Abstract

This study was prompted by the unsustainable issues facing the garment industry and the trend toward digitalisation in the post-coronavirus disease 2019 (COVID-19) pandemic era. COVID-19 substantially affected global trade, which caused significant garment industry stagnation due to embargoes and international restrictions. Consequently, the stagnation led to a significant inventory backlog and hindered product distribution, which compelled garment companies to turn to online commerce. A circular economy (CE) attempts to halt commodity flow and convert waste into resources; therefore, it can alleviate the substantial garment industry pollution and waste produced under a linear economy and maximise product life cycles. Industrial Revolution 4.0 incorporates technological innovation and information technology to transform the garment industry, which technologically enhances manufacturing intelligence and inspires garment industry transformation into a CE. This systematic literature review discusses the necessity of transforming the garment industry into a CE and the technological advantages and challenges to promoting sustainable garment industry development. The findings demonstrated that transforming the garment industry into a CE can not only resolve its environmental pollution and excess supply issues but can also accommodate new supply and demand requirements, such as market digitisation, consumer personalisation, and industry chain transparency. Finally, a technology integration initiative was proposed to promote garment industry transformation into a CE by digitising product development to achieve sustainable development.

1 Introduction

The garment industry, a significant sector supporting the global economy, is complex and features worldwide supply chains. In the garment industry, the value of raw materials and labour can be compared globally to identify the most convenient and profitable channels for development [1]. Sustainable garment industry development has accelerated with the effect of Industrial Revolution 4.0 (IR4.0) and the coronavirus disease 2019 (COVID-19) pandemic. IR4.0, or the Fourth Industrial Revolution, represents the future phase of digitalisation in manufacturing, driven by transformative trends, including increased data and connectivity, advances in analytics, the evolution of human–machine interaction, and improvements in robotics [2]. The IR4.0 inspired the garment industry to use technology to develop sustainability, also prompted its digitisation and virtualisation.

Economic globalisation enabled the rapid expansion of the garment industry, which resulted in overproduction, resource underutilisation, and environmental pollution issues and challenges [3]. The garment industry is the second largest global polluter, where it generates approximately 40 million tonnes of textile waste annually [4]. For example, clothing and textile consumption in the United Kingdom generates two million tonnes of clothing waste annually, which is worth approximately £38 billion [5]. Nevertheless, most UK clothing waste is transported to landfills or incinerated [6]. It was estimated that the United Kingdom would generate 2.59 billion tonnes of waste yearly by 2023 and that the total global waste volume would increase to 3.40 billion tonnes by 2050 [7]. Furthermore, the garment industry carbon footprint exceeds that of all maritime and international flights combined [4].

International advocacy for sustainable development dates back to 1987. The World Commission on Environment and Development proposed the concept of sustainable development: that is, “the ability to meet the needs of the present without compromising the needs of future generations” [8]. Currently, the Division for Sustainable Development Goals of the United Nations Department of Economic and Social Affairs has indicated that it will provide substantive support and capacity building for the sustainable development goals (SDGs) and their related thematic issues globally [9]. This demonstrates that sustainable development strategies will be the long-term guide for future global development.

The circular economy (CE) separates economic growth from resource consumption [10] and strives to reduce waste generation and prioritise sustainability [11]. The CE redistributes and reuses the waste generated at various garment production stages as a sustainable resource. The garment industry has attempted to practice sustainability, such as through thrift shops, upcycling, slow fashion, and open-source design [12]. Nonetheless, these sustainable design practices are all subject to limitations, such as product hygiene issues in second-hand commerce [4], technical limitations, additional costs, and pollution in upcycling initiatives [13]. Furthermore, slow garment initiatives cannot compete with economies of scale [14]. Almost all sustainability initiatives are industry specific and motivated by the need to overcome significant pain points, which neglect the importance of integration (integrated development thinking). Therefore, it is reasonable for the garment industry to transform into a CE. Garment industry CE transformation and sustainability is a broad circular system that requires complete chain participation and collaboration. Therefore, integrating resources, technologies, and stakeholder partnerships is an important research direction for future garment industry sustainability.

The COVID-19 pandemic substantially affected the global economy and compelled many countries to close their borders, especially during 2019–2022 [15]. The rapid spread of COVID-19 impeded the free flow of business activity and prevented in-person communication between designers, manufacturers, and customers [2]. Furthermore, the post-pandemic outbreak customer demand shifted towards a desire for low-cost, flexible designs [16] and easier means of purchasing. Matthew Drinkwater, who is the head of the Fashion Innovation Agency at London College of Fashion, University of the Arts London, noted that the pandemic compelled garment brands to engage and experiment with immersive technology [17] and switch to digital and virtual garments [2]. Many brands began experimenting with online campaigns and business services to sustain their original market, while others used online short-form video marketing to promote their products through continuous webcasts. Some brands also recognised the potential of virtual simulation technology and created online virtual showcases.

Simultaneously, the IR4.0 concept (smart manufacturing) led the garment industry to consider how manufacturing flexibility, mass customisation, and high-quality and efficient production could be achieved by integrating technology and connected technologies [18,19]. Integrating digital and technological tools from the supply chain and creation to display and retail would enable brands to embrace industry changes through technological innovation [2]. Thus, the COVID-19 epidemic and IR4.0 accelerated technology use to drive sustainable garment industry development, which provides more justification for a CE model.

Transforming the garment industry into a CE is an advantageous means of sustainably developing the industry. The sustainability concept is effective for the environment, economy, and society. The CE goal is to close the production and energy loop so that “waste becomes production” [13]. Garment companies and brands should consider their business model sustainability, which is paralleled by CE model practices. Garment companies attempting to transition to a CE can utilise the probable approaches of localised changes and improved outcomes. Nevertheless, recent research revealed that the circular sustainability model is a dynamic development model that requires all industry segments and stakeholders to contribute to sustainable development and that the many contributions should act like gears to achieve circularity. For example, recycling production surplus is expected to influence the future of the garment industry with technological advances. Furthermore, IR4.0 uses technology to integrate technologies, resources, and trends and upgrade the industry model. Garment industry digitalisation and science technicalisation could lead to significant sustainability and industrial transparency [20]. Such changes in industry design can match workers’ skills with production needs and customer demands to enhance post-pandemic and future competitiveness [21]. The integrated digital product development model will minimise product development time and improve accuracy in terms of the completion of garments as commodities and customer satisfaction regarding such garments. Thus, the garment industry would be able to maximise production and substantially eliminate waste from product development, which would enable sustainable industrial development.

This study had two research objectives: (1) to use a systematic literature review (SLR) to explore the necessity of transforming the garment industry into a CE, and (2) to explore the advantages and challenges of digital technology in transforming the garment industry into a CE via the co-occurrence of critical information in the literature through the VOSviewer (Version 1.6.19 provided from Nees Jan van Eck and Ludo Waltman) literature visualisation tool.

2 Methodology

An SLR is a detailed literature description and analysis that follows a methodology designed to yield a research evaluation foundation. A scientific methodological design improves the efficiency and precision of the substantial and complex literature selection process [22]. The aforementioned research objectives were analysed based on the understanding of the phenomena and were categorised and summarised to refine the findings and search rules. Therefore, this study drew on Levy and Ellis [23] and Minsuk et al.’s [24] SLR and co-occurrence methods for the systematic review analysis. Both methods are characterised by a well-documented, reproducible, and transparent search process [25]. The literature platforms searched were Web of Science (WoS) and Scopus, as these two indexed databases allow users to export metadata to perform bibliometrics analysis [26] to conduct keyword co-occurrence analysis with VOSviewer.

2.1 Research design: The necessity of transforming the garment industry into a CE

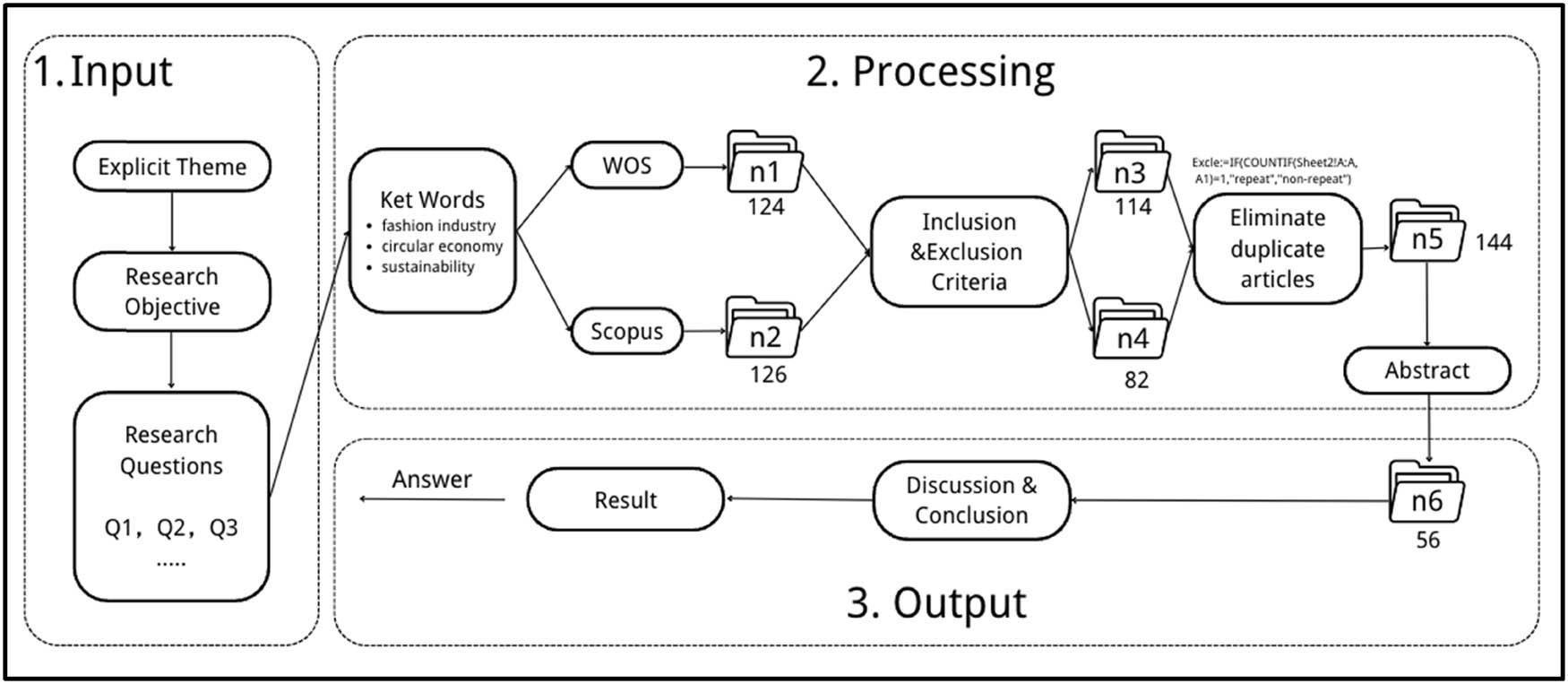

Literature study with reference to the systematic approach proposed by Levy and Ellis [23], which consists of three components: inputs, processing and outputs [4] (Figure 1). Part 1 of the study investigated the necessity of transforming the garment industry into a CE. The input section clarified the research direction and leading questions, which aided the study scope narrowing, filtered helpful information, and aided the rapid generation of findings. The leading questions (Q) are as follows:

Framework of investigation of the necessity of transforming the garment industry into a CE.

Q1: What is currently the most significant issue in garment industry development?

Q2: What obstacles does sustainable garment industry development face?

Q3: What can a CE contribute to the garment industry?

Processing requires keywords based on the leading questions, which were as follows: “garment industry,” “CE,” and “sustainability.” A combined keyword identification search of WoS (n1) and Scopus (n2) retrieved 124 documents and 126 documents, respectively, which were screened according to the inclusion and exclusion criteria. The filtering criteria were document type (only papers and review papers), language (only English texts), and year (published in the last 5 years [2019–2023]). After the screening, the two platforms yielded 114 papers (n3) and 82 (n4) papers, respectively.

In the secondary screening, articles that appeared on both platforms (duplicates) were removed. By using the WoS search list as a reference, 52 duplicate articles were screened out of the Scopus search list using the function algorithm to check duplicate data in Excel, which yielded n5: 144 non-duplicate articles for both platforms. A final screening of n5 was conducted, where the screening criterion was abstract relevance, which yielded n6: 56 articles. In the output stage, the contents of the articles were analysed and the leading questions were answered. Finally, the results were discussed and summarised, and conclusions were obtained in the output stage.

2.2 Research design: The advantage of the digital technology approach in promoting sustainable garment industry development

Research on garment industry technology adoption to aid the achievement of sustainable development was analysed. First, in response to the current paucity of research on technology use for sustainable garment industry development, relevant global research was searched, analysed, and compared to the extent to which other manufacturing industries use technology for smart manufacturing. Specifically, the extent to which digital science and technology have propelled the garment industry into a CE and sustainable development was examined. Subsequently, the technological tools and techniques relevant to sustainable garment industry development were refined. Finally, the findings from parts 1 and 2 of the study were analysed and discussed to assess which approaches to develop garment industry sustainability using technological tools demonstrated potential and advantages. Subsequently, the application and potential challenges of the approaches were examined.

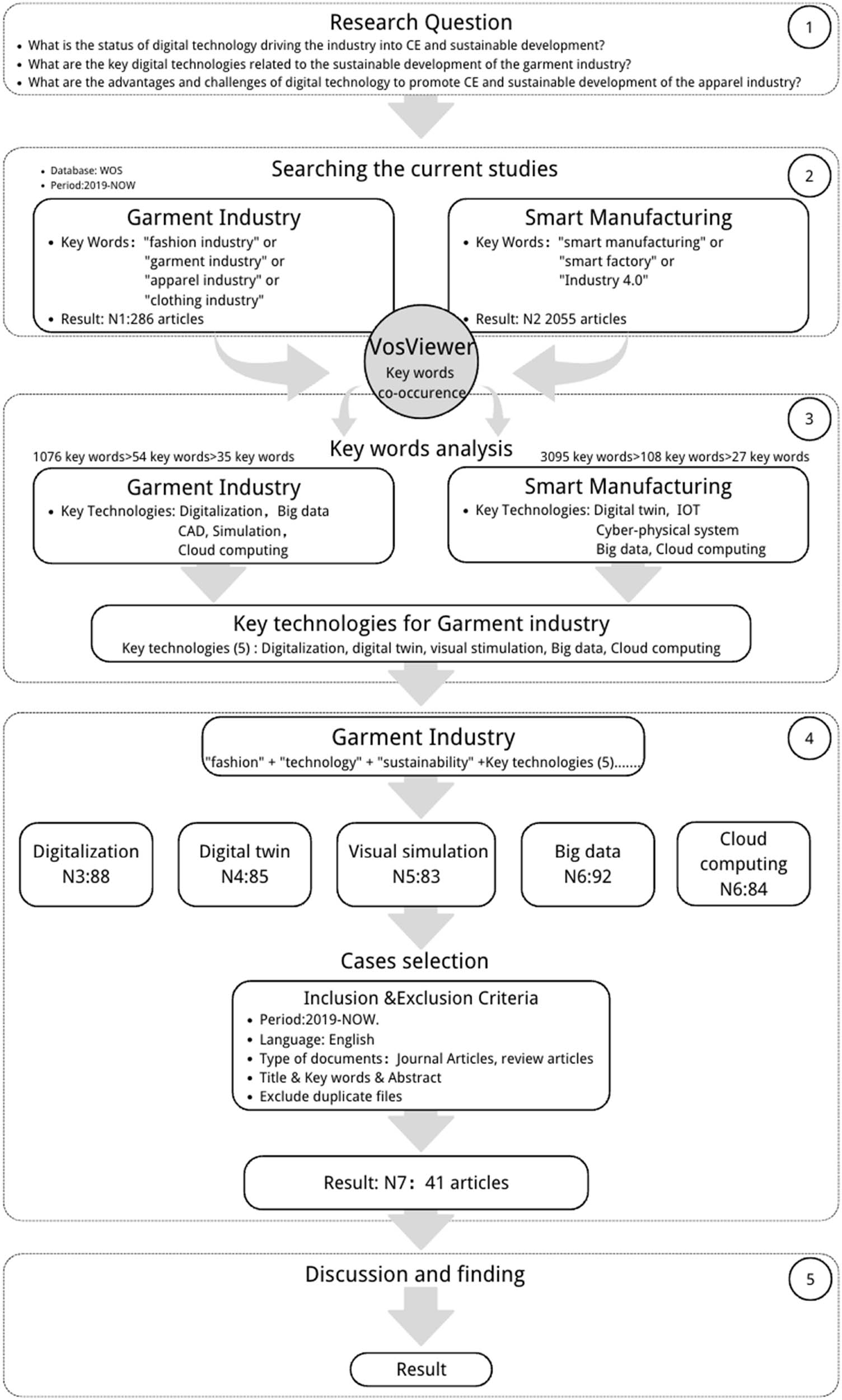

Minsuk et al.’s [24] keyword co-occurrence study was referenced via VOSviewer. “Garment industry” and “smart manufacturing” studies in the WoS index database were searched using keywords containing the meaning of “digital technology” and “smart manufacturing,” respectively. The keyword analysis was used to derive the digital technology involved in each manufacturing process. The study design was divided into five steps (Figure 2).

The research framework of the advantages of digital technologies in driving sustainable garment industry development.

The following research questions guided this study:

Q1: What is the current status of technology driving the garment industry into a CE and sustainability?

Q2: What are the key technologies relevant to garment industry sustainability?

Q3: What are the strengths and challenges of technologies in driving the garment industry into a CE and sustainability?

The preliminary search was conducted by searching WoS for the keywords “garment industry” and “smart manufacturing.” For the garment industry, four keywords with similar meanings were chosen: “clothing industry,” “garment industry,” “garment industry,” and “garment industry.” The search yielded N1: 286 articles, which were obtained by removing duplicate documents from both platforms. For smart manufacturing, the search was conducted using three similar keywords: “smart manufacturing,” “smart factory,” and “IR 4.0.” Given the substantial volume of articles, the burden of manual retrieval is extensive. Furthermore, the availability of some articles is restricted as they are not open-source resources, posing challenges to subsequent literature access. Consequently, extra filtering criteria were incorporated into the intelligent manufacturing literature retrieval process. Only open-access articles were subjected to an additional round of filtering, resulting in a refined collection of 2,055 articles, denoted as N2.

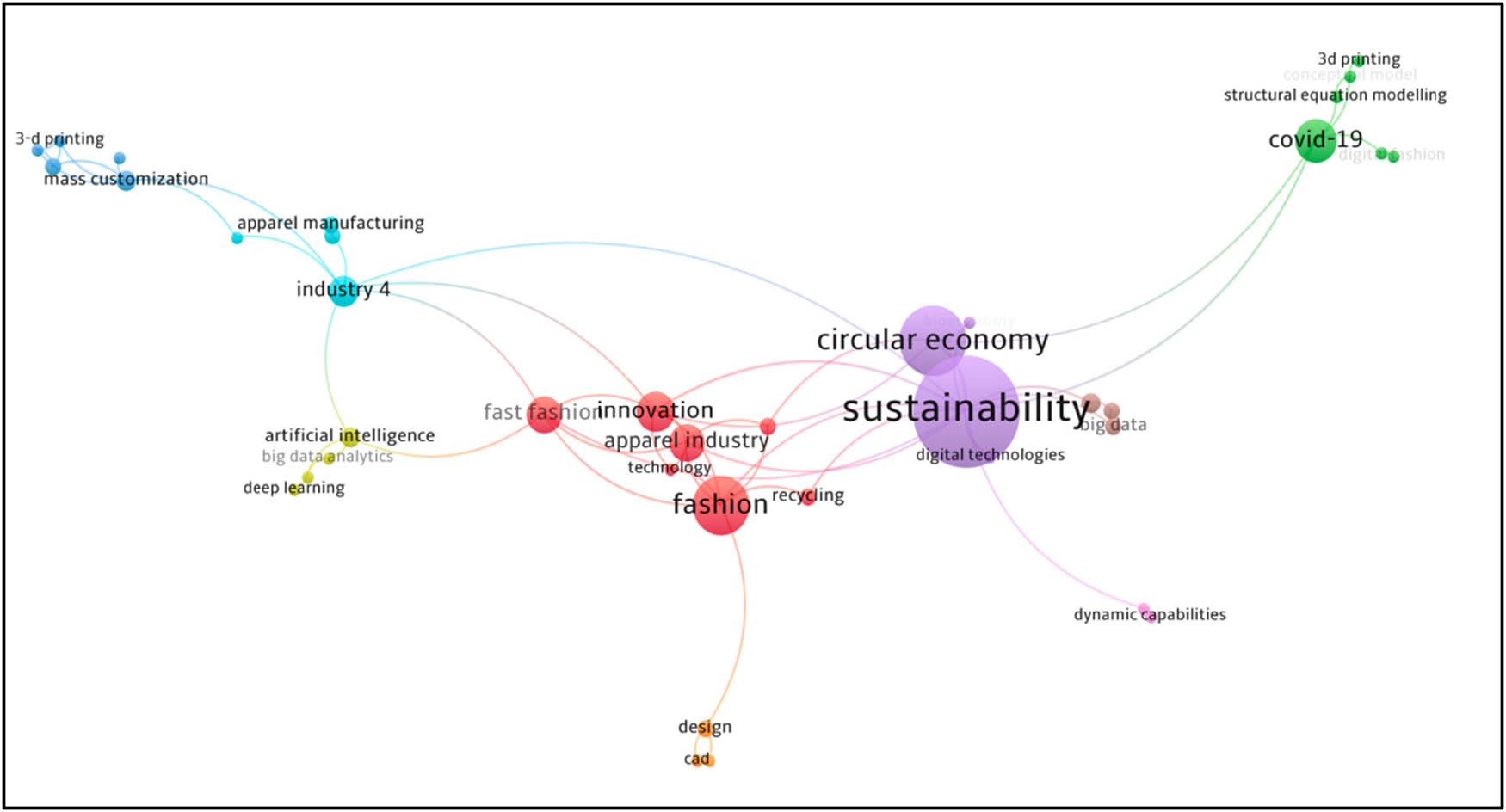

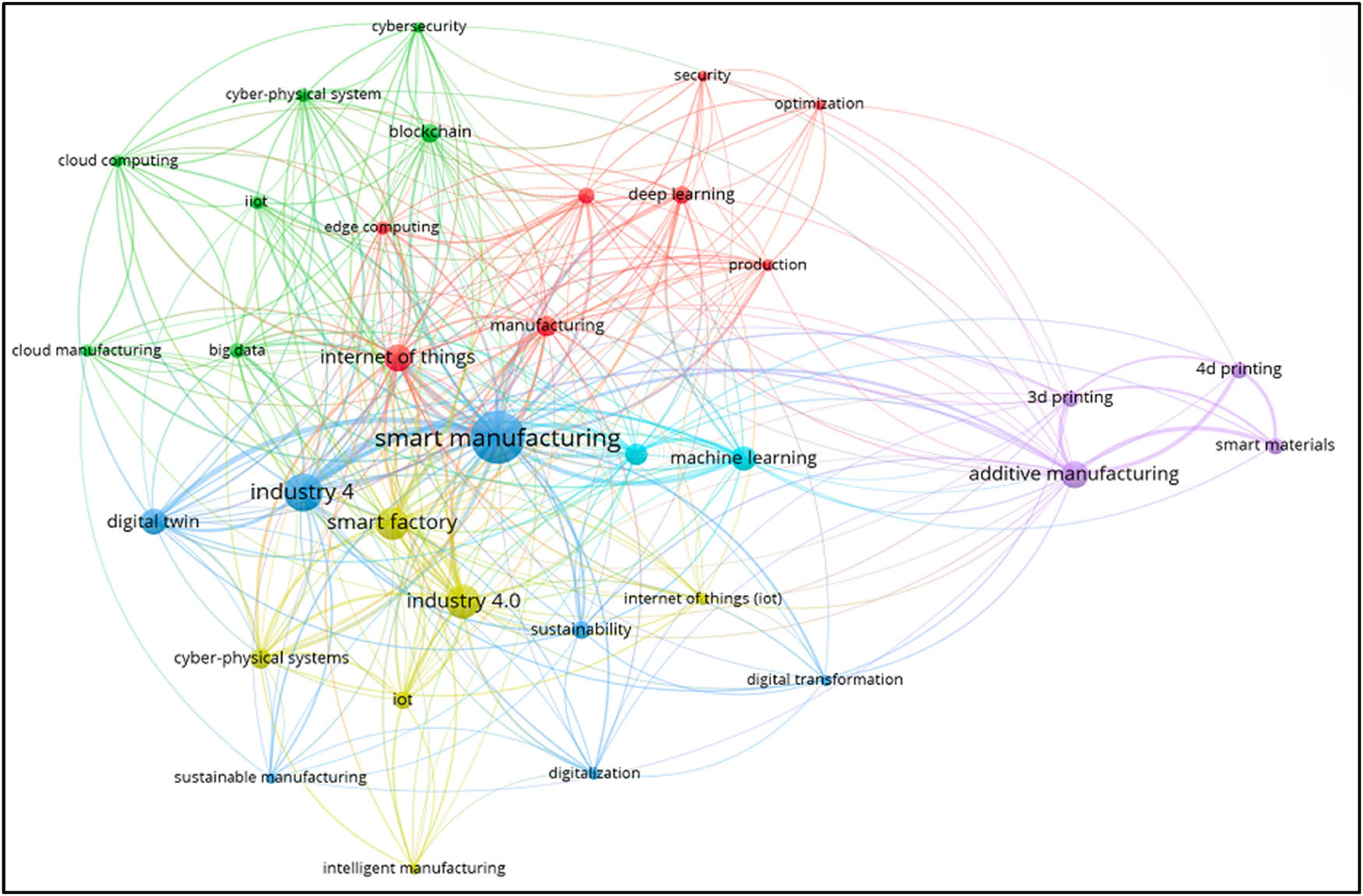

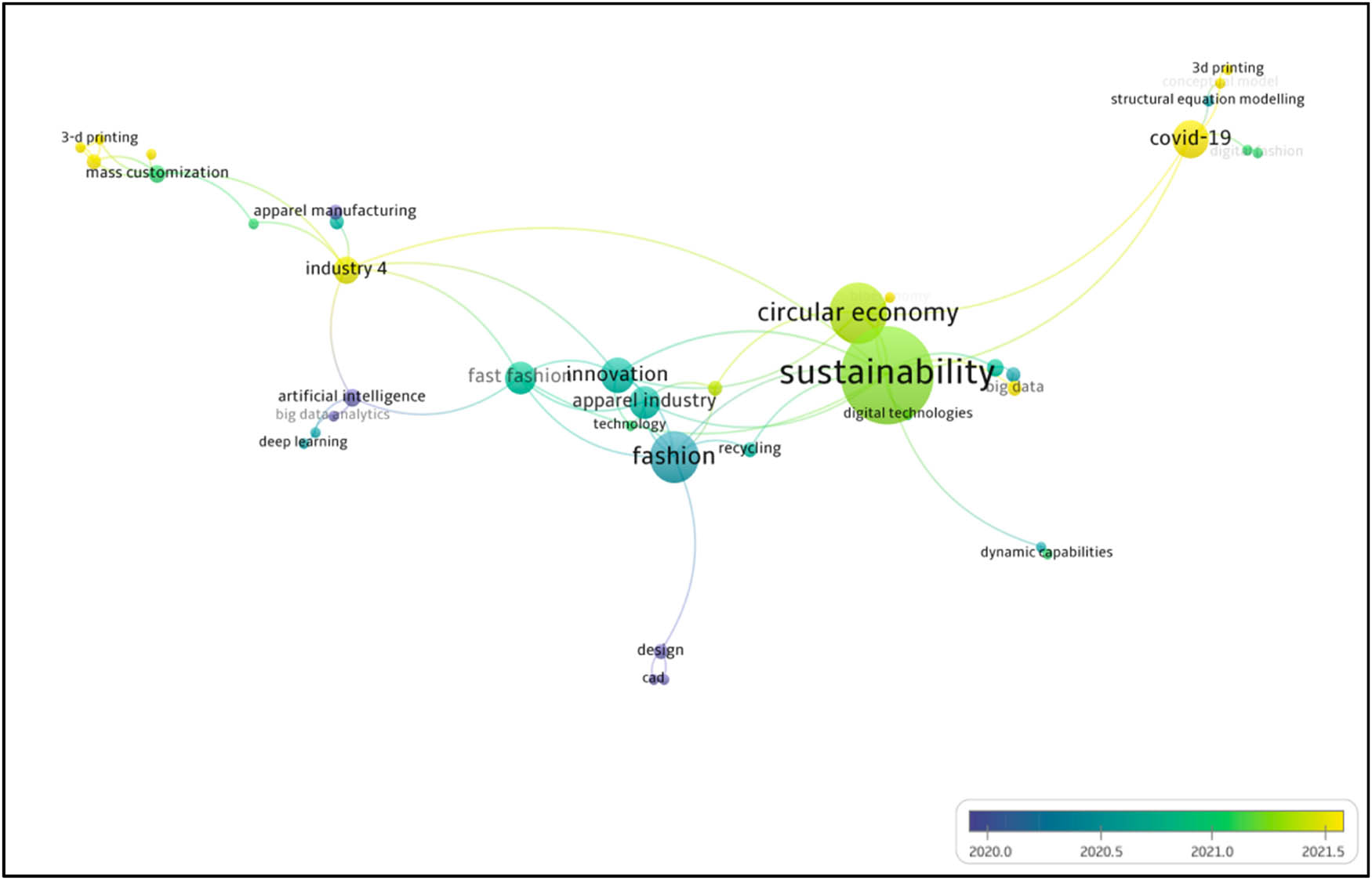

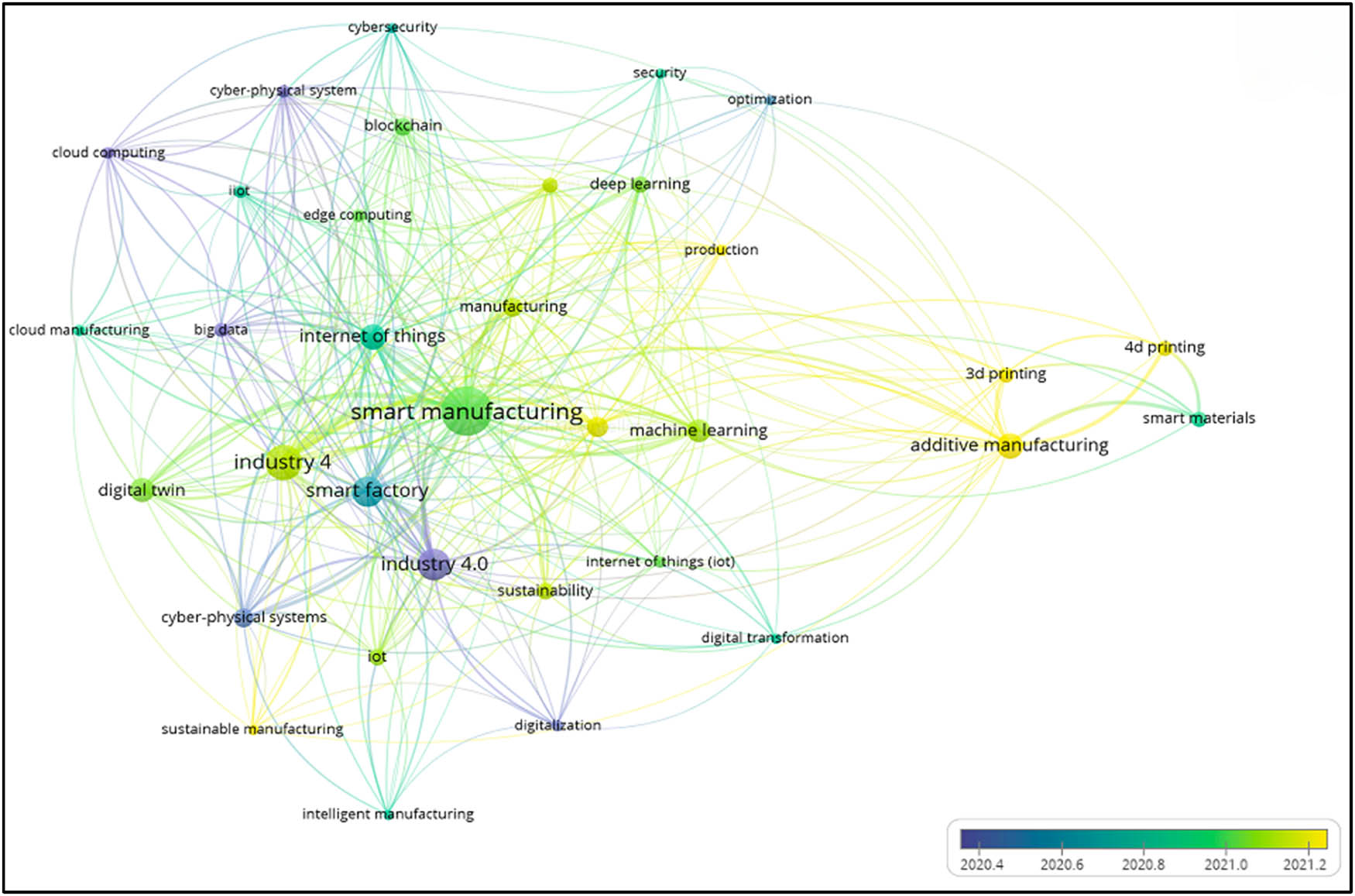

Keyword analysis of the obtained studies was conducted using the VOSviewer bibliographic analysis tool, where author keyword co-occurrence was analysed. The keyword relevance was determined by analysing the number of times the authors’ keywords appeared together. Given that the primary study purpose was to use keyword analysis to extract the technological tools that benefited the garment industry, N1 and N2 were exported as tab-delimited files and imported into VOSviewer. The “garment industry” literature analysis yielded 1,076 keywords. The minimum keyword frequency was two occurrences, following which 155 keywords were filtered out to exclude keywords unrelated to technology and the garment industry. The VOSviewer network visualisation diagram depicted 38 keywords (Figure 3). The “smart manufacturing” literature analysis yielded 3,095 keywords, where the keyword frequency was set to “at least 10 occurrences.” Subsequently, 108 keywords were screened out and keywords unrelated to technological means and smart manufacturing were excluded. Eventually, the VOSviewer network visualisation diagram depicted 34 keywords (Figure 4).

Co-occurrence graph of keywords related to the garment industry (key technologies occurrence times: big data 8, CAD 5, visual simulation 3, cloud computing 3. Unit: times).

Co-occurrence graph of keywords related to the smart manufacturing (key technologies occurrence times: DT 61, CPS 57, IOT 29, big data 22, cloud computing 15. Unit: times).

To identify commonalities, research distilled the most frequently occurring key technologies from research in the apparel industry and smart manufacturing. The key garment industry technologies were digitalisation (similar keywords with related meanings appeared in several instances, such as “digital technology,” “digital transformation,” “digital application,” “digital fashion,” and “digitalisation”; therefore, all meanings were combined and represented by “digitalisation”), big data, computer-aided design (CAD), virtual simulation, and cloud computing. The key smart manufacturing technologies were digital twin (DT), cyber-physical system (CPS), Internet of things (IOT), big data, and cloud computing.

Comparison of the garment industry and smart manufacturing technology-related keywords identified the following technology tool intersection areas: digitalisation, DT, big data, and cloud computing. As virtual simulation and DT technology featured intersecting technology areas, they were included in the garment industry key technology category. Eventually, the keywords “digitalisation,” “DT,” “virtual simulation,” “big data,” and “cloud computing” were identified as the top five garment industry-related critical technologies.

Subsequently, specific cases where garment technology contributed to sustainable garment industry development were searched based on the aforementioned five critical technologies, which were also used as keywords. The WoS was searched with the keyword scheme “fashion + sustainability + 5 Key technologies” for journal articles and review articles in English from the previous 5 years (Figure 2), and 432 papers were obtained. Continuing with the filtration of the 432 papers, a rapid review of titles and abstracts was executed. The filtering criterion was that the articles must mention the five key technologies discussed earlier in either the titles or the abstracts. Ultimately, 41 (N7) of the 432 papers were chosen for in-depth reading, analysis, and summarisation.

3 Findings and discussion

3.1 Necessity of transforming the garment industry into a CE

The garment industry is one of the most polluting production industries globally, where it emits approximately 1.2 billion tonnes of carbon dioxide and 500,000 tonnes of microplastic fibres per year [27]. The emergence of fast fashion has accelerated garment industry evolution, which yielded considerable economic profits while worsening the waste and pollution issue. The adoption of more product lines each year has resulted in new styles and lower prices accompanying the continual demand and trend changes, which resulted in an approximately 50% increase in clothing production and an approximately 40% decrease in garment use [28]. Each quarter, an average 12% of garments become inventory regardless of whether they are mainstream or niche brands, which indicates that US$180 billion in sales is wasted each quarter [29]. Consequently, the fast-paced product development and production intensify pressure on designers and worker exploitation.

Electronic (e)-commerce development has resulted in the garment industry becoming increasingly digitally connected. Demand and supply are constantly shifting in the market environment and consumers’ lifestyles; therefore, the garment industry should redefine its business model to maintain market dynamics and sustain competitiveness. The term “sustainable development” has influenced society since its inception in 1972. The United Nations (UN) launched its SDGs in 2015, where all nations were urged to “take action to protect the planet” via 17 SDGs [30], which include industrial innovation. While the linear economic system of the garment industry does not enable sustainable development, the industry focus on sustainability is currently a fundamental driver of industry development [31], which is a strategically essential trend [32].

The CE is a closed material flow cycle that aims to separate economic growth from resource consumption while maintaining the highest product component value and resource use [33]. The CE model prioritises sustainability [11] and promotes product cycle maximisation as a critical strategy to extend product sustainability [34]. Jose and Ramakrishna [35] stated that sustainability research should involve social well-being, resource sustainability, environmental protection, CE, and knowledge integration. Therefore, the garment industry should emphasise sustainability and ethics in product development and production [36]. The CE responds to new supply and demand requirements, such as market digitisation, consumer personalisation, and industry chain transparency. Thus, transforming to a CE can resolve the environmental pollution and excess supply caused by the garment industry.

3.2 Advantages of digital technologies in driving sustainable garment industry development

VOSviewer keyword filtering summarised the most frequent digital technology-related keywords in the garment industry and smart manufacturing. The garment industry keywords were “digitalisation,” “big data,” “CAD,” “simulation,” and “cloud computing.” The key digital technologies were identified by grouping similar technological tools, where “digitalisation” represented all other related technologies. The five smart manufacturing keywords were “DT,” “IOT,” “CPS,” “big data,” and “cloud computing.” Figure 5 depicts the VOSviewer overlay visualisation, where the garment industry technology-related keywords are depicted in yellow or yellow-green. The year scale in the bottom right corner of the figure demonstrates that the aforementioned keywords appeared between 2021 and the present. Similarly, the relevant smart manufacturing technology-related keywords are depicted in blue and purple in Figure 6. The year scale in the bottom right corner of the figure demonstrates that these keywords appeared in early 2000.

Year distribution map of co-occurrence keywords related to the garment industry. (Bottom right is the year interval.).

Year distribution map of co-occurrence keywords related to smart manufacturing. (Bottom right is the year interval.).

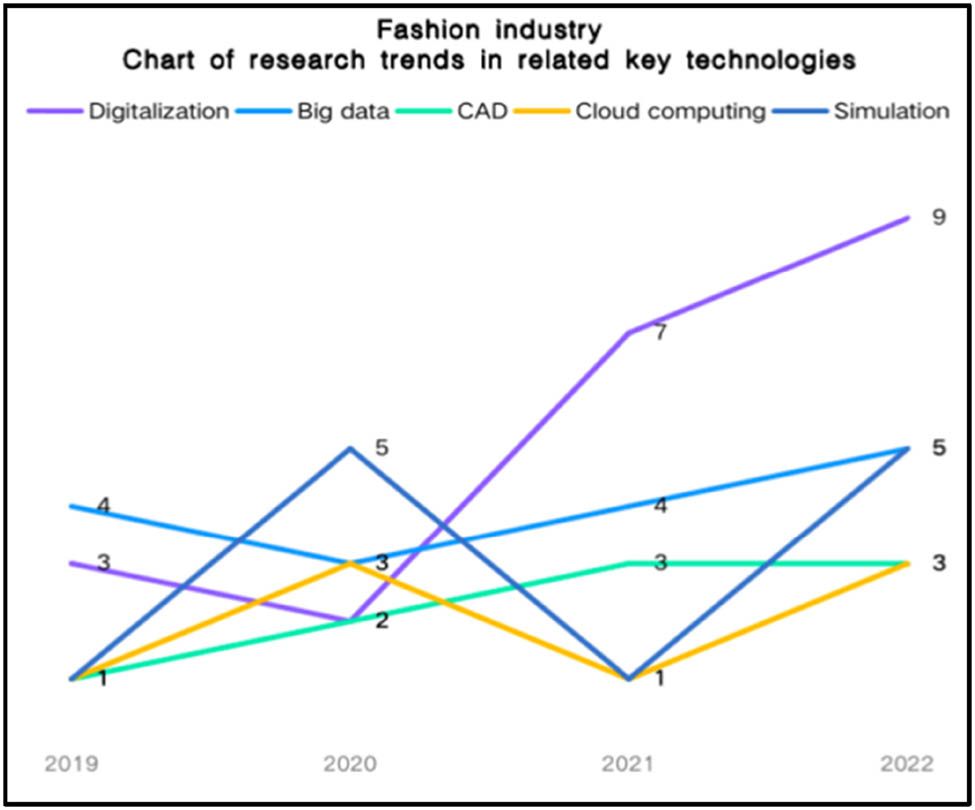

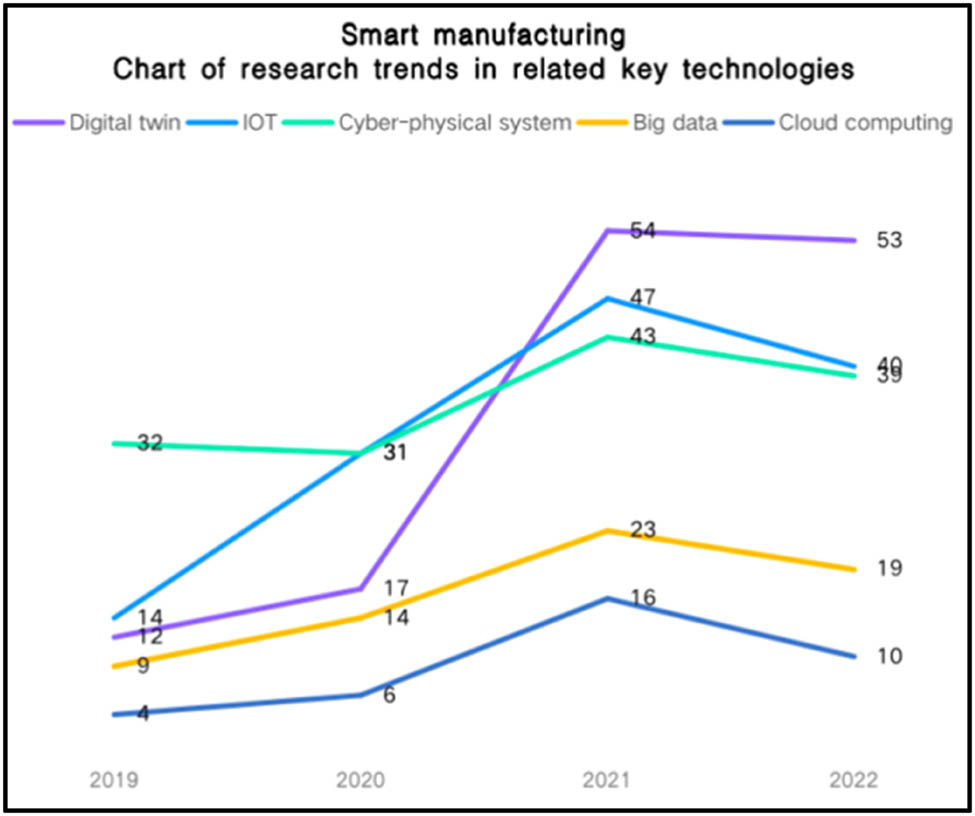

Initially, technology use in the garment industry developed more gradually and with a more rudimentary intelligence level. The ten key technologies with the highest number of occurrences in each of the two segments were selected. The most frequently occurring key technologies in the apparel industry are big data (eight times), CAD (five times), visual simulation (three times), and cloud computing (three times). The most frequent key technologies in smart manufacturing are DT (61 times), CPS (57 times), IOT (29 times), big data (22 times), and cloud computing (15 times). As further proof, the ten fashion industry and smart manufacturing keywords extracted were searched in WoS with the search rule TOPIC (“Research field”) AND AUTHOR KEYWORDS (“Each Key technology”) AND (PUBLICATION DATE, last 5 years). The number and year distribution of the retrieved studies associated with each key technology were counted separately (Table 1). The total data demonstrated that there was a significant gap between the number of studies on technology in the garment industry and smart manufacturing in the last 5 years. Furthermore, current data from 2023 demonstrated comparatively preliminary technology research in the garment industry, where there was only one study, while 18 smart manufacturing-related studies were published before February 2023.

Search rule

| Class | Query string | 2019 | 2020 | 2021 | 2022 | 2023 | Sum |

|---|---|---|---|---|---|---|---|

| Fashion industry | TOPIC(“Fashion industry”) AND AUTHOR KEYWORDS(“digitalization”) AND (PUBLICATION DATE, last 5 years) | 3 | 2 | 7 | 9 | 1 | 22 |

| TOPIC(“Fashion industry”) AND AUTHOR KEYWORDS(“big data”) AND (PUBLICATION DATE, last 5 years) | 4 | 3 | 4 | 5 | 0 | 16 | |

| TOPIC(“Fashion industry”) AND AUTHOR KEYWORDS(“CAD”) AND (PUBLICATION DATE, last 5 years) | 1 | 1 | 3 | 3 | 0 | 8 | |

| TOPIC(“Fashion industry”) AND AUTHOR KEYWORDS(“cloud computing”) AND (PUBLICATION DATE, last 5 years) | 1 | 3 | 1 | 3 | 0 | 8 | |

| TOPIC(“Fashion industry”) AND AUTHOR KEYWORDS(“simulation”) AND (PUBLICATION DATE, last 5 years) | 1 | 5 | 1 | 5 | 0 | 12 | |

| Smart manufacturing | TOPIC(“Smart manufacturing”) AND AUTHOR KEYWORDS(“digital twin”) AND (PUBLICATION DATE, last 5 years) | 12 | 17 | 54 | 53 | 4 | 140 |

| TOPIC(“Smart manufacturing”) AND AUTHOR KEYWORDS(“IOT”) AND (PUBLICATION DATE, last 5 years) | 14 | 31 | 47 | 40 | 3 | 135 | |

| TOPIC(“Smart manufacturing”) AND AUTHOR KEYWORDS(“cyber-physical system”) AND (PUBLICATION DATE, last 5 years) | 32 | 31 | 43 | 39 | 6 | 151 | |

| TOPIC(“Smart manufacturing”) AND AUTHOR KEYWORDS(“big data”) AND (PUBLICATION DATE, last 5 years) | 9 | 14 | 23 | 19 | 4 | 69 | |

| TOPIC(“Smart manufacturing”) AND AUTHOR KEYWORDS(“cloud computing”) AND (PUBLICATION DATE, last 5 years) | 4 | 6 | 16 | 10 | 1 | 37 |

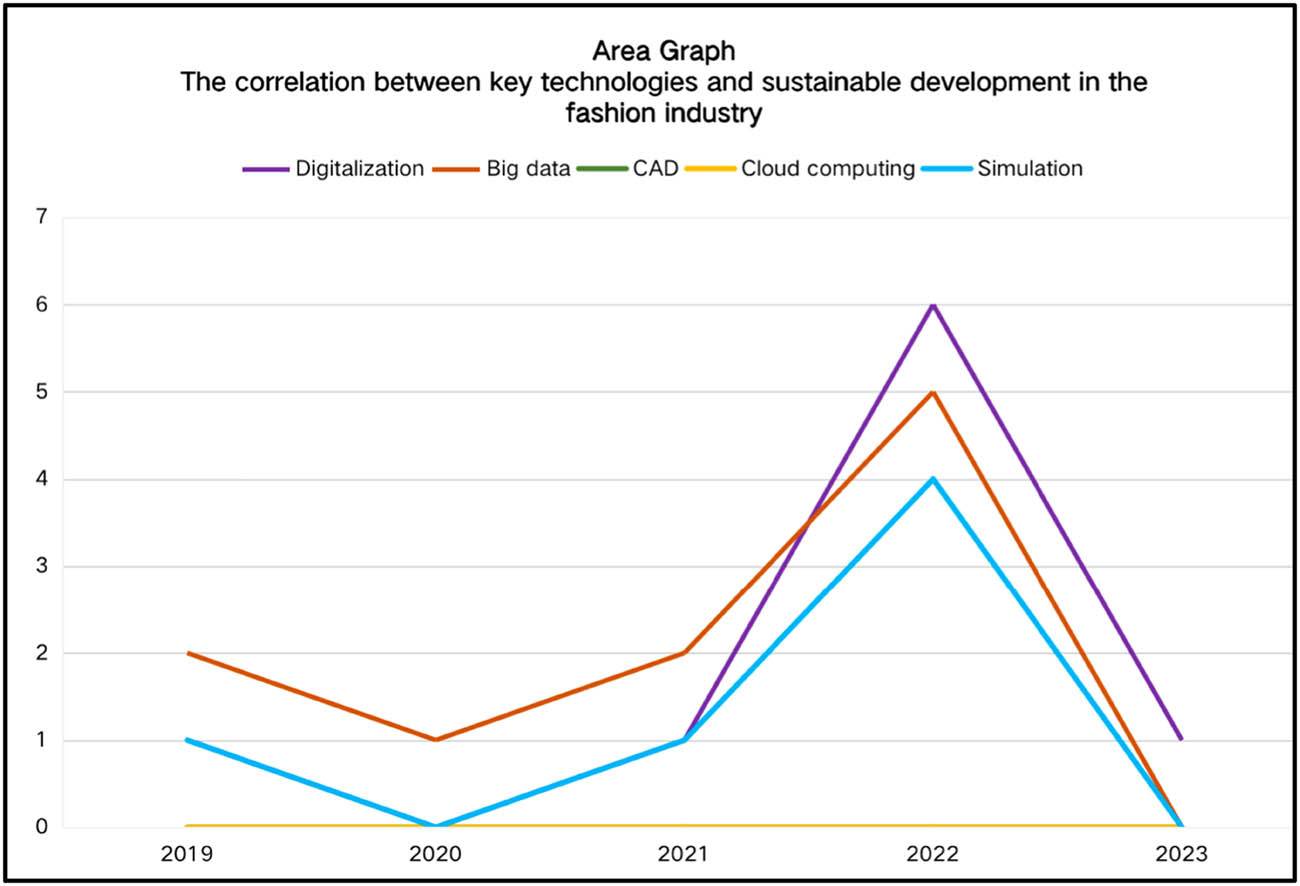

The data in Table 1 were visualised as line graphs (Figures 7 and 8). As data collection was completed at the beginning of 2023, the search results could not predict the number of studies in the related fields for 2023. Trend observation of the line graphs demonstrated that the 2023 data had no observational value; therefore, it was ignored in the line graph. Analysis of Figure 7 demonstrated that it was generally evident that the garment industry is conscious of integrating technology into industrial development. Furthermore, garment industry digitisation research trended upward in the past 5 years but started late and progressed more gradually. In addition, such research was significantly more prevalent than that on other technologies. Moreover, bionic technologies research was also relatively active. Figure 8 demonstrates that DT technology research was more prevalent compared to research on other smart manufacturing technologies.

Research trends in garment industry-related key technologies.

Research trends in smart manufacturing-related key technologies.

Based on the Form 1 search, a “sustainability” condition was added to the five garment industry keyword searches. The search rule was TOPIC (“Research field”) AND AUTHOR KEYWORDS (“Key technology”) AND AUTHOR KEYWORDS (“sustainability”) AND (PUBLICATION DATE, last 5 years). The search results were tallied (Table 2), and the data were visualised (Figure 9). Three of the five garment industry technological tools were associated with sustainability: digitalisation, big data, and simulation. The findings suggested that the garment industry pursued a greater commitment to use these three technological tools for sustainability, specifically digitalisation, with a relatively high number of relevant literature searches in 2022 and early 2023.

Fashion industry search rule

| Class | Query string | 2019 | 2020 | 2021 | 2022 | 2023 | Sum |

|---|---|---|---|---|---|---|---|

| Fashion industry | TOPIC(“Fashion industry”) AND AUTHOR KEYWORDS(“digitalization”) AND AUTHOR KEYWORDS(“sustainability”) AND (PUBLICATION DATE, last 5 years) | 1 | 0 | 1 | 6 | 1 | 9 |

| TOPIC(“Fashion industry”) AND AUTHOR KEYWORDS(“big data”) AND AUTHOR KEYWORDS(“sustainability”) AND (PUBLICATION DATE, last 5 years) | 2 | 1 | 2 | 5 | 0 | 10 | |

| TOPIC(“Fashion industry”) AND AUTHOR KEYWORDS(“CAD”) AND AUTHOR KEYWORDS(“sustainability”) AND (PUBLICATION DATE, last 5 years) | 0 | 0 | 0 | 0 | 0 | 0 | |

| TOPIC(“Fashion industry”) AND AUTHOR KEYWORDS(“cloud computing”) AND AUTHOR KEYWORDS(“sustainability”) AND (PUBLICATION DATE, last 5 years) | 0 | 0 | 0 | 0 | 0 | 0 | |

| TOPIC(“Fashion industry”) AND AUTHOR KEYWORDS(“simulation”) AND AUTHOR KEYWORDS(“sustainability”) AND (PUBLICATION DATE, last 5 years) | 1 | 0 | 1 | 4 | 0 | 6 |

Correlation between key technologies and sustainable development in the garment industry. (Literature statistics shows that only three aspects of digitalization, big data, and simulation are discussed in apparel industry during the period 2019–2023, and there is no discussion about two aspects of CAD and Cloud computing.).

The aforementioned analysis demonstrated that garment industry digitisation to achieve industrial intelligence in IR4.0 is in the preliminary development stage compared to other manufacturing industries. Nonetheless, the garment industry is consciously using technology for sustainable development and joining smart manufacturing, specifically in the areas of digitalisation, big data, and simulation, which reflected the research interest. The garment industry is one of the most labour-intensive manufacturing industries [24]. Given garment industry operation irregularity, product development and production processes are difficult to automate, where products change constantly according to fashion trends and production processes vary with the size and design.

The introduction of IR4.0 has the potential to move away from the traditional approach. The IR4.0 attempts to achieve manufacturing flexibility, mass customisation, better quality, and higher productivity by integrating technological tools [19]. Traditional garment product development is a typical iterative optimisation process that involves repeated trials using physical samples [37] and at least three physical samples before proceeding to production, which requires energy, materials, and workforce throughout. Therefore, product development alone produces a significant amount of waste. The garment industry tends to involve consumers in the customisation process, which allows them to interact directly with the product [38]. Thus, a technological connection of the complex quantitative relationship between consumers’ ambiguous needs and product design parameters [39] provides decision support to sustainable garment industry development.

The COVID-19 pandemic substantially affected global value chains [40]. Geographical blockades reduced consumers’ access to physical shops and their overall demand for garment products and ended global and regional distribution activities [41]. This unavoidable market depression forced the garment industry to reconsider its development. Subsequently, garment companies invested in digital management and operations, which included digitising company processes, remotely managing markets with digital technology, and offering new digital shopping experiences [42].

Most garment companies understood digital technology application through the benefits of digital technology for garment industry remote management and marketing and its role in continued market functioning. Among the key digitalisation-related technologies, the emergence of DT strongly indicated sustainable garment industry development. The DT technology is an entity-based technology that digitally mirrors the entity’s appearance and characteristics [43]. Computers enable digital modelling of physical entities in software to create composite views of real-world entities and processes, such as virtual models of buildings, products, or humans [44]. Therefore, DT can contribute to sustainable garment industry development [45]. Theoretically, designers who use DT technology to develop products through computer modelling without using physical materials can reduce working time, conserve material and labour costs, and produce no pollution or waste while putting a garment into physical production only when the new product has been accurately evaluated. Digitising garment product development eliminates the traditional practice of multiple physical product iterations and enables sustainable product development. Nevertheless, DT is constantly developing and the technology has not been optimised. Therefore, it is currently costly for garment companies to utilise DT for product development [44].

Another technology that functioned well with DT was virtual simulation. The clothing industry had experimented with virtual simulation technology for fittings and displays long before the COVID-19 pandemic outbreak. Earlier virtual simulation was perpetually used as a technology-themed marketing tool. Beautiful virtual models and perfectly fitted virtual try-on effects led to customers misunderstanding the garment authenticity. Thus, the received garments did not fit as well on the customers as they did the virtual models [46]. Therefore, using DT technology for sustainable development places even greater demands on virtual simulation technology. The garment industry must create accurate, realistic avatars to represent the customer’s body type for virtual fittings to enable digital product development.

The garment industry has a considerable amount and variety of data [47], such as supply chain and retail data. Accordingly, big data are also involved in garment industry development. Currently, the garment industry applies big data technology mainly in retail and consumer research, for example, researching consumer purchase history, studying popular items, and determining consumers’ seasonal preferences in different regions.

Garment retail and marketing mainly uses three key digitalisation technologies (DT, visual simulation, and big data). These technologies exist and are used independently of each other and do not significantly affect garment industry sustainability. Nonetheless, the fragmented technology use leads to its underutilisation. For example, the inability to obtain accurate body modelling data in DT technology yields body modelling that varies significantly from the actual model, which results in subsequent garment modelling that cannot fit the actual target, thereby presenting a technical barrier to DT technology use. Virtual simulation technology remains undeveloped when simulating fabric draping effects, and simulation algorithms are required to consider various parameters, such as the mechanical properties of the fabric [46]. In the garment industry, big data are highly complex and its realisation requires much data collection between multiple stakeholders. Therefore, technology integration is proposed as an advantageous approach for sustainable garment industry development to streamline the industry chain through technological interplay.

Traditionally, garment industry product development relies on two-dimensional (2D) pattern-making and the evaluation of three-dimensional (3D) body models [48]. This traditional linear model leads to a longer production process and increased fabric loss rate, which affect sustainable garment production [49]. In addition, inventory backlog stemming from design homogeneity is detrimental to garment chain sustainability in China.

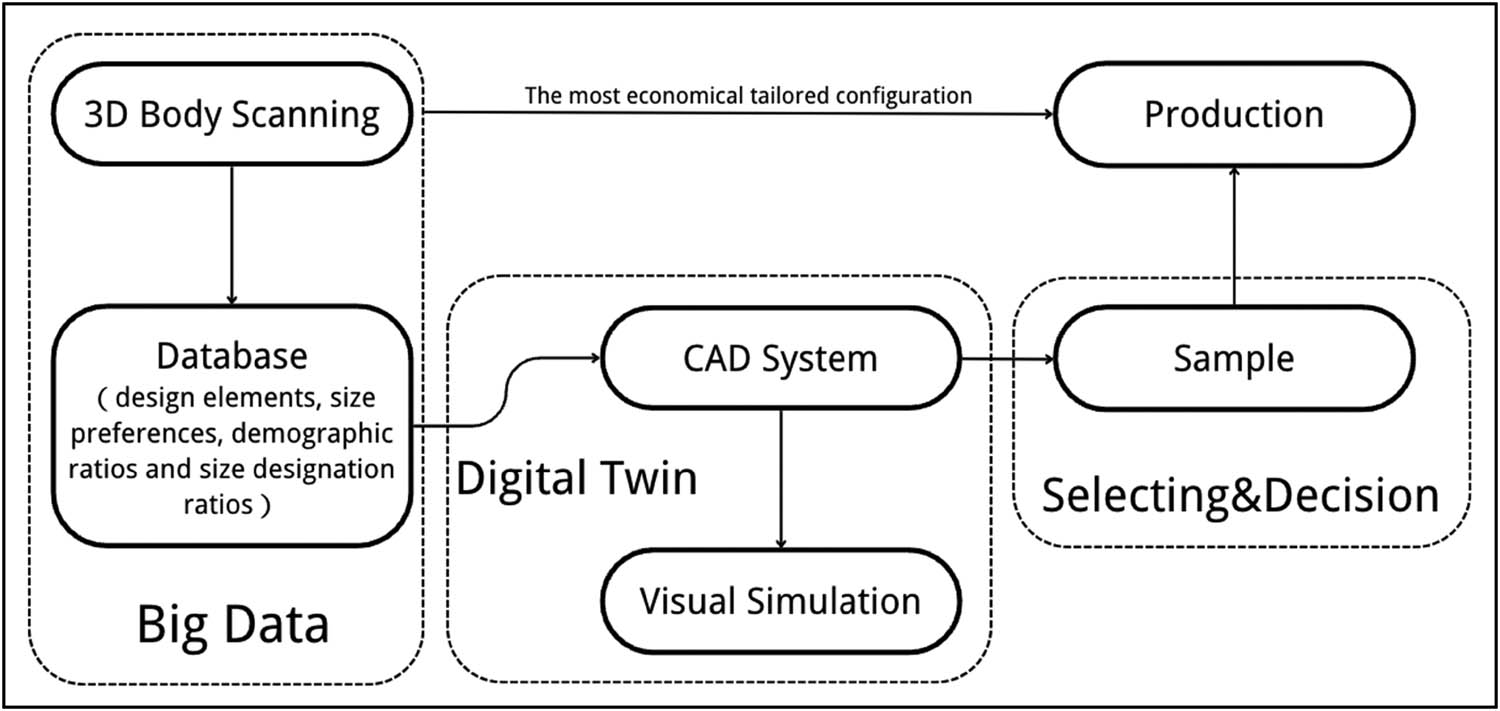

As consumer demand for personalisation continues growing, the market demand for ready-to-wear that meets consumer’s physical characteristics and individual needs is also gradually expanding. To cope with this increasing consumer demand, apparel companies have had to increase production, which has led to inventory build-up and resource wastage and exacerbated sustainability issues such as environmental pollution. The cooperative application of technologies here becomes a potential key to solving this problem. The authors address this issue by proposing a technology integration initiative that combines technologies and tools (Figure 10). The initiative enables the complete digitisation of the development process of apparel products and helps mass production by predicting production ratios through big data and computer algorithms. It is worth mentioning here that databases play an important role in predicting the data, which contains several aspects such as design elements, size preferences, demographic ratios, and size designation ratios. This will significantly improve the garment fit and personalisation satisfaction of apparel products and reduce inventory risk by controlling the proportion of different sizes produced. The new initiative, shown in Figure 10, applies to various processing modes, be it made-to-measure, mass production, or mass customisation. A 3D body scanning will provide accurate body data for made-to-measure garments; the size preference database will be able to predict the right size and be used for mass production or mass customisation in conjunction with the proportions of individual size designation as predicted by the population ratio database and the body size proportion database. In addition, computer algorithms based on the Big Data Element Database and the Preference Database can predict design requirements through probabilistic matching, or designers can provide design solutions. Once the design solution and size chart have been determined, the design will be presented through DT technology. This technology creates avatars that match the target body based on 3D body scan data, combines CAD and visual simulation to create 2D garment patterns, simulates garment piece stitching, makes fit adjustments, and ultimately presents the simulation. After iterating the design on the computer, the samples will be output. Sample input to the production step involves big data technology, which presents the most economical cutting solution through an efficient cutting database, minimising wasteful production.

Technology integration initiative.

The technology integration initiative promotes garment industry transformation into a CE and sustainable development by digitising garment industry product development. Digital product development constitutes a zero-physical sample product development model, where traditional product iterations are digitised and upgraded without waste or pollution. The highly accurate product development will increase product satisfaction, extend product life, and reduce inventory generation. Big data technology renders the output more appropriate and aligned with consumer expectations.

The technology integration initiative faces technical and operational challenges. For example, how algorithmic techniques can achieve the mechanical characteristics of material draping in a virtual simulation, and how big data and 3D body scanning technology can improve anthropometric measurement accuracy. In addition, the garment industry is highly focused on design, perception, and emotional input, and garment design is not a technology-driven field compared to the industrial design [48]. Each aspect of the data integration initiative requires technical skills to implement ideas, which challenges designers and critical operators, specifically for DT technology product design. Such design requires not only designers to provide designs but also requires pattern makers to create paper samples, and virtual simulation technology to virtually stitch and render the simulated effects, which is a complex and specialised skill set. Given that very few people have in-depth knowledge of the aforementioned skills, specifically pattern design, the ability to combine multiple skills with technology to produce results simultaneously is another significant obstacle.

4 Conclusion

The necessity of CE transformation in the garment industry and the promising digital technology-promoted practices and challenges of sustainable garment industry development were studied against the background of CE- and IR4.0-driven garment industry resistance against unsustainable development. First, the importance of a CE for future garment industry development was discussed using an SLR. Transforming to a CE would resolve the environmental pollution and excess supply issues of the garment industry and accommodate new supply and demand requirements (market digitisation, consumer personalisation, and industry chain transparency). Second, the analysis of author keyword co-occurrence in fashion digital technology literature yielded five key technologies (digitalisation, DT, virtual simulation, big data, and cloud computing). Combining the “garment industry” and “sustainability” keywords led to the selection of three key technologies (DT, virtual simulation, and big data) for the detailed research. Finally, the technology integration initiative was proposed as a practical approach to transform the garment industry into a CE and achieve sustainable development.

This study contributed to the literature based on the following aspects: (1) it clarified the necessity of transforming the garment industry into a CE and provided a reference for developing existing garment enterprises; (2) it provided a feasible solution for the garment industry in terms of precise design and production to resolve the practical and unsustainable issue of product backlog caused by homogenous design; and (3) it proposed the technology integration initiative to demonstrate the prospect of sustainable garment industry development.

Given the limited length of this article, strict crucial technology-related screening rules were established. In addition, keywords that appeared less frequently in keyword co-occurrence were screened out, which also yielded technology-related content. As the garment industry is in the exploratory stage of technology use for reform, the various technology tools and ideas may be innovations, and these less common technologies should be acknowledged. Although a technology integration initiative was proposed, several technical challenges remain to be overcome if the initiative is to be achieved, such as body data measurement accuracy and the simulation effect of fabric draping gravity characteristics in virtual simulations. The technical challenges will be overcome individually and the integration concept will be refined as technology improves. Therefore, enhancing the proposed approach through more advanced and intelligent technology is an essential direction for future research.

Acknowledgements

The authors thank the Changzhou Vocational Institute of Textile and Garment for providing financial support during the PhD period.

-

Funding information: The authors state no funding involved.

-

Conflict of interest: Authors state no conflict of interest.

References

[1] Joung, H. M. (2014). Fast-fashion consumers’ post-purchase behaviours. International Journal of Retail & Distribution Management, 42(8), 688–697. 10.1108/IJRDM-03-2013-0055.Suche in Google Scholar

[2] McKinsey & Company. (2022). What are Industry 4.0, the Fourth Industrial Revolution, and 4IR? Retrieved from https://www.mckinsey.com/featured-insights/mckinsey-explainers/what-are-industry-4-0-the-fourth-industrial-revolution-and-4ir.Suche in Google Scholar

[3] Cooper, N. B., Bartlett, S., Dubé, S. (2022). Progress report: The circular fashion ecosystem project. PHASE 2: Developing the roadmap for change. Institute of Positive Fashion’s Circular garment Ecosystem Project. https://instituteofpositivefashion.com/uploads/files/1/CFE/Circular_Fashion_Ecosytem_Report.pdf.Suche in Google Scholar

[4] De Aguiar Hugo, A., de Nadae, J., da Silva Lima, R. (2021). Can fashion be circular? A literature review on circular economy barriers, drivers, and practices in the fashion industry’s productive chain. Sustainability, 13(21), 12246. 10.3390/su132112246.Suche in Google Scholar

[5] Department for Environment, Food and Rural Affairs [DEFRA]. (2007). Sustainable clothing roadmap: Meeting briefing note. The Department for Environment Food and Rural Affairs (DEFRA) (London). http://archive.defra.gov.uk/environment/business/products/roadmaps/clothing/documents/clothing-briefing-Sept07.pdf [Retrieved June 2013].Suche in Google Scholar

[6] Kerr, J., Landry, J. (2017). Pulse of the garment industry. Global Garment Agenda, Copenhagen, Sweden.Suche in Google Scholar

[7] Suchek, N., Fernandes, C. I., Kraus, S., Filser, M., Sjögrén, H. (2021). Innovation and the circular economy: A systematic literature review. Business Strategy and the Environment, 30(8), 3686–3702.10.1002/bse.2834Suche in Google Scholar

[8] Geissdoerfer, M., Savaget, P., Bocken, N. M., Hultink, E. J. (2017). The circular economy: A new sustainability paradigm? Journal of Cleaner Production, 143, 757–768.10.1016/j.jclepro.2016.12.048Suche in Google Scholar

[9] United Nations. (2023). About the Sustainable Development Goals. https://sdgs.un.org/about [Retrieved September 21, 2023].Suche in Google Scholar

[10] Geng, Y., Doberstein, B. (2008). Developing the circular economy in China: Challenges and opportunities for achieving ‘leapfrog development’. The International Journal of Sustainable Development & World Ecology, 15(3), 231–239.10.3843/SusDev.15.3:6Suche in Google Scholar

[11] Earley, R., Goldsworthy, K. (2015). Designing for fast and slow circular fashion systems: Exploring strategies for multiple and extended product cycles. Product Lifetimes and the Environment (PLATE) Conference Nottingham Trent University (pp. 1–7).Suche in Google Scholar

[12] Cramer, J. (2013). The living wardrobe: A redirective fashion practice. Crafting the Future. Proceedings of the 10th European Academy of Design Conference (pp. 1–19).Suche in Google Scholar

[13] Brydges, T. (2021). Closing the loop on take, make, waste: Investigating circular economy practices in the Swedish fashion industry. Journal of Cleaner Production, 293, 126245. 10.1016/j.jclepro.2021.126245.Suche in Google Scholar

[14] Neumann, H. L., Martinez, L. M., Martinez, L. F. (2020). Sustainability efforts in the fast fashion industry: Consumer perception, trust and purchase intention. Sustainability Accounting, Management and Policy Journal, 12(3), 571–590.10.1108/SAMPJ-11-2019-0405Suche in Google Scholar

[15] Ikram, M. (2023). The consequences of COVID-19 disruption on sustainable economy in the top 30 high-tech innovative countries. Global Journal of Flexible Systems Management, 24, 247–269.10.1007/s40171-023-00338-zSuche in Google Scholar PubMed PubMed Central

[16] Mair, S. (2020). Sustainability in the twenty-first century: Applying sustainomics to implement the sustainable development goals. Environmental Politics, 29(4), 752–754.10.1080/09644016.2020.1741766Suche in Google Scholar

[17] Roberts-Islam, B. (2020). Virtual catwalks and digital fashion: How COVID-19 is changing the garment industry. Forbes. https://www.forbes.com/sites/brookerobertsislam/2020/04/06/virtual-catwalks-and-digital-fashion-how-covid-19-is-changing-the-fashion-industry/? sh = 6bf5c038554e.Suche in Google Scholar

[18] Dantas, T. E. T., de-Souza, E. D., Destro, I. R., Hammes, G., Rodriguez, C. M. T., Soares, S. R. (2020). How the combination of circular economy and industry 4.0 can contribute towards achieving the sustainable development goals. Sustainable Production and Consumption, 26, 213–227.10.1016/j.spc.2020.10.005Suche in Google Scholar

[19] Zhong, R. Y., Xu, X., Klotz, E., Newman, S. T. (2017). Intelligent manufacturing in the context of industry 4.0: A review. Engineering, 3(5), 616–630.10.1016/J.ENG.2017.05.015Suche in Google Scholar

[20] Tareque, A., Islam, N. (2021). Digital leadership: The perspectives of the apparel manufacturing. International Business Research, 14(2), 124–135.10.5539/ibr.v14n2p124Suche in Google Scholar

[21] Zakaria, N. (Ed.). (2022). Digital manufacturing technology for sustainable anthropometric apparel. Elsevier, Oxford, United Kingdom.Suche in Google Scholar

[22] Briner, R. B., Denyer, D. (2012). Systematic review and evidence synthesis as a practice and scholarship tool. In: Rousseau, D. M. (Ed.). Handbook of evidence-based management: Companies, classrooms and research (pp. 112–129). Oxford University Press, New York.10.1093/oxfordhb/9780199763986.013.0007Suche in Google Scholar

[23] Levy, Y., Ellis, T. J. (2006). A systems approach to conduct an effective literature review in support of information systems research. Informing Science, 9, 181–211.10.28945/479Suche in Google Scholar

[24] Minsuk, K., Pierre, D., Juho, K. (2020). Integrating learning sciences and machine learning to design effective feedback for a programming tutor. Proceedings of the 10th International Conference on Learning Analytics and Knowledge (LAK ‘20) (pp. 173–182). ACM, New York, NY, USA.Suche in Google Scholar

[25] Gast, J., Gundolf, K., Cesinger, B. (2017). Doing business in a green way: A systematic review of the ecological sustainability entrepreneurship literature and future research directions. Journal of Cleaner Production, 147, 44–56.10.1016/j.jclepro.2017.01.065Suche in Google Scholar

[26] Gonçalves, A. T. T., Moraes, F. T. F., Marques, G. L., Lima, J. P., Lima, R. D. S. (2018). Urban solid waste challenges in the BRICS countries: A systematic literature review. Revista Ambiente & Água, 13, 1–20.10.4136/ambi-agua.2157Suche in Google Scholar

[27] Gazzola, P., Pavione, E., Pezzetti, R., Grechi, D. (2020). Trends in the fashion industry. The perception of sustainability and circular economy: A gender/generation quantitative approach. Sustainability, 12(7), 2809. 10.3390/su12072809.Suche in Google Scholar

[28] Atstja, D., Cudečka-Puriņa, N., Vesere, R., Abele, L., Spivakovskyy, S. (2021). Challenges of textile industry in the framework of CE: Case from Latvia. International Conference on Sustainable, Circular Management and Environmental Engineering (ISCMEE 2021), 255, 01014. 10.1051/e3sconf/202125501014.Suche in Google Scholar

[29] Dolfe, S. (2021). Otrium: Solving fashion’s overstock problem once and for all. https://www.indexventures.com/perspectives/otrium-solving-fashions-overstock-problem-once-and-for-all/.Suche in Google Scholar

[30] United Nations. (2016). Sustainable development goals. Brussels, Belgium. https://www.un.org/sustainabledevelopment/blog/2015/12/sustainable-development-goals-kickoff-with-start-of-new-year/ [Retrieved March 22, 2022].Suche in Google Scholar

[31] Gazzola, P., Grechi, D., Ossola, P., Pavione, E. (2019). Certified Benefit Corporations as a new way to make sustainable business: The Italian example. Corporate Social Responsibility and Environmental Management, 26(6), 1435–1445.10.1002/csr.1758Suche in Google Scholar

[32] Kapferer, J. N., Michaut-Denizeau, A. (2014). Is luxury compatible with sustainability? Luxury consumers’ viewpoint. Journal of Brand Management, 21(1), 1–22.10.1057/bm.2013.19Suche in Google Scholar

[33] Webster, K. (2015). The circular economy: A wealth of flows. Ellen MacArthur Foundation, United Kingdom. https://ellenmacarthurfoundation.org/the-circular-economy-a-wealth-of-flows-2nd-edition.Suche in Google Scholar

[34] Mishra, S., Jain, S., Malhotra, G. (2021). The anatomy of circular economy transition in the fashion industry. Social Responsibility Journal, 17(4), 524–542.10.1108/SRJ-06-2019-0216Suche in Google Scholar

[35] Jose, R., Ramakrishna, S. (2021). Comprehensiveness in the research on sustainability. Materials Circular Economy, 3, 1–2.10.1007/s42824-020-00015-xSuche in Google Scholar

[36] Pavione, E., Pezzetti, R., Matteo, D. A. (2016). Emerging competitive strategies in the global luxury industry in the perspective of sustainable development: The case of Kering Group. Management Dynamics in the Knowledge Economy, 4(2), 241–261.Suche in Google Scholar

[37] Meng, Y., Mok, P. Y., Jin, X. (2012). Computer aided clothing pattern design with 3D editing and pattern alteration. Computer-Aided Design, 44(8), 721–734.10.1016/j.cad.2012.03.006Suche in Google Scholar

[38] Rincon-Guevara, O., Samayoa, J., Deshmukh, A. (2020). Product design and manufacturing system operations: An integrated approach for product customization. Procedia Manufacturing, 48, 54–63.10.1016/j.promfg.2020.05.020Suche in Google Scholar

[39] Wang, Z., Tao, X., Zeng, X., Xing, Y., Xu, Z., Bruniaux, P. (2023). Design of customized garments towards sustainable fashion using 3D digital simulation and machine learning-supported human–product interactions. International Journal of Computational Intelligence Systems, 16(1), 16.10.1007/s44196-023-00189-7Suche in Google Scholar

[40] Di Maria, E., Bettiol, M., Capestro, M. (2023). How Italian fashion brands beat COVID-19: Manufacturing, sustainability, and digitalization. Sustainability, 15(2), 1038. https://www.mdpi.com/2071-1050/15/2/1038#.10.3390/su15021038Suche in Google Scholar

[41] He, H., Harris, L. (2020). The impact of Covid-19 pandemic on corporate social responsibility and marketing philosophy. Journal of Business Research, 116, 176–182.10.1016/j.jbusres.2020.05.030Suche in Google Scholar PubMed PubMed Central

[42] Kim, H. Y., Lee, Y., Cho, E., Jung, Y. J. (2020). Digital atmosphere of fashion retail stores. Fashion and Textiles, 7, 1–17.10.1186/s40691-020-00217-6Suche in Google Scholar

[43] Kritzinger, W., Karner, M., Traar, G., Henjes, J., Sihn, W. (2018). Digital twin in manufacturing: A categorical literature review and classification. Ifac-PapersOnline, 51(11), 1016–1022.10.1016/j.ifacol.2018.08.474Suche in Google Scholar

[44] Wagner, R., Kabalska, A. (2022). Sustainable value in the fashion industry: A case study of value construction/destruction using digital twins. Sustainable Development, 31, 1652–1667. 10.1002/sd.2474.Suche in Google Scholar

[45] Carvalho, R., da Silva, A. R. (2021). Sustainability requirements of digital twin-based systems: A meta systematic literature review. Applied Sciences, 11(12), 5519. 10.3390/app11125519.Suche in Google Scholar

[46] Balach, M., Cichocka, A., Frydrych, I., Kinsella, M. (2021). Developing real avatars for the apparel industry and analysing fabric draping in the virtual domain. Autex Research Journal, 23, 1–7. 10.2478/aut-2021-0015.Suche in Google Scholar

[47] Jain, S., Kumar, V. (2020). Garment categorization using data mining techniques. Symmetry, 12(6), 984. 10.3390/sym12060984.Suche in Google Scholar

[48] Papahristou, E. (2016). The effective integration of 3D virtual prototype in the product development process of the textile/clothing industry. (Doctoral dissertation). Technical University of Crete School, Greece.Suche in Google Scholar

[49] Ji, Y., Jiang, G., Cong, H. (2019). Sustainable improvements for customized platform effectiveness in garment production. Autex Research Journal, 19(4), 355–362.10.2478/aut-2019-0019Suche in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Artikel in diesem Heft

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry