Abstract

This work aimed to study the effect of zinc oxide (ZnO) filler suspension on the mechanical, electrical, and thermal properties of polylactic acid (PLA)/ZnO and cPLA/ZnO. Fused deposition modelling, one of the additive manufacturing methods, was used to fabricate the PLA specimen. PLA was used as the main material in this project, and the ZnO suspension was added during the printing process. The speed of the dispenser (low speed = 1,000 rpm, medium speed = 1,400 rpm, and high speed = 1,800 rpm) was the parameter that was varied to control the filler content of the composite. All the samples underwent a tensile test to determine the mechanical properties, followed by the scanning electron microscopy (SEM) test to analyse the fracture surface properties of the tensile test. SEM observations showed the PLA samples’ inherent smooth appearance, but the PLA/ZnO composite showed a rougher surface. PLA and cPLA composites showed an enhanced storage modulus but lower loss modulus than the pure samples. Because of the high thermal and electrical conductivity of carbon black and ZnO, cPLA composites had higher electrical and thermal conductivity than PLA composites.

1 Introduction

Polylactic acid (PLA) is a polyester polymerized from lactic acid (LA) with excellent biocompatibility and biodegradability (1). PLA resembles polypropylene, polyethylene, and polystyrene in terms of properties (2). It can be produced using currently available production equipment (2). PLA is generated from LA, often present in plants and animals as a metabolic byproduct or intermediate product. LA and hydrolytic breakdown products of PLA are harmless by nature (1). PLA is biologically degradable by common microorganisms after hydrolysis. Furthermore, the ease with which PLA melts upon heating enables some unique applications in 3D printing.

However, the poor mechanical properties of PLA can be improved by incorporating carbon fibre into the raw material. Carbon fibre will aid in strengthening the PLA because of its excellent mechanical characteristics, corrosion resistance, and high specific strength and modulus (3). Carbon fibre-reinforced PLA composites have higher flexural strength, flexural modulus, and flexural toughness than pure PLA composites by 11.82%, 16.82%, and 21.86%, respectively, based on previous research (4). To guarantee that the complete characteristics of 3D-printed CF-reinforced composites are enhanced, the interfacial properties of 3D-printed thermoplastic composites must be improved (5). PLA carbon fibre is a combination of 85% PLA and 15% carbon fibre to produce tougher PLA parts. They reported that additive manufacturing technology with CF polymer composites improved the strength and stiffness of many components. According to particular research, when CF is treated with concentrated nitric acid, the surface roughness of the CF rises, which improves the mechanical interlock and interfacial adhesion between CF and matrix (4).

In addition, the major disadvantage of these pure polymer materials is that they have poor mechanical characteristics, which include low tensile strength and Young’s modulus (6). As a result, reinforcing fillers are necessary so that the composite material may combine the benefits of the polymer matrix and fillers into a single material that can be used in various applications. Adding particle reinforcement to the polymer material is one of the effective ways to increase the mechanical characteristics of each material. There are many types of reinforcement, such as metal particles, carbon/graphene fibres, metal oxides, organic fillers, and other forms. Metal oxides have been found to have excellent physical and mechanical properties, as well as being inexpensive and simple to synthesize (7,8).

Inorganic fillers act as rigid fillers and nucleating agents, especially during annealing, to increase the crystallization of PLA and thus cause the modulus, tensile strength, and crystallinity to be higher (9). Controlling the ratio of two kinds of PLA is also an effective way to monitor the degradation of PLA (9). In addition, incorporating nanofillers, such as organo-modified layered silicates, silver, zinc oxide (ZnO), graphite derivatives, carbon nanotubes (CNTs), and silica, is a realistic and feasible approach for improving the antibacterial, barrier, thermal, and mechanical properties of PLA (9). However, the cost of silver restricts the application. Metal oxides like ZnO and TiO2 are widely used in health-oriented applications due to their cost-effectiveness, versatility, and special physicochemical features (9).

Additive manufacturing processes, such as 3D printing, are based on computer-aided data sources and have resulted in tremendous convenience to technology today. Additive manufacturing attracts the attention of researchers and engineers in many fields, especially in medical applications, aerospace, spare part products, and others. The reasons are due to fast design, and final geometrical components can be produced in a short running time. Material extrusion-based additive manufacturing is especially suited for printing electrical components using various materials at a low cost. Additional machining processes are reduced or skipped entirely, while final costs and material waste are significantly reduced. The most prevalent approach in 3D printing is fused deposition modelling (FDM), which primarily uses a polymer filament (10). The filament will be heated at the extruder nozzle to ensure that the filament’s plastic composite is in a semi-liquid condition. After that, the filament is extruded onto the platform or over previously printed layers. The thermoplastic nature of the polymer filament is critical for this process, as it allows the filaments to fuse during printing and then solidify at ambient temperature immediately (11). FDM builds a cross-sectional layer of extruded filament to form 3D geometry (12). Usually, materials used involve PLA, ABS, and polyetherimide.

This research aims to improve the properties of PLA reinforced with a conductive ZnO reinforcement filler produced by additive manufacturing. ZnO belongs to the class of transparent conducting oxides, which can be used as transparent electrodes in electronic devices (13). The RepRap Mendelmax 1.5 FDM 3D printer fabricated PLA and cPLA polymer composites. The impact of using precoated ZnO fillers was significant in this study. The performance of the composites was investigated using thermogravimetric analysis (TGA), FTIR, tensile testing, scanning electron microscopy (SEM) inspection, dynamic mechanical analysis, electrical impedance testing, and thermal conductivity testing.

2 Materials and methods

2.1 Raw materials

The raw materials used in this study were 1.75 mm-diameter PLA filaments (Cytron Technology Sdn Bhd), 1.75 mm-diameter cPLA filaments (Guangdong, China) and reagent-grade with ZnO powder ≥99% purity (Take It Global Sdn Bhd). ZnO was utilized without any further purification.

2.2 Composite fabrication

Before beginning the printing process, ZnO powder was mechanically ground for 30 min using a pestle and mortar to deagglomerate it. Twenty grams of PLA filaments (Cytron Technology Sdn Bhd) were thoroughly combined with 250 mL of acetone and stirred magnetically until PLA was completely dissolved. To keep the particles from settling to the bottom, ZnO powder was added to the PLA/acetone solution in 0.5:2 ratio with 5 mL of dispersion agents. Finally, the suspension was left at room temperature for 6 h.

The feedstocks for the FDM technique were PLA and carbon PLA filaments with a diameter of 1.75 mm. All specimens were printed at 0° raster angle and 100% infill density at a zigzag pattern by varying the content of ZnO fillers. The samples were printed in dog bone shapes for tensile testing in accordance with ASTM D638 by utilizing the open-source RepRap Mendelmax 1.5 FDM desktop 3D printer. The 3D printer was modified by attaching a filler dispenser near the extrusion nozzle. The movement or speed of the filler dispenser was regulated by altering the voltage provided to the controller, which was driven by a DC motor. To achieve consistent filler distribution, the filler dispenser and extrusion nozzle worked concurrently during printing. The ZnO suspension was disseminated as a filler reinforcement into the PLA matrix in this investigation at three distinct dispenser speeds: 1,000, 1,400, and 1,800 rpm. Extruder temperatures of PLA and cPLA were set at 200°C and 230°C, respectively. The build plate temperature was fixed at 60°C for both samples with print cooling. FDM parameters like 0.2 mm layer height, 0° of top and bottom direction, 0.4 mm of nozzle diameter, and 70°C T g of PLA were used during the experiment.

2.3 Characterization method

TGA was performed in a nitrogen environment using a thermogravimetric analyser (PerkinElmer, TGA7) at temperatures ranging from 25°C to 800°C with a heating rate of 10°C‧min−1. The proportion of the filler was introduced into the composites by changing the speed of the dispenser. TGA was used to evaluate the ZnO filler content of the composites in weight percentage (wt%). For cPLA containing carbon fibre, nitrogen gas was used to burn off PLA, and second, oxygen was used to burn off the carbon; thus, the final residue will be ZnO filler. A Perkin Elmer Spectrometer 2000 was used for FTIR measurements, and all the experiments were conducted at ambient temperature. The PLA, cPLA, PLA/ZnO, and cPLA/ZnO composites were selected for FTIR testing in this study to characterize the outcome. Tensile testing was performed on printed samples in accordance with ASTM D638 using a Universal Instron machine set at a crosshead speed of 5 mm‧min−1 at room temperature. At least five samples for each ratio were tested. An SEM model JEOL JSM-6460LA instrument operating at 15 kV was used to evaluate the fracture surface morphology of pure and composite samples. To minimize the electrostatic charge built up during observation, the specimens were sputter-coated with platinum by utilizing a Quorum Q150R coater. A dynamic mechanical analyser (PYRIS Diamond DMA) was used to measure the storage and loss moduli of composites. The heating rate under continuous nitrogen flow was 5°C‧min−1. To perform the study, the procedures were conducted at 30–120°C. The samples were cut into rectangular shapes with dimensions of 50 mm × 45 mm × 1 mm under tension mode. An absolute axial heat flow approach was used to determine thermal conductivity. The data collected were utilized to calculate thermal conductivity using Eq. 1, where K is the thermal conductivity,

3 Results and discussion

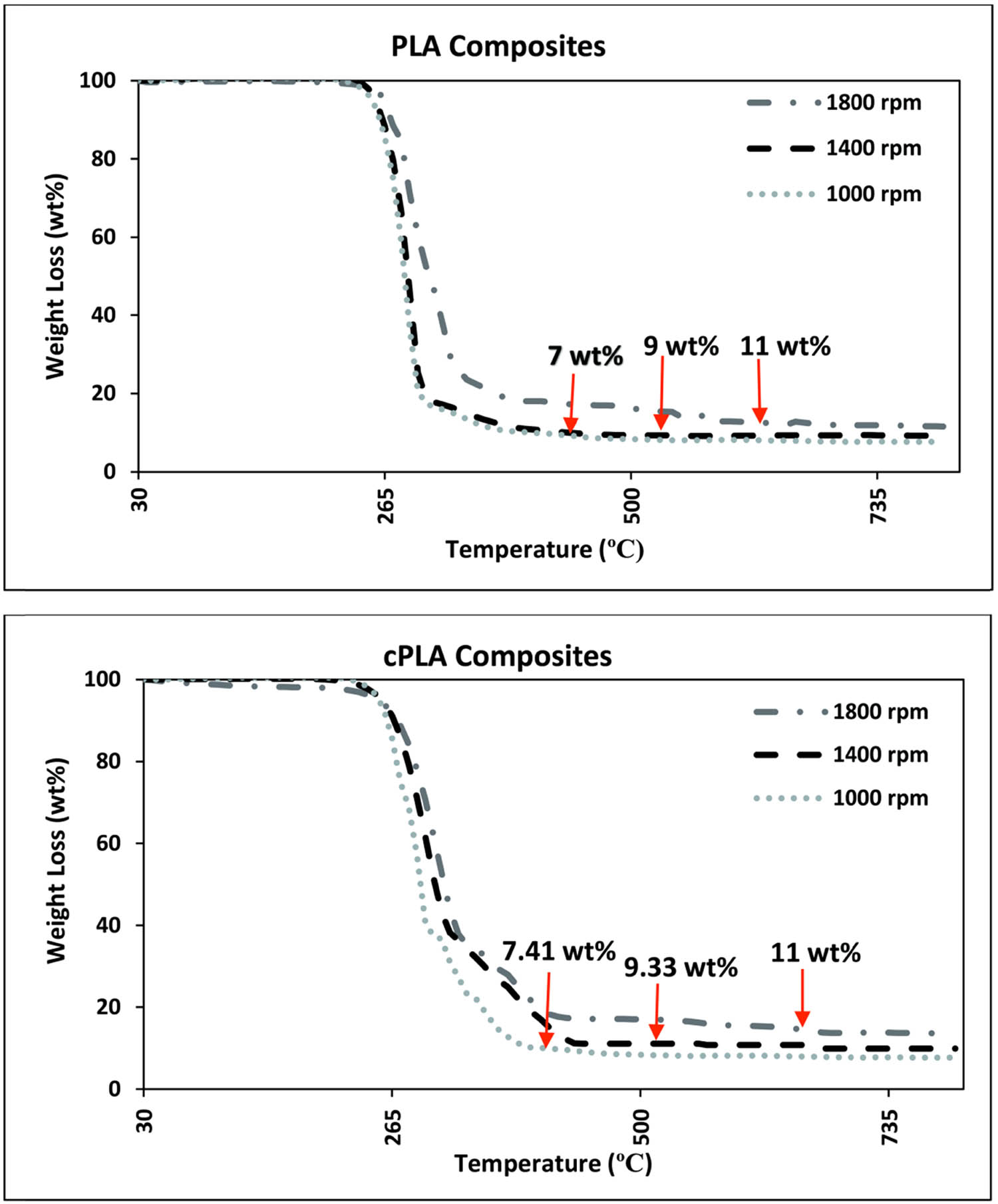

TGA determined the ZnO suspension content (wt%) inside produced PLA composites. Figure 1 illustrates the thermograms of specimens printed at varied dispenser speeds, which were 1,000, 1,400, and 1,800 rpm.

Thermograms for PLA and cPLA composites printing with different dispenser speeds.

The TGA curve revealed that PLA/ZnO and cPLA/ZnO decompose in a single stage and two stages, respectively. The deterioration of PLA began at about 270°C, as seen by the weight loss. The decomposition process was completed at almost 500°C with the remaining residue mass indicating the amount of ZnO filler incorporated into composites. Based on Figure 1, 11 wt% ZnO filler was dispensed onto the PLA with the high dispenser speed. During the printing procedure, 9 wt% and 7 wt% ZnO were dispensed on the composites at 1,400 and 1,000 rpm dispenser speeds, respectively. For cPLA, the thermal decomposition began at 290°C with a total mass loss of 60%. Switching the gas from nitrogen to oxygen at approximately 380°C resulted in carbon oxidation. When the dispenser speed was increased to medium or high, the filler amount was increased to 9.33 and 11 wt%, respectively. This demonstrated that the filler content could be regulated by adjusting the dispenser’s motor speeds.

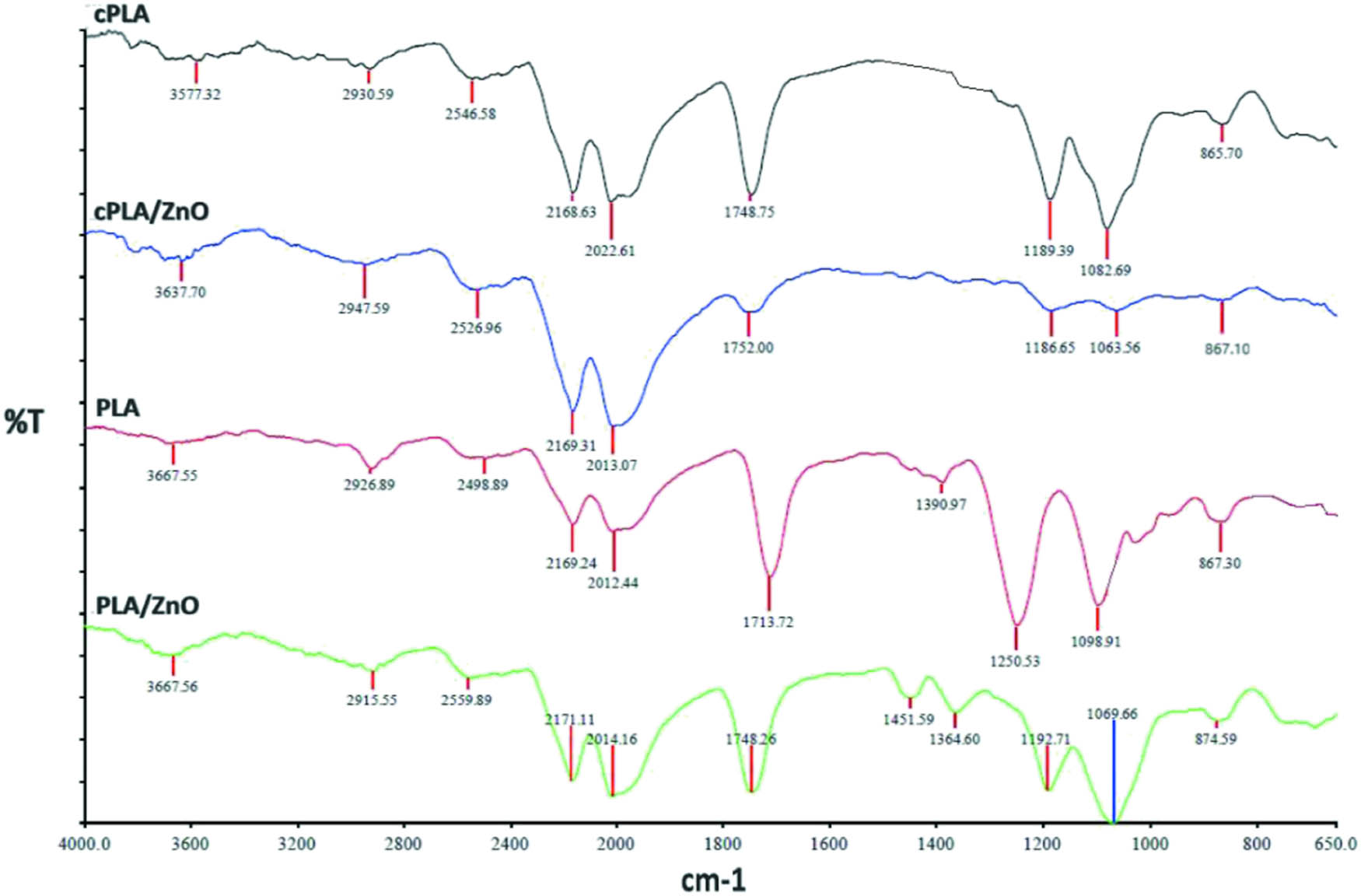

FTIR analysis is a technique to detect the presence of functional groups across the infrared spectrum of the PLA/ZnO composites. All the samples had almost identical FTIR spectra, implying that they have the same chemical composition and structure.

Figure 2 shows the structural comparison of pure PLA, cPLA, PLA/ZnO, and cPLA/ZnO composite spectra. The first peak found for both PLA samples and composites ranged between 3,577 and 3,700 cm−1, and the second peak found fell in the range of 2,900–2,950 cm−1. These first peaks indicate the presence of hydroxyl O–H stretching, while the second peaks are allocated to the stretching of C–H in both pure samples and composites. The 2,559.29 cm−1 region band reflects the hydroxyl group by absorbing hydrogen on ZnO. There were peaks found at 2,012.44 and 2,171.11 cm−1 wavelengths for both samples, respectively, which were assigned to C≡C stretching, while the strong peaks for PLA located at 1,713 cm−1 range indicated the presence of C═O stretching vibration of the carbonyl group for the ester unit (14).

FTIR spectra of pure PLA, cPLA, PLA and cPLA composites.

Next, the peaks at 1,451.59 and 1,364.60 cm−1 for pure PLA and PLA/ZnO composites were assigned to C–H deformation, which is symmetric and asymmetric bending, respectively. Additionally, the spectrum in the region of 1,080–1,260 cm−1 indicated the presence of strong C–O–C stretching (14). A huge shift occurred for PLA at 1,713 and 1,250 cm−1 due to the absence of ZnO reinforcement. The peak decrease for composites could be attributed to the interaction of ZnO in the pure PLA polymer matrix. Since ZnO accounts for a small part of the composites, its normal peaks are not as prominent as shown in Figure 2 (15). According to Figure 2, the absorption band at about 860 cm−1 corresponding to the C–C stretching showed evidence of amorphous phases of PLA contributing to the low density or disappearance of peaks (16). Overall, the FTIR spectra for the composites in the studied range practically revealed that the intensity of ZnO reinforcement did not change in any peaks in the PLA except for the peak at 3,450 cm−1 and assigned formation of secondary forces such as weak hydrogen bonds between the PLA polymer and ZnO (17). All PLA/ZnO composites exhibited a similar band to pure PLA, with a less noticeable change in the peak area.

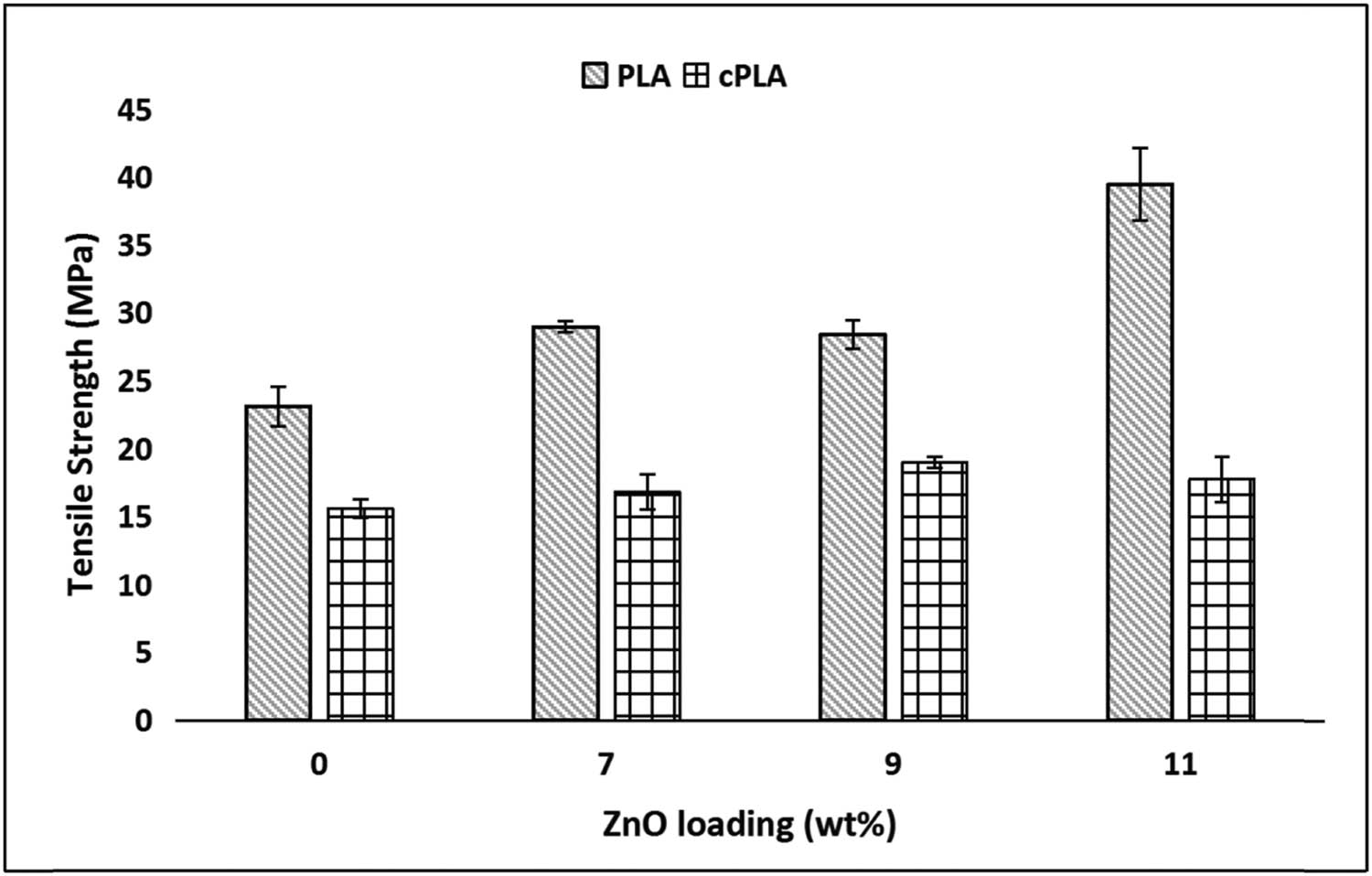

Figure 3 shows the effect of different ZnO loadings on the tensile strength of PLA and cPLA composites. The tensile strength increased progressively for PLA and slightly increased for cPLA as the filler loading increased, as seen in the graph. The tensile strength increased from 29.12 MPa to a maximum value of 39.50 MPa when filler loading increased to 11 wt%. The results revealed that the ZnO mixed well in PLA, implying that good interfacial adhesion will facilitate effective stress transfer. This is owing to the tensile load being transferred to the filler before it fails (18).

Effect of ZnO loading on tensile strengths of PLA/ZnO and cPLA/ZnO composites.

However, pure PLA and the cPLA control sample have low tensile strength compared to all the composites. This illustrates ductility behaviour because the pure samples had minimal stress to fracture the samples. The tensile strength of the cPLA composite is significantly lower than that of PLA. This is because of the weak bonding between carbon, PLA, and ZnO. Initially, the carbon fibre dispersed well into the PLA filament. The cPLA filament melted at the same melting temperature as the original PLA during printing. It will develop the cluster formation of carbon when PLA is in the molten state and results in carbon fibre that is no longer uniformly dispersed (18). Adding ZnO will hinder cluster attachment and finally cause secondary agglomeration (19). There was a slight increase in tensile strength when the ZnO loading increased to 9 wt% and dropped when it reached 11 wt%. This is because when ZnO filler reaches a high population, non-homogeneous ZnO induces the lump and agglomeration making stress transmission from matrix to fibre complicated and disrupting the matrix phase’s continuity (20). This was proven by the SEM micrograph, as shown in Figure 4.

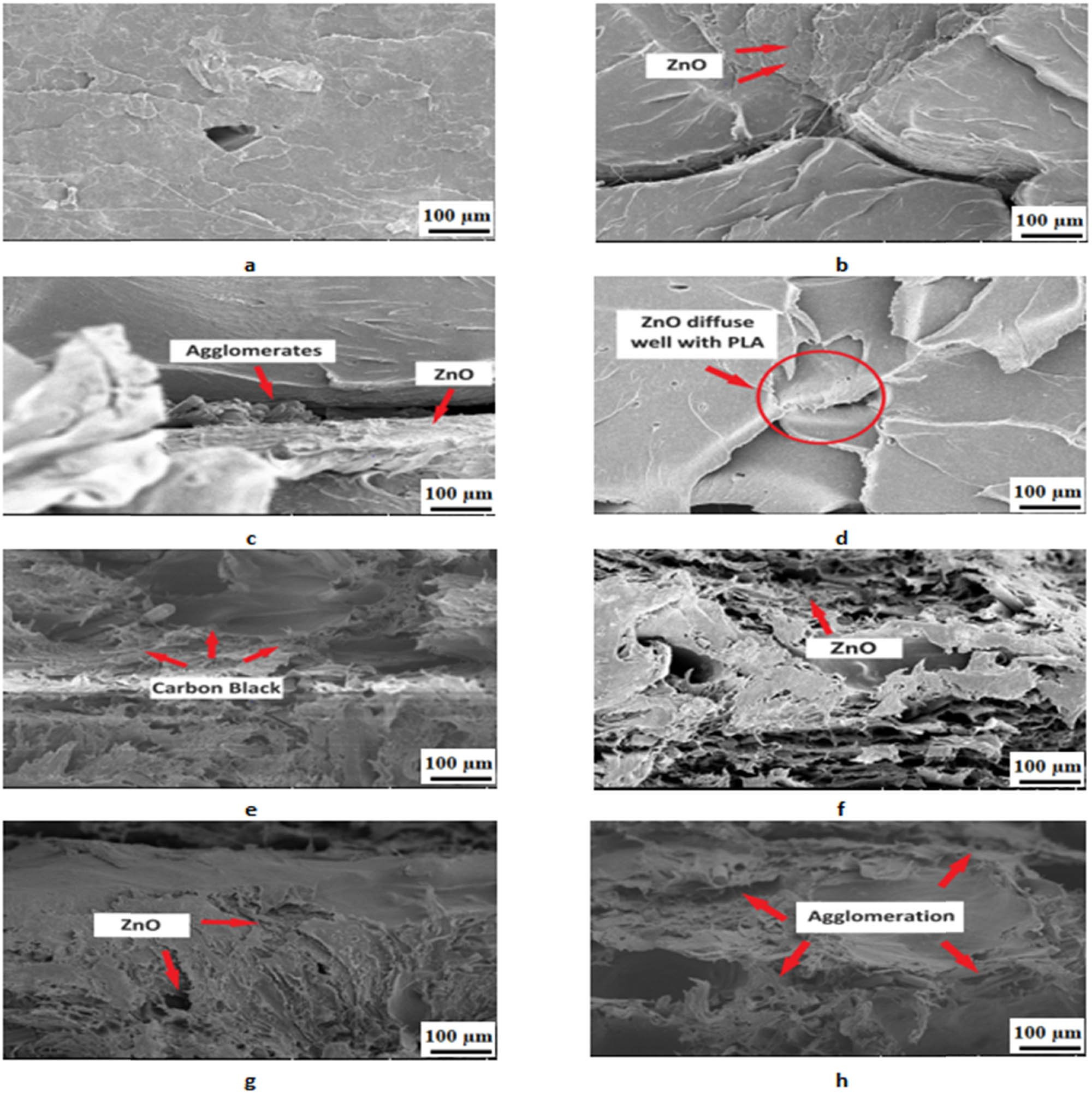

(a) SEM micrographs of the pure PLA sample, (b) PLA sample with 4 wt% ZnO, (c) PLA sample with 7 wt% ZnO, (d) PLA sample with 11 wt% ZnO, (e) pure cPLA sample, (f) cPLA sample with 4 wt% ZnO, (g) cPLA sample with 7 wt% ZnO, and (h) cPLA sample with 11 wt% ZnO.

Figure 4b and c shows the SEM micrograph of PLA printed with 7 and 9 wt% ZnO fillers. ZnO fillers diffused effectively inside the PLA matrix and produced adhesion with the PLA interface, as demonstrated in Figure 4d. There was an increase in the tensile strength for all composites filled with ZnO fillers compared to the unfilled control samples (Figure 4a). When the filler loading was increased to 9 wt%, the tensile strength decreased by 1.5%. This is because when filler loading was increased to a critical level, non-homogeneous ZnO fillers are expected to induce agglomerates, which generate a stress concentration zone that causes cracking and finally weakens the tensile strength of PLA composites (21). The PLA reinforced with 11 wt% ZnO filler achieved the maximum tensile strength due to the strengthening impact of the filler on the composites, as shown in Figure 4d (22).

Based on previous studies, Alig et al. investigated the effect of filler arrangement and agglomeration on the mechanical, electrical, and thermal characteristics of a CNT-filled composite (23). Due to poor dispersion in the polymer matrix, first or primary agglomerates developed during the CNT manufacturing process. Secondary agglomerates (agglomerates formed as a result of secondary processing, such as melt mixing, extrusion, or injection moulding) formed inside the composites due to non-Brownian diffusion of particles having attractive interactions. The tensile characteristics degraded by the presence of secondary agglomerates that were more loosely packed (23). Initial agglomerates formed during the printing process when PLA was heated to its melting temperature, resulting in poor carbon black (CB) dispersion inside PLA. When the ZnO filler solution was applied, there will be a lack of bonding because the temperature decrease leads to a loss in tensile strength. The SEM micrograph showed the formation of agglomerates in Figure 4h, while Figure 4e illustrates well dispersion of CB in PLA samples.

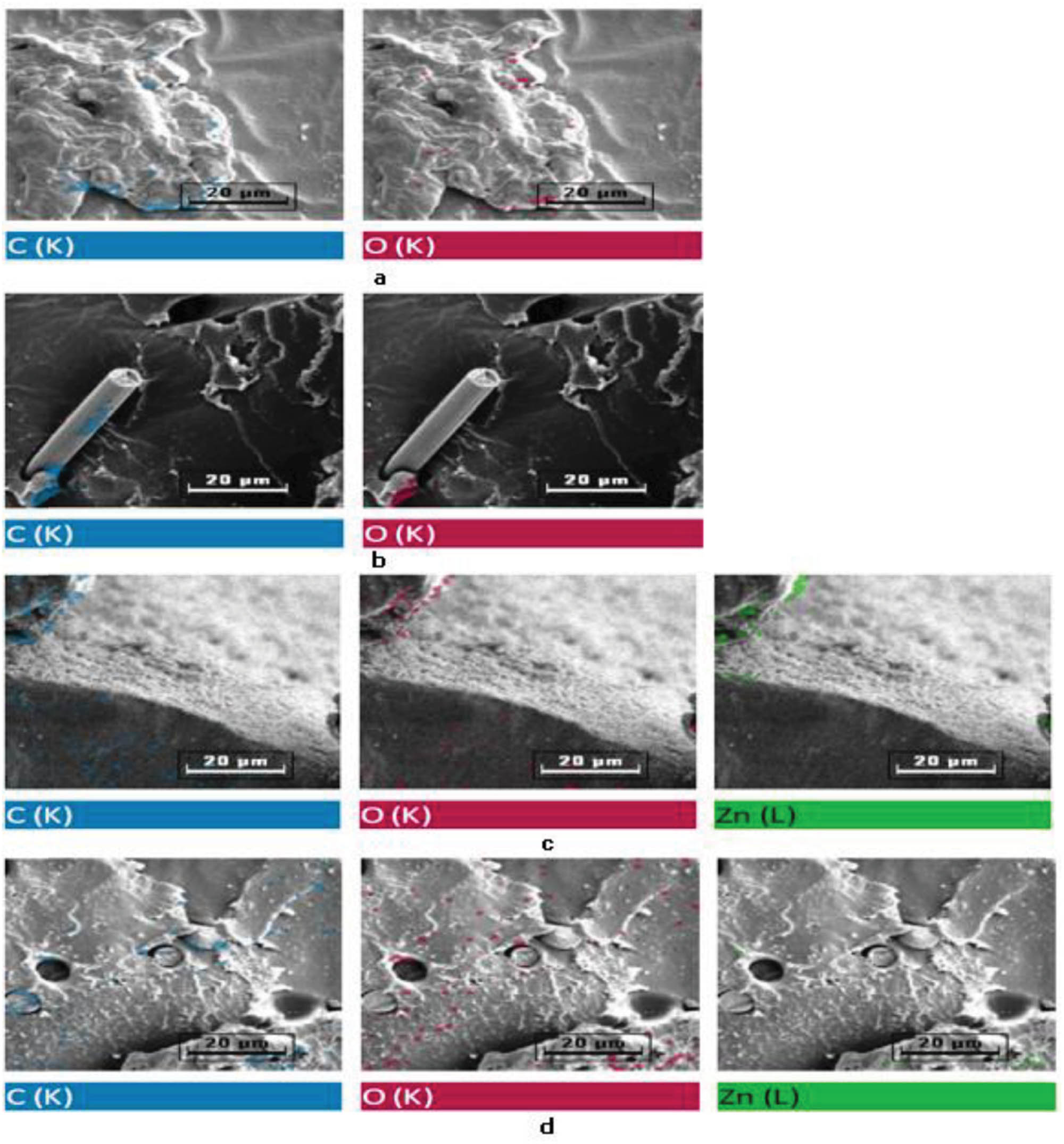

Elemental mapping is required to understand the distribution of fillers and the concurrence with the explanation given previously. The presence of ZnO filler distribution was confirmed in composites, as shown in Figure 5c and d.

(a) Elemental mapping of pure PLA sample, (b) pure cPLA sample, (c) PLA sample with 11 wt% ZnO, (d) cPLA sample with 4 wt% ZnO.

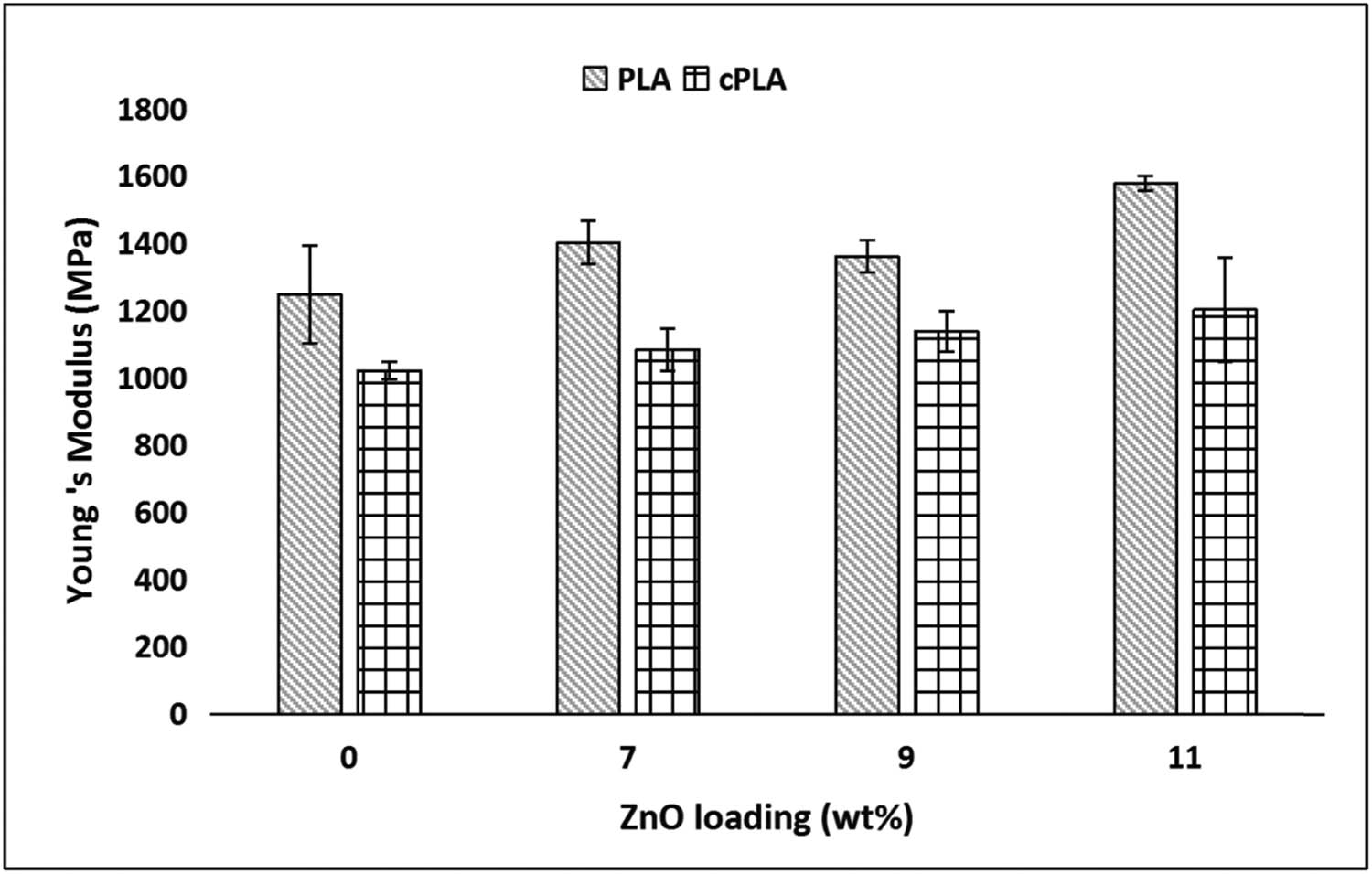

Figure 6 shows the effect of ZnO loading on the tensile modulus of the PLA and cPLA composites. Filled PLA had a greater tensile modulus than unfilled PLA. When the filler content increased, the tensile modulus increased from 1,247.18 to 1,578.08 MPa. At 11 wt% ZnO loading, the maximum value of 1.58 GPa was achieved. The tensile modulus of cPLA composites demonstrated a similar trend to PLA due to the stiffening role of fillers. Fillers functioned as obstacles that restricted the polymer chains from moving freely and therefore reduced the flexibility of the composites (18). Filler rigidity increased the modulus and contributed to the ability to tolerate deformation. Furthermore, the cPLA composites had lower tensile modulus than the PLA composites with the same filler amount. This may be due to the carbon fibre creating the uneven arrangement of clusters resulting in the loss of adhesion between the reinforcer and matrix, thus reflecting the reduced stiffness (24).

Effect of ZnO loading on Young’s modulus of PLA/ZnO and cPLA/ZnO composites.

Kumar et al. studied the effects of alumina filler concentration on Young’s modulus of the ABS/alumina composite (25). The alumina loading varied from 1 to 5 vol% within ABS. At a filler loading of 5 vol%, the modulus increased by 9% compared to that of pure ABS. The concentration of particles filled between the polymer chain was much higher and thus the polymer chain segment would deform itself in a less mobile manner, accounting for the higher Young’s modulus. The results were similar to the experimental results, which showed that with 11 wt% loading, the moduli of PLA/ZnO and cPLA/ZnO increased by 27% and 18%, respectively (26).

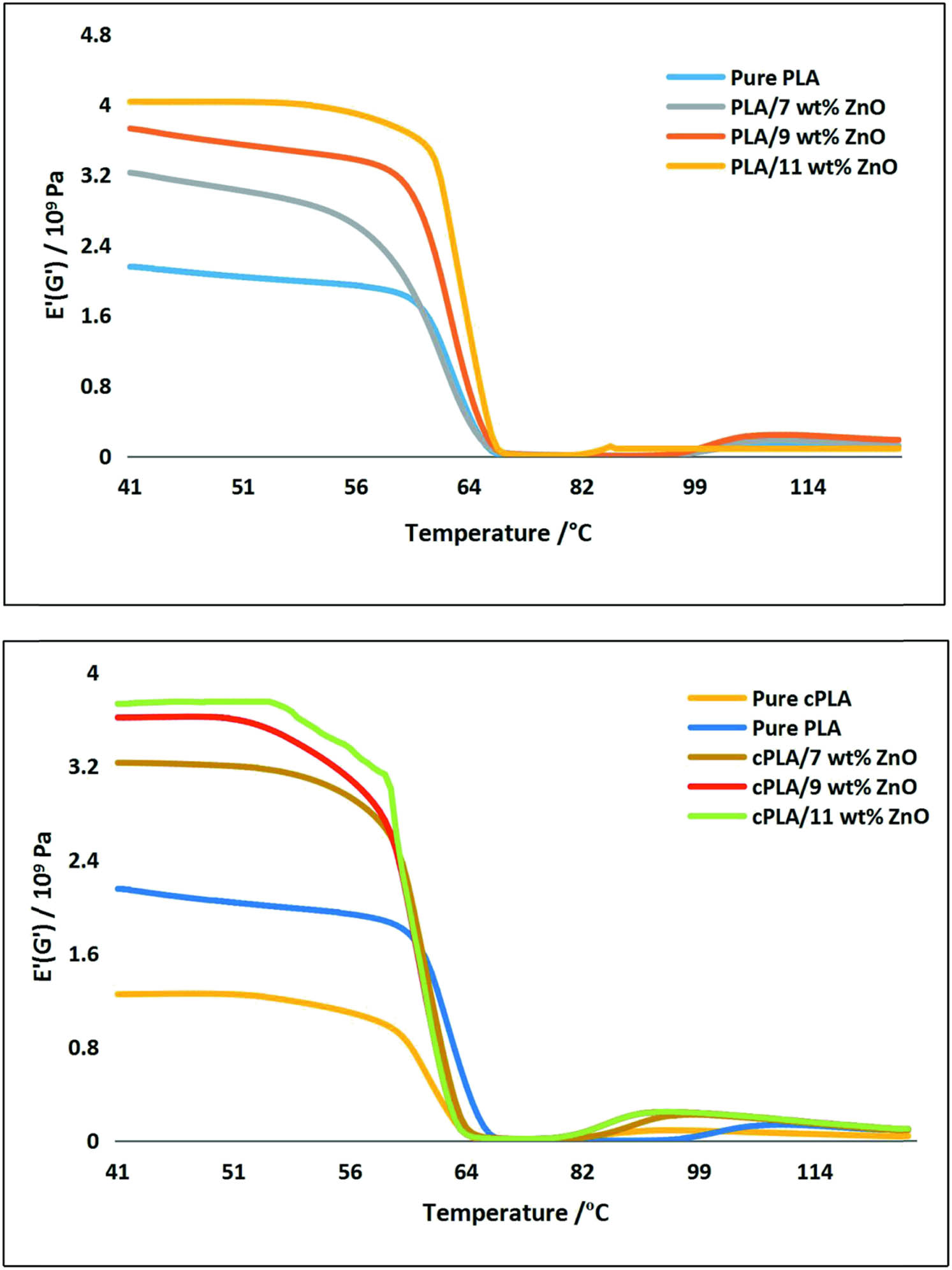

Figure 7 demonstrates the effect of different ZnO loadings on the dynamic storage moduli, E′, of PLA and cPLA composites. The storage modulus reduced dramatically when temperature increased, and there was a significant drop in the T g region. At the same temperatures, the storage moduli of PLA and cPLA composites were greater than those of pure PLA and cPLA. At all temperatures, the storage moduli increased as the filler loading increased, and the composite with the highest filler loading, PLA and cPLA reinforced with 11 wt% ZnO, had the highest E′ value. This was linked to the inclusion of stiffness improvement with the filler addition (27). The fillers reinforcing impact and strong matrix/filler interaction boosted the composites’ overall rigidity (20). This inhibited the mobility of molecular chains of the matrix, thus increasing the stiffness of the composite materials (28).

Dynamic storage moduli (E′) of PLA/ZnO and cPLA/ZnO.

However, cPLA/ZnO composites had a lower E′ than PLA/ZnO composites due to the presence of CB and ZnO clusters, which lowered the material’s stiffness. According to previous studies, Santos et al. discovered a similar result when they investigated the characteristics of ABS reinforced with titanium dioxide (TiO2) and CB. The agglomerate formation was found to be a fault that caused stiffness deterioration. Because of the inadequate interaction between CB and TiO2 in the ABS matrix, a better degree of stress transfer at the boundary became impossible (29).

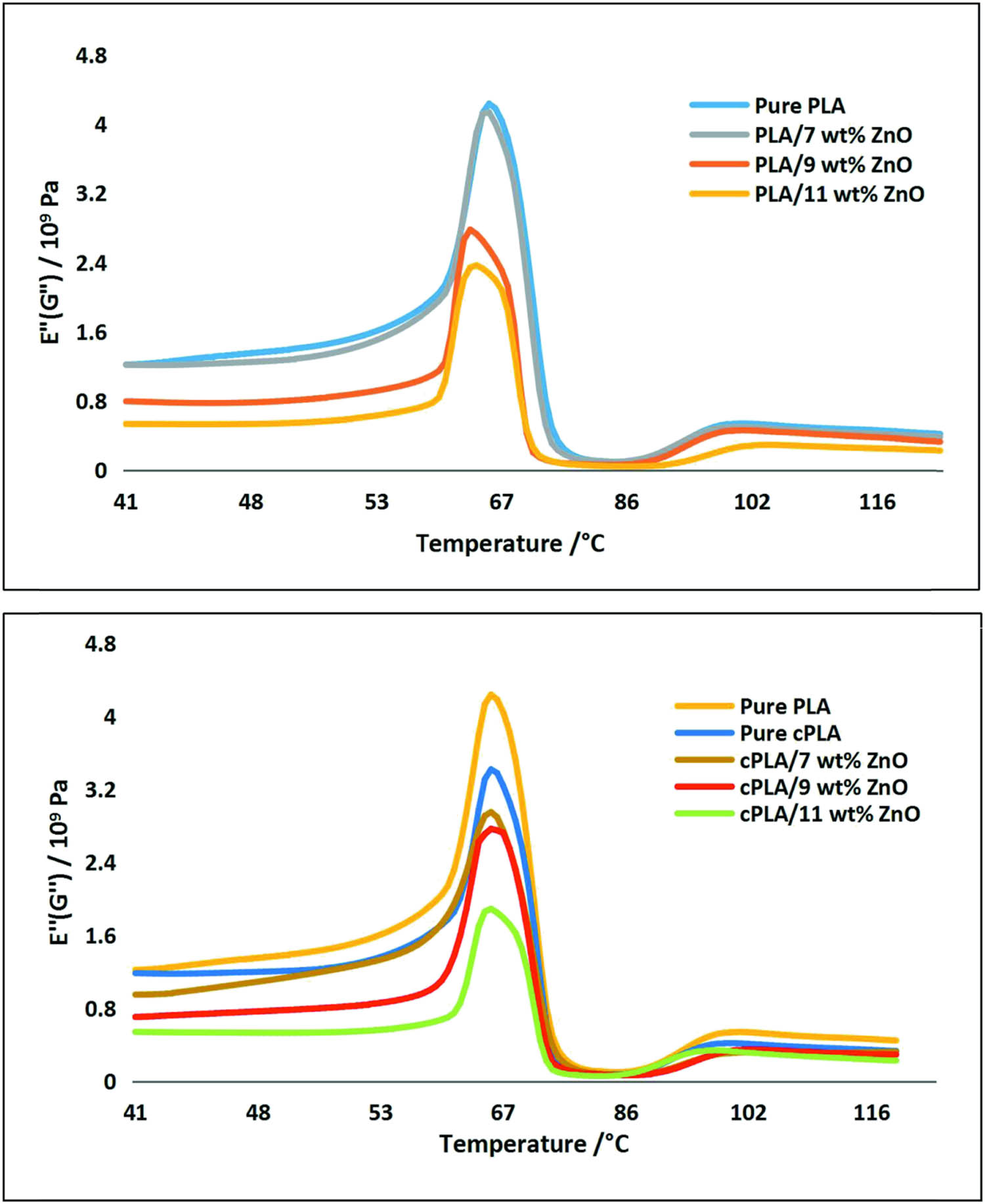

Figure 8 displays the effect of different ZnO loadings on the dynamic loss moduli, E″, of PLA and cPLA composites. The curve representing the loss modulus remains constant at low temperatures and increases gradually until reaching the peak value because intermolecular bonding is destroyed (30). It was observed that the loss modulus decreased continuously after the highest peak as the mobility of the chain improved. Owing to the decrease in stiffness, more energy is dissipated; therefore, the highest loss modulus is observed for less rigid samples (31). The reduction in the intensity of the matrix chains’ motion is associated with an increase in T g. At the same temperature, the loss modulus of composites with increasing filler loading was lower. This might be owing to the polymer chain’s constrained mobility, which results in less energy being dissipated due to the chain restriction. The result showed that the loss modulus tends to lose energy, which is inversely proportional to the storage modulus (31).

Loss moduli (E″) of PLA/ZnO and cPLA/ZnO composites.

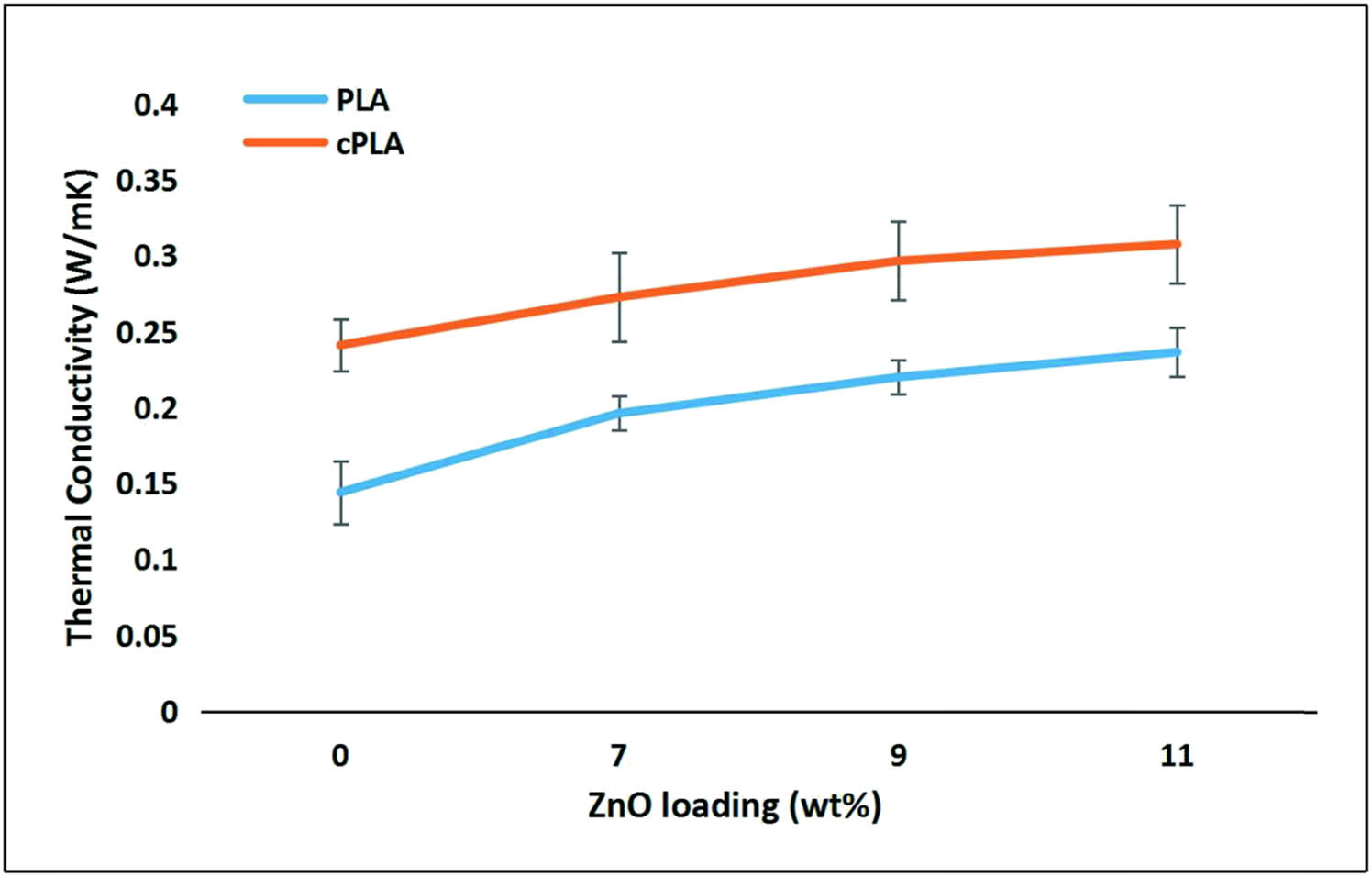

Figure 9 shows the increasing trend in thermal conductivity when the ZnO loading increased from 7 to 11 wt% for both composites. This is owing to the use of a filler with a higher thermal conductivity than the PLA matrix, which causes higher heat dissipation between the ZnO filler and the PLA matrix. The maximum thermal conductivity was attained by 11 wt% cPLA, which was 0.3074 W‧mK−1, while the lowest reading was acquired by pure PLA, which was 0.1412 W‧mK−1. Because the matrix acts as a thermal barrier for heat propagation, more fillers will mix well with PLA and produce conductive pathways to transport heat rapidly (32). As we can see, when the ZnO filler is increased, the thermal conductivity of PLA composites increases from 0.1962 to 0.2361 W‧mK−1, indicating that more filler particles are packed together to generate effective close contact between them and form conductive pathways (33). Due to naturally high thermal conductivity CB, the thermal conductivity of cPLA composites was greater than that of PLA composites (34). Fillers are well dispersed inside the polymer matrix at 7 and 9 wt%. Some fillers developed agglomerates at larger 11 wt% filler loadings, promoting quick heat conduction and increasing thermal conductivity at 0.3074 W‧mK−1 (32). This can be proved through SEM micrographs Figure 4h reveals the generation of agglomerates inside the composites. This is similar to the result of previous studies, which found that CB particles formed conductive clusters and networks in the poly(ethylene-oxide) polymer matrix when the sample approached the percolation threshold, therefore improving thermal conductivity (35).

Thermal conductivity of PLA and cPLA composites.

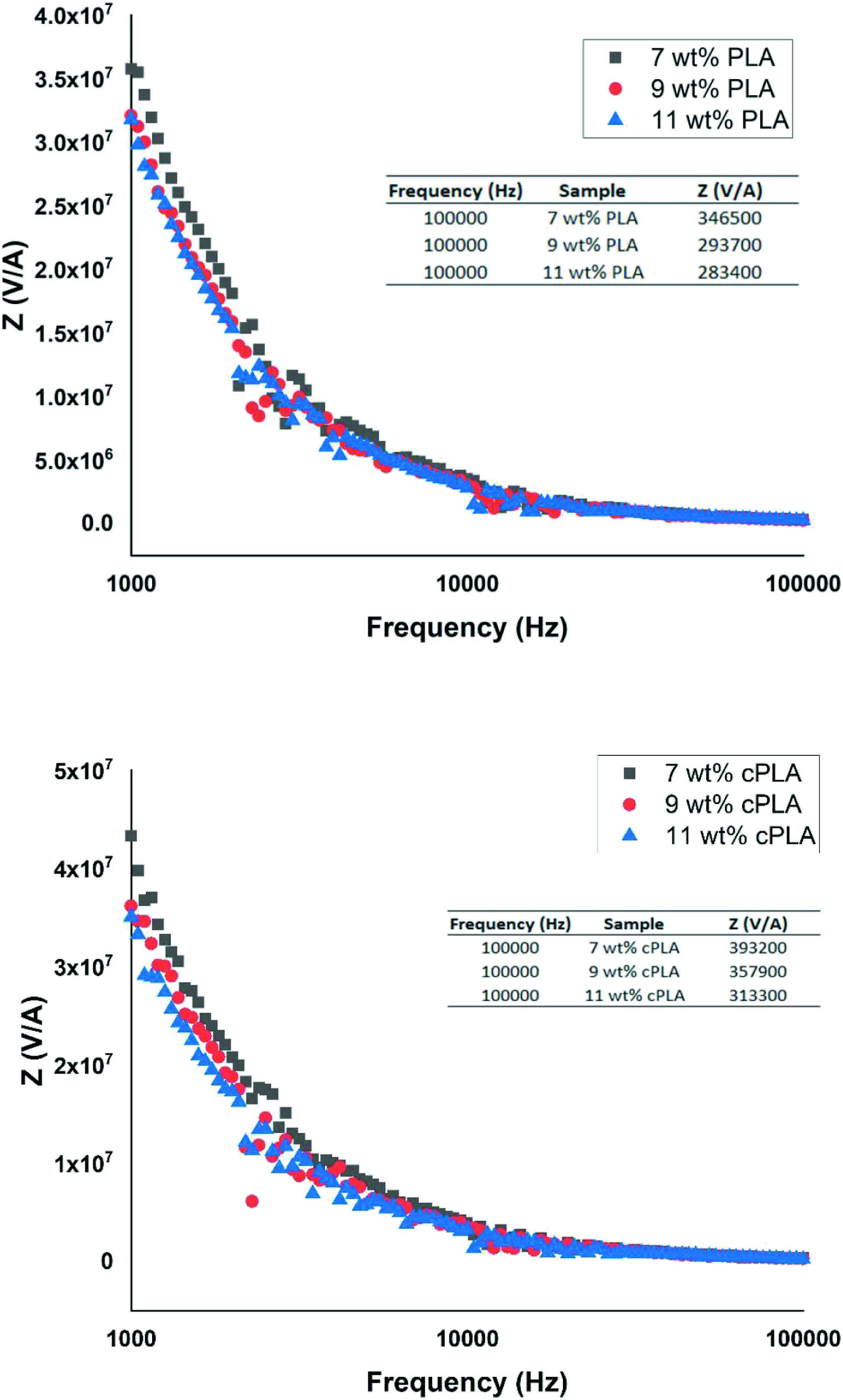

Figure 10 shows a comparison of the impedance testing of PLA/ZnO and cPLA/ZnO composites. The 7 wt% of cPLA composite had the highest impedance at 10 kHz frequency. This is due to the CB component in cPLA. The electrical conductivity of PLA/ZnO and cPLA/ZnO composites steadily enhanced with the inclusion of ZnO fillers. When the fillers achieved their percolation threshold value, conductive networks of ZnO formed within the matrix (36). CB and ZnO filler generated a high electrically conductive network, facilitating carrier mobility inside the polymer chains and hence decreasing the impedance of materials (37). The previous research stated that PLA has low permittivity due to its small polarization of the macromolecules (38). Among the polymer, epoxy was used due to its high impedance properties. However, epoxy has low toughness. Previous research stated that the impedance in zinc-rich epoxy was 80 Ω‧cm2 at 100,000 Hz (39). All PLA/ZnO and cPLA/ZnO composites had lower impedance when frequency increased. Therefore, cPLA/ZnO was suitable for replacing epoxy composites. According to Abdalhadi et al., the matrix of OPEFB/PLA with Fe2O3 filler was homogeneous and the number of voids was reduced (38). Therefore, suitable ZnO suspension content was also an important factor that could influence the properties of composites.

Impedance testing of PLA/ZnO and cPLA/ZnO composites.

4 Conclusions

This study shows that the 11 wt% PLA/ZnO composites have the highest mechanical properties which are tensile strength and Young’s modulus. According to the results, the mechanical properties of the samples with filler addition were greater than those of the pure samples. These enhancements were made possible by improving the interfacial adhesion between the PLA matrix and the ZnO suspension. Because of the stiffening effect and high strength of the ZnO suspension, tensile strength and Young’s modulus were improved by incorporating ZnO into the PLA matrix. The detailed morphology can be achieved by SEM analysis due to the uniform diffusion of ZnO in the PLA, indicating excellent interfacial adhesion that will facilitate effective stress transfer. This eventually leads to high tensile strength and dynamic mechanical properties. Because of the existence of CB and ZnO clusters, cPLA/ZnO composites have a lower E′ but higher E′′ than PLA/ZnO composites. In addition, the inherent high thermal and impedance of cPLA/ZnO compared to those of pure and PLA composites is due to the incorporation of the carbon fibre and conductive ZnO into PLA. This is because the formation of a conductive path between them transmits heat and electricity quickly. Our approach expands the good mechanical, electrical, and thermal conductivity performances by integrating the ZnO suspension into PLA to provide superior-quality electrical instruments for the future.

Acknowledgement

The authors thank the Faculty of Chemical Engineering Technology, University Malaysia Perlis (UniMAP) for providing the research and testing facilities.

-

Funding information: The authors would like to acknowledge the support from the Fundamental Research Grant Scheme (FRGS) under a grant number of FRGS/1/2018/TK05/UNIMAP/02/14 from the Ministry of Higher Education Malaysia.

-

Author contributions: Mei Ai Tan: writing – original draft, writing – review and editing, methodology, formal analysis; Cheow Keat Yeoh: writing – review and editing; Pei Ling Teh: project administration; Nor Azura Abdul Rahim: resources; Cheah Chie Song: visualization.

-

Conflict of interest: The authors state no conflict of interest.

References

(1) Hagen R. A comprehensive reference||polylactic acid. Polym Sci. 2012;231–6. 10.1016/b978-0-444-53349-4.00269-7.Search in Google Scholar

(2) Vasile C, Rapa M, Stefan M, Stan M, Macavei S, Darie-Nita RN, et al. New PLA/ZnO:Cu/Ag bionanocomposites for food packaging. Express Polym Lett. 2017;11(7):531–44. 10.3144/expresspolymlett.2017.51.Search in Google Scholar

(3) Liang L, Huang T, Yu SX, Cao WW, Xu TT. Study on 3D printed graphene/carbon fiber multi-scale reinforced PLA composites. Mater Lett. 2021;300(6):130173. 10.1016/J.MATLET.2021.130173.Search in Google Scholar

(4) Ning F, Cong W, Hu Y, Wang H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties. J Compos Mater. 2017;51(4):451–62. 10.1177/0021998316646169.Search in Google Scholar

(5) Al Zahmi S, Alhammadi S, El Hassan A, Ahmed W. Carbon fiber/PLA recycled composite. Polymers. 2022;14:2194. 10.3390/polym14112194.Search in Google Scholar PubMed PubMed Central

(6) Ning F, Cong WL, Hu ZL, Huang K. Additive manufacturing of thermoplastic matrix composites using fused deposition modeling: A comparison of two reinforcements. J Compos Mater. 2017;51(27):3733–42. 10.1177/0021998317692659.Search in Google Scholar

(7) Weng Z, Wang J, Senthil T, Wu L. Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing. Mater Des. 2016;102:276–83. 10.1016/j.matdes.2016.04.045.Search in Google Scholar

(8) Sudeepan J, Kumar K, Barman TK, Sahoo P. Study of mechanical and tribological properties of ABS/clay polymer composite using Taguchi optimization method. J Manuf Technol Res. 2014;6(3/4):153–75.10.1016/j.mspro.2014.07.050Search in Google Scholar

(9) Diani J, Liu Y, Gall K. Finite strain 3D thermoviscoelastic constitutive model. Polym Eng Sci. 2006;46(4):486–92. 10.1002/pen.20497.Search in Google Scholar

(10) Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos Part B Eng. 2018;143:172–96. 10.1016/j.compositesb.2018.02.012.Search in Google Scholar

(11) Mohamed OA, Masood SH, Bhowmik JL. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv Manuf. 2015;3(1):42–53. 10.1007/s40436-014-0097-7.Search in Google Scholar

(12) Dehghanghadikolaei A. Additive manufacturing as a new technique of fabrication. J Sci Eng Res. 2018;5(8):123–31. 10.14302/issn.2831-8846.j3dpa-18-2207.Search in Google Scholar

(13) Lim JH, Yeoh CK, Abdullah C, Teh PL. Band structure and thermoelectric properties of inkjet printed ZnO and ZnFe2O4 thin films. Ceram Int. 2016;42(10):12064–73. 10.1016/j.ceramint.2016.04.135.Search in Google Scholar

(14) Chu Z, Zhao T, Li L, Fan F, Qin Y. Characterization of antimicrobial poly (lactic acid)/nano-composite films with silver and zinc oxide nanoparticles. Materials (Basel). 2017;10(6):659. 10.3390/ma10060659.Search in Google Scholar PubMed PubMed Central

(15) Brounstein Z, Yeager CM, Labouriau A. Development of antimicrobial PLA composites for fused filament fabrication. Polymers. 2021;13(4):580. 10.3390/polym13040580.Search in Google Scholar PubMed PubMed Central

(16) Szyma M, Chyli M, Pieczywek PM, Walkiewicz A, Pertile G, Frac M, et al. Evaluation of nanocomposite made of polylactic acid and nanocellulose from carrot pomace modified with silver nanoparticles. Polymer. 2020;12(4):812. 10.3390/polym12040812.Search in Google Scholar PubMed PubMed Central

(17) Junpha J, Wisitsoraat A, Prathumwan R, Chaengsawang W, Khomungkhun K, Subannajui K. Electronic tongue and cyclic voltammetric sensors based on carbon nanotube/polylactic composites fabricated by fused deposition modelling 3D printing. Mater Sci Eng C. 2020;117:111319. 10.1016/j.msec.2020.111319.Search in Google Scholar PubMed

(18) Hamzah KA, Yeoh CK, Noor MM, Teh PL, Aw YY, Sazali SA, et al. Mechanical properties and thermal and electrical conductivity of 3D printed ABS-copper ferrite composites via 3D printing technique. J Thermoplast Compos Mater. 2019;35:1–14. 10.1177/0892705719869405.Search in Google Scholar

(19) Aw YY, Yeoh CK, Idris MA, Teh PL, Elyne WN, Hamzah KA, et al. Influence of filler precoating and printing parameter on mechanical properties of 3D printed acrylonitrile butadiene styrene/zinc oxide composite. Polym Plast Technol Eng. 2018;58(1):1–13. 10.1080/03602559.2018.1455861.Search in Google Scholar

(20) Yang Z, Peng H, Wang W, Liu T. Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J Appl Polym Sci. 2010;116(5):2658–67. 10.1002/app.31787.Search in Google Scholar

(21) Fu Y, Feng XQ, Lauke B, Mai YW. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites. Compos Part B Eng. 2008;39(6):933–61. 10.1016/j.compositesb.2008.01.002.Search in Google Scholar

(22) Tian XY, Liu TF, Wang QR, Dilmurat Q, Li DC, Ziegmann G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J Clean Prod. 2017;142(4):1609–18. 10.1016/j.jclepro.2016.11.139.Search in Google Scholar

(23) Alig I, Potschke P, Lellinger D, Skipa T, Pegel S, Kasaliwal GR, et al. Establishment, morphology and properties of carbon nanotube networks in polymer melts. Polymer. 2012;53(1):4–28. 10.1016/j.polymer.2011.10.063.Search in Google Scholar

(24) Chigondo F, Shoko P, Nyamunda BC, Moyo M. Maize stalk as reinforcement in natural rubber composites. Int J Sci Technol Res. 2013;2(6):263–71.Search in Google Scholar

(25) Kumar V, RamKumar J, Aravindan S, Malhotra SK, Vijai K, Shukla M. Fabrication and characterization of ABS nano composite reinforced by nano sized alumina particulates. Int J Plast Technol. 2009;13(2):133–49. 10.1007/s12588-009-0011-5.Search in Google Scholar

(26) Mehraein H. Impact of process parameters on mechanical properties of 3D printed polycaprolactone parts. Master Science: Wichita State University; 2018.Search in Google Scholar

(27) Margem FM, Monteiro SN, Neto JB, Rodriguez RJS, Soares BG. The dynamic-mechanical behavior of epoxy matrix composites reinforced with ramie fibers. Rev Mater. 2010;15(2):167–71. 10.1590/S1517-70762010000200012.Search in Google Scholar

(28) Manoharan S, Suresha B, Ramadoss G, Bharath B. Effect of short fiber reinforcement on mechanical properties of hybrid phenolic composites. J Mater. 2014;2014:1–9. 10.1155/2014/478549.Search in Google Scholar

(29) Santos RM, Botelho GL, Machado AV. Development of acrylonitrile-butadiene-styrene composites with enhanced UV stability. J Mater Sci. 2014;49(2):510–8. 10.1007/s10853-013-7728-4.Search in Google Scholar

(30) Abu-Abdeen M. Static and dynamic mechanical properties of poly(vinyl chloride) loaded with aluminum oxide nanopowder. Mater Des. 2012;33(1):523–8. 10.1016/j.matdes.2011.04.059.Search in Google Scholar

(31) Arivazhagan A, Masood SH. Dynamic mechanical properties of ABS material processed by fused deposition modelling. Int J Eng Res Appl. 2012;2(3):2009–14.Search in Google Scholar

(32) Kochetov R, Korobko AV, Andritsch T, Morshuis PHF, Picken SJ, Smit JJ. Modelling of the thermal conductivity in polymer nanocomposites and the impact of the interface between filler and matrix. J Phys D Appl Phys. 2011;44(39):395401. 10.1088/0022-3727/44/39/395401.Search in Google Scholar

(33) Nikzad M, Masood SH, Sbarski I. Thermo-mechanical properties of a highly filled polymeric composites for fused deposition modeling. Mater Des. 2011;32(6):3448–56. 10.1016/j.matdes.2011.01.056.Search in Google Scholar

(34) Tsekmes IA, Kochetov R, Morshuis PHF, Smit JJ. Thermal conductivity of polymeric composites: A review. Proceeding IEEE International Conference on Solid Dielectric (ICSD); 2013 June 30-July 4. Bologna, Italy. Netherlands; 2013. p. 678–81.10.1109/ICSD.2013.6619698Search in Google Scholar

(35) Elimat ZM, Al-Hussami SA, Zihlif AM. Effect of carbon black on the thermoelectrical properties of poly(ethylene-oxide) composites. J Compos Mater. 2013;47(28):3525–34. 10.1177/00219983124672.Search in Google Scholar

(36) Park W, Hu J, Jauregui LA, Ruan X, Chen YP. Electrical and thermal conductivities of reduced graphene oxide/polystyrene composites. Appl Phys Lett. 2014;104(11):113101. 10.1063/1.4869026.Search in Google Scholar

(37) Ju H, Kim M, Kim J. Enhanced thermoelectric performance of highly conductive poly(3,4-ethylenedioxythiophene)/carbon black nanocomposites for energy harvesting. Microelectron Eng. 2015;136:8–14. 10.1016/j.mee.2015.03.030.Search in Google Scholar

(38) Abdalhadi DM, Abbas Z, Ahmad AF, Matori KA, Esa F. Controlling the properties of OPEFB/PLA polymer composite by using Fe2O3 for microwave applications. Fibers Polym. 2018;19(7):1513–21. 10.1007/s12221-018-8118-y.Search in Google Scholar

(39) Du XM, Xu PJ, Cong PL, Zhou ZJ. Compatibilization and toughness modification of linear aliphatic epoxy compound on paving epoxy asphalt. Mater Struct. 2020;53(2):1–12. 10.1617/s11527-020-01473-0.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites