Abstract

The present work aims to fabricate new inexpensive epoxy-based composites with a concentration described by the formula (90 − x)epoxy + 10Sb2O3 + xPbO, where x = 5, 10, 15, and 20 wt%. The impacts of the substitution of epoxy by PbO on the composite density and radiation shielding properties of the fabricated composites were studied. The density of the fabricated composites varied between 1.30 and 1.49 g·cm−3, enriching the PbO concentration. Utilizing the narrow beam transmission method, the linear attenuation coefficient (LAC) of the fabricated composites was measured using the NaI (Tl) detector as well as radioactive sources Am-241 and Cs-137. The LAC increased by 84% and 18% at gamma-ray energy of 0.059 and 0.662 MeV, when the PbO concentration raised between 5 and 20 wt%, respectively. Then the transmission rate and half-value layer of the fabricated composites were reduced by raising the PbO concentration. Therefore, the fabricated composite has good shielding properties in the low gamma-ray energy interval to be suitable for medical applications and low radioactive waste container constructions.

1 Introduction

It is imperative that any radiation that is produced by devices that continue to utilize the use of radiation be contained and prevented, to the greatest extent feasible, from reaching out to either people or the natural environment. Ionizing radiation can cause major health problems if it is exposed to it for an extended period of time, which is why radiological shields are commonly utilized to protect people from its potentially dangerous effects. Radiation shields are layers of substances that are positioned between a source of radiation and a target region to protect from radiation (1). Materials used for radiation shielding have been developed specifically to absorb the maximum amount of radiation that can be accommodated by the given setting. It may be necessary for a radiation shield to be lightweight, flexible, cheap, and eco-friendly and have the capacity to absorb radiation for very long periods, based on the particulars of the situation (2,3,4,5,6,7,8,9,10).

Epoxy resins are widely used as a foundational material for the fabrication of various composite materials. The exceptional performance of epoxy resins is well known. Epoxy resins provide a number of useful properties when correctly cured, such as cure in a vast range of temperature conditions, corrosion resistance, excellent capabilities in terms of electrical insulation and retention, high compression, tensile, and bending strengths, low cost, and low toxicity. When epoxy resins are mixed with other fillers, they produce composite materials that have features that are useful in a wide variety of applications. This is due to the fact that epoxy resins function effectively even when subjected to extreme conditions. Epoxy resin, when combined with heavy metal oxides, can be shaped into an effective shield of ionizing radiation (11,12,13,14,15). There have been many different ways explored to get a deeper understanding of the resistance of altered epoxy composites to ionizing radiation. In addition, a great deal of effort has been put into developing novel radiation-shielding polymers that are based on epoxy and have a high level of functionality (16,17,18,19). One of the primary goals of nuclear engineers is to produce radioactive shielding materials using epoxy with high atomic number fillers like Pb, Sb, or W (20,21,22,23). These days, polymeric composites are effective, environmentally friendly materials with several uses in radiation protection equipment used in X-ray rooms, hospital computerized tomography (CT) rooms, and other settings. In addition, polymeric materials can be used in the construction of containers that are used in the transportation of low-level liquid radioactive wastes (LLW) and intermediate-level liquid radioactive wastes (ILWs) (24,25,26,27).

The most significant industrial antimony is produced in the antimony(iii) oxide Sb2O3 compound. Sb2O3 is an important catalyst that is used in the vulcanization of rubber as well as the manufacturing of polyethylene terephthalate plastic. On the other hand, lead oxide is one of the main compounds that are preferable for radiation shielding applications due to its compactness and high density of lead (28). The walls, floors, and ceilings of the lab and consultation rooms were constructed using lead-lined plywood and lead-lined drywall. When there are cutouts or penetrations, lead angles are intended to offer leak-proof nuclear shielding (29). Furthermore, epoxy reinforced with PbO compounds is an eco-friendly material that does not produce any type of lead dust on the surface of fabricated materials. Lead dust has the main dangerous effect on human health because lead dust may become airborne and be inadvertently inhaled or ingested by humans (30).

Based on the effective gamma radiation shielding properties of PbO and Sb2O3, as well as the benefits of epoxy composites, such as their softness, easy fabrication, and excellent environmental adaptability, the current work novelty is to fabricate new composites based on inexpensive epoxy reinforced with Sb2O3/PbO to be utilized in radiation shielding applications. An experimental evaluation of the fabricated composites’ gamma ray shielding capacity was performed in the low- and mid-gamma-ray energy intervals.

2 Materials and methods

This work used a two-component epoxy thermosetting resin: type A represents the epoxy resin, while type B is the hardener. The density of the pure epoxy resin used in this work is 1.1 g·cm−3 under a solidification time of 24 h. The utilized epoxy resin and curing agent utilized in the current work were supplied by SlabDOC (Ivanovo, Russia), where the epoxy resin and its curing agent were mixed in a ratio of 2:1. In addition, two different oxides, Sb2O3 (Fluka, purity >98%) and PbO (Sigma-Aldrich, purity >99%), were used as doping compounds to prepare the current radiation shielding materials. Four different sample compositions were formed by the molding and curing process. For all fabricated composites, the concentration of Sb2O3 was kept constant at 10 wt%, while the PbO compound was inserted at concentrations ranging from 5 to 20 wt%. After weighing the epoxy matrix, the required amount of PbO and Sb2O3 doping compounds are added. The mixture is mixed well under magnetic stirring for 15 min to ensure that the particles are evenly dispersed throughout the matrix. The mixture was thoroughly stirred before being put into a cylindrical mold with a diameter of 3 cm and a height of up to 3 cm. It was then left to freely set for 24 h without any outside interference before being removed from the mold (Figure 1). For each composite, four different thicknesses were fabricated to measure the radiation shielding parameters experimentally.

The prepared epoxy reinforced by Sb2O3/PbO composites.

In order to determine the density of the newly developed Sb2O3/PbO-doped epoxy composites, the electric balance with an uncertainty of ±0.001 mg was used to measure the fabricated composites’ mass in the air (W air, g) and immersed in the ethanol (W e, g). Then, the fabricated composites’ density was measured by applying the Archimedes principle (Eq. 1) (31):

In the above equation, ρ e is 0.789 g·cm−3. The chemical composition and the density of the pure curing epoxy in addition to the fabricated composites are illustrated in Table 1.

The composition of the newly developed composites

| Chemical composition (wt%) | |||||

|---|---|---|---|---|---|

| Pure cured epoxy | Sb10Pb5 | Sb10Pb10 | Sb10Pb15 | Sb10Pb20 | |

| H | 6.97 | 5.91 | 5.56 | 5.20 | 4.85 |

| C | 43.89 | 37.32 | 35.09 | 32.87 | 30.66 |

| Na | 0.23 | 0.20 | 0.18 | 0.17 | 0.16 |

| O | 36.42 | 32.83 | 31.35 | 29.88 | 28.41 |

| Na | 2.35 | 1.98 | 1.87 | 1.75 | 1.63 |

| Cl | 8.47 | 7.19 | 6.76 | 6.33 | 5.90 |

| K | 1.50 | 1.27 | 1.19 | 1.12 | 1.04 |

| Co | 0.17 | 0.14 | 0.13 | 0.13 | 0.12 |

| Sb | 0.00 | 8.47 | 8.46 | 8.45 | 8.45 |

| Pb | 0.00 | 4.71 | 9.40 | 14.09 | 18.78 |

| Density (g·cm−3) | 1.03 | 1.30 | 1.35 | 1.40 | 1.49 |

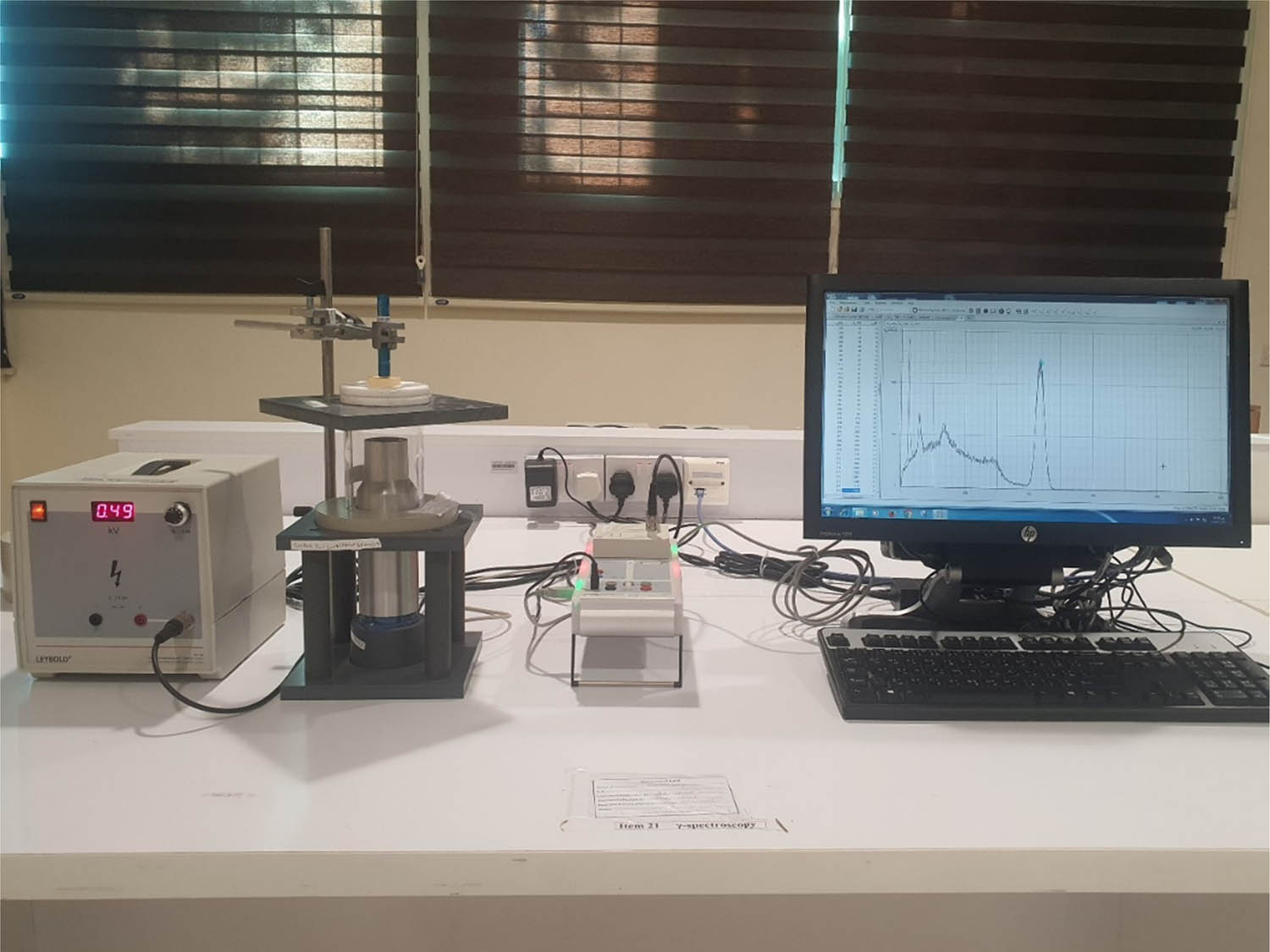

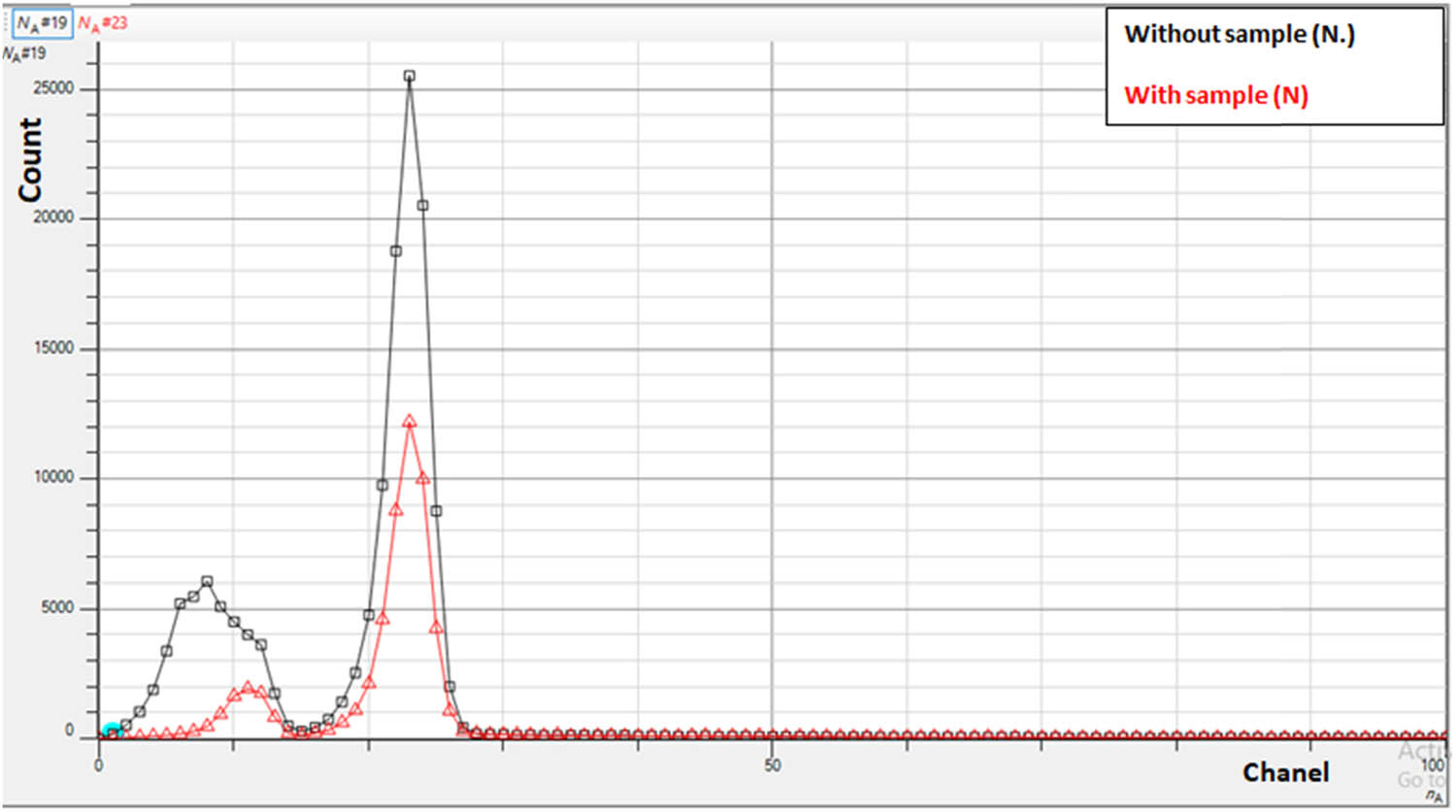

A collimated gamma-ray method with the help of a NaI (Tl) detector was utilized to measure the linear attenuation coefficient (LAC). The NaI (Tl) crystal is a Harshaw type with dimensions 250 mm × 60 mm and can detect gamma-ray photons with energy intervals between 15 keV and 3 MeV. The NaI (Tl) resolution is less than 7.5% at 0.662 MeV. The NaI crystal was capsuled by an aluminum sheet with a thickness of 0.4 mm. The setup that was utilized for this study can be seen in Figure 2. Two radioactive sources Am-241 (with the energy of 0.059 MeV) and Cs-137 (with the energy of 0.662 MeV) were employed to measure the fabricated composites’ LAC. The measurement was carried out both with and without a prepared composite, and the peak in the spectrum was identified with the use of the CASSY Lab 2. The radioactive source’s activity concentration was determined in the presence (N) and absence (N 0) of the substance being tested (Figure 3), and as a result, the LAC was computed experimentally using the following formula (4,32,33,34):

where x (cm) represents the thickness of the fabricated composites. The thicknesses of the fabricated epoxy composites were measured using an X-PERT digital caliper with measurement ranges of 0–150 mm (0–6 IN) and measurement uncertainty of 0.01 mm (0.0005 IN) produced in Moscow, Russia.

The experimental setup for the NaI (Tl) detector used to measure the attenuation factors of the current composites.

The experimental spectrum for Am-241 radioactive source measured by NaI (Tl) using CASSY Lab 2 software.

The transmission rate (TR), which is the ratio of the number of photons transmitted from the fabricated samples’ thickness (N) to the total number of photons emitted from the radioactive source (N o), can be described as follows (35,36):

Other shielding parameters, such as the half-value layer (HVL), mean free path, and tenth value layer (TVL), were estimated using the measured LAC data as follows (37,38,39):

3 Results and discussion

3.1 Density of the prepared samples

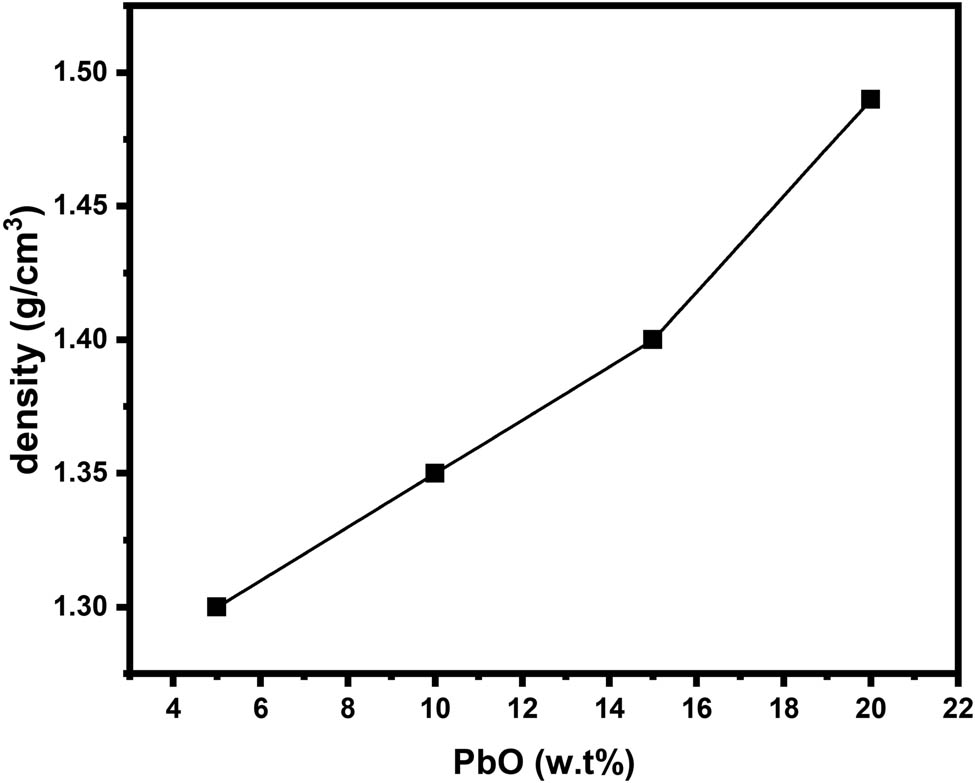

It is known that the density (ρ) is an important factor for the radiation shielding study, so we first examine the density of the new materials as a function of PbO content in Figure 4. It is reported that ρ lies within the range of 1.30–1.49 g·cm−3, and this is higher than the pure epoxy, which is in the order of 1.1 g·cm−3. The fabricated composites’ ρ values increased with raising the PbO concentration from 5% to 20%, which is a logical finding since the amount of epoxy is decreased as we move from Sb10Pb5 to Sb10Pb20, while the amount of PbO is increased and it is known that the lead has a very high density, so we expected an enhancement in the density with increasing the content of PbO. However, the density of the manufactured composites was only increased by a factor of 14.6% when the PbO concentration was increased from 5 to 20 wt%.

The influence of the fabricated composites’ on the PbO concentration added to the fabricated composites.

3.2 Radiation shielding properties

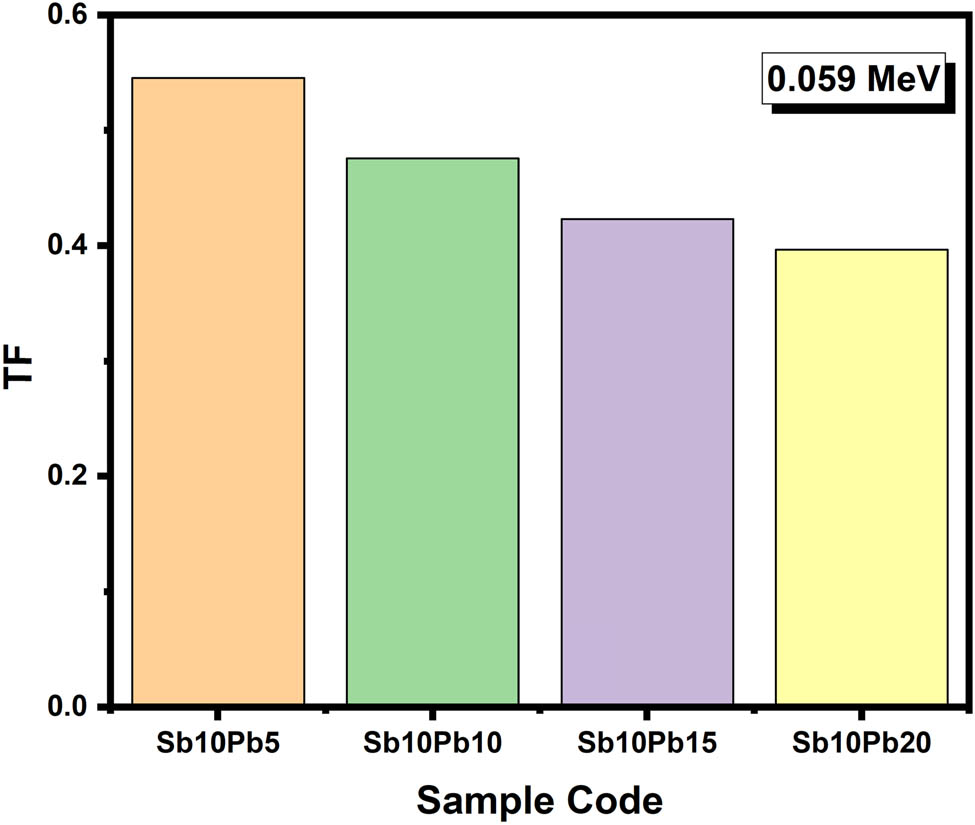

The transmission ratio is affected by the enrichment of PbO concentration, where the enrichment of PbO content between 5 and 20 wt% significantly decreases the TF ratio from 0.55 to 0.4, respectively, at 0.059 MeV, as illustrated in Figure 5. The enrichment of PbO concentration in the fabricated composites increases the effective atomic number (Z eff) and the interaction cross sections (electronic [σ e] and atomic [σ a]) as illustrated in Tables S1–S10. Therefore, the interactions between the incident photons and the electrons of the fabricated composites increased, followed by an increase in the amount of energy consumed inside the fabricated materials. As a result, the transposed photons do not have enough energy to penetrate the thickness of the fabricated composites and the TF values decreased. In addition, the TF results show an increase as energy is increased. The increase in gamma-ray energy is followed by a decrease in the interaction cross-sections, which causes a decrease in the number of interactions inside the fabricated composites. Therefore, the TF values increased as the incident gamma-ray energy increased.

Dependence of the transmission rate TF vs the PbO insertion ratio in the fabricated composites.

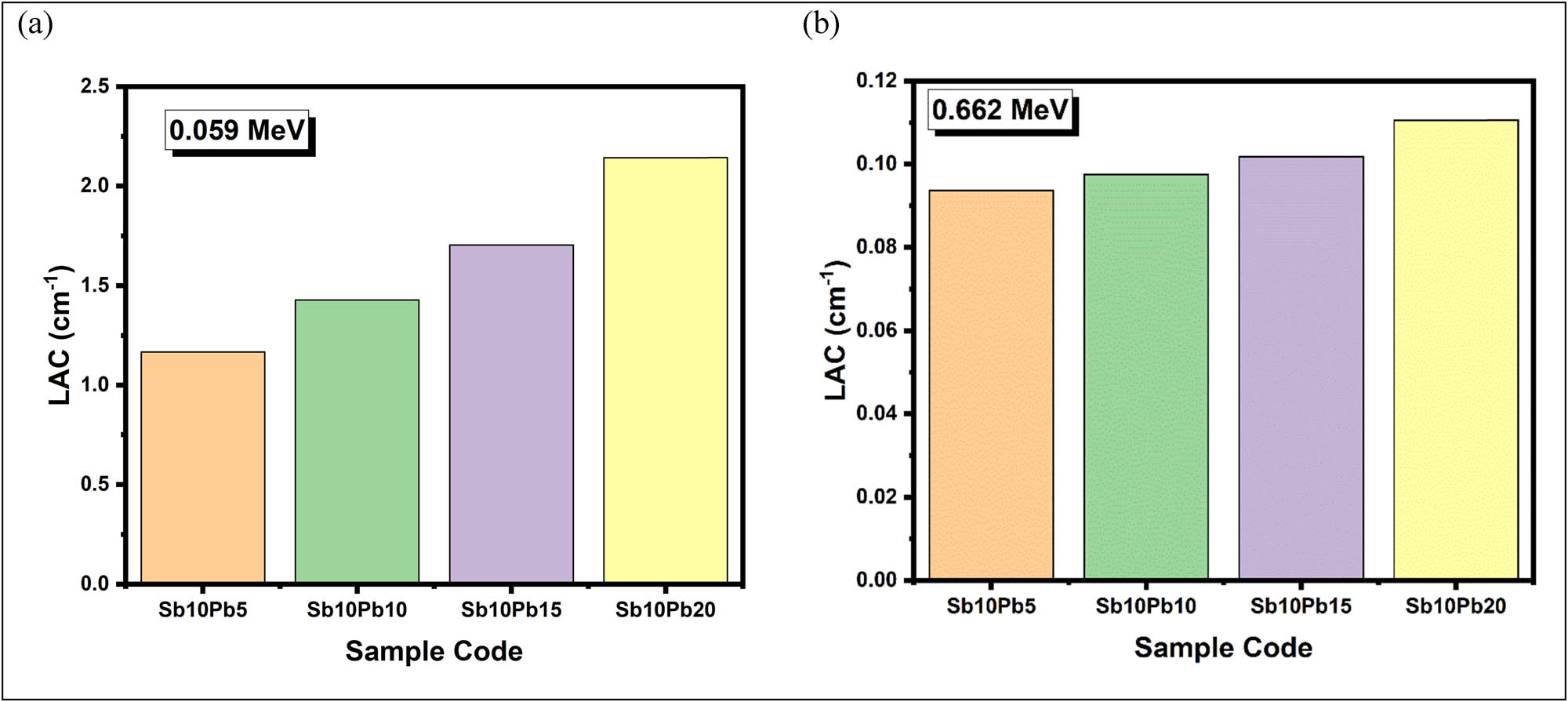

Besides, LAC values were examined for the current composites-based epoxy with different contents of PbO at 0.059 and 0.662 MeV. Figure 6a illustrates that the LAC values were enhanced by 84% from 1.168 to 2.143 cm−1 by raising the PbO content from 5 to 20 wt%, respectively. The high enhancement is attributed to the cross-section of phonetic interaction (PEcs), which changes with

Variation of the LAC of the fabricated composites vs the PbO concentration at (a) 0.059 MeV and (b) 0.662 MeV.

Figure 6a and b confirms a decrease in the LAC values as the incident gamma-ray energy increases. The decrease in LAC is attributed to the PE and CS interactions, which are prevalent interactions at low and intermediate gamma-ray energy. Moreover, the measured mass attenuation coefficient (MAC, cm2·g−1) for the fabricated composites was compared to the theoretically calculated MAC (41) in Table 2 for energies 0.059 and 0.662 MeV. The comparison shows agreement between the experimental and theoretical calculations, with a difference ranging ±15%. The high difference is attributed to the uncertainty in the NaI (Tl) measurements as well as the uncertainty in thickness and chemical composition measurements.

Comparison between the experimentally measured MAC and the theoretically calculated MAC using the Phy-X/PSD program

| MAC (cm2·g−1) | ||||||

|---|---|---|---|---|---|---|

| EXP | Phy-X | Diff (%) | EXP | Phy-X | Diff (%) | |

| Sb10Pb5 | 0.8982 | 1.0293 | 12.7310 | 0.0721 | 0.0827 | 12.8914 |

| Sb10Pb10 | 1.0591 | 1.2590 | 15.8778 | 0.0723 | 0.0842 | 14.0850 |

| Sb10Pb15 | 1.2181 | 1.4880 | 18.1364 | 0.0728 | 0.0855 | 14.8400 |

| Sb10Pb20 | 1.4387 | 1.7167 | 16.1947 | 0.0742 | 0.0868 | 14.4444 |

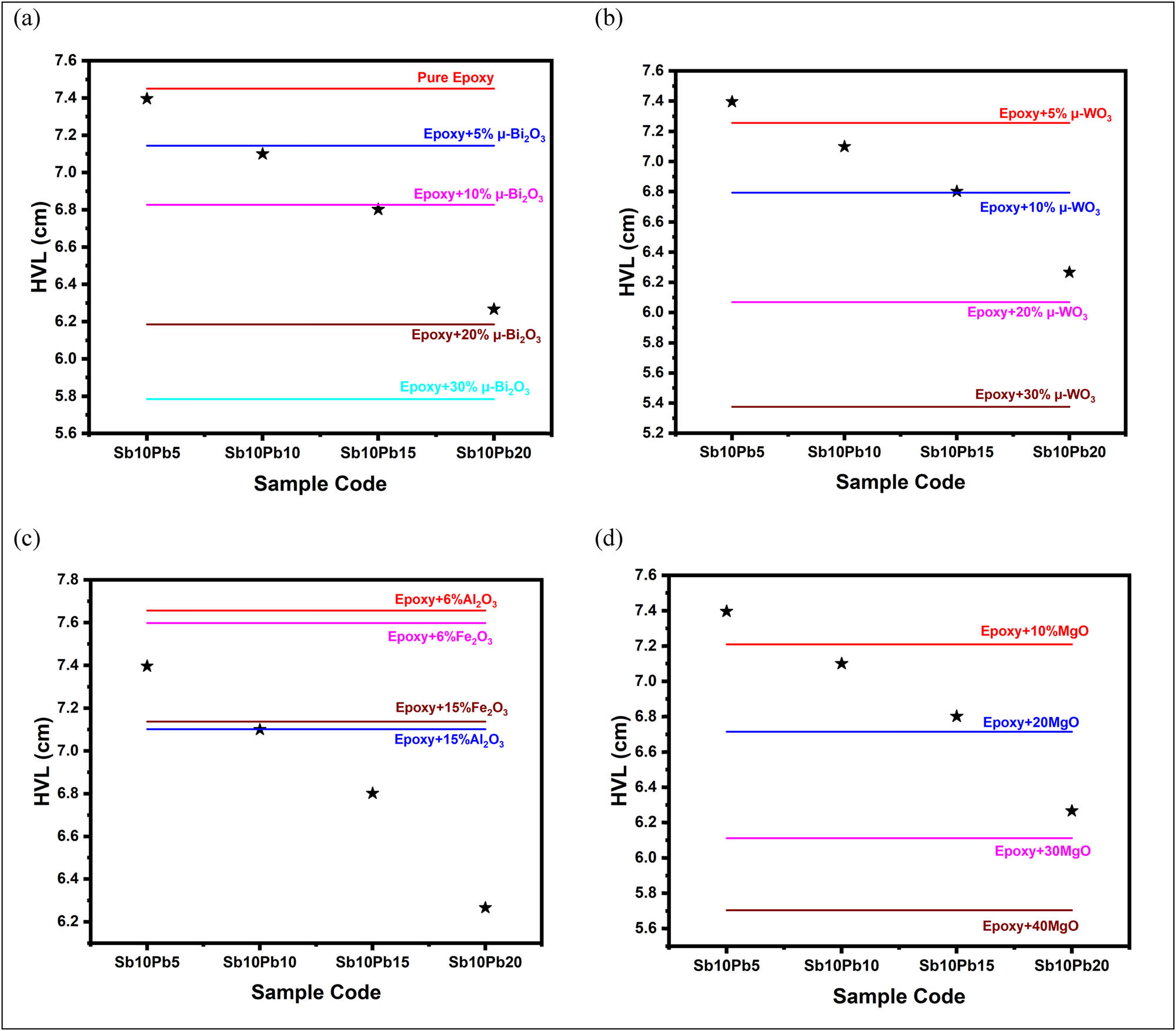

In addition, the role of the incrementation of PbO contents on the half-value layer of the fabricated composites was studied at 0.059 and 0.662 MeV (Figure 7a and b). Figure 7a depicts a decrease in the HVL values from 0.593 to 0.323 cm, raising the PbO content between 5 and 20 wt%, respectively, at 0.059 MeV. The decrease in the HVL is related to the reverse proportionality between the HVL and the LAC values, where LAC = 0.693/LAC. At 0.059 MeV, the HVL considered for all composites is very small (<0.6 cm), which indicates that a thin layer of the prepared composites can be effectively developed to shield the low-energy radiation.

Variation of the HVL of the fabricated composites vs the PbO concentration at (a) 0.059 MeV and (b) 0.662 MeV.

Figure 7b shows the dependence of the HVL values on the PbO concentration at 0.662 MeV. Unlike the HVL in the first case (i.e., 0.059 MeV), the HVL is relatively high at 0.662 MeV and spans from 6.26 to 7.39 cm. It means that a sample of the composite with a thickness of 6–7 cm is capable to lessen the intensity of half of the beam of the gamma-ray with an energy of 0.662 MeV. So, it is unsuitable to use epoxy resin samples that contain 10% Sb2O3 and different amounts of PbO (up to 20%) with a thickness smaller than 6 cm in applications that require attenuating photons with energies ≥0.662 MeV. In addition, from Figure 7b, we found that the HVL is maximum for Sb10Pb5 and minimum for Sb10Pb20, which again reaffirms the importance of using heavy metal oxide (PbO in our study) to improve the attenuation capabilities of the prepared composites.

In order to validate the fabricated composites, a comparison between the HVL of the current composites and the HVL of similar epoxy reinforced with some heavy metal oxide was performed and is presented in Figure 8a–d. At 0.662 MeV, Figure 8a shows a comparison of the HVL of the fabricated composites to the HVL of epoxy reinforced by Bi2O3 compounds (42). The first observation from the data given in this figure is that the HVL for all the current epoxy composites and the epoxy-based micro Bi2O3 particles is lower than the HVL for the pure epoxy. This shows the importance of PbO or Bi2O3 in the radiation shielding field. On the other hand, Sb10Pb10 has an HVL close to that reported for the epoxy with 5% of Bi2O3. Moreover, Sb10Pb15 has an HVL close to that reported for the epoxy with 10% of Bi2O3, while Sb10Pb20 has an HVL slightly higher than that for the epoxy with 20% of Bi2O3.

Comparison between the HVL of the current samples and the HVL of previously published epoxy reinforced with: (a) Bi2O3 compound, (b) WO3 compound, (d) Al2O3 and Fe2O3 compounds, and (d) MgO compound.

Figure 8b shows a comparison of the fabricated composites’ HVL to the HVL of the selected epoxy-based micro WO3 particles (42). Obviously, the epoxy sample with 5% WO3 has a higher HVL than Sb10Pb10 and a lower HVL than Sb10Pb5. Sb10Pb15 and epoxy with 10% of WO3 have very close HVL. While, due to the high density of epoxy composites with 20% and 30% of Bi2O3, they have a lower HVL than all the prepared SbPb-composites.

In Figure 8c, epoxy composites with Al2O3 and Fe2O3 (14) were selected and the HVL for these composites with the HVL for the currently fabricated composites were compared. The prepared composites, Sb10Pb15 and Sb10Pb20, have much lower HVL than epoxy with Al2O3 and Fe2O3, thus they possess better attenuation competence. Sb10Pb10 has a very close HVL with an epoxy sample containing 15% Al2O3.

Figure 8d shows a comparison of the HVL of epoxy composites doped with various concentrations of micro-MgO ranging from 10 to 40 wt% (11) with the currently fabricated composites HVL. The currently prepared composites, such as Sb10Pb20, have a much lower HVL than epoxy with 10% and 20% of MgO, while our SbPb-composites have a higher HVL than the epoxy with 30% and 40% of MgO.

4 Conclusion

Four different sample compositions containing Sb2O3 and PbO were formed by the molding and curing process. The experimental data show a rise in the LAC at 0.059 increased from 1.168 to 2.143 cm−1. The aforementioned improvement is connected to a drop in the HVL values from 0.323 and 0.593 cm, enriching the PbO from 5 to 20 wt%, respectively. Increasing the energy to 0.662 MeV causes a decrease in the LAC associated with an increase in the HVL values, where the LAC enhanced by 18% is associated with a decrease in the HVL values from 6.26 and 7.39 cm, raising the PbO concentrations between 5 and 20 wt%, respectively, at 0.662 MeV. The enhancement in the LAC values is related to the reduction in the TF values, where the TF values were reduced from 0.55 to 0.40 by raising the PbO concentration between 5 and 20 wt%, respectively, at 0.059 keV. The fabricated epoxy-reinforced Sb2O3/PbO composites have a good shielding property at low- and mid-gamma-ray energy, but they are not effective to attenuate photons with energy higher than 0.662 MeV. Therefore, the fabricated new composites can be a suitable candidate for the construction of the LLW and ILW containers as well as for their efficient use in medical applications to shield the low and intermediate gamma-ray energetic photons.

-

Funding information: The authors express their gratitude to Princess Nourah bint Abdulrahman University Researchers Supporting Project number (PNURSP2023R2), Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia.

-

Author contributions: Aljawhara H. Almuqrin: writing – review and editing, project administration; Heba Jamal ALasali: formal analysis, resources, methodology; M. I. Sayyed: writing – original draft, methodology; K. G. Mahmoud: visualization, writing – review and editing.

-

Conflict of interest: The authors state that there is no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article (and its supplementary information files).

References

(1) Tishkevich DI, Grabchikov SS, Grabchikova EA, Vasin DS, Lastovskiy SB, Yakushevich AS, et al. Modeling of paths and energy losses of high-energy ions in single-layered and multilayered materials. IOP Conf Ser Mater Sci Eng. 2020;848:012089. 10.1088/1757-899X/848/1/012089.Search in Google Scholar

(2) More CV, Lokhande RM, Pawar PP. Effective atomic number and electron density of amino acids within the energy range of 0.122–1.330 MeV. Radiat Phys Chem. 2016;125:14–20. 10.1016/j.radphyschem.2016.02.024.Search in Google Scholar

(3) Vignesh S, Winowlin Jappes JT, Nagaveena S, Krishna Sharma R, Adam Khan M, More CV, et al. Development of lightweight polymer laminates for radiation shielding and electronics applications. Int J Polym Sci. 2022;2022:1–13. 10.1155/2022/5252528.Search in Google Scholar

(4) More CV, Bhosale RR, Pawar PP. Detection of new polymer materials as gamma-ray-shielding materials. Radiat Eff Defects Solids. 2017;172:469–84. 10.1080/10420150.2017.1336765.Search in Google Scholar

(5) Tishkevich DI, Grabchikov SS, Lastovskii SB, Trukhanov SV, Vasin DS, Zubar TI, et al. Function composites materials for shielding applications: Correlation between phase separation and attenuation properties. J Alloy Compd. 2019;771:238–45. 10.1016/j.jallcom.2018.08.209.Search in Google Scholar

(6) Dong M, Xue X, Yang H, Liu D, Wang C, Li Z. A novel comprehensive utilization of vanadium slag: As gamma ray shielding material. J Hazard Mater. 2016;318:751–7. 10.1016/j.jhazmat.2016.06.012.Search in Google Scholar PubMed

(7) Sayyed MI, El-Mesady IA, Abouhaswa AS, Askin A, Rammah YS. Comprehensive study on the structural, optical, physical and gamma photon shielding features of B2O3-Bi2O3-PbO-TiO2 glasses using WinXCOM and Geant4 code. J Mol Struct. 2019;1197:656–65. 10.1016/j.molstruc.2019.07.100.Search in Google Scholar

(8) Dong M, Xue X, Yang H, Li Z. Highly cost-effective shielding composite made from vanadium slag and boron-rich slag and its properties. Radiat Phys Chem. 2017;141:239–44. 10.1016/j.radphyschem.2017.07.023.Search in Google Scholar

(9) Naseer KA, Sathiyapriya G, Marimuthu K, Piotrowski T, Alqahtani MS, Yousef ES. Optical, elastic, and neutron shielding studies of Nb2O5 varied Dy3+ doped barium-borate glasses. Opt (Stuttg). 2022;251:168436. 10.1016/j.ijleo.2021.168436.Search in Google Scholar

(10) Kamislioglu M. Research on the effects of bismuth borate glass system on nuclear radiation shielding parameters. Results Phys. 2021;22:103844. 10.1016/j.rinp.2021.103844.Search in Google Scholar

(11) Sayyed MI, Yasmin S, Almousa N, Elsafi M. Shielding properties of epoxy matrix composites reinforced with MgO micro- and nanoparticles. Materials. 2022;15:6201. 10.3390/ma15186201.Search in Google Scholar PubMed PubMed Central

(12) Elsafi M, Almousa N, Almasoud FI, Almurayshid M, Alyahyawi AR, Sayyed MI. A novel epoxy resin-based composite with zirconium and boron oxides: An investigation of photon attenuation. Cryst (Basel). 2022;12:1370. 10.3390/cryst12101370.Search in Google Scholar

(13) Zali VS, Jahanbakhsh O, Ahadzadeh I. Preparation and evaluation of gamma shielding properties of silicon-based composites doped with WO3 micro- and nanoparticles. Radiat Phys Chem. 2022;197:110150. 10.1016/j.radphyschem.2022.110150.Search in Google Scholar

(14) Aldhuhaibat MJR, Amana MS, Jubier NJ, Salim AA. Improved gamma radiation shielding traits of epoxy composites: Evaluation of mass attenuation coefficient, effective atomic and electron number. Radiat Phys Chem. 2021;179:109183. 10.1016/j.radphyschem.2020.109183.Search in Google Scholar

(15) Alavian H, Samie A, Tavakoli-Anbaran H. Experimental and Monte Carlo investigations of gamma ray transmission and buildup factors for inorganic nanoparticle/epoxy composites. Radiat Phys Chem. 2020;174:108960. 10.1016/j.radphyschem.2020.108960.Search in Google Scholar

(16) Li J, Wu Z, Huang C, Li L. Gamma irradiation effects on cyanate ester/epoxy insulation materials for superconducting magnets. Fusion Eng Des. 2014;89:3112–6. 10.1016/j.fusengdes.2014.09.012.Search in Google Scholar

(17) Li R, Gu Y, Yang Z, Li M, Hou Y, Zhang Z. Gamma ray shielding property, shielding mechanism and predicting model of continuous basalt fiber reinforced polymer matrix composite containing functional filler. Mater Des. 2017;124:121–30. 10.1016/j.matdes.2017.03.045.Search in Google Scholar

(18) Liu Y, Liu B, Gu Y, Wang S, Li M. Gamma radiation shielding property of continuous fiber reinforced epoxy matrix composite containing functional filler using Monte Carlo simulation. Nucl Mater Energy. 2022;33:101246. 10.1016/j.nme.2022.101246.Search in Google Scholar

(19) Noor Azman NZ, Siddiqui SA, Low IM. Synthesis and characterization of epoxy composites filled with Pb, Bi or W compound for shielding of diagnostic X-rays. Appl Phys A. 2013;110:137–44. 10.1007/s00339-012-7464-7.Search in Google Scholar

(20) Oto B, Kavaz E, Durak H, Aras A, Madak Z. Effect of addition of molybdenum on photon and fast neutron radiation shielding properties in ceramics. Ceram Int. 2019;45:23681–89. 10.1016/j.ceramint.2019.08.082.Search in Google Scholar

(21) Gökçe HS, Öztürk BC, Çam NF, Andiç-Çakır Ö. Gamma-ray attenuation coefficients and transmission thickness of high consistency heavyweight concrete containing mineral admixture. Cem Concr Compos. 2018;92:56–69. 10.1016/j.cemconcomp.2018.05.015.Search in Google Scholar

(22) Kamislioglu M. An investigation into gamma radiation shielding parameters of the (Al:Si) and (Al + Na):Si-doped international simple glasses (ISG) used in nuclear waste management, deploying Phy-X/PSD and SRIM software. J Mater Sci Mater Electron. 2021;32:12690–704. 10.1007/s10854-021-05904-8.Search in Google Scholar

(23) Şensoy AT, Gökçe HS. Simulation and optimization of gamma-ray linear attenuation coefficients of barite concrete shields. Constr Build Mater. 2020;253:119218. 10.1016/j.conbuildmat.2020.119218.Search in Google Scholar

(24) Shin SH, Choi WN, Yoon S, Lee UJ, Park HM, Park SH, et al. Radiological analysis of transport and storage container for very low-level liquid radioactive waste. Nucl Eng Technol. 2021;53:4137–41. 10.1016/j.net.2021.06.024.Search in Google Scholar

(25) Tashlykov OL, Litovchenko Y, Vasutin NA, Sayyed MI, Khandaker MU, Mahmoud KA. Improvement in the design of shielding containers for intermediate-level radioactive waste. Radiat Phys Chem. 2022;200:110229. 10.1016/j.radphyschem.2022.110229.Search in Google Scholar

(26) Mahmoud KA, El-Soad AMA, Kovaleva EG, Almousa N, Sayyed MI, Tashlykov OL. Modeling a three-layer container based on halloysite nano-clay for radioactive waste disposal. Prog Nucl Energy. 2022;152:104379. 10.1016/j.pnucene.2022.104379.Search in Google Scholar

(27) Vujović M, Vujisić M. Applicability of polymer and composite inner linings in containers for borehole disposal of sealed radioactive sources − A simulation-based study of radiation effects. Prog Nucl Energy. 2021;137:103793. 10.1016/j.pnucene.2021.103793.Search in Google Scholar

(28) Mirji R, Lobo B. Radiation shielding materials: A brief review on methods, scope and significance; 2017. https://www.researchgate.net/publication/317687481.Search in Google Scholar

(29) AbuAlRoos NJ, Baharul Amin NA, Zainon R. Conventional and new lead-free radiation shielding materials for radiation protection in nuclear medicine: A review. Radiat Phys Chem. 2019;165:108439. 10.1016/j.radphyschem.2019.108439.Search in Google Scholar

(30) Hulbert SM, Carlson KA. Is lead dust within nuclear medicine departments a hazard to pediatric patients? J Nucl Med Technol. 2009;37:170–2. 10.2967/jnmt.109.062281.Search in Google Scholar PubMed

(31) Aloraini DA, Almuqrin AH, Sayyed MI, Kumar A, Gaikwad DK, Tishkevich DI, et al. Experimental and theoretical analysis of radiation shielding properties of strontium-borate-tellurite glasses. Opt Mater (Amst). 2021;121:111589. 10.1016/j.optmat.2021.111589.Search in Google Scholar

(32) Liang S, Qin Y, Gao W, Wang M. A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding. E-Polymers. 2022;22:223–33. 10.1515/epoly-2022-0023.Search in Google Scholar

(33) Gao L, Zhang J, Cui Y, Wang X. Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites. E-Polymers. 2023;23:20228100. 10.1515/epoly-2022-8100.Search in Google Scholar

(34) More C, Pawar P, Badawi M, Thabet A. Extensive theoretical study of gamma-ray shielding parameters using epoxy resin-metal chloride mixtures. Nucl Technol Radiat Prot. 2020;35:138–49. 10.2298/NTRP2002138M.Search in Google Scholar

(35) Mahmoud KA, Sayyed MI, Almuqrin AH, Elhelaly MA, Alhindawy IG. Synthesis of glass powders for radiation shielding applications based on zirconium minerals’ leach liquor. Radiat Phys Chem. 2023;207:110867. 10.1016/j.radphyschem.2023.110867.Search in Google Scholar

(36) Alhindawy IG, Gamal H, Almuqrin AH, Sayyed MI, Mahmoud KA. Impacts of the calcination temperature on the structural and radiation shielding properties of the NASICON compound synthesized from zircon minerals. Nucl Eng Technol. 2023;55(5):1885–91. 10.1016/j.net.2023.02.014.Search in Google Scholar

(37) Aygün B. High alloyed new stainless steel shielding material for gamma and fast neutron radiation. Nucl Eng Technol. 2020;52:647–53. 10.1016/j.net.2019.08.017.Search in Google Scholar

(38) Saleh A. Comparative shielding features for X/Gamma-rays, fast and thermal neutrons of some gadolinium silicoborate glasses. Prog Nucl Energy. 2022;154:104482. 10.1016/j.pnucene.2022.104482.Search in Google Scholar

(39) Aygün B. Neutron and gamma radiation shielding properties of high-temperature-resistant heavy concretes including chromite and wolframite. J Radiat Res Appl Sci. 2019;12:352–9. 10.1080/16878507.2019.1672312.Search in Google Scholar

(40) Mahmoud KG, Sayyed MI, Almuqrin AH, Arayro J, Maghrbi Y. Monte Carlo investigation of gamma radiation shielding features for Bi2O3/epoxy composites. Appl Sci. 2023;13:1757. 10.3390/app13031757.Search in Google Scholar

(41) Erdem Ş, Özgür F, Al B, Sayyed MI, Kurudirek M. Phy-X/PSD: Development of a user friendly online software for calculation of parameters relevant to radiation shielding and dosimetry. Radiat Phys Chem. 2020;166. 10.1016/j.radphyschem.2019.108496.Search in Google Scholar

(42) Karabul Y, İçelli O. The assessment of usage of epoxy based micro and nano-structured composites enriched with Bi2O3 and WO3 particles for radiation shielding. Results Phys. 2021;26:104423. 10.1016/j.rinp.2021.104423.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites