Abstract

Epoxy resin (EP)/cyanate ester (CE) copolymer, an important structural material with high temperature resistance and low dielectric constant in aerospace, microelectronics, and related fields, is still of great flammability danger. In this work, copper phenyl phosphonate (CuPP), a flame retardant used in EP/CE copolymer was synthesized by the reaction of phenyl phosphonic acid and copper nitrate trihydrate. The fire and thermal behavior of EP/CE/CuPP composites were studied in detail. The results suggested that the UL-94 rating and limiting oxygen index of EP/CE composite with 5 wt% CuPP (EP/CE/CuPP5) reach V-1 level and 30.6%, respectively. Compared with pure EP/CE copolymer, the peak heat release rate and total heat release values of EP/CE/CuPP5 decreased by 34.5% and 18.9%, respectively. The glass transition temperature of EP/CE/CuPP composite is higher than that of pure EP/CE copolymer, suggesting that the fire-retardant composite has higher work temperature and better heat resistance.

1 Introduction

Epoxy resin (EP) is widely used in many industrial fields due to its excellent comprehensive properties, such as adhesion, chemical resistance, and mechanical properties. However, due to the existence of some strong polar groups, such as hydroxyl group, the dielectric properties of EP resin are not enough to meet the special requirements for high-speed electronics. The cyanate ester (CE) resin has outstanding heat resistance and low dielectric constant; therefore, it is usually used to improve the related properties of EP resin (1,2,3,4,5,6). For example, Kim studied the curing behavior and thermal stability of EP/CE copolymers and found that the curing reaction of EP/CE copolymer was faster than that of pure EP resin and the initial decomposition temperature of the copolymer was raised with the increase of CE content (7). Similarly, Jayakumari et al. (8) observed that with the increase of CE content, the mechanical strength of EP/CE copolymer was increased, and the thermal stability of the copolymer also was improved. Liang and Zhang (9) found that the processability of CE resin was improved via copolymerization with EP resin, and the modified resin had excellent dielectric properties. Lin (10) found that the incorporation of phosphorus element into CE, which was a frequent way to improve the flame retardancy of resin, would not sacrifice the dielectric properties.

Although EP/CE copolymer has low dielectric properties and good heat resistance, it is still of great flammability danger. Traditional halogen-containing flame retardant produces a great deal of smoke and toxic substances during burning; thus, its application is restricted in some fields, especially in the electronic and electrical fields (11). There is some research on the halogen-free flame retardancy of EP/CE copolymer. For example, Ho (12) found that, compared with the control pure EP resin, the EP/CE composites with 2-(6-oxido-6H-dibenz(c, e)(1,2)-oxaphosphorin-6-yl)-1,4-benzenedio (containing 2 wt% phosphorus content) have better flame retardancy and higher glass transition temperature (T g). Toldy et al. (13) successfully prepared the copolymer containing bisphenol-A diglycidyl ether and phenolic CE, modified the copolymer by 9,10-dihydro-9-oxa-10-phosphazephenanthrene-10-oxide (DOPO), and then found that the EP/CE/DOPO composites with 2 wt% phosphorus content reach UL-94 V-0 level. Our team (14) enhanced the flame retardancy of EP/CE composite by adding the compound of DOPO and wollastonite (Wo) and reported that the EP/CE composites with 7 wt% DOPO and 3 wt% Wo reached UL-94 V-0 level with LOI of 35.5%.

However, the difficulties of halogen-free flame-retardant research for EP/CE copolymer are concentrated mainly on the high curing temperature (more than 200°C) and active groups (i.e. –OH and –NH2) affecting the curing reaction, which restricts the application of most halogen-free flame retardants in this system. Moreover, the majority of halogen-free flame retardants generally result in a reduction in the thermal stability of EP/CE composites, such as T g (13,15).

Metal organic phosphates have received great concern in the research on flame retardant for polymers because of their water insolubility and good compatibility with polymer matrix. Müller and Schartel (16) compared the flame retardancy of three metal organic phosphates (MPAlP, MPZnP, and MPMgP) in EP and found that the three composites containing them (20 wt%) showed at least a 50% reduction in PHRR, while a reduction in smoke and carbon monoxide generation and an increase in the amount of fire residue were observed. Liu and colleagues (17) synthesized metal-phosphorus hybrid nanomaterials with various metal centers (Al, Zn, and Fe) through a hydrothermal reaction between metal hydroxides and phosphite/phosphonic acid. It was found that the addition of metal organic phosphates significantly improved the flame retardancy of the EP, while according to the TG-IR results, the increase in flame retardancy is likely to be due to the delayed release of the flammable components resulted from the metal centres of the metal organic phosphates. And in our recent work (18), a metal organic phosphonate (CuPB) was synthesized and used to modify EP, and the EP composite with only 3.0 wt% CuPB can pass the UL-94 V-0 rating. However, there are few reports on the use of metal organic phosphates in EP/CE copolymer.

