Abstract

The present work aims to study the effect of the CuSO4 additive on the physical and radiation-shielding properties of polyepoxide resins. As a result, a series of four samples with the chemical composition xCuSO4 + (100 − x) (epoxy resin and hardener) was synthesized. The fabrication of samples was performed under atmospheric pressure and at room temperature. The density of the fabricated CuSO4-doped polyepoxides resin was measured experimentally using an MH-300A densimeter with an accuracy of 0.001 mg·cm−3. A narrow beam transmission method with an NaI (Tl) detector was used to evaluate and describe the effect of CuSO4 on the linear attenuation coefficient of the fabricated composites in the γ-ray energy interval, which ranged between 33 and 1,332 keV. The estimated results showed a high enhancement in the µ values that increased from 0.259 to 1.749 cm−1, raising the CuSO4 concentration from 0 to 40 wt% at a γ-photon energy of 33 keV. The enhancement in the µ values decreased with an increase in the γ-photon energy to 1,332 keV, whereas the µ values increased from 0.077 to 0.102 cm−1 with an increase in the CuSO4 concentration between 0 and 40 wt%, respectively. This showed that increased µ values positively affected the half-value thickness (Δ 0.5, cm), mean free path (λ, cm), lead equivalent thickness (Δ eq, cm), and the transmission factor (%); all of the mentioned parameters suffer a considerable decrease with increasing CuSO4 concentration between 0 and 40 wt%.

1 Introduction

Radiation is a type of energy that originates from a source, travels across space, and has the potential to penetrate a variety of materials. Ionizing radiation and nonionizing radiation are the two basic classifications of radiation based on their capacity to ionize materials (1,2). Nonionizing radiation like visible light, radio waves, and microwaves do not have enough energy to pick up electrons from the atom (3). Ionizing radiation is electromagnetic radiation that has a higher energy than nonionizing radiation, enabling it to eject electrons from atoms and generate ions. Ionizing radiation is made up of various particles and photons, like X-rays, γ rays, alpha, beta, etc. (4). The use of high-energy ionizing radiation, particularly γ-radiation, is growing swiftly in a variety of disciplines, covering industries, nuclear reactors, medical diagnostics, nuclear research facilities, food irradiation, nuclear waste storage sites, biological investigations, defect detection in casting processes, nuclear medical imaging and therapy, space exploration, high-energy physics experiments, etc. (5,6).

Because γ-rays are so powerful and piercing, unintentional exposure to them can have negative effects on humans, the environment, and other objects. Additionally, this may result in radiation sickness, organ damage, cancer, cell mutations, component failure, and other undesirable effects in humans (7). Thus, a specific focus is required for the creation of innovative γ-ray protective materials. Along with the employees’ proximity to the radioactive isotopes, one must also take into account the energy and activity concentration of the radioactive sources (8). The two well-known radiation shields with the highest densities are concrete and steel (9); however, they are unbending and inflexible. As a result, these materials are ideal for shielding applications involving radioactive sources, nuclear power plants (NPPs), and rooms. Recently, several studies detailed the usage of various materials for radiation shielding in NPPs, hospitals, and X-ray facilities, including concrete, glasses, ceramics, and alloys (10,11,12).

Polymers typically have fairly poor mechanical properties but their flexibility makes them helpful in applications where this property is needed. They typically deform under heavy loads and strain. By introducing inorganic particles via reinforcing processes, mechanical qualities like tensile strength, modulus, or stiffness can be improved (13).

By adjusting the volume percentage, shape, and size of the filler particles, these qualities can be customized. The reinforcement of nanofillers with a very large aspect ratio and stiffness in a polymer matrix can result in superior improvement in mechanical characteristics (14).

Many researchers have recently worked to create innovative solutions for trash recycling and treatment involving polymer composite materials (15). To create ecologically friendly and sustainable materials, recycling and the addition of various filler elements to recycled polymers that can be composted easily (16) are crucial (17). There have been numerous attempts to use biodegradable fillers that can also improve the performance of the composite (18,19). Other researchers were focused on creating thermoplastic composites using recyclable fibers to reduce the usage of fillers while preserving a healthy, clean environment (20,21).

The current work is novel in that it aims to create a new non-expensive lightweight polymer composite that can attenuate low- and intermediate-energy γ-ray photons and test its ability to withstand γ-ray energies emitted by radioactive isotopes used in medical and industrial applications.

2 Materials and methods

2.1 Sample preparation

The copper ions showed better radiation-shielding properties than Fe ions and other heavy metallic ions. Therefore, the ability of CuSO4 powder to enhance the γ-ray shielding properties of epoxy materials was investigated. A series of polyepoxide resins consisting of four samples was reinforced with various concentrations of the CuSO4 compound (the purity of CuSO4 was ≈99.95%, and was supplied by Himreactiv, Yekaterinburg, Russia). The equation (100 − x) (part A + part B) + xPbO, where x = 0%, 10%, or 40% by weight, demonstrated the chemical composition of the four samples, where part A is the polyepoxides resin, while part B is the curing agent. Additionally, SlabDOC (Ivanovo, Russia) with a purity of 98% supplies the epoxy (parts A and B). The required amounts from each component constituting the composite (part A, part B, and CuSO4) were determined accurately using an electronic balance with an accuracy of ±0.01 mg. For all fabricated composites, the resin-to-curing agent was kept constant at 2:1. A vertical blender was used to mix the composite components for 15 min. After that, the mixture was cast in a silicon cylindrical mold with dimensions of 3 cm × 3 cm. The solidification of the synthesized samples was performed at room temperature overnight. The density of the fabricated concrete was determined using a MXBAOHENG MH-300A density meter (Guangdong, China) and the immersing liquid was water with a density ρ L ≈ 1 g·cm−3, according to the Archimedes principle (see Eq. 1). The uncertainty in the density measurements was ±0.001 g·cm−3 (22,23).

where W a and W L are the weight of the composite in the dry air and immersing liquid, respectively.

2.2 Structural characterization

The characterization of the polymer samples was performed using X-ray diffraction (XRD)(Malvern Panalytical Empyrean device model, 2020, Netherlands). About 200 mg of each sample was pounded by hand (an agate mortar) to reach a powder size of 0.1 mm. Then, a continuous scan was applied with 0.03 step size (2θ) at 40 kV and 30 mA for a tube of Cu target and Ni filter.

A scanning electron microscope (SEM; Thermo Scientific Prisma E, USA), assisted with the EDX device, was used to determine the chemical composition (Table 1) of the studied polyepoxide-doped CuSO4 composites as well as its morphological characteristics. SEM images were captured using an accelerating voltage of 30 kV and a magnification factor of 300×.

Chemical composition of the fabricated composites as detected by EDX spectroscopy

| E-Cu0% | Chemical composition (wt%) | |||

|---|---|---|---|---|

| E-Cu10% | E-Cu20% | E-Cu40% | ||

| C | 63.7 | 59.3 | 56.6 | 42.8 |

| O | 36.1 | 35.4 | 37 | 46.8 |

| S | 0 | 0.1 | 2 | 2.8 |

| Cl | 0.2 | 0.2 | 0.1 | 0.1 |

| Cu | 2.1 | 4.3 | 7.6 | |

| ρ (g·cm−3) | 1.127 ± 0.022 | 1.186 ± 0.023 | 1.271 ± 0.025 | 1.424 ± 0.028 |

2.3 γ-ray shielding evaluation

The γ-ray shielding properties were evaluated experimentally using the narrow beam transmission method and a NaI (Tl) detector, as illustrated in Figure 1. The count for radioactive sources (Ba-133, Na-22, Cs-137, and Co-60) was detected before and after using the fabricated composites. Moreover, the thickness of the fabricated composites was measured using a micrometer with an uncertainty of 0.01 µm. The linear attenuation coefficient (µ, cm−1) represents the slope of the relation between the experimentally measured counts Ln(N o/N t) and the composite thickness (24,25):

The experimental setup for the experimental measurements.

where N o and N t are the total emitted photon number and transmitted photon number, respectively. The mass attenuation coefficient (µ m, cm2·g−1) can be determined according to Eq. 3 based on the µ and ρ material values:

The thickness required to absorb half of the applied γ-photons is known as the half-value thickness (Δ

0.5, cm), where it is inversely proportional to the µ value, as illustrated in Eq. 4. Additionally, the transmission factor (TF, %) and the radiation protection efficiency (RPE, %) for the fabricated composites can be determined based on the recorded values of

3 Results and discussion

3.1 Physical properties

The density of the fabricated composites was measured experimentally, as illustrated in Figure 2. The CuSO4 compound partially replaced the epoxy (polyepoxides resin and hardener) in the composites, which made the composites denser. The density increased by a factor of 26.35%, where it increased from 1.127 to 1.424 g·cm−3 with an increase in the CuSO4 concentration from 0 to 40 wt%. This increase is due to the partial replacement of the light epoxy material with a density of 1.127 g·cm−3 by dense CuSO4 (ρ = 3.65 g·cm−3).

The variation of the fabricated polymetric samples versus CuSO4 concentrations.

3.2 XRD

XRD is a powerful technique that can be used to characterize the structure and properties of materials. It is a valuable tool for studying the interaction between polymers and other materials (26). The XRD pattern of a polymer doped with 10% and 40% CuSO4 is similar, but the intensity of 40% CuSO4 peaks is high compared to the sample with 10% CuSO4 (Figure 3). This behavior is attributed to the concentration of CuSO4 in the sample. The position of the CuSO4 peaks is the same for both samples, and no shift in 2θ values is detected; moreover, the crystal structure of CuSO4 is the same regardless of the concentration. The presence of CuSO4 peaks in the XRD pattern indicates that CuSO4 has been successfully doped into the polymer. The intensity of the CuSO4 peaks can be used to determine the concentration of CuSO4 in the sample. Here is an example of the XRD pattern of a polymer doped with 10% CuSO4 concentration: the X-ray diffraction pattern matches with PDF-Card No (72-1299) of copper sulfate hydrate (CuSO4 (H2O)5). The most intense peak appears at 2θ = 19.95° with a d-spacing of 4.44 Å. However, the PDF-Card No (76-689) of copper sulfate hydrate (CuSO4(H2O)3): the most intense peak appears at 2θ = 18.63° with a d-spacing of 4.75 Å (27). The XRD pattern of a polymer-doped CuSO4 can be used to study the crystal structure of t CuSO4, the concentration of CuSO4 in the sample, and the interaction between the CuSO4 and the polymer. The presence of new peaks in the XRD pattern may indicate that CuSO4 has caused the polymer to crystallize or that it has created new defects in the polymer (28).

XRD diffraction pattern of epoxy (E-Cu0%) and epoxy-reinforced CuSO4 composites (E-Cu10% and E-Cu20%).

The chemical composition obtained from SEM-EDX for the fabricated polyepoxides-reinforced CuSO4 composites shows an increase in the Cu concentrations by increasing the CuSO4 doping ratio in the fabricated composites. The increase in the Cu concentration is accompanied by a reduction in the C and O concentrations, which consisted of the pure polyepoxide resin (Table 1). Therefore, the EDX spectra affirm the diffusion of CuSO4 fillers in the fabricated samples, as well as the presence of polyepoxide resin, and traces of Ca, Ti, and Ni in the samples.

The backscattered electron images of the investigated samples show the distribution of the CuSO4 composites within the fabricated composites, as illustrated in Figure 4. The SEM images showed an increase in the filler particles with an increase in the CuSO4 concentration; moreover, the grain size of the filler particles varied up to 22 µm.

SEM and EDX analysis for the fabricated epoxy-based CuSO4 composites. (a) E-Cu0%, (b) E-Cu20%, and (c) E-Cu40%.

3.3 Radiation shielding capacity

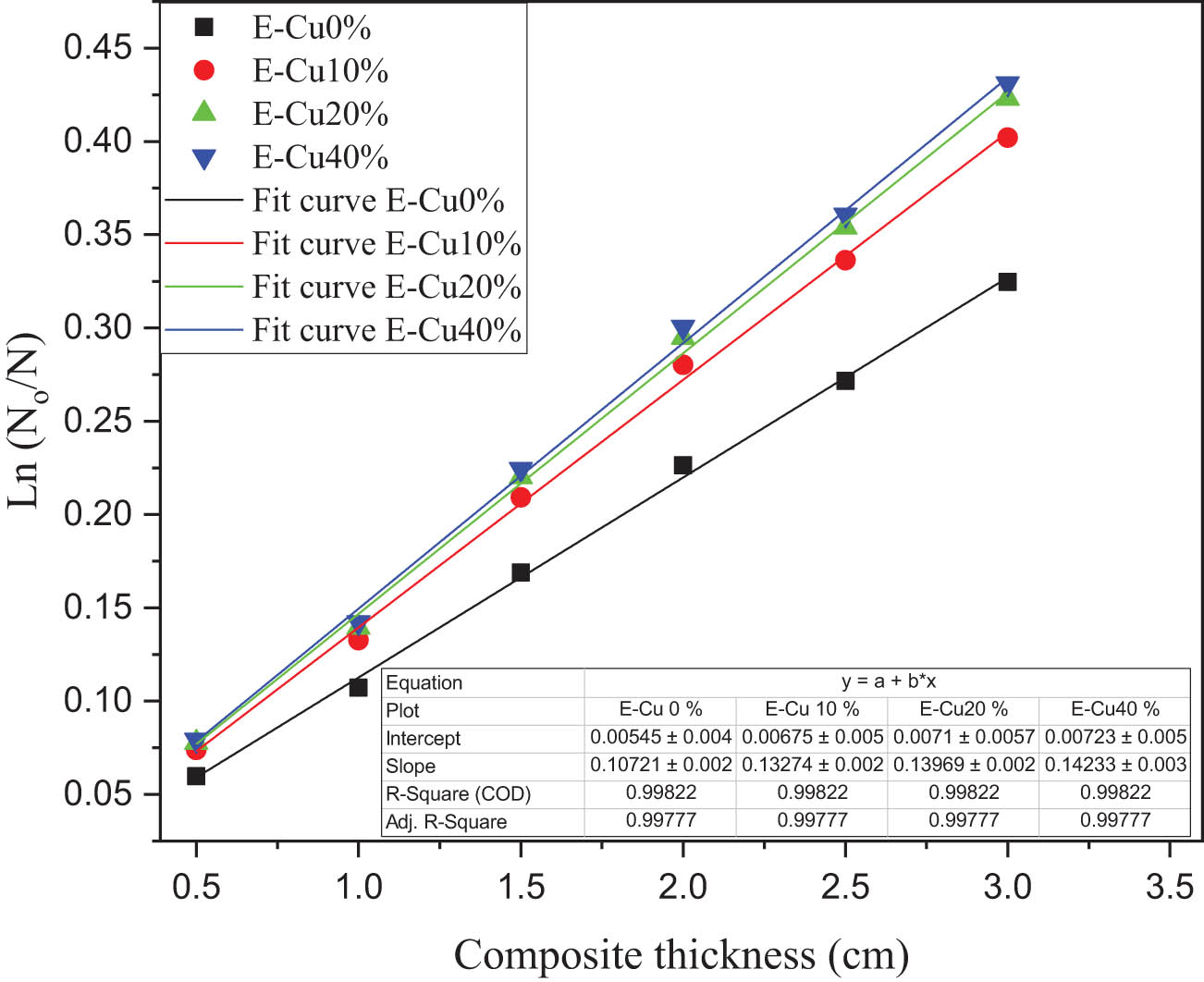

The linear attenuation coefficient measures and predicts the capacity of the current polymer to attenuate the incoming photon energy. The intensity of incoming photons affected the variation in polymer composite thickness. Figure 5 illustrates that the transmitted intensity of the incoming photon affects the thickness of the polymer composites, which increased from 0.5 to 5 cm. This variation is due to the ability of the polymer composites (E-Cu) to decrease the intensity of the incoming photons and allow part of them to pass and transmit through the composite materials (slope). This is called the linear attenuation coefficient. We can observe in Figure 5 that the linear attenuation coefficient values varied from 0.10 to 0.14 cm for E-Cu0% and E-Cu40%, respectively.

Variation of the ln(N o/N) versus the composite thickness (cm).

Figure 6 shows the changes in the linear attenuation coefficients of the investigated polymer composites depending on the energy of the photons that hit them. The linear attenuation coefficient values of the E-Cu composites decrease when the incoming photon energy increases from 33 to 1,332 keV. At a minimum energy range of 33–662 keV, the incoming γ-photons interact with the polymer composites and attenuate a large amount of the photons, while the rest penetrate the materials. In this range of energy, the dominant interaction is a photoelectric effect (PE), and its cross-section is inversely proportional to the incoming photon energy I. With the increase in the incoming photon energy, the µ values are diminished due to the second type of interaction called Compton scattering (CS). Through the CS interaction, some of the incoming γ photons are slowed down inside the polymer composites, while the rest have enough energy to go outside the material, where the cross-section (CS ∝ ZE −1) is measured. At high γ photon energies, the interaction will be governed by the pair production (PP) phenomenon, where the result of the interaction is two electrons. Figure 6 reveals that at a low photon energy of 33 keV, the maximum values of µ vary from 0.259 to 1.749 cm−1 for the polymer composites E-Cu0% and E-Cu40%, respectively. At a high photon energy of 1,332 keV, minimum µ values between 0.077 and 0.10 cm−1 are obtained for the polymer composites E-Cu0% and E-Cu40%, respectively.

Dependence of the linear attenuation coefficient (µ, cm−1) on the incident γ-photon energy.

The second effect of the µ values is the variation of CuSO4 in the polymer composites (Figure 7). The addition of CuSO4 to the polymer composites leads to an improvement in their physical properties. The compactness of the polymer composite molecules increased, and the interactions between the incoming photons and the molecules of materials increased. Thus, the polymer composites have the ability to attenuate the incoming γ photons. Figure 7 shows the results of tests that changed with the concentration of CuSO4 at three different incoming γ energies: 33, 662, and 1,173 keV. The lowest experimental values of the µ are 0.259, 0.107, and 0.078 cm−1 at 33, 662, and 1,173 keV, respectively, with a low CuSO4 concentration of 0 wt%, while the highest values are 0.259, 0.107, and 0.078 cm−1 at 33, 662, and 1,173 keV, respectively, with a high CuSO4 concentration of 40 wt%.

Variation of µ values versus CuSO4-doping concentrations.

The mass attenuation coefficient (µ m, cm2·g−1) for the fabricated E-Cu composites was evaluated based on the experimental µ values as well as the measured density for the synthesized composites. The µ m values increased with increasing concentration of the additive CuSO4, yielding0.0980, 0.1153, 0.1132, and 0.1030 cm2·g−1, respectively, for E-Cu0%, E-Cu10%, E-Cu20%, E-Cu40% composites, at a γ-ray energy of 662 keV. In order to validate the shielding capacity of the fabricated E-Cu composites, the aforementioned µ m values were compared to those of some polymetric composites (29,30,31,32,33,34,35,36,37,38), as demonstrated in Figure 8. According to the comparative results shown in Figure 8, the highest µ m values were recorded for HDP nano-PbO (50%), with an m value of 0.1140 cm2·g−1, at a γ-photon energy of 662 keV. The fabricated composites in the current study have µ m values better than that reported for composites E@PbO, E@CuO, E@Halloysite, E@Bi2O3, E@Basalt, SBR-TiO2, SBR-Fe2O3, SBR-ZnO, SBRMoO, polyster-Bi2O3 (10%), polyster-Bi2O3 (15%), polyster-Bi2O3 (20%), HDP, polyster-PbI2 (10%), polyster-PbI2 (20%), polyacrylamide-ZnO (5%), polyacrylamide-ZnO (10%), polyacrylamide-ZnO (15%), polyacrylamide-ZnO (20%), UP-nanoclay, UP-nanoclay-PbO (10%), UP-nanoclay-PbO (20%), UP-nanoclay-PbO (30%), Per hydro-polysilaxane, Polydimethyl silaxane, methylsilses quioxane, silalkalyene polymer, pure epoxy, epoxy/Al2O3 (6%), epoxy/Al2O3 (15%), epoxy/Fe2O3 (6%), epoxy/Fe2O3 (15%) with µ m values of 0.0730, 0.0678, 0.0655, 0.0722, 0.0603, 0.0258, 0.0262, 0.0284, 0.0304, 0.0798, 0.0851, 0.0848, 0.0790, 0.0820, 0.0849, 0.0820, 0.0810, 0.0810, 0.0800, 0.0740, 0.0780, 0.0830, 0.0840, 0.0810, 0.0820, 0.0800, 0.0810, 0.0832, 0.0824, 0.0827, 0.0827, and 0.0814 cm2·g−1, respectively, at 662 keV.

Comparison between the mass attenuation coefficient (µ m, cm2·g−1) of the fabricated E-Cu composites and those of previously reported polymetric composites.

Compared to Figure 6, Figure 9 shows that the half-value layer (Δ 0.5) values increase with the increase in the incoming γ-photon energy from 33 to 1,332 keV. The polymer composite material has enough resistance to reduce the incoming photon energy to half through the interactions. At constant CuSO4 concentrations, the Δ 0.5 values changed gradually with increasing incoming γ-photon energy. The variation of the highest Δ 0.5 values is between 2.68 and 9.05 cm at zero CuSO4 concentrations (E-Cu0%). This clarifies that the polymer composites with zero CuSO4 concentrations do not have enough resistance to diminish the incoming γ-photon energy to a half through interactions with PE, CS, and PP. In contrast, when the concentration of CuSO4 inside the polymer composites increases from 10% to 40%, the 0.5 values decrease. At a high CuSO4 concentration (E-Cu40%), the minimum values range from 0.40 to 6.78 cm.

Variation of the half-value thickness (Δ 0.5, cm) values versus the incident γ-photon energy.

Figure 10 shows the mean free path (λ, cm) and the lead equivalent thickness (Δ eq, cm) measured experimentally (for example, when the incoming energy of a γ photon is 81 keV). Figure 10 demonstrates the variation of λ and Δ eq values with e CuSO4 concentrations, where the λ values decrease from 7.32 to 4.27 cm. This decrease is because the number of collisions is lower when the concentration of CuSO4 in the polymer composites increases from 10% to 40%. As a result, the γ photons' capacity to permeate the polymer composite materials also increases.

Dependence of the half-value thickness (Δ 0.5, cm), mean free path (λ, cm), and lead equivalent thickness (Δ eq, cm) versus CuSO4 concentrations.

The Δ eq values are calculated to describe the equivalent thickness of the polymer composite material that can be applied to obtain the same performance of lead to attenuate the incoming γ photons. The variations between the Δ eq values and the incoming photon energies are graphically presented in Figure 10. As illustrated in Figure 10, the Δ eq values decrease with an increase in the CuSO4 concentrations from 10% to 40% inside the synthetic polymer composites. This decrease is observed in the PE interaction, where the decrease in µ values of pure Pb is higher than the calculated µ values of the fabricated polymer composites. For instance, the Δ eq values reduced from 7.40 to 4.32 cm when CuSO4 doping increased from 0% to 40%.

The TF of the synthetic polymer composites was computed and is presented in Figure 7. Figure 7 shows the changes in TF as the energy of the incoming γ photons increases from 33 to 1,332 keV at different concentrations of CuSO4. The TF values decrease from 66% to 7% at a low γ energy of 33 keV with an increase in the concentration of CuSO4 from 0% to 40%. Under the application of a low γ energy range, the γ photons interact inside the polymer composites, and the dominant interaction is PE. Therefore, the γ photons do not have the energy to transmit through the polymer composite material. Consequently, the TF will decrease with an increase in the percentage of CuSO4 concentrations. As the energy of the incoming γ photons increases, CS interactions become more common. Hence, a small amount of γ energy can be used to collect photons inside the polymer composite material. Figure 11 also shows the RPE values with the increasing incoming γ-photon energy of the polymer composites. The incoming photons with high energies will penetrate the polymer composite materials, and the RPE values will be diminished. For example, at a low γ energy of 33 keV, the RPE alternated between an increase of 33% and 92% for the E-Cu0% and E-Cu40%, respectively, while with the application of high γ energy (1,332 keV), the RPE values decreased and changed between 11% and 14% for the E-Cu0% and E-Cu40%, respectively.

Variation of the transmission values (TF%) and radiation protection efficiency (RPE%) versus the incident γ-photon energy for E-Cu0% and E-Cu40% samples.

Figure 12 shows the changes in TF and RPE values when CuSO4 is added to the polymer composites studied with a thickness of 1 cm and a γ-photon energy of 662 keV. TF and RPE values have inverse relations with the increasing concentrations of CuSO4 in the polymer composites. When the CuSO4 concentrations increased from 0% to 40%, the TF values decreased from 84% to 80% and RPE increased from 16% to 20%. This increase in the RPE values, which leads to the polymer composite material, will impulse the γ photons to escape outside (i.e., N a increase). Therefore, the transmission rate will decrease (i.e., N t decrease) with the increase of CuSO4 concentrations.

Variation of the transmission values (TF%) and radiation protection efficiency (RPE%) versus the CuSO4 concentration at a γ-photon energy of 662 keV.

Figure 13 manifests the mutation of TF and RPE data by elevating the thickness of the polymer composite materials from 0.5 to 5 cm. Two polymer composites with CuSO4 concentrations of 0% and 40% with a constant γ energy (662 keV) were used to study this change. The thickness of the polymer composites has a significant effect on the TF and RPE values. γ photons can easily pass through composite materials with a thickness of 0.5 cm and a low impulse. For E-Cu0% and E-Cu40%, the TF values drop from 95% to 92% and the RPE increases from 5% to 7%. With the increased thickness of the composites, the γ photons will make a lot of interactions, and their transmission (TF) decreases, accompanied by an increase in the impulse (RPE) of the polymer composite material.

Dependence of the transmission values (TF%) and radiation protection efficiency (RPE%) on the fabricated composites thickness (cm) at a γ-photon energy of 662 keV.

4 Conclusion

Because of the high γ-ray interaction cross-section for Cu, it is utilized in the current study to modify the radiation shielding properties of polyepoxide resins. Therefore, a series of four polyepoxide resins reinforced with various concentrations of CuSO4 was created. According to the density experimental examination, the addition of CuSO4 contents to the polyepoxide resin enhances its density where the synthesized composites’ density increased by 26% when the CuSO4 concentration changed from 0 to 40 wt% in the synthesized composites. Additionally, the experimental examination of the fabricated composites shielding capacity shows an enhancement in their linear attenuation coefficient with an increase in the CuSO4 concentration within the fabricated composites. The fabricated composites’ linear attenuation coefficient enhanced by 71.48%, 51.27%, 32.76%, 27.43%, and 33.50% at γ-photon energies of 81, 122, 662, 1,173, and 1,332 keV, respectively, when the CuSO4 concentration increased from 0 and 40 wt%. The enhancement in the linear attenuation coefficient decreased the Δ 0.5, λ, Δ eq, and TF values. The current synthesized composites have good shielding capacity and can be used in shielding low and intermediate γ-ray energies in γ knife, radiotherapy, and X-ray rooms, according to the comparison of the mass attenuation coefficient of the fabricated composites with the previously reported polymetric material.

Acknowledgement

This work was supported and funded by the Deanship of Scientific Research at Imam Mohammad Ibn Saud Islamic University (IMSIU) (grant number IMSIU RG23105).

-

Author contributions: All authors contributed equally to the manuscript.

-

Conflict of interest: The authors declare that they have no conflict of interest.

-

Ethical approval: Not applicable.

-

Data availability statement: No data associated in the manuscript.

References

(1) Singh VP, Badiger NM, Chanthima N, Kaewkhao J. Evaluation of gamma-ray exposure buildup factors and neutron shielding for bismuth borosilicate glasses. Radiat Phys Chem. 2014;98:14–21. 10.1016/j.radphyschem.2013.12.029.Search in Google Scholar

(2) Singh VP, Badiger NM, Kaewkhao J. Radiation shielding competence of silicate and borate heavy metal oxide glasses: Comparative study. J Non Cryst Solids. 2014;404:167–73. 10.1016/j.jnoncrysol.2014.08.003.Search in Google Scholar

(3) Oto B, Yıldız N, Akdemir F, Kavaz E. Investigation of gamma radiation shielding properties of various ores. Prog Nucl Energy. 2015;85:391–403. 10.1016/j.pnucene.2015.07.016.Search in Google Scholar

(4) Sayyed MI. Radiation shielding performance of amorphous silicates in the system SiO2-Na2O– RO (R = Cd, Pb or Zn). Silicon. 2023. 10.1007/s12633-023-02671-5.Search in Google Scholar

(5) Naseer KA, Marimuthu K, Mahmoud KA, Sayyed MI. Impact of Bi2O3 modifier concentration on barium–zincborate glasses: physical, structural, elastic, and radiation-shielding properties. Eur Phys J Plus. 2021;136:116. 10.1140/epjp/s13360-020-01056-6.Search in Google Scholar PubMed PubMed Central

(6) Issa SAM, Kumar A, Sayyed MI, Dong MG, Elmahroug Y. Mechanical and gamma-ray shielding properties of TeO2-ZnO-NiO glasses. Mater Chem Phys. 2018;212:12–20. 10.1016/j.matchemphys.2018.01.058.Search in Google Scholar

(7) Sayyed MI, El-Mesady IA, Abouhaswa AS, Askin A, Rammah YS. Comprehensive study on the structural, optical, physical and gamma photon shielding features of B2O3-Bi2O3-PbO-TiO2 glasses using WinXCOM and Geant4 code. J Mol Struct. 2019;1197:656–65. 10.1016/j.molstruc.2019.07.100.Search in Google Scholar

(8) ICRP. The 2007 Recommendations of the international commission on radiological protection. ICRP Publication 103. Ann. ICRP. Vol. 37; 2007. p. 2–4.Search in Google Scholar

(9) Sayyed MI, Mahmoud KA, Islam S, Tashlykov OL, Lacomme E, Kaky KM. Application of the MCNP 5 code to simulate the shielding features of concrete samples with different aggregates. Radiat Phys Chem. 2020;174:108925. 10.1016/j.radphyschem.2020.108925.Search in Google Scholar

(10) Sayyed MI, Mahmoud KA, Tashlykov OL, Khandaker MU, Faruque MRI. Enhancement of the shielding capability of soda–lime glasses with Sb2O3 dopant: A potential material for radiation safety in nuclear installations. Appl Sci. 2021;11:326. 10.3390/app11010326.Search in Google Scholar

(11) Hanfi MY, Sayyed MI, Lacomme E, Akkurt I, Mahmoud KA. The influence of MgO on the radiation protection and mechanical properties of tellurite glasses. Nucl Eng Technol. 2021;53(6):2000–10. 10.1016/j.net.2020.12.012.Search in Google Scholar

(12) Kilic G, Ilik E, Mahmoud KA, El-Agawany FI, Alomairy S, Rammah YS. The role of B2O3 on the structural, thermal, and radiation protection efficacy of vanadium phosphate glasses. Appl Phys A. 2021;127:265. 10.1007/s00339-021-04409-9.Search in Google Scholar

(13) Al-Saleh WM, Dahi MRH, Sayyed MI, Almutairi HM, Saleh IH, Elsafi M. Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings. e-Polymers. 2023;23(1):20230096. 10.1515/epoly-2023-0096.Search in Google Scholar

(14) Almuqrin AH, Yasmin S, Abualsayed MI, Elsafi M. An experimental investigation into the radiation-shielding performance of newly developed polyester containing recycled waste marble and bismuth oxide. Appl Rheol. 2023;33(1):20220153. 10.1515/arh-2022-0153.Search in Google Scholar

(15) Turner TA, Pickering SJ, Warrior NA. Development of recycled carbon fibre moulding compounds – Preparation of waste composites. Compos B Eng. 2011;42:517–25. 10.1016/j.compositesb.2010.11.010.Search in Google Scholar

(16) Adeosun SO, Lawal GI, Balogun SA, Akpan EI. Review of green polymer nanocomposites. J Miner Mater Charact Eng. 2012;11:385–416. 10.4236/jmmce.2012.114028.Search in Google Scholar

(17) Nagaraja N, Manjunatha H, Seenappa L, Sathish K, Sridhar K. Ramalingam H. Gamma, X-ray and neutron shielding properties of boron polymers. Indian J Pure Appl Phys (IJPAP). 2020;58:271–6.10.1016/j.radphyschem.2020.108723Search in Google Scholar

(18) Lee S-Y, Kang I-A, Doh G-H, Yoon H-G, Park B-D, Wu Q. Thermal and mechanical properties of wood flour/talc-filled polylactic acid composites: Effect of filler content and coupling treatment. J Thermoplast Compos Mater. 2008;21:209–23. 10.1177/0892705708089473.Search in Google Scholar

(19) Qu P, Gao Y, Wu G-F, Zhang L-P. Nanocomposites of Poly(lactic acid) reinforced with cellulose nanofibrils. BioRes. 2010;5(3):1811–23.10.15376/biores.5.3.1811-1823Search in Google Scholar

(20) Kaushik A, Singh M, Verma G. Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw. Carbohydr Polym. 2010;82:337–45. 10.1016/j.carbpol.2010.04.063.Search in Google Scholar

(21) Zadegan S, Hosainalipour M, Rezaie HR, Ghassai H, Shokrgozar MA. Synthesis and biocompatibility evaluation of cellulose/hydroxyapatite nanocomposite scaffold in 1-n-allyl-3-methylimidazolium chloride. Mater Sci Eng C. 2011;31:954–61. 10.1016/j.msec.2011.02.021.Search in Google Scholar

(22) Albarzan B, Almuqrin AH, Koubisy MS, Wahab EAA, Mahmoud KA, Shaaban K, et al. Effect of Fe2O3 doping on structural, FTIR and radiation shielding characteristics of aluminium-lead-borate glasses. Prog Nucl Energy. 2021;141:103931. 10.1016/j.pnucene.2021.103931.Search in Google Scholar

(23) Abouhaswa AS, Sayyed MI, Altowyan AS, Al-Hadeethi Y, Mahmoud KA. Synthesis, structural, optical and radiation shielding features of tungsten trioxides doped borate glasses using Monte Carlo simulation and phy-X program. J Non Cryst Solids. 2020;543:120134. 10.1016/j.jnoncrysol.2020.120134.Search in Google Scholar

(24) Dong MG, Tishkevich DI, Hanfi MY, Semenishchev VS, Sayyed MI, Zhou SY, et al. WCu composites fabrication and experimental study of the shielding efficiency against ionizing radiation. Radiat Phys Chem. 2022;200:110175. 10.1016/j.radphyschem.2022.110175.Search in Google Scholar

(25) Akman F, Ogul H, Ozkan I, Kaçal MR, Agar O, Polat H, et al. Study on gamma radiation attenuation and non-ionizing shielding effectiveness of niobium-reinforced novel polymer composite. Nucl Eng Technol. 2022;54:283–92. 10.1016/j.net.2021.07.006.Search in Google Scholar

(26) Hanfi MY, Sakr AK, Ismail AM, Atia BM, Alqahtani MS, Mahmoud KA. Physical characterization and radiation shielding features of B2O3As2O3 glass ceramic. Nucl Eng Technol. 2023;55:278–84. 10.1016/j.net.2022.09.006.Search in Google Scholar

(27) Howard CJ, Sabine TM, Dickson F. Structural and thermal parameters for rutile and anatase. Acta Crystallogr B. 1991;47:462–8. 10.1107/S010876819100335X.Search in Google Scholar

(28) Epp J. X-ray diffraction (XRD) techniques for materials characterization. Materials characterization using nondestructive evaluation (NDE) methods. Elsevier; 2016. p. 81–124. 10.1016/B978-0-08-100040-3.00004-3.Search in Google Scholar

(29) Mahmoud ME, El-Khatib AM, Badawi MS, Rashad AR, El-Sharkawy RM, Thabet AA. Fabrication, characterization and gamma rays shielding properties of nano and micro lead oxide-dispersed-high density polyethylene composites. Radiat Phys Chem. 2018;145:160–73. 10.1016/j.radphyschem.2017.10.017.Search in Google Scholar

(30) Sharma A, Sayyed MI, Agar O, Kaçal MR, Polat H, Akman F. Photon-shielding performance of bismuth oxychloride-filled polyester concretes. Mater Chem Phys. 2020;241:122330. 10.1016/j.matchemphys.2019.122330.Search in Google Scholar

(31) Mahmoud ME, El-Khatib AM, Badawi MS, Rashad AR, El-Sharkawy RM, Thabet AA. Recycled high-density polyethylene plastics added with lead oxide nanoparticles as sustainable radiation shielding materials. J Clean Prod. 2018;176:276–87. 10.1016/j.jclepro.2017.12.100.Search in Google Scholar

(32) Hou Y, Li M, Gu Y, Yang Z, Li R, Zhang Z. Gamma ray shielding property of tungsten powder modified continuous basalt fiber reinforced epoxy matrix composites. Polym Compos. 2018;39:E2106–15. 10.1002/pc.24469.Search in Google Scholar

(33) Farnaz Nasehi MII. Evaluation of X and gamma-rays attenuation parameters for polyacrylamide and ZnO composites as ligh. J Nucl Med Radiat Ther. 2019;10:1000404.Search in Google Scholar

(34) Bagheri K, Razavi SM, Ahmadi SJ, Kosari M, Abolghasemi H. Thermal resistance, tensile properties, and gamma radiation shielding performance of unsaturated polyester/nanoclay/PbO composites. Radiat Phys Chem. 2018;146:5–10. 10.1016/j.radphyschem.2017.12.024.Search in Google Scholar

(35) Atta E, Zakaria KM, Madbouly A. Research article study on polymer clay layered nanocomposites as shielding materials for ionizing radiation. Int J Recent Sci Res. 2015;6:4263–9.Search in Google Scholar

(36) Aldhuhaibat MJR, Amana MS, Jubier NJ, Salim AA. Improved gamma radiation shielding traits of epoxy composites: Evaluation of mass attenuation coefficient, effective atomic and electron number. Radiat Phys Chem. 2021;179:109183. 10.1016/j.radphyschem.2020.109183.Search in Google Scholar

(37) Akman F, Kaçal MR, Almousa N, Sayyed MI, Polat H. Gamma-ray attenuation parameters for polymer composites reinforced with BaTiO3 and CaWO4 compounds. Prog Nucl Energy. 2020;121:103257. 10.1016/j.pnucene.2020.103257.Search in Google Scholar

(38) Mahmoud KA, Tashlykov OL, Kropachev Y, Samburov A, Zakharova P, Abu El-Soad AM. A close look for the γ-ray attenuation capacity and equivalent dose rate form composites based epoxy resin: An experimental study. Radiat Phys Chem. 2023;212:111063. 10.1016/j.radphyschem.2023.111063.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites