Abstract

As the key components of sealing applications, rubber seals are subject to complicated environmental conditions during the service lifetime. In this study, the aging of three typical rubber materials, ethylene–propylene–diene monomer rubber, liquid silicone rubber, and fluorine rubber, was tested under different high- and low-temperature cycle aging environments. The experimental results confirm that the reciprocating temperature cycle causes a type of fatigue failure, which could result in an increase in the rubber compression set. In addition, a novel accelerated aging test method was proposed based on the dominant damage mechanism of rubber material caused by the temperature cycle treatments. Based on this method, the long-term aging test results of rubber samples under high- and low-temperature cycle conditions can be predicted. This method could significantly shorten the aging test time and reduce the test cost.

1 Introduction

Rubber, a sealing material with excellent mechanical properties, has been extensively applied in the sealing of energy power equipment in aviation, aerospace, transportation, electric power, etc. (1,2,3). The durability and reliability of rubber seals are critical for the lifetime (4,5,6). During long-term operation, the sealing materials age and degrade under the action of oxygen, high temperature, water, acid, temperature cycles, etc.

Chang et al. (7) investigated the aging of silicone rubbers with different types of hardness subjected to dry and humidified air at different temperatures. With increasing temperature, the aging of silicone rubbers became more severe, as indicated by the variations in the permanent compression set value, mechanical properties, and surface morphology. Li et al. (8) studied the aging mechanism of silicone rubbers in simulated proton exchange membrane fuel cells (PEMFCs) in humid, acidic, and high-temperature environments. The results indicate that the aging mechanism is mainly due to decomposition in the backbone and hydrolysis of the crosslinking. Wang et al. (9) investigated the chemical and mechanical degradation of a type of silicone rubber. The weight loss test results indicate that the exposure time and the compression load had great influences on the weight loss of the silicone rubber specimens. The specimens degraded more severely in strong acid solutions and when greater compression loads were applied. The degradation mechanism could have been chain scissoring in silicone rubber and the hydrolysis of the crosslinking positions. Wu et al. (10) studied the degradation of silicone rubber as a PEMFC sealing material during different cold-start processes. The results indicate that rubber under temperature cycle has an aging trend similar to that of thermo-oxygen aging. With an increasing number of temperature cycles, the hardness of silicone rubber increased, and its weight tended to decrease. In addition, some studies on the aging of reactor sealing materials, including accelerated aging experiments of rubber materials at different compression rates, voltages, and vibrations, investigated the changes in material properties and seal failure forms (11,12,13,14).

The lifetime prediction of rubbers, which are influenced by many factors, is a complex problem. It is of great significance to study the aging mechanism and the interaction among these factors for the prediction of the actual service life of rubbers. Existing research on PMFEC sealing rubber material aging has primarily focused on the roles of high temperature, acidity, and some other significant factors in the rubber aging process, whereas some potential aging factors have been ignored, such as the temperature cycle (15). For example, the rubber seals of PEMFCs are used in vehicles; when the vehicles do not work, the temperature of the rubber seals remains consistent with the environmental temperature. The temperature of the fuel cell stack can be as low as −40°C in winter in some cold regions (16,17), and it can reach up to 90°C after the vehicle starts (18,19). During the whole life cycle, the temperature of PEMFC rubber seals tends to change periodically over a wide temperature range. Such temperature cycles often occur up to several thousand times, thus negatively affecting the sealing performance and service life of rubber materials (20). Although existing research has investigated the aging of silicone rubber under temperature cycle conditions and analyzed the corresponding aging mechanism, the effects on the temperature cycles and thermal aging were not distinguished. First, controlled trials under a cycle temperature aging environment were designed in this study to solve the above problem. The effect of temperature cycles on the aging of rubber samples was analyzed after the effect on thermal aging was ruled out. The compression set measurement results suggest that the greater the number of temperature cycles, the larger the compression permanent deformation of the rubber samples. The attenuated total reflection-Fourier transformed infrared (ATR-FTIR) test results show that temperature cycles will cause molecular chain degradation in rubber. Rubber samples undergo recurrent thermal stress when subjected to repeated cycles of high- and low-temperature fluctuations. In general, the effect of the temperature cycle on the rubber is a type of thermal fatigue failure. Second, the impact of thermal aging and thermal fatigue on rubber’s compression set was investigated. Finally, a test method was provided in this work to estimate the effect of thermal fatigue on the compression set of rubber by employing an equivalent strain cycle test instead of a temperature cycle aging test. In this study, the aging process of rubbers under high- and low-temperature cycling environments was explained, and a prediction technique of rubber compression set under the influence of thermal cycling and thermal fatigue was put forward. This method can serve as a reference for the actual life prediction of rubber static sealing, such as sealing gaskets in PEMFCs, lithium batteries, and many other sealing applications.

2 Materials and methods

2.1 Experimental materials

To get some broad conclusions, three rubber compounds that are frequently utilized in seals were used. Figure 1 presents the rubber samples employed in this study. Liquid silicone rubber (LSR), ethylene propylene diene monomer rubber (EPDM), and fluorine rubber (FPM), as shown in Figure 1, were employed for the rubber test in this research (the hardness of the three rubber materials is 70HA, provided by Zhongding Sealing Parts Co., Ltd., Joint Research Center, Ningguo, Anhui, China). Referring to GB/T 7759.1-2015, type A rubber compression was selected as samples (21), and the samples were molded into cylinders 29.0 ± 0.5 mm in diameter and 12.5 ± 0.5 mm in height.

Rubber samples of (a) LSR, (b) EPDM, and (c) FPM.

2.2 Experimental testing

2.2.1 Compression set test

The compression set is a crucial metric for assessing the rubbers’ service life in static sealing. In accordance with GB/T 20028-2005 and GB/T 27800-2021 standards, in the field of lifespan prediction, the relationship between compression set and aging time is typically established through aging experiments, and aging time is then calculated using the critical value of compression set for rubbers, where the critical value of compression set is associated with service circumstances. In this study, compression set was utilized to demonstrate how rubber lifetime is affected by aging (22,23).

According to GB/T 7759.1-2015, samples were compressed by 25% (the compression strain of samples was 25%). Up to the designed aging time, samples were taken out of the aging box and cooled for 2 h at room temperature. Then, the fixtures were released and the samples were kept at room temperature for 30 min. In order to obtain reliable results, three samples were used at each test point. The thickness of the samples was measured, and the compression set can be determined by the following equation:

where H 0 is the initial height of the rubber samples, H 1 is the free recovery height of the rubber samples at room temperature after the compression set test, and H s is the height of the limit block.

2.2.2 ATR-FTIR test

ATR-FTIR was used to analyze the changes in the molecular structure and functional groups on the surface of rubber samples. Attenuated total reflection technology can be used to identify specific molecules and groups located on the surface layer and analyze the chemical degradation mechanism of rubber during the aging process. ATR-FTIR measurements were performed using a Nicolet 50 FTIR spectrometer (Thermo Fisher Scientific, Waltham, MA, USA). Samples were scanned from 400 to 4,000 cm−1 at a resolution of 0.5 cm−1.

2.3 Experimental procedure

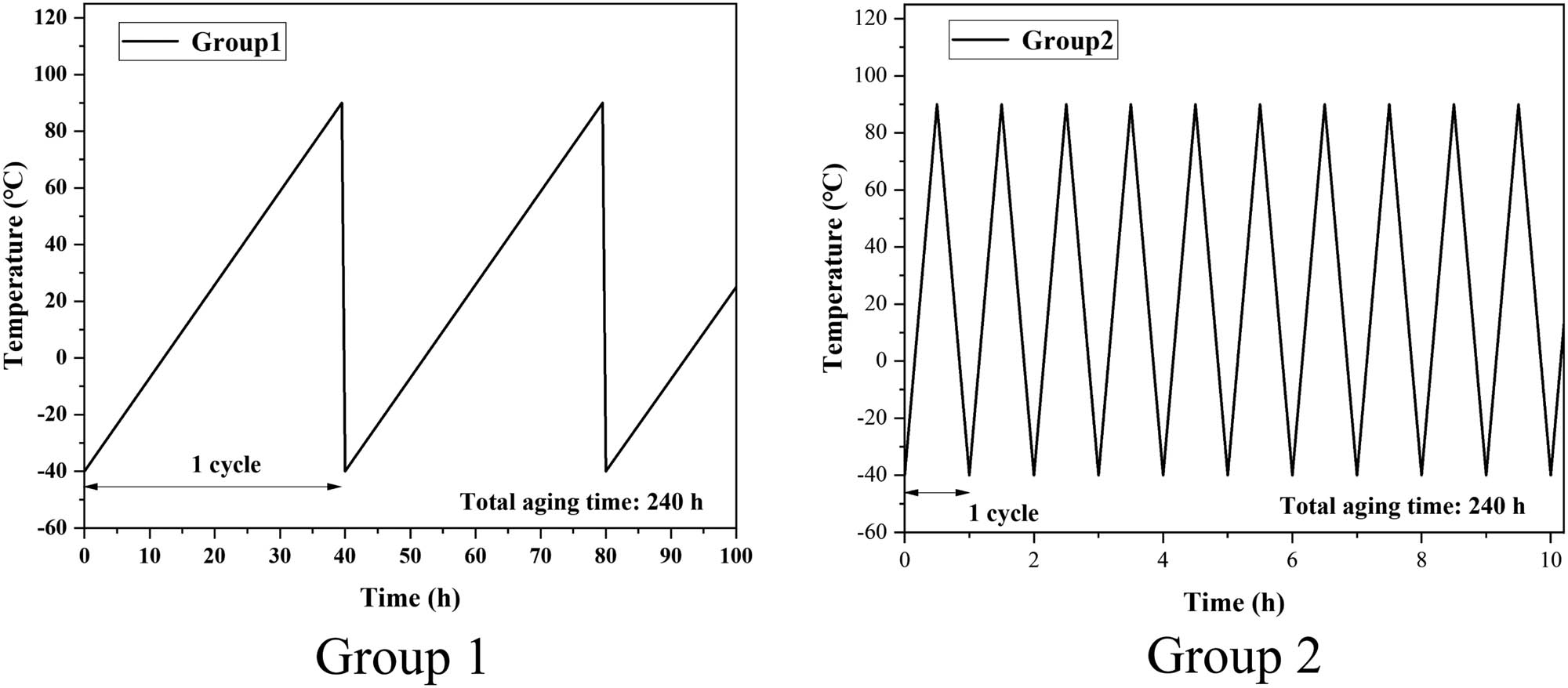

2.3.1 Temperature cycle control aging experiment-A

A temperature cycle control aging test was designed, as shown in Figure 2, to investigate the changes of rubber caused by temperature in an onboard environment. The highest temperature was set up to 90°C, and the lowest temperature was −40°C. It took 40 h for the Group 1 samples to experience one temperature cycle time and 1 h for those of Group 2 samples. The total aging time was 240 h. During the specific aging time, the two groups of rubber samples experienced the same degree of high-temperature aging. Based on the differences between the two experiments, the effect on thermal aging in the high- and low-temperature cycles was excluded. The compression set and ATR-FTIR test data of the control samples of the two groups were examined, and then, the effect of the temperature cycles on the rubber was studied.

Temperature cycle control aging experiment-A.

2.3.2 Temperature cycle control aging experiment-B

High-temperature aging and temperature cycle aging tests were conducted based on the compression set measurement results to conduct an in-depth study on the coupling relationship between thermal aging and thermal cycle factors with regard to the permanent compression deformation of rubber during the aging process. The Group 3 samples were aged at a constant temperature of 90°C, and the Group 4 samples were aged in a high- and low-temperature cycle aging environment with highest and lowest temperatures of 90°C and −40°C, respectively, as shown in Figure 3. Since the growth rate of the permanent compression set of rubber under a high-temperature environment is much higher than that under a low-temperature environment, the high-temperature holding time served as the aging time in the aging test (24,25). The total aging time was 288 h in high-temperature condition.

Temperature cycle control aging experiment-B.

2.3.3 Equivalent strain cycle experiment

Fatigue could result in the damage of some network structures in rubber that are damaged. With an increasing number of cycles, the fatigue damage of rubber gradually accumulates and ultimately affects the performance of rubber material (26,27). There are significant differences in the thermal expansion coefficients of the rubber material and metal fixture in the temperature cycle environment, so the thermal expansion of rubber is constrained, and the thermal stress cycle occurs in the process. In accordance with the analysis and verification results of the main failure mechanism of rubber material caused by the temperature cycle, a novel test method was developed by replacing the temperature cycle aging test with an equivalent strain cycle fatigue test to predict the compression set of rubber samples caused by reciprocating temperature change.

Since the thermal expansion coefficient of the rubber material is significantly higher than that of the metal fixture, the deformation of the metal fixture during the temperature-changing process can be ignored. The stress amplitude Δσ of rubber in the reciprocating temperature-changing process can be obtained as follows (15):

where α is the thermal expansion coefficient of the rubber material, ΔT is the ambient temperature difference, and E is the modulus of the rubber.

The same stress cycle process can be achieved by loading the repeated strain cycle load on the rubber sample. The equal effect change amplitude required for loading is expressed as follows:

For the aging experimental environment in this study, the highest ambient temperature was set to 90°C, and the lowest temperature was set to −40°C. Table 1 lists the thermal expansion coefficient of the three materials and the strain amplitude of the strain cycle experimental loading.

Rubber material parameters

| Material | Thermal expansion coefficient (α) | Strain amplitude (Δε) |

|---|---|---|

| LSR | 272 × 10−6 °C−1 | 3.54 × 10−2 |

| EPDM | 235 × 10−6 °C−1 | 3.06 × 10−2 |

| FPM | 210 × 10−6 °C−1 | 2.73 × 10−2 |

The equivalent strain cycle experiment of rubber was performed using a universal testing machine. The initial compression state of the rubbers should be the same as which in the aging test. The surface of the metal head was coated with a thin layer of silicone oil lubricant; then, the rubber was compressed to a 25% strain state. This compression state was maintained for 24 h to avoid the effect of the stress relaxation on the experimental results. After the compressed stress stabilized, the state at this moment was taken as the initial condition for the strain cycle experiment. First, the pressure head of the testing machine compressed the strain amplitude of

where E 0 is the tangent modulus at the current compression ratio and N is the number of cycles.

The changing relationship between the accumulated residual strain and cycle number N refers to the form of the S‒N fatigue curve formula, and the fitting expression is written as follows:

where K and d are experimental constants.

Next, combined with Eqs. 4 and 5, the compression set of rubber samples caused by circulation is written as follows:

To verify the feasibility of the proposed method, the predicted results calculated by Eq. 6 were compared and analyzed with the experimental data of the temperature cycle control aging experiment.

3 Results and discussion

3.1 Temperature cycle control aging experiment-A test results

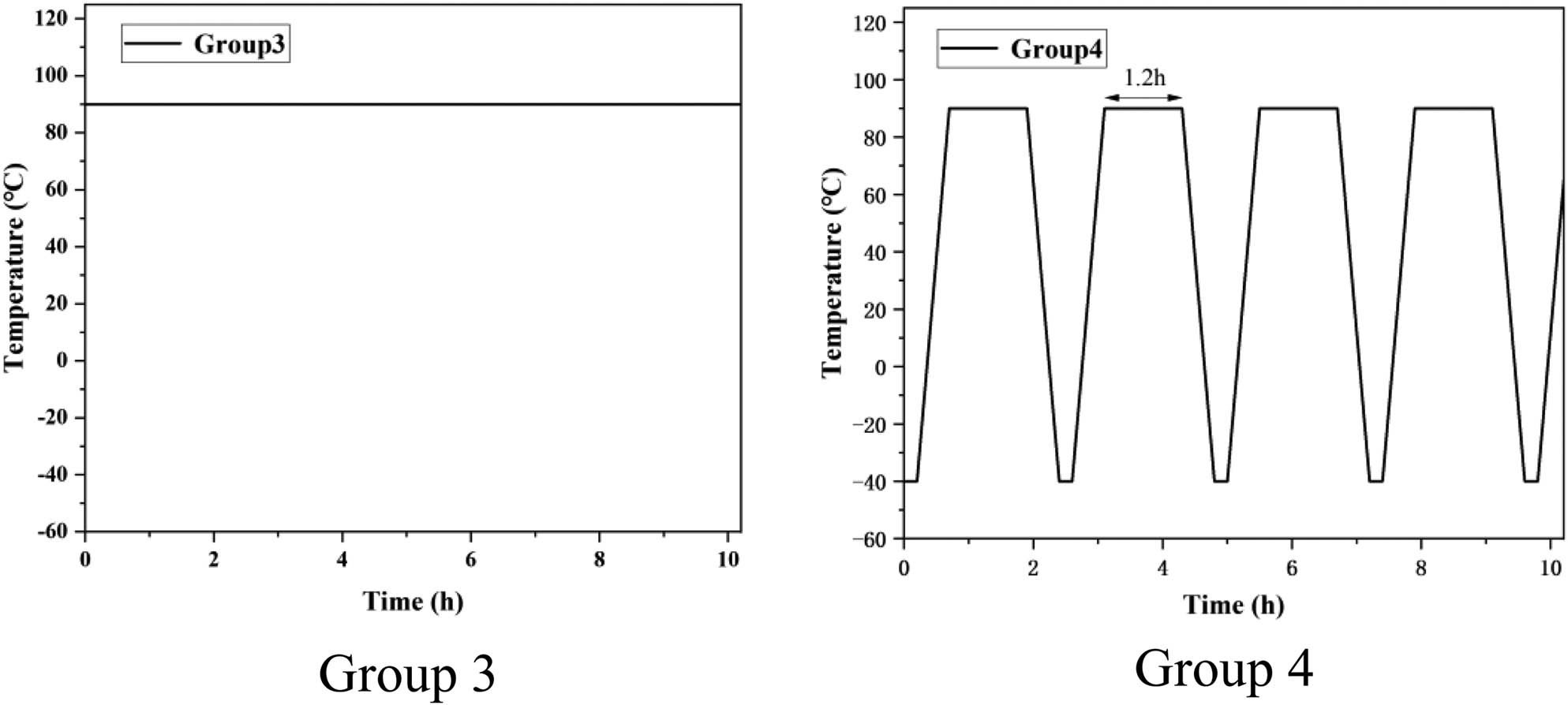

The experimental samples were placed into two aging environments, Group 1 and Group 2 (Figure 3), for aging experiments to indicate the effect of reciprocating temperature changes on the rubber. The effect of the number of cycles on the permanent compression deformation test and chemical degradation of rubber was examined by comparing the two groups of experimental samples.

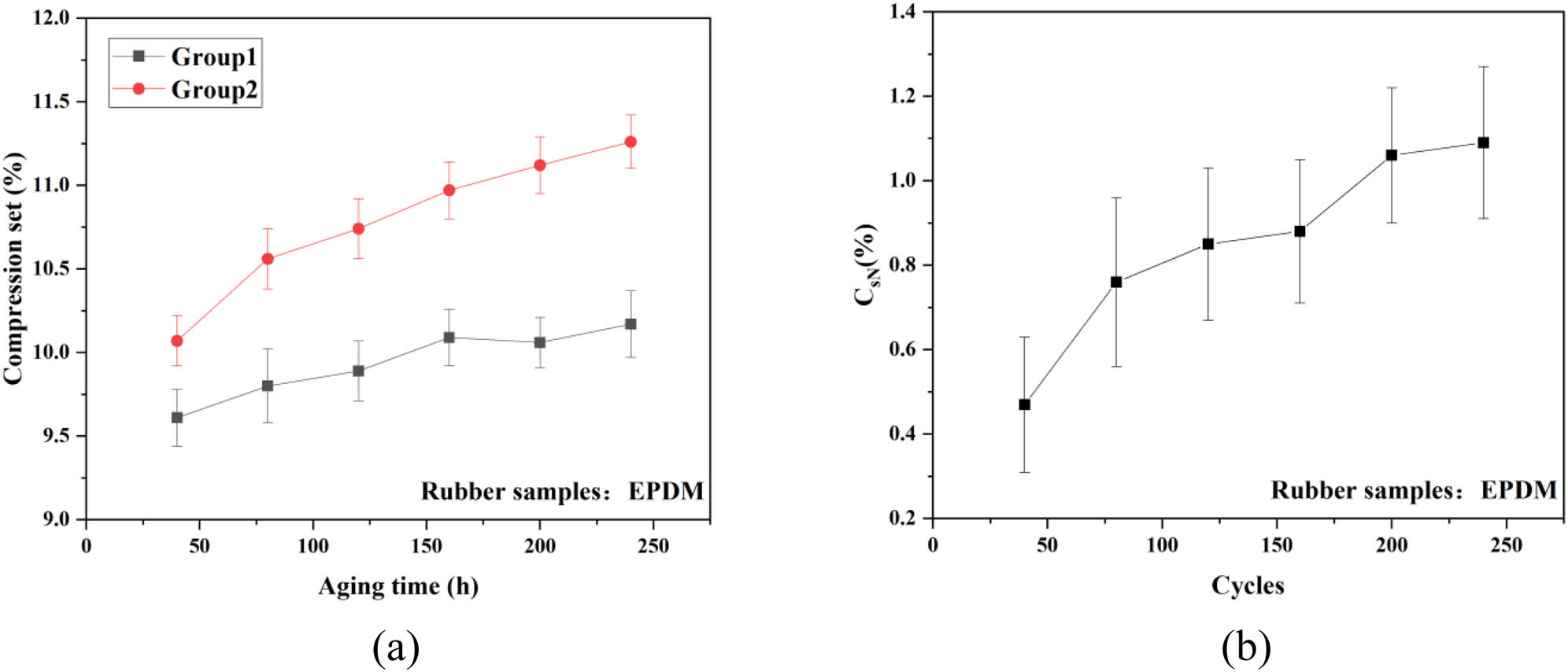

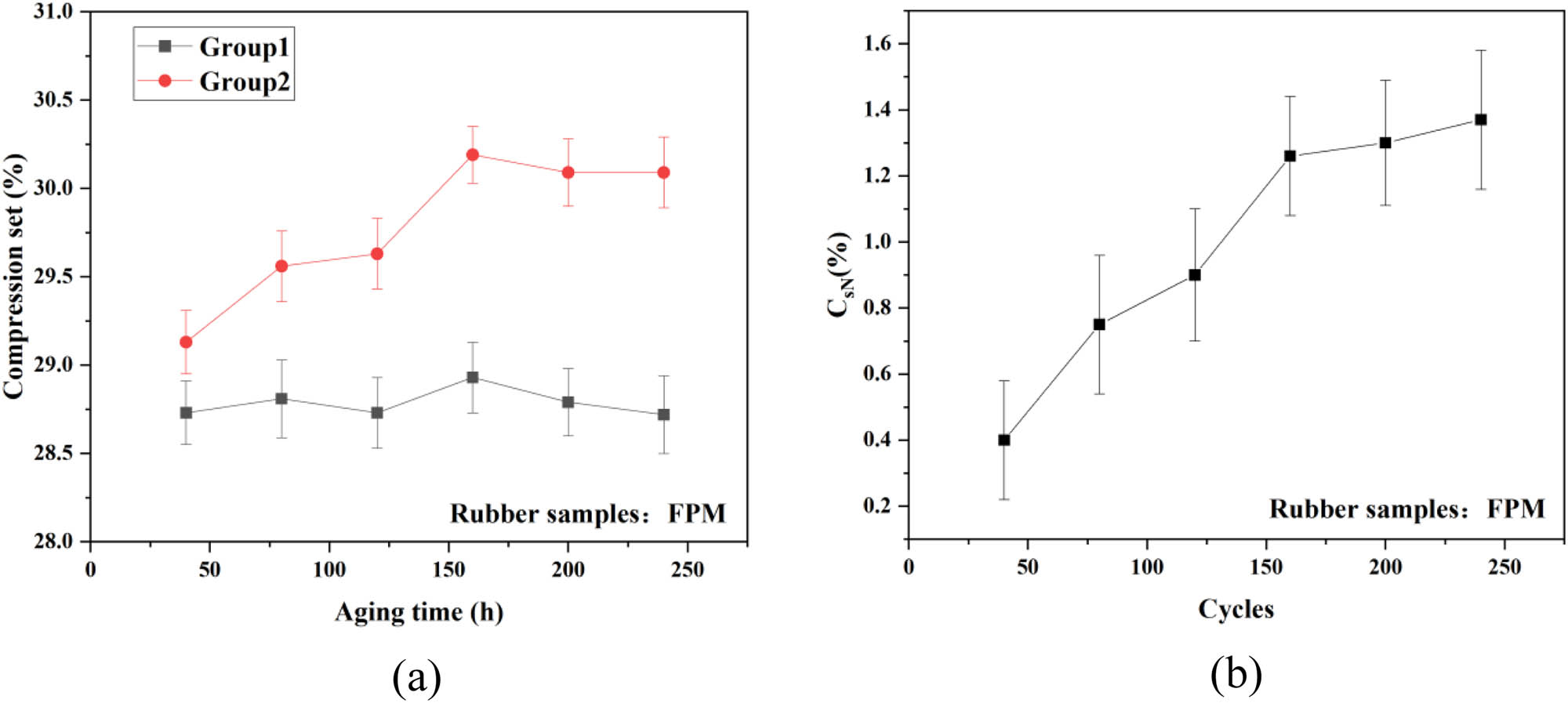

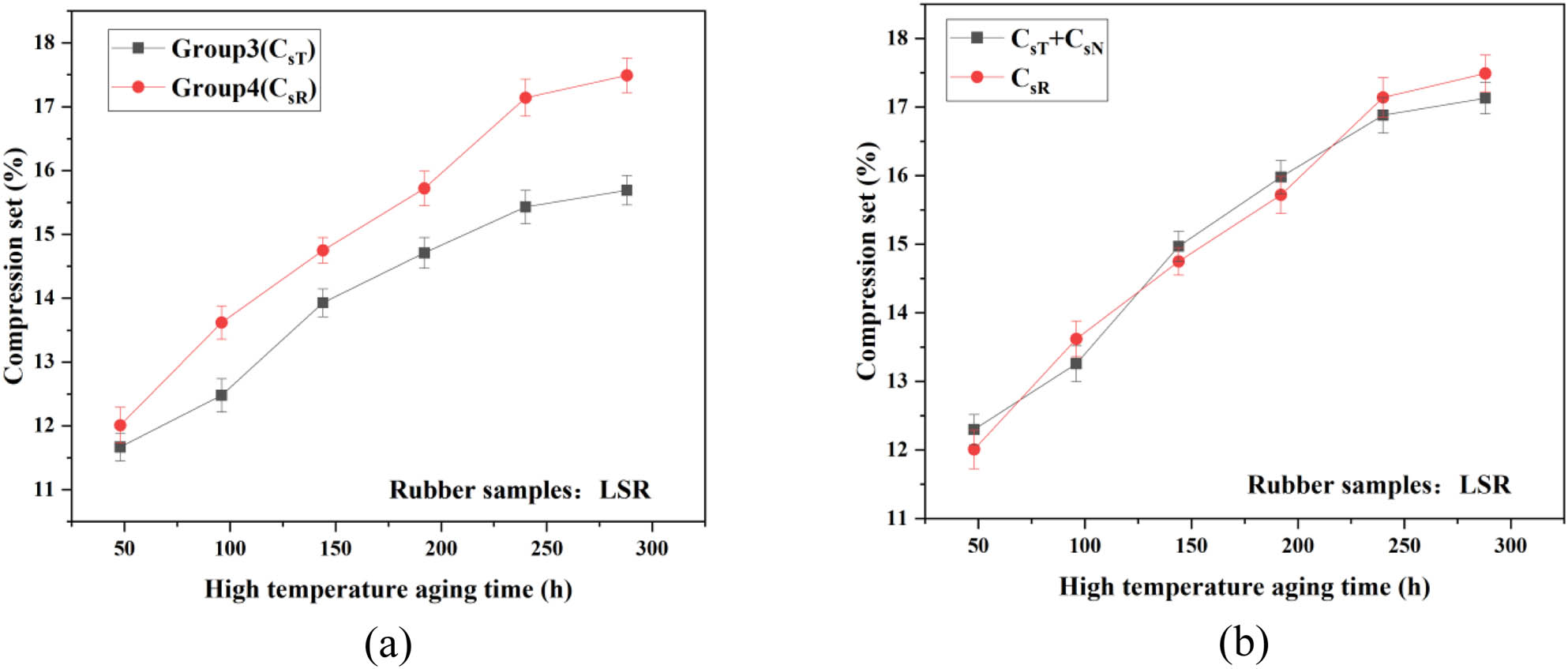

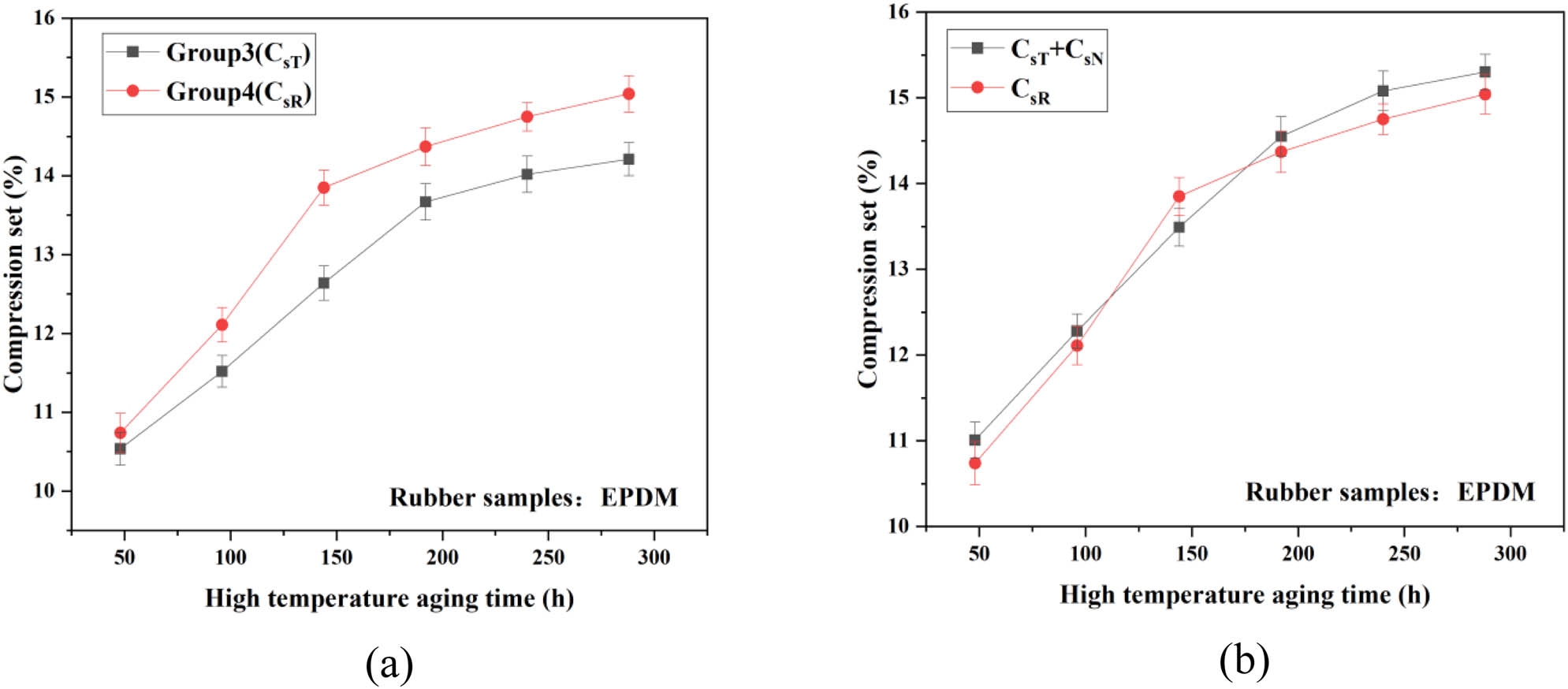

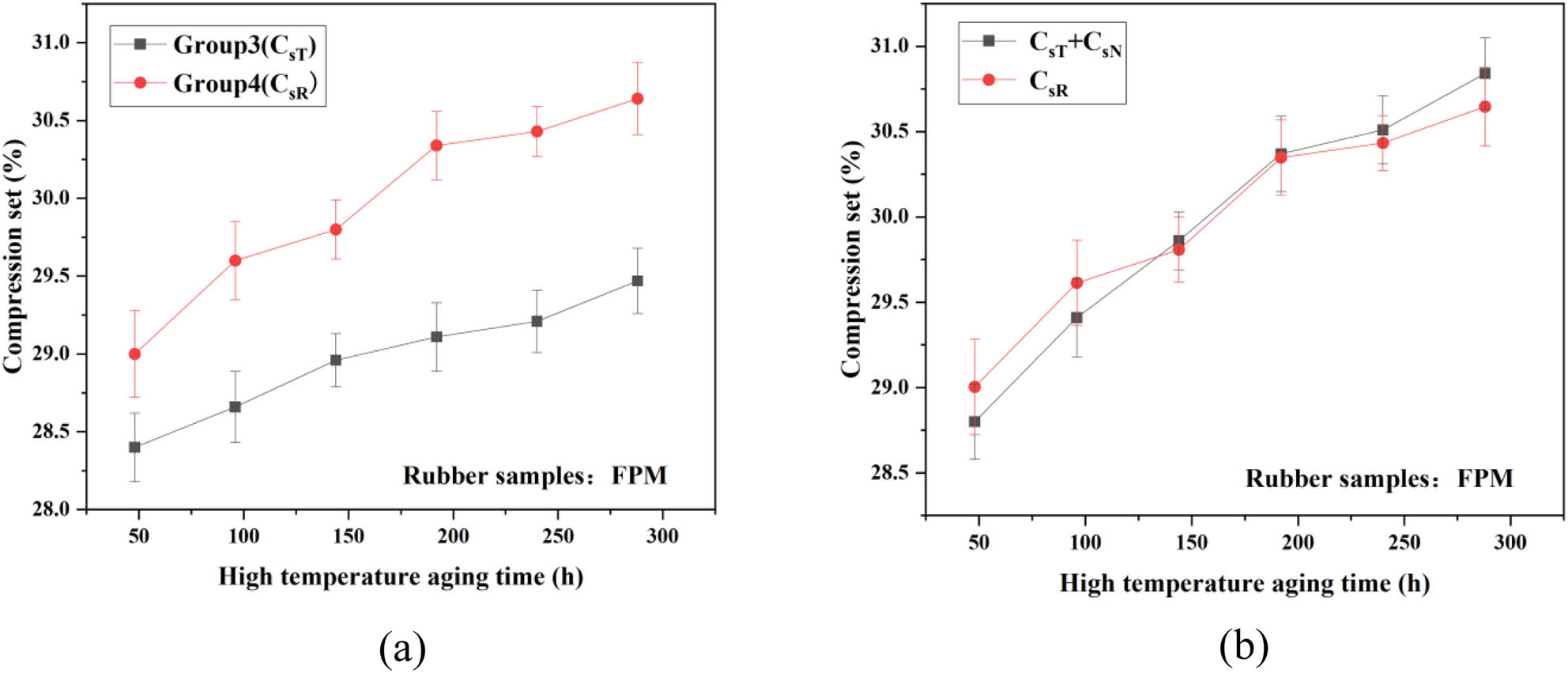

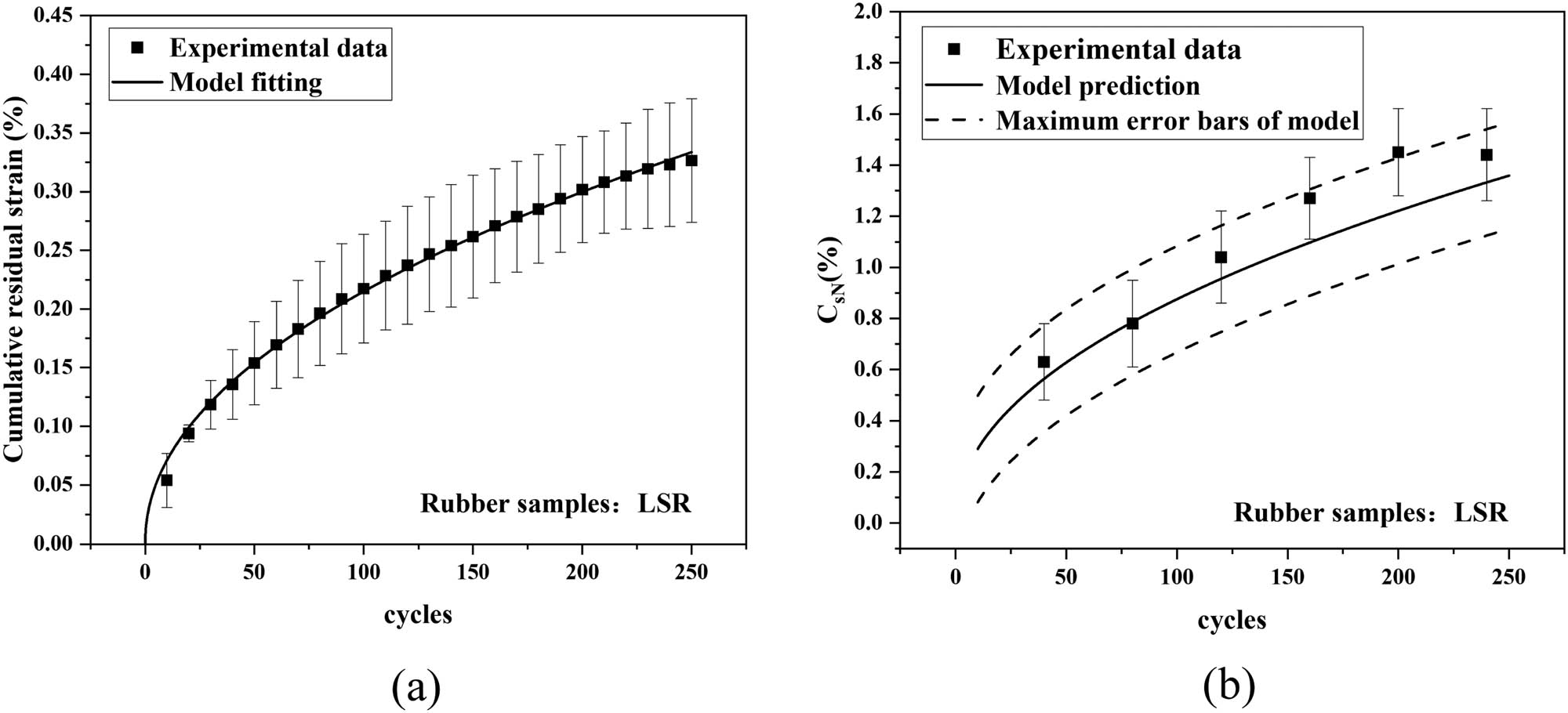

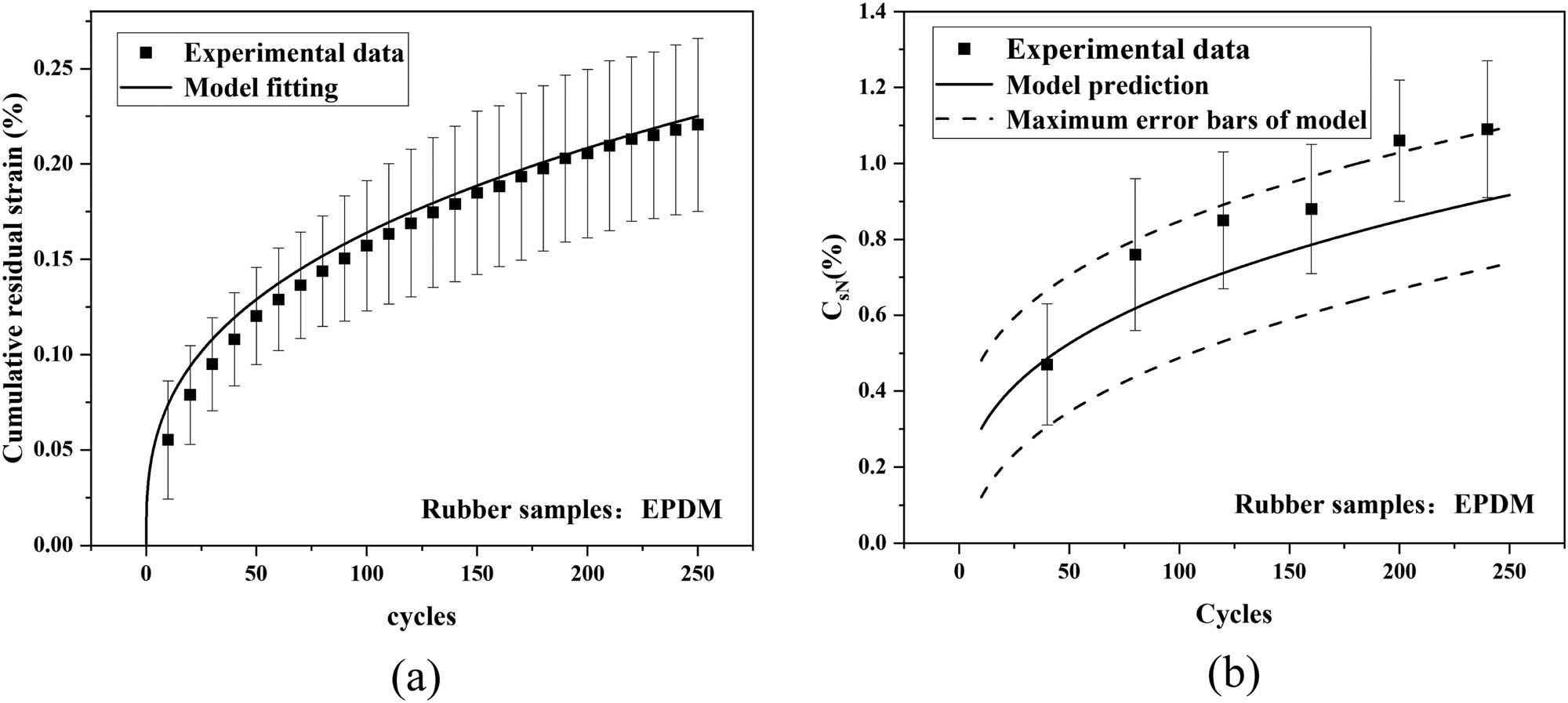

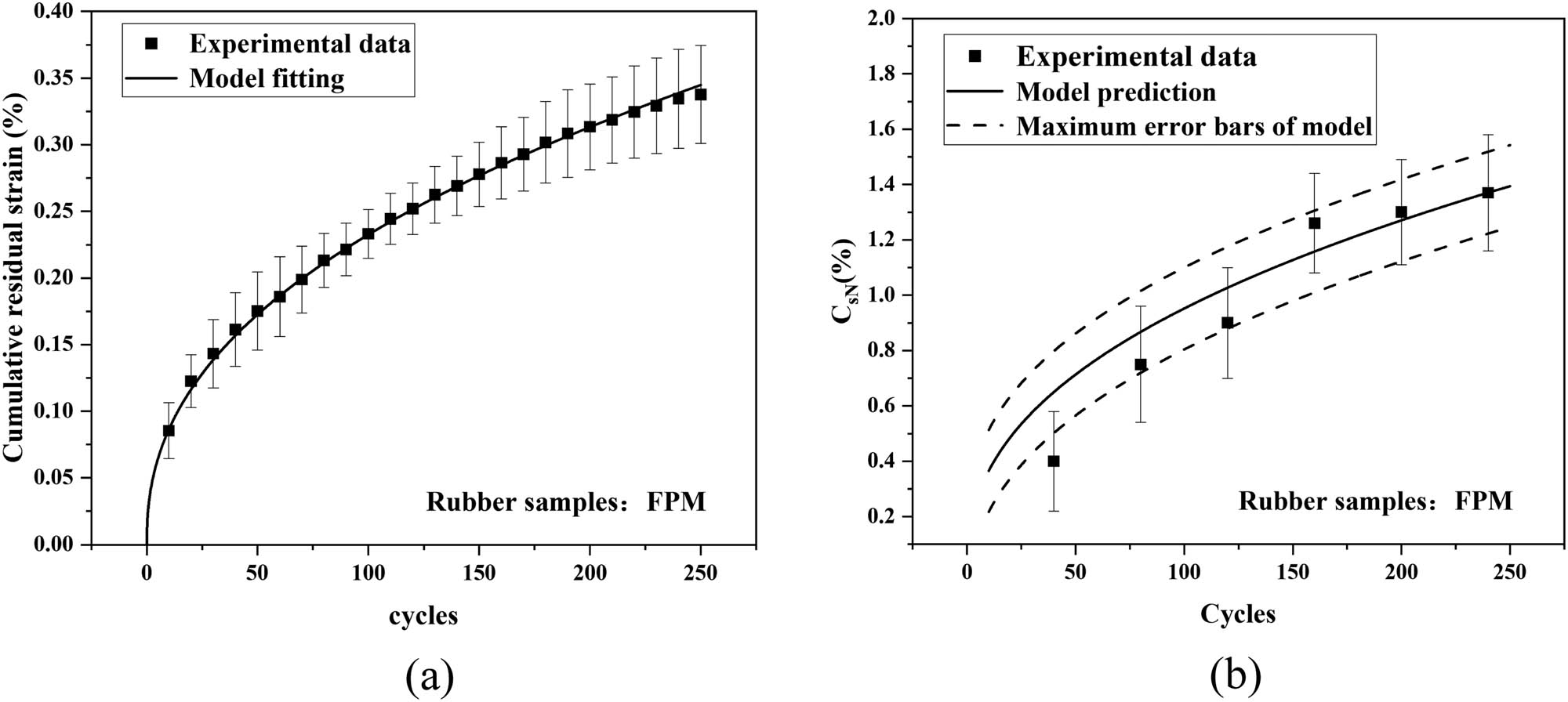

3.1.1 Compression set test results

Figures 4a, 5a and 6a illustrate the test results of the permanent compression deformation of three types of rubber samples in Group 1 and Group 2 under environmental aging. Under the same aging time, the permanent compression set of rubber samples in the Group 2 aging condition was larger, whereas the Group 2 samples experienced more cycles. These results suggest that the rubber materials that experience more temperature cycles in the experiment were subjected to a greater permanent compression set caused by reciprocating changes in temperature. The experimental data were processed to determine the relationship between the cycle number N and the permanent compression deformation of rubber caused by circulation, where the permanent compression deformation caused by circulation is expressed as C sN . As depicted in Figures 4b, 5b and 6b, the increase in cycle number N will result in a greater permanent compression deformation C sN of rubber samples. Under the experimental conditions of N cycles, the cumulative residual strain satisfied the following relationship: LSR > FPM > EPDM.

Compression set test results of LSR under (a) different environmental aging and (b) different cycle number N conditions.

Compression set test results of EPDM under (a) different environmental aging and (b) different cycle number N conditions.

Compression set test results of FPM under (a) different environmental aging and (b) different cycle number N conditions.

The performance deterioration of rubber materials is a complex process of chemical and physical changes. Physical and chemical changes will unavoidably take place when rubbers are compressed. As a result of these changes, rubbers begin to aging, and one macroscopic sign of this aging is an increase in compression permanent deformation. If the compression force disappears, these changes will prevent rubbers from returning to its original state; thus, compression permanent deformation is generated. The temperature, time of the compression state, and aging environment all affect the value of permanent compression deformation. High temperatures cause physical and chemical changes in rubbers that permanently alter their original network. On a macro-level, this is manifested as compression permanent deformation. Under the temperature cycling environment, due to the significant differences in the thermal expansion coefficients of the rubber material and the metal fixture in the temperature cycle environment, the rubber will experience periodic reciprocating thermal stress during the aging process, while the periodic stress load can also cause the damage effect on the rubber network even if the stress loads are much lower. With an increasing number of cycles, the fatigue damage of the material will be more serious, which further leads to the deterioration of the performance of the rubber material. This process explains the greater compression set of rubber samples under reciprocating temperature changes.

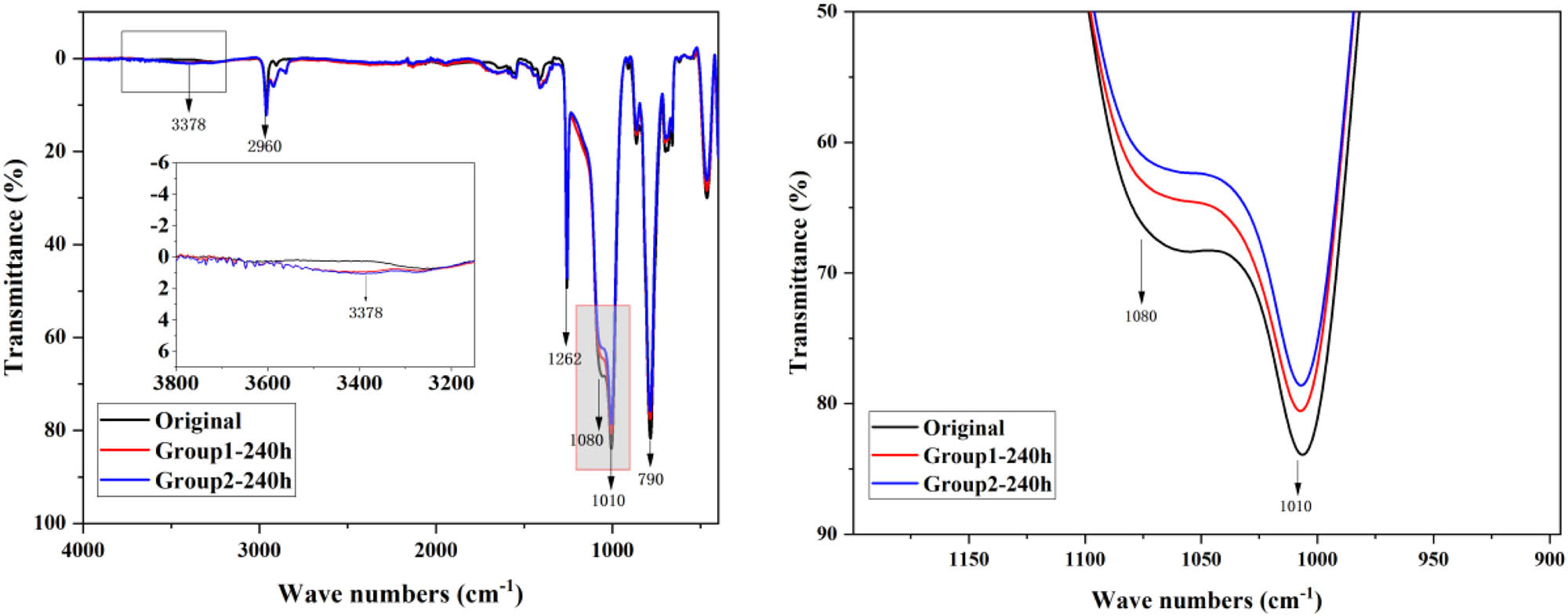

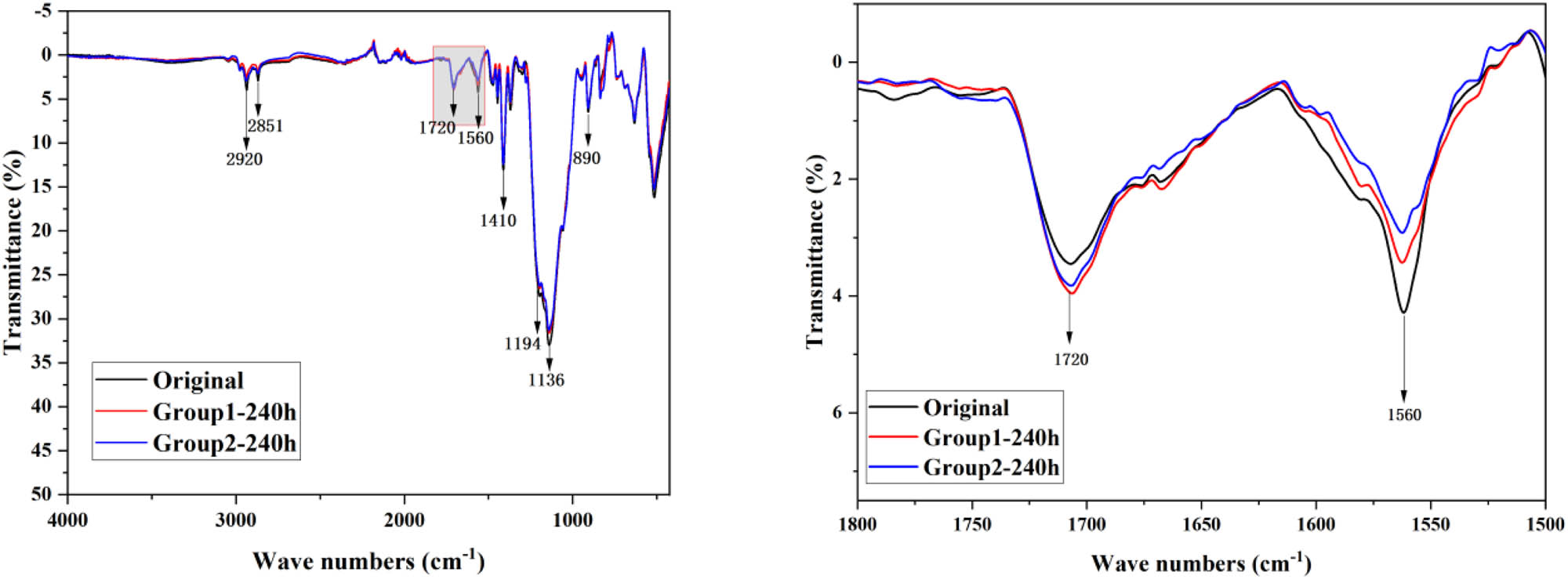

3.1.2 ATR-FTIR test results

The ATR-FTIR spectra of LSR samples subjected to different aging conditions are shown in Figure 7. The peaks at 3,378 cm−1 are assigned to the –OH bond stretching vibration. The peaks at 2,960 cm−1 are assigned to the C–H bond stretching vibration from methyl groups. The peaks at 1,262 cm−1 are assigned to Si–CH3 bond stretching vibrations. The peaks at 1,080 and 1,010 cm−1 are assigned to Si–O–Si bond stretching vibrations. The peaks at 790 cm−1 are assigned to Si–(CH3)2 bond stretching vibrations (13,28,29). A comparison of the spectra of the original and aged samples indicates that the peak at 3,378 cm−1 assigned to the –OH bond increased for the aged sample, which was due to the oxidation reaction during the aging process. A comparison of the spectra of the Group 1 and Group 2 aged samples indicates that the peaks at 1,080 and 1,010 cm−1 assigned to the Si–O–Si bond were lower for the Group 2 samples, which means that some rubber molecular chains were damaged due to the influence of the thermal stress cycle.

ATR-FTIR spectra of the LSR samples.

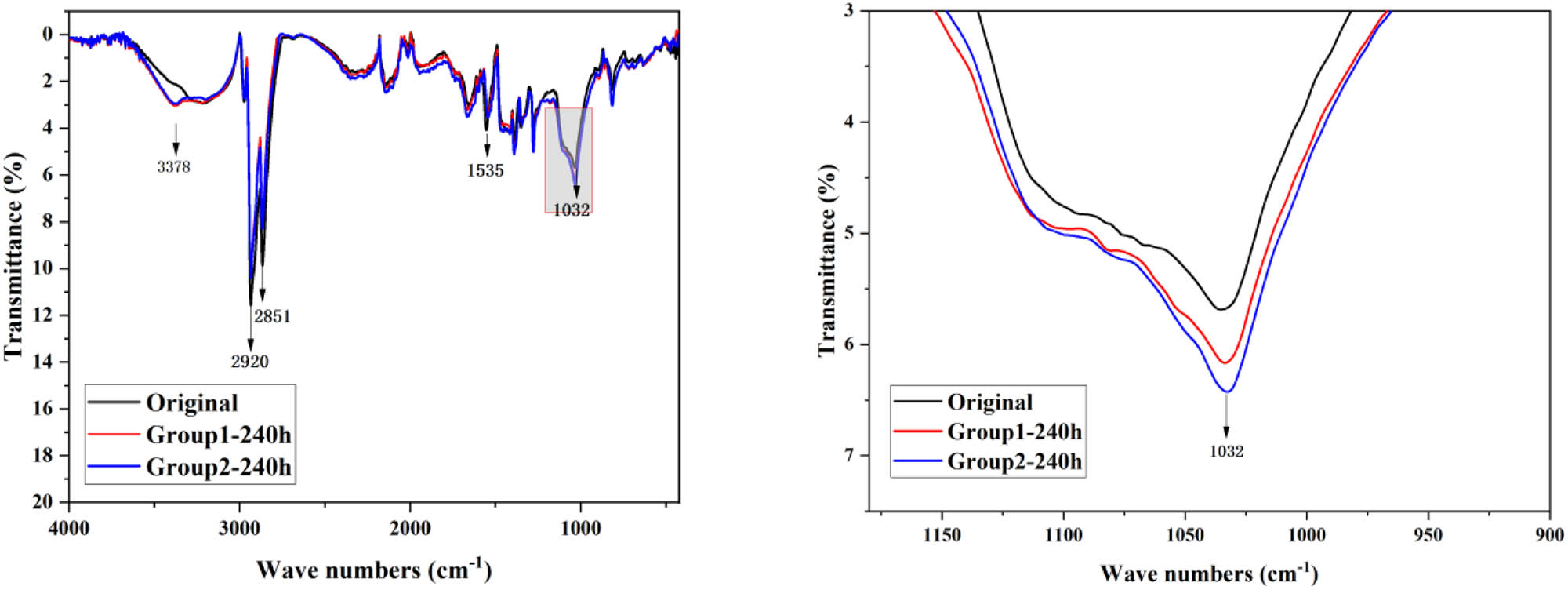

The ATR-FTIR spectra of EPDM samples subjected to different aging conditions are shown in Figure 8. The peaks at 3,378 cm−1 are assigned to the –OH bond stretching vibration. The peaks at 2,960 and 2,815 cm−1 are assigned to methylene stretching vibrations. The peaks at 1,535 cm−1 are assigned to zinc stearate. The peaks at 1,032 cm−1 are assigned to the C–O bond stretching vibration from aliphatic esters (30–33). A comparison of the spectra of the original and aged samples indicates that the peak at 3,378 cm−1 assigned to the –OH bond and the peak at 1,032 cm−1 assigned to the C–O bond increased for the aged samples, which was due to the formation of new oxygen-containing groups from the oxidation reaction during the aging process. A comparison of the spectra of the Group 1 and Group 2 aged samples indicates that the peak at 1,032 cm−1 assigned to the C–O bond was slightly higher for the Group 2 samples, which may be because some rubber molecular chains were damaged due to the effects on the thermal stress cycle, and the free radicals at the fracture combined with oxygen could generate additional C–O bonds.

ATR-FTIR spectra of the EPDM samples.

The ATR-FTIR spectra of FPM samples subjected to different aging conditions are shown in Figure 9. The peaks at 2,920 and 2,815 cm−1 are assigned to methylene stretching vibrations. The peak at 1,720 cm−1 is assigned to the C═O bond stretching vibration. The peaks at 1,560 cm−1 are assigned to the C═C bond stretching vibration. The peak at 1,410 cm−1 is assigned to the CF bond stretching vibration. The peaks at 1,194 and 1,136 cm−1 are assigned to CF2 bond stretching vibrations. The peak at 890 cm−1 is assigned to the CF3 bond stretching vibration (34–36). A comparison of the spectra of the original and aged samples indicates that the peaks assigned to CF and CF2 bonds decreased for the aged samples, which was due to the degradation of FPM during the aging process. In addition, the peak at 1,720 cm−1 assigned to the C–O bond increased for the aged samples, which was due to some of the C═C bonds in the rubber molecular chain being oxidized to form C═O bonds. A comparison of the spectra of the Group 1 and Group 2 aged samples indicates that the peak at 1,560 cm−1 assigned to the C═C bond was lower for the Group 2 samples because some rubber molecular chains were damaged due to the effects on the thermal stress cycle.

ATR-FTIR spectra of the FPM samples.

The comprehensive analysis result of the infrared spectra of the above three rubber materials (LSR, EPDM, and FPM) suggests that high temperature primarily affects the thermal oxygen aging reaction of rubber. During the reciprocating temperature change, the thermal stress cycle caused by the difference in thermal expansion performance between the rubber and the metal fixture causes the fatigue damage of the rubber material and the fracturing of molecular chains with the stress concentration in rubber.

3.2 Temperature cycle control aging experiment-B test results

Figures 10a, 11a and 12a present the permanent compression deformation test results of the experimental rubber samples in the aging environments of Group 3 and Group 4. Under the same high-temperature aging time, the rubber samples in the aging environment of Group 3 were only affected by thermal aging, while the rubber samples in the Group 4 aging environment were simultaneously affected by thermal aging and thermal cycling. Based on the findings of Group 3, it can be stated that the compression set rise rate of FPM is less than that of EPDM and LSR per unit aging time. This is due to the superior thermal aging resistance of FPM. Under the same high-temperature aging time, the rubber samples in the aging environment of Group 4 had more serious permanent compression deformation, consistent with the rule obtained in the above temperature cycle control aging experiment. In a high- and low-temperature cycle aging environment, the thermal aging of rubber at high temperatures was the major factor leading to the increase in its permanent compression deformation, and the temperature circulation further facilitated the increase in the permanent compression deformation of rubber.

Compression set test results of LSR of (a) C sT and C sR , and (b) C sT + C sN and C sR .

Compression set test results of EPDM of (a) C sT and C sR , and (b) C sT + C sN and C sR .

Compression set test results of FPM of (a) C sT and C sR , and (b) C sT + C sN and C sR .

In the experiment, the compression set of rubber samples in the environment of Group 3 (continuous constant high-temperature environment) is expressed as C sT . The compression set of rubber samples in the environment of Group 4 (high- and low-temperature cycle environment) is expressed as C sR . The compression set of rubber caused by thermal cycling over the aging time is expressed as C sN , which can be obtained according to the experimental data in Figures 4b, 5b and 6b.

Once C sT + C sN is calculated, the result is compared with C sR , as depicted in Figures 10b, 11b and 12b. The above result reveals that the two sets of data overlap within the allowable range of error, so the corresponding relation can be written as follows:

Since C sT + C sN is approximately equal to C sR , the effects of thermal aging and thermal cycling on the permanent compression deformation of rubber are considered to be independent of each other within the allowable range of error.

In a temperature cycle aging environment, the thermal stress cycle caused fatigue damage to rubber. Due to the small frequency of the cycle, it had a low amplitude and small number of total cycle times, so it pertains to the scope of mild fatigue, and the molecular chain inside the rubber may have ruptured (network damage), whereas no macro-fracturing occurred (generation of new free surface area). Under these conditions, the fatigue damage is insufficient to affect the thermal aging of rubber, or its effect on thermal aging can be ignored.

3.3 Equivalent strain cycle test results

Figures 13a, 14a and 15a illustrate the test results of the equivalent strain cycle experiments of the three rubber samples, suggesting that the cumulative residual strain of the rubber samples will increase with an increasing number of cycles. Eq. 4 is modified to fit the experimental data, and the results of the fitting parameters are listed in Table 2.

Accumulated residual strain (a) and cycle-induced compression set prediction (b) of LSR samples.

Accumulated residual strain (a) and cycle-induced compression set prediction (b) of EPDM samples.

Accumulated residual strain (a) and cycle-induced compression set prediction (b) of FPM samples.

Rubber material parameters

| Material | K | D | Correlation coefficient (R 2) |

|---|---|---|---|

| LSR | 1.67 × 10−4 | 0.48 | 0.99 |

| EPDM | 2.54 × 10−4 | 0.35 | 0.94 |

| FPM | 2.38 × 10−4 | 0.43 | 0.99 |

The fitting parameters are substituted into Eq. 5 to obtain the compression set caused by the circulation, and the predicted results are compared with the experimental test results, as presented in Figures 4b, 5b and 6b. As depicted in Figures 10b, 11b and 12b, the predicted results are consistent with the test results of the compression set in the above experiment. This indicates that temperature cycling promotes the growth of the rubber compression set due to the reciprocating thermal stress during aging. In addition, the compression set of rubber samples caused by circulation can be examined through an equivalent strain cycle test instead of a temperature cycle test in the allowable error range.

In the high-temperature acceleration aging compression test, the compressed permanent deformation can be regarded as a function of temperature and time. The variable rate of compressing set between different temperatures meets the Arrhenius relationship, and its expression can be written as follows (37):

where A is the characteristic factor, E a is the apparent activation energy, R is the gas constant, and T is the absolute temperature.

The relationship between the aging estimate index representing the aging characteristics and the aging time can be described as the following expression (38,39):

where B is the test constant, and β is the experimental constant, which need to be determined by high-temperature accelerated aging experiments.

Combined with Eqs. 6, 7, and 9, the prediction model of the compression set of rubber samples in a high- and low-temperature environment can be written as follows:

where t is the high-temperature aging time experienced by the rubber and N(t) is the number of temperature cycles experienced by the rubber during the high-temperature aging time.

Therefore, for the compression set prediction of rubber samples in a high- and low-temperature cycle environment, the high-temperature accelerated and equivalent strain cycle experiments can be conducted separately to test the two aging factors (thermal aging and thermal fatigue) in the temperature cycle process, respectively, and then, the test results are imported into the prediction model to obtain the long-term compression set test results of rubber samples under high- and low-temperature cycle conditions. In this test, a high-temperature accelerated aging environment is required, whereas a temperature cycling environment, particularly a low-temperature environment, is not necessary. As a result, the time required to conduct an aging test is greatly shortened, and the cost of the test is decreased.

4 Conclusions

Through the temperature cycle aging test and strain cycle test, the effects of thermal cycling on the aging process of three typical rubber materials (LSR, EPDM, and FPM) were investigated. The following conclusions can be made.

Thermal cycling raises the compression set of rubber in an aging environment, which is due to thermal fatigue caused by the substantial differential in thermal expansion characteristics between the rubber sample and the metal fixture under the situation of temperature cycling aging condition.

The ATR-FTIR test results reveal that a section of the molecular chain was broken during the temperature cycle operation.

When subjected to a temperature cycle aging condition between −40°C and 90°C, the coupling effects of thermal aging and thermal cycling on the compression set of rubber are roughly independent of one another.

The suggested accelerated aging test technique for rubber is performed using high-temperature accelerated aging and equivalent strain cycle tests, and the test results are imported into the proposed model to forecast the long-term aging compression set test results under temperature cycling conditions.

-

Funding information: This work was supported by the National Key R&D Program of China (No. 2021YFB3800400) and Tsinghua University-Weichai Joint Research Institute of Power and Intelligent Manufacturing (No. WCDL-GH-2020-0215).

-

Author contributions: Sen Li: writing – original draft, methodology, experimental data acquisition; Yuchao Ke: resources, technical or material support; Lingyun Xie: resources, technical or material support; Zhenzhen Zhao: resources, technical or material support; Xiaoyu Huang: experimental design, experimental data processing; Yichun Wang: resources, instructional support; Zixi Wang: writing – review and editing, instructional support, resources.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

(1) Wu J, Dong JY, Wang YS, Gond BK. Thermal oxidation ageing effects on silicone rubber sealing performance. Polym Degrad Stabil. 2017;135:43–53. 10.1016/j.polymdegradstab.2016.11.017.Search in Google Scholar

(2) Zhang J, Xie JX. Investigation of static and dynamic seal performances of a rubber O-ring. J Tribol-T ASME. 2018;140(4):042202. 10.1115/1.4038959.Search in Google Scholar

(3) Zheng YR, Tan Y, Zhou CL, Chen GH, Li JQ, Liu YS, et al. A review on effect of hydrogen on rubber seals used in the high-pressure hydrogen infrastructure. Int J Hydrog Energy. 2020;45:23721–38. 10.1016/j.ijhydene.2020.06.069.Search in Google Scholar

(4) Lin CW, Chien CH, Tan JZ, Chao YJ, Van Zee JW. Chemical degradation of five elastomeric seal materials in a simulated and an accelerated PEM fuel cell environment. J Power Sources. 2011;196:1955–66. 10.1016/j.jpowsour.2010.10.012.Search in Google Scholar

(5) Pehlivan‐Davis S, Clarke J, Armour S. Comparison of accelerated aging of silicone rubber gasket material with aging in a fuel cell environment. J Appl Polym Sci. 2013;129:1446–54. 10.1002/app.38837.Search in Google Scholar

(6) Yang DJ, Ma JW, Zhang Q, Li B, Ming PW, Zhang CM. Accelerated Test of Silicone Rubbers Exposing to PEMFC environment. Prog Nat Sci-Mater. 2020;30:882–9. 10.1016/j.pnsc.2020.10.008.Search in Google Scholar

(7) Chang HW, Wan ZM, Chen X, Wan JH, Luo L, Zhang HN, et al. Temperature and humidity effect on aging of silicone rubbers as sealing materials for proton exchange membrane fuel cell applications. Appl Therm Eng. 2016;104:472–8. 10.1016/j.applthermaleng.2016.05.095.Search in Google Scholar

(8) Li G, Zhu D, Jia W, Zhang F. Analysis of the aging mechanism and life evaluation of elastomers in simulated proton exchange membrane fuel cell environments. E-Polymers. 2021;21(1):921–9. 10.1515/epoly-2021-0078.Search in Google Scholar

(9) Wang ZQ, Tan JZ, Wang YK, Liu ZH, Feng QY. Chemical and mechanical degradation of silicone rubber under two compression loads in simulated proton‐exchange membrane fuel‐cell environments. J Appl Polym Sci. 2019;136:47855. 10.1002/app.47855.Search in Google Scholar

(10) Wu F, Chen B, Pan M. Degradation of the Sealing Silicone Rubbers in a Proton Exchange Membrane Fuel Cell at Cold Start Conditions. Int J Electrochem Sci. 2020;15:3013–28. 10.20964/2020.04.54.Search in Google Scholar

(11) Li G, Gong JM, Tan JZ, Zhu DS, Jia WH. Stress relaxation behavior and life prediction of gasket materials used in proton exchange membrane fuel cells. J Cent South Univ. 2019;26:623–31. 10.1007/s11771-019-4033-7.Search in Google Scholar

(12) Qiu DK, Liang P, Peng LF, Yi PY, Ni XM. Material behavior of rubber sealing for proton exchange membrane fuel cells. Int J Hydrog Energy. 2020;45:5465–73. 10.1016/j.ijhydene.2019.07.232.Search in Google Scholar

(13) Lou WT, Xie CY, Guan XF. Coupled effects of temperature and compressive strain on aging of silicone rubber foam. Polym Degrad Stabil. 2022;195:109810. 10.1016/j.polymdegradstab.2021.109810.Search in Google Scholar

(14) Mehmood B, Akbar M, Ullah R. Accelerated aging effect on high temperature vulcanized silicone rubber composites under DC voltage with controlled environmental conditions. Eng Fail Anal. 2020;118:104870. 10.1016/j.engfailanal.2020.104870.Search in Google Scholar

(15) Cui T, Chao YJ, Van Zee JW. Sealing force prediction of elastomeric seal material for PEM fuel cell under temperature cycling. Int J Hydrog Energy. 2014;39:1430–8. 10.1016/j.ijhydene.2013.10.086.Search in Google Scholar

(16) Zhan ZG, Yuan C, Hu ZR, Wang H, Sui PC, Djilali N, et al. Experimental study on different preheating methods for the cold-start of PEMFC stacks. Energy. 2018;162:1029–40. 10.1016/j.energy.2018.08.003.Search in Google Scholar

(17) Balliet RJ, Newman J. Cold start of a polymer-electrolyte fuel cell III. Optimization of operational and configurational parameters. J Electrochem Soc. 2011;158:B948. 10.1149/1.3592485.Search in Google Scholar

(18) Rabat H, Brault P. Plasma sputtering deposition of PEMFC porous carbon platinum electrodes. Fuel Cell. 2008;8:81–6. 10.1002/fuce.200700036.Search in Google Scholar

(19) Hoogers G. Fuel cell technology handbook. Boca Raton, Florida: CRC Press; 2002.10.1201/9781420041552Search in Google Scholar

(20) Wen X, Yuan X, Lan L, Hao L, Wang Y, Li S, et al. RTV silicone rubber degradation induced by temperature cycling. Energies. 2017;10:1054. 10.3390/en10071054.Search in Google Scholar

(21) GB/T 7759.1-2015. Rubber, vulcanized or thermoplastic-Determination of compression set-Part 1: At ambient or elevated temperatures; 2015. https://openstd.samr.gov.cn/bzgk/gb/newGbInfo? hcno=342685DE40B30EB423BBA94665F1C6E8.Search in Google Scholar

(22) GB/T 20028.1-2005. Rubber, vulcanized or thermoplastic -- Estimation of life-time and maximum temperature of use from an Arrhenius plot; 2005. https://openstd.samr.gov.cn/bzgk/gb/newGbInfo?hcno=12F45170DF8F6E9782639E5E8E5360F8.Search in Google Scholar

(23) GB/T 27800.1-20217800.1-2021. Determination of the life for static sealing rubber products; 2021. https://openstd.samr.gov.cn/bzgk/gb/newGbInfo?hcno=4F2A49FFEEF3EF8600949A7D4B7023E1.Search in Google Scholar

(24) Chang SW, Choi SS, Lee SB, Kim HS. Useful lifetime prediction of rubber components using accelerated testing. IEEE T Reliab. 2010;59:11–7. 10.1109/TR.2010.2042103.Search in Google Scholar

(25) Xue C, Gao HY, Hu GX. Viscoelastic and fatigue properties of graphene and carbon black hybrid structure filled natural rubber composites under alternating loading. Constr Build Mater. 2020;265:120299. 10.1016/j.conbuildmat.2020.120299.Search in Google Scholar

(26) Liu J, Li XB, Xu LK, He T. Service lifetime estimation of EPDM rubber based on accelerated aging tests. J Mater Eng Perform. 2017;26:1735–40. 10.1007/s11665-017-2519-8.Search in Google Scholar

(27) Dorfmann A, Ogden RW. A constitutive model for the Mullins effect with permanent set in particle-reinforced rubber. Int J Solids Struct. 2004;41:1855–78. 10.1016/j.ijsolstr.2003.11.014.Search in Google Scholar

(28) Kashi S, Varley R, De Souza M, Al-Assafi S, Fox B. Mechanical, thermal, and morphological behavior of silicone rubber during accelerated aging. Polym-Plast Technol. 2018;57:1687–96. 10.1080/03602559.2017.1419487.Search in Google Scholar

(29) Zhang H, Tu YP, Lu Y, Xu Z, Chen CH, Xie LF. Study on aging characteristics of silicone rubber insulator sheds using FTIR. In IEEE International Symposium on Electrical Insulation; 2012. p. 83–6. 10.1109/ELINSL.2012.6251431.Search in Google Scholar

(30) Zhao QL, Li XG, Gao J. Aging of ethylene–propylene–diene monomer (EPDM) in artificial weathering environment. Polym Degrad Stabil. 2007;92:1841–6. 10.1016/j.polymdegradstab.2007.07.001.Search in Google Scholar

(31) Tan JZ, Chao YJ, Wang HF, Gong JM, Van Zee JW. Chemical and mechanical stability of EPDM in a PEM fuel cell environment. Polym Degrad Stabil. 2009;94:2072–8. 10.1016/j.polymdegradstab.2009.07.009.Search in Google Scholar

(32) Liu J, Wang B, Zhang LW, Zhu L, Luo TY. Thermal aging behavior of ethylene propylene diene monomer (EPDM) rubber. Appl Mech Mater. 2015;727:47–50. 10.4028/www.scientific.net/AMM.727-728.47.Search in Google Scholar

(33) Choi SS, Chung HS, Joo YT, Yang KM, Lee SH. Analysis of whitening phenomenon of EPDM article by humid aging. J Appl Polym Sci. 2012;123:2451–7. 10.1002/app.34826.Search in Google Scholar

(34) Xia LC, Wang M, Wu H, Duo SY. Effects of cure system and filler on chemical aging behavior of fluoroelastomer in simulated proton exchange membrane fuel cell environment. Int J Hydrog Energy. 2016;41:2887–95. 10.1016/j.ijhydene.2015.12.043.Search in Google Scholar

(35) Kader MA, Bhowmick AK. Thermal ageing, degradation and swelling of acrylate rubber, fluororubber and their blends containing polyfunctional acrylates. Polym Degrad Stabil. 2003;79:283–95. 10.1016/S0141-3910(02)00292-6.Search in Google Scholar

(36) Wang QL, Pei JK, Li G, He X, Niu YH, Li GX. Accelerated aging behaviors and mechanism of fluoroelastomer in lubricating oil medium. Chin J Polym Sci. 2020;38:853–66. 10.1007/s10118-020-2410-1.Search in Google Scholar

(37) Celina MC. Review of polymer oxidation and its relationship with materials performance and lifetime prediction. Polym Degrad Stabil. 2013;98:2419–29. 10.1016/j.polymdegradstab.2013.06.024.Search in Google Scholar

(38) Gao C, Zhang Z, Hao Y, Yang L, Peng J, Wang G, et al. A review on test methods and lifetime prediction of GIS seal rings. 2018 International Conference on Power System Technology (POWERCON); 2018 November 6–8; Guangzhou, China. Piscataway: IEEE; 2018. p. 3891–902. 10.1109/POWERCON.2018.8601582.Search in Google Scholar

(39) Zeng C, Liu Y, Lin L, Luo H, Lin W, Xiao T, et al. Experimental research on aging and operating life of O-ring used in GIS. 2017 4th International Conference on Electric Power Equipment - Switching Technology (ICEPE-ST); 2017 October 22–25; Xi’an, China. Piscataway: IEEE; 2017. p. 857–862. 10.1109/ICEPE-ST.2017.8188980.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites

Articles in the same Issue

- Research Articles

- Chitosan nanocomposite film incorporating Nigella sativa oil, Azadirachta indica leaves’ extract, and silver nanoparticles

- Effect of Zr-doped CaCu3Ti3.95Zr0.05O12 ceramic on the microstructure, dielectric properties, and electric field distribution of the LDPE composites

- Effects of dry heating, acetylation, and acid pre-treatments on modification of potato starch with octenyl succinic anhydride (OSA)

- Loading conditions impact on the compression fatigue behavior of filled styrene butadiene rubber

- Characterization and compatibility of bio-based PA56/PET

- Study on the aging of three typical rubber materials under high- and low-temperature cyclic environment

- Numerical simulation and experimental research of electrospun polyacrylonitrile Taylor cone based on multiphysics coupling

- Experimental investigation of properties and aging behavior of pineapple and sisal leaf hybrid fiber-reinforced polymer composites

- Influence of temperature distribution on the foaming quality of foamed polypropylene composites

- Enzyme-catalyzed synthesis of 4-methylcatechol oligomer and preliminary evaluations as stabilizing agent in polypropylene

- Molecular dynamics simulation of the effect of the thermal and mechanical properties of addition liquid silicone rubber modified by carbon nanotubes with different radii

- Incorporation of poly(3-acrylamidopropyl trimethylammonium chloride-co-acrylic acid) branches for good sizing properties and easy desizing from sized cotton warps

- Effect of matrix composition on properties of polyamide 66/polyamide 6I-6T composites with high content of continuous glass fiber for optimizing surface performance

- Preparation and properties of epoxy-modified thermosetting phenolic fiber

- Thermal decomposition reaction kinetics and storage life prediction of polyacrylate pressure-sensitive adhesive

- Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites

- Doping silver nanoparticles into reverse osmosis membranes for antibacterial properties

- Melt-blended PLA/curcumin-cross-linked polyurethane film for enhanced UV-shielding ability

- The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding

- Prolonged action fertilizer encapsulated by CMC/humic acid

- Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO

- Fabrication of polylactic acid nanofibrous yarns for piezoelectric fabrics

- Copper phenyl phosphonate for epoxy resin and cyanate ester copolymer with improved flame retardancy and thermal properties

- Synergistic effect of thermal oxygen and UV aging on natural rubber

- Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites

- The role of natural hybrid nanobentonite/nanocellulose in enhancing the water resistance properties of the biodegradable thermoplastic starch

- Performance optimization of geopolymer mortar blending in nano-SiO2 and PVA fiber based on set pair analysis

- Preparation of (La + Nb)-co-doped TiO2 and its polyvinylidene difluoride composites with high dielectric constants

- Effect of matrix composition on the performance of calcium carbonate filled poly(lactic acid)/poly(butylene adipate-co-terephthalate) composites

- Low-temperature self-healing polyurethane adhesives via dual synergetic crosslinking strategy

- Leucaena leucocephala oil-based poly malate-amide nanocomposite coating material for anticorrosive applications

- Preparation and properties of modified ammonium polyphosphate synergistic with tris(2-hydroxyethyl) isocynurate for flame-retardant LDPE

- Thermal response of double network hydrogels with varied composition

- The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites

- Investigation of MXene-modified agar/polyurethane hydrogel elastomeric repair materials with tunable water absorption

- Damping performance analysis of carbon black/lead magnesium niobite/epoxy resin composites

- Molecular dynamics simulations of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate (TKX-50) and TKX-50-based PBXs with four energetic binders

- Preparation and characterization of sisal fibre reinforced sodium alginate gum composites for non-structural engineering applications

- Study on by-products synthesis of powder coating polyester resin catalyzed by organotin

- Ab initio molecular dynamics of insulating paper: Mechanism of insulating paper cellobiose cracking at transient high temperature

- Effect of different tin neodecanoate and calcium–zinc heat stabilizers on the thermal stability of PVC

- High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing

- Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin

- Influence of the molecular structure of phenylamine antioxidants on anti-migration and anti-aging behavior of high-performance nitrile rubber composites

- Fiber-reinforced polyvinyl alcohol hydrogel via in situ fiber formation

- Preparation and performance of homogenous braids-reinforced poly (p-phenylene terephthamide) hollow fiber membranes

- Synthesis of cadmium(ii) ion-imprinted composite membrane with a pyridine functional monomer and characterization of its adsorption performance

- Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites

- Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings

- Preparation and characterization of polymeric cross-linked hydrogel patch for topical delivery of gentamicin

- Mechanical properties of rCB-pigment masterbatch in rLDPE: The effect of processing aids and water absorption test

- Pineapple fruit residue-based nanofibre composites: Preparation and characterizations

- Effect of natural Indocalamus leaf addition on the mechanical properties of epoxy and epoxy-carbon fiber composites

- Utilization of biosilica for energy-saving tire compounds: Enhancing performance and efficiency

- Effect of capillary arrays on the profile of multi-layer micro-capillary films

- A numerical study on thermal bonding with preheating technique for polypropylene microfluidic device

- Development of modified h-BN/UPE resin for insulation varnish applications

- High strength, anti-static, thermal conductive glass fiber/epoxy composites for medical devices: A strategy of modifying fibers with functionalized carbon nanotubes

- Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components

- Bentonite/hydroxyethylcellulose as eco-dielectrics with potential utilization in energy storage

- Study on wall-slipping mechanism of nano-injection polymer under the constant temperature fields

- Synthesis of low-VOC unsaturated polyester coatings for electrical insulation

- Enhanced apoptotic activity of Pluronic F127 polymer-encapsulated chlorogenic acid nanoparticles through the PI3K/Akt/mTOR signaling pathway in liver cancer cells and in vivo toxicity studies in zebrafish

- Preparation and performance of silicone-modified 3D printing photosensitive materials

- A novel fabrication method of slippery lubricant-infused porous surface by thiol-ene click chemistry reaction for anti-fouling and anti-corrosion applications

- Development of polymeric IPN hydrogels by free radical polymerization technique for extended release of letrozole: Characterization and toxicity evaluation

- Tribological characterization of sponge gourd outer skin fiber-reinforced epoxy composite with Tamarindus indica seed filler addition using the Box–Behnken method

- Stereocomplex PLLA–PBAT copolymer and its composites with multi-walled carbon nanotubes for electrostatic dissipative application

- Enhancing the therapeutic efficacy of Krestin–chitosan nanocomplex for cancer medication via activation of the mitochondrial intrinsic pathway

- Variation in tungsten(vi) oxide particle size for enhancing the radiation shielding ability of silicone rubber composites

- Damage accumulation and failure mechanism of glass/epoxy composite laminates subjected to repeated low velocity impacts

- Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins

- Numerical simulation into influence of airflow channel quantities on melt-blowing airflow field in processing of polymer fiber

- Cellulose acetate oleate-reinforced poly(butylene adipate-co-terephthalate) composite materials

- Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins

- Recyclable polytriazole resins with high performance based on Diels-Alder dynamic covalent crosslinking

- Adsorption and recovery of Cr(vi) from wastewater by Chitosan–Urushiol composite nanofiber membrane

- Comprehensive performance evaluation based on electromagnetic shielding properties of the weft-knitted fabrics made by stainless steel/cotton blended yarn

- Review Articles

- Preparation and application of natural protein polymer-based Pickering emulsions

- Wood-derived high-performance cellulose structural materials

- Flammability properties of polymers and polymer composites combined with ionic liquids

- Polymer-based nanocarriers for biomedical and environmental applications

- A review on semi-crystalline polymer bead foams from stirring autoclave: Processing and properties

- Rapid Communication

- Preparation and characterization of magnetic microgels with linear thermosensitivity over a wide temperature range

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Synthesis and characterization of proton-conducting membranes based on bacterial cellulose and human nail keratin

- Fatigue behaviour of Kevlar/carbon/basalt fibre-reinforced SiC nanofiller particulate hybrid epoxy composite

- Effect of citric acid on thermal, phase morphological, and mechanical properties of poly(l-lactide)-b-poly(ethylene glycol)-b-poly(l-lactide)/thermoplastic starch blends

- Dose-dependent cytotoxicity against lung cancer cells via green synthesized ZnFe2O4/cellulose nanocomposites