Herein, copper phenyl phosphonate (CuPP) was successfully synthesized via simple method. The burning behaviors of EP/CE/CuPP composites were evaluated by LOI, UL-94, and cone colorimeter test. Moreover, the thermal and mechanical properties were studied.

2 Materials and methods

2.1 Materials

Copper nitrate trihydrate (Cu(NO3)2·3H2O, A.R.), deionized water, absolute ethanol, and sodium hydroxide (NaOH, A.R.) were obtained from Sinopharm Group Chemical Reagent Co., Ltd (China). Phenyl phosphonic acid (PPA, A.R.) was supplied by Aladdin Reagent Co., Ltd (China). Bisphenol-A dicyanate ester (CE) resin was purchased from Jiangsu Wuqiao Resin Plant (China). Diglycidyl ether of bisphenol-A epoxy resin (EP) with an epoxy equivalent weight of 186 g/eq was provided by Sinopec Group Company (China).

2.2 Preparation of CuPP

0.1 mol PPA was dissolved in 100 mL of deionized water. Then, 100 mL of Cu(NO3)2·3H2O aqueous solution (1 mol·L−1) was added dropwise under vigorous stirring and the pH value of the mixture was remained about 5 via the addition of NaOH. Then, the mixture was stirred at room temperature for 24 h. The precipitate was centrifuged and washed several times with deionized water and dried at 105°C for 24 h. Finally, the products were ground and sieved to obtain CuPP powder (200 meshes).

2.3 Preparation of EP/CE and its composites

Different amounts of CuPP were added into EP and CE solution (molar ratio of EP and CE = 1:1) were blended under vigorous stirring at 150°C for 1.5 h and then degassed in a vacuum oven at 150°C for 5 min. Subsequently, the mixture was poured into a Teflon mold and cured by the following protocol: 150°C for 2 h, 180°C for 2 h, 200°C for 2 h, and 220°C for 2 h. The synthesis recipe of the EP/CE/CuPP composites is listed in Table 1.

Formulations of EP/CE and its composites

| Sample code | Component (wt%) | |

|---|---|---|

| EP/CE* | CuPP | |

| Pure EP/CE | 100 | 0 |

| EP/CE/CuPP3 | 97 | 3 |

| EP/CE/CuPP5 | 95 | 5 |

| EP/CE/CuPP7 | 93 | 7 |

*EP:CE = 1:1 (molar ratio).

2.4 Characterization

Fourier transform infrared (FTIR) spectra were collected between 400 and 4,000 cm−1 using an EQUINOX 55 (Bruker, Germany) by the KBr tablet method. X-ray diffraction (XRD) spectrum of CuPP was carried out on a D/MAX 2550VB3 X-ray diffraction spectrometer (Nippon Electric Motor, Japan) at a scanning speed of 5°·min−1, ranging from 3° to 80°. Transmission electron microscope (TEM) graph of CuPP was carried out on JEM-2100F transmission electron microscope (Nippon Electric Motor, Japan). Scanning electron microscope (SEM) graphs were obtained by an S-2360 N instrument (Hitachi, Japan) with an electron high-tension voltage of 10 kV. The surface of the specimens was pre-treated with the gold spray to increase conductivity and prevent charge accumulation. Raman spectroscopic analysis was performed by a LabRAM HR Evolution laser confocal Raman spectrometer (HORIBA, France) with a laser wavelength of 532 nm. Thermogravimetric analysis (TGA) measurements were performed via a STA 6000 thermal gravimetric analyzer (PerkinElmer, USA) from 100°C to 700°C at a scan rate of 10°C·min−1 under nitrogen. The test sample mass was 10 ± 1 mg. Differential scanning calorimeter (DSC) analysis was carried out on a Q100 differential scanning calorimetry (TA, USA), and the samples of 7 ± 1 mg were heated from 50°C to 300°C with a heating rate of 10°C·min−1 under nitrogen. Each material was subjected to two measurements, and the results were averaged.

The fire behavior of the EP/CE copolymer and its composites were studied by LOI test, UL-94 burning test, and cone calorimeter test (CCT). LOI was measured on HC-2 Oxygen Indexer (Jiangning, China) according to GB/T 2406-2009 with the form Ⅳ sample size of 100 mm × 6.5 mm × 3 mm. UL-94 test with the sample size of 125 mm × 13 mm × 3 mm was performed on CFZ-3 instrument (Jiangning, China) in accordance with GB/T 2408-2021. CCT was tested in a cone calorimeter (FTT, UK) with the sample size of 100 mm × 100 mm × 3 mm at a heat flux of 35 kW·m−2 according to ISO 5660-1. Samples for LOI and UL-94 tests were measured fifth and those for CCT were measured twice; their average results were obtained.

The tensile strengths were measured by CMT5105 universal testing machine (MTS, USA) according to GB/T 1040-2006 by using type 1A dumbbell-shaped samples with an overall length of 170 mm, a gauge length of 50 mm, and a thickness of 4 mm. The impact strengths were measured according to GB/T 1043-2008 by SANS E21 pendulum impact testing machine (SANS, China) with the sample size of 80 mm × 10 mm × 4 mm. Five specimens of each material were measured in the tensile and impact strength tests, respectively.

3 Results and discussion

3.1 Characterization of CuPP

Figure 1a presents the FTIR spectrum of CuPP and PPA. As shown in Figure 1a, the absorption peaks in 2,000–1,600 cm−1 are related to the C–H stretching vibration of the benzene ring. The peak at 1,431 cm−1 corresponds to the absorption of the P–C bond. The strong peaks near 1,014 and 934 cm−1 are due to the stretching vibration of the P–O bond. The above results agree with the infrared results of phenyl phosphonates in the literature (19). In addition, the coordination between PPA and copper ion in CuPP can be proved from three aspects: the disappearance of P–OH peak in 2,700–2,560 cm−1 (20), the shift of P═O peak (from 1,220 to 1,186 cm−1), and the appearance of peak at 1,031 cm−1 (21). Figure 1b shows the XRD graph of CuPP. Three strong diffraction peaks at 2θ = 5.68°, 11.44°, and 17.22° correspond to the (010), (020), and (030) crystal planes of CuPP, respectively (19,22). The above results indicate that CuPP was successfully synthesized. Figure 1c shows the TEM image of CuPP. The microstructure of CuPP presents a lamellar structure, which possibly increases the physical barrier effect of the char. Obviously, the thermal decomposition of CuPP has three steps. Before 300°C, CuPP has nearly no weight loss (only 0.54 wt%) and the temperature at 5 wt% mass loss (T 5%) is 379°C, indicating that CuPP has high initial thermal stability. The first step occurring between 300 and 400°C with a weight loss of 5.76 wt% is attributed to dehydration and condensation of phosphonic acid groups. The mass loss at the second step in the range 400–500°C is related to the oxidation of some phosphorus group and the formation of Cu2P2O7 (21,23) while the pyrolysis of benzene rings occurs when the temperature is higher than 500°C (24).

Characterization of CuPP: (a) FTIR spectra, (b) XRD pattern, (c) TEM, and (d) TGA and DTG curves.

3.2 Fire behavior of EP/CE and its composites

3.2.1 LOI and UL-94

The flame retardancy of EP/CE and its composites is preliminarily evaluated through LOI and UL-94 vertical burning test and the results are arranged in Table 2. The pure EP/CE has an LOI value of 25.7% and no UL-94 test rating. The LOI values of EP/CE/CuPP3, EP/CE/CuPP5, and EP/CE/CuPP7 increase to 28.2%, 30.6%, and 30.7%, respectively. For the UL-94 results, EP/CE/CuPP5 and EP/CE/CuPP7 composites achieve UL-94 V-1 rating.

LOI values and UL-94 ratings of EP/CE and its composites

| Sample code | LOI (%) | UL-94 rating |

|---|---|---|

| Pure EP/CE | 25.7 ± 0.2 | NR* |

| EP/CE/CuPP3 | 28.2 ± 0.2 | NR |

| EP/CE/CuPP5 | 30.6 ± 0.1 | V-1 |

| EP/CE/CuPP7 | 30.7 ± 0.1 | V-1 |

*No rating.

Based on the results of LOI and UL-94, it can be inferred that the incorporation of CuPP improves flame retardancy of EP/CE copolymer. However, the observed improvement in flame retardancy tends to level off at CuPP concentration of 5 wt% or higher, which may be due to the worse dispersion of the flame retardant in the resin matrix, leading to some agglomeration of particles.

3.2.2 Cone calorimeter study

To gain a better understanding of the fire behavior of EP/CE/CuPP, we conducted forced flaming combustion studies using the CCT. CCT is widely recognized as a scientific method to study material burning behavior under conditions of developing fire scenarios. The related results are presented in Figure 2 and Table 3.

CCT results of EP/CE and its composites: (a) HRR, (b) THR, (c) TSR, and (d) THR-pHRR/TTI.

CCT results of EP/CE and its composites

| Sample code | TTI | pHRR | THR | EHC | TSR | Residue |

|---|---|---|---|---|---|---|

| (s) | (kW·m−2) | (MJ·m−2) | (MJ·kg−1) | (m2·m−2) | (wt%) | |

| Pure EP/CE | 103 ± 3 | 522 ± 32 | 77.4 ± 3.4 | 21.0 ± 2.5 | 3,440 ± 148 | 19.0 ± 0.7 |

| EP/CE/CuPP5 | 69 ± 4 | 342 ± 28 | 62.8 ± 2.3 | 17.1 ± 2.0 | 3,363 ± 103 | 22.8 ± 0.4 |

| EP/CE/CuPP7 | 68 ± 3 | 333 ± 6 | 60.8 ± 2.6 | 16.9 ± 2.7 | 3,335 ± 180 | 23.7 ± 1.1 |

According to reference (25), the heat release rate (HRR) curve of all samples exhibits thermally thick charring pattern. After ignition, the HRR of pure EP/CE rapidly ascends to its first peak and then gradually decreases over time due to the barrier effect of the char layer. At 300–350 s, a second weak peak appears, which is attributed to a fragile and broken carbon layer, resulting in a thermally thick non-charring situation. In contrast, the addition of CuPP has resulted in a notable advancement in the time to ignition (TTI), which is possibly due to the early decomposition of the matrix caused by CuPP. Compared with pure EP/CE, the composite containing 5 wt% CuPP exhibits a significant reduction of peak of heat release rate (pHRR) up to 34%, with the second peak disappearing, indicating that CuPP has a strengthening effect on the char layer, which corresponds to the increase of residue yield.

According to Petrella (26), the total heat release (THR) is plotted against the pHRR/TTI ratio (Figure 2d). The horizontal axis represents the propensity for a fire to spread rapidly, while the vertical axis measures the propensity for a prolonged fire. This graphical representation provides a clear and concise means of assessing fire risk. It is found that the incorporation of CuPP into the EP/CE has resulted in a reduction of both the THR and pHRR/TTI values. This reduction may be attributed to two reasons. First, the presence of CuPP serves to dilute the combustible content of the composite. Second, the char layer formed by burning EP/CE/CuPP is stronger than that of pure EP/CE, thus improving its fire performance.

The average effective heat of combustion (EHC) is a critical parameter for evaluating the activity of a flame retardant in the gas phase (27). It can be observed that the EHC of EP/CE/7CuPP exhibits a reduction of approximately 20% in comparison to that of pure EP/CE, suggesting that CuPP can exert a flame-retardant effect in the gas phase. Meanwhile, the total smoke release (TSR) values of the EP/CE/CuPP composites remain nearly unchanged.

3.2.3 Char analysis

The SEM images and macroscopic appearance of the residual chars of pure EP/CE and EP/CE/CuPP5 after CCT are shown in Figure 3.

SEM, macroscopic appearance, and EDS spectra images of residual chars: (a) pure EP/CE and (b) EP/CE/CuPP5.

The residual char of pure EP/CE (Figure 3a) exhibits a broken and fragile appearance, and SEM image reveals a smooth surface but with large cracks. For EP/CE/CuPP5 (Figure 3b), the residue exhibits a grey-green lamellar structure on a macroscopic scale, and SEM image reveals many bubble-like protrusions on the compact and continuous residual char, which can act as a stable protective layer. To further investigate the elemental composition of the residues char, EDS is applied, and the results are presented in Figure 3 and Table 4. It can be observed that the residual char from pure EP/CE contains only C, O, and N, while the residue from CuPP/EP/CE5 contains P and Cu elements besides C, O, and N.

Element compositions of the residual char of pure EP/CE and EP/CE/CuPP5

| Sample code | Element composition (%) | ||||

|---|---|---|---|---|---|

| C | N | O | P | Cu | |

| Pure EP/CE | 78.35 | 6.34 | 15.31 | 0 | 0 |

| EP/CE/CuPP5 | 31.56 | 9.50 | 9.25 | 15.16 | 34.53 |

Moreover, Raman is used to study the residual chars to explore the graphitization degree of carbon layer (28). The Raman spectra of the residues of pure EP/CE and EP/CE/CuPP5 are shown in Figure 4. The I D/I G ratio from pure EP/CE is 3.235, whereas the ratio from EP/CE/CuPP5 decreases to 2.930. The reduction in the ratio shows that the addition of CuPP improves the graphitization degree of the residual chars. This phenomenon probably results from the phosphorus-containing acid produced by the pyrolysis of CuPP and which can promote the formation of more ordered graphitized carbon (29).

Raman spectra of residual chars: (a) pure EP/CE and (b) EP/CE/CuPP5.

Based on the analysis of the obtained data aforementioned, it can be inferred that the action of the flame retardant CuPP is predominantly exhibited within the condensed phase. During the combustion of the EP/CE/CuPP composites, CuPP decomposes to produce phosphorus-containing acids, which promote the matrix to form the carbonaceous char layer, which not only results in a reduction in the release of combustible volatiles but also prevents the transfer of heat and material between the condensed and gas phases.

3.3 Thermal behavior of EP/CE/CuPP composites

3.3.1 DSC study

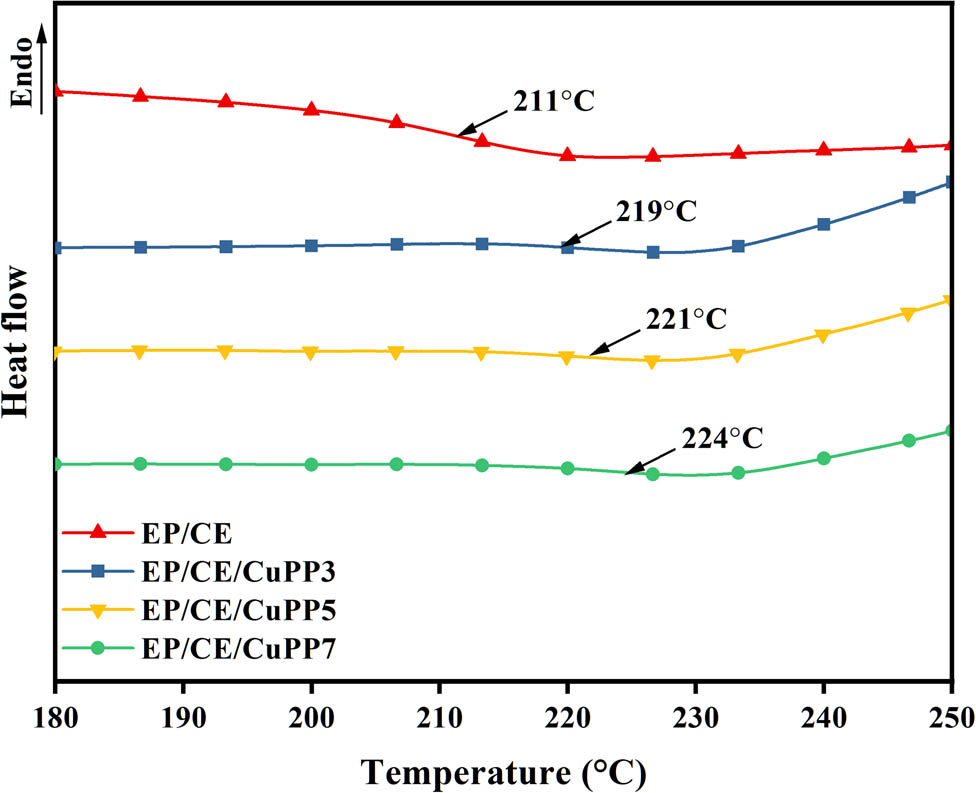

The glass transition temperatures (T g) of EP/CE and its composites are carried out by DSC and the curves are presented in Figure 5. The T g of pure EP/CE is 211°C, while the T g values of the EP/CE/CuPP composites with 3, 5, and 7 wt% CuPP are 219, 221, and 224°C, respectively. The increase of T g of the composites may be attributed to the presence of rigid CuPP nanosheets, which act as a physical crosslinking point within the EP/CE crosslinking network. The CuPP nanosheets prevent the movement of polymer molecular chains and reduces free volume, which lead to an increase in the network density and T g (30,31).

DSC curves of EP/CE and its composites.

3.3.2 TGA study

The TGA curves of EP/CE and its composites are shown in Figure 6 and the results are listed in Table 5. It is evident that all samples have one decomposition step. The temperature at 5 wt% weight loss (T 5%) of pure EP/CE is 364°C, and the temperature at the maximum mass loss rate (T max) appears at 414°C. For EP/CE/CuPP composites, due to the early decomposition of CuPP, T 5% and T max values gradually drop with the increased addition of CuPP. The residue of pure EP/CE at 700°C is 11.0 wt% while the residues of EP/CE/CuPP are more than 15 wt%, which may be caused by the fact that the decomposition products of CuPP are helpful to promote char formation of the resin.

TGA curves of EP/CE and its composites.

TGA results of EP/CE and its composites

| Sample code | T 5% (°C) | T max (°C) | Char residue at 700°C (wt%) |

|---|---|---|---|

| Pure EP/CE | 364 ± 2 | 414 ± 2 | 11.0 ± 1.0 |

| EP/CE/CuPP3 | 351 ± 3 | 407 ± 3 | 17.5 ± 1.5 |

| EP/CE/CuPP5 | 342 ± 2 | 406 ± 2 | 18.4 ± 0.6 |

| EP/CE/CuPP7 | 340 ± 2 | 400 ± 3 | 19.5 ± 1.1 |

3.4 Mechanical properties of EP/CE composites

The mechanical properties of EP/CE and its composites are shown in Figure 7. Although the T g and network density of the composite increase with the addition of CuPP, the mechanical properties actually decrease instead. The decrease in the mechanical properties of EP/CE/CuPP composites is likely to be related to the high loading and the poor dispersion of CuPP particles in the matrix, resulting in stress concentration and deterioration in the mechanical properties (32).

Mechanical properties of EP/CE and its composites.

To further explore the mechanism of adding CuPP on the mechanical properties of EP/CE copolymer, the microstructures of fractured surface of the composites are investigated by SEM. As shown in Figure 8a, pure EP/CE exhibits a typical brittle feature with many river-like cracks on the smooth surface. The fractured surfaces of the EP/CE/CuPP composites (Figure 8b–d) with a lot of layered protrusions and tough whirls are much coarser than that of pure sample. The layered protrusions and tough whirls can absorb energy during finite cracks propagation, thereby raising the toughness and preventing further damage of the materials, theoretically. However, many cavitation produced by particle peeling is observed from the fractured surface of the EP/CE/CuPP composites, which can be contributed to the local stress concentration after the incorporation of CuPP and thus deterioration of mechanical performance of the composites.

SEM images of fractured surfaces of EP/CE and its composites: (a) pure EP/CE, (b) EP/CE/CuPP3, (c) EP/CE/CuPP5, and (d) EP/CE/CuPP7.

4 Conclusion

In this work, CuPP, a novel flame retardant, was facilely synthesized and confirmed by FTIR, XRD, TGA, and TEM. EP/CE composites with CuPP were successfully prepared as well, and the effects of the CuPP on flame retardancy, thermal resistance and mechanical properties of the EP/CE composites were studied. The EP/CE/CuPP5 composite showed the outstanding flame retardancy with a LOI of 30.6% and UL-94 V-1 rating. The PHRR and THR values of EP/CE/CuPP5 decrease by 34.5% and 18.9%, respectively, compared with those of samples without CuPP. SEM, EDS, and Raman spectra of residues prove that CuPP exerts its flame-retardant role in the EP/CE copolymer mainly in the condensed phase. The T g values of the EP/CE/CuPP composites are all higher than the one of pure EP/CE, but the introduction of CuPP leads to a decrease in mechanical properties of EP/CE/CuPP composites.

-

Funding information: This work was financially supported by the National Natural Science Foundation of China (21975185).

-

Author contributions: Zhilin Cao: writing – original draft, writing – review and editing, visualization, investigation, formal analysis; Changxin Ren: writing – original draft, investigation, conceptualization; Zhengzhou Wang: supervision, project administration.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data sets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

(1) Chen Y, Li Z, Liu Y, Teng C, Cui W. Curing mechanism and mechanical properties of Al2O3/cyanate ester–epoxy composites. J Electron Mater. 2020;49(2):1473–81. 10.1007/s11664-019-07836-w.Search in Google Scholar

(2) Zhang X, Wang F, Zhu Y, Qi H. Cyanate ester composites containing surface functionalized BN particles with grafted hyperpolyarylamide exhibiting desirable thermal conductivities and a low dielectric constant. RSC Adv. 2019;9(62):36424–33. 10.1039/C9RA06753A.Search in Google Scholar

(3) Chen Y, Li Z, Liu Y, Teng C, Cui W. Effect of Al2O3 on microstructure and dielectric properties of epoxy-cyanate ester composite material. J Mater Sci: Mater Electron. 2019;30(23):20614–23. 10.1007/s10854-019-02427-1.Search in Google Scholar

(4) Chandramohan A, Dinkaran K, Kumar AA, Alagar M. Synthesis and characterization of epoxy modified cyanate ester POSS nanocomposites. High Perform Polym. 2012;24(5):405–17. 10.1177/0954008312441640.Search in Google Scholar

(5) Lei Y, Xu M, Jiang M, Huang Y, Liu X. Curing behaviors of cyanate ester/epoxy copolymers and their dielectric properties. High Perform Polym. 2017;29(10):1175–84. 10.1177/0954008316672291.Search in Google Scholar

(6) Liu Z, Yuan L, Liang G, Gu A. Tough epoxy/cyanate ester resins with improved thermal stability, lower dielectric constant and loss based on unique hyperbranched polysiloxane liquid crystalline: Cyanate Ester Resins with Hyperbranched Polymer Liquid Crystalline. Polym Adv Technol. 2015;26(12):1608–18. 10.1002/pat.3590.Search in Google Scholar

(7) Kim BS. Effect of cyanate ester on the cure behavior and thermal stability of epoxy resin. J Appl Polym Sci. 1997;65(1):85–90. 10.1002/(SICI)1097-4628(19970705)65:1<85:AID-APP11>3.0.CO;2-Y.Search in Google Scholar

(8) Jayakumari LS, Thulasiraman V, Sarojadevi M. Synthesis and characterization of cyanate epoxy composites. High Perform Polym. 2007;19(1):33–47. 10.1177/0954008306072147.Search in Google Scholar

(9) Liang G, Zhang M. Enhancement of processability of cyanate ester resin via copolymerization with epoxy resin. J Appl Polym Sci. 2002;85(11):2377–81. 10.1002/app.10872.Search in Google Scholar

(10) Lin CH. Synthesis of novel phosphorus-containing cyanate esters and their curing reaction with epoxy resin. Polymer. 2004;45(23):7911–26. 10.1016/j.polymer.2004.09.023.Search in Google Scholar

(11) Preston CML, Amarasinghe G, Hopewell JL, Shanks RA, Mathys Z. Evaluation of polar ethylene copolymers as fire retardant nanocomposite matrices. Polym Degrad Stab. 2004;84(3):533–44. 10.1016/j.polymdegradstab.2004.02.004.Search in Google Scholar

(12) Ho T, Hwang H, Shieh J, Chung M. Thermal, physical and flame-retardant properties of phosphorus-containing epoxy cured with cyanate ester. React Funct Polym. 2009;69(3):176–82. 10.1016/j.reactfunctpolym.2008.12.019.Search in Google Scholar

(13) Toldy A, Szlancsik Á, Szolnoki B. Reactive flame retardancy of cyanate ester/epoxy resin blends and their carbon fibre reinforced composites. Polym Degrad Stab. 2016;128:29–38. 10.1016/j.polymdegradstab.2016.02.015.Search in Google Scholar

(14) Wang Z, Gao X, Li W. Epoxy resin/cyanate ester composites containing DOPO and wollastonite with simultaneously improved flame retardancy and thermal resistance. High Perform Polym. 2020;32(6):710–8. 10.1177/0954008319897095.Search in Google Scholar

(15) Toldy A, Niedermann P, Szebenyi G, Szolnoki B. Mechanical properties of reactively flame retarded cyanate ester/epoxy resin blends and their carbon fibre reinforced composites. Express Polym Lett. 2016;10(12):1016–25. 10.3144/expresspolymlett.2016.94.Search in Google Scholar

(16) Müller P, Schartel B. Melamine poly(metal phosphates) as flame retardant in epoxy resin: Performance, modes of action, and synergy. J Appl Polym Sci. 2016;133(24):43549–62. 10.1002/app.43549.Search in Google Scholar

(17) Liu L, Huang Y, Yang Y, Ma J, Yang J, Yin Q. Preparation of metal-phosphorus hybridized nanomaterials and the action of metal centers on the flame retardancy of epoxy resin. J Appl Polym Sci. 2017;134(48):45445–55. 10.1002/app.45445.Search in Google Scholar

(18) Wang W, Wang Z. Flame retardancy, thermal decomposition and mechanical properties of epoxy resin modified with copper N, N’-piperazine (bismethylene phosphonate). J Therm Anal Calorim. 2022;147(3):2155–69. 10.1007/s10973-021-10592-x.Search in Google Scholar

(19) Zhou T, Wu T, Xiang H, Li Z, Xu Z, Kong Q, et al. Simultaneously improving flame retardancy and dynamic mechanical properties of epoxy resin nanocomposites through synergistic effect of zirconium phenylphosphate and POSS. J Therm Anal Calorim. 2019;135(4):2117–24. 10.1007/s10973-018-7387-4.Search in Google Scholar

(20) Xie J, Chang J, Wang X. Application of infrared spectroscopy in organic chemistry and pharmaceutical chemistry. revised ed. Beijing: Science Press; 2001.Search in Google Scholar

(21) Hayashi H, Hudson MJ. Reaction of the phenyiphosphonate anion with the layered basic copper(II) nitrate [Cu2(OH)3NO3]. J Mater Chem. 1995;5(1):115–9. 10.1039/jm9950500115.Search in Google Scholar

(22) Kong Q, Wu T, Zhang J, Wang DY. Simultaneously improving flame retardancy and dynamic mechanical properties of epoxy resin nanocomposites through layered copper phenylphosphate. Compos Sci Technol. 2018;154:136–44. 10.1016/j.compscitech.2017.10.013.Search in Google Scholar

(23) Yucesan G, Yu MH, Ouellette W, O’Connor CJ, Zubieta J. Secondary metal–ligand cationic subunits {ML}n+ as structural determinants in the oxovanadium/phenylphosphonate/{ML}n+ system, where {ML} is a Cu2+/organonitrogen moiety. Cryst Eng Comm. 2005;7(80):480–90. 10.1039/b506250k.Search in Google Scholar

(24) Wang J, Yuan B, Mu X, Feng X, Tai Q, Hu Y. Two-dimensional metal phenylphosphonates as novel flame retardants for polystyrene. Ind Eng Chem Res. 2017;56(25):7192–206. 10.1021/acs.iecr.7b00858.Search in Google Scholar

(25) Schartel B, Hull TR. Development of fire-retarded materials—Interpretation of cone calorimeter data. Fire Mater. 2007;31(5):327–54. 10.1002/fam.949.Search in Google Scholar

(26) Petrella RV. The Assessment of Full-Scale Fire Hazards from Cone Calorimeter Data. J Fire Sci. 1994;12(1):14–43. 10.1177/073490419401200102.Search in Google Scholar

(27) Schartel B, Braun U. Comprehensive fire behaviour assessment of polymeric materials based on cone calorimeter investigations. e-Polymers. 2003;3(1):177–90. 10.1515/epoly.2003.3.1.177.Search in Google Scholar

(28) Sadezky A, Muckenhuber H, Grothe H, Niessner R, Pöschl U. Raman microspectroscopy of soot and related carbonaceous materials: Spectral analysis and structural information. Carbon. 2005;43(8):1731–42. 10.1016/j.carbon.2005.02.018.Search in Google Scholar

(29) Qian X, Song L, Jiang S, Tang G, Xing W, Wang B, et al. Novel Flame Retardants Containing 9,10-Dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and unsaturated bonds: synthesis, characterization, and application in the flame retardancy of epoxy acrylates. Ind Eng Chem Res. 2013;52(22):7307–15. 10.1021/ie400872q.Search in Google Scholar

(30) Chen Y, Chen E, Wu T. Organically modified layered zinc phenylphosphonate reinforced stereocomplex-type poly(lactic acid) nanocomposites with highly enhanced mechanical properties and degradability. J Mater Sci. 2015;50(23):7770–8. 10.1007/s10853-015-9348-7.Search in Google Scholar

(31) Kong Q, Sun Y, Zhang C, Guan H, Zhang J, Wang DY, et al. Ultrathin iron phenyl phosphonate nanosheets with appropriate thermal stability for improving fire safety in epoxy. Compos Sci Technol. 2019;182:107748–57. 10.1016/j.compscitech.2019.107748.Search in Google Scholar

(32) Zhang Z, Liang G, Wang X. Epoxy-functionalized polyhedral oligomeric silsesquioxane/cyanate ester resin organic-inorganic hybrids with enhanced mechanical and thermal properties: Epoxy functionalized POSS/cyanate ester resin hybrids. Polym Int. 2014;63(3):552–9. 10.1002/pi.4557.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites