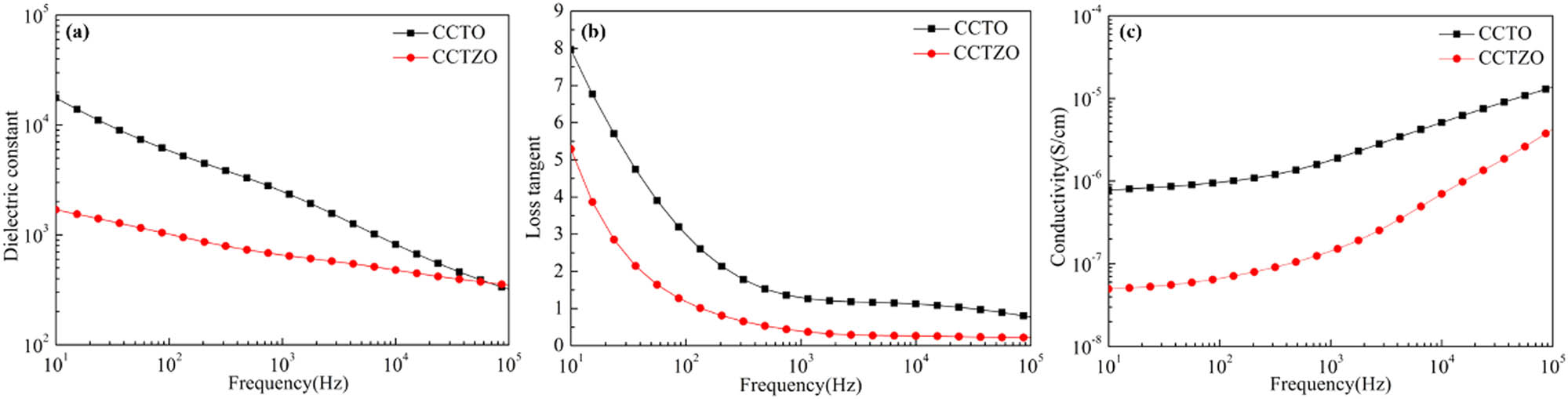

3.2 Dielectric properties of CCTO and CCTZO fillers

The dependence of dielectric constant, loss tangent, and conductivity of the CCTO and CCTZO particles on frequency in the frequency range of 10–105 Hz at room temperature is shown in Figure 3. It was presented that the dielectric constant of CCTO and CCTZO particles decreased with the increase in the frequency and the decrease in CCTO particles was faster. Additionally, the dielectric constant of CCTZO particles was lower than that of CCTO particles in the range of whole frequency. Particularly, the dielectric constant of CCTZO particles reached 1.67 × 103 at 10 Hz and decreased an order of magnitude compared with that of CCTO (∼1.85 × 104), which may be attributed to lattice distortion caused by Zr4+ ions. Figure 3b displays the dependence of loss tangent as a function of frequency for CCTO and CCTZO particles in the frequency range of 10–105 Hz at room temperature. It can be found that the loss tangent of CCTO and CCTZO particles dramatically decreased as the frequency increased from 10 to 103 Hz. With the further increase of frequency, the loss tangent of CCTO particles tended to be stable and then decreased slightly, while that of CCTZO particles were remaining stable. Most significantly, the loss tangent of CCTZO particles had a prominently smaller value than that of CCTO in the whole frequency. In addition, the strong increase in the low-frequency dielectric loss tangent was likely associated with the interfacial polarization theory on DC conduction, which was consistent with the relevant literature (27). The low-frequency dielectric constant values at room temperature of CCTO and CCTZO ceramics were extremely large (104–105) and were accompanied by the large loss tangent and DC conductivity as shown in Figure 3b and c, which were intrinsically attributed to a small polaronic hopping mechanism at the interfacial area between the grains and grain boundaries or inside the mixed-valent structure (14,28,29). Figure 3c shows the dependence of conductivity on frequency for CCTO and CCTZO particles in the frequency range of 10–105 Hz at room temperature. It can be found that the conductivity of CCTO and CCTZO particles increased dramatically with the increase in frequency. Additionally, it was remarkably different in Figure 3c that the conductivity of CCTZO particles was obviously lower than that of CCTO particles in the whole frequency. In particular, the conductivity of CCTZO particles decreased an order of magnitude compared with CCTO below 103 Hz. According to the above analysis, the conclusion can be drawn that Zr doping could dramatically decrease the dielectric loss and conductivity of CCTZO ceramics, which may be related to the Zr doping process. Redundant Zr ions were deposited within the domain or grain boundary regions of the CCTZO particles, resulting in improvement in the insulating property of these regions, which was based on the fact that Zr has the characteristic of impeding electronic directional movement (26).

Dependence of (a) dielectric constant, (b) loss tangent, and (c) conductivity of the CCTO and CCTZO particles on frequency.

3.3 Dielectric properties of LDPE composite films

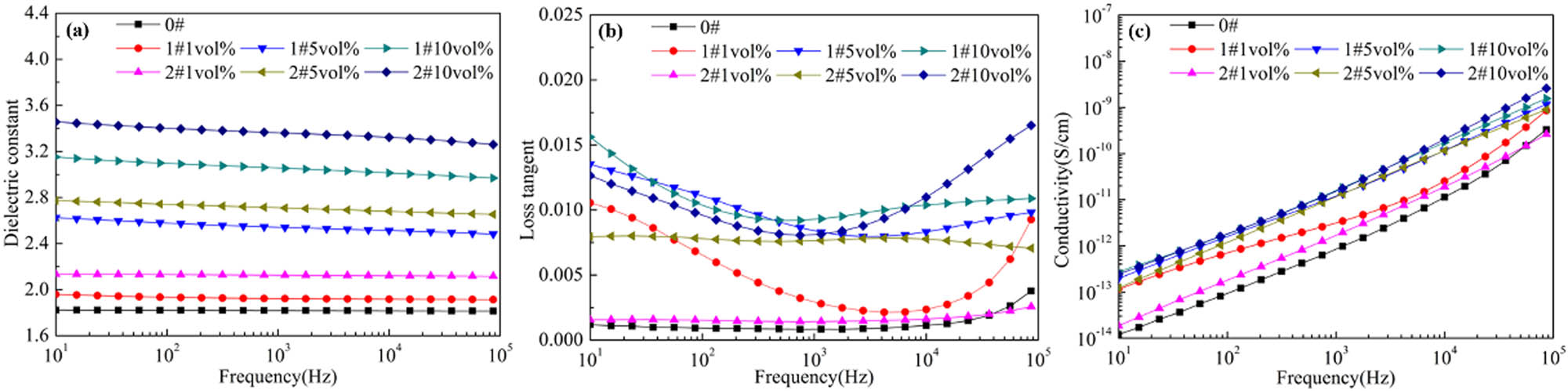

Figure 4 shows the dependence of dielectric constant, dielectric loss tangent, and conductivity of CCTO/LDPE and CCTZO/LDPE composites with different ceramic volume fractions on frequency in the frequency range of 10–105 Hz at room temperature. As shown in Figure 4, it can be found that the dielectric constants of all samples of 0#, 1#, and 2# decreased slightly with the increasing frequency, especially when the content of the filler was over 5 vol%, which was attributed to the fact that dipoles orientation lagged behind the increasing frequency of the electric field, resulting in a reduction of the dielectric constant (30). Meanwhile, the dielectric constant of 1# or 2# sample filled with CCTO or CCTZO particles was higher than that of 0# sample. Additionally, it was clearly demonstrated that the dielectric constant of LDPE composites could be significantly improved by incorporating CCTO or CCTZO particles into the polymer matrix, especially with increasing filler content and the value of 2# sample was higher than that of 1# sample at the same loading content of fillers as well. In particular, the dielectric constant of 1#10 vol% and 2#10 vol% sample was 3.14 and 3.45, which was 71.6 and 88.5% higher than that of 0# sample, respectively. The increase of the dielectric constant for those composites was likely to derive from the giant dielectric property of ceramic filler and the interfacial action between filler and polymer matrix (31,32).

Dependence of (a) dielectric constant, (b) loss tangent, and (c) conductivity of CCTO/LDPE and CCTZO/LDPE composites with different volume fractions on frequency.

Figure 4b shows the dependence of loss tangent for LDPE composites on the frequency. It can be clearly observed that the loss tangent of 1# and 2# samples has a strong dependence on the frequency; i.e., the value decreased at the low frequency and then increased with the further increasing frequency. In addition, the loss tangent of 1# or 2# sample increased with increasing loading content of CCTO or CCTZO fillers. It is noteworthy that the loss tangent of 2# sample was lower than that of 1# sample at the same loading content below 104 Hz. Especially, the loss tangent of 2#10 vol% sample was about 0.013 at 10 Hz, which was lower than that of 1#10 vol% sample (tan δ ∼ 0.017).

The dependence of the conductivity of the LDPE composites on the frequency is shown in Figure 4c. It is obviously found that the conductivity of all samples has a like-linear increase with increasing frequency. Furthermore, the conductivity of 2# sample was lower than that of 1# sample. In particular, the conductivity of 1#10 vol% and 2#10 vol% samples were 2.77 × 10−13 and 2.42 × 10−13 S·cm−1, respectively. Above all, it can be concluded that the CCTZO particles with a lower dielectric constant and a smaller grain size more significantly enhance the dielectric properties of LDPE material compared with CCTO fillers, resulting in the increase of the dielectric constant and the decrease of the dielectric loss tangent and conductivity for CCTZO/LDPE composites, which are closely related to the interfacial effect in LDPE composites.

Furthermore, compared with some typical polymer composites filled with doped ceramic, such as Na1/2Y1/2Cu3Ti4O12 (NYCTO) (33), Na1/3Cd1/3Y1/3Cu3Ti4O12 (NCYCTO) (34), Na1/2Bi1/2Cu3Ti4O12 (NBCTO) (35), and Na1/3Ca1/3Bi1/3Cu3Ti4O12 (NCBCTO) (36), Zr-doped CCTZO ceramics can improve the dielectric properties of polymer materials better, in particular, and reduce dielectric loss of polymer. When the filler concentration was up to 50 vol%, the dielectric constant of the NYCTO/PVDF micro-composite, NBCTO/PVDF, and NCBCTO/PVDF nanocomposites were 84, 261, and 210.8 at 1 kHz, accompanying dielectric losses were 0.11, 0.4, and 0.83, respectively (33,34,35,36). Therefore, compared with micron-sized ceramics, nano-sized ACuTi4O12 ceramic doped at A sit gave rise to larger dielectric loss. However, the Zr-doped CCTZO ceramic at B sit improved the dielectric property of the polymer matrix better, which possessed low dielectric loss and high dielectric constant. Especially, the dielectric loss of CCTZO/PVDF composites was only 0.008 at 1 kHz, which was lower than that of NYCTO/PVDF, NBCTO/PVDF, and NCBCTO/PVDF composites. Above all, these excellent properties of CCTZO/LDPE composite are beneficial to its practical application.

3.4 Interfacial effect in LDPE composite films

To further demonstrate the dielectric response of LDPE composites filled with different ceramic particles, the interfacial parameters of the particle distance and interfacial area in the interfacial regions for CCTO/LDPE and CCTZO/LDPE composite materials were calculated. Generally, the size of the interfacial region between filler and polymer matrix in polymer composite materials can reflect the degree of the interfacial polarization effectively, impacting the dielectric property of the material (37,38). According to the related literature report, the interfacial area in 1 m3 of the ceramic/polymer composite was calculated by assuming a spherical shape and taking the average size of ceramic particles (39). The average distance of neighboring particles d for CCTO/LDPE and CCTZO/LDPE composites was calculated using Eq. 2 (40):

where f is the volume fraction, and r is the average radius of ceramic particles. Calculated results of the CCTO/LDPE and CCTZO/LDPE composites filled with different loading content for CCTO or CCTZO particle fillers are shown in Table 1.

The average distance and interfacial area of the CCTO/LDPE and CCTZO/LDPE composites with different loading content for CCTO or CCTZO particle fillers at 10 Hz

| Sample | Dielectric constant | Average distance (μm) | Interfacial area (m2) |

|---|---|---|---|

| 1#1 vol% | 1.96 | 27.29 | 4.72 × 103 |

| 1#5 vol% | 2.62 | 11.86 | 2.92 × 104 |

| 1#10 vol% | 3.14 | 7.33 | 5.98 × 104 |

| 2#1 vol% | 2.14 | 5.50 | 3.04 × 104 |

| 2#5 vol% | 2.80 | 2.31 | 1.50 × 105 |

| 2#10 vol% | 3.45 | 1.45 | 3.0 × 105 |

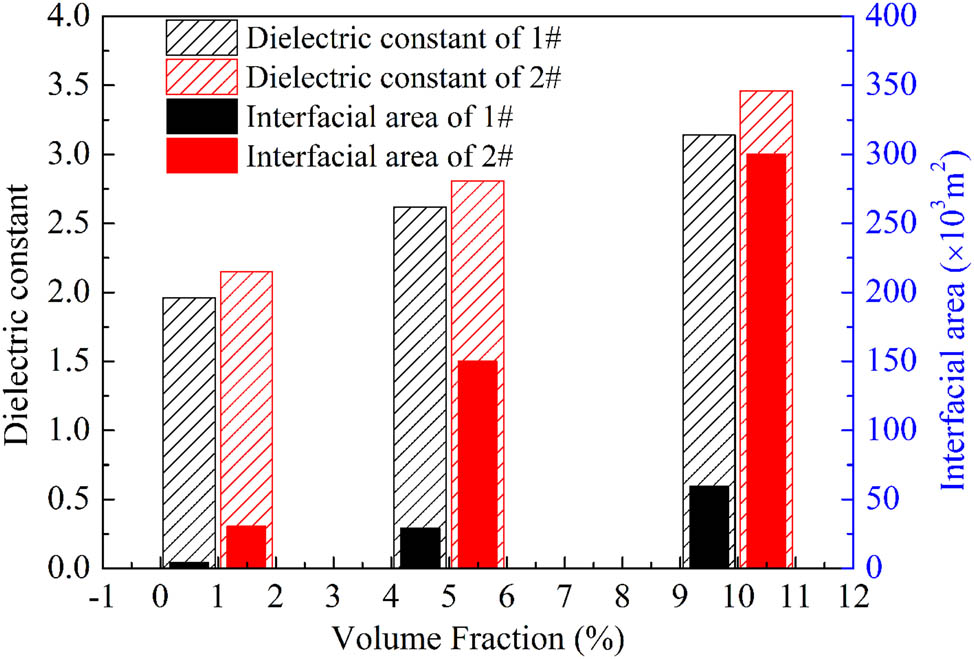

Moreover, the dielectric constant and internal interface area of the CCTO/LDPE and CCTZO/LDPE composites filled with different loading content are also given in Figure 5. A significant found was that the dielectric constant and interfacial area of all composites increased dramatically with increasing loading content. In addition, the interfacial area in 2# sample material was larger than that in 1# sample material at the same loading content. According to Table 1, it can be clearly found that the average distance of CCTO or CCTZO particles in the LDPE matrix gradually reduced, and the average distance of CCTZO particles in 2# sample material was smaller than that of CCTO particles in 1# sample material at the same loading content. In particular, the average distance of filled particles in 1#10 vol% and 2#10 vol% composite was 7.33 and 1.45 μm, and their interfacial area was 5.98 × 104 and 3.0 × 105 m2, respectively. These clearly showed that the interfacial area in 2# material increased an order of magnitude more than that in 1# material. In addition, as the filler loading increased from 1 to 10 vol%, the average distance of 1# sample decreased from 27.29 to 7.33 μm, while that of 2# sample decreased from 5.50 to 1.45 μm; however, the dielectric constant of 1# sample increased from 1.96 to 3.14, and that of 2# sample increased from 2.14 to 3.45. This phenomenon showed that the dielectric constant of the LDPE-based composites increased as the interparticle distance decreased. This relationship between the dielectric constant and interparticle distance of the CCTO/LDPE and CCTZO/LDPE composites was consistent with the LSNO/PVDF composite system in the relevant literature (27), where the particles became compact, and the average distances of LSNO fillers decreased as the filler loading increased. Above all, it can be indicated that larger interfacial areas existed in the LDPE composites filled by the CCTZO particles with a small size and enhanced size uniformity. Thus, the interfacial polarization effect in the CCTZO/LDPE composite became the dominant factor, further enhancing the dielectric constant of composites, which was proved in Figure 4a. Nevertheless, the decrease in the dielectric loss tangent and conductivity of CCTZO/LDPE composites may be originated from (i) the smooth surface and free of porosity within the CCTZO/LDPE composite system, resulting in the smaller DC conductance and its loss; (ii) the electrons transfer in the interfacial regions between CCTZO particles and LDPE matrix maybe inhibited by the insulated LDPE matrix material; and (iii) the CCTZO crystal structure and its effect on the molecular chain movements and crystalline of the LDPE polymer. Besides, it should be noticed the effect of the ceramic fillers before and after doped by Zr element on the electric field distribution within the LDPE composite materials.

Comparison diagram of dielectric constant and interfacial area of the CCTO/LDPE and CCTZO/LDPE composites with different loading concentrations.

3.5 Electric field distribution of LDPE composite films

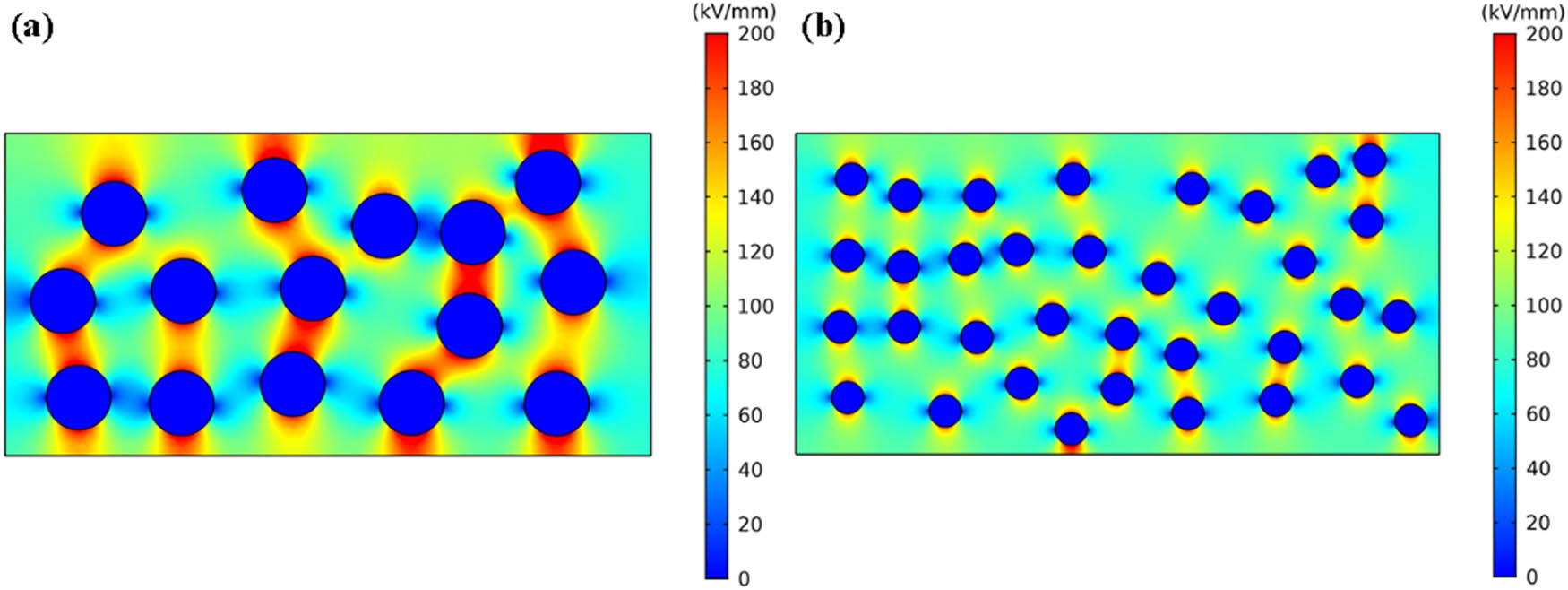

In general, the breakdown strength of the ceramic/polymer composite system used to be due to the distribution degree of the electric field in the matrix material, which was significantly affected by the morphology and grain size of fillers, and even the dielectric characteristic difference of fillers and matrix (41,42). Therefore, the internal electric field distribution in LDPE-based composites was researched by the finite element analysis method. The finite element simulation diagrams for electric field distribution of the LDPE composites filled with 10 vol% ceramics are shown in Figure 6. It can be observed that the ceramic fillers with different grain sizes and dielectric properties caused different degrees of electric field distortion in the LDPE composites. For the CCTO/LDPE composite system embedded by CCTO particles, serious electric field distortion occurred on the upper and lower ends of CCTO particles along the electric field, easily forming the paths for the electric breakdown. On the contrary, the CCTZO particle fillers with smaller grain size and lower dielectric loss caused slight electric field distortion in the LDPE matrix. This clearly shows CCTZO ceramics with a small size and dielectric difference are beneficial to improve the insulation properties of the LDPE polymer composites.

Finite element simulation diagrams for Electric field distribution of the LDPE composite loaded with (a) 10 vol% CCTO and (b) 10 vol% CCTZO ceramics.

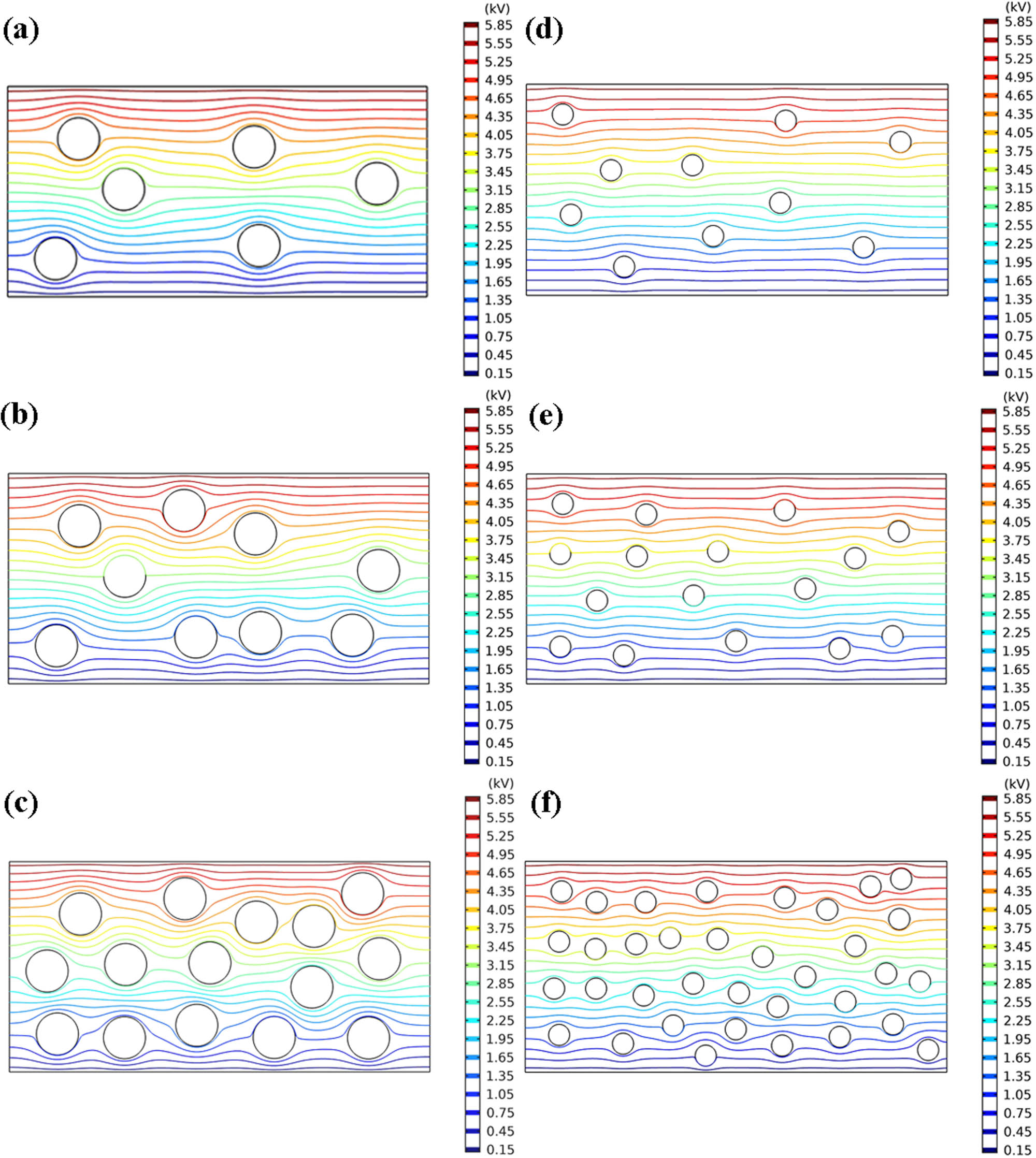

Aiming to further study the effect of loading content of the different ceramic on the internal electric field in LDPE-based composites, the electrical potential distribution within LDPE composites respectively filled by CCTO and CCTZO particles was simulated and the results are shown in Figure 7a–f. As can be seen from Figure 7a–c that the electrical potential distribution in the CCTO/LDPE composite was more and more non-uniform with an increase in volume fraction of CCTO particles, which ought to result from the poor compatibility of CCTO particles and LDPE matrix and serious defects in the composites, such as holes, which is shown in Figure 2a. However, an obvious found can be obtained from Figure 7d–f that the electrical potential distribution in the CCTZO/LDPE composites maintained perfect uniformity with an increase in volume fraction of CCTZO particles. Therefore, the conclusion can be drawn from the above phenomena that Zr-modified CCTZO particles with a small grain size can improve the internal electric field distribution in the LDPE composites preferably, compared with CCTO particles with a larger grain size. The excellent characteristics of improving electric field distortion probably will make dipoles in the interfacial regions of CCTZO/LDPE composites distributed along the electric field direction, resulting in enhancing the interfacial polarization and thereby increasing the dielectric constant of composites.

Simulation diagrams for the electrical potential distribution of the LDPE composite loaded with (a) 1 vol% CCTO, (b) 5 vol% CCTO, (c) 10 vol% CCTO, (d) 1 vol% CCTZO, (e) 5 vol% CCTZO, and (f) 10 vol% CCTZO ceramics.

4 Conclusions

In this work, the CCTO and Zr-doped CCTZO particles were prepared by a sol–gel combustion method, and then, the corresponding CCTO/LDPE and CCTZO/LDPE composites were prepared by a melt-blending and hot briquetting process. The effect of Zr doping on the microstructure and dielectric characteristics of CCTO ceramics was studied preferentially. Zr doping could reduce the grain size of CCTO particles from 10 to 2 μm, enhance size uniformity, and markedly decrease its dielectric loss and conductivity by an order of magnitude. In addition, the effect of the ceramics before and after doped on the microstructure and dielectric properties of the LDPE-based composites were also researched. CCTZO particles with a small size and uniformity could form much more interfacial area in the LDPE matrix and dramatically enhance the interface polarization of the CCTZO/LDPE composites compared with that of CCTO/LDPE ones, thereby improving the dielectric properties of CCTZO/LDPE composites. Especially, when the CCTZO filler concentration was 10 vol%, the interfacial area in the CCTZO/LDPE composite was 3.0 × 105 m2 and the dielectric constant of the CCTZO/LDPE composite was 3.45 at 10 Hz, which was 88.5% higher than pure LDPE. Meanwhile, it possessed a low loss tangent of about 0.013 and conductivity of about 2.42 × 10−13 S·cm−1. The finite element simulation for the electric field distribution also indicated that Zr-doped CCTZO particles could homogenize electric field distribution in the LDPE composites more effectively compared with CCTO particles. These results provide a simple but effective method to achieve the LDPE composites with high dielectric constant, low dielectric loss, low conductivity, and strong homogenization of the electric field, which are further beneficial to the application in high voltage field.

-

Funding information: This work was supported by the Heilongjiang Provincial Natural Science Foundation of China (JJ2020LH2012) and the High-level Talent Scientific Research Start-up Project for Changzhou Institute of Technology (YN22001).

-

Author contributions: Liang Gao: writing – original draft, conducting the experiment and characterization, project administration and funding acquisition; Jiaqi Zhang: drawing graphs; Yang Cui: simulation analysis; Xuan Wang: methodology and review.

-

Conflict of interest: The authors state no conflict of interest.

References

(1) Yang K, Ren YR, Wu KN, Li JY, Jing ZH, Zhang ZJ, et al. Enhancing electrical properties of impact polypropylene copolymer for eco-friendly power cable insulation by manipulating the multiphase structure through molten-state annealing. Compos Sci Technol. 2022;223:109422. 10.1016/j.compscitech.2022.109422.Search in Google Scholar

(2) Guo M, David É, Fréchette M, Demarquette NR. Polyethylene/polyhedral oligomeric silsesquioxanes composites: Dielectric, thermal and rheological properties. Polymer. 2017;115:60–9. 10.1016/j.polymer.2017.03.015.Search in Google Scholar

(3) Chi P, Qin YX, Tao YC, Liang R. Research on condition assessment of XLPE cable based on signal propagation characteristics. Electr Pow Syst Res. 2021;195:107136. 10.1016/j.epsr.2021.107136.Search in Google Scholar

(4) Yu JZ, Chen XR, Zhou H. Electric field calculation and optimization for stress cone of DC cable joint based on the coaxial double-layer insulation model. IEEE Trans Dielectr Electr Insul. 2020;27:33–41. 10.1109/TDEI.2019.008284.Search in Google Scholar

(5) Jiang XW, Wang SH, Wang WH, Han R. Effect of surface state on DC breakdown characteristics of thermally aged double-layered polyester films. J Electron Mater. 2021;50:2400–8. 10.1007/s11664-021-08771-5.Search in Google Scholar

(6) Erdogan M, Yildiz Ş, Cicek A, Inanir F. Two-dimensional finite-element analysis of pinning-induced stress in HTS power transmission cables made of 2G superconducting tapes with and without magnetic substrate. IEEE Trans Appl Supercond. 2016;26:1–7. 10.1109/TASC.2016.2544827.Search in Google Scholar

(7) Eigner A, Semino S. 50 years of electrical-stress control in cable accessories. IEEE Electr Insul Mag. 2013;29:47–55. 10.1109/MEI.2013.6585856.Search in Google Scholar

(8) Dang ZM, Yuan JK, Yao SH, Liao RJ. Flexible nanodielectric materials with high permittivity for power energy storage. Adv Mater. 2013;25:6334–65. 10.1002/adma.201301752.Search in Google Scholar PubMed

(9) Zhang CC, Kong XQ, Liu WX, Yang JM, Zhao H. Regulation of PANI nanofiber conductivity and its influence on the DC dielectric properties of LDPE. Polym Test. 2021;101:107299. 10.1016/j.polymertesting.2021.107299.Search in Google Scholar

(10) Zhang C, Xing ZL, Hu XN, Chen LR, Yan SY, Li GX, et al. Effect of magnetic compound electrode on space charge injection and accumulation in LDPE. Appl Phys Lett. 2020;117:212903. 10.1063/5.0022231.Search in Google Scholar

(11) Yan ZY, Zhao H, Han BZ, Yang JM, Chen JQ. The suppression of space charge accumulation in CB/LDPE nanocomposites and its association with molecule relaxation. e-Polymers. 2018;18:49–56. 10.1515/epoly-2017-0111.Search in Google Scholar

(12) Roma C, Morales MG, Olariu MA, McNally T. Effect of selective distribution of MWCNTs on the solid-state rheological and dielectric properties of blends of PMMA and LDPE. J Mater Sci. 2020;55:8526–40. 10.1007/s10853-020-04622-6.Search in Google Scholar

(13) Hwang SK, Bae I, Cho SM, Kim RH, Jung HJ, Park C. High performance multi-level non-volatile polymer memory with solution-blended ferroelectric polymer/high-k insulators for low voltage operation. Adv Funct Mater. 2013;23:5484–93. 10.1002/adfm.201300372.Search in Google Scholar

(14) Han RL, Liu YP, Shi JC, Chen GX, Li QF. Enhanced dielectric properties and breakdown strength of polymer/carbon nanotube composites by coating an SrTiO3 layer. e-Polymers. 2021;21:272–8. 10.1515/epoly-2021-0028.Search in Google Scholar

(15) Sachidanandan ERR, Paramanandam T, Sahadevan R. A comparative study on dielectric, structure, and thermal behavior of micro- and nano-sized CCTO in nylon 6,9 matrix. Polym Compos. 2017;38:927–35. 10.1002/pc.23654.Search in Google Scholar

(16) Jesurani S, Kanagesan S, Hashim M, Ismail I. Dielectric properties of Zr doped CaCu3Ti4O12 synthesized by sol–gel route. J Alloy Compd. 2013;551:456–62. 10.1016/j.jallcom.2012.11.043.Search in Google Scholar

(17) Chen XY, Zhang B, Ni L, Zhou Y, Li MY, Chang AM. New negative temperature coefficient ceramics in Zr-doped CaCu3Ti4O12 system. J Alloy Compd. 2020;821:153476. 10.1016/j.jallcom.2019.153476.Search in Google Scholar

(18) Najafabadi AH, Ghasemi A, Mozaffarinia R. Development of novel magnetic-dielectric ceramics for enhancement of reflection loss in X band. Ceram Int. 2016;42:13625–34. 10.1016/j.ceramint.2016.05.157.Search in Google Scholar

(19) Matias JA, Silva IB, Silva AO, Oliveira JB, Silva DR, Morales MA. (Bi13Co11)Co2O40-Co3O4 nanocomposites: approach to different fuels in sol-gel combustion synthesis using the Box-Behnken design. Ceram Int. 2022;48:481–94. 10.1016/j.ceramint.2021.09.124.Search in Google Scholar

(20) Zhang D, Wang X, He LJ, Song W, Sun Z, Han B, et al. Preparation and characteristic of magnetic LDPE/Fe3O4 nano-composite films. J Mater Sci Mater Electron. 2013;24:1796–800. 10.1007/s10854-012-1014-0.Search in Google Scholar

(21) Hu J, Liu Y, Zhang SF, Tang BT. Novel designed core-shell nanofibers constituted by single element-doped BaTiO3 for high-energy-density polymer nanocomposites. Chem Eng J. 2022;428:131046. 10.1016/j.cej.2021.131046.Search in Google Scholar

(22) Boonlaknorn J, Chanlek N, Thongbai P. Giant dielectric permittivity of CaCu3Ti4O12 via a green solution-egg white method. J Sol-Gel Sci Technol. 2020;93:643–9. 10.1007/s10971-019-05182-1.Search in Google Scholar

(23) Lin Y, Feng DY, Gao M, Ji YD, Jin LB, Yao G, et al. Reducing dielectric loss in CaCu3Ti4O12 thin films by high-pressure oxygen annealing. J Mater Chem C. 2015;3:3438–44. 10.1039/C5TC00197H.Search in Google Scholar

(24) Holzwarth U, Gibson N. The scherrer equation versus the ‘Debye-Scherrer equation’. Nat Nanotechnol. 2011;6:534. 10.1038/nnano.2011.145.Search in Google Scholar PubMed

(25) Abdul-Kader AM, Salem AM, Al-Omari AH, El-Gendy YA, Al-Rashdi A. Improve the structure and optical surface properties of LDPE by ion bombardment technique. Opt Mater. 2021;114:110940. 10.1016/j.optmat.2021.110940.Search in Google Scholar

(26) Chi QG, Gao L, Wang X, Lin JQ, Sun J, Lei QQ. Effects of Zr doping on the microstructures and dielectric properties of CaCu3Ti4O12 ceramics. J Alloy Compd. 2013;559:45–8. 10.1016/j.jallcom.2013.01.090.Search in Google Scholar

(27) Meeporn K, Chanlek N, Thongbar P. Significant enhancement of dielectric permittivity and percolation behaviour of La2-xSrxNiO4/poly(vinylidene fluoride) composites with different Sr doping concentrations. RSC Adv. 2020;10:2747–56. 10.1039/c9ra09719h.Search in Google Scholar PubMed PubMed Central

(28) Meeporn K, Thongbai P, Yanwong T, Maensiri S. Greatly enhanced dielectric permittivity in La1.7Sr0.3NiO4/poly(vinylidene fluoride) nanocomposites that retained a low loss tangent. RSC Adv. 2017;7:17128–36. 10.1039/c7ra01675a.Search in Google Scholar

(29) Chouket A, Bidault O, Optasanu V, Cheikhrouhou A, Cheikhrouhou-Koubaa W, Khitouni M. Enhancement of dielectric response by Al-substitution in La1.6Sr0.4NiO4 nickelates. RSC Adv. 2016;6:24543–48. 10.1039/C5RA27071E.Search in Google Scholar

(30) Gao L, Wang X, Wang HC, Lei QQ. Improvement of dielectric performance and interfacial polarization of polyvinylidene fluoride composites with CaCu3Ti4O12@Ni hybrid nanofibers. J Mater Sci Mater Electron. 2018;29:10600–13. 10.1007/s10854-018-9124-y.Search in Google Scholar

(31) Yang J, Zhu XT, Wang HL, Wang X, Hao CC, Fan RH, et al. Achieving excellent dielectric performance in polymer composites with ultralow filler loadings via constructing hollow-structured filler frameworks. Compos Part A Appl Sci Manuf. 2020;131:105814. 10.1016/j.compositesa.2020.105814.Search in Google Scholar

(32) Zhang YY, Guo HT, Jiang SH, Hu ZY, Zha GJ, Liu KM, et al. Synthesis and properties of PI composite films using carbon quantum dots as fillers. e-Polymers. 2022;22:577–84. 10.1515/epoly-2022-0054.Search in Google Scholar

(33) Kum-onsa P, Thongbai P. Improved dielectric properties of poly(vinylidene fluoride) composites incorporating Na1/2Y1/2Cu3Ti4O12 particles. Mater Today Commun. 2020;25:101654. 10.1016/j.mtcomm.2020.101654.Search in Google Scholar

(34) Peng ZH, Zhou XB, Wang JT, Zhu J, Liang PF, Chao XL, et al. Origin of colossal permittivity and low dielectric loss in Na1/3Cd1/3Y1/3Cu3Ti4O12 ceramics. Ceram Int. 2020;46:11154–9. 10.1016/j.ceramint.2020.01.136.Search in Google Scholar

(35) Tuichai W, Danwittayakul S, Thongbai P. Significantly enhanced dielectric permittivity and suppressed dielectric loss in Na1/2Bi1/2Cu3Ti4O12/poly(vinylidene fluoride) nanocomposites. Ceram Int. 2018;44:S133–6. 10.1016/j.ceramint.2018.08.158.Search in Google Scholar

(36) Kum-onsa P, Thongbai P, Maensiri S, Chindaprasirt P. Greatly enhanced dielectric permittivity in poly(vinylidene fluoride)-based polymeric composites induced by Na1/3Ca1/3Bi1/3Cu3Ti4O12 nanoparticles. J Mater Sci Mater Electron. 2016;27:9650–5. 10.1007/s10854-016-5023-2.Search in Google Scholar

(37) Feng Y, Li WL, Hou YF, Yu Y, Cao WP, Zhang TD, et al. Enhanced dielectric properties of PVDF-HFP/BaTiO3-nanowire composites induced by interfacial polarization and wire-shape. J Mater Chem C. 2015;3:1250–60. 10.1039/C4TC02183E.Search in Google Scholar

(38) Yang Y, Zhu BP, Lu ZH, Wang ZY, Fei CL, Yin D, et al. Polyimide/nanosized CaCu3Ti4O12 functional hybrid films with high dielectric permittivity. Appl Phys Lett. 2013;102:042904. 10.1063/1.4789504.Search in Google Scholar

(39) Yang WH, Yu SH, Sun R, Du RX. Nano- and microsize effect of CCTO fillers on the dielectric behavior of CCTO/PVDF composites. Acta Mater. 2011;59:5593–602. 10.1016/j.actamat.2011.05.034.Search in Google Scholar

(40) Chi QG, Dong JF, Zhang CH, Wong CP, Wang X, Lei QQ. Nano iron oxide-deposited calcium copper titanate/polyimide hybrid films induced by an external magnetic field: Toward a high dielectric constant and suppressed loss. J Mater Chem C. 2016;4:8179–88. 10.1039/C6TC01655C.Search in Google Scholar

(41) Pan ZB, Ding QL, Yao LM, Huang SW, Xing S, Liu JJ, et al. Simultaneously enhanced discharge energy density and efficiency in nanocomposite film capacitors utilizing two-dimensional NaNbO3@Al2O3 platelets. Nanoscale. 2019;11:10546–54. 10.1039/C9NR00874H.Search in Google Scholar

(42) Zou KL, Dan Y, Yu YX, Zhang Y, Zhang QF, Lu YM, et al. Flexible dielectric nanocomposites with simultaneously large discharge energy density and high energy efficiency utilizing (Pb,La)(Zr,Sn,Ti)O3 antiferroelectric nanoparticles as fillers. J Mater Chem A. 2019;7:13473–82. 10.1039/C9TA01299K.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites