Abstract

Biomass films with ultraviolet (UV)-shielding ability have attracted considerable attention. Curcumin was introduced into castor oil-based polyurethane (CCPU) as a chain extender, which was melt with polylactic acid (PLA) as a reinforcement to obtain biomass UV-shielding film. The excellent UV absorption and antioxidant qualities of curcumin contributed to the impressive UV-shielding capacity (97.6% UV radiation absorption) and antioxidant (51% free radical scavenging) of PLA/CCPU-20 film. In the scanning electron microscopic images of film fracture, the mixing of CCPU elastomer into the PLA matrix caused the blend films to exhibit significant toughening fracture characteristics compared to the pure PLA film. The excellent thermal stability, low water swelling degree, and low water solubility of PLA/CCPU blend films were maintained after CCPU was added to the PLA matrix. Therefore, the PLA/CCPU blend films can be considered as a potential packaging material because of its favorable UV-shielding properties and film stability.

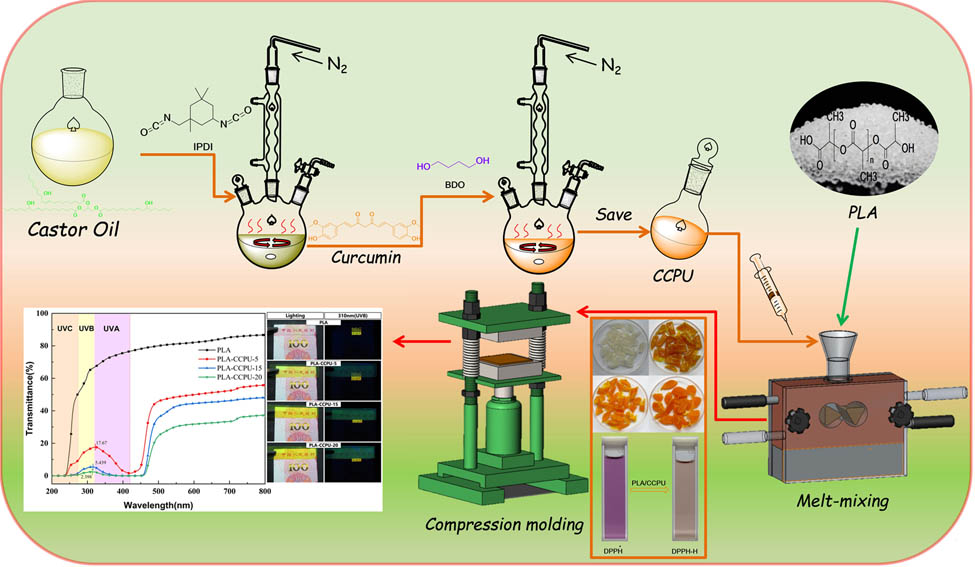

Graphical abstract

Schematic for the preparation of the PLA/CCPU blend films.

1 Introduction

Food and organic industrial products may deteriorate or age if directly exposed to ultraviolet (UV) light (1,2,3,4,5). Traditional packaging and coating materials such as rubber, plexiglas, paints, dyes, and paper often focus only on mechanical properties and overlook the damage of UV rays (6), which will greatly affect the beauty and safety of the product. Research into packaging materials with UV-shielding capabilities is urgently needed. On the other hand, functional biomass materials are constantly being proposed and improved in the hope of replacing traditional plastics (7,8). The large volume of plastic products used in the packaging industry per year has accelerated the depletion of fossil resources and caused uncontrollable environmental pollution problems (9,10). Therefore, it is particularly important to more actively use biomass materials as substrates to prepare UV-shielding blend (composite) films that can absorb UV radiation.

In recent years, functional biomass fillers with UV-shielding properties have been intensively researched (11). It was found that the main components of some renewable natural resources, such as phenols and ketones (12), can effectively block UV radiation. Common biomass materials with UV absorption capacity include lignin (13,14,15), amaranth (16), curcumin (17), and grape seed (18). In particular, curcumin is an easily available hydroxyl-terminated natural compound that can be isolated from the plant Curcuma longa and used as a phyto-polyphenol pigment, which is safe and nontoxic and has excellent antioxidant and antibacterial properties (19,20,21). Curcumin is a diketone natural pigment with both benzene ring and ketone carbonyl structures in its molecular structure, and benefiting from the combined action of adjacent carbon–carbon double bonds and carbonyl groups, curcumin can effectively absorb a wide range of UV rays (22,23). However, the absorption of UV radiation by curcumin also imposes limitations on its bioavailability, and curcumin is extremely unstable under sunlight when used alone (24,25). Surprisingly, the preparation and application of curcumin-based biomass materials may be a way to alleviate this limitation. Several studies (26,27) have shown that grafting small molecules onto the backbone or side chains of polymers is an innovative strategy to obtain the functional polymers. Curcumin can be introduced into polyurethane (PU) molecules as a chain extender through the reaction of the terminal hydroxyl group with the isocyanate group (–NCO) without destroying the benzene ring and ketone carbonyl structure of curcumin itself (28), which means that the UV-shielding ability of curcumin can be retained after the chemical cross-linking (29,30). Curcumin-based PU is an environment-friendly material that can be greatly used as a blend component to toughen and modify conventional polymers (31,32,33). Furthermore, it has been documented that curcumin can be ideally dispersed during the preparation of curcumin-based PUs, thus avoiding the problem of poor utilization of curcumin due to potential agglomeration (34) and ensuring that curcumin can be firmly linked to the PU backbone, which in turn prevent a significant migration of curcumin (35,36,37). Therefore, it can be inferred that the stability of curcumin in curcumin-based PUs is also applicable to other blend systems in which polymers are mixed with curcumin-based PUs.

In the packaging, polylactic acid (PLA)-based materials with UV-shielding capabilities are also highly anticipated (38). PLA is derived from renewable resources (e.g., corn), and it is an easily accessible biomass material that is environment-friendly (39,40). In recent years, PLA has attracted a lot of attention from researchers because of its advantages such as excellent transparency, thermoplastics, and nontoxicity (41,42). However, the disadvantages of pure PLA, such as brittleness, limited ductility, and photodegradation of the pure PLA film under UV light, have restricted the promotion of PLA materials in packaging (43). Therefore, it is necessary to obtain PLA-based packaging, such as functional blend films, to handle the specific protection needs of different products (44,45,46). Blending pure PLA with functional fillers is one of the promising and effective methods to prepare the PLA-based blend films with UV-shielding capability (47,48,49).

Generally, the processing methods of PLA can be divided into two categories: dry processing and wet processing (50). In addition, the solution-casting method and melt co-mingling molding process are two more mature technological methods. Considering the disadvantages of the solution-casting method for the film production (51,52), such as long processing time, difficulty in controlling the volatilization of harmful solvent, and unsuitability for the large-scale industrial production, it may be more reasonable to use a more industrialized method for the film production. In some studies, melt mixing and compression molding have been indicated to have the potential to efficiently produce the PLA/PU uniform blends without excessive dependence on solvents (53,54). Therefore, preparing a curcumin-based PU and then compounding it with pure PLA by the melt co-mingling molding process (melt mixing and compression molding) is a worthwhile attempt to process UV-shielding films.

In summary, in this article, the PLA-based blend films containing 5, 15, and 20 wt% castor oil-based polyurethane (CCPU) were built by melt mixing and compression molding to block UV radiation. Furthermore, besides the desire to obtain better UV-shielding films compared to the pure PLA film, we also reported in detail the chemical properties, optical properties, mechanical properties, thermal stability, antioxidant activity, and water contact properties of the PLA/CCPU blend films which we wish to prepare to evaluate their potential usefulness.

2 Experimental section

2.1 Materials

PLA (Ingeo 4032D, M n = 25,000 g·mol−1) pellets were obtained from NatureWorks LLC (Minnesota, USA). Prior to melt compounding, PLA pellets were oven-dried at 80°C for 24 h. Castor oil (M w = 933.44 g·mol−1, USP), isophorone diisocyanate (IPDI, M w = 222.28 g·mol−1, ≥99%), and 2,2-diphenyl-1-picrylhydrazyl (DPPH, ≥97%, HPLC) were purchased from Aladdin (Shanghai, China) Co., Ltd. Curcumin (C21H20O6, M w = 368.38 g·mol−1, ≥98%) and 1,4-butanediol (BDO, M w = 90.12 g·mol−1, ≥99%) were obtained from Adamas-beta. Acetone (≥99.5%, AR) and methanol (≥99.5%, AR) were available from Sinopharm Chemical Reagent Co., Ltd. Acetone was stored in a 4 Å molecular sieve for further use. All chemicals were used without additional purification.

2.2 Preparation of CCPU

The preparation methods of thermoplastic polyurethane (TPU) have been reported in several studies (55). In this article, it was first necessary to obtain CCPU that cross-linked curcumin and to retain an excess of –NCO in the fabricated samples. Typically, IPDI (27 mmol, 6 g) and castor oil (10.7 mmol, 10 g) were added into a three-necked round-bottomed flask, stirred, and heated at a temperature of 80°C under nitrogen atmosphere for 2 h. Next, curcumin (0.8 mmol, 0.3 g) was added into the reaction for 1 h to help TPU exhibit a great UV-shielding ability. At this point, the addition of 5–10 mL acetone can help curcumin react more completely. Finally, the reaction was continued for 1 h using BDO (5.5 mmol, 0.5 g) as a chain extender for PU. The resulting viscous fluid was the CCPU. The nonreactive –NCO in the CCPU was retained with 9.3 mmol. The CCPU was cooled to room temperature under vacuum conditions, bottled and sealed, and stored in 4 Å molecular sieve for additional use.

2.3 Fabrication of PLA/CCPU blend films

The pure PLA melt and PLA/CCPU blends containing 5, 15, and 20 wt% CCPU were obtained by melt mixing in an internal mixer (SU-70; Suyan Science & Technology Co., Ltd, Changzhou, China). The rotation speed of the internal mixer was set at 30 rpm, and PLA was mixed with CCPU at 180°C for 15 min. Subsequently, the PLA/CCPU blends were pressed by a hot presser (R-3212; Wuhan Qien Science & Technology Development Co., Ltd, Wuhan, China) at 180°C and 10 MPa for 5 min, and the blend films were obtained from a mold (100 mm × 10 mm × 0.15 ± 0.05 mm) for characterization. The nomenclature of the PLA/CCPU blend films was abbreviated as PLA/CCPU-X, where X indicates the weight percentage of CCPU in the blend films (X includes 0, 5, 15, and 20).

3 Film testing and performance characterization

3.1 Fourier transform infrared (FT-IR)

The chemical analysis of the PLA/CCPU blend films was performed in the 4,000–300 cm−1 range using a spectrometer (Nicolet iS50, Thermo Scientific, Britain) in attenuated total reflection (ATR) infrared mode.

3.2 Scanning electron microscopy (SEM)

The cross-sectional morphology of the PLA/CCPU blend films was measured on an SEM (FEI Quanta 200, Netherlands). PLA/CCPU blend films that were treated with two different methods (cryo-fractured and tensile fracture) and sprayed with gold for 90 s were characterized at 5 kV under a high-vacuum mode. Images were captured at 1,000× magnification using SEM.

3.3 Ultraviolet-visible spectroscopy (UV-Vis)

The UV-shielding ability of the blend films was determined using an UV-Vis spectrometer (Ultrospec 2000; Scinteck, UK) in the wavelength range of 200–800 nm. The size of the film samples for testing was selected as 60 mm × 50 mm × 0.15 ± 0.05 mm.

3.4 Transmittance (T) and haze (H)

The T and H of the blend films were estimated using an optical tester (TH-09; Hangzhou Color Spectrum Technology Co., LTD, Hangzhou, China), according to ASTM D1003-00 (2000).

3.5 Thermogravimetry analysis (TGA)

The TGA of the blend films (10 mg) was performed in the range of 25–600°C on a TGA device (STA7300; Hitachi Limited, Japan), under N2 atmosphere, whose flow rate was set as 20 mL·min−1 with a heating rate of 10°C·min−1.

3.6 Mechanical properties

The tensile properties of the PLA/CCPU blend films were measured on a universal tensile tester (Instron 3343, USA), equipped with a 5 KN load cell and with a crosshead speed set as 1 mm·min−1. A suitable film size (55 mm × 5 mm × 0.15 ± 0.05 mm) was cut, and the distance between grips was set as 5 mm to test the tensile properties, according to ASTM D882-12.

3.7 Water contact angle (WCA)

The WCA of the blend films was recorded on an optical, high-speed, contact angle-measuring system (CAST3, KINO, USA), and the images were acquired and evaluated by built-in software of the machine to estimate the surface wettability of films.

3.8 Swelling degree (SD) and solubility (S)

The SD and S of the blend films were estimated through Eqs. 1 and 2 (56). In the test, the film samples were first cut into pieces of a suitable size (1.5 cm × 1.5 cm) and dried at 105°C for 24 h (record the weight of the pieces as W i). Then, the dry pieces were immersed in 40 mL of distilled water for 24 h, and the filter paper was used to discard the excess of liquid water before each weight (record the weight of the pieces as W swollen). Finally, the pieces were dried again at 105°C for 24 h (record the weight of the pieces as W s).

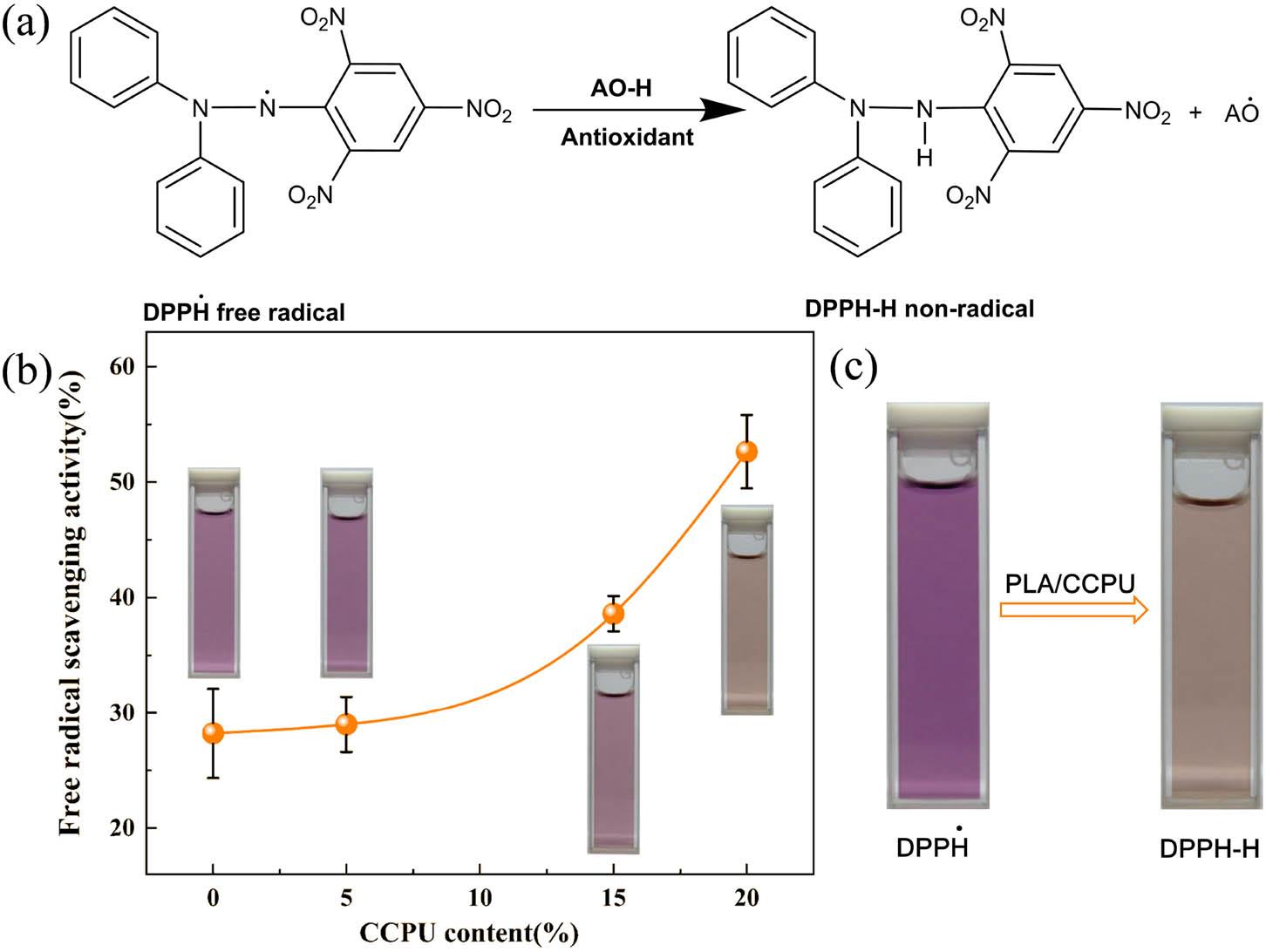

3.9 Antioxidant activity of the films

The antioxidant activity of the blend films was measured by the DPPH free radical scavenging method (57). First, DPPH solution was prepared by dissolving 0.004% DPPH in methanol. Second, 50 mg of samples from each of the four films (PLA, PLA/CCPU-5, -15, and -20) was taken in four brown bottles containing 10 mL of DPPH solution and was incubated in the dark for 30 min, and then, the UV-vis absorbance of the four incubated solutions at 517 nm was measured using a UV-vis spectrophotometer (Ultrospec 2000; Scinteck, UK), and the data were recorded as A 1. The DPPH solution without the addition of sample was used as a control, and it was also tested at the UV-vis absorbance at 517 nm, and the data were recorded as A 0. Finally, the free radical scavenging rate was calculated using Eq. 3 to estimate the antioxidant activity of PLA/CCPU blend films:

where A 0 and A 1 represent the absorbance of the control group and the experimental group, respectively. Ideally, the test samples should be tested in triplicate.

4 Results and discussion

4.1 Chemical analysis

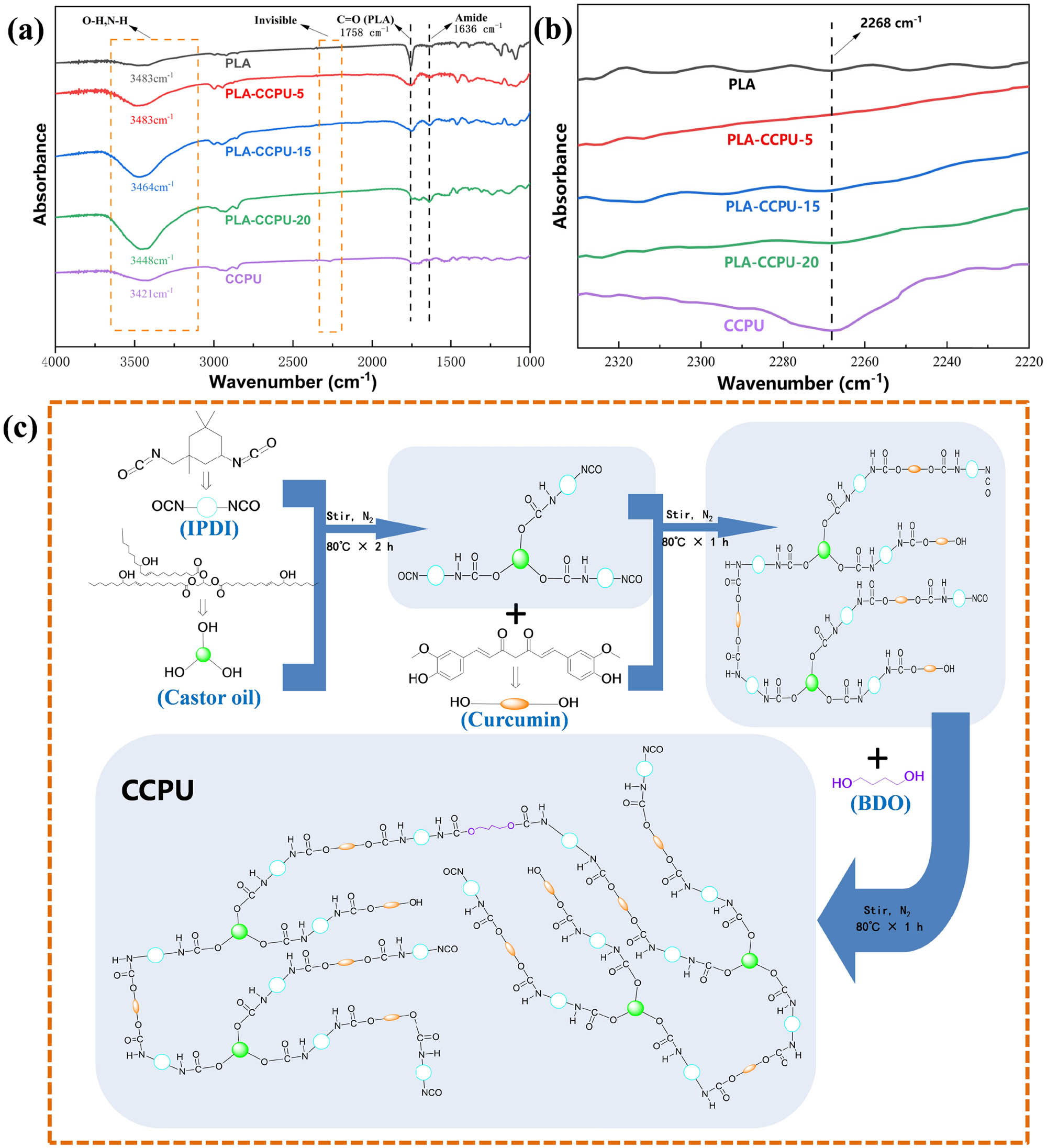

The chemical changes in the PLA/CCPU blend films were investigated by FT-IR-ATR. Spectra for the pure PLA film and PLA/CCPU blend films were collected as references to identify any differences. FT-IR spectra (Figure 1a) indicate that the N–H stretching vibration of CCPU, centered at around 3,421 cm−1, exhibited a significant blue shift from 3,421 to 3,483 cm−1. This is due to the interaction with the stretching vibration of the PLA ester O–H group and the CCPU ester N–H group (58). The stretching vibration of the PLA ester C═O groups at 1,758 cm−1 can be clearly identified from these PLA/CCPU blend films. Additionally, the amide bands (i.e., C═O stretching) at 1,636 cm−1 are also clearly visible in all of the PLA/CCPU blend films. The presence of these characteristic bands associated with amide groups confirms the existence of CCPU in the PLA/CCPU blend films (59). Notably, the PLA/CCPU blend films showed a significant absence of the –NCO absorption band at 2,268 cm−1 (Figure 1b), which indicates that IPDI has been totally reacted in the melt mixing. The absorption peak at 2,268 cm−1 of CCPU in the FT-IR spectra is attributed to the unreacted −NCO during the process of CCPU preparation, which is consistent with the fact.

(a) FT-IR spectra of the CCPU and four films (PLA, PLA/CCPU-5, -15, and -20). (b) FT-IR spectra near the wavenumbers at 2,268 cm−1. (c) Schematic diagram illustrating possible reaction mechanism of CCPU.

Based on the aforementioned results, the reaction mechanism of synthetic CCPU is illustrated schematically in Figure 1c. Castor oil reacted with excess IPDI to form a short-chain molecular structure, and then curcumin and BDO were added for chain extension to obtain CCPU.

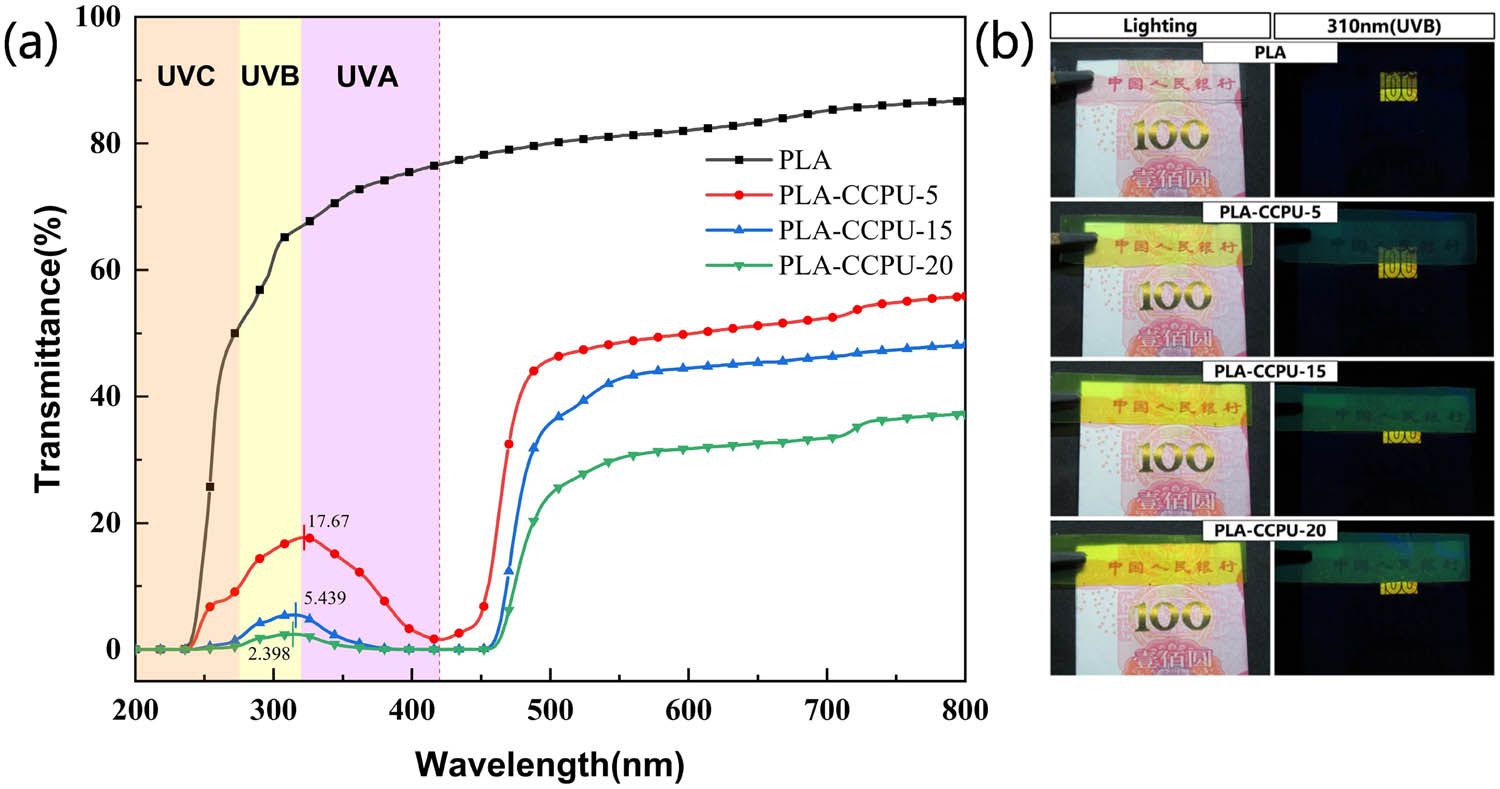

4.2 UV protection

Figure 2a gives the UV-vis light spectra of the PLA/CCPU blend films in the wavelength range of 200–800 nm. Figure 2b illustrates a comparative experiment in which the fluorescence anti-counterfeiting features on the banknote were covered by four different films (PLA, PLA/CCPU-5, −15, and −20), and then irradiated with ultraviolet light (UVB, 310 nm). The purpose of the experiment was to determine whether ultraviolet light could pass through the PLA/CCPU blend films by observing the clarity of the anti-counterfeiting marks. In the UV-vis light spectra, the pure PLA film shows a significant T to visible light and UV light. However, with the addition of CCPU, the PLA/CCPU blend films gradually attained a better UV-shielding ability, which exhibited the inhibition enhancement of films’ UV light T in the light wavelength range of 200–400 nm. Meanwhile, the UV light (UVB, 310 nm) could not pass through the PLA/CCPU-20 blend film, and the fluorescence anti-counterfeiting features of banknote have failed lighting by UV light in the comparative experiment (see Figure 2b, PLA/CCPU-20); it is proven that the addition of CCPU could enhance the UV-shielding ability of the PLA/CCPU blend films (60). In general, electronic excitation will be induced within curcumin structure when curcumin is exposed to solar radiation (61). In photochemical studies of UV radiation absorption, on the one hand, the electronic excitation energy is rapidly converted into vibrational energy at the conjugated carbon–carbon double-bond structure and dissipated to the surroundings in the form of heat without damaging the curcumin structure (62,63); on the other hand, the hydrogen atom in hydroxyl group on the benzene ring of curcumin will transfer to the carbonyl group driven by the excitation of electrons, which may be another reason why the excitation energy of electrons is absorbed (64,65).

(a) The UV-vis spectra of the PLA/CCPU blend films (PLA, PLA/CCPU-5, -15, and -20). (b) Demonstration of UV-shielding effect by the PLA/CCPU blend films.

In conclusion, the enhanced UV-shielding capability of the PLA/CCPU blend films is attributed to the increased content of CCPU in the PLA/CCPU blends, and the core reason is the absorption of UV radiation by the conjugated carbon–carbon double-bond structure of curcumin as well as a combination of other reasons.

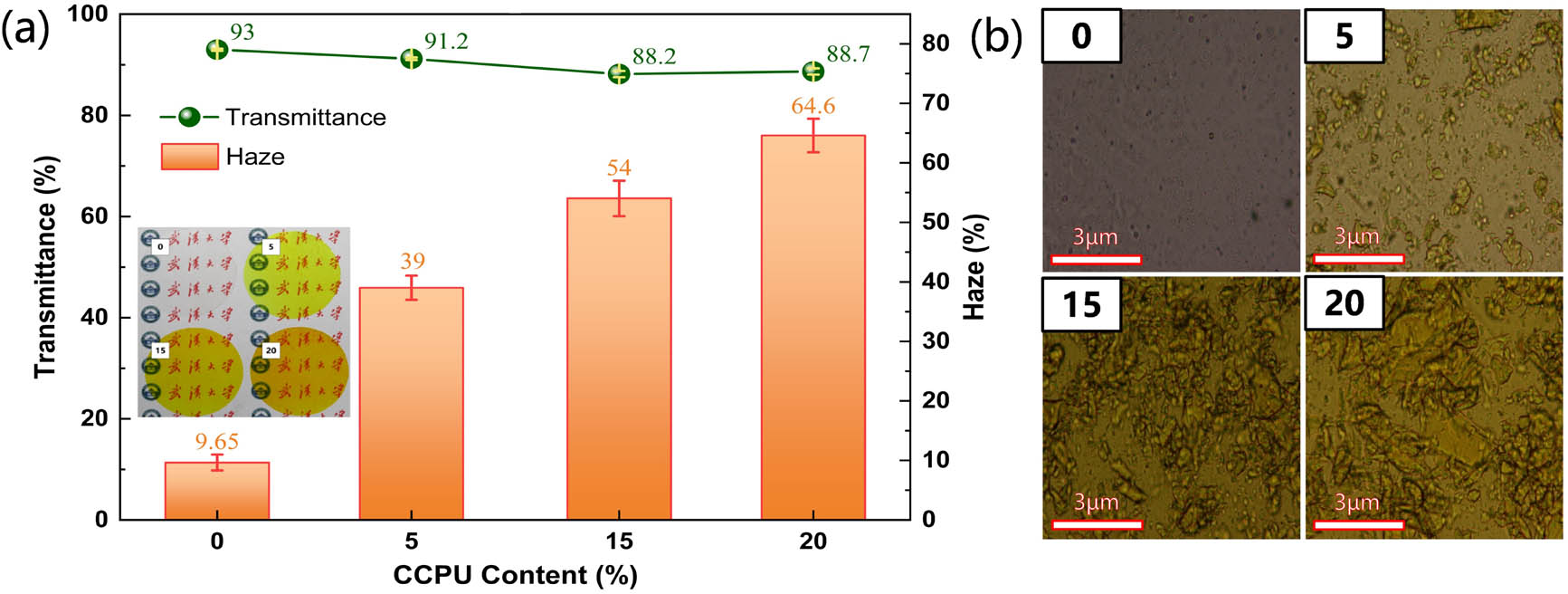

4.3 Optical properties

Light T and H are two important indicators for judging film’s optical properties (66). Figure 3a clearly shows the variation of the PLA/CCPU blend films of light T and H (PLA, PLA/CCPU-5, -15, and -20). In the test results, the pure PLA film has high light T and low H. The PLA/CCPU blend films exhibited an H characteristic because of the different refractive index between PLA and CCPU (67). Moreover, with the increase of CCPU content, the H characteristics of the films became more pronounced. The magnified image of the PLA/CCPU blend films (Figure 3b) revealed that the increase of CCPU particles in the PLA matrix caused the particles to be closer to each other, leading to the aggregation of particles, which resulted in an increasing number of light-scattering microregions that covered a wider area in the PLA/CCPU blend films.

(a) The light T and H of the PLA/CCPU blend films. (b) The images of four films taken by electron microscopy (PLA, PLA/CCPU-5, -15, and -20).

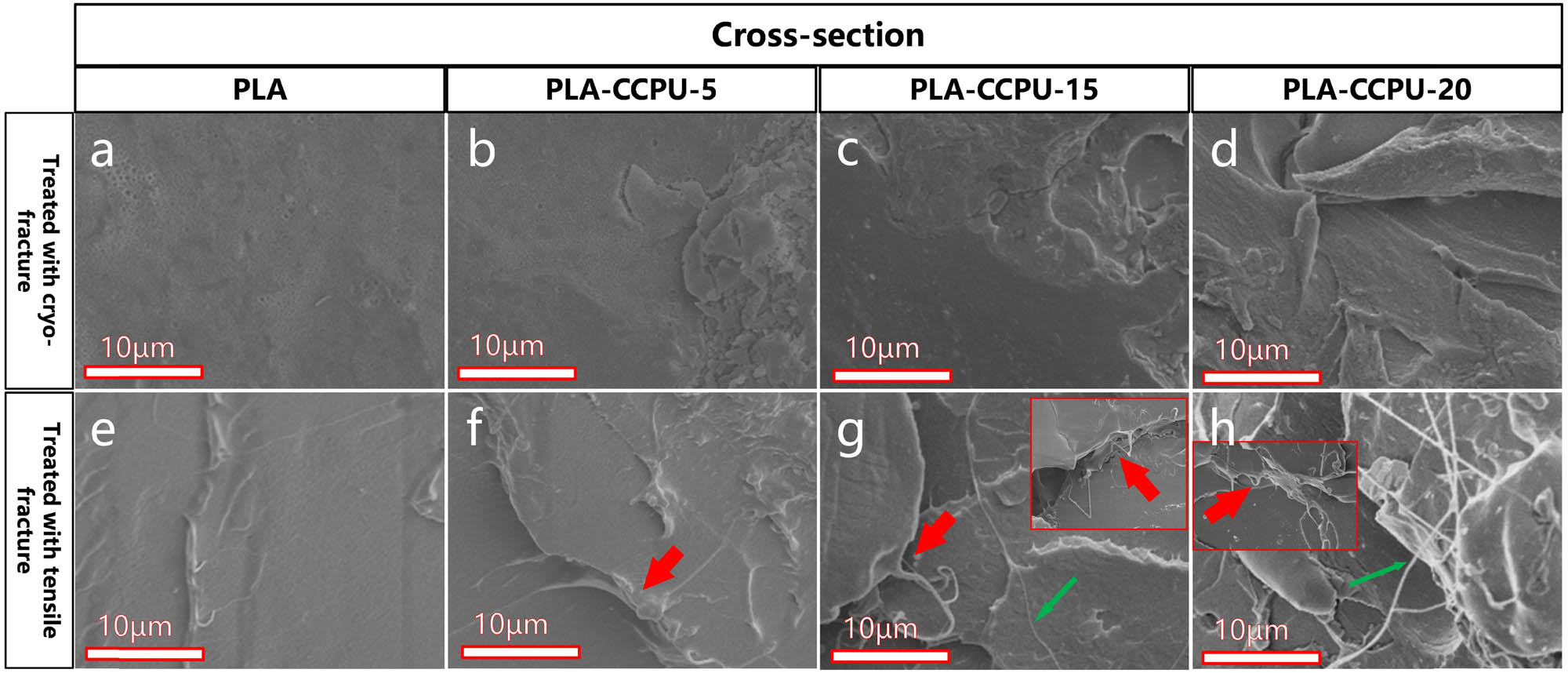

4.4 Microstructural analysis

Figure 4 provides the fracture cross-sectional images of the PLA/CCPU blend films by SEM for two different treatments. One of the SEM views is a cross-sectional image of the blend films treated with cryo-fracture (Figure 4a–d), and the other is treated with tensile fracture (Figure 4e–h). The morphological structure and toughness effect of the PLA/CCPU blend films can be effectively studied. In the SEM images of Figure 4e, the smooth fracture surface observed in the pure PLA film after tensile failure indicates a typical brittle mode fracture of PLA (68). Compared with the pure PLA film, the fracture surface of the PLA/CCPU blend films becomes rougher when the CCPU content reached 5–20 wt%. Moreover, the PLA matrix of the blend films appeared clearly twisted fibers (marked by the red thick arrows) arising from the fracture cross-section, and the PLA fibrous phase (marked by the green thin arrows) induced by the CCPU phase, which together indicate the characteristics of toughened fracture of the PLA/CCPU blend films (69). Meanwhile, we do not observe an obvious separation between the continuous phase (PLA) and the dispersed phase (CCPU) in the SEM images of the PLA/CCPU blend films treated with cryo-fracture (Figure 4f–h). It is indicated that the PLA and CCPU have a great interfacial compatibility (70).

SEM images of the PLA and PLA/CCPU blend films’ cross-section, which used different methods for treating films (treated with cryo-fracture (a–d); treated with tensile fracture (e–h)).

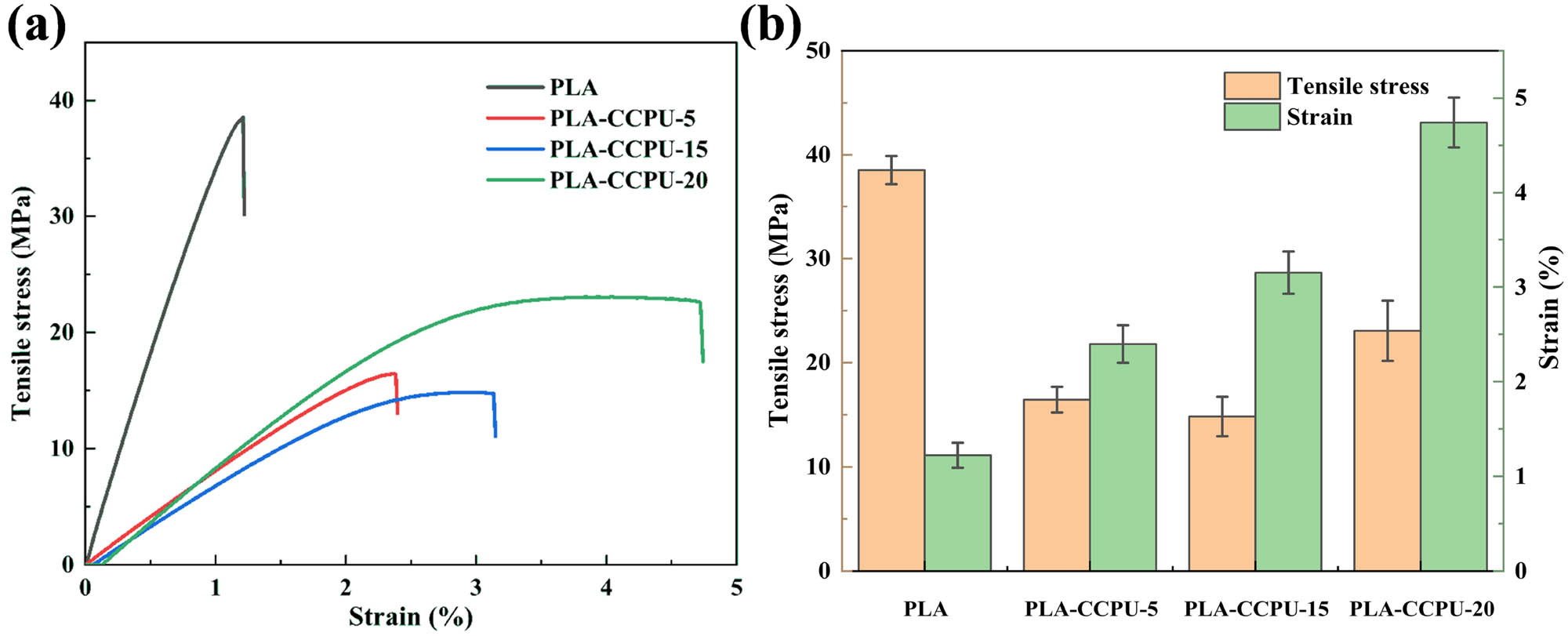

4.5 Mechanical properties

The representative stress–strain curves of the PLA/CCPU blend films with different contents of CCPU are shown in Figure 5a. Pure PLA film shows a typical brittle fracture pattern in stress–strain curves, while the PLA/CCPU blend films exhibited a distinct yielding process after CCPU loaded. In Figure 5b, the elongation at break of four films (PLA, PLA/CCPU-5, -15, and -20) displayed a regular increasing trend from 1.22% to 4.74%, which shows a bit toughness improvement of the PLA film. The SEM images of their films of tensile fracture surface may also explain these mechanical testing results.

The tensile testing of four films (PLA, PLA/CCPU-5, -15, and -20): (a) stress–strain curves and (b) tensile strength and strain histogram to clearly observe the trend of mechanical properties of the PLA/CCPU blend films.

4.6 Thermal properties

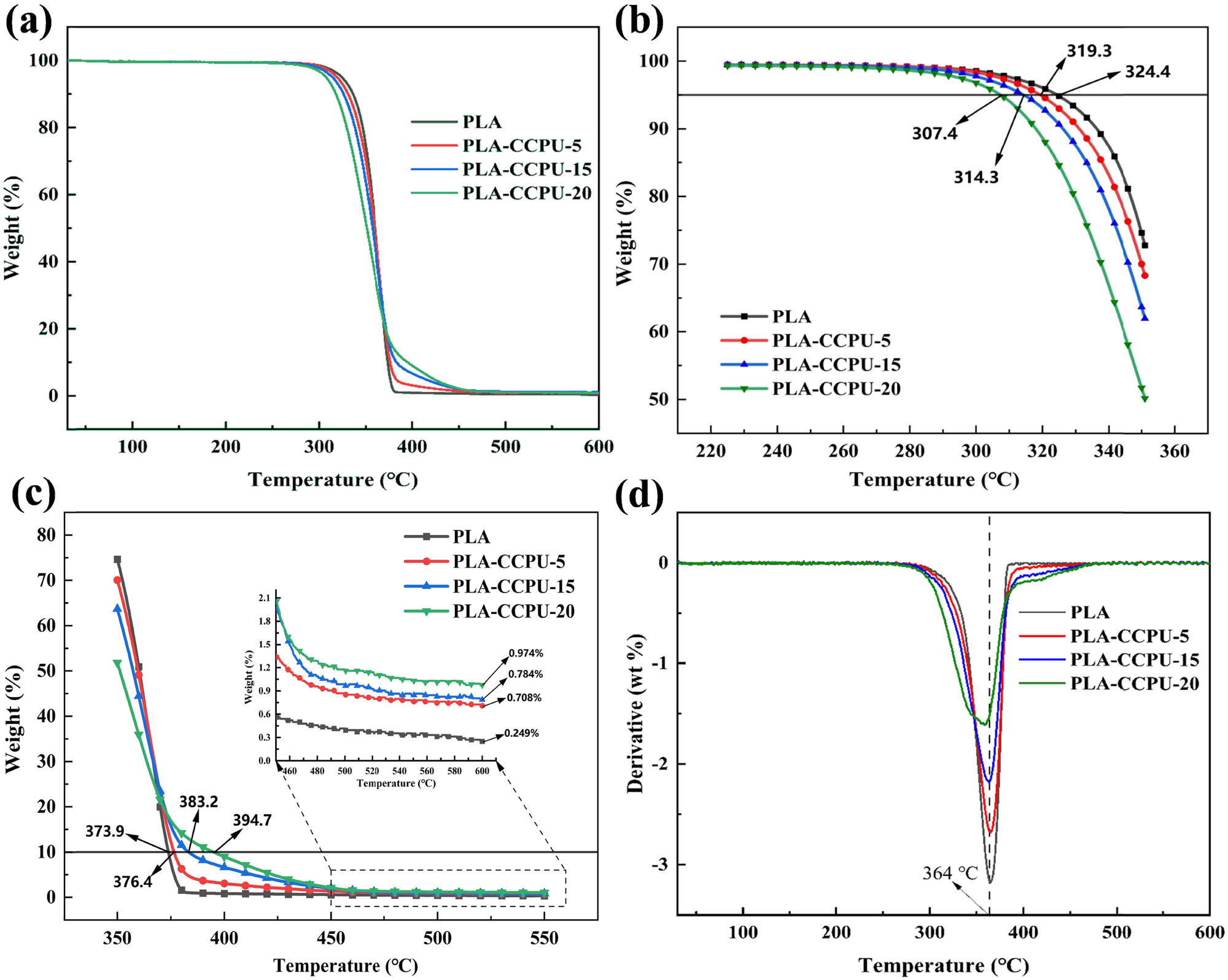

Figure 6 shows the TGA and DTG thermograms to analyze the thermal stability of all PLA/CCPU blend films (PLA, PLA/CCPU-5, -15, and -20). In Figure 6a, all the blend films had a good stability (<0.8 wt% loss) between 0°C and 250°C, which provided compelling evidence that the PLA/CCPU blend films satisfy the common requirement of heat treatment.

TG curves of the PLA/CCPU blend films (PLA, PLA/CCPU-5, -15, and -20): (a) TGA, (b) the local magnification of TGA thermogram (220–350°C), (c) the local magnification of TGA thermogram (350–550°C), and (d) DTG.

In the range of 220–300°C, all blend films that contain the CCPU present a slow mass-losing process compared to the pure PLA film, all due to the common reason that in this work the CCPU does not have structural water and the PU bonds will start to disintegrate at 220°C (71,72). Meanwhile, in Figure 6b, the thermal stability of CCPU at the initial stage of decomposition was estimated using the temperature at which the PLA/CCPU blends lost 5 wt% (T 5) (73). In the results, it was determined that the blend films that contained more CCPU had a stronger thermal instability due to the lower temperature of T 5 for the PLA/CCPU-20 film (T 5-PLA/CCPU-20/307°C < 314°C < 319°C < 324°C). Between the 220 and 360°C range, the addition of CCPU continues to constitute a negative effect of enhanced thermal instability on the PLA/CCPU blend films.

However, the cross-linking of small amounts of curcumin on the PU backbone was demonstrated to intensify the thermal stability of PUs (74), as seen in Figure 6c for T 90 (temperature at which 90 wt% of the blend film was lost), where the curcumin had retarded the thermal degradation of CCPU in the PLA/CCPU blend films due to the presence of benzene ring (T 90-PLA/CCPU-20/394°C > 383°C > 376°C > 373°C). In Figure 6d, pure PLA film and the PLA/CCPU blend films showed a maximum weight loss near 364°C, which may be related to the degradation with the PLA and the CCPU chains (75). With increasing temperature, the PLA or the CCPU that fabricated with a type of aliphatic isocyanate (IPDI) and aliphatic polyol (castor oil) both showed an almost complete degradation at 600°C (76). However, it can be seen in the enlarged view of Figure 6c that the PLA/CCPU blend films still have a mass residue close to 1%, which may be due to the residue of curcumin. This result is similar to another study that curcumin remained nearly 40% residual of mass at 600°C (21), which indirectly reflects that the curcumin was added in very small amounts inside the PLA/CCPU-20 film.

In summary, melting the CCPU with PLA could result in a UV-shielding films with favorable thermal stability, and the thermal stability of the PLA/CCPU blend films is influenced to a degree by the amount of CCPU added and the amount of curcumin added. Fortunately, despite these effects, the PLA/CCPU blend films still have an excellent thermal stability, and it is still possible to process and apply these films at high temperatures.

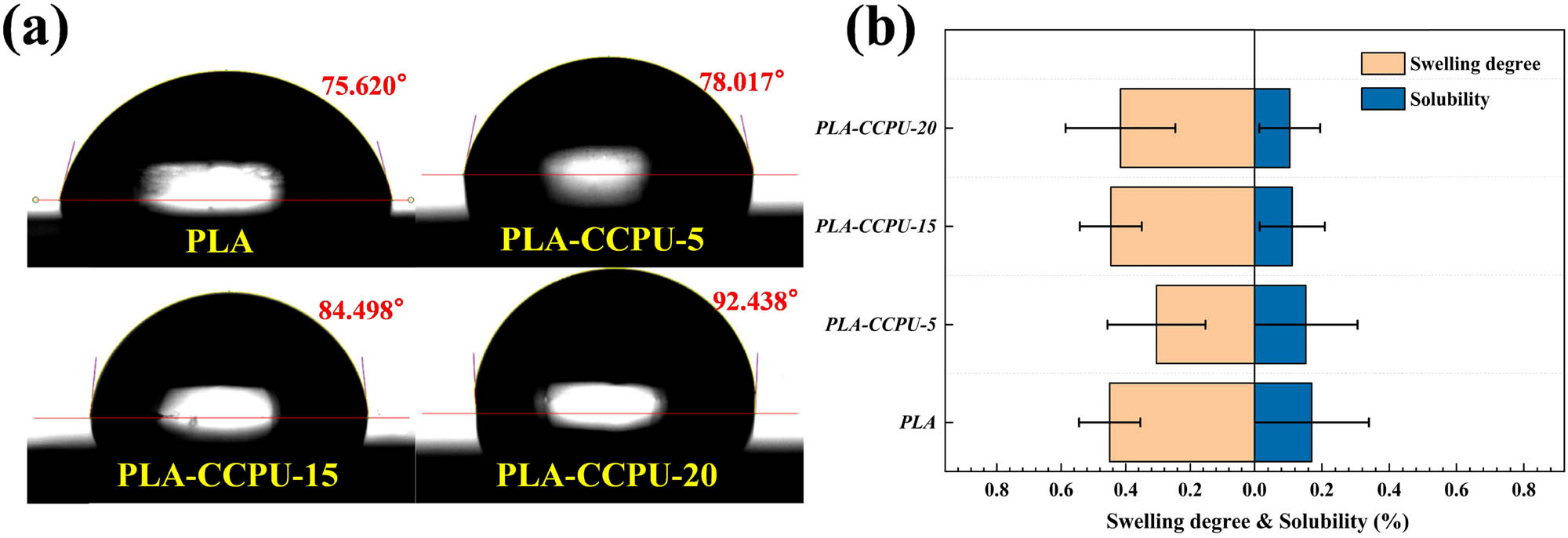

4.7 Interaction with water

Figure 7 illustrates a series of test results of the pure PLA film and the PLA/CCPU blend films’ interaction with distilled water. Figure 7a shows the WCA details of four films (PLA, PLA/CCPU-5, -15, and -20). The WCA value of the PLA/CCPU blend films compared with that of the pure PLA film was increased from 75.62° (PLA) to 92.43° (PLA/CCPU-20) after the CCPU blended with the PLA matrix. On the one hand, the hydrophobic property of the benzene ring on curcumin molecule helped the PLA/CCPU blend films to form a micro-hydrophobic surface (77,78). On the other hand, the local cross-linking between CCPU and the PLA shortens the distance of neighboring PLA long chains in the interior of the PLA/CCPU blend films, which is another reason for the larger WCA value obtained for the PLA/CCPU blend films (79).

(a) The WCA value of the PLA/CCPU blend films (PLA, PLA/CCPU-5, -15, and -20). (b) The SD and S of four films (PLA, PLA/CCPU-5, -15, and -20) in distillation water.

Furthermore, we also tested the water SD and water S of each PLA/CCPU blend film (PLA, PLA/CCPU-5, -15, and -20). The test results were used to verify whether the loading of CCPU would affect the stability of the pure PLA film in distilled water (80,81). In Figure 7b, the pure PLA film and the PLA/CCPU blend films both show low water SD (<0.6 wt%) and low water S (<0.4 wt%). Therefore, the PLA/CCPU blend films may be applied in a humid environment, and they have higher potential to prevent the damage of film’s mechanical properties caused by water swelling and water S.

4.8 Antioxidant activity

Figure 8a explains the principle of free radical scavengers capturing individual electrons in DPPH solution. As the amount of curcumin molecule is increased in the DPPH solution, more hydrogen radicals are provided from the curcumin and a higher number of DPPH free radicals are consequently converted to a stabilized form (DPPH-H) (82), which presents itself getting a change in solution color from purple to yellowish (Figure 8c). The degree of DPPH solution yellowing in the test can indirectly evaluate the antioxidant capacity of the PLA/CCPU blend film. In Figure 8b, the free radical scavenging rate of PLA/CCPU-20 (curcumin content 0.36 wt%) film was increased from 28% (pure PLA) to 51% (PLA/CCPU-20). Therefore, a tiny amount of curcumin was loaded to PU to obtain the CCPU, and the blended PLA with the CCPU resulted in the formation of the PLA/CCPU blend films with better antioxidant properties.

(a) Reaction mechanism of the DPPH with free radical scavenger. (b) The free radical scavenging activity curves of the PLA/CCPU blend films (PLA, PLA/CCPU-5, -15, and -20). (c) Discoloration of DPPH solution when the PLA/CCPU blend film was added to the DPPH solution.

5 Conclusion

In this article, the PLA/CCPU blend films were obtained by melt mixing and compression molding. The UV-shielding ability of the PLA/CCPU blend films was significantly better than that of the pure PLA film, and the UV ray-blocking rate of the PLA/CCPU-20 film nearly achieved 97.6%. The SEM images showed that when 20 wt% CCPU was added into the PLA matrix, the fracture surface of the PLA/CCPU blend films presented a ductile fracture characteristic, and the elongation at break of four films (PLA, PLA/CCPU-5, -15, and -20) displayed a regular increasing trend from 1.22% to 4.74%. Due to the addition of CCPU and the core reason that curcumin has excellent antioxidant properties, the PLA/CCPU-20 film also showed a strong free radical scavenging rate (51%). Meanwhile, the PLA/CCPU-20 film continues to maintain a great thermal stability and moisture resistance (WCA: 92.438°, SD: 0.4%, S: 0.1%) compared to the pure PLA film. Owing to the combined qualities of the PLA/CCPU blend films, such as UV-shielding, thermal stability, moisture resistance, flexibility, and anti-oxidation, the PLA/CCPU blend films may suppose to be potentially packaging films.

-

Funding information: This work was supported by the Nature Science Associate Foundation (NSAF) of China (Grant number: U1830127).

-

Author contributions: Xuya Fu: methodology, investigation, formal analysis, visualization, writing – original draft; Tao Zhang: conceptualization, writing – review and editing; Wenshuo Zhang: formal analysis, writing – review and editing; Yuye Zhong: formal analysis, visualization; Shuliang Fang: investigation, data curation; Guannan Wang: investigation, formal analysis; Ying Li: data curation; Yajun Deng: formal analysis; Xinghai Liu: resources; Houbin Li: validation, writing – review and editing, supervision.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The raw/processed data required to reproduce these findings are available from the corresponding author on a reasonable request.

References

(1) Grifoni D, Carreras G, Sabatini F, Zipoli G. UV hazard on a summer’s day under Mediterranean conditions, and the protective role of a beach umbrella. Int J Biometeorol. 2005;50:75–82. 10.1007/s00484-005-0278-y.Search in Google Scholar PubMed

(2) Khosrovyan A, Kahru A. Evaluation of the potential toxicity of UV-weathered virgin polyamide microplastics to non-biting midge Chironomus riparius. Env Pollut. 2021;287:117334. 10.1016/j.envpol.2021.117334.Search in Google Scholar PubMed

(3) Basumatary IB, Mukherjee A, Katiyar V, Kumar S. Biopolymer-based nanocomposite films and coatings: recent advances in shelf-life improvement of fruits and vegetables. Crit Rev Food Sci Nutr. 2022;62:1912–35. 10.1080/10408398.2020.1848789.Search in Google Scholar PubMed

(4) Calvo ME, Castro Smirnov JR, Míguez H. Novel approaches to flexible visible transparent hybrid films for ultraviolet protection. J Polym Sci Part B: Polym Phys. 2012;50:945–56. 10.1002/polb.23087.Search in Google Scholar

(5) Egambaram OP, Kesavan Pillai S, Ray SS. Materials science challenges in skin UV protection: A review. Photochem Photobiol. 2020;96:779–97. 10.1111/php.13208.Search in Google Scholar PubMed

(6) Lu T, Solis-Ramos E, Yi Y, Kumosa M. UV degradation model for polymers and polymer matrix composites. Polym Degrad Stabil. 2018;154:203–10. 10.1016/j.polymdegradstab.2018.06.004.Search in Google Scholar

(7) Moustafa H, Youssef AM, Darwish NA, Abou-Kandil AI. Eco-friendly polymer composites for green packaging: Future vision and challenges. Compos Part B-Engineering. 2019;172:16–25. 10.1016/j.compositesb.2019.05.048.Search in Google Scholar

(8) Zhao L, Duan G, Zhang G, Yang H, He S, Jiang S. Electrospun functional materials toward food packaging applications: A review. Nanomaterials (Basel). 2020;10(1):150. 10.3390/nano10010150.Search in Google Scholar PubMed PubMed Central

(9) Wallis C. Terrestrial fugitive plastic packaging: the blind spot in resolving plastic pollution. Green Mater. 2020;8:3–5. 10.1680/jgrma.19.00044.Search in Google Scholar

(10) Jambeck JR, Geyer R, Wilcox C, Siegler TR, Perryman M, Andrady A, et al. Plastic waste inputs from land into the ocean. Science. 2015;347:768–71. 10.1126/science.1260352.Search in Google Scholar PubMed

(11) Rojas A, Velasquez E, Patino Vidal C, Guarda A, Galotto MJ, Lopez de Dicastillo C. Active PLA packaging films: Effect of processing and the addition of natural antimicrobials and antioxidants on physical properties, release kinetics, and compostability. Antioxid (Basel). 2021;10(12):1976. 10.3390/antiox10121976.Search in Google Scholar PubMed PubMed Central

(12) Pang B, Wu Z-Y, Wang Z-B, You B-Q, Guo Y-R, Li S, et al. Design of a ZnO@ plant polyphenol/poly (vinyl alcohol) film via plant polyphenol-induced cross-linking and its enhanced UV shielding and antibacterial performance. ACS Sustain Chem Eng. 2022;10:9369–80. 10.1021/acssuschemeng.2c01444.Search in Google Scholar

(13) Zhang Y, Naebe M. Lignin: A review on structure, properties, and applications as a light-colored UV absorber. ACS Sustain Chem Eng. 2021;9:1427–42. 10.1021/acssuschemeng.0c06998.Search in Google Scholar

(14) Yang H, Shi B, Xue Y, Ma Z, Liu L, Liu L, et al. Molecularly engineered lignin-derived additives enable fire-retardant, UV-shielding, and mechanically strong polylactide biocomposites. Biomacromolecules. 2021;22:1432–44. 10.1021/acs.biomac.0c01656.Search in Google Scholar PubMed

(15) Sadeghifar H, Venditti R, Jur J, Gorga RE, Pawlak JJ. Cellulose-lignin biodegradable and flexible UV protection film. ACS Sustain Chem Eng. 2016;5:625–31. 10.1021/acssuschemeng.6b02003.Search in Google Scholar

(16) Chandrappa H, Bhajantri RF, Prarthana N. Simple fabrication of PVA-ATE (Amaranthus tricolor leaves extract) polymer biocomposites: An efficient UV-Shielding material for organisms in terrestrial and aquatic ecosystems. Optical Mater. 2020;109:110204. 10.1016/j.optmat.2020.110204.Search in Google Scholar

(17) Liu J, Wang H, Wang P, Guo M, Jiang S, Li X, et al. Films based on κ-carrageenan incorporated with curcumin for freshness monitoring. Food Hydrocoll. 2018;83:134–42. 10.1016/j.foodhyd.2018.05.012.Search in Google Scholar

(18) Miglioranza BMG, Spinelli FR, Stoffel F, Piemolini-Barreto LT. Biodegradable film for raisins packaging application: Evaluation of physico-chemical characteristics and antioxidant potential. Food Chem. 2021;365:130538. 10.1016/j.foodchem.2021.130538.Search in Google Scholar PubMed

(19) Prasad S, DuBourdieu D, Srivastava A, Kumar P, Lall R. Metal-curcumin complexes in therapeutics: An approach to enhance pharmacological effects of curcumin. Int J Mol Sci. 2021;22(13):7094. 10.3390/ijms22137094.Search in Google Scholar PubMed PubMed Central

(20) Rai M, Pandit R, Gaikwad S, Yadav A, Gade A. Potential applications of curcumin and curcumin nanoparticles: from traditional therapeutics to modern nanomedicine. Nanotechnol Rev. 2015;4:161–72. 10.1515/ntrev-2015-0001.Search in Google Scholar

(21) Qiao YC, Duan LJ. Curcumin-loaded polyvinyl butyral film with antibacterial activity. e-Polymers. 2020;20:673–81. 10.1515/epoly-2020-0042.Search in Google Scholar

(22) Kim S, Choi K. Occurrences, toxicities, and ecological risks of benzophenone-3, a common component of organic sunscreen products: a mini-review. Env Int. 2014;70:143–57. 10.1016/j.envint.2014.05.015.Search in Google Scholar PubMed

(23) Castillo ML, López-Tobar E, Sanchez-Cortes S, Flores G, Blanch GP. Stabilization of curcumin against photodegradation by encapsulation in gamma-cyclodextrin: A study based on chromatographic and spectroscopic (Raman and UV-visible) data. Vibrational Spectrosc. 2015;81:106–11. 10.1016/j.vibspec.2015.10.008.Search in Google Scholar

(24) Chopra D, Ray L, Dwivedi A, Tiwari SK, Singh J, Singh KP, et al. Photoprotective efficiency of PLGA-curcumin nanoparticles versus curcumin through the involvement of ERK/AKT pathway under ambient UV-R exposure in HaCaT cell line. Biomaterials. 2016;84:25–41. 10.1016/j.biomaterials.2016.01.018.Search in Google Scholar PubMed

(25) Kang J, Kim YH, Choi SJ, Rho SJ, Kim YR. Improving the stability and curcumin retention rate of curcumin-loaded filled hydrogel prepared using 4alphaGTase-treated rice starch. Foods. 2021;10(1):150. 10.3390/foods10010150.Search in Google Scholar PubMed PubMed Central

(26) Zdyrko B, Swaminatha Iyer K, Luzinov I. Macromolecular anchoring layers for polymer grafting: comparative study. Polymer. 2006;47:272–9. 10.1016/j.polymer.2005.11.029.Search in Google Scholar

(27) Lee B, Maher MJ, Schibur HJ, Hillmyer MA, Bates FS. Toughening polylactide with graft-block polymers. Acs Appl Polym Mater. 2022;4:3408–16. 10.1021/acsapm.2c00036.Search in Google Scholar

(28) Zhang T, Deng Y, Zhang W, Wang G, Zhong Y, Su C, et al. A self-colored waterborne polyurethane film with natural curcumin as a chain extender and excellent UV-Absorbing properties. Polymer. 2022;239:124465. 10.1016/j.polymer.2021.124465.Search in Google Scholar

(29) Zhang T, Zhang W, Deng Y, Chu Y, Zhong Y, Wang G, et al. Curcumin-based waterborne polyurethane-gelatin composite bioactive films for effective UV shielding and inhibition of oil oxidation. Food Control. 2022;141:109199. 10.1016/j.foodcont.2022.109199.Search in Google Scholar

(30) Mahmood K, Zia KM, Zuber M, Salman M, Anjum MN. Recent developments in curcumin and curcumin based polymeric materials for biomedical applications: A review. Int J Biol Macromol. 2015;81:877–90. 10.1016/j.ijbiomac.2015.09.026.Search in Google Scholar PubMed

(31) Ma QY, Du L, Wang LJ. Tara gum/polyvinyl alcohol-based colorimetric NH3 indicator films incorporating curcumin for intelligent packaging. Sens Actuators B-Chemical. 2017;244:759–66. 10.1016/j.snb.2017.01.035.Search in Google Scholar

(32) Feng Y, Xiao K, He Y, Du B, Hong J, Yin H, et al. Tough and biodegradable polyurethane-curcumin composited hydrogel with antioxidant, antibacterial and antitumor properties. Mater Sci Eng C Mater Biol Appl. 2021;121:111820. 10.1016/j.msec.2020.111820.Search in Google Scholar PubMed

(33) Mahmood K, Noreen I, Riaz M, Zuber M, Salman M, Rehman S, et al. Synthesis and characterization of novel curcumin based polyurethanes varying diisocyanates structure. J Polym Res. 2016;23:1–9. 10.1007/s10965-016-1125-z.Search in Google Scholar

(34) Zia F, Zia KM, Zuber M, Rehman S, Tabasum S, Sultana S. Synthesis and characterization of chitosan/curcumin blends based polyurethanes. Int J Biol Macromol. 2016;92:1074–81. 10.1016/j.ijbiomac.2016.08.005.Search in Google Scholar PubMed

(35) Pavlopoulou E, Chrissopoulou K, Pispas S, Hadjichristidis N, Anastasiadis SH. The micellization of well-defined single graft copolymers in block copolymer/homopolymer blends. Polym (Basel). 2021;13(5):833. 10.3390/polym13050833.Search in Google Scholar PubMed PubMed Central

(36) Shlosman K, Suckeveriene RY, Rosen-Kligvasser J, Tchoudakov R, Zelikman E, Semiat R, et al. Controlled migration of antifog additives from LLDPE compatibilized with LLDPE grafted maleic anhydride. Polym Adv Technol. 2014;25:1484–91. 10.1002/pat.3390.Search in Google Scholar

(37) Liu T, Zhang HM, Zuo M, Zhang WJ, Zhu WP, Zheng Q. Selective location and migration of poly(methyl methacrylate)- grafted clay nanosheets with low grafting density in poly(methyl methacrylate)/poly (styrene-co-acrylonitrile) blends. Compos Sci Technol. 2019;169:110–9. 10.1016/j.compscitech.2018.11.021.Search in Google Scholar

(38) Garlotta D. A literature review of poly(lactic acid). J Polym Environ. 2001;9:63–84. 10.1023/a:1020200822435.Search in Google Scholar

(39) Sha L, Chen Z, Chen Z, Zhang A, Yang Z. Polylactic acid based nanocomposites: Promising safe and biodegradable materials in biomedical field. Int J Polym Sci. 2016;2016:1–11. 10.1155/2016/6869154.Search in Google Scholar

(40) Armentano I, Bitinis N, Fortunati E, Mattioli S, Rescignano N, Verdejo R, et al. Multifunctional nanostructured PLA materials for packaging and tissue engineering. Prog Polym Sci. 2013;38:1720–47. 10.1016/j.progpolymsci.2013.05.010.Search in Google Scholar

(41) Park JW, Shin JH, Shim GS, Sim KB, Jang SW, Kim HJ. Mechanical strength enhancement of polylactic acid hybrid composites. Polym (Basel). 2019;11(2):349. 10.3390/polym11020349.Search in Google Scholar PubMed PubMed Central

(42) Lasprilla AJ, Martinez GA, Lunelli BH, Jardini AL, Filho RM. Poly-lactic acid synthesis for application in biomedical devices - a review. Biotechnol Adv. 2012;30:321–8. 10.1016/j.biotechadv.2011.06.019.Search in Google Scholar PubMed

(43) Zhao X, Liu J, Li J, Liang X, Zhou W, Peng S. Strategies and techniques for improving heat resistance and mechanical performances of poly(lactic acid) (PLA) biodegradable materials. Int J Biol Macromol. 2022;218:115–34. 10.1016/j.ijbiomac.2022.07.091.Search in Google Scholar PubMed

(44) Mestdagh F, De Meulenaer B, De Clippeleer J, Devlieghere F, Huyghebaert A. Protective influence of several packaging materials on light oxidation of milk. J Dairy Sci. 2005;88:499–510. 10.3168/jds.S0022-0302(05)72712-0.Search in Google Scholar PubMed

(45) Auras R, Harte B, Selke S. An overview of polylactides as packaging materials. Macromol Biosci. 2004;4:835–64. 10.1002/mabi.200400043.Search in Google Scholar PubMed

(46) Wang J, Han X, Zhang C, Liu K, Duan G. Source of nanocellulose and its application in nanocomposite packaging material: A review. Nanomaterials (Basel). 2022;12(18):3158. 10.3390/nano12183158.Search in Google Scholar PubMed PubMed Central

(47) Liu L, Xu Y, Pan Y, Xu M, Di Y, Li B. Facile synthesis of an efficient phosphonamide flame retardant for simultaneous enhancement of fire safety and crystallization rate of poly (lactic acid). Chem Eng J. 2021;421:127761. 10.1016/j.cej.2020.127761.Search in Google Scholar

(48) Wang C, Gong C, Qin Y, Hu Y, Jiao A, Jin Z, et al. Bioactive and functional biodegradable packaging films reinforced with nanoparticles. J Food Eng. 2022;312:110752. 10.1016/j.jfoodeng.2021.110752.Search in Google Scholar

(49) Qi X, Ren Y, Wang X. New advances in the biodegradation of Poly(lactic) acid. Int Biodeterior Biodegrad. 2017;117:215–23. 10.1016/j.ibiod.2017.01.010.Search in Google Scholar

(50) Milovanovic S, Pajnik J, Lukic I. Tailoring of advanced poly(lactic acid)‐based materials: A review. J Appl Polym Sci. 2021;139(12):51839. 10.1002/app.51839.Search in Google Scholar

(51) Nagarajan V, Mohanty AK, Misra M. Perspective on polylactic acid (PLA) based sustainable materials for durable applications: Focus on toughness and heat resistance. ACS Sustain Chem Eng. 2016;4:2899–916. 10.1021/acssuschemeng.6b00321.Search in Google Scholar

(52) Jiang S, Sun H, Wang H, Ladewig BP, Yao Z. A comprehensive review on the synthesis and applications of ion exchange membranes. Chemosphere. 2021;282:130817. 10.1016/j.chemosphere.2021.130817.Search in Google Scholar PubMed

(53) Guo Z, Wang ZB, Qin YJ, Zhang JT, Qi Y, Liu BG, et al. Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends. e-Polymers. 2022;22:733–41. 10.1515/epoly-2022-0059.Search in Google Scholar

(54) Blanco I, Siracusa V. Kinetic study of the thermal and thermo-oxidative degradations of polylactide-modified films for food packaging. J Therm Anal Calorim. 2012;112:1171–7. 10.1007/s10973-012-2535-8.Search in Google Scholar

(55) Khan A, Naveed M, Rabnawaz M. Melt-reprocessing of mixed polyurethane thermosets. Green Chem. 2021;23:4771–9. 10.1039/d1gc01232k.Search in Google Scholar

(56) Gürler N, Paşa S, Temel H. Silane doped biodegradable starch-PLA bilayer films for food packaging applications: Mechanical, thermal, barrier and biodegradability properties. J Taiwan Inst Chem Eng. 2021;123:261–71. 10.1016/j.jtice.2021.05.030.Search in Google Scholar

(57) Yang CX, Tang HB, Wang YF, Liu Y, Wang J, Shi WZ, et al. Development of PLA-PBSA based biodegradable active film and its application to salmon slices. Food Packaging Shelf Life. 2019;22:100393. 10.1016/j.fpsl.2019.100393.Search in Google Scholar

(58) Xu A, Wang Y, Gao J, Wang J. Facile fabrication of a homogeneous cellulose/polylactic acid composite film with improved biocompatibility, biodegradability and mechanical properties. Green Chem. 2019;21:4449–56. 10.1039/c9gc01918a.Search in Google Scholar

(59) Liu H, Chen N, Shan P, Song P, Liu X, Chen J. Toward fully bio-based and supertough PLA blends via in situ formation of cross-linked biopolyamide continuity network. Macromolecules. 2019;52:8415–29. 10.1021/acs.macromol.9b01398.Search in Google Scholar

(60) Zheng Q, Huang J, Li H, Chen L. Preparation of highly visible transparent ZnO/cellophane UV-shielding film by RF magnetron sputtering. Ceram Int. 2019;45:3729–34. 10.1016/j.ceramint.2018.11.038.Search in Google Scholar

(61) Karsili TN, Marchetti B, Ashfold MN, Domcke W. Ab initio study of potential ultrafast internal conversion routes in oxybenzone, caffeic acid, and ferulic acid: implications for sunscreens. J Phys Chem A. 2014;118:11999–2010. 10.1021/jp507282d.Search in Google Scholar PubMed

(62) Tuna D, Sobolewski AL, Domcke W. Photochemical mechanisms of radiationless deactivation processes in urocanic acid. J Phys Chem B. 2014;118:976–85. 10.1021/jp411818j.Search in Google Scholar PubMed

(63) Zayat M, Garcia-Parejo P, Levy D. Preventing UV-light damage of light sensitive materials using a highly protective UV-absorbing coating. Chem Soc Rev. 2007;36:1270–81. 10.1039/b608888k.Search in Google Scholar PubMed

(64) Xiao JP, Li Y. Screening of benzophenone ultraviolet absorbers with high-efficiency light absorption capacity, low-permeability and low-toxicity by 3D-QSAR model. J Mol Liq. 2022;347:118364. 10.1016/j.molliq.2021.118364.Search in Google Scholar

(65) Shamoto Y, Yagi M, Oguchi-Fujiyama N, Miyazawa K, Kikuchi A. Photophysical properties of hexyl diethylaminohydroxybenzoylbenzoate (Uvinul A Plus), a UV-A absorber. Photochem Photobiol Sci. 2017;16:1449–57. 10.1039/c7pp00164a.Search in Google Scholar PubMed

(66) Menamparambath MM, Yang K, Kim HH, Bae OS, Jeong MS, Choi JY, et al. Reduced haze of transparent conductive films by smaller diameter silver nanowires. Nanotechnology. 2016;27:465706. 10.1088/0957-4484/27/46/465706.Search in Google Scholar PubMed

(67) Preston C, Xu Y, Han X, Munday JN, Hu L. Optical haze of transparent and conductive silver nanowire films. Nano Res. 2013;6:461–8. 10.1007/s12274-013-0323-9.Search in Google Scholar

(68) Yang R, Cao H, Zhang P, Chen L, Zou G, Zhang X, et al. Highly toughened and heat-resistant poly(lactic acid) with balanced strength using an unsaturated liquid crystalline polyester via dynamic vulcanization. ACS Appl Polym Mater. 2020;3:299–309. 10.1021/acsapm.0c01095.Search in Google Scholar

(69) Zhang Y, Jing J, Liu T, Xi LD, Sai T, Ran SY, et al. A molecularly engineered bioderived polyphosphate for enhanced flame retardant, UV-blocking and mechanical properties of poly(lactic acid). Chem Eng J. 2021;411:128493. 10.1016/j.cej.2021.128493.Search in Google Scholar

(70) He L, Song F, Li D-F, Zhao X, Wang X-L, Wang Y-Z. Strong and tough polylactic acid based composites enabled by simultaneous reinforcement and interfacial compatibilization of microfibrillated cellulose. ACS Sustain Chem Eng. 2020;8:1573–82. 10.1021/acssuschemeng.9b06308.Search in Google Scholar

(71) Chiang M-F, Wu T-M. Intercalation of γ-PGA in Mg/Al layered double hydroxides: An in situ WAXD and FTIR investigation. Appl Clay Sci. 2011;51:330–4. 10.1016/j.clay.2010.12.021.Search in Google Scholar

(72) Oprea S. Synthesis and properties of polyurethane elastomers with castor oil as crosslinker. J Am Oil Chemists’ Soc. 2009;87:313–20. 10.1007/s11746-009-1501-5.Search in Google Scholar

(73) Stirna U, Lazdina B, Vilsone D, Lopez MJ, Vargas-Garcia MD, Suarez-Estrella F, et al. Structure and properties of the polyurethane and polyurethane foam synthesized from castor oil polyols. J Cell Plast. 2012;48:476–88. 10.1177/0021955x12445178.Search in Google Scholar

(74) Shah SAA, Athir N, Imran M, Cheng J, Zhang JY. Thermo-mechanically improved curcumin and zwitterion incorporated polyurethane-urea elastomers. Polym Degrad Stabil. 2019;164:28–35. 10.1016/j.polymdegradstab.2019.03.018.Search in Google Scholar

(75) Lim LT, Auras R, Rubino M. Processing technologies for poly(lactic acid). Prog Polym Sci. 2008;33:820–52. 10.1016/j.progpolymsci.2008.05.004.Search in Google Scholar

(76) Ionescu M, Radojcic D, Wan XM, Shrestha ML, Petrovic ZS, Upshaw TA. Highly functional polyols from castor oil for rigid polyurethanes. Eur Polym J. 2016;84:736–49. 10.1016/j.eurpolymj.2016.06.006.Search in Google Scholar

(77) Wang JC, Wu YK, Cao YJ, Li GS, Liao YF. Influence of surface roughness on contact angle hysteresis and spreading work. Colloid Polym Sci. 2020;298:1107–12. 10.1007/s00396-020-04680-x.Search in Google Scholar

(78) Zhang W, Zhang T, Deng Y, Guan Z, Zhong Y, Fang S, et al. Environmentally friendly gelatin-based ink with durability on low surface energy substrates for anti-counterfeiting printing. J Clean Prod. 2022;362:132518. 10.1016/j.jclepro.2022.132518.Search in Google Scholar

(79) Roy S, Rhim JW. Carboxymethyl cellulose-based antioxidant and antimicrobial active packaging film incorporated with curcumin and zinc oxide. Int J Biol Macromol. 2020;148:666–76. 10.1016/j.ijbiomac.2020.01.204.Search in Google Scholar PubMed

(80) Datta D, Halder G. Effect of media on degradability, physico-mechanical and optical properties of synthesized polyolefinic and PLA film in comparison with casted potato/corn starch biofilm. Process Saf Environ Prot. 2019;124:39–62. 10.1016/j.psep.2019.02.002.Search in Google Scholar

(81) Kluver E, Baltzer M, Langer A, Meyer M. Additive manufacturing with thermoplastic collagen. Polym (Basel). 2022;14(5):974. 10.3390/polym14050974.Search in Google Scholar PubMed PubMed Central

(82) Cvek M, Paul UC, Zia J, Mancini G, Sedlarik V, Athanassiou A. Biodegradable films of PLA/PPC and curcumin as packaging materials and smart indicators of food spoilage. ACS Appl Mater Interfaces. 2022;14:14654–67. 10.1021/acsami.2c02181.Search in Google Scholar PubMed PubMed Central

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites