Abstract

The foamed polypropylene (PP) composites were prepared by injection molding process. Fourier’s law and software were used to calculate and simulate the internal temperature distribution of PP composites, respectively, and the influence of the temperature distribution on the foaming quality of foamed PP composites was further analyzed. The result showed that the calculative and simulated results of temperature distribution in different thermal transfer directions had great reproducibility. In different isothermal planes, the temperature from the nozzle to the dynamic mold gradually decreased. The isothermal plane with a temperature of 370.36 K had a better foaming quality, average diameter of cell and cell density were 28.46 µm and 3.7 × 1010 cells·cm−3, respectively. In different regions of the same isothermal plane, the temperature gradually decreased from the center to the edge. The foaming quality in the region (c) at a temperature of 335.86 K was ideal, and the average diameter of cell and the cell density were 26.5 µm and 2.39 × 1010 cells·cm−3, respectively. This work could provide prediction for improving the foaming quality of foamed polyolefin composites.

1 Introduction

Nowadays, the foamed polyolefin composites (1,2) have attracted increasing attention due to their excellent comprehensive properties. Compared with traditional polyolefin composites, the foamed polyolefin composites possess specific properties, including good thermal stability, excellent sound absorption property, low thermal conductivity and dielectric constant, etc. (2,3). Thus, foamed polyolefin composites have been widely used in transportation, military industry, aerospace, electronics, daily necessities, and so on (4). Injection molding process is an effective method for massive production of foamed polyolefin composites (5) and has been considered as one of the most common method for foamed polyolefin composites (6,7). Compared with general foaming materials (8,9), foamed PP composites has an ideal environment friendly foam material. However, there will be thermal loss in the injection molding process, which will lead to the change in foaming quality of foamed PP composites. Therefore, it has become a new research direction to explore the influence of temperature distribution on the foaming quality of foamed PP composites.

Recently, more and more researchers have focused on the research of foamed PP composites. Yeh et al. (10) studied the effect of mold temperature on the structure of cells for PP/rice husk natural fiber composites. The result showed that with the decrease in the mold temperature, the cell density decreased more significantly. Wang et al. (5) studied the influence of different barrel temperatures on the properties of foamed PP components. They found that the sample weight and cell density decreased with increase in the barrel temperature. Chung et al. (11) used semi-crystalline PP and polystyrene (PS) as matrix materials, then studied the effects of melting temperature and mold temperature on the weight, specific gravity, and expansionary rate of samples. The result showed that semi-crystalline PP exhibited the highest expansionary rate at high melting temperature and low mold temperature, while PS exhibited the highest expansionary rate at medium melting temperature and low mold temperature. Liu et al. (12) studied the effect of foaming temperature on the cell structure of ultra-high molecular weight polyethylene and supercritical carbon dioxide by foaming process. The result showed that the cell size and cell density were affected by crystal structure, temperature, and higher foaming temperature leaded to larger cell size and lower cell density. Nakano and Shimbo (13) used a device that allows precise control of temperature and pressure to obtain samples and discussed the relationship between the cell density, foaming time, and foaming temperature. The result showed that the cell density of foamed PS and polycarbonate (PC) composites became larger at lowtemperature. The effects of foaming temperature and mold temperature on the foaming quality of foamed PP composites had been investigated, and some significant theoretical results had been obtained. However, there were few studies on the effect of internal temperature distribution on the foaming quality of foamed PP composites.

In this study, we investigated the injection molding process of foamed PP composites using Fourier’s law and simulation calculations. The effect of the variation in the temperature field in different regions of the material on the structure of the vesicles in each micro-region was investigated. This provides a reference for the development of foamed PP composites with different cell structures.

2 Materials and methods

2.1 Materials

PP T-30s was supplied by Anhui Fengyuan Co., Ltd, with the melt mass flow rate (MFR) of 3.2 g per 10 min. Low-density polyethylene (LDPE) 2426H was supplied by Lanzhou Petrochemical Co., with the MFR of 1.8 g per 10 min. Azodicarbonamide (AC) was gained from Shenzhen Jiaxinhao Plastic Products Co., Ltd. Zinc stearate [Zn(St)2] was supplied by Wenzhou Jia Da Plastic Additives Co., Ltd. Zinc oxide (ZnO) was supplied by Xiangyun County Hongxiang Co., Ltd. Montmorillonite (MMT) was supplied by Wuhan Hanhong Chemical Plant.

2.2 Sample preparation

2.2.1 Preparation of PP/MMT blend

The PP and MMT were dried at 60°C for 8 h before processing. MMT was added to PP at 3 wt% on a twin-screw extruder (CTE20, Coperion Koryo Nanjing Machinery Co., Ltd, Nanjing, China) for obtaining the masterbatch, and the parameters of the extrusion process were as follows: temperature of 175–185°C, screw speed of 100 rpm, feeding speed of and 10 rpm.

2.2.2 Preparation of foaming agent masterbatch

AC and LDPE were dried at 60°C for 4 h before the process. Afterwards, they were blended in a torque rheometer (XSS-300, Shanghai Kechuang Rubber & Plastic Machinery Equipment Co., Ltd), with a LDPE/AC weight ratio of 90/10 (14). The temperature was set to 110°C.

2.2.3 Preparation of foaming auxiliary masterbatch

ZnO and Zn(St)2 were dried at 60°C for 4 h before processing. ZnO and Zn(St)2 were evenly mixed at a mass fraction ratio of 5:1, then added to 94 parts of PP and evenly mixed (15). The foaming auxiliary masterbatch was prepared by twin screw extrude (CTE20, Coperion Koryo Nanjing Machinery Co., Ltd, Nanjing, China). The temperature of each section of the extrude from hopper to the nozzle was set from 175°C to 185℃. The screw rotation speed was 100 rpm and the feeding speed was 10 rpm.

2.2.4 Preparation of foam

The PP/MMT blend was dried at 80°C for 8 h. Then, the PP matrix, the foaming masterbatch and the foaming auxiliary masterbatch were uniformly mixed at 85:10:5 mass fraction ration (16). The foamed samples were prepared by the injection molding machine (EM120-V, Zhende plastic machinery Co., Ltd) and the temperature from hopper to nozzle was set from 165°C to 190°C. The technique parameters are shown in Table 1.

Foamed polypropylene composites injection molding technique parameters

| Injection pressure (bar) | Mold temperature (°C) | Melting temperature (°C) | Injection speed (%) | Cooling time (s−1) |

|---|---|---|---|---|

| 50 | 35.6 | 190 | 95 | 30 |

2.2.5 Slice of samples

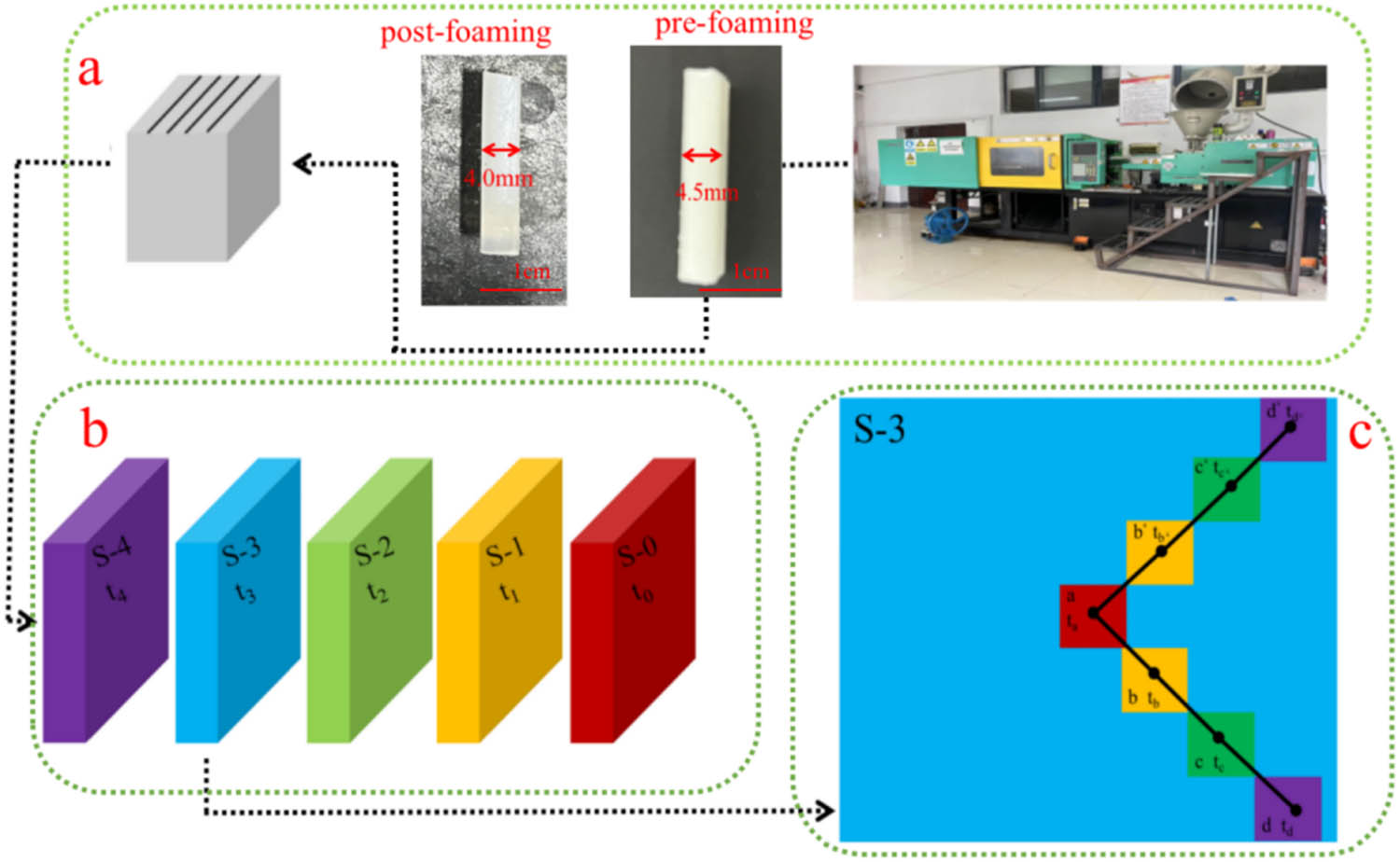

First, the foamed sample was obtained by injection molding, The thickness of foamed spline is larger than that of unfoamed spline, and the thickness difference is 0.5 mm. Uniform slicing were made along the thickness direction of the foamed sample (Figure 1a). Then, the different isothermal planes of the samples (Figure 1b) and different regions of the same isothermal plane (Figure 1c) were obtained with a self-made cutter.

Schematic diagram of slices (a), different isothermal planes (b), and (c) different regions of the same isothermal plane.

According to the order of slices, the different isothermal planes of the sample were set as follows: melting plane (S-0), isothermal plane (S-1), isothermal plane (S-2), isothermal plane (S-3), isothermal plane (S-4), and dynamite mold plane (S-5), and the temperatures were set as t 0, t 1, t 2, t 3, t 4, and t 5, respectively.

For different regions of the same isothermal plane, region (a), region (b), region (c), and region (d), and their respective symmetrical regions, region (b'), region (c'), and region (d') were set. The temperatures set were t a, t b, t c, t d, t b′, t c′, and t d′, respectively. Since t b = t b, t c′ = t c′, and t d = t d′, region (a), region (b), region (c), and region (d) were investigated.

2.3 Characterization

2.3.1 Scanning electron microscopy (SEM)

SEM (TM-4000Plus, Hitachi Scientific Instruments Co. Japan) was used to observe the morphology of the samples. Take the cut sample on the conductive adhesive, spray gold for 40 s, give the material conductivity, and then place the sample in the SEM for surface morphology test. The average size and distribution of cell size in the samples were analyzed with Nano-Measure software (Media Cybernetic, Rockville, MD, USA), and the distribution of cell size could be denoted with a distribution coefficient (S d ), as shown by Eqs. 1–4 (17,18).

where n is the number of cells in the SEM image, D

i

is the diameter of a single cell (µm),

3 Results and discussion

3.1 Calculation and simulation of temperature distribution

3.1.1 Calculation of temperature distribution

According to the Fourier’s law (19), for a uniformly textured object, the thermal energy per unit time, Q, was proportional to the temperature gradient, and the thermal transfer area, A, was perpendicular to the direction of thermal flow, as shown in Eqs. 5–7.

where Q is the thermal energy (W); q is the heat flux (W·m−2);

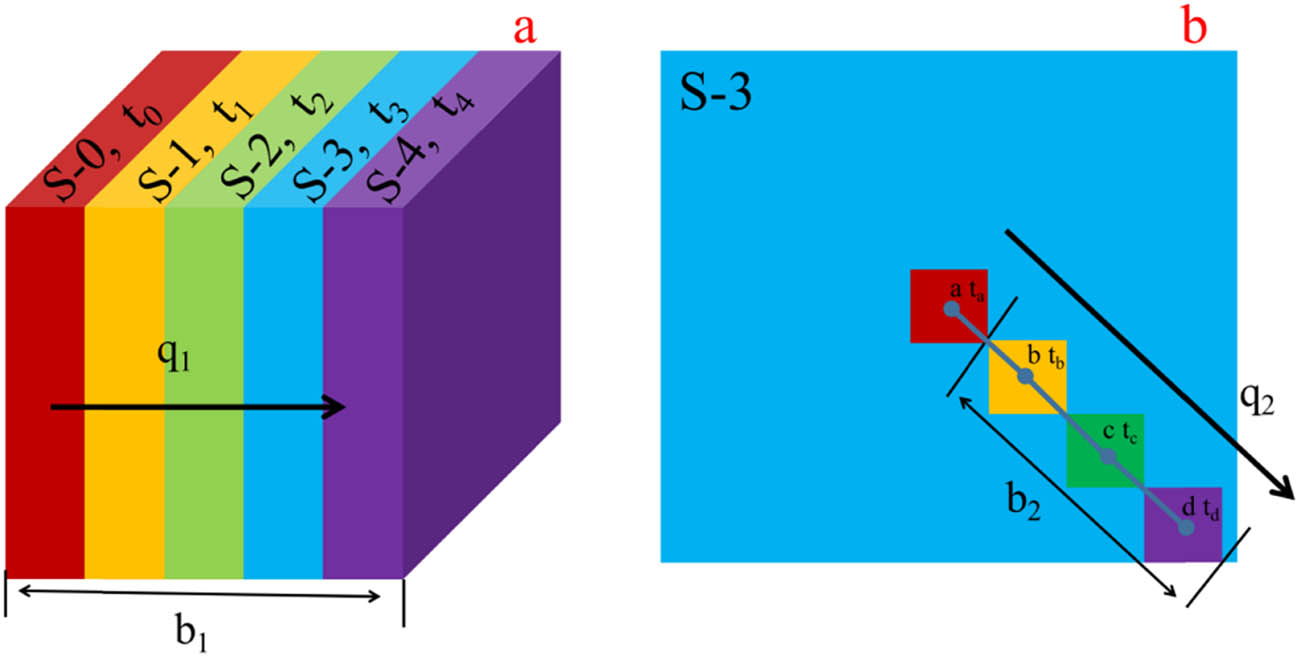

Schematic diagram of thermal transfer direction of PP composites: (a) different isothermal planes and (b) different regions of the same isothermal plane.

Schematic diagram of the parameters of PP composites: (a) different isothermal planes and (b) different regions of the same isothermal plane.

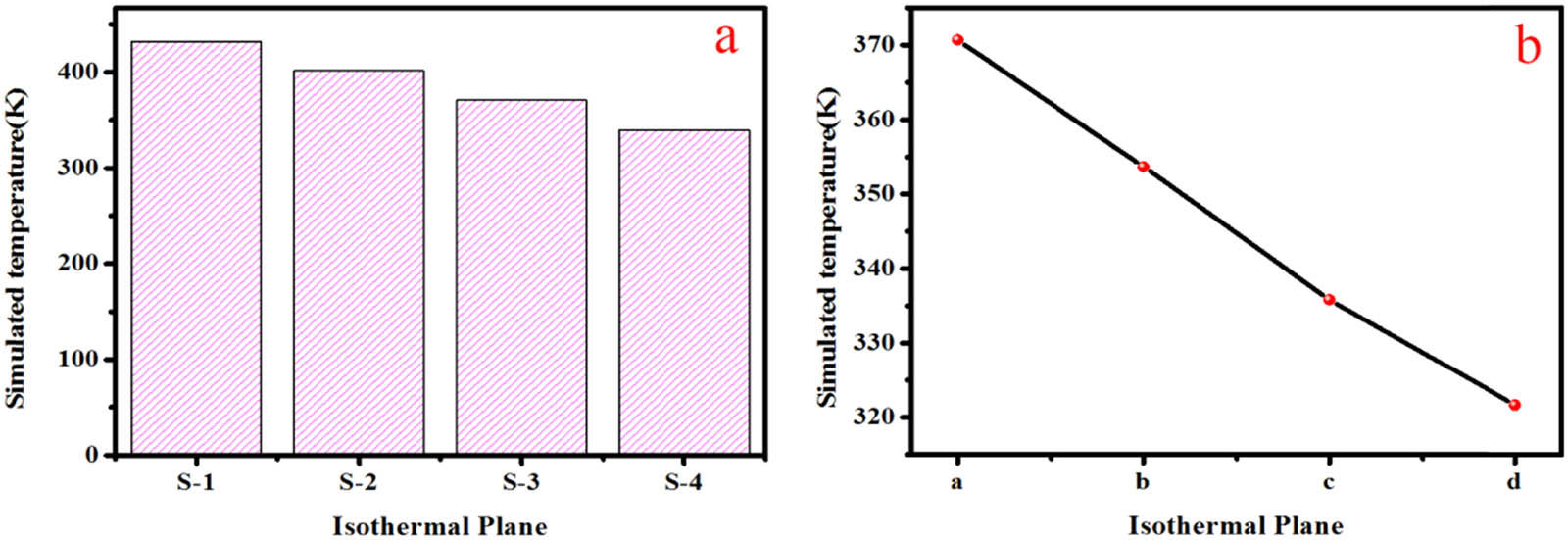

Using the above Eqs. 5 and 6, the thermal fluxes q 1 = 7,548.5 W·m−2 and q 2 = 2,728 W·m−2 could be calculated, respectively, and the temperature values of the different isothermal planes and the different regions of the same isothermal plane could be calculated by Eq. 7, as shown in Figure 4.

Calculation of the thermal transfer direction inside the foamed PP composites: (a) different isothermal planes and (b) different regions of the same isothermal plane.

Figure 4 showed the calculative values of temperature distribution for PP composites. It could be seen that the temperature of isothermal plane from nozzle to dynamic mold plane gradually decreased from 432.12 to 339.48 K (Figure 4a). The main reason for this phenomenon was that the thermal loss between the nozzle and dynamic mold plane gradually increased during the injecting molding process, which led to the gradual decrease in temperature. According to Figure 4b, it could be seen that the calculative values of temperature distribution from the center to edge gradually decreased on the isothermal plane (S-3), and the temperature in the central region (a) was the highest with a value of 370.36 K. The temperature in region (b) was 389 K, in region (c) was 335.86 K, and in region (d) was 318.3 K. This was mainly due to the thermal transfer from high temperature to low temperature.

3.1.2 Simulation of temperature distribution

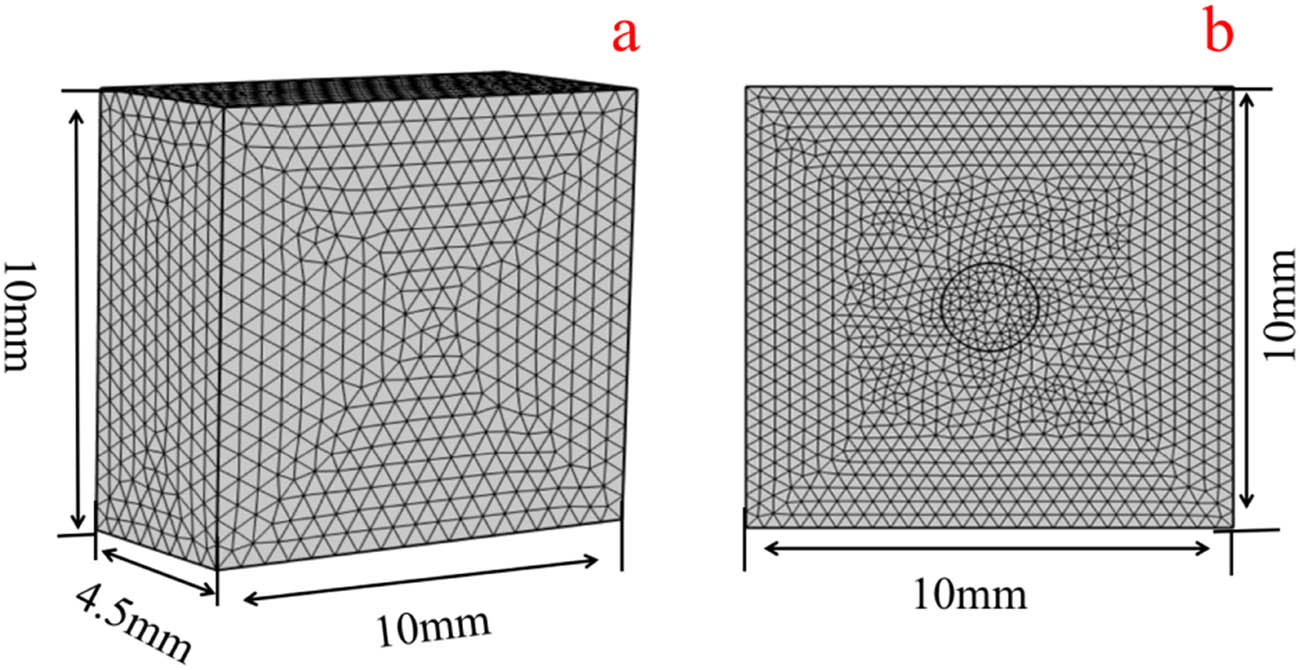

The solid thermal transfer interface in the software was used to simulate PP composites (21,22). The cubic model (Figure 5a) was established with the size of 10 mm × 10 mm × 4.5 mm, and the plane model with the size of 10 mm × 10 mm, respectively (Figure 5b). The thermal conductivity was 0.22 W·m−1·K−1 (23), the constant pressure thermal capacity was 1,900 J·kg−1·K−1 (24), and the thermal transfer parameter was 1,225 W·m−2·K−1 (25).

Schematic diagram of the size of the simulation model of PP composites: (a) cubic model and (b) plane model.

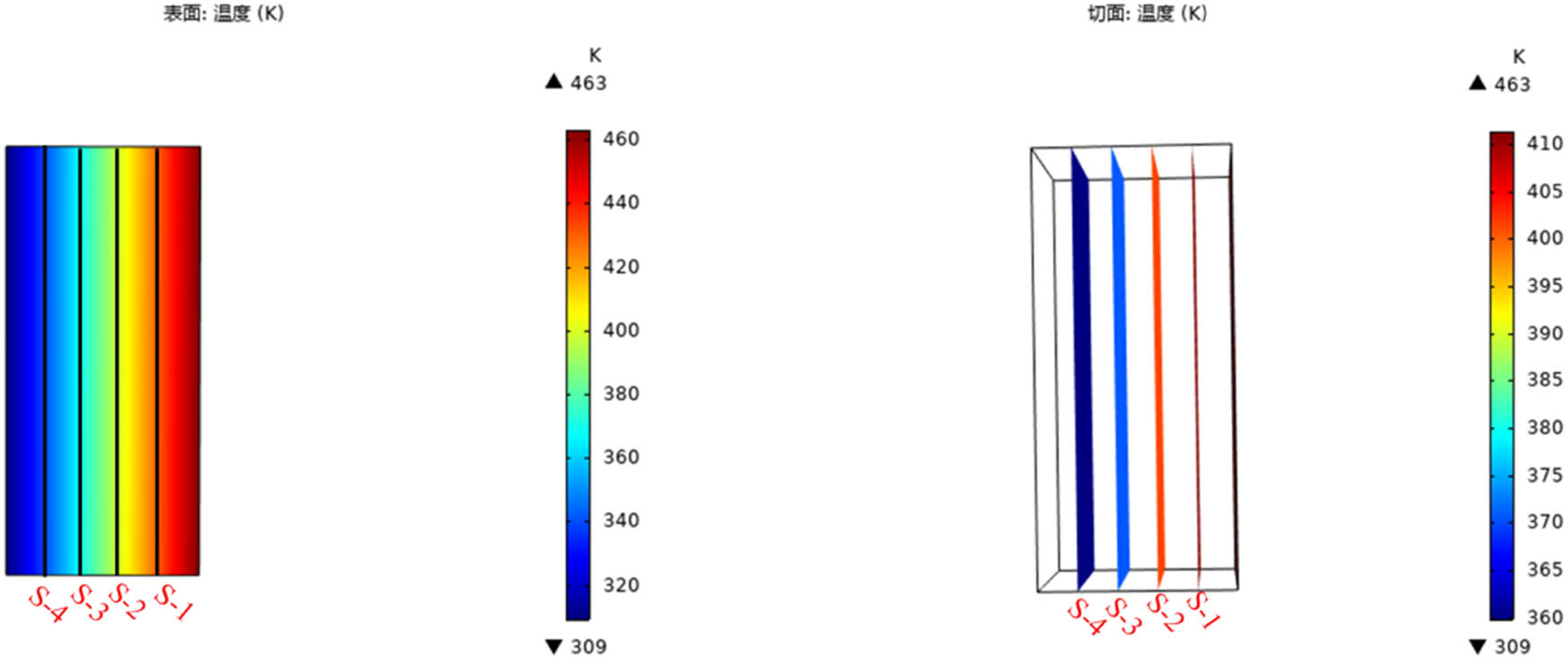

Figures 6 and 8a show the trends of simulation temperature and specific simulation values of different isothermal planes, respectively. From isothermal planes of S-1 to S-4, the simulated temperature gradually decreased from 432.12 to 339.91 K (Figures 6 and 8a). Figure 7 shows the trends of simulated temperature in different regions of the same isothermal plane. It could be seen that the simulated temperature in central region (a) was the highest with a value of 370.68 K, and gradually decreased from the central region to other regions. The simulated temperature in region (d) was the lowest with a value of 321.66 K (Figures 7 and 8b). The simulated results were consistent with the calculative results in Section 2.1.1. The calculated and simulated results provide a basis for improving the foaming quality of foamed PP composites.

Simulation temperature results of different isothermal planes of PP composites.

Schematic of software simulation of the thermal transfer from the center to the edge on the same plane.

Simulation of the thermal transfer direction inside the PP: (a) different isothermal planes and (b) different regions of the same isothermal plane.

3.2 Effect of temperature distribution on foaming quality of foamed PP composites

3.2.1 Effect of foaming quality of foamed PP composites on different isothermal planes

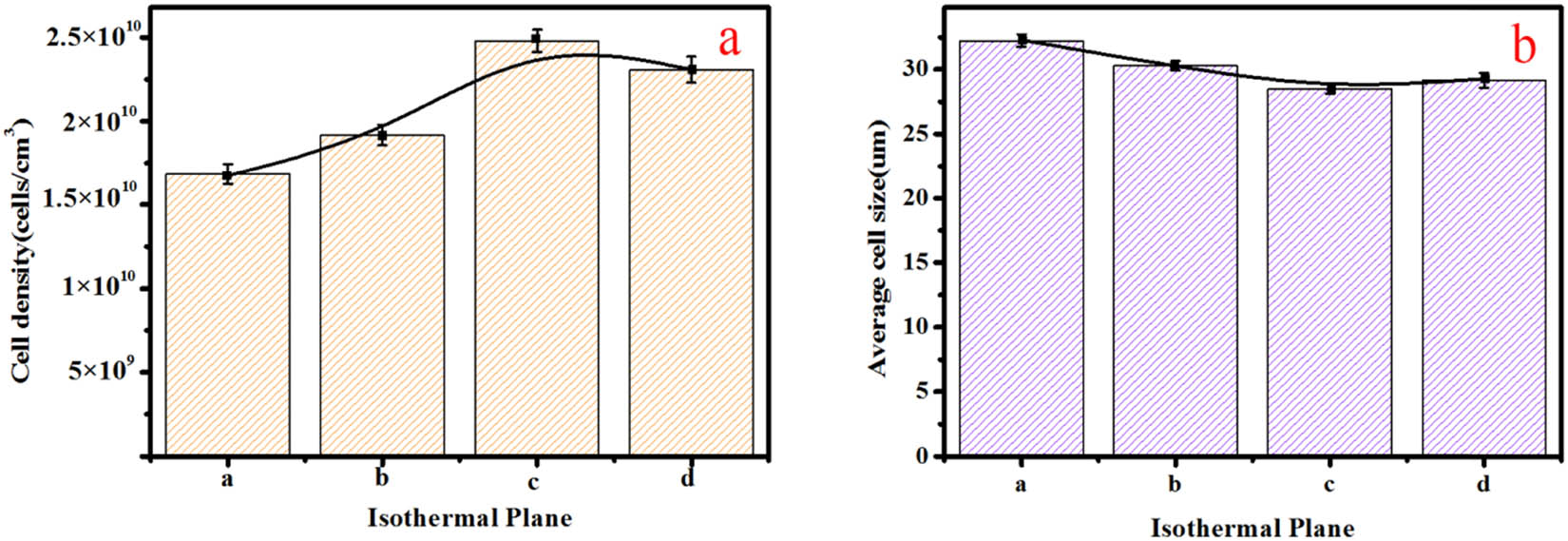

Figure 9 shows the cell distribution and cell morphology of the foamed PP composites in different isothermal planes. It could be seen that the cell size of S-1, S-2, S-3, and S-4 were mainly concentrated among 30–45, 25–30, 25–30, and 30–40 μm, respectively. The cell diameter of S-3 was relatively concentrated and evenly distributed. Figure 10 shows the cell structure parameters of foamed PP composites with different isothermal planes. From isothermal planes of S-1 to S-4, the cell size first decreased and then increased, while the cell density first increased and then decreased (Figure 10a and b). According to the result of calculation and simulation, the temperature decreased gradually from the isothermal planes of S-1 to S-4, and increased the polymer melt viscosity, strength of melt, strengthened the ability to hinder cell growth and reduced the cell growth, and made the average cell diameter smaller and the cell density larger. However, the average diameter of cells increased gradually from S-3 to S-4, and the cell density decreased with the increase in cell size. The main reason was that few cells would be produced at the nozzle during injection molding process, and when the resin was ejected from the nozzle, the formed cells deformed due to the migration of resin (26). For different isothermal planes, when the melt touched the mold (Figure 11), the surface tension of the cells did not drag the stretched cells back into a circle and the cells cooled and shaped rapidly (27,28). It could be observed that the cell size of the isothermal plane (S-4) was larger.

Foaming quality of foamed PP composites in different planes.

Parameters of the cell structure of different planes of PP foamed composites: (a) cell density and (b) average cell diameter.

The schematic of the foaming process with adjustable volume: (a) injection process and (b) open mold.

3.2.2 Effect of foaming quality of foamed PP composites on different regions of the same isothermal plane

From the influence of temperature distribution of different isothermal planes on the foamed PP composites, it could be seen that the foaming quality on the isothermal plane at 370.36 K was ideal. Therefore, the influence of foaming quality of foamed PP composites on different regions of the same isothermal plane is explored, and the results are shown in Figures 12–14.

Structure of cells in different regions of the same isothermal plane.

Quality of cells in different regions of the same isothermal plane for foamed PP composites: (a–d) distribution of cells at various regions and (a1–d1) electron micrographs of cells in different regions.

Structural parameters of the cells in different regions of the same isothermal plane for the PP foam: (a) cells density and (b) average cell diameter.

Figures 12 and 13 show the cell distribution diagram and cell morphology diagram of different regions of the same isothermal plane for foamed PP materials. It could be seen that the cells’ size in region (a) were mainly concentrated among 30–40 µm, in region (b) among 25–35 µm, in region (c) among 25–30 µm, and in region (d) among 30–35 µm, and the cells’ diameter in region (c) were relatively smaller and the cells uniformity were relatively greater. Figure 14 shows the parameters of cell structure for the foamed PP composites in different regions of the same isothermal plane. On the same isothermal plane, the cell density first increased and then decreased, while the cell size first decreased and then increased. The foaming quality in region (a) was poor, and the average cell diameter and cell density were 31.5 μm and 1.6 × 1010 cells·cm−3, respectively. The foaming quality in region (c) was better, and the average cell diameter and cell density were 26.5 μm and 2.39 × 1010 cells·cm−3, respectively. According to the results of calculation and simulation, the temperature decreased gradually from different regions of the same isothermal plane from region (a) to region (d), and increased the polymer melt viscosity, melt strength, strengthened the ability to hinder cell growth and reduced the cell growth, and made the average cell diameter smaller and the cell density larger (28,29). At the same time, in the injection molding process, the cells from the nozzle were deformed due to the migration of the resin. For different regions of the same iso-thermal plane, when the melt contact with both sides of the mold (Figure 11), then the cells cooled rapidly so that the surface tension of the cells did not drag the stretched and deformed cells back to the round (27–30). It could be observed that the cell size in the region (d) was larger.

4 Conclusion

Fourier’s law and software were used to calculate and simulate the internal temperature distribution of PP composites, the temperature gradually decreased from nozzle (S-0) to dynamic mold plane (S-5) in different isothermal planes, that is, from 463 to 308.6 K. On the same isothermal plane, the calculative temperature decreased gradually from the center to the edge of the isothermal plane, and the temperature in the center region (a) was the highest with a value of 370.36 K.

Software simulation showed that the simulated temperature decreased gradually from S-1 to S-4 isothermal plane, from 432.12 to 339.91 K. For different regions of the same isothermal plane, the simulated temperature decreased gradually from the central region to other regions. The simulated temperature in the central region (a) was the highest with a value of 370.68 K, and the simulated temperature in the central region (d) was the lowest with a value of 321.66 K. The simulated results were consistent with the calculated results.

Among the different isothermal planes, the isothermal plane with a temperature of 370.36 K (S-3) had a better foaming quality, the average cell diameter and cell density were 28.46 µm and 3.7 × 1010 cells·cm−3, respectively. In different regions of the isothermal plane at 335.86 K, the foaming quality in region (c) was more desirable, the average cell diameter and cell density were 26.5 µm and 2.39 × 1010 cells·cm−3, respectively.

Acknowledgments

I would like to express my gratitude to all those who helped me during the writing of this thesis. I sincerely thank my teacher Professor Gong for his help and financial support. In addition, I would like to thank Guizhou Normal University for providing a learning platform. Finally, I would like to thank the editors of e-polymers for their help.

-

Funding information: This work was supported by the National Natural Science Foundation of China (No. 52063008), the Natural Science Foundation Funding Projects of Guizhou Province (No. ZK [2021]050), the Foundation of Guizhou Scientific Research Institute (QianKeFuQi [2018] 4010), and the Hundred Talents Project of Guizhou Province (No. [2016]5673).

-

Author contributions: Xin Yang and Wei Gong: designed and performed the experiments; Xin Yang, Jia-Jie Xu, and Zhi-peng Yang: data curation and formal analysis; Xin Yang: writing – original draft; Xiang-lin Pei and Jin-cheng Zhong: writing – review and editing; Wei Gong: funding acquisition. All authors have read and agreed to the published version of the manuscript.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The data presented in this study are available on request from the corresponding author.

References

(1) Gong W, Fu H, Zhang C, Ban D, He Y, Pei XL, et al. Study on foaming quality and impact property of foamed polypropylene composites. Polym. 2018;10(12):1375–86. 10.3390/polym10121375.Search in Google Scholar PubMed PubMed Central

(2) Li M, Huang T, Qin Y, Shen C, Gao S. Preparation process orthogonal optimization and mechanical properties of microcellular foam polypropylene. Macromol Mater Eng. 2021;306(10):2100350–61. 10.1002/mame.202100350.Search in Google Scholar

(3) Liu B, Jiang T, Zeng X, Deng R, Gu J, Gong W, et al. Polypropylene/thermoplastic polyester elastomer blend: crystallization properties, rheological behavior, and foaming performance. Polym Advan Technol. 2021;32(5):2102–17. 10.1002/pat.5240.Search in Google Scholar

(4) Hamidinejad M, Zhao B, Zandieh A, Moghimian N, Filleter T, Park B. Enhanced electrical and electromagnetic interference shielding properties of polymer–graphene nanoplatelet composites fabricated via supercritical-fluid treatment and physical foaming. ACS Appl Mater Inter. 2018;10(36):30752–61. 10.1021/acsami.8b03777.Search in Google Scholar PubMed

(5) Wang J, Mao Q, Jiang N. Effects of injection molding parameters on properties of insert-injection molded polypropylene single-polymer composites. Polym. 2021;14(1):23–33. 10.3390/polym14010023.Search in Google Scholar PubMed PubMed Central

(6) Gong W, Wang DJ, Jiang TH, Zeng X, Zhang C, He L. Cell growth, deformation and model establishment of micro-foamed polystyrene material. J Mater Res Technol. 2021;13:2260–71. 10.1016/j.jmrt.2021.05.077.Search in Google Scholar

(7) Ren J, Lin L, Jiang J, Li Q, Hwang SS. Effect of gas counter pressure on the surface roughness, morphology, and tensile strength between microcellular and conventional injection-molded PP parts. Polym. 2022;14(6):1078–89. 10.3390/polym14061078.Search in Google Scholar PubMed PubMed Central

(8) Albuquerque RQ, Brütting C, Standau T. A machine learning investigation of low-density polylactide batch foams. Epoly. 2022;22(1):318–31. 10.1515/epoly-2022-0031.Search in Google Scholar

(9) Yang K, Gong P, Yang L. The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures. Epoly. 2022;22(1):12–8. 10.1515/epoly-2022-0003.Search in Google Scholar

(10) Yeh SK, Yang SH, Han L, Liu HY, Liao YS, Chang YC. Foam extrusion of polypropylene–rice husk composites using CO2 as the blowing agent. J Cell Plast. 2019;55(4):401–19. 10.1177/0021955X19839744.Search in Google Scholar

(11) Chung CY, Hwang SS, Chen SC, Lai MC. Effects of injection molding process parameters on the chemical foaming behavior of polypropylene and polystyrene. Polym. 2021;13(14):2331–45. 10.3390/polym13142331.Search in Google Scholar PubMed PubMed Central

(12) Liu J, Qin S, Wang G, Wang G, Zhang H, Zhou H, et al. Batch foaming of ultra-high molecular weight polyethylene with supercritical carbon dioxide: Influence of temperature and pressure. Polym Test. 2021;93:106974–86. 10.1016/j.polymertesting.2020.106974.Search in Google Scholar

(13) Nakano S, Shimbo M. Experiments on solid-state cell nucleation in polystyrene and polycarbonate as a function of foaming temperature and foaming time. Cell Polym. 2006;25(3):127–42. 10.1177/026248930602500301.Search in Google Scholar

(14) Xi Z, Chen J, Liu T, Zhao L, Turng LS. Experiment and simulation of foaming injection molding of polypropylene/nano-calcium carbonate composites by supercritical carbon dioxide. Chin J Chem Eng. 2016;24(1):180–89. 10.1016/j.cjche.2015.11.01.Search in Google Scholar

(15) Ghanbari A, Seyedin S, Nofar M. Mechanical properties and foaming behavior of polypropylene/elastomer/recycled carbon fiber composites. Polym Composite. 2021;42(7):3482–92. 10.1002/pc.26073.Search in Google Scholar

(16) Zhou XX, Yu Y, Chen LH. Effects of zirconaluminate coupling agent on mechanical properties, rheological behavior and thermal stability of bamboo powder/polypropylene foaming composites. Eur Wood Wood Pro. 2015;73(2):199–7. 10.1007/s00107-014-0853-1.Search in Google Scholar

(17) Cao L, Jiang T, Liu B. Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6. Epolys. 2022;22(1):249–63. 10.1515/epoly-2022-0030.Search in Google Scholar

(18) Luo D, Pei XL, Fu H, Yang X, Long S, Zhang L, et al. Modification of sodium bicarbonate and its effect on foaming behavior of polypropylene. Epoly. 2021;21(1):366–76. 10.1515/epoly-2021-0032.Search in Google Scholar

(19) Simoncelli M, Marzari N, Cepellotti A. Generalization of Fourier’s law into viscous heat equations. Phys Rev X. 2020;10(1):011019–130. 10.1103/PhysRevX.10.011019.Search in Google Scholar

(20) Krause B, Rzeczkowski P, Pötschke P. Thermal conductivity and electrical resistivity of melt-mixed polypropylene composites containing mixtures of carbon-based fillers. Polym. 2019;11(6):1073–85. 10.3390/polym11061073.Search in Google Scholar PubMed PubMed Central

(21) Riou M, Ausias G, Grohens Y. Thermoplastic foaming with thermo-expandable microcapsules: Mathematical modeling and numerical simulation for extrusion process. Chem Eng Sci. 2020;227:115852–67. 10.1016/j.ces.2020.115852.Search in Google Scholar

(22) Li Y, Yao Z, Chen Z, Cao K, Qiu SL, Zhu FJ, et al. Numerical simulation of polypropylene foaming process assisted by carbon dioxide: Bubble growth dynamics and stability. Chem Eng Sci. 2011;66(16):3656–65. 10.1016/j.ces.2011.04.035.Search in Google Scholar

(23) Ahmadi M, Rouhi S, Ansari R. Evaluating the thermal conductivity coefficient of polypropylene/graphene nanocomposites: A hierarchical investigation. J Mater. 2021;235(12):2762–70. 10.1177/14644207211035415.Search in Google Scholar

(24) Barborik T, Zatloukal M. Effect of heat transfer coefficient, draw ratio, and die exit temperature on the production of flat polypropylene membranes. Phys Fluids. 2019;31(5):053101–24. 10.1063/1.5094842.Search in Google Scholar

(25) Ma DD, Xia GD, Li YF, Jia YT, Wang J. Effects of structural parameters on fluid flow and heat transfer characteristics in microchannel with offset zigzag grooves in sidewall. Inter J Mass Tran. 2016;101:427–35. 10.1016/j.ijheatmasstransfer.2016.04.091.Search in Google Scholar

(26) Li M, Li S, Liu B, Jiang T, Zhang D, Gong W. Rheological behavior, crystallization properties, and foaming performance of chain-extended poly (lactic acid) by functionalized epoxy. RSC Adv. 2021;11(52):32799–809. 10.1039/d1ra06382k.Search in Google Scholar PubMed PubMed Central

(27) Gong W, Pei X, Yin X, Ban D, Fu H, He L. Synthesis of high-temperature thermally expandable microcapsules and their effects on foaming quality and surface quality of foamed ABS materials. Epoly. 2020;20(1):519–27. 10.1016/j.jmrt.2021.05.077.Search in Google Scholar

(28) Deng R, Jiang T, Zhang C, Zeng X, Liu B, Yang J, et al. In-situ visualization of the cell formation process of foamed polypropylene under different foaming environments. Polym. 2021;13(9):1468–79. 10.3390/poly13091468.Search in Google Scholar

(29) Llewelyn G, Rees A, Griffiths CA, Scholz SG. Advances in microcellular injection moulding. J Cell Plast. 2020;56(6):646–74. 10.1177/0021955x20912207.Search in Google Scholar

(30) Liu Y, Zhu T, Bi J. Investigation on microstructures and mechanical properties of isotactic polypropylene parts fabricated by different process conditions with different aging periods. Polym. 2020;12(12):2828–38. 10.3390/polym12122828.Search in Google Scholar PubMed PubMed Central

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites