Abstract

Eggshells were utilized as a cost effective catalyst to assist in biodiesel formation. Eggshells were calcined using different calcination conditions such as temperature and time. The eggshells underwent calcination under 1000 °C in which calcium carbonate was completely converted into calcium oxide under open air conditions. The calcined eggshell catalyst was characterized by X-ray diffraction (XRD). Then the eggshell derived CaO catalyst was subjected to transesterification of used cooking oil (UCO). The parametrics in the transesterification of used cooking oil such as a methanol to oil ratio, weight of catalyst and reaction temperature were evaluated. The optimum result exhibited a 4:1 methanol to oil ratio, 2wt % catalyst, and a 65 °C reaction temperature within two hours. Pure calcined CaO acted as the control of the experiment that was subject to the most optimum eggshell derived catalyst transesterification conditions. The catalytic activity for both the pure calcined CaO and the calcined eggshell derived catalyst were comparable. The biodiesel formation was identified by gas chromatography mass spectrometry (GC-MS).

1 Introduction

The continuous increase in crude oil prices and the depletion of petroleum reserves, has aroused researchers to develop alternative ways to replace gas-derived fuels. Biodiesel has appeared as an alternative fuel to replace gas-based fuels [1]. Costs of raw materials, usually refined vegetable oil, add to the production cost [2]. As a consequence, the ideas of used cooking oil (UCO) as raw material feedstock are generated [3]. Many scientists applied homogenous alkaline catalysts in biodiesel production due to the low cost and high availability. CaO is one of widely-used catalysts due to its abundant availability in nature, its high activity and low cost [4].

During the past few years, researchers have begun focusing on the regeneration of waste materials such as eggshells as useful substances. Eggshell waste comprises a big portion of food industrial waste as eggs are a daily diet in many countries. For instance, dried eggs, liquid eggs, and frozen eggs are the diversified form of egg products that are found in markets. An egg is considered a relatively cheap food that provides complete nutrition with protein sources (6g), unsaturated fatty acids (10%), essential minerals and vitamins such as A, D [5]. The egg industry is a leader is one of the major sectors iof the world food market.

According to literature, there are many added-values derived from waste eggshells such as calcium phosphate bioceramics [6], hydroxyapatite(HA) as implanted constituents [7], and as absorption of dyes[8]. Waste eggshells consist of a majority of calcium carbonate compounds, nearly 95% of which are suitable as activated heterogeneous catalysts used in biodiesel production [9]. Calcium oxide components can be generated from eggshell waste after calcination and used in the transesterification process.

This study addresses the following objectives: one is to synthesize a potential catalyst from eggshell waste and to identify most effective calcination conditions for the calcined eggshells derived catalyst. The second objective is to determine the effect of the methanol to oil ratio, the weight of the catalyst and the reaction temperature using the most effective calcined eggshell conditions derived catalyst to form biodiesel.

2 Materials and methods

2.1 Catalyst preparation

The wasted chicken eggshells were collected by selling Char Keow Teow stall. The eggshells were peeled from their membranes to remove any interference substances and impurities such as organics materials. After that, chicken eggshells were rinsed three times with tap water. Then, the eggshells were dried in a hot air oven for 24 hours at 60 oC [9].

Next, the dried eggshells were pulverized into fine powder using a blender. The powder was sieved to constant sizes such as 0.045 mm by using a buger sieve with the help of an automatic sieve shaker. Next, eggshell powders were transferred into a furnace to generate calcium oxide. The eggshells, potential catalysts were cooled down and placed in a desiccator to reduce the probability of reacting with any humidity and CO2 in the air. The acidic particles like CO2 and H2O are considered poisonous to the catalyst’s active site [10] . Hence, the calcined eggshells needed to be kept in the desiccator to avoid contact with those particles. Additionally, the silica gel needed to have a blue color instead of a pink color. Blue silica gel is made up of cobalt chloride, and it will turn pink when saturated with water and cannot absorb any moisture.

Different conditions were applied to synthesize eggshells as potential catalysts. For instance, eggshells calcination using a muffle furnace under 800 °C for 4 hours (Condition 1), eggshells calcination using a tube furnace under 1000 oC for two hours with nitrogen gas flow (Condition 2), and eggshells calcination using a tube furnace under 1000 oC for two hours without nitrogen gas flow (Condition 3).

Pure calcium oxide acted as a experimental control and was subjected to the same calcination conditions.

2.2 Characterization of catalyst using X-Ray Diffraction (XRD)

In order to prove the potential of eggshells as catalysts, XRD analysis was conducted in the uncalcined or calcined chicken eggshell powder. Apart from that, pure calcium oxides either uncalcined or calcined were observed in XRD.

With the 2θ range from 10o to 90o, the XRD powder diffraction analysis of the samples were carried out using Cu K-α radiation with a 2o/min scanning speed and a 0.04o step size[9].

The components found in the respective calcination methods were identified. The diffraction pattern was determined by referring to the International Centre for Diffraction Data (ICDD) using the powder diffraction file PDF-2 Release 2014 as a reference database.

2.3 Pre-treatment of used cooking oil

Used cooking oil was collected from the cafeteria of the Jeli Campus at the University of Malaysia, Kelatan. First, dispersed particles and any residues in the oil were filtered using cheese cloth. Then, centrifugation was employed to discard any impurities or fat sediment. Then the oil was filtered using filter paper to get a better quality oil. Next, oil was heated at 110oC for 50 minutes to evaporate any trace amount of moisture in a 2L beaker using a hot plate with magnetic stirrer [11].

2.4 FFA identification

Total quantities of FFA in the oil samples were identified using the titration method [12] before any reactions were carried out. First, the amount of 0.5 grams of potassium hydroxide (KOH) was weighted and dissolved into 500 mL of distilled water in a 1 L beaker. The potassium hydroxide solution (KOH) was then transferred into a burette.

1 mL of used cooking oil was dissolved into 10 mL of isopropyl alcohol in a 50 mL beaker. The beaker consisted of used cooking oil. The isopropyl alcohol was heated in a water bath for 15 minutes at 60 o C. Color changes were observed ranging from a dark brown to a plain yellowish solution as the used cooking oil slowly dissolved into isopropyl alcohol.

The dissolved solution of used cooking oil together with isopropyl alcohol was then transferred into a 500 mL Erlenmeyer flask. Then two drops of phenolphthalein were added. Potassium hydroxide (KOH) was added slowly from the burette into the alcohol-oil mix solution, and the solution mixture was swirled gently. The light pink color appeared which lasted for 10 seconds revealing the endpoint measurement and the final volume of potassium hydroxide (KOH) which was then recorded. The experiment was repeated three times to collect the average titration value.

The calculation formula for the FFA% from a titration value is shown in Equation 1

t indicates amount (mL) of titration sample

b indicates amount (mL) of the blank sample

N indicates normality (N) of the titration sample

v indicates quantity (g) of the oil sample

2.5 Synthesis of biodiesel through transesterification

The reaction took place using a 250 mL Erlenmeyer flask, a magnetic stirrer, a reflux condenser, a hot plate, a thermometer, and a 1 L beaker which acted as a water bath. First, the calcined eggshell catalyst was mixed with methanol for one hour to produce calcium methioxide.

50 mL of used cooking oil was then transferred accordingly into a new Erlenmeyer flask. The calcium methioxide solution which had stirred for one hour was poured into the oil. The content was refluxed under magnetic stirring for two hours in a closed vessel to avoid the evaporation of methanol[13]. The reaction duration was fixed at hours due to the longer reaction time, there will be hindrance to the catalyst hence suppress the biodiesel yield [14].

Three parameters were studied using calcined eggshells as a potential catalyst. Those were the weight of the calcined eggshell catalyst (1.0 wt %, 2.0 wt %, 3.0 wt%, 4.0 wt%, 5.0 wt%), the reaction temperature (35 oC, 45 oC , 55 oC, 65 oC ) and the methanol to oil ratio(1:1, 2:1, 3:1, 4:1, 5:1). The reaction temperature was set below 65 o C due to the boiling point of methanol being at 65 o C. Methanol starts to bubble as it boilswhich would hinder the three-phase interface reaction (methanol, CaO, and oil) to take place[15].

2.6 Separation and purification

After transesterification, the solution mixture underwent a gravity separation overnight in a separatory funnel. After that, the separation was complete with densities and the upper layer as methyl ester, methanol and the bottom layer as glycerine[16].

The upper layer was subjected to centrifugation at 6000 rpm for 15 minutes to remove the residue catalyst; meanwhile the bottom layer was withdrawn and discarded. Next, warm water was required to purify the sample product by rinsing out the impurities such as methanol, glycerol, CaO, and soap. Warm water was introduced slowly to avoid emulsion and soap formation [17]. The washing of biodiesel was stopped until the water appeared transparent and clear compared to the cloudy yellowish solution from previous rinsings.

Then, the sample product was subjected to heating to evaporate the residual moisture. Finally, the biodiesel was cooled to room temperature and sealed with a parafilm kept in a dark place.

2.7 Analysis of fatty acid and methyl esters content

The fatty acid component of used cooking oil and its methyl esters content of sample products were carried out using Agilent 7890 N gas chromatography with an Agilent 7693 mass selective detector. The capillary column applied had a 30 m x 0.25 mm dimension i.d 0.25 lm film thickness (Agilent Technologies) with HP- 5MS (5% phenyl methylsiloxane).

The gas chromatograph setting was achieved accordingly using a fatty methyl ester(FAME) procedure. The molecular mass was set at a range from 30 – 300. The desired compounds were matched according to the peak and retention time based on the NIST (National Institute of Standards and Technology) library.

3 Results and Discussion

3.1 Conversion of eggshell into potential catalyst

3.1.1 XRD pattern of different calcination methods of eggshell samples

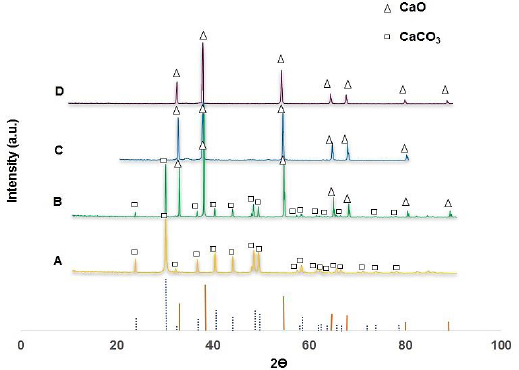

XRD analysis was carried out to identify the component and crystallinity of eggshell components. Figure 1 represented an XRD pattern of eggshells before calcination and after calcination at two different temperatures ranges, that were 800°C and 1000°C and with two different conditions such as with closed air, open air and with nitrogen flow or without nitrogen flow.

XRD pattern of samples of eggshell (A) eggshell before calcination, (B) eggshell with 800°C close atmosphere calcination, (C) eggshell with 1000°C nitrogen gas flow calcination, (D) eggshell with 1000°C open air calcination

Based on the pattern of the X-ray diffraction on raw eggshells, only calcium carbonate existed in the raw eggshell powder before calcination (A). This depicted that calcium carbonate was the prime compound in the eggshell. Calcium carbonate was the major compound for the eggshells after close atmosphere calcination under temperature 800°C (B) as observed in figure 1. After closed atmosphere calcination at 800°C (B), the intensity of calcium carbonate was slightly reduced compared to before calcination and some of calcium oxide phases were appeared.

The intensity of the calcium carbonate for calcination at 800°C(B) changed compared to the uncalcined eggshells which was due to the calcium carbonate gradually transforming into calcium oxide[15]. A similar study demonstrated that the calcium carbonate did not completely convert into calcium oxide during the 800°C calcination process[18].

A calcium oxide peak only appeared after calcination at 1000°C with nitrogen gas flow (C) and in open air (D). This was due to the high thermal transition that occurred in the eggshells causing complete decomposition of the calcium carbonate into calcium oxide which occurred at 1000°C.

The XRD pattern for both the open air calcined eggshells at 1000°C (D) and the nitrogen gas flow calcined eggshells at 1000°C (C) showed identical and highly crystallite clear peaks. The crystallite size of eggshells after calcination under 1000°C higher compared calcination under 800°C[19].

The calcination of eggshells for two hours at 800°C , the major phase being CaCO3 and the minor phase being CaO[20], showed similarities with this study. It was reported that CaO acted as a major component after calcination at 900°C for four hours. However, one of the researchers concluded that the best calcination temperature for eggshells waste was above 800°C for two hours and went on to report that the eggshell was calcined at 700°C for two hours and contained CaO as the minor phase and CaCO3 as the major phase[9].

The calcination of the eggshell waste within the two to four-hour timeframe found the catalyst activities comparative to the transesterification process[21]. Extending the calcination timeframewould diminish the catalyst and surpress the active site whereby dropping the catalytic activity of the eggshell in transesterification. Therefore, it was suggested that the timeframe should not exceed 4 hours accordingly with the different calcination temperature.

3.1.2 XRD pattern of different calcination methods of Pure CaO samples

The XRD analysis was carried out to identify the pure calcium oxide component and to determine whether it had potential in becomingva catalyst without calcination, or calcination under different conditions. Figure 2 displays an X-ray diffractogram of pure calcium oxide before calcination, and pure calcium oxide after being subjected to different calcination conditions.

XRD pattern of samples of Pure CaO (A) Pure CaO before calcination, (B) Pure CaO with 800°C close atmosphere calcination, (C) Pure CaO with 1000°C nitrogen gas flow calcination,(D) Pure CaO with 1000°C open air calcination

Based on the pattern of the X-ray diffraction of pure calcium oxide before calcination (A), two main components appeared to include calcium oxide and calcium hydroxide. The presence of calcium hydroxide was probably due to the uptake of moisture from the surrounding environment. This indicated that the pure calcium oxide should be subjected into in order to get rid other than calcium oxide component before carried on with transesterification process.

However, after calcination at 800°C (B), the calcium oxide peak appeared with high crystallinity and exhibited a lesser calcium hydroxide component than before calcination (A). However, calcium hydroxide did not fully convert into calcium oxide under calcination at 800°C (B). Thus, this indicated that the calcium oxide transformation required a higher temperature or longer calcination timeframe to completely remove the moisture content in CaO.

As depicted from figure 2, the calcium oxide peak only appeared after calcination at 1000°C with a nitrogen gas flow (C) and with open air (D). This showed that the calcination at a higher temperature, but shorter time could help eliminate the water content in CaO.

The XRD pattern for both open air calcined eggshells at 1000°C (D) and nitrogen gas flow calcined eggshells at 1000°C (C) showed high crystallite. The method for the open air calcined eggshell at 1000°C (D) was selected to make the potential catalyst as it could be achieved at a reduced cost compared to the nitrogen gas method and the cost for purchasing).

3.2 Optimization of transesterification using calcined eggshell derived catalyst

3.2.1 Effect of methanol to oil ratio towards biodiesel formation

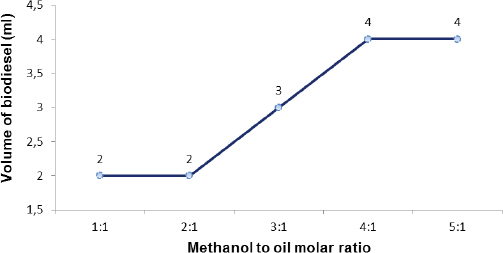

A different methanol to oil molar ratio in this study was investigated from 1:1 to 5:1 as other factors remained constant. The reaction took place at a temperature of under 65o C for two hours, and used a 3wt% calcined eggshell catalyst and 50 ml of used oil.

Figure 3 depicted that the methanol to oil ratio of 1:1 to 5:1, biodiesel yield increase from 2ml to 4ml. Initially, the methanol to oil molar ratio from 1:1 to 2:1 did not have any further change, it stagnated at 2 ml of biodiesel yield.

The effect of different methanol to oil ratios on the transesterification of used cooking oil. Conditions: reaction time of 2 hours, reaction temperature of 65°C, catalyst weight of 3wt%.

However, the volume of biodiesel gradually increased from 2ml to 4ml, from 2:1 to 4:1 of methanol to oil ratio respectively. As the methanol volume increased so did the biodiesel yield due to calcium methioxide, Ca(CH3O)2 that formed during the pre-treatment of the calcium oxide with methanol before transesterification. This triggered the reaction equilibrium to shift to the right. Calcium methioxide can boost the reaction between oil and methanol [21].

The biodiesel yield no longer increased and stayed at 4ml for the 4:1 to 5:1 methanol to oil ratio. This could be ascribed to the excess of methanol preventing the gravity separation of methyl ester and glycerol fragment into two phases [14]. Researchers demonstrated that the higher methanol to oil ratio would promote a better FAME yield. However, the further increment in the methanol to oil ratio based on the system, caused the transesterification process to be reversible. The glycerol residues would shift the equilibrium to the left and hence the FAME yield would drop [22].

The biodiesel yield was relatively low compared to other studies; this was probably due to the slightly higher FFA content from used cooking oil. The biodiesel yield was highly related to the FFA content [23]. Researchers suggested that the way to maximize the methyl esters yield was to reduce the FFA content to 2% before carry on with transesterification.

3.2.2 Effect of catalyst concentration towards biodiesel formation

The effect of catalyst concentration, varying quantities from 1 wt% to 5 wt% according to the weight of initial used cooking oil towards the biodiesel formation were investigated. The reaction took place at a temperature below 65o C for two hours, and used 150ml methanol(4:1) and 50 ml used oil. The outcomes were revealed in figure 4.

The effect of different catalyst concentrations on the transesterification of used cooking oil. Conditions: reaction time of 2 hours, reaction temperature of 65°C, methanol to oil ratio 4:1.

From figure 4, the conversion rate was identified to be slightly accelerated from 1wt% to 2 wt% of catalyst concentration that was from 3ml to 4ml. This result described that the increment in weight of the catalyst boosted the contact between the reactant and the catalyst[15]. The more the catalyst used, the faster the reaction due to the faster collision between reactants molecules.

However, the for the further increase of catalyst concentration from 2 wt% to 3 wt%, volume of biodiesel drops from 4ml to 3ml, following by no any fluctuation in biodiesel volume for catalyst concentration of 4wt% and 5 wt%.

The drop in biodiesel yield was due to the FFA and the water residue in used cooking oil which tended to react and cause soap formation during the transesterification process. The free fatty acids reacted with the alkaline catalyst that lead to saponification. Saponification depleted the alkaline catalyst inevitably lowering the effectiveness of the catalyst, hence collecting a lower biodiesel yield [15].

In addition, as the CaO used more, the leaching process from the CaO catalyst increased, resulting in more of the CaO to react with FFAs whereby turning into calcium soap during the purification process. Besides, there were certain amounts of biodiesel to form an emulsion during the washing process wherebylowering its yield. The amount of catalyst use was increased.[24].

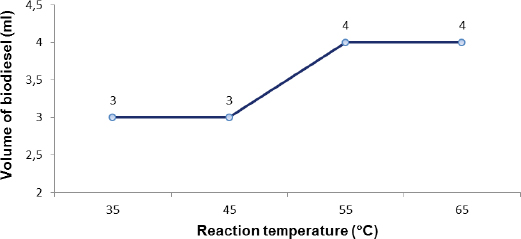

3.2.3 The reaction temperature profile towards biodiesel formation

The reaction temperature was set higher than the room temperature such as 35 °C, 45°C, 55°C, and 65°C. The reaction took place using 150ml (4:1) methanol and 50 ml used oil and 3 wt% catalyst concentration for two hours. Figure 5 revealed that a slightly increase in temperature resulted in a higher biodiesel yield. At the beginning, the FAME yield was 3ml although the temperature increased from 35°C to 45°C. This result showed that the low temperature did not favor a transesterification reaction. However, the additional increase of the reaction temperature from 45°C to 55°C, lifted the volume of biodiesel from 3ml to 4ml, subsequently no variation in the biodiesel volume was noted for a further increase of the reaction temperature from 55°C to 65°C.

The effect of different temperatures on the transesterification of used cooking oil. Conditions: reaction time of 2 hours, methanol to oil ratio 4:1, catalyst weight 2wt%.

The further increase in biodiesel volume in alignment with the increase of the reaction temperature attributed to the solubility of the methanol towards triglycerides.

However, increasing the reaction temperature further did not influence the biodiesel yield [25]. This is due to the boiling point of methanol at nearly 68°C, the evaporation of methanol and the bubbling which would adversely hinder a reaction if the temperature were higher than 65°C [15].

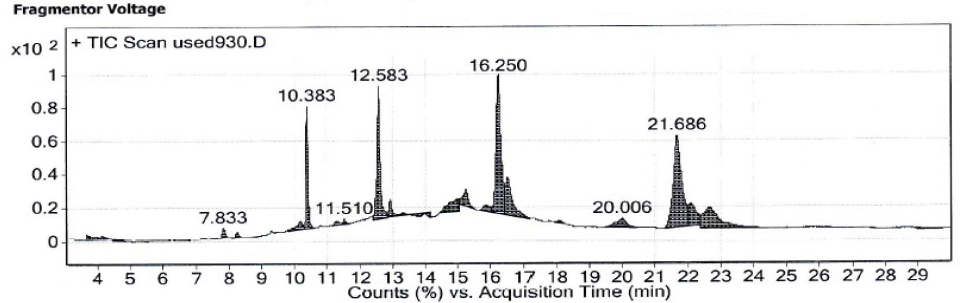

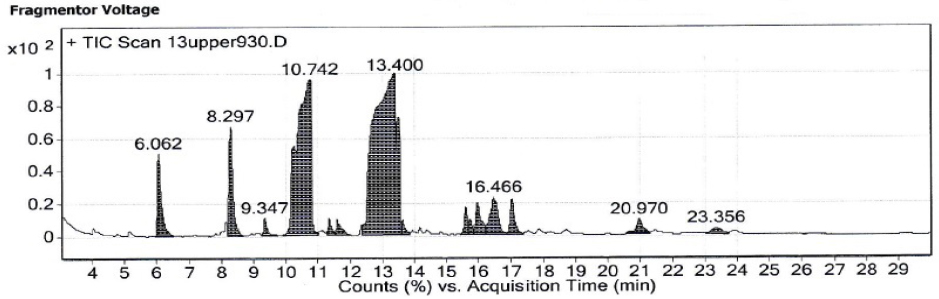

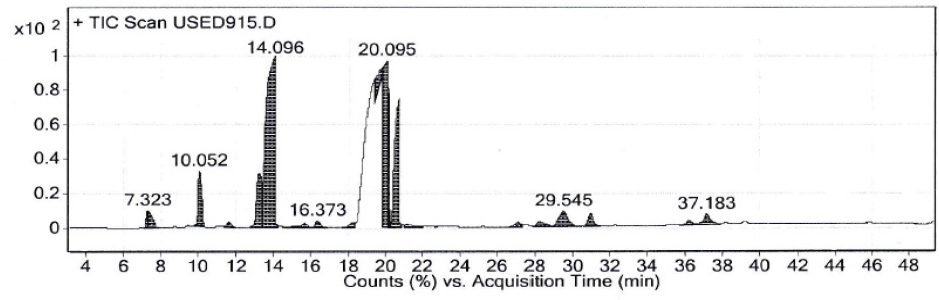

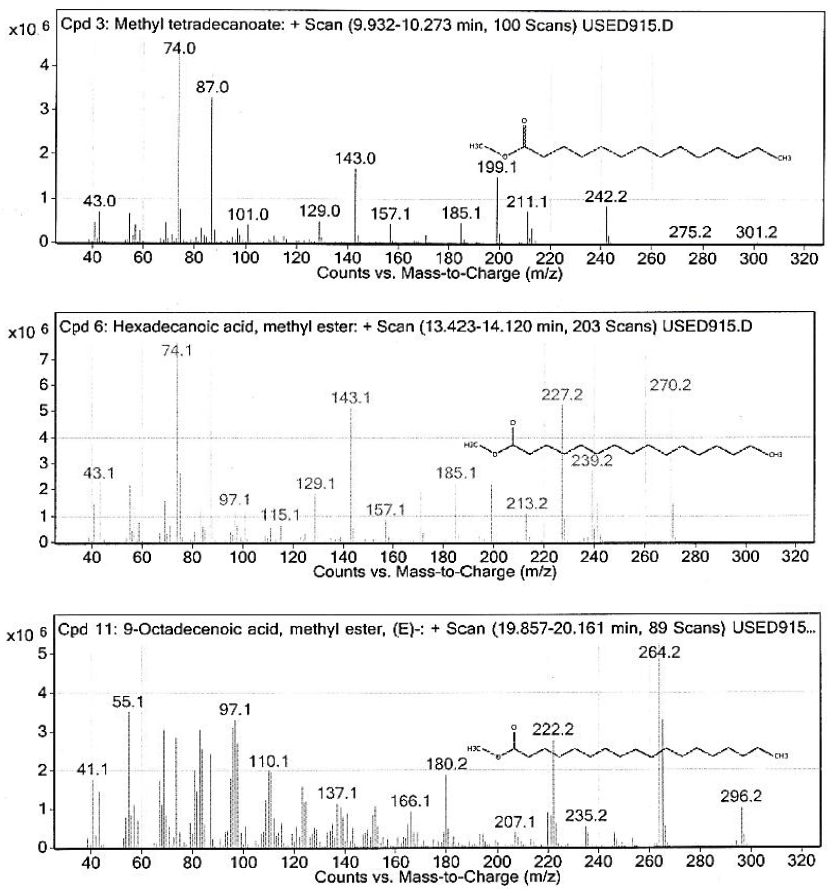

3.3 Product analysis using GC-MS

Figure 6, 7 and 8 show the chromatograms of the initial used cooking oil after transesterification using calcined eggshells and after transesterification using calcined CaO. The chromatogram peaks exhibit the outcome of separation of particular compounds, which were detected by the gas chromatogram. Chromatograms of natural derived CaO from calcined eggshells and pure calcined CaO after transesterification display some similarity in terms of peak shape and size as revealed in figures 7 & 8. The chromatogram peak and its components using calcined eggshells and using calcined pure CaO are exactly the same in table 1 &2.

The chromatograms of used cooking oil before transesterification.

The chromatograms of used cooking oil after transesterification using calcined eggshell.

The chromatograms of used cooking oil after transesterification using calcined CaO.

GC-MS analysis of sample product using calcined eggshell as the catalyst.

| No | Systemic name | Common name | Formula | Molecular mass |

|---|---|---|---|---|

| 1 | 9- Octadecenoic acid, methyl ester, (E) | Methyl 9-octadecenoate | C19H36O2 | 296 |

| 2 | Hexadecanoic acid, methyl ester | Methyl palmitate | C17H34O2 | 270 |

| 3 | Methyl tetradecanoate | Methyl myristate | C15H30O2 | 242 |

GC-MS analysis of sample product using calcined CaO as catalyst.

| No | Systemic name | Common name | Formula | Molecular mass |

|---|---|---|---|---|

| 1 | Hexadecanoic acid, methyl ester | Methyl palmitate | C17H34O2 | 270 |

| 2 | 9- Octadecenoic acid, methyl ester, (E) | Methyl 9-octadecenoate | C19H36O2 | 296 |

| 3 | Methyl tetradecanoate | Methyl myristate | C15H30O2 | 242 |

There are four methyl ester components in both chromatograms such as methyl tetradecanoate, hexadecanoic acid, methyl ester, 9-Octadecenoic acid, methyl ester, and 5,8,11,14-Eicosatetraenoic acid, methyl ester.

Besides, with the aid of mass spectrum, the selection of resemble mass to charge ratio of each possible compounds could be done more precisely. The desired compounds were selected based on the NIST library that comprises a database of mass spectra. The mass spectrum and its respective structure are displayed in used cooking oil, oil after transesterification using calcined eggshells and oil after transesterification using calcined CaO are displayed in figure 9 & 10.

Mas spectrum of selected components after transesterification using calcined eggshell.

Mass spectrum of selected components after transesterification using calcined CaO.

The three major components obtained from the mass spectrum analysis report were tabulated accordingly in tables 1 & 2. From table 1, methyl 9-octadecenoate, methyl palmitate and methyl myristate were formed as a biodiesel product after transesterification using calcined eggshells. Additionally, table 2 depicted methyl 9-octadecenoate, methyl palmitate and methyl myristate that were formed as a biodiesel product after transesterification using calcined CaO. In brief, the natural eggshells derived CaO can be used to replace the chemical CaO in future prospect.

4 Conclusion

In this study, different calcination methods on eggshell waste were developed to identify the calcium oxide component that acted as a catalyst and which was used in transesterification. Among different calcination methods, the open air calcination was the best option compared to the nitrogen gas flow method. The formerdid not require an extra cost in purchasing the nitrogen gas. The ggshell derived catalyst consisted only of CaO as an end product during the calcination process which was comparable to the calcined pure calcium oxide based on the XRD pattern. The optimal transesterification carried out using calcined eggshells was by the 4:1 methanol to oil ratio, 2wt % of catalyst weight and a reaction temperature of 65°C for 2 hours. Pure calcined calcium oxide acted as the experimental control and was subjected accordingly to the optimum calcined eggshell parameter. Bothmethyl ester components appeared almost at the same. It can be assumed that the natural derived CaO was capable of showing its catalytic activities during the transesterification process. Hence, it is assumed that the waste calcined eggshell can be replaced by the chemical calcium oxide. The cost of the biodiesel production could reduce the synthesizing catalyst from the waste materials.

Acknowledgement

The authors express their sincere appreciation to the faculty of Agro Based Industry and the faculty of Bioengineering and Technology, at the Universiti of Malaysia Kelantan, Jeli Campus for the financial support and good facilities which made this study possible.

References

[1] Abuhabaya, A., Fieldhouse, J., & Brown, D. (2013). Influence of production variables for biodiesel synthesis on yields and fuel properties, and optimization of production conditions. Fuel, 103 963-969.10.1016/j.fuel.2012.09.067Search in Google Scholar

[2] Ho, S.-H., Wong, Y.-D., & Chang, V. W.-C. (2014). Evaluating the potential of biodiesel (via recycled cooking oil) use in Singapore, an urban city. Resources, Conservation and Recycling 91, 117–124.10.1016/j.resconrec.2014.08.003Search in Google Scholar

[3] Sheinbaum-Pardo, C., Calderón-Irazoque, A., & Ramírez-Suárez, M. (2013). Potential of biodiesel from waste cooking oil in Mexico. Biomass and bioenergy56, 230-238.10.1016/j.biombioe.2013.05.008Search in Google Scholar

[4] Wei, Z., Xu, C., & Li, B. (2009). Application of waste eggshell as low-cost solid catalyst for biodiesel production. Bioresource technology 100(11), 2883-2885.10.1016/j.biortech.2008.12.039Search in Google Scholar

[5] Sun, D. W. (Ed.). (2011). Handbook of frozen food processing and packaging CRCPress. 150-288.Search in Google Scholar

[6] Ho, W. F., Hsu, H. C., Hsu, S. K., Hung, C. W., & Wu, S. C. (2013). Calcium phosphate bioceramics synthesized from eggshell powders through a solid state reaction. Ceramics international 39(6), 6467-6473.10.1016/j.ceramint.2013.01.076Search in Google Scholar

[7] Noor Idayu, A. (2011). Synthesis Of Hydroxyapatite Powder From Eggshell Waste For Bioceramic Purpose. 20-23.Search in Google Scholar

[8] Guru, P. S., & Dash, S. (2014). Sorption on eggshell waste—A review on ultrastructure, biomineralization and other applications. Advances in colloid and interface science 209, 49-67.10.1016/j.cis.2013.12.013Search in Google Scholar

[9] Wei, Z., Xu, C., & Li, B. (2009). Application of waste eggshell as low-cost solid catalyst for biodiesel production. Bioresource technology 100(11), 2883-2885.10.1016/j.biortech.2008.12.039Search in Google Scholar

[10] Hattori, H. (2001). Solid base catalysts: generation of basic sites and application to organic synthesis. Applied Catalysis A: General 222(1), 247-259.10.1016/S0926-860X(01)00839-0Search in Google Scholar

[11] Phan, A. N., & Phan, T. M. (2008). Biodiesel production from waste cooking oils. Fuel 87(17), 3490-3496.10.1016/j.fuel.2008.07.008Search in Google Scholar

[12] Rabu, R. A., Janajreh, I., & Honnery, D. (2013). Transesterification of waste cooking oil: Process optimization and conversion rate evaluation. Energy Conversion and Management 65, 764-769.10.1016/j.enconman.2012.02.031Search in Google Scholar

[13] Mekhilef, S., Siga, S., & Saidur, R. (2011). A review on palm oil biodiesel as a source of renewable fuel. Renewable and Sustainable Energy Reviews 15(4), 1937-1949.10.1016/j.rser.2010.12.012Search in Google Scholar

[14] Viriya-Empikul, N., Krasae, P., Nualpaeng, W., Yoosuk, B., & Faungnawakij, K. (2012). Biodiesel production over Ca-based solid catalysts derived from industrial wastes. Fuel 92(1), 239-244.10.1016/j.fuel.2011.07.013Search in Google Scholar

[15] Tan, Y. H., Abdullah, M. O., Nolasco-Hipolito, C., & Taufiq-Yap, Y. H. (2015). Waste ostrich-and chicken-eggshells as heterogeneous base catalyst for biodiesel production from used cooking oil: Catalyst characterization and biodiesel yield performance. Applied Energy 160, 58-70.10.1016/j.apenergy.2015.09.023Search in Google Scholar

[16] Chen, M., Xiao, F., Putman, B., Leng, B., & Wu, S. (2014). High temperature properties of rejuvenating recovered binder with rejuvenator, waste cooking and cotton seed oils. Construction and Building Materials 59, 10-16.10.1016/j.conbuildmat.2014.02.032Search in Google Scholar

[17] Navajas, A., Issariyakul, T., Arzamendi, G., Gandía, L. M., & Dalai, A. K. (2013). Development of eggshell derived catalyst for transesterification of used cooking oil for biodiesel production. Asia‐Pacific Journal of Chemical Engineering 8(5), 742-748.10.1002/apj.1715Search in Google Scholar

[18] Raihana, M. F., Hamdi, M., & Ramesh, S. (2008). Novel chemical conversion of eggshell to hydroxyapatite powder. In 4th Kuala Lumpur International Conference on Biomedical Engineering 2008 (pp. 333-336). Springer Berlin Heidelberg.10.1007/978-3-540-69139-6_85Search in Google Scholar

[19] Jazie, A. A., Pramanik, H., Sinha, A. S. K., & JAZIE, A. (2013). Egg shell as eco-friendly catalyst for transesterification of rapeseed oil: optimization for biodiesel production. Special Issue of International Journal of Suistanable Development and Green Economics (IJSDGE) 2(1), 27-32.10.1007/s40243-013-0011-4Search in Google Scholar

[20] Buasri, A., Worawanitchaphong, P., Trongyong, S., & Loryuenyong, V. (2014). Utilization of Scallop Waste Shell for Biodiesel Production from Palm Oil–Optimization Using Taguchi Method. APCBEE Procedia 8, 216-221.10.1016/j.apcbee.2014.03.030Search in Google Scholar

[21] Viriya-Empikul, N., Krasae, P., Puttasawat, B., Yoosuk, B., Chollacoop, N., & Faungnawakij, K. (2010). Waste shells of mollusk and egg as biodiesel production catalysts. Bioresource technology 101(10), 3765-3767.10.1016/j.biortech.2009.12.079Search in Google Scholar PubMed

[22] Fadhil, A. B., Al-Tikrity, E. T., & Albadree, M. A. (2015). Transesterification of a novel feedstock, Cyprinus carpio fish oil: Influence of co-solvent and characterization of biodiesel. Fuel 162, 215-223.10.1016/j.fuel.2015.09.001Search in Google Scholar

[23] Seenuvasan, M., Selvi, P. K., Kumar, M. A., Iyyappan, J., & Kumar, K. S. (2014). Standardization of non-edible Pongamia pinnata oil methyl ester conversion using hydroxyl content and GC–MS analysis. Journal of the Taiwan Institute of Chemical Engineers 45(4), 1485-1489.10.1016/j.jtice.2013.11.002Search in Google Scholar

[24] Zhang, Y., Dube, M. A., McLean, D., & Kates, M. (2003). Biodiesel production from waste cooking oil: 1. Process design and technological assessment.Bioresource technology 89(1),1-16.10.1016/S0960-8524(03)00040-3Search in Google Scholar

[25] Moradi, G. R., Mohadesi, M., Ghanbari, M., Moradi, M. J., Hosseini, S., & Davoodbeygi, Y. (2015). Kinetic comparison of two basic heterogenous catalysts obtained from sustainable resources for transesterification of waste cooking oil.10.18331/BRJ2015.2.2.5Search in Google Scholar

© 2018 Y.C. Wong, R.X. Ang, published by De Gruyter.

This work is licensed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 License.

Articles in the same Issue

- Regular Articles

- The effect of CuO modification for a TiO2 nanotube confined CeO2 catalyst on the catalytic combustion of butane

- The preparation and antibacterial activity of cellulose/ZnO composite: a review

- Linde Type A and nano magnetite/NaA zeolites: cytotoxicity and doxorubicin loading efficiency

- Performance and thermal decomposition analysis of foaming agent NPL-10 for use in heavy oil recovery by steam injection

- Spectroscopic (FT-IR, FT-Raman, UV, 1H and 13C NMR) insights, electronic profiling and DFT computations on ({(E)-[3-(1H-imidazol-1-yl)-1-phenylpropylidene] amino}oxy)(4-nitrophenyl)methanone, an imidazole-bearing anti-Candida agent

- A Simplistic Preliminary Assessment of Ginstling-Brounstein Model for Solid Spherical Particles in the Context of a Diffusion-Controlled Synthesis

- M-Polynomials And Topological Indices Of Zigzag And Rhombic Benzenoid Systems

- Photochemical Transformation of some 3-benzyloxy-2-(benzo[b]thiophen-2-yl)-4Hchromen-4-ones: A Remote Substituent Effect

- Dynamic Changes of Secondary Metabolites and Antioxidant Activity of Ligustrum lucidum During Fruit Growth

- Studies on the flammability of polypropylene/ammonium polyphosphate and montmorillonite by using the cone calorimeter test

- DSC, FT-IR, NIR, NIR-PCA and NIR-ANOVA for determination of chemical stability of diuretic drugs: impact of excipients

- Antioxidant and Hepatoprotective Effects of Methanolic Extracts of Zilla spinosa and Hammada elegans Against Carbon Tetrachlorideinduced Hepatotoxicity in Rats

- Prunus cerasifera Ehrh. fabricated ZnO nano falcates and its photocatalytic and dose dependent in vitro bio-activity

- Organic biocides hosted in layered double hydroxides: enhancing antimicrobial activity

- Experimental study on the regulation of the cholinergic pathway in renal macrophages by microRNA-132 to alleviate inflammatory response

- Synthesis, characterization, in-vitro antimicrobial properties, molecular docking and DFT studies of 3-{(E)-[(4,6-dimethylpyrimidin-2-yl)imino]methyl} naphthalen-2-ol and Heteroleptic Mn(II), Co(II), Ni(II) and Zn(II) complexes

- M-Polynomials and Topological Indices of Dominating David Derived Networks

- Human Health Risk Assessment of Trace Metals in Surface Water Due to Leachate from the Municipal Dumpsite by Pollution Index: A Case Study from Ndawuse River, Abuja, Nigeria

- Analysis of Bowel Diseases from Blood Serum by Autofluorescence and Atomic Force Microscopy Techniques

- Hydrographic parameters and distribution of dissolved Cu, Ni, Zn and nutrients near Jeddah desalination plant

- Relationships between diatoms and environmental variables in industrial water biotopes of Trzuskawica S.A. (Poland)

- Optimum Conversion of Major Ginsenoside Rb1 to Minor Ginsenoside Rg3(S) by Pulsed Electric Field-Assisted Acid Hydrolysis Treatment

- Antioxidant, Anti-microbial Properties and Chemical Composition of Cumin Essential Oils Extracted by Three Methods

- Regulatory mechanism of ulinastatin on autophagy of macrophages and renal tubular epithelial cells

- Investigation of the sustained-release mechanism of hydroxypropyl methyl cellulose skeleton type Acipimox tablets

- Bio-accumulation of Polycyclic Aromatic Hydrocarbons in the Grey Mangrove (Avicennia marina) along Arabian Gulf, Saudi Coast

- Dynamic Change of Secondary Metabolites and spectrum-effect relationship of Malus halliana Koehne flowers during blooming

- Lipids constituents from Gardenia aqualla Stapf & Hutch

- Effect of using microwaves for catalysts preparation on the catalytic acetalization of glycerol with furfural to obtain fuel additives

- Effect of Humic Acid on the Degradation of Methylene Blue by Peroxymonosulfate

- Serum containing drugs of Gua Lou Xie Bai decoction (GLXB-D) can inhibit TGF-β1-Induced Epithelial to Mesenchymal Transition (EMT) in A549 Cells

- Antiulcer Activity of Different Extracts of Anvillea garcinii and Isolation of Two New Secondary Metabolites

- Analysis of Metabolites in Cabernet Sauvignon and Shiraz Dry Red Wines from Shanxi by 1H NMR Spectroscopy Combined with Pattern Recognition Analysis

- Can water temperature impact litter decomposition under pollution of copper and zinc mixture

- Released from ZrO2/SiO2 coating resveratrol inhibits senescence and oxidative stress of human adipose-derived stem cells (ASC)

- Validated thin-layer chromatographic method for alternative and simultaneous determination of two anti-gout agents in their fixed dose combinations

- Fast removal of pollutants from vehicle emissions during cold-start stage

- Review Article

- Catalytic activities of heterogeneous catalysts obtained by copolymerization of metal-containing 2-(acetoacetoxy)ethyl methacrylate

- Antibiotic Residue in the Aquatic Environment: Status in Africa

- Regular Articles

- Mercury fractionation in gypsum using temperature desorption and mass spectrometric detection

- Phytosynthetic Ag doped ZnO nanoparticles: Semiconducting green remediators

- Epithelial–Mesenchymal Transition Induced by SMAD4 Activation in Invasive Growth Hormone-Secreting Adenomas

- Physicochemical properties of stabilized sewage sludge admixtures by modified steel slag

- In Vitro Cytotoxic and Antiproliferative Activity of Cydonia oblonga flower petals, leaf and fruit pellet ethanolic extracts. Docking simulation of the active flavonoids on anti-apoptotic protein Bcl-2

- Synthesis and Characterization of Pd exchanged MMT Clay for Mizoroki-Heck Reaction

- A new selective, and sensitive method for the determination of lixivaptan, a vasopressin 2 (V2)-receptor antagonist, in mouse plasma and its application in a pharmacokinetic study

- Anti-EGFL7 antibodies inhibit rat prolactinoma MMQ cells proliferation and PRL secretion

- Density functional theory calculations, vibration spectral analysis and molecular docking of the antimicrobial agent 6-(1,3-benzodioxol-5-ylmethyl)-5-ethyl-2-{[2-(morpholin-4-yl)ethyl] sulfanyl}pyrimidin-4(3H)-one

- Effect of Nano Zeolite on the Transformation of Cadmium Speciation and Its Uptake by Tobacco in Cadmium-contaminated Soil

- Effects and Mechanisms of Jinniu Capsule on Methamphetamine-Induced Conditioned Place Preference in Rats

- Calculating the Degree-based Topological Indices of Dendrimers

- Efficient optimization and mineralization of UV absorbers: A comparative investigation with Fenton and UV/H2O2

- Metabolites of Tryptophane and Phenylalanine as Markers of Small Bowel Ischemia-Reperfusion Injury

- Adsorption and determination of polycyclic aromatic hydrocarbons in water through the aggregation of graphene oxide

- The role of NR2C2 in the prolactinomas

- Chromium removal from industrial wastewater using Phyllostachys pubescens biomass loaded Cu-S nanospheres

- Hydrotalcite Anchored Ruthenium Catalyst for CO2 Hydrogenation Reaction

- Preparation of Calcium Fluoride using Phosphogypsum by Orthogonal Experiment

- The mechanism of antibacterial activity of corylifolinin against three clinical bacteria from Psoralen corylifolia L

- 2-formyl-3,6-bis(hydroxymethyl)phenyl benzoate in Electrochemical Dry Cell

- Electro-photocatalytic degradation of amoxicillin using calcium titanate

- Effect of Malus halliana Koehne Polysaccharides on Functional Constipation

- Structural Properties and Nonlinear Optical Responses of Halogenated Compounds: A DFT Investigation on Molecular Modelling

- DMFDMA catalyzed synthesis of 2-((Dimethylamino)methylene)-3,4-dihydro-9-arylacridin-1(2H)-ones and their derivatives: in-vitro antifungal, antibacterial and antioxidant evaluations

- Production of Methanol as a Fuel Energy from CO2 Present in Polluted Seawater - A Photocatalytic Outlook

- Study of different extraction methods on finger print and fatty acid of raw beef fat using fourier transform infrared and gas chromatography-mass spectrometry

- Determination of trace fluoroquinolones in water solutions and in medicinal preparations by conventional and synchronous fluorescence spectrometry

- Extraction and determination of flavonoids in Carthamus tinctorius

- Therapeutic Application of Zinc and Vanadium Complexes against Diabetes Mellitus a Coronary Disease: A review

- Study of calcined eggshell as potential catalyst for biodiesel formation using used cooking oil

- Manganese oxalates - structure-based Insights

- Topological Indices of H-Naphtalenic Nanosheet

- Long-Term Dissolution of Glass Fibers in Water Described by Dissolving Cylinder Zero-Order Kinetic Model: Mass Loss and Radius Reduction

- Topological study of the para-line graphs of certain pentacene via topological indices

- A brief insight into the prediction of water vapor transmissibility in highly impermeable hybrid nanocomposites based on bromobutyl/epichlorohydrin rubber blends

- Comparative sulfite assay by voltammetry using Pt electrodes, photometry and titrimetry: Application to cider, vinegar and sugar analysis

- MicroRNA delivery mediated by PEGylated polyethylenimine for prostate cancer therapy

- Reversible Fluorescent Turn-on Sensors for Fe3+ based on a Receptor Composed of Tri-oxygen Atoms of Amide Groups in Water

- Sonocatalytic degradation of methyl orange in aqueous solution using Fe-doped TiO2 nanoparticles under mechanical agitation

- Hydrotalcite Anchored Ruthenium Catalyst for CO2 Hydrogenation Reaction

- Production and Analysis of Recycled Ammonium Perrhenate from CMSX-4 superalloys

- Topical Issue on Agriculture

- New phosphorus biofertilizers from renewable raw materials in the aspect of cadmium and lead contents in soil and plants

- Survey of content of cadmium, calcium, chromium, copper, iron, lead, magnesium, manganese, mercury, sodium and zinc in chamomile and green tea leaves by electrothermal or flame atomizer atomic absorption spectrometry

- Biogas digestate – benefits and risks for soil fertility and crop quality – an evaluation of grain maize response

- A numerical analysis of heat transfer in a cross-current heat exchanger with controlled and newly designed air flows

- Freshwater green macroalgae as a biosorbent of Cr(III) ions

- The main influencing factors of soil mechanical characteristics of the gravity erosion environment in the dry-hot valley of Jinsha river

- Free amino acids in Viola tricolor in relation to different habitat conditions

- The influence of filler amount on selected properties of new experimental resin dental composite

- Effect of poultry wastewater irrigation on nitrogen, phosphorus and carbon contents in farmland soil

- Response of spring wheat to NPK and S fertilization. The content and uptake of macronutrients and the value of ionic ratios

- The Effect of Macroalgal Extracts and Near Infrared Radiation on Germination of Soybean Seedlings: Preliminary Research Results

- Content of Zn, Cd and Pb in purple moor-grass in soils heavily contaminated with heavy metals around a zinc and lead ore tailing landfill

- Topical Issue on Research for Natural Bioactive Products

- Synthesis of (±)-3,4-dimethoxybenzyl-4-methyloctanoate as a novel internal standard for capsinoid determination by HPLC-ESI-MS/MS(QTOF)

- Repellent activity of monoterpenoid esters with neurotransmitter amino acids against yellow fever mosquito, Aedes aegypti

- Effect of Flammulina velutipes (golden needle mushroom, eno-kitake) polysaccharides on constipation

- Bioassay-directed fractionation of a blood coagulation factor Xa inhibitor, betulinic acid from Lycopus lucidus

- Antifungal and repellent activities of the essential oils from three aromatic herbs from western Himalaya

- Chemical composition and microbiological evaluation of essential oil from Hyssopus officinalis L. with white and pink flowers

- Bioassay-guided isolation and identification of Aedes aegypti larvicidal and biting deterrent compounds from Veratrum lobelianum

- α-Terpineol, a natural monoterpene: A review of its biological properties

- Utility of essential oils for development of host-based lures for Xyleborus glabratus (Coleoptera: Curculionidae: Scolytinae), vector of laurel wilt

- Phenolic composition and antioxidant potential of different organs of Kazakh Crataegus almaatensis Pojark: A comparison with the European Crataegus oxyacantha L. flowers

- Isolation of eudesmane type sesquiterpene ketone from Prangos heyniae H.Duman & M.F.Watson essential oil and mosquitocidal activity of the essential oils

- Comparative analysis of the polyphenols profiles and the antioxidant and cytotoxicity properties of various blue honeysuckle varieties

- Special Issue on ICCESEN 2017

- Modelling world energy security data from multinomial distribution by generalized linear model under different cumulative link functions

- Pine Cone and Boron Compounds Effect as Reinforcement on Mechanical and Flammability Properties of Polyester Composites

- Artificial Neural Network Modelling for Prediction of SNR Effected by Probe Properties on Ultrasonic Inspection of Austenitic Stainless Steel Weldments

- Calculation and 3D analyses of ERR in the band crack front contained in a rectangular plate made of multilayered material

- Improvement of fuel properties of biodiesel with bioadditive ethyl levulinate

- Properties of AlSi9Cu3 metal matrix micro and nano composites produced via stir casting

- Investigation of Antibacterial Properties of Ag Doped TiO2 Nanofibers Prepared by Electrospinning Process

- Modeling of Total Phenolic contents in Various Tea samples by Experimental Design Methods

- Nickel doping effect on the structural and optical properties of indium sulfide thin films by SILAR

- The effect mechanism of Ginnalin A as a homeopathic agent on various cancer cell lines

- Excitation functions of proton induced reactions of some radioisotopes used in medicine

- Oxide ionic conductivity and microstructures of Pr and Sm co-doped CeO2-based systems

- Rapid Synthesis of Metallic Reinforced in Situ Intermetallic Composites in Ti-Al-Nb System via Resistive Sintering

- Oxidation Behavior of NiCr/YSZ Thermal Barrier Coatings (TBCs)

- Clustering Analysis of Normal Strength Concretes Produced with Different Aggregate Types

- Magnetic Nano-Sized Solid Acid Catalyst Bearing Sulfonic Acid Groups for Biodiesel Synthesis

- The biological activities of Arabis alpina L. subsp. brevifolia (DC.) Cullen against food pathogens

- Humidity properties of Schiff base polymers

- Free Vibration Analysis of Fiber Metal Laminated Straight Beam

- Comparative study of in vitro antioxidant, acetylcholinesterase and butyrylcholinesterase activity of alfalfa (Medicago sativa L.) collected during different growth stages

- Isothermal Oxidation Behavior of Gadolinium Zirconate (Gd2Zr2O7) Thermal Barrier Coatings (TBCs) produced by Electron Beam Physical Vapor Deposition (EB-PVD) technique

- Optimization of Adsorption Parameters for Ultra-Fine Calcite Using a Box-Behnken Experimental Design

- The Microstructural Investigation of Vermiculite-Infiltrated Electron Beam Physical Vapor Deposition Thermal Barrier Coatings

- Modelling Porosity Permeability of Ceramic Tiles using Fuzzy Taguchi Method

- Experimental and theoretical study of a novel naphthoquinone Schiff base

- Physicochemical properties of heat treated sille stone for ceramic industry

- Sand Dune Characterization for Preparing Metallurgical Grade Silicon

- Catalytic Applications of Large Pore Sulfonic Acid-Functionalized SBA-15 Mesoporous Silica for Esterification

- One-photon Absorption Characterizations, Dipole Polarizabilities and Second Hyperpolarizabilities of Chlorophyll a and Crocin

- The Optical and Crystallite Characterization of Bilayer TiO2 Films Coated on Different ITO layers

- Topical Issue on Bond Activation

- Metal-mediated reactions towards the synthesis of a novel deaminolysed bisurea, dicarbamolyamine

- The structure of ortho-(trifluoromethyl)phenol in comparison to its homologues – A combined experimental and theoretical study

- Heterogeneous catalysis with encapsulated haem and other synthetic porphyrins: Harnessing the power of porphyrins for oxidation reactions

- Recent Advances on Mechanistic Studies on C–H Activation Catalyzed by Base Metals

- Reactions of the organoplatinum complex [Pt(cod) (neoSi)Cl] (neoSi = trimethylsilylmethyl) with the non-coordinating anions SbF6– and BPh4–

- Erratum

- Investigation on Two Compounds of O, O’-dithiophosphate Derivatives as Corrosion Inhibitors for Q235 Steel in Hydrochloric Acid Solution

Articles in the same Issue

- Regular Articles

- The effect of CuO modification for a TiO2 nanotube confined CeO2 catalyst on the catalytic combustion of butane

- The preparation and antibacterial activity of cellulose/ZnO composite: a review

- Linde Type A and nano magnetite/NaA zeolites: cytotoxicity and doxorubicin loading efficiency

- Performance and thermal decomposition analysis of foaming agent NPL-10 for use in heavy oil recovery by steam injection

- Spectroscopic (FT-IR, FT-Raman, UV, 1H and 13C NMR) insights, electronic profiling and DFT computations on ({(E)-[3-(1H-imidazol-1-yl)-1-phenylpropylidene] amino}oxy)(4-nitrophenyl)methanone, an imidazole-bearing anti-Candida agent

- A Simplistic Preliminary Assessment of Ginstling-Brounstein Model for Solid Spherical Particles in the Context of a Diffusion-Controlled Synthesis

- M-Polynomials And Topological Indices Of Zigzag And Rhombic Benzenoid Systems

- Photochemical Transformation of some 3-benzyloxy-2-(benzo[b]thiophen-2-yl)-4Hchromen-4-ones: A Remote Substituent Effect

- Dynamic Changes of Secondary Metabolites and Antioxidant Activity of Ligustrum lucidum During Fruit Growth

- Studies on the flammability of polypropylene/ammonium polyphosphate and montmorillonite by using the cone calorimeter test

- DSC, FT-IR, NIR, NIR-PCA and NIR-ANOVA for determination of chemical stability of diuretic drugs: impact of excipients

- Antioxidant and Hepatoprotective Effects of Methanolic Extracts of Zilla spinosa and Hammada elegans Against Carbon Tetrachlorideinduced Hepatotoxicity in Rats

- Prunus cerasifera Ehrh. fabricated ZnO nano falcates and its photocatalytic and dose dependent in vitro bio-activity

- Organic biocides hosted in layered double hydroxides: enhancing antimicrobial activity

- Experimental study on the regulation of the cholinergic pathway in renal macrophages by microRNA-132 to alleviate inflammatory response

- Synthesis, characterization, in-vitro antimicrobial properties, molecular docking and DFT studies of 3-{(E)-[(4,6-dimethylpyrimidin-2-yl)imino]methyl} naphthalen-2-ol and Heteroleptic Mn(II), Co(II), Ni(II) and Zn(II) complexes

- M-Polynomials and Topological Indices of Dominating David Derived Networks

- Human Health Risk Assessment of Trace Metals in Surface Water Due to Leachate from the Municipal Dumpsite by Pollution Index: A Case Study from Ndawuse River, Abuja, Nigeria

- Analysis of Bowel Diseases from Blood Serum by Autofluorescence and Atomic Force Microscopy Techniques

- Hydrographic parameters and distribution of dissolved Cu, Ni, Zn and nutrients near Jeddah desalination plant

- Relationships between diatoms and environmental variables in industrial water biotopes of Trzuskawica S.A. (Poland)

- Optimum Conversion of Major Ginsenoside Rb1 to Minor Ginsenoside Rg3(S) by Pulsed Electric Field-Assisted Acid Hydrolysis Treatment

- Antioxidant, Anti-microbial Properties and Chemical Composition of Cumin Essential Oils Extracted by Three Methods

- Regulatory mechanism of ulinastatin on autophagy of macrophages and renal tubular epithelial cells

- Investigation of the sustained-release mechanism of hydroxypropyl methyl cellulose skeleton type Acipimox tablets

- Bio-accumulation of Polycyclic Aromatic Hydrocarbons in the Grey Mangrove (Avicennia marina) along Arabian Gulf, Saudi Coast

- Dynamic Change of Secondary Metabolites and spectrum-effect relationship of Malus halliana Koehne flowers during blooming

- Lipids constituents from Gardenia aqualla Stapf & Hutch

- Effect of using microwaves for catalysts preparation on the catalytic acetalization of glycerol with furfural to obtain fuel additives

- Effect of Humic Acid on the Degradation of Methylene Blue by Peroxymonosulfate

- Serum containing drugs of Gua Lou Xie Bai decoction (GLXB-D) can inhibit TGF-β1-Induced Epithelial to Mesenchymal Transition (EMT) in A549 Cells

- Antiulcer Activity of Different Extracts of Anvillea garcinii and Isolation of Two New Secondary Metabolites

- Analysis of Metabolites in Cabernet Sauvignon and Shiraz Dry Red Wines from Shanxi by 1H NMR Spectroscopy Combined with Pattern Recognition Analysis

- Can water temperature impact litter decomposition under pollution of copper and zinc mixture

- Released from ZrO2/SiO2 coating resveratrol inhibits senescence and oxidative stress of human adipose-derived stem cells (ASC)

- Validated thin-layer chromatographic method for alternative and simultaneous determination of two anti-gout agents in their fixed dose combinations

- Fast removal of pollutants from vehicle emissions during cold-start stage

- Review Article

- Catalytic activities of heterogeneous catalysts obtained by copolymerization of metal-containing 2-(acetoacetoxy)ethyl methacrylate

- Antibiotic Residue in the Aquatic Environment: Status in Africa

- Regular Articles

- Mercury fractionation in gypsum using temperature desorption and mass spectrometric detection

- Phytosynthetic Ag doped ZnO nanoparticles: Semiconducting green remediators

- Epithelial–Mesenchymal Transition Induced by SMAD4 Activation in Invasive Growth Hormone-Secreting Adenomas

- Physicochemical properties of stabilized sewage sludge admixtures by modified steel slag

- In Vitro Cytotoxic and Antiproliferative Activity of Cydonia oblonga flower petals, leaf and fruit pellet ethanolic extracts. Docking simulation of the active flavonoids on anti-apoptotic protein Bcl-2

- Synthesis and Characterization of Pd exchanged MMT Clay for Mizoroki-Heck Reaction

- A new selective, and sensitive method for the determination of lixivaptan, a vasopressin 2 (V2)-receptor antagonist, in mouse plasma and its application in a pharmacokinetic study

- Anti-EGFL7 antibodies inhibit rat prolactinoma MMQ cells proliferation and PRL secretion

- Density functional theory calculations, vibration spectral analysis and molecular docking of the antimicrobial agent 6-(1,3-benzodioxol-5-ylmethyl)-5-ethyl-2-{[2-(morpholin-4-yl)ethyl] sulfanyl}pyrimidin-4(3H)-one

- Effect of Nano Zeolite on the Transformation of Cadmium Speciation and Its Uptake by Tobacco in Cadmium-contaminated Soil

- Effects and Mechanisms of Jinniu Capsule on Methamphetamine-Induced Conditioned Place Preference in Rats

- Calculating the Degree-based Topological Indices of Dendrimers

- Efficient optimization and mineralization of UV absorbers: A comparative investigation with Fenton and UV/H2O2

- Metabolites of Tryptophane and Phenylalanine as Markers of Small Bowel Ischemia-Reperfusion Injury

- Adsorption and determination of polycyclic aromatic hydrocarbons in water through the aggregation of graphene oxide

- The role of NR2C2 in the prolactinomas

- Chromium removal from industrial wastewater using Phyllostachys pubescens biomass loaded Cu-S nanospheres

- Hydrotalcite Anchored Ruthenium Catalyst for CO2 Hydrogenation Reaction

- Preparation of Calcium Fluoride using Phosphogypsum by Orthogonal Experiment

- The mechanism of antibacterial activity of corylifolinin against three clinical bacteria from Psoralen corylifolia L

- 2-formyl-3,6-bis(hydroxymethyl)phenyl benzoate in Electrochemical Dry Cell

- Electro-photocatalytic degradation of amoxicillin using calcium titanate

- Effect of Malus halliana Koehne Polysaccharides on Functional Constipation

- Structural Properties and Nonlinear Optical Responses of Halogenated Compounds: A DFT Investigation on Molecular Modelling

- DMFDMA catalyzed synthesis of 2-((Dimethylamino)methylene)-3,4-dihydro-9-arylacridin-1(2H)-ones and their derivatives: in-vitro antifungal, antibacterial and antioxidant evaluations

- Production of Methanol as a Fuel Energy from CO2 Present in Polluted Seawater - A Photocatalytic Outlook

- Study of different extraction methods on finger print and fatty acid of raw beef fat using fourier transform infrared and gas chromatography-mass spectrometry

- Determination of trace fluoroquinolones in water solutions and in medicinal preparations by conventional and synchronous fluorescence spectrometry

- Extraction and determination of flavonoids in Carthamus tinctorius

- Therapeutic Application of Zinc and Vanadium Complexes against Diabetes Mellitus a Coronary Disease: A review

- Study of calcined eggshell as potential catalyst for biodiesel formation using used cooking oil

- Manganese oxalates - structure-based Insights

- Topological Indices of H-Naphtalenic Nanosheet

- Long-Term Dissolution of Glass Fibers in Water Described by Dissolving Cylinder Zero-Order Kinetic Model: Mass Loss and Radius Reduction

- Topological study of the para-line graphs of certain pentacene via topological indices

- A brief insight into the prediction of water vapor transmissibility in highly impermeable hybrid nanocomposites based on bromobutyl/epichlorohydrin rubber blends

- Comparative sulfite assay by voltammetry using Pt electrodes, photometry and titrimetry: Application to cider, vinegar and sugar analysis

- MicroRNA delivery mediated by PEGylated polyethylenimine for prostate cancer therapy

- Reversible Fluorescent Turn-on Sensors for Fe3+ based on a Receptor Composed of Tri-oxygen Atoms of Amide Groups in Water

- Sonocatalytic degradation of methyl orange in aqueous solution using Fe-doped TiO2 nanoparticles under mechanical agitation

- Hydrotalcite Anchored Ruthenium Catalyst for CO2 Hydrogenation Reaction

- Production and Analysis of Recycled Ammonium Perrhenate from CMSX-4 superalloys

- Topical Issue on Agriculture

- New phosphorus biofertilizers from renewable raw materials in the aspect of cadmium and lead contents in soil and plants

- Survey of content of cadmium, calcium, chromium, copper, iron, lead, magnesium, manganese, mercury, sodium and zinc in chamomile and green tea leaves by electrothermal or flame atomizer atomic absorption spectrometry

- Biogas digestate – benefits and risks for soil fertility and crop quality – an evaluation of grain maize response

- A numerical analysis of heat transfer in a cross-current heat exchanger with controlled and newly designed air flows

- Freshwater green macroalgae as a biosorbent of Cr(III) ions

- The main influencing factors of soil mechanical characteristics of the gravity erosion environment in the dry-hot valley of Jinsha river

- Free amino acids in Viola tricolor in relation to different habitat conditions

- The influence of filler amount on selected properties of new experimental resin dental composite

- Effect of poultry wastewater irrigation on nitrogen, phosphorus and carbon contents in farmland soil

- Response of spring wheat to NPK and S fertilization. The content and uptake of macronutrients and the value of ionic ratios

- The Effect of Macroalgal Extracts and Near Infrared Radiation on Germination of Soybean Seedlings: Preliminary Research Results

- Content of Zn, Cd and Pb in purple moor-grass in soils heavily contaminated with heavy metals around a zinc and lead ore tailing landfill

- Topical Issue on Research for Natural Bioactive Products

- Synthesis of (±)-3,4-dimethoxybenzyl-4-methyloctanoate as a novel internal standard for capsinoid determination by HPLC-ESI-MS/MS(QTOF)

- Repellent activity of monoterpenoid esters with neurotransmitter amino acids against yellow fever mosquito, Aedes aegypti

- Effect of Flammulina velutipes (golden needle mushroom, eno-kitake) polysaccharides on constipation

- Bioassay-directed fractionation of a blood coagulation factor Xa inhibitor, betulinic acid from Lycopus lucidus

- Antifungal and repellent activities of the essential oils from three aromatic herbs from western Himalaya

- Chemical composition and microbiological evaluation of essential oil from Hyssopus officinalis L. with white and pink flowers

- Bioassay-guided isolation and identification of Aedes aegypti larvicidal and biting deterrent compounds from Veratrum lobelianum

- α-Terpineol, a natural monoterpene: A review of its biological properties

- Utility of essential oils for development of host-based lures for Xyleborus glabratus (Coleoptera: Curculionidae: Scolytinae), vector of laurel wilt

- Phenolic composition and antioxidant potential of different organs of Kazakh Crataegus almaatensis Pojark: A comparison with the European Crataegus oxyacantha L. flowers

- Isolation of eudesmane type sesquiterpene ketone from Prangos heyniae H.Duman & M.F.Watson essential oil and mosquitocidal activity of the essential oils

- Comparative analysis of the polyphenols profiles and the antioxidant and cytotoxicity properties of various blue honeysuckle varieties

- Special Issue on ICCESEN 2017

- Modelling world energy security data from multinomial distribution by generalized linear model under different cumulative link functions

- Pine Cone and Boron Compounds Effect as Reinforcement on Mechanical and Flammability Properties of Polyester Composites

- Artificial Neural Network Modelling for Prediction of SNR Effected by Probe Properties on Ultrasonic Inspection of Austenitic Stainless Steel Weldments

- Calculation and 3D analyses of ERR in the band crack front contained in a rectangular plate made of multilayered material

- Improvement of fuel properties of biodiesel with bioadditive ethyl levulinate

- Properties of AlSi9Cu3 metal matrix micro and nano composites produced via stir casting

- Investigation of Antibacterial Properties of Ag Doped TiO2 Nanofibers Prepared by Electrospinning Process

- Modeling of Total Phenolic contents in Various Tea samples by Experimental Design Methods

- Nickel doping effect on the structural and optical properties of indium sulfide thin films by SILAR

- The effect mechanism of Ginnalin A as a homeopathic agent on various cancer cell lines

- Excitation functions of proton induced reactions of some radioisotopes used in medicine

- Oxide ionic conductivity and microstructures of Pr and Sm co-doped CeO2-based systems

- Rapid Synthesis of Metallic Reinforced in Situ Intermetallic Composites in Ti-Al-Nb System via Resistive Sintering

- Oxidation Behavior of NiCr/YSZ Thermal Barrier Coatings (TBCs)

- Clustering Analysis of Normal Strength Concretes Produced with Different Aggregate Types

- Magnetic Nano-Sized Solid Acid Catalyst Bearing Sulfonic Acid Groups for Biodiesel Synthesis

- The biological activities of Arabis alpina L. subsp. brevifolia (DC.) Cullen against food pathogens

- Humidity properties of Schiff base polymers

- Free Vibration Analysis of Fiber Metal Laminated Straight Beam

- Comparative study of in vitro antioxidant, acetylcholinesterase and butyrylcholinesterase activity of alfalfa (Medicago sativa L.) collected during different growth stages

- Isothermal Oxidation Behavior of Gadolinium Zirconate (Gd2Zr2O7) Thermal Barrier Coatings (TBCs) produced by Electron Beam Physical Vapor Deposition (EB-PVD) technique

- Optimization of Adsorption Parameters for Ultra-Fine Calcite Using a Box-Behnken Experimental Design

- The Microstructural Investigation of Vermiculite-Infiltrated Electron Beam Physical Vapor Deposition Thermal Barrier Coatings

- Modelling Porosity Permeability of Ceramic Tiles using Fuzzy Taguchi Method

- Experimental and theoretical study of a novel naphthoquinone Schiff base

- Physicochemical properties of heat treated sille stone for ceramic industry

- Sand Dune Characterization for Preparing Metallurgical Grade Silicon

- Catalytic Applications of Large Pore Sulfonic Acid-Functionalized SBA-15 Mesoporous Silica for Esterification

- One-photon Absorption Characterizations, Dipole Polarizabilities and Second Hyperpolarizabilities of Chlorophyll a and Crocin

- The Optical and Crystallite Characterization of Bilayer TiO2 Films Coated on Different ITO layers

- Topical Issue on Bond Activation

- Metal-mediated reactions towards the synthesis of a novel deaminolysed bisurea, dicarbamolyamine

- The structure of ortho-(trifluoromethyl)phenol in comparison to its homologues – A combined experimental and theoretical study

- Heterogeneous catalysis with encapsulated haem and other synthetic porphyrins: Harnessing the power of porphyrins for oxidation reactions

- Recent Advances on Mechanistic Studies on C–H Activation Catalyzed by Base Metals

- Reactions of the organoplatinum complex [Pt(cod) (neoSi)Cl] (neoSi = trimethylsilylmethyl) with the non-coordinating anions SbF6– and BPh4–

- Erratum

- Investigation on Two Compounds of O, O’-dithiophosphate Derivatives as Corrosion Inhibitors for Q235 Steel in Hydrochloric Acid Solution