Abstract

In this study, we developed flexible composites using silicone rubber (SR) or polydimethylsiloxane as the matrix and WO3 and BaO nanoparticles as filler to analyze their radiation-shielding performance. The linear attenuation coefficient (LAC) values for the prepared composites were reported to range from 0.059 to 1.333 MeV by using the experimental method. At 0.059 MeV, the SR with 40% of BaO NPs possesses the highest LAC, followed by SR with 20% of BaO and WO3 NPs. The SRs S-2 and S-4 that contain WO3 and/or BaO exhibit continuously greater LAC values than the sample S-1. Numerically, the LAC for S-2 (with 40% of BaO NPs) is 1.6 times greater than that for S-1 (free BaO and WO3) at 0.662 MeV, while the LAC for S-2 is 1.47 times more than that for S-1 at 1.275 MeV. We examined the impact of the thickness of the prepared composites on the attenuation performance by studying the transmission factor (TF) at two different thicknesses (1 and 2 cm). For S-1 and S-2, the TF decreases due to the increase of the thickness from 1 to 2 cm. The TF for S-1 with a thickness of 1 cm is 75% at 0.059 MeV, while it is 56% (for 2 cm). We evaluated the percentage decrease in the TF at 0.059 MeV for every SR as the thickness changes from 1 to 2 cm. For S-3, S-4, S-5, and S-6, the percentage decrease in the TF is extremely significant varying from 98% to 99%. This suggests that increasing the thickness of these SR samples from 1 to 2 cm has a major effect on the shielding capabilities they possess, particularly at low energies.

1 Introduction

The application of ionizing radiation in industry and medicine (such as Positron emission tomography, diagnostic imaging, radiotherapy, etc.) has expanded globally in recent years as a result of significant technical improvement. But even at modest levels, many radiation types have unavoidable negative impacts on living beings, increasing the risks to people’s health. Consequently, the use of appropriate radiation shielding techniques plays an essential role in reducing risks to health and protecting people from risks associated with radiation (1–3). Over the past few decades, the need for effective and reliable materials has increased in response to these potential negative effects. Heavy metals like lead and tungsten have been widely utilized for many years to block ionizing radiation (4–6). The use of lead has been constrained in a number of practical uses due to its poor chemical stability, heaviness, and toxicity, as well as its detrimental impacts on human health. However, experts consider that it is important to identify suitable light-shielding materials in place of conventional lead shields. Regarding this, numerous investigators produced reinforced polymer composite materials containing high atomic number components that have high absorption abilities (7–10). There are many advantages of using polymers as radiation shielding materials. In comparison to more conventional shielding materials, they are lightweight materials. They are thus a desirable solution for uses where weight is an issue, for example, in aerospace or healthcare. In addition, polymers are flexible, implying they may be molded into different forms to fulfill the requirements of a wide range of applications. Polymers, in contrast to more conventional shielding substances such as lead, are non-toxic and acceptable for use in a variety of applications, including medical ones. Polymers are typically less expensive than conventional materials used for radiation shielding, which makes them an appealing choice for applications in which cost is a primary consideration. It is possible to adjust the characteristics of polymers such that they are suitable for a variety of radiation shielding applications. Investigators can improve the attenuation qualities of a polymer, for instance, by altering the chemical structure of the polymer to make it more or less resistant to a specific kind of radiation (11–16).

Silicone rubber (SR) is a flexible polymeric substance that has found broad application across a range of sectors due to the one-of-a-kind qualities that it possesses. Because of its great chemical resistance, and electrical insulating capabilities, SR is a common material option for purposes in which elevated temperatures, harsh substances, or high voltages are involved. Considering its biocompatibility and its resistance to chemicals, SR is frequently utilized in the medical sector for the production of implantable medical devices. In addition, SR is utilized within the construction and electrical industries as an insulator and sealant, respectively (17,18). SR is an essential component of current industry and engineering because of its significant impact across a number of different markets. It is essential to include heavy metal oxides (HMOs) as fillers in the SR for improving the density of the product, and this may result in greater attenuation efficiency (19). When the density of the SR is increased, it becomes more successful at shielding gamma radiation, which ultimately leads to greater attenuation effectiveness. When compared to other HMOs, BaO and WO3 have high densities, allowing them to effectively block and absorb gamma photons. Also, because both W and Ba have high atomic numbers, we expect that a lesser quantity of these compounds (i.e., BaO and WO3) can offer a comparable degree of protection as a greater quantity of materials with a lower density. In contrast to lead, which is harmful to the environment and should be avoided for radiation shielding purposes, WO3 and BaO are non-hazardous alternatives that can be used instead (20–23).

Conversely, the topic of nanotechnology is expanding at a rapid rate and has a huge opportunity to change many different industries, including medicine, electronics, and radiation protection (24). Nanotechnology works with materials between 1 and 100 nm in size. Materials often have distinct properties on this scale that can be used in many applications. Many potential advantages come with radiation protection using heavy nanometal oxides. It is possible to embed nanoparticles into a wide variety of materials to improve the radiation shielding properties of those materials without significantly increasing the size or weight of the materials. This may be of paramount importance in situations where weight and space are limited, such as those dealing with space exploration (25).

In light of the previously mentioned information, this study aims to investigate the possibility of preparing SR for radiation shielding applications using WO3 and BaO nanoparticles. The impact of the concentration of WO3 and BaO nanoparticles on the gamma-ray shielding capabilities will be investigated in this study. The results of this study can help in the design of novel materials that are superior for radiation shielding uses across a variety of industries.

2 Materials and methods

New flexible composites were prepared to examine their shielding ability, SR or polydimethylsiloxane was used as matrix in this study while the WO3 and BaO nanoparticles were used as fillers in the compositions. A polydimethylsiloxane liquid was used with the chemical composition and physical properties found in the previous literature (26,27). The purity and the particle size of the used nanoparticles were measured by using EDX analysis and TEM images, respectively (28,29), as shown in Figure 1, where the purity was 99.8% and 97.3% for WO3 and BaO while the average size was 20 ± 5 and 30 ± 5 nm, respectively.

EDX analysis and TEM images of (a) WO3 nanoparticles and (b) BaO nanoparticles.

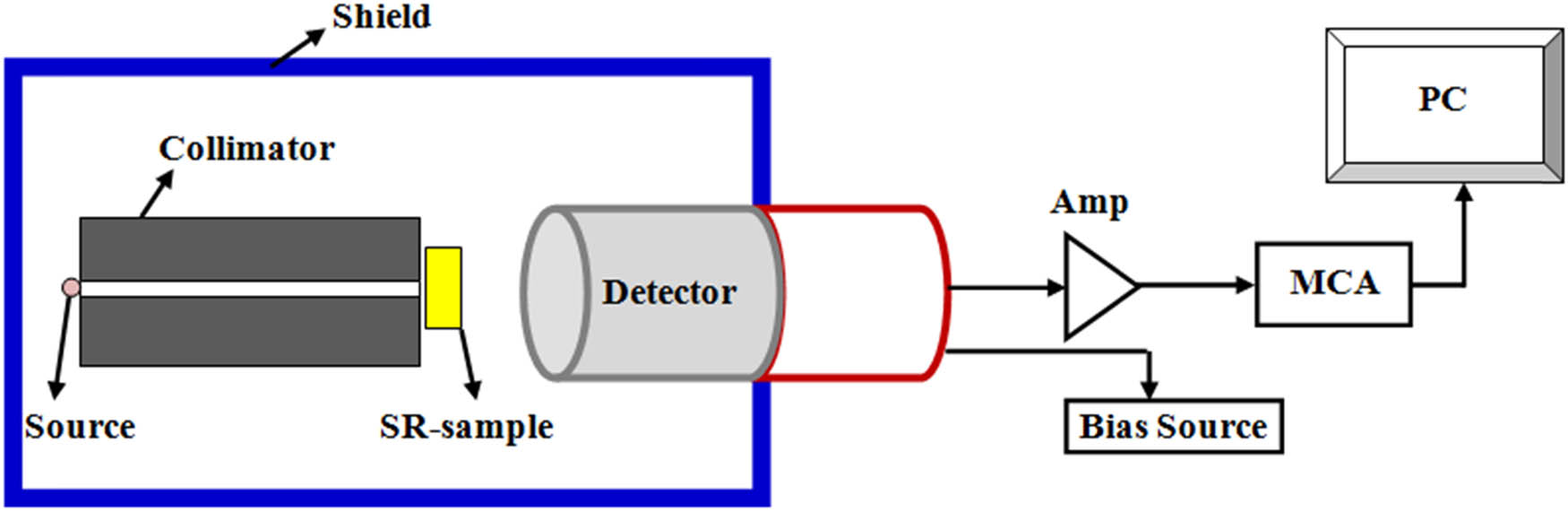

The flexible composites were prepared according to the mixing percentages given in Table 1. The mixture was stirred and placed in plastic crucibles of different thicknesses and left to dry to become flexible composites. The composites were exposed to different point sources (Cs-137, Am-241, and Co-60) that emit different energies ranging from 0.060 to 1.333 MeV to calculate the shielding ability of the present flexible SR composites with an HPGe detector (30,31), which was used to detect the incident gamma-ray photons.

Chemical compositions of the prepared flexible composites

| Code | Silicon rubber (wt%) | WO3 NPs (wt%) | BaO NPs (wt%) | Hardener (wt%) |

|---|---|---|---|---|

| S-1 | 100 | — | — | 5 |

| S-2 | 60 | 40 | — | 4 |

| S-3 | 60 | — | 40 | 4 |

| S-4 | 60 | 20 | 20 | 4 |

| S-5 | Double layers of S-2 and S-3 (S-2 upper toward the source and S-3 down) | |||

| S-6 | Double layers of S-3 and S-2 (S-3 upper toward the source and S-4 down) | |||

First, the detector was calibrated before the measurements. Then, the count rate (

The experimental setup for determining the LAC of fixable SR composites.

The other important shielding factors such as half- and tenth-value layers (HVL, TVL) and radiation shielding efficiency (RSP) can be expressed based on experimental values of count rates by the following equations (35–37):

3 Results and discussion

In this study, we explored the radiation shielding capabilities of SR with various percentages of WO3 and BaO. Four different SR samples S-1, S-2, S-3, and S-4 were prepared, and each has a unique ratio of WO3 and BaO in its composition.

3.1 Stress–strain curve

Before the shielding performance test, the stress–strain curve of the presented flexible composites is shown in Figure 3. The results showed that all prepared composites are flexible despite the addition of WO3 and BaO nanoparticles. The highest elasticity was observed for pure SR (S-1), and it was found that the addition of WO3-NPs gives better elasticity than the addition of BaO-NPs to SR, but both percentages added together with matrix materials (S-4) gave elasticity better than WO3-NPs when added individually. The maximum strains before cutting the sample or splitting it as a result of the applied stress were 209%, 128%, 104%, and 152% for S-1, S-2, S-3, and S-4, respectively.

Stress–strain curve of advanced SR samples.

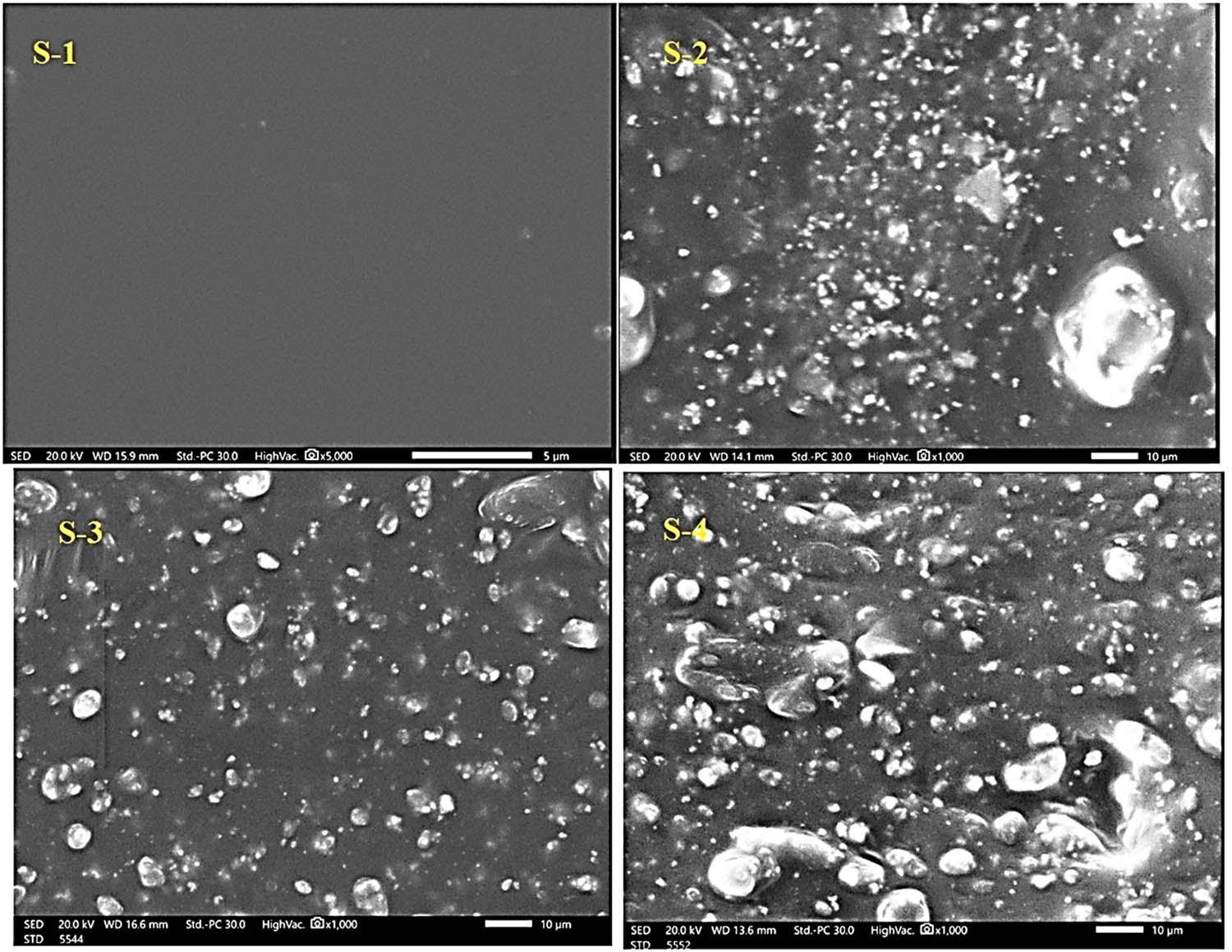

3.2 Scanning electron microscopy (SEM)

SEM was used to display the distribution of both WO3-NPs and BaO-NPs as fillers in the SR, as shown in Figure 4. It is clear that the distribution of particles was better with small sizes as shown in S-2, as small sizes can penetrate between particles and each other and fill voids in liquid SR, and this is the role nanoparticles play in terms of homogeneous distribution and penetration between particles and each other. This, in turn, leads to a greater chance of collision with the incoming radiation, and thus higher absorption. This is required to raise the material’s performance as a shield against ionizing radiation.

SEM images of prepared advanced silicone rubber samples.

3.3 Radiation shielding performance

We aimed to determine the effect of WO3 and BaO levels on the attenuation of gamma radiation, so we examined the radiation shielding performance of these different SR compositions. Additionally, we wanted to determine which SR composition is particularly efficient for use in radiation protection conditions. The first useful parameter that describes the radiation attenuation performance of the prepared samples is the LAC values. By using the experimental method, we measured LAC values for the SR with WO3 and BaO in the range of 0.059–1.333 MeV (Figure 5). It is important to note that researchers and manufacturers dealing with radiation shielding materials typically have as their primary objective the preparation of novel materials that have a high LAC for obtaining a medium that is ideal for radiation shielding. As shown in Figure 5, there is a drop in the LAC that corresponds to an increase in the energy level. The findings in Figure 5 support the idea that the LAC is primarily influenced by three key variables: the density and the composition of the shield, and the radiation energy. At the first examined energy (0.059 MeV), S-3 possesses the highest LAC (5.66 cm−1), followed by S-4 with a LAC value of 4.07 cm−1. S-1, which does not contain WO3 and BaO, has the smallest LAC value (0.29 cm−1), with S-2 having a LAC value of 2.44 cm−1. This suggests that an increase in LAC at lower energies is greatly influenced by the presence of WO3 and BaO in the SR samples. The LAC values for S2, S3, and S4 are quite comparable at higher energies (E = 0.662–1.333 MeV), with values spanning 0.148–0.157 cm−1 at 0.662 MeV and 0.099–0.102 cm−1 at 1.333 MeV. This suggests that at higher energies, the variation in radiation attenuation characteristics caused by the inclusion of WO3 and BaO is minimal. The SRs S-2 and S-4 that contain WO3 and/or BaO continuously exhibit greater LAC values than the sample S-1. This finding suggests that adding WO3 and/or BaO to SR samples improves their radiation attenuation capabilities over the energy region studied. We can emphasize the significance of utilizing WO3 and BaO as radiation attenuation compounds in the SR by examining the LAC values between S-1 (which is free of WO3 and BaO) and S-2. The LAC value for S-2 is much larger than that of S-1 at 0.059 MeV. When WO3 is added to the SR structure, an 8.36-fold improvement in the LAC is observed. The LAC values for S-2 are continuously higher compared to those for S-1 as the energy increases. In particular, the LAC for S-2 is 1.6 times greater than that for S-1 at 0.662 MeV, while the LAC for S-2 is 1.47 times more than that for S-1 at 1.275 MeV. These findings show that, although to a smaller extent than at the lowest energy level, the addition of WO3 to the SR composition still improves the radiation attenuation qualities at higher energy regions.

The LAC values for S-1 to S-4.

We calculated the transmission factor (TF) for the SR prepared with WO3 and BaO, and the results are shown in Figure 6. At 0.059 MeV, S-1 (free of both WO3 and BaO) possesses the highest values of TF (75%), which implies that S-1 has the lowest attenuation performance. The lowest TF value (0.29%), which denotes the maximum radiation attenuation, is seen in S-3, which contains 40% BaO. The TF values of S-2, which contains 40% WO3, and S-4, which contains 20% WO3 and 20% BaO, show stronger radiation attenuation characteristics than S-1. All SR samples had higher TF values as the energy increased, which denotes lower radiation attenuation at higher energies. This pattern is in line with the LAC results that were previously addressed, which showed that the LAC values decreased as the energy increased. The TF values for states S-1, S-2, S-3, and S-4 are reasonably similar to one another at higher energy levels, with values varying from 93.2 to 90.48% at 1.333 MeV. If we compare the TF between S-1 and S-2, we found that S-2 has a much smaller TF than the S-1 (8% and 75%, respectively, at 0.059 MeV). This implies that the addition of WO3 in S-2 decreases considerably the TF at 0.059 MeV. However, the difference in TF between S-1 and S-2 decreases as the energy of the radiation increases. For instance, the TF at 1.333 MeV is 93% for S-1 and 90% for S-2, which means that the impact of WO3 on TF becomes less important at higher energies. According to these data, at low energies, the presence of WO3 in sample S-2 causes a large decrease in the TF, whereas, at higher energies, the difference between the two samples starts to diminish. The decrease in TF that occurs as a result of introducing WO3 or BaO in the SR mixture can be attributed to a variety of factors, namely the effect of absorption and scattering. When WO3 or BaO are included in the matrix of SR, the material can absorb more photons, particularly in the lower energy region. The presence of more electron shells and a higher atomic number in W and Ba in comparison to the other components in the SR matrix are responsible for the greater absorption.

The TF for S-1 to S-4.

To study the impact of the thickness on the TF, we plotted the TF for S-1 with two different thicknesses (1 and 2 cm) in Figure 7, and for the two thicknesses of S-2 in Figure 8. The same behavior is found for the remaining SR, so we only show the results for S-1 and S-2. For S-1 and S-2, the TF decreases due to the increase of the thickness from 1 to 2 cm. This is to be predicted because a thicker specimen would more likely absorb or scatter photons, which would lower the TF. When the energy is smaller, the impact of increased thickness on the TF is more noticeable. For instance, when comparing the TF for S-1 at 0.059, we found that the TF is 75% (for a thickness of 1 cm), while it is 56% (for 2 cm). Whereas, at 1.333 MeV, the TF changes from 93.2% to 68.9% for 1 and 2 cm, respectively. This tendency is reported for the samples ranging from S-2 to S-6, demonstrating that the significance of the effect of sample thickness increases with decreasing energy value. The length of the path required for photons to traverse the SR samples doubles as the sample thickness increases from 1 to 2 cm. This causes more interactions between the photons and the atoms in the SR samples, which in turn increases the possibility of the material either absorbing or scattering the radiation. This explains the decrease in TF that was caused by the increase in thickness from 1 to 2 cm.

The TF for S-1 with thicknesses of 1 and 2 cm.

The TF for S-2 with thicknesses of 1 and 2 cm.

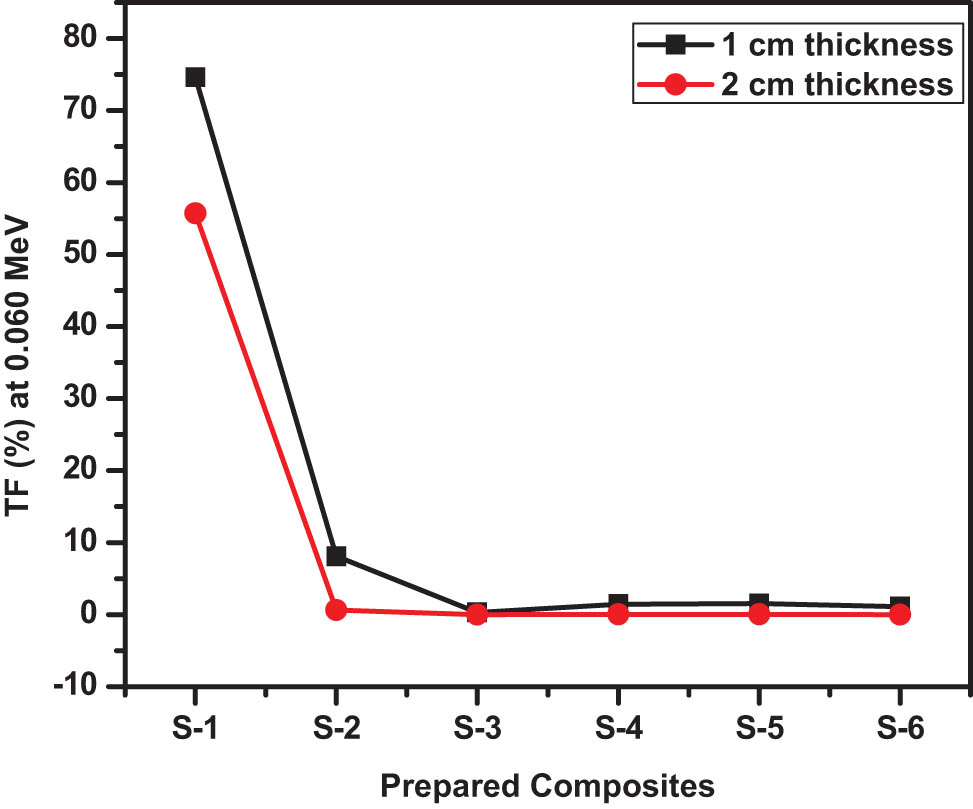

We evaluated the percentage decrease in the TF at 0.059 MeV for every SR as the thickness varies from 1 to 2 cm (Figure 9). For S-3, S-4, S-5, and S-6, the percentage decrease in the TF is extremely significant varying from 98% to 99%. This suggests that increasing the thickness of these SR samples from 1 to 2 cm has a major effect on their shielding capabilities, particularly at low energies. Even though the thickness is increased, the percentage decrease in the TF for S-1 at 0.059 keV is less obvious (only 25%) than it is for the other SR samples, which may indicate that S-1 has smaller successful radiation shielding capabilities at 0.059 MeV. The shielding ability of sample S-2 is significantly impacted by the increase in thickness, as seen by the fact that it experiences a considerable percentage decrease in TF at 0.059 MeV (about 91%). So, for the majority of samples, the TF at the 0.059 MeV significantly decreases as the thickness increases from 1 to 2 cm, with S-1 being the exception and exhibiting a smaller decrease.

The percentage decrease in the TF at 0.060 MeV for every SR as the thickness varies from 1 to 2 cm.

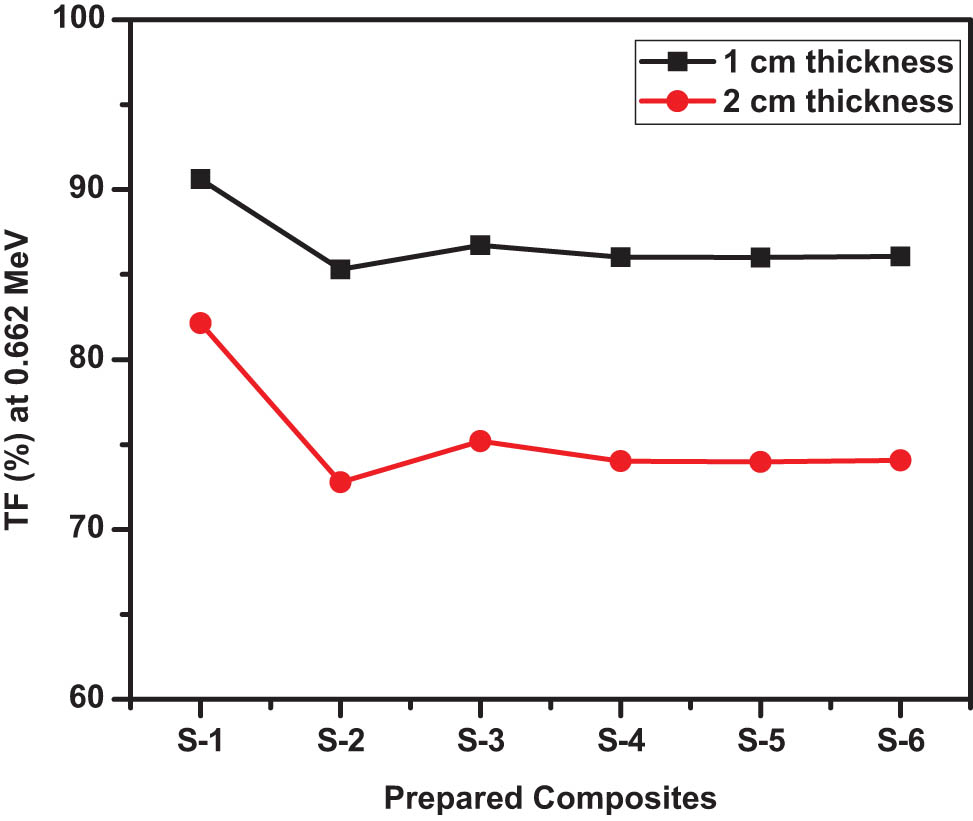

Moreover, we evaluated the percentage decrease in the TF at 0.662 MeV for every SR as the thickness varies from 1 to 2 cm (Figure 10). The percentage decrease in the TF, ranging from 9.3% to 14.7% for all SR samples at 0.662 MeV, seems less significant than it is for the first energy (0.059 MeV). This shows that at 0.0662 MeV, the effect of increasing the thickness from 1 to 2 cm on the radiation shielding qualities is less important. Among the samples, S-1 shows the least amount of TF reduction (9.4%), confirming that it has less effective radiation shielding. The percentage decreases in TF for SR-2 to SR-6 range from 13.3% to 13.9%, which is fairly consistent. This suggests that at this energy level, the thickness increase has the same effect on their shielding effectiveness.

The percentage decrease in the TF at 0.662 MeV for every SR as the thickness varies from 1 to 2 cm.

We prepared double-layer SR samples: S-5 and S-6, where S-5 is made of two layers containing S-2 and S-3 (S-2 upper toward the source and S-3 down), while S-6 is made of two layers containing S-2 and S-3 (S-3 upper toward the source and S-2 down). We compared the TF of S-2, S-3, S5, and S-6 to determine the effect of using a double layer on the transmission of the photons via the prepared SR (Figure 11). At 0.059 MeV, the TF is higher for the two-layer SR (S-5 and S-6) in comparison to the one-layered A-3. But the TF for S-5 and A-6 is lower than S-2. This suggests that the combinations of two layers have a positive influence on TF at 0.059 MeV in comparison to S-3, but does not reach the quality of S-2. Comparing S-5 and S-6 at 0.059 MeV, the TF is lower for S-6 than S-5. This means that having S-2 (with 40% of WO3) as the upper layer and S-3 (with 40% of BaO) as the lower layer is more efficient in shielding the photons with an energy of 0.059 MeV. For E ≥ 0.0662 MeV, the TF for S-5 and S-6 are close to that for S-2 and S-3. This suggests that the order of the layers does not remarkably affect the TF. We can conclude from Figure 11 that compared to the single-layered S-3, the double-layered samples S-5 and S-6 show better TF, especially in the low-energy region. S-5 has a greater TF than S-6 at 0.059 MeV, indicating that the arrangement of the layers might affect the transmission qualities.

The TF for S2, S-3, S-5, and S-6 (thickness, 1 cm).

The HVL, which measures the material’s radiation attenuating capacity, is the thickness of the material needed for lowering the radiation intensity by 50%. We plotted the HVL for S-1 to S-4 in Figure 12. The highest HVL is found for S-1 at all the examined energies, varying from 2.37 at 0.059 MeV to 9.90 cm at 1.333 MeV. This means that S-1 (free of WO3 and BaO) needs a higher thickness to attenuate photons by 50% compared to S-2, S-3, and S-4. Hence, S-1 possesses the worse shielding performance among the four SR samples, mainly due to the absence of HMOs like WO3 and BaO, which are recognized for their radiation-shielding qualities. On the other hand, S-2 has lower HVL than S-1 and varied between 0.28 and 6.70 cm at 1.333 MeV. This implies that S-2 is a better radiation attenuator than S-1, necessitating a thinner thickness to accomplish a comparable level of radiation attenuation. The improved efficiency of S-2 as a shield may be connected to its composition, which includes 40% WO3, an HMO that is well-known for its radiation shielding capabilities. At 0.059 MeV, S-3 has lower HVL values in comparison to S-2. This suggests that S-3 is more successful in reducing radiation at this energy; hence, a thinner layer is required to attain a decrease of 50% of the radiation’s intensity. The inclusion of barium in S-3, in contrast to the presence of tungsten in S-2, is one of the possible reasons for the superior performance of S-3 as a shielding material when compared to S-2 at this energy. In comparison to W, the K-absorption edge of Ba is located at a lower energy, which indicates that Ba has a stronger capacity to absorb radiations with low energies by the process of the photoelectric mechanism. Therefore, the inclusion of barium in S-3 adds to its greater shielding efficiency at 0.059 MeV in comparison to S-2, which consists of tungsten. While sample S-4 has HVL values that, for E ≥ 0.662 MeV, fall somewhere between those of sample S-2 and sample S-3. The different sample compositions are likely responsible for the variation in the degree of protection they provide. S-4 consists of 20% WO3 and 20% BaO, compared to 40% WO3 and 40% BaO in S-2 and S-3, respectively. In comparison to introducing two HMOs at lower percentages (20% WO3 and 20% BaO), introducing WO3 at higher levels (40%) results in improved attenuation capabilities. As a result, the efficacy of the shielding provided by S-4 is somewhere between that of S-2 and S-3 owing to the presence of WO3 and BaO at a concentration of 20% each.

The HVL for S-1 to S-4.

Besides, we reported the mean free path (MFP) for the SR samples, and the results are shown in Figure 13. A lower MFP implies that the shielding is more effective since the photons have a greater chance of interacting with the material and becoming attenuated as a result of those interactions. When the MFP values for S-1 (without HMOs) are compared to those for S-2, S-3, and S-4, it is evident that the inclusion of HMOs considerably enhances the efficacy of the shielding provided by the materials. The HMOs in specimens S-2, S-3, and S-4 contribute, in many ways, to the efficiency of the shielding provided by these samples. Since heavy metals have more atoms, the photoelectric effect is more likely to occur when photons are of low energy. In addition, HMOs have very high densities, which means that there are a greater number of atoms per volume available to interact with the radiation that is being emitted. Additionally, HMOs have a larger electron density, which adds to an increased probability of either Compton scattering or pair production at higher photon energy. When compared to the MFP values of S-1, those of S-2 and S-3, which consist of much greater percentages (40%) of WO3 and BaO, respectively, are considerably lower. This shows that large amounts of HMOs serve a vital function in increasing radiation shielding in some way. Comparing sample S-4, containing 20% WO3 and 20% BaO, to sample S-1 reveals that sample S-4 displays superior shielding efficiency. But its MFP values tend to be greater than those of S-2 and S-3, which indicates that its general shielding effectiveness is not as effective as it is with the samples that contain 40% of a single HMO. Hence, when compared to sample S-1, which has no HMOs, the MFPs that occur from the inclusion of WO3 and BaO in samples S-2, S-3, and S-4 are smaller, and the samples’ ability to shield gamma radiation is improved.

The MFP for S-1 to S-4.

Finally, the present SR samples have been compared with other related flexible composites and are reported in Table 2. The comparison indicated that the present flexible SR impeded with both WO3-NPs and BaO-NPs has a good shielding material against gamma-ray radiation.

Comparison of the present work with related published work

| Flexible composite | LAC (cm−1) | HVL (cm) | Reference | ||||

|---|---|---|---|---|---|---|---|

| 0.060 MeV | 0.662 MeV | 1.333 MeV | 0.060 MeV | 0.662 MeV | 1.333 MeV | ||

| SR-BT40 | 5.042 | 0.164 | 0.114 | 0.137 | 4.235 | 6.073 | (38) |

| SR-BT50 | 6.489 | 0.170 | 0.122 | 0.107 | 4.071 | 5.682 | |

| SR-50 mMgO | 0.421 | 0.141 | 0.100 | 1.645 | 4.930 | 6.916 | (24) |

| SR-50nMgO | 0.614 | 0.186 | 0.128 | 1.128 | 3.720 | 5.405 | |

| SR-W50 | 3.911 | 0.197 | 0.121 | 0.177 | 3.519 | 5.707 | (39) |

| SR-W60 | 5.501 | 0.237 | 0.142 | 0.126 | 2.928 | 4.884 | |

| S-2 | 2.516 | 0.159 | 0.103 | 0.275 | 4.363 | 6.704 | This work |

| S-3 | 5.828 | 0.143 | 0.097 | 0.119 | 4.864 | 7.147 | |

| S-4 | 4.237 | 0.150 | 0.100 | 0.164 | 4.608 | 6.928 | |

4 Conclusion

In order to evaluate their radiation-shielding capabilities, we produced flexible composites employing SR or polydimethylsiloxane as the matrix and WO3 and BaO nanoparticles as fillers. Utilizing an experimental technique, the LAC values for the developed composites were reported to range from 0.059 to 1.333 MeV. We observed a high increase in the LAC at low energy, which suggests that the attenuation performance of these composites is greatly influenced by the presence of WO3 and BaO. At higher energies, the LAC values for S2, S3, and S4 are quite comparable, which indicates that at higher energies, the variation in radiation attenuation characteristics caused by the inclusion of WO3 and BaO gets less important. We prepared double-layer SR samples (coded as S-5 and S-6) and compared the TF among S-2, S-3, S5, and S-6 to determine the effect of using a double layer on the transmission of the photons via the prepared SR. At 0.059 MeV, the TF is higher for the two-layered SR (S-5 and S-6) in comparison to the one-layered A-3. But the TF for S-5 and A-6 is lower than S-2. We concluded that the combinations of two layers have a positive influence on TF at 0.059 MeV in comparison to S-3, but does not reach the quality of S-2. The HVL results revealed that S-1 (free of WO3 and BaO) needs a higher thickness to attenuate photons by 50% compared to S-2, S-3, and S-4. S-2 has lower HVL than S-1 and varied between 0.28 and 6.70 cm at 1.333 MeV. This implies that S-2 is a better radiation attenuator than S-1, necessitating a thinner thickness to accomplish a comparable level of radiation attenuation.

-

Funding information: The authors express their gratitude to Princess Nourah bint Abdulrahman University Researchers Supporting Project number (PNURSP 2023R57), Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia.

-

Author contributions: Dalal A. Alorain: writing – original draft, formal analysis; Aljawhara H. Almuqrin: funding, formal analysis, visualization, project administration; M. I. Sayyed: formal analysis, visualization, writing – original draft, formal analysis; resources; Mohamed Elsafi: methodology, concept, writing – review and editing, formal analysis.

-

Conflict of interest: The authors state no conflict of interest.

References

(1) Kozlovskiy AL, Zdorovets MV. Effect of doping of Ce4+/3+ on optical, strength and shielding properties of (0.5-x)TeO2-0.25MoO-0.25Bi2O3-xCeO2 glasses. Mater Chem Phys. 2021;263:124444.10.1016/j.matchemphys.2021.124444Search in Google Scholar

(2) Chaiphaksa W, Borisut P, Chanthima N, Kaewkhao J, Sanwaranatee NW. Mathematical calculation of gamma rays interaction in bismuth gadolinium silicate glass using WinXCom program. Mater Today Proc. 2022;65:2412–5.10.1016/j.matpr.2022.05.529Search in Google Scholar

(3) Acikgoz A, Demircan G, Yılmaz D, Aktas B, Yalcin S, Yorulmaz N. Structural, mechanical, radiation shielding properties and albedo parameters of alumina borate glasses: Role of CeO2 and Er2O3. Mater Sci Eng B. 2022;276:115519.10.1016/j.mseb.2021.115519Search in Google Scholar

(4) Zubair M, Ahmed E, Hartanto D. Comparison of different glass materials to protect the operators from gamma-rays in the PET using MCNP code. Radiat Phys Chem. 2022;190:109818.10.1016/j.radphyschem.2021.109818Search in Google Scholar

(5) Aygün B. High alloyed new stainless steel shielding material for gamma and fast neutron radiation. Nucl Eng Technol. 2020;52:647–53.10.1016/j.net.2019.08.017Search in Google Scholar

(6) Aygün B. Neutron and gamma radiation shielding Ni based new type super alloys development and production by Monte Carlo Simulation technique. Radiat Phys Chem. 2021;188:109630.10.1016/j.radphyschem.2021.109630Search in Google Scholar

(7) Issa SAM, Kumar A, Sayyed MI, Dong MG, Elmahroug Y. Mechanical and gamma-ray shielding properties of TeO2-ZnO-NiO glasses. Mater Chem Phys. 2018;212:12–20.10.1016/j.matchemphys.2018.01.058Search in Google Scholar

(8) Sayyed MI, Mhareb MHA, Alajerami YSM, Mahmoud KA, Imheidat MA, Alshahri F, et al. Optical and radiation shielding features for a new series of borate glass samples. Optik. 2021;239:166790.10.1016/j.ijleo.2021.166790Search in Google Scholar

(9) Geidam IG, Matori KA, Halimah MK, Chan KT, Muhammad FD, Ishak M, et al. Oxide ion polarizabilities and gamma radiation shielding features of TeO2–B2O3–SiO2 glasses containing Bi2O3 using Phy-X/PSD software. Mater Today Comm. 2022;31:103472.10.1016/j.mtcomm.2022.103472Search in Google Scholar

(10) Aktas B, Acikgoz A, Yilmaz D, Yalcin S, Dogru K, Yorulmaz N. The role of TeO2 insertion on the radiation shielding, structural and physical properties of borosilicate glasses. J Nucl Mater. 2022;563:153619.10.1016/j.jnucmat.2022.153619Search in Google Scholar

(11) Nazlıcan S¸, Bozkurt AM, Karabul YA, Kılıç M, Ozdemir ZG. Low cost radiation shielding material for low energy radiation applications: Epoxy/Yahyali Stone composites. Prog Nucl Energy. 2021;135:103703.10.1016/j.pnucene.2021.103703Search in Google Scholar

(12) Korkut T, Umaç ZI, Aygün B, Karabulut A, Yapıcı S, Sahin R. Neutron equivalent dose rate measurements of gypsum-waste tire rubber layered structures. Int J Polym Anal Charact. 2013;18:423–9.10.1080/1023666X.2013.814025Search in Google Scholar

(13) Prasad R, Pai AR, Oyadiji SO, Thomas S, Parashar SKS. Utilization of hazardous red mud in silicone rubber/MWCNT nanocomposites for high performance electromagnetic interference shielding. J Clean Prod. 2022;377:134290.10.1016/j.jclepro.2022.134290Search in Google Scholar

(14) Özdemir T, Yılmaz SN. Mixed radiation shielding via 3-layered polydimethylsiloxane rubber composite containing hexagonal boron nitride, boron (III) oxide, bismuth (III) oxide for each layer. Radiat Phys Chem. 2018;152:17–22.10.1016/j.radphyschem.2018.07.007Search in Google Scholar

(15) Özdemir T, Güngör A, Akbay IK, Uzun H, Babucçuoglu Y. Nano lead oxide and epdm composite for development of polymer based radiation shielding material: Gamma irradiation and attenuation tests. Radiat Phys Chem. 2018;144:248–55.10.1016/j.radphyschem.2017.08.021Search in Google Scholar

(16) Kim S, Ahn Y, Song SH, Lee D. Tungsten nanoparticle anchoring on boron nitride nanosheet-based polymer nanocomposites for complex radiation shielding. Compos Sci Technol. 2022;221:109353.10.1016/j.compscitech.2022.109353Search in Google Scholar

(17) Nagaraj N, Manjunatha HC, Vidya YS, Seenappa L, Sridhar KN, Damodara PS. Investigations on Lanthanide polymers for radiation shielding purpose. Radiat Phys Chem. 2022;199:110310.10.1016/j.radphyschem.2022.110310Search in Google Scholar

(18) Ekinci N, Mahmoud KA, Sarıtas S, Aygün B, Hessien AA, Bilici I, et al. Development of Tincal based polypropylene polymeric materials for radiation shielding applications: Experimental, theoretical, and Monte Carlo investigations. Mater Sci Semicond Process. 2022;146:106696.10.1016/j.mssp.2022.106696Search in Google Scholar

(19) Almurayshid M, Alsagabi S, Alssalim Y, Alotaibi Z, Almsalam R. Feasibility of polymer-based composite materials as radiation shield. Radiat Phys Chem. 2021;181:109425.10.1016/j.radphyschem.2021.109425Search in Google Scholar

(20) Sharma A, Sayyed MI, Agar O, Tekin HO. Simulation of shielding parameters for TeO2-WO3-GeO2 glasses using FLUKA code. Results Phys. 2019;13:102199.10.1016/j.rinp.2019.102199Search in Google Scholar

(21) Fidan M, Acikgoz A, Demircan G, Yilmaz D, Aktas B. Optical, structural, physical, and nuclear shielding properties, and albedo parameters of TeO2–BaO–B2O3–PbO–V2O5 glasses. J Phys Chem Solids. 2021;163:110543.10.1016/j.jpcs.2021.110543Search in Google Scholar

(22) Kumar A, Gaikwad DK, Obaid SS, Tekin HO, Agar O, Sayyed MI. Experimental studies and Monte Carlo simulations on gamma ray shielding competence of (30 + x)PbO-10WO3-10Na2O−10MgO–(40-x)B2O3. Prog Nucl Energy. 2020;119:103047.10.1016/j.pnucene.2019.103047Search in Google Scholar

(23) Al-Hadeethi Y, Tijani SA. The use of lead-free transparent 50BaO-(50-x)borosilicate-xBi2O3 glass system as radiation shields in nuclear medicine. J Alloy Compd. 2019;803:625–30.10.1016/j.jallcom.2019.06.259Search in Google Scholar

(24) Sayyed MI, Al-Ghamdi H, Almuqrin AH, Yasmin S, Elsafi M. A study on the gamma radiation protection effectiveness of nano/Micro-MgO-reinforced novel silicon rubber for medical applications. Polymers. 2022;14:2867.10.3390/polym14142867Search in Google Scholar PubMed PubMed Central

(25) Hannachi E, Sayyed MI, Slimani Y, Elsafi M. Experimental investigation on the physical properties and radiation shielding efficiency of YBa2Cu3Oy/M@M3O4 (M = Co, Mn) ceramic composites. J Alloy Compd. 2022;904:164056.10.1016/j.jallcom.2022.164056Search in Google Scholar

(26) Al-Ghamdi H, Elsafi M, Almuqrin AH, Yasmin S, Sayyed MI. Investigation of the gamma-ray shielding performance of CuO-CdO-Bi2O3 Bentonite ceramics. Materials. 2022;15:5310.10.3390/ma15155310Search in Google Scholar PubMed PubMed Central

(27) Al-Ghamdi H, El-Nahal MA, Saleh IH, Elsafi M, Sayyed MI, Almuqrin AH. Determination of 238U and 40K radionuclide concentrations in some granite rocks by gamma spectroscopy and energy dispersive X-ray analysis. Materials. 2022;15:5130.10.3390/ma15155130Search in Google Scholar PubMed PubMed Central

(28) Sayyed MI, Yasmin S, Almousa N, Elsafi M. The radiation shielding performance of polyester with TeO2 and B2O3. Processes. 2022;10:1725.10.3390/pr10091725Search in Google Scholar

(29) Sayyed MI, Hashim S, Hannachi E, Slimani Y, Elsafi M. Effect of WO3 nanoparticles on the radiative attenuation properties of SrTiO3 perovskite ceramic. Crystals. 2022;12(11):1602.10.3390/cryst12111602Search in Google Scholar

(30) Sayyed MI, Almurayshid M, Almasoud FI, Yasmin S, Elsafi M. Developed a new radiation shielding absorber composed of waste marble, polyester, PbCO3, and CdO to reduce waste marble considering environmental safety. Materials. 2022;15(23):8371.10.3390/ma15238371Search in Google Scholar PubMed PubMed Central

(31) Aloraini DA, Elsafi M, Almuqrin AH, Sayyed MI. Coincidence summing factor calculation for volumetric γ-ray sources using Geant4 simulation. Sci Technol Nucl Install. 2022;2022:5718920.10.1155/2022/5718920Search in Google Scholar

(32) D’Souza AN, Padasale B, Murari MS, Almuqrin AH, Kamath SD. TeO2 for enhancing structural, mechanical, optical, gamma and neutron radiation shielding performance of bismuth borosilicate glasses. Mater Chem Phys. 2023;293:126657.10.1016/j.matchemphys.2022.126657Search in Google Scholar

(33) Hannachi E, Sayyed MI, Slimani Y, Elsafi M. Structural, optical and radiation shielding peculiarities of strontium titanate ceramics mixed with tungsten nanowires: An experimental study. Optic Mater. 2023;135:113317.10.1016/j.optmat.2022.113317Search in Google Scholar

(34) Elsafi M, Almousa N, Al-Harbi N, Yasmin S, Sayyed MI. Ecofriendly and radiation shielding properties of newly developed epoxy with waste marble and WO3 nanoparticles. J Mater Res Technol. 2023;22:269–77.10.1016/j.jmrt.2022.11.128Search in Google Scholar

(35) Hannachi E, Sayyed MI, Slimani Y, Baykal A, Elsafi M. Structure and radiation-shielding characteristics of BTO/MnZnFeO ceramic composites. J Phys Chem Solids. 2023;174:111132.10.1016/j.jpcs.2022.111132Search in Google Scholar

(36) Sayyed MI, Almousa N, Elsafi M. Green conversion of the hazardous cathode ray tube and red mud into radiation shielding concrete. Materials. 2022;15(15):5316.10.3390/ma15155316Search in Google Scholar PubMed PubMed Central

(37) Almuqrin AH, Elsafi M, Yasmin S, Sayyed MI. Morphological and gamma-ray attenuation properties of high-density polyethylene containing bismuth oxide. Materials. 2022;15:6410.10.3390/ma15186410Search in Google Scholar PubMed PubMed Central

(38) Elsafi M, ALasali HJ, Almuqrin AH, Mahmoud KG, Sayyed MI. Experimental assessment for the photon shielding features of silicone rubber reinforced by tellurium borate oxides. Nucl Eng Technol. 2023;55(6):2166–71.10.1016/j.net.2023.02.022Search in Google Scholar

(39) Al-Ghamdi H, Hemily HM, Saleh IH, Ghataas ZF, Abdel-Halim AA, Sayyed MI, et al. Impact of WO3-nanoparticles on silicone rubber for radiation protection efficiency. Materials. 2022;15(16):5706.10.3390/ma15165706Search in Google Scholar PubMed PubMed Central

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites