Abstract

Protection of buildings against the pernicious radiation types can be achieved by simultaneous structural and shielding parameters. Those shields are mainly made of heavyweight concrete, which causes many serious problems in the areas of technology, supply logistics, financial supply, Occupational Safety & Health Administration, and substitutions of structural and material solutions. This work presents a case study of the construction of the university building with rooms requiring protection against malicious radiations. Apart from that, it presents the problems and solutions that occurred during the construction from the perspective of the works contractor. This study was also expanded to include the analysis of alternatives for construction-materials. The obtained results were used to develop a generalized scheme, which will be helpful in the preparation and implementation of any facilities requiring fixed radiation shields.

1 Introduction

Radiation shielding concrete (RSC) is a technical solution aimed at minimizing the risk associated with the impact of ionizing radiation on the human body, and at the same time they are part of the building structure or fill out the construction [1]. RSC must, therefore, meet the health protection requirements of both: persons whose exposure to radiation is continuous (workplace), and in the case of incidental events (affecting the general public) [2]. Moreover, as an element of the building structure, they must meet the conditions of the ultimate limit state and serviceability, requirements for sound and thermal insulation as well as tightness and durability.

The design and construction of RSC requires an interdisciplinary approach – which is in relation to issues in the field of construction as well as nuclear physics and medicine. In objects where ionizing radiation is anticipated, it is also possible to use structural elements as a help for radiation absorption. For this purpose, high-density concretes based on heavyweight aggregates such as rare and expensive minerals like barite and magnetite are used [3]. However, the construction of partitions with the use of high-density aggregate creates many realization problems in the areas of technology, supply logistics, finance, Occupational Safety & Health Administration (OSHA), and substitution of structural and material solutions. Therefore, for such an investment, there is a need to apply the appropriate methodology in the design and technological decisions of the contractor. It is needed especially in the situation of carrying out investments in the “design and build” system or leaving the decision of implementation, including design, to the general contractor.

This article aims to specify the realization problems occurring during the construction of RSC, which were identified by case studies method. Presented set of experiences will help construction engineers identify sources of risk for this kind of projects. The performed analysis of decision-making processes (DMP) will organize and improve the scheme of the DMP to find substitutive technological and organizational solutions.

This work contains an introduction to the issue of designing permanent radiation shields. Section 3 presents a case study of the construction of a teaching building with rooms requiring radiological protection. During the analysis of the investment project, special attention was paid to the issue of shields, the adopted solution was assessed against the background of alternatives. Based on the observations, the decisions as well as the sources of risks related to the execution of shielding elements have been presented. Section 6 presents general conclusion and work achievements.

2 Preparation issues of radiation shields

The basis for the proper design of the shield is knowledge of the radiation source characteristics, including [4]:

the energy range of the primary beam (prior to any interaction),

type of radiation (electromagnetic radiation: X-rays; gamma radiation (γ); and particle radiation: alpha radiation (α), beta radiation (β), and neutron radiation [particles of non-zero rest energy]),

radiation geometry (beam geometry).

It is also important to determine the exposure of user groups to radiation and to determine the maximum level of radiation dose that a person can take during the year. Operating scenarios are not insignificant as they determine the theoretical dose level, expressed by the residence coefficient.

Shielding is used as part of radiological protection, and the following materials are used in the construction of covers such as concrete mixes [5,6], lead, steel, paraffin, polymers [4,7,8,9,10,11], modified cement pastes [12,13,14], glass materials [15], and; bricks [16,17]. Each of them has additional specific features in relation to acting as a shield against the harmful effects of a given type of radiation. Heavy shields are suitable for retaining both α and β radiations as well as γ radiation, but they should not be used in direct contact with fast neutrons because, as a result of their collision with a heavy core of the shield, radioactive isotopes are formed [18]. Lightweight materials (e.g., polyethylene and paraffin) are effective against fast neutrons; however, when a neutron hits light hydrogen nuclei, gamma radiation is produced which must be stopped by heavier shielding. Therefore, a multilayer shielding solution is commonly applied [1]. High-density concretes have a significant advantage over other materials because they can meet both structural and protective requirements. It contains a mixture of many heavy and light elements and thus, has good characteristics for neutron and photon attenuation [1,19,20]. Other advantages include high durability with stable shielding installations, availability of required components, low cost, low maintenance, structural integrity, and efficient manufacturing [21].

High-density concretes are those with a density greater than 2,600 kg/m3. The volumetric weight is shaped by the quantitative and qualitative share of heavy aggregate fraction. Natural heavyweight aggregates used in high-density concrete are primarily barite, as well as hematite, magnetite, serpentine [22], goethite [23], limonite and ilmenite [24,25,26]. In RSC, the steel slag [23] and boric acid [27] could also be applied.

As the density of concrete increases, its shielding capacity also increases. The content of appropriate elements in the aggregate makes it possible to reduce the thickness of concrete layers while maintaining mechanical properties [2,5,20,28]. High density of concrete mixture, during construction execution, causes some technological difficulties, e.g., high pressure of concrete mixture on the formwork, difficulties in feeding the concrete mixture, and aggregate segregation. As a result, the quality of the structure may be insufficient and it will not provide the assumed technical parameters in terms of bearing capacity, durability, or shielding.

In addition, it should be remembered that it is necessary to properly design and manufacture shields because of the need to maintain the durability of the material in a sufficiently long period of use of this type of premises. Such structures must be designed for a specific period of time and properties (prescription to performance, P2P), which causes many difficulties, especially due to the lack of proven models to predict the quality of concrete after 50 or 100 years of use [6,29].

3 Case study

3.1 Description of the investment

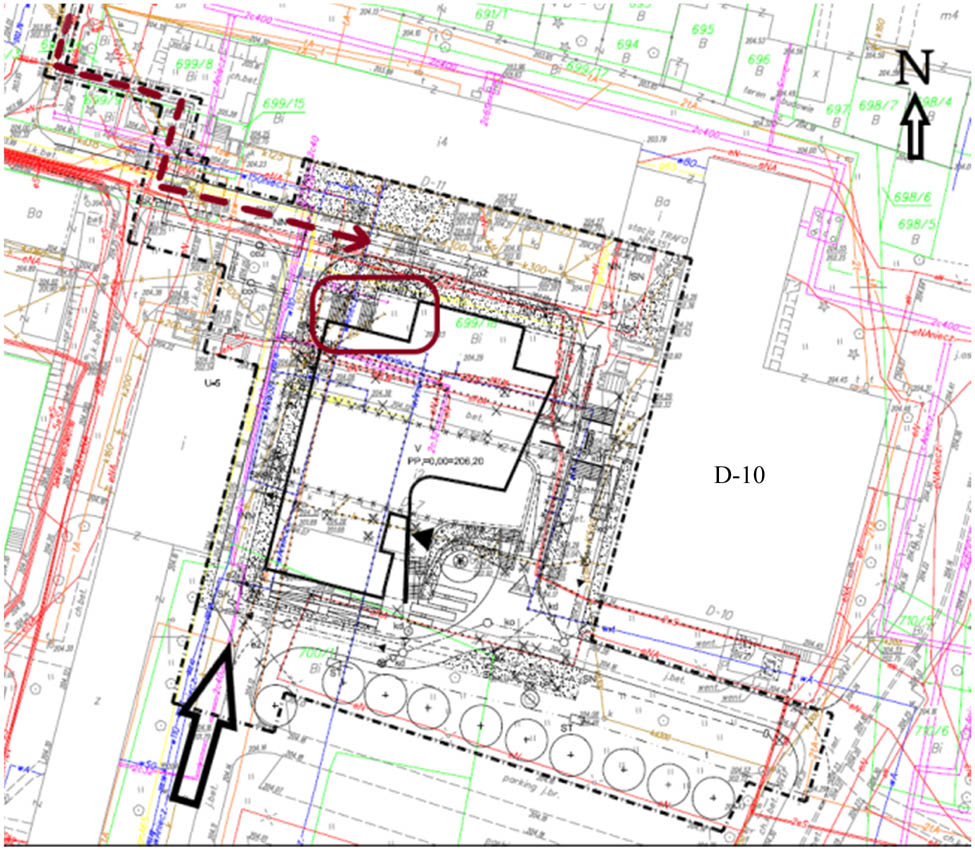

The subject of the research is the construction investment of the Faculty of Physics and Applied Computer Science (FPACS) currently being implemented in the AGH university (2019–2021). The building structure was designed in a slab-beam-column system with a height of four aboveground floors and one underground floor. In the basement, the building outline is enlarged for the multi-parking underground car park and technical rooms. In addition, a dilated connector is being designed between the building under construction and the existing pavilion D-10 (Figure 2). Consultations with future users of the facility indicated the need for a room for storing radioactive waste, which was included in the tender announcement.

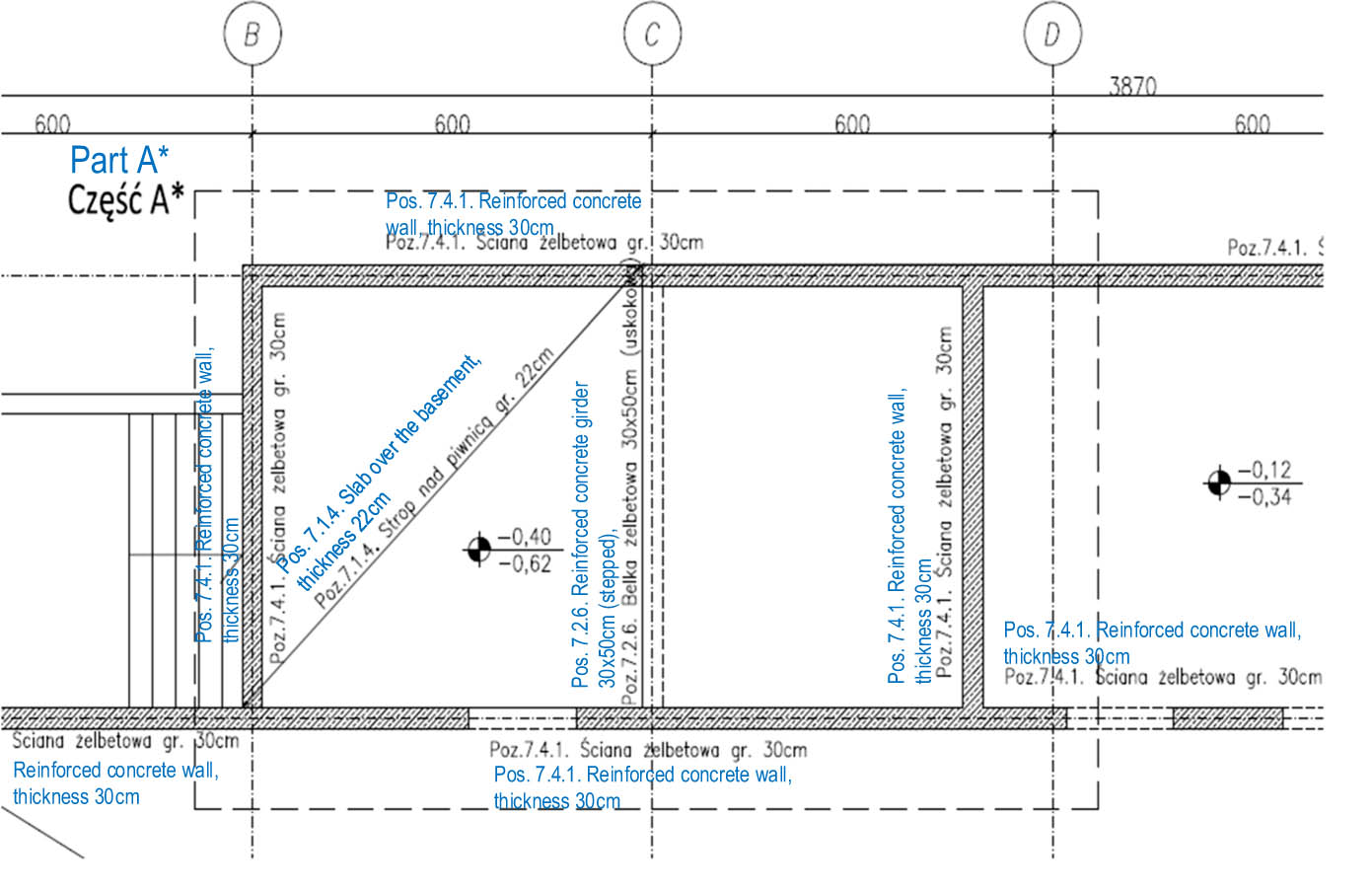

In the case of the analyzed project, the shield design was shown on the shutters in the existing building, built in the 1980s, which met the shield requirements for stored radiation sources and operational conditions. No other design solutions were considered. The adopted solution guaranteed that the requirements would be met without having to draw up a radiation protection project. The design adopted the use of fixed guards made of 30 cm thick barite concrete (Figure 1). However, the investor has left the possibility for the contractor to use an alternative material solution.

The room marked “Part A*” designed from high-density concrete class C30/37, (documentation AGH university).

The technical documentation did not pose any special requirements for the covers and their description was laconic. The material presents assumptions, such as: “locally, barite concrete should be used in a portion of the source/radioactive waste storage areas.” The place of use of RSC was identified in the documentation as “Part A.” Due to the design guidelines, the entire underground structure had to be made in waterproof concrete technology. Finally, in the room intended for the storage of radioactive waste, it was decided to make both walls and slabs of high-density concrete.

3.2 Realization problems

3.2.1 Potential sources of risk

The design and implementation of a permanent RSC have constituted a significant source of risk for the contractor in the building project as well as a potential element of competitive advantage. The primary sources of risk and its negative impacts were related to cost, time, and difficulty in availability of materials including aggregate for concrete and their logistics. However, the contractor has gained experience and increased the image. In addition, there is a possibility of financial benefits in future projects, if the shielding solutions need to be optimized. In the analyzed case, the lack of a detailed radiological protection project that should normally be provided by the investor, made it difficult not only to optimize the construction-material and technological-organizational solutions by potential contractors but also correctly design a feasible solution, including a substitution one.

Due to the uniqueness of the investment and the need to use hard-to-reach aggregates for high-density concrete, a potential contractor, who wants to assess the investment risk and include it in the offer price, should provide an alternative material solution.

The company that won the tender obtained information about radiation sources used in existing AGH university laboratories, which will be stored in the room. In addition, a worst-case scenario against radiation exposure to workers was assumed. The contractor decided to use high-density concrete for all partitions of the room.

3.2.2 High-density concrete logistics planning

During the construction, the contractor did not find a concrete plant in Poland, which would provide heavyweight concrete offer. However, ordering this type of concrete mix is possible abroad, most likely from western or southern neighbors. But due to technological reasons (time of concrete mix transport), this solution was not feasible. The general contractor (GC) surveyed the market by sending inquiries to local concrete plants. In response, the prices were obtained (for mixture with barite or magnetite aggregates) ranging between 4,300 PLN/m3 and 5,000 PLN/m3 (PLN – Polish Zloty New). It was decided to take advantage of the cheapest offer. The mix was to be produced in Cracow after importing magnetite and delivered to the construction site. Due to the time needed to deliver aggregate, it was necessary to place an order for magneto-concrete in advance.

An aspect that had to be considered during planning the transport of mix deliveries was its weight. Due to the tonnage restrictions on Polish roads (currently, due to EU law, the maximum axle load for heavy goods vehicles cannot exceed 115 kN; before 2019 it was mostly 80 kN), it was not possible to supply the mixture by filling the entire, most commonly used concrete mixers with a capacity of 10 or 11 m3. Therefore, a mixture with a density of 3,500 kg/m3 was delivered to the construction site in concrete mixers only half-filled (5–6 m3). In the end, about 70 m3 of magnetite concrete was used in the building.

3.2.3 Preparatory works

In addition to the abovementioned logistic problem, an additional difficulty was the organizing of a suitable device for feeding the mixture [11]. Despite numerous inquiries, the contractor could not find a provider willing to rent the pump. The stated reason was the concern about pump or boom damages, due to the high volumetric weight of the mixture, danger of blocking of the mixture in the pipeline as well as rubbing the rubber hose for feeding the mix. The contractors most often suggested using a concreting bin; however, due to the long transport time of the mix using the basket and its weight (in this case only half the capacity of the basket can be filled), it was purposeful to look for a solution that would provide the shortest time for building the mix. Eventually, a subcontractor was found who agreed to inject the mix at the construction site with a concrete pump.

Another problem was the location of the pump as close as possible to build-in point. As can be seen in Figures 2 and 3, the entrance to the building was from the south, i.e., on the opposite corner of the build-in point. The low reach of the pump arm for feeding the magneto-concrete mix prevented the task from being carried out from this position. Therefore, the delivery and location of the pump from the north side of the investment was planned, with much more difficult access (dashed arrow in Figure 2). To prevent blocking the passage of concrete trucks and pumps on the day of the planned concreting, the capacity of the temporary access road was monitored.

A schematic plan of the area development of the FPACS building with possible access. Source: AGH university procurement documentation.

An image showing the construction site marking the shielding location during the concrete casting. Own source, 25.11.2019.

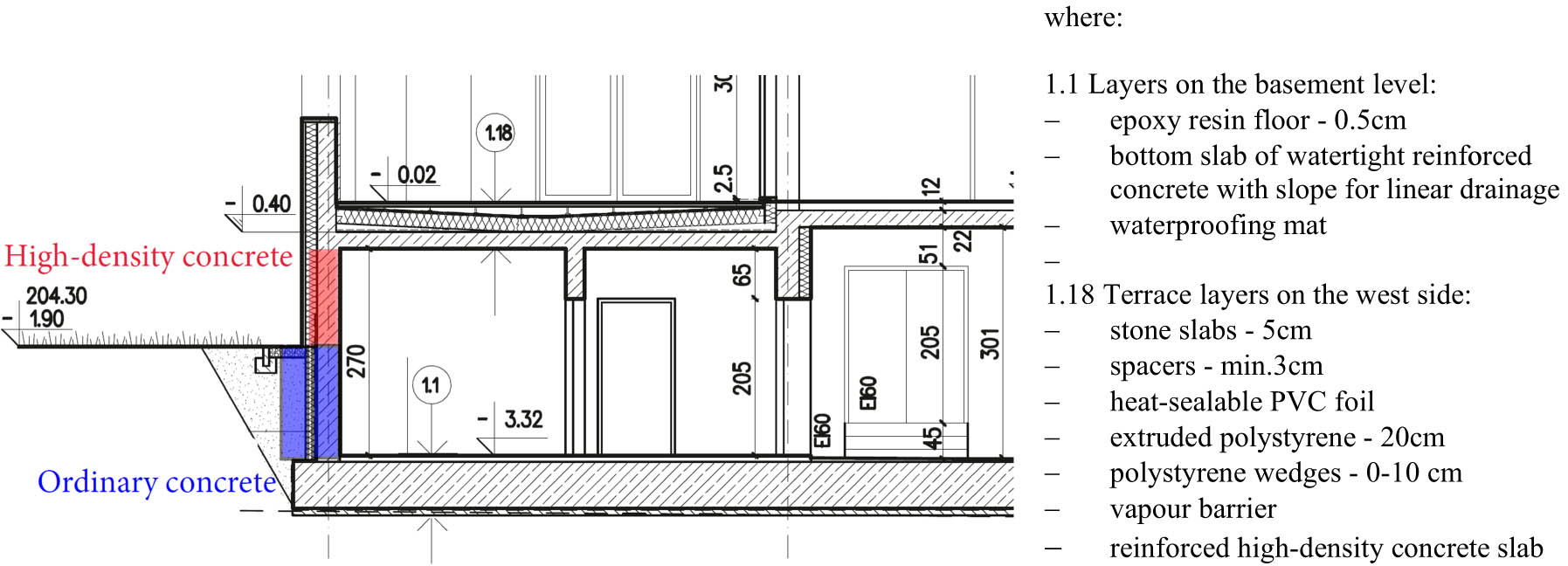

4 Analysis of the implementation of design solutions

The consideration of alternative material solutions was also carried out. It required knowledge of the types of radiation sources and the conditions of human exposure to radiation. In the course of the work, such information was obtained. Unfortunately, the design conditions prevented changes in the building outline or reduction in the required floor area. Such a scenario could have brought a savings of 250,000 PLN. Another solution considered would be making sandwich partitions from concrete with a density of 2,300 kg/m3 and a layer of steel or lead. However, this would require significant changes in the project. Modification of the above variant would be the use of a combined partition consisting partly of high-density concrete and partly of layered partition made of plain concrete, where its thickness would be expanded with a free-standing band along the wall to the height of the underground (Figure 4). In the project, a ground floor made of plain concrete could also be considered.

Variant solution of the RSC.

The indicated solution does not change the outline of the building or reduce the usable area. From a technological point of view, it would be problematic to make a contact between two concretes of different densities [30]. And the proposed solution would require the approval of the investor, designer, and radiation protection specialist, i.e., a separate project in this case. The considered solution would reduce the cost of the RSC from 350,000 to 180,000 PLN. The cost difference was estimated by comparing the price per cubic yard of plain concrete (250 PLN/m3 [Franco]) and heavy concrete (4,300 PLN/m3 [Franco]).

5 Analysis of the decision-making process

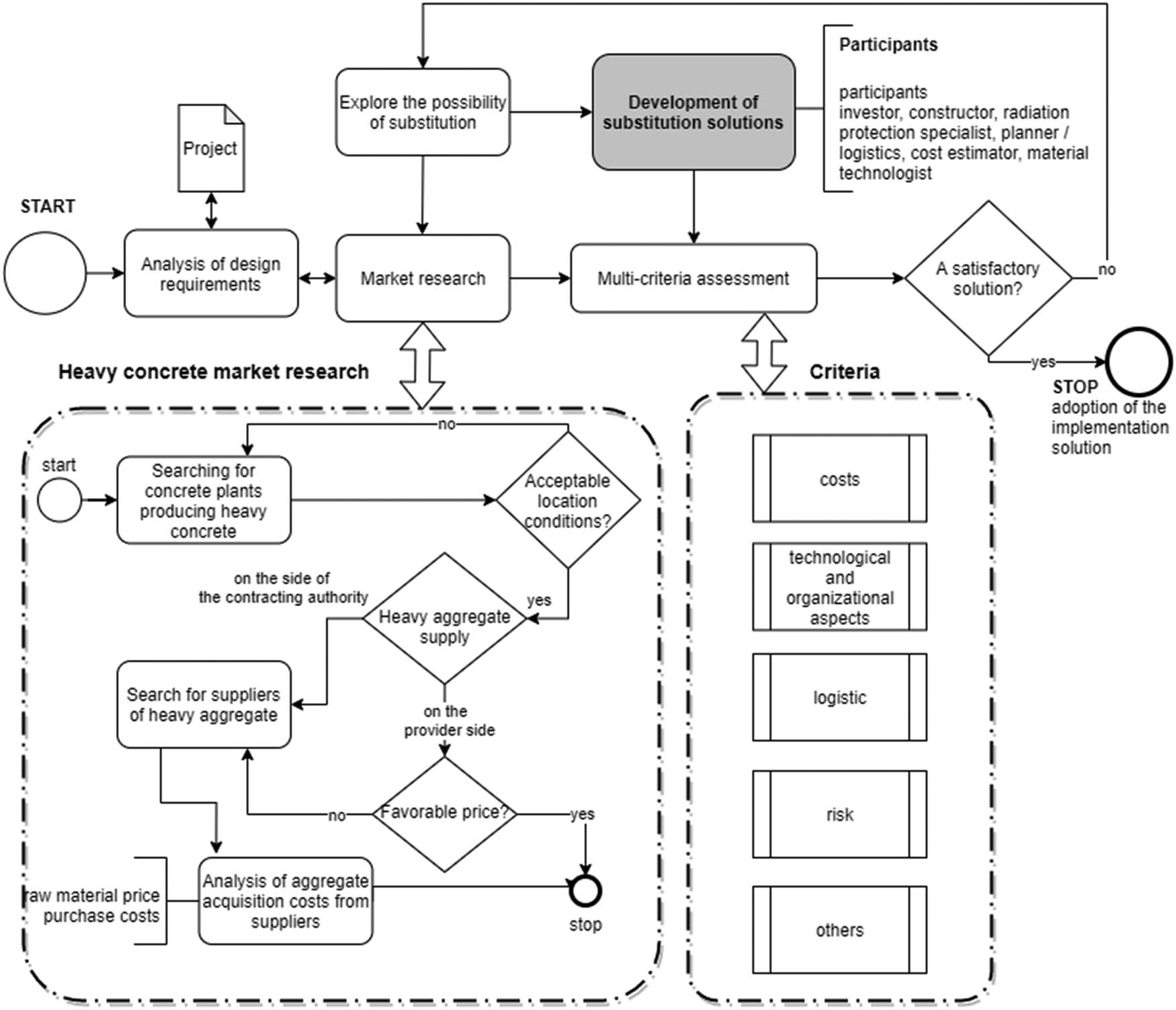

Due to the perceived problems of the project requiring the implementation of RSC, a diagram of the decision-making process is presented. The diagram describes the selection of the implementation solution and assessment of design variants from the perspective of the works contractor (Figure 5).

A schematic diagram of the decision-making process in the area of the RSC.

Submission of an offer for the investment (contractor), which includes, in whole or in part, the execution of the concrete fixed shell, should start with the assessment of the initial design. To this end, it is necessary to analyze the design requirements and conduct market research of suppliers of building materials and services.

In the process of market research, it is necessary to find heavy concrete suppliers, or plants that offer the service of producing ready-mixed concrete (including heavy concrete) according to the customer’s order and on the basis of delivered semi-products. The analyses should include only those suppliers for which the location conditions do not go beyond the adopted level of technological risk associated with the transport of the concrete mix. It is necessary to assess the conditions of supplying heavy aggregate, which most strongly determines the unit price of concrete for these suppliers. If the concrete plant has an aggregate supply chain and the material price is favorable according to the contractor, an initial design solution should be adopted. However, if the aggregate supplier is the purchaser or the price is not favorable, then a market study should be carried out for heavy aggregate suppliers, taking into account the raw material prices and associated purchase costs. It should also be considered to use a substitution material when searching for the best offer. In addition, in the field of technology and organization related to the implementation of heavy RSC, it is necessary to analyze the contract conditions for reinforced formwork and concrete mix laying services.

Having data on the market of materials and services and knowing the technological and organizational requirements, logistics, costs, and risks associated with the implementation of the design solution and other criteria relevant to the contractor in the next step, multi-criteria assessment of variants should be carried out. Then, on this basis, a decision should be made whether to accept the solution for implementation or to look for a substitution solution.

Possible replacement operations should be examined in terms of the market (access to materials and services). It should also be designed taking into account the requirements of the developer, designers, radiation protection specialists, planners, cost estimators, and material technologists. Substitution solutions should also be assessed from the perspective of the criteria adopted in the assessment and on this basis the implementation option should be selected.

Multi-criteria variant assessment of the project, deepened by market research, not only allows for proper mapping of the investment implementation costs but also for the assessment of the project’s risk. By the substitution analysis, the contractor in the tender procedure has the option of lowering the price and thus gaining an advantage over the competition.

6 Conclusion

When designing permanent covers and taking into account safety, technical, functional, financial, technological, and organizational criteria, the design decision becomes a complex multi-criteria issue, requiring cooperation of an interdisciplinary team. However, there is a basic problem that the designer (in the general contracting system) does not know the contractor. This leads to the designer only taking into account technological and organizational aspects, without focusing on the individual preferences of the contractor. Making decisions at the design stage also involves a high risk of changes in market prices of materials and the unavailability of raw materials that are running out. This situation results in a higher level of risk for the contractor who will in turn include the risk in the offer price. Defining the requirements for the cover seems to be a more advantageous solution, leaving the question of its implementation entirely to the contractor. In the analyzed example, approximately 4,000 tons of concrete mix was built into the investment, including less than 2% of magnetite. However, due to the significant difference in the price of this material, this small amount accounted for as much as 25% of the cost of the concrete delivered.

The submission of an offer for the construction of an object containing RSC should be preceded by a detailed analysis of the requirements for the shields. An assessment of the design variant should be made, taking into account the current market situation. Research on substitutional solutions can lead to optimization of the project in terms of individual preferences contractor.

Each potential solution should be assessed holistically and multi-criteria – low raw material costs can be associated with e.g., high transport costs or high implementation risk, etc. It is recommended, if possible, to cooperate with contractors to consult the solutions proposed in the project to avoid problems at the implementation stage.

-

Conflict of interest: Authors state no conflict of interest.

References

[1] Gostkowska B. Ochrona radiologiczna. Wielkości, jednostki i obliczenia. Warsaw: Centralne Laboratorium Ochrony Radiologicznej; 2005.Search in Google Scholar

[2] Pohl E. Technika jądrowa w budownictwie. Warszawa: Arkady; 1967.Search in Google Scholar

[3] Tyagi G, Singhal A, Routroy S, Bhunia D, Lahoti M. Radiation shielding concrete with alternate constituents: an approach to address multiple hazards. J Hazard Mater. 2021;404:124201. Available from: https://www.sciencedirect.com/science/article/pii/S0304389420321919.10.1016/j.jhazmat.2020.124201Search in Google Scholar PubMed

[4] Szymańska M, Ciupek K. Promieniowanie jonizujące-ochrona radiologiczna, zastosowanie a odpady promieniotwórcze. Poznań: Fundacja Forum Atomowe; 2011.Search in Google Scholar

[5] Ablewicz Z, Dubrowski WB. Osłony przed promieniowaniem jonizującym: materiały, konstrukcje, wykonywanie. Warsaw: Arkady; 1989.Search in Google Scholar

[6] Brandt AM, Jóźwiak-Niedźwiedzka D, Nowowiejski G, Denis P. Wyniki badania betonu osłonowego z kruszywem magnetytowym. VIII Conference “Dni Betonu – Tradycja i Nowoczesność”. Wisla: Dni Betonu; 2014.Search in Google Scholar

[7] Zalegowski K, Piotrowski T, Garbacz A. Influence of polymer modification on the microstructure of shielding concrete. Mater (Basel). 2020;13(3):498.10.3390/ma13030498Search in Google Scholar PubMed PubMed Central

[8] Szajerski P, Celinska J, Gasiorowski A, Anyszka R, Walendziak R, Lewandowski M. Radiation induced strength enhancement of sulfur polymer concrete composites based on waste and residue fillers. J Clean Prod. 2020;271:122563.10.1016/j.jclepro.2020.122563Search in Google Scholar

[9] Özdemir T, Güngör A, Akbay IK, Uzun H, Babucçuoglu Y. Nano lead oxide and epdm composite for development of polymer-based radiation shielding material: Gamma irradiation and attenuation tests. Radiat Phys Chem. 2018;144:248–55.10.1016/j.radphyschem.2017.08.021Search in Google Scholar

[10] Peymanfar R, Keykavous-Amand S, Abadi MM, Yassi Y. A novel approach toward reducing energy consumption and promoting electromagnetic interference shielding efficiency in the buildings using Brick/polyaniline nanocomposite. Constr Build Mater. 2020;263:120042.10.1016/j.conbuildmat.2020.120042Search in Google Scholar

[11] Szajerski P, Bogobowicz A, Gasiorowski A. Cesium retention and release from sulfur polymer concrete matrix under normal and accidental conditions. J Hazard Mater. 2020;381:121180.10.1016/j.jhazmat.2019.121180Search in Google Scholar PubMed

[12] Florez R, Colorado HA, Giraldo CHC, Alajo A. Preparation and characterization of Portland cement pastes with Sm2O3 microparticle additions for neutron shielding applications. Constr Build Mater. 2018;191:498–506.10.1016/j.conbuildmat.2018.10.019Search in Google Scholar

[13] Florez R, Colorado HA, Alajo A, Giraldo CHC. The material characterization and gamma attenuation properties of Portland cement-Fe3O4 composites for potential dry cask applications. Prog Nucl Energy. 2019;111:65–73.10.1016/j.pnucene.2018.10.022Search in Google Scholar

[14] Ramadan M, Amin MS, Sayed MA. Superior physico-mechanical, fire resistivity, morphological characteristics and gamma radiation shielding of hardened OPC pastes incorporating ZnFe2O4 spinel nanoparticles. Constr Build Mater. 2020;234:117807.10.1016/j.conbuildmat.2019.117807Search in Google Scholar

[15] El-Khayatt AM, Saudy HA. Preparation and characterization of zinc, lanthanum white sand glass for use in nuclear applications. Radiat Phys Chem. 2020;166:108497.10.1016/j.radphyschem.2019.108497Search in Google Scholar

[16] Alorfi HS, Hussein MA, Tijani SA. The use of rocks in lieu of bricks and concrete as radiation shielding barriers at low gamma and nuclear medicine energies. Constr Build Mater. 2020;251:118908.10.1016/j.conbuildmat.2020.118908Search in Google Scholar

[17] Mahmoud KA, Sayyed MI, Tashlykov OL. Gamma ray shielding characteristics and exposure buildup factor for some natural rocks using MCNP-5 code. Nucl Eng Technol. 2019;51(7):1835–41.10.1016/j.net.2019.05.013Search in Google Scholar

[18] Sala F. Dozymetria i ochrona przed promieniowaniem jonizujacym: aspekty fizyczne, techniczne, prawne i społeczne. Warsaw: Uczelniana Oferta Dydaktyczna PW; 2009.Search in Google Scholar

[19] Al-Buriahi MS, Singh VP. Comparison of shielding properties of various marble concretes using GEANT4 simulation and experimental data. J Aust Ceram Soc. 2020;56(3):1127–33.10.1007/s41779-020-00457-1Search in Google Scholar

[20] Saidani K, Ajam L, Ben, Ouezdou M. Barite powder as sand substitution in concrete: Effect on some mechanical properties. Constr Build Mater. 2015;95:287–95.10.1016/j.conbuildmat.2015.07.140Search in Google Scholar

[21] Li Z. Advanced concrete technology. Hoboken, New Jersey: John Wiley & Sons; 2011.10.1002/9780470950067Search in Google Scholar

[22] Kansouh WA. Radiation distribution through serpentine concrete using local materials and its application as a reactor biological shield. Ann Nucl Energy. 2012;47:258–63.10.1016/j.anucene.2012.05.008Search in Google Scholar

[23] Abdel-Rahman M, El-Samrah MG, Kany A. Study characteristics of new concrete mixes and their mechanical, physical, and gamma radiation attenuation features. Z für Anorg und Allg Chem. 2017;644(2):92–9.10.1002/zaac.201700420Search in Google Scholar

[24] Esen Y, Doğan ZM. Investigation of usability of limonite aggregate in heavy-weight concrete production. Prog Nucl Energy. 2018;105:185–93.10.1016/j.pnucene.2018.01.011Search in Google Scholar

[25] Topçu İB. Properties of heavyweight concrete produced with barite. Cem Concr Res. 2003;33(6):815–22. Available from: https://www.sciencedirect.com/science/article/pii/S0008884602010633.10.1016/S0008-8846(02)01063-3Search in Google Scholar

[26] Ouda AS. Development of high-performance heavy density concrete using different aggregates for gamma-ray shielding. Prog Nucl Energy. 2015;79:48–55. Available from: https://www.sciencedirect.com/science/article/pii/S0149197014002960.10.1016/j.pnucene.2014.11.009Search in Google Scholar

[27] Zayed AM, Masoud MA, Shahien MG, Gökçe HS, Sakr K, Kansouh WA, et al. Physical, mechanical, and radiation attenuation properties of serpentine concrete containing boric acid. Constr Build Mater. 2021;272:121641.10.1016/j.conbuildmat.2020.121641Search in Google Scholar

[28] Brandt AM. Beton jako materiał osłon przed promieniowaniem jądrowym – przegląd. Cem Wapno Bet. 2013;R.18/80(2):115–32.Search in Google Scholar

[29] Dybel P, Walach D, Ostrowski K. The top-bar effect in specimens with a single casting point at one edge in high-performance self-compacting concrete. J Adv Concr Technol. 2018;16:282–92.10.3151/jact.16.282Search in Google Scholar

[30] Wałach D. Impact of delays during concreting of reinforced high-performance concrete beams. Proc Eng. 2016;161:356–61. Available from: 10.1016/j.proeng.2016.08.574.Search in Google Scholar

© 2021 Aleksandra Radziejowska et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Electrochemical studies of the synergistic combination effect of thymus mastichina and illicium verum essential oil extracts on the corrosion inhibition of low carbon steel in dilute acid solution

- Adoption of Business Intelligence to Support Cost Accounting Based Financial Systems — Case Study of XYZ Company

- Techno-Economic Feasibility Analysis of a Hybrid Renewable Energy Supply Options for University Buildings in Saudi Arabia

- Optimized design of a semimetal gasket operating in flange-bolted joints

- Behavior of non-reinforced and reinforced green mortar with fibers

- Field measurement of contact forces on rollers for a large diameter pipe conveyor

- Development of Smartphone-Controlled Hand and Arm Exoskeleton for Persons with Disability

- Investigation of saturation flow rate using video camera at signalized intersections in Jordan

- The features of Ni2MnIn polycrystalline Heusler alloy thin films formation by pulsed laser deposition

- Selection of a workpiece clamping system for computer-aided subtractive manufacturing of geometrically complex medical models

- Development of Solar-Powered Water Pump with 3D Printed Impeller

- Identifying Innovative Reliable Criteria Governing the Selection of Infrastructures Construction Project Delivery Systems

- Kinetics of Carbothermal Reduction Process of Different Size Phosphate Rocks

- Plastic forming processes of transverse non-homogeneous composite metallic sheets

- Accelerated aging of WPCs Based on Polypropylene and Birch plywood Sanding Dust

- Effect of water flow and depth on fatigue crack growth rate of underwater wet welded low carbon steel SS400

- Non-invasive attempts to extinguish flames with the use of high-power acoustic extinguisher

- Filament wound composite fatigue mechanisms investigated with full field DIC strain monitoring

- Structural Timber In Compartment Fires – The Timber Charring and Heat Storage Model

- Technical and economic aspects of starting a selected power unit at low ambient temperatures

- Car braking effectiveness after adaptation for drivers with motor dysfunctions

- Adaptation to driver-assistance systems depending on experience

- A SIMULINK implementation of a vector shift relay with distributed synchronous generator for engineering classes

- Evaluation of measurement uncertainty in a static tensile test

- Errors in documenting the subsoil and their impact on the investment implementation: Case study

- Comparison between two calculation methods for designing a stand-alone PV system according to Mosul city basemap

- Reduction of transport-related air pollution. A case study based on the impact of the COVID-19 pandemic on the level of NOx emissions in the city of Krakow

- Driver intervention performance assessment as a key aspect of L3–L4 automated vehicles deployment

- A new method for solving quadratic fractional programming problem in neutrosophic environment

- Effect of fish scales on fabrication of polyester composite material reinforcements

- Impact of the operation of LNG trucks on the environment

- The effectiveness of the AEB system in the context of the safety of vulnerable road users

- Errors in controlling cars cause tragic accidents involving motorcyclists

- Deformation of designed steel plates: An optimisation of the side hull structure using the finite element approach

- Thermal-strength analysis of a cross-flow heat exchanger and its design improvement

- Effect of thermal collector configuration on the photovoltaic heat transfer performance with 3D CFD modeling

- Experimental identification of the subjective reception of external stimuli during wheelchair driving

- Failure analysis of motorcycle shock breakers

- Experimental analysis of nonlinear characteristics of absorbers with wire rope isolators

- Experimental tests of the antiresonance vibratory mill of a sectional movement trajectory

- Experimental and theoretical investigation of CVT rubber belt vibrations

- Is the cubic parabola really the best railway transition curve?

- Transport properties of the new vibratory conveyor at operations in the resonance zone

- Assessment of resistance to permanent deformations of asphalt mixes of low air void content

- COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Review Articles

- FMEA method in operational reliability of forest harvesters

- Examination of preferences in the field of mobility of the city of Pila in terms of services provided by the Municipal Transport Company in Pila

- Enhancement stability and color fastness of natural dye: A review

- Special Issue: ICE-SEAM 2019 - Part II

- Lane Departure Warning Estimation Using Yaw Acceleration

- Analysis of EMG Signals during Stance and Swing Phases for Controlling Magnetorheological Brake applications

- Sensor Number Optimization Using Neural Network for Ankle Foot Orthosis Equipped with Magnetorheological Brake

- Special Issue: Recent Advances in Civil Engineering - Part II

- Comparison of STM’s reliability system on the example of selected element

- Technical analysis of the renovation works of the wooden palace floors

- Special Issue: TRANSPORT 2020

- Simulation assessment of the half-power bandwidth method in testing shock absorbers

- Predictive analysis of the impact of the time of day on road accidents in Poland

- User’s determination of a proper method for quantifying fuel consumption of a passenger car with compression ignition engine in specific operation conditions

- Analysis and assessment of defectiveness of regulations for the yellow signal at the intersection

- Streamlining possibility of transport-supply logistics when using chosen Operations Research techniques

- Permissible distance – safety system of vehicles in use

- Study of the population in terms of knowledge about the distance between vehicles in motion

- UAVs in rail damage image diagnostics supported by deep-learning networks

- Exhaust emissions of buses LNG and Diesel in RDE tests

- Measurements of urban traffic parameters before and after road reconstruction

- The use of deep recurrent neural networks to predict performance of photovoltaic system for charging electric vehicles

- Analysis of dangers in the operation of city buses at the intersections

- Psychological factors of the transfer of control in an automated vehicle

- Testing and evaluation of cold-start emissions from a gasoline engine in RDE test at two different ambient temperatures

- Age and experience in driving a vehicle and psychomotor skills in the context of automation

- Consumption of gasoline in vehicles equipped with an LPG retrofit system in real driving conditions

- Laboratory studies of the influence of the working position of the passenger vehicle air suspension on the vibration comfort of children transported in the child restraint system

- Route optimization for city cleaning vehicle

- Efficiency of electric vehicle interior heating systems at low ambient temperatures

- Model-based imputation of sound level data at thoroughfare using computational intelligence

- Research on the combustion process in the Fiat 1.3 Multijet engine fueled with rapeseed methyl esters

- Overview of the method and state of hydrogenization of road transport in the world and the resulting development prospects in Poland

- Tribological characteristics of polymer materials used for slide bearings

- Car reliability analysis based on periodic technical tests

- Special Issue: Terotechnology 2019 - Part II

- DOE Application for Analysis of Tribological Properties of the Al2O3/IF-WS2 Surface Layers

- The effect of the impurities spaces on the quality of structural steel working at variable loads

- Prediction of the parameters and the hot open die elongation forging process on an 80 MN hydraulic press

- Special Issue: AEVEC 2020

- Vocational Student's Attitude and Response Towards Experiential Learning in Mechanical Engineering

- Virtual Laboratory to Support a Practical Learning of Micro Power Generation in Indonesian Vocational High Schools

- The impacts of mediating the work environment on the mode choice in work trips

- Utilization of K-nearest neighbor algorithm for classification of white blood cells in AML M4, M5, and M7

- Car braking effectiveness after adaptation for drivers with motor dysfunctions

- Case study: Vocational student’s knowledge and awareness level toward renewable energy in Indonesia

- Contribution of collaborative skill toward construction drawing skill for developing vocational course

- Special Issue: Annual Engineering and Vocational Education Conference - Part II

- Vocational teachers’ perspective toward Technological Pedagogical Vocational Knowledge

- Special Issue: ICIMECE 2020 - Part I

- Profile of system and product certification as quality infrastructure in Indonesia

- Prediction Model of Magnetorheological (MR) Fluid Damper Hysteresis Loop using Extreme Learning Machine Algorithm

- A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters

- Facile rheological route method for LiFePO4/C cathode material production

- Mosque design strategy for energy and water saving

- Epoxy resins thermosetting for mechanical engineering

- Estimating the potential of wind energy resources using Weibull parameters: A case study of the coastline region of Dar es Salaam, Tanzania

- Special Issue: CIRMARE 2020

- New trends in visual inspection of buildings and structures: Study for the use of drones

- Special Issue: ISERT 2021

- Alleviate the contending issues in network operating system courses: Psychomotor and troubleshooting skill development with Raspberry Pi

- Special Issue: Actual Trends in Logistics and Industrial Engineering - Part II

- The Physical Internet: A means towards achieving global logistics sustainability

- Special Issue: Modern Scientific Problems in Civil Engineering - Part I

- Construction work cost and duration analysis with the use of agent-based modelling and simulation

- Corrosion rate measurement for steel sheets of a fuel tank shell being in service

- The influence of external environment on workers on scaffolding illustrated by UTCI

- Allocation of risk factors for geodetic tasks in construction schedules

- Pedestrian fatality risk as a function of tram impact speed

- Technological and organizational problems in the construction of the radiation shielding concrete and suggestions to solve: A case study

- Finite element analysis of train speed effect on dynamic response of steel bridge

- New approach to analysis of railway track dynamics – Rail head vibrations

- Special Issue: Trends in Logistics and Production for the 21st Century - Part I

- Design of production lines and logistic flows in production

- The planning process of transport tasks for autonomous vans

- Modeling of the two shuttle box system within the internal logistics system using simulation software

- Implementation of the logistics train in the intralogistics system: A case study

- Assessment of investment in electric buses: A case study of a public transport company

- Assessment of a robot base production using CAM programming for the FANUC control system

- Proposal for the flow of material and adjustments to the storage system of an external service provider

- The use of numerical analysis of the injection process to select the material for the injection molding

- Economic aspect of combined transport

- Solution of a production process with the application of simulation: A case study

- Speedometer reliability in regard to road traffic sustainability

- Design and construction of a scanning stand for the PU mini-acoustic sensor

- Utilization of intelligent vehicle units for train set dispatching

- Special Issue: ICRTEEC - 2021 - Part I

- LVRT enhancement of DFIG-driven wind system using feed-forward neuro-sliding mode control

- Special Issue: Automation in Finland 2021 - Part I

- Prediction of future paths of mobile objects using path library

- Model predictive control for a multiple injection combustion model

- Model-based on-board post-injection control development for marine diesel engine

- Intelligent temporal analysis of coronavirus statistical data

Articles in the same Issue

- Regular Articles

- Electrochemical studies of the synergistic combination effect of thymus mastichina and illicium verum essential oil extracts on the corrosion inhibition of low carbon steel in dilute acid solution

- Adoption of Business Intelligence to Support Cost Accounting Based Financial Systems — Case Study of XYZ Company

- Techno-Economic Feasibility Analysis of a Hybrid Renewable Energy Supply Options for University Buildings in Saudi Arabia

- Optimized design of a semimetal gasket operating in flange-bolted joints

- Behavior of non-reinforced and reinforced green mortar with fibers

- Field measurement of contact forces on rollers for a large diameter pipe conveyor

- Development of Smartphone-Controlled Hand and Arm Exoskeleton for Persons with Disability

- Investigation of saturation flow rate using video camera at signalized intersections in Jordan

- The features of Ni2MnIn polycrystalline Heusler alloy thin films formation by pulsed laser deposition

- Selection of a workpiece clamping system for computer-aided subtractive manufacturing of geometrically complex medical models

- Development of Solar-Powered Water Pump with 3D Printed Impeller

- Identifying Innovative Reliable Criteria Governing the Selection of Infrastructures Construction Project Delivery Systems

- Kinetics of Carbothermal Reduction Process of Different Size Phosphate Rocks

- Plastic forming processes of transverse non-homogeneous composite metallic sheets

- Accelerated aging of WPCs Based on Polypropylene and Birch plywood Sanding Dust

- Effect of water flow and depth on fatigue crack growth rate of underwater wet welded low carbon steel SS400

- Non-invasive attempts to extinguish flames with the use of high-power acoustic extinguisher

- Filament wound composite fatigue mechanisms investigated with full field DIC strain monitoring

- Structural Timber In Compartment Fires – The Timber Charring and Heat Storage Model

- Technical and economic aspects of starting a selected power unit at low ambient temperatures

- Car braking effectiveness after adaptation for drivers with motor dysfunctions

- Adaptation to driver-assistance systems depending on experience

- A SIMULINK implementation of a vector shift relay with distributed synchronous generator for engineering classes

- Evaluation of measurement uncertainty in a static tensile test

- Errors in documenting the subsoil and their impact on the investment implementation: Case study

- Comparison between two calculation methods for designing a stand-alone PV system according to Mosul city basemap

- Reduction of transport-related air pollution. A case study based on the impact of the COVID-19 pandemic on the level of NOx emissions in the city of Krakow

- Driver intervention performance assessment as a key aspect of L3–L4 automated vehicles deployment

- A new method for solving quadratic fractional programming problem in neutrosophic environment

- Effect of fish scales on fabrication of polyester composite material reinforcements

- Impact of the operation of LNG trucks on the environment

- The effectiveness of the AEB system in the context of the safety of vulnerable road users

- Errors in controlling cars cause tragic accidents involving motorcyclists

- Deformation of designed steel plates: An optimisation of the side hull structure using the finite element approach

- Thermal-strength analysis of a cross-flow heat exchanger and its design improvement

- Effect of thermal collector configuration on the photovoltaic heat transfer performance with 3D CFD modeling

- Experimental identification of the subjective reception of external stimuli during wheelchair driving

- Failure analysis of motorcycle shock breakers

- Experimental analysis of nonlinear characteristics of absorbers with wire rope isolators

- Experimental tests of the antiresonance vibratory mill of a sectional movement trajectory

- Experimental and theoretical investigation of CVT rubber belt vibrations

- Is the cubic parabola really the best railway transition curve?

- Transport properties of the new vibratory conveyor at operations in the resonance zone

- Assessment of resistance to permanent deformations of asphalt mixes of low air void content

- COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Review Articles

- FMEA method in operational reliability of forest harvesters

- Examination of preferences in the field of mobility of the city of Pila in terms of services provided by the Municipal Transport Company in Pila

- Enhancement stability and color fastness of natural dye: A review

- Special Issue: ICE-SEAM 2019 - Part II

- Lane Departure Warning Estimation Using Yaw Acceleration

- Analysis of EMG Signals during Stance and Swing Phases for Controlling Magnetorheological Brake applications

- Sensor Number Optimization Using Neural Network for Ankle Foot Orthosis Equipped with Magnetorheological Brake

- Special Issue: Recent Advances in Civil Engineering - Part II

- Comparison of STM’s reliability system on the example of selected element

- Technical analysis of the renovation works of the wooden palace floors

- Special Issue: TRANSPORT 2020

- Simulation assessment of the half-power bandwidth method in testing shock absorbers

- Predictive analysis of the impact of the time of day on road accidents in Poland

- User’s determination of a proper method for quantifying fuel consumption of a passenger car with compression ignition engine in specific operation conditions

- Analysis and assessment of defectiveness of regulations for the yellow signal at the intersection

- Streamlining possibility of transport-supply logistics when using chosen Operations Research techniques

- Permissible distance – safety system of vehicles in use

- Study of the population in terms of knowledge about the distance between vehicles in motion

- UAVs in rail damage image diagnostics supported by deep-learning networks

- Exhaust emissions of buses LNG and Diesel in RDE tests

- Measurements of urban traffic parameters before and after road reconstruction

- The use of deep recurrent neural networks to predict performance of photovoltaic system for charging electric vehicles

- Analysis of dangers in the operation of city buses at the intersections

- Psychological factors of the transfer of control in an automated vehicle

- Testing and evaluation of cold-start emissions from a gasoline engine in RDE test at two different ambient temperatures

- Age and experience in driving a vehicle and psychomotor skills in the context of automation

- Consumption of gasoline in vehicles equipped with an LPG retrofit system in real driving conditions

- Laboratory studies of the influence of the working position of the passenger vehicle air suspension on the vibration comfort of children transported in the child restraint system

- Route optimization for city cleaning vehicle

- Efficiency of electric vehicle interior heating systems at low ambient temperatures

- Model-based imputation of sound level data at thoroughfare using computational intelligence

- Research on the combustion process in the Fiat 1.3 Multijet engine fueled with rapeseed methyl esters

- Overview of the method and state of hydrogenization of road transport in the world and the resulting development prospects in Poland

- Tribological characteristics of polymer materials used for slide bearings

- Car reliability analysis based on periodic technical tests

- Special Issue: Terotechnology 2019 - Part II

- DOE Application for Analysis of Tribological Properties of the Al2O3/IF-WS2 Surface Layers

- The effect of the impurities spaces on the quality of structural steel working at variable loads

- Prediction of the parameters and the hot open die elongation forging process on an 80 MN hydraulic press

- Special Issue: AEVEC 2020

- Vocational Student's Attitude and Response Towards Experiential Learning in Mechanical Engineering

- Virtual Laboratory to Support a Practical Learning of Micro Power Generation in Indonesian Vocational High Schools

- The impacts of mediating the work environment on the mode choice in work trips

- Utilization of K-nearest neighbor algorithm for classification of white blood cells in AML M4, M5, and M7

- Car braking effectiveness after adaptation for drivers with motor dysfunctions

- Case study: Vocational student’s knowledge and awareness level toward renewable energy in Indonesia

- Contribution of collaborative skill toward construction drawing skill for developing vocational course

- Special Issue: Annual Engineering and Vocational Education Conference - Part II

- Vocational teachers’ perspective toward Technological Pedagogical Vocational Knowledge

- Special Issue: ICIMECE 2020 - Part I

- Profile of system and product certification as quality infrastructure in Indonesia

- Prediction Model of Magnetorheological (MR) Fluid Damper Hysteresis Loop using Extreme Learning Machine Algorithm

- A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters

- Facile rheological route method for LiFePO4/C cathode material production

- Mosque design strategy for energy and water saving

- Epoxy resins thermosetting for mechanical engineering

- Estimating the potential of wind energy resources using Weibull parameters: A case study of the coastline region of Dar es Salaam, Tanzania

- Special Issue: CIRMARE 2020

- New trends in visual inspection of buildings and structures: Study for the use of drones

- Special Issue: ISERT 2021

- Alleviate the contending issues in network operating system courses: Psychomotor and troubleshooting skill development with Raspberry Pi

- Special Issue: Actual Trends in Logistics and Industrial Engineering - Part II

- The Physical Internet: A means towards achieving global logistics sustainability

- Special Issue: Modern Scientific Problems in Civil Engineering - Part I

- Construction work cost and duration analysis with the use of agent-based modelling and simulation

- Corrosion rate measurement for steel sheets of a fuel tank shell being in service

- The influence of external environment on workers on scaffolding illustrated by UTCI

- Allocation of risk factors for geodetic tasks in construction schedules

- Pedestrian fatality risk as a function of tram impact speed

- Technological and organizational problems in the construction of the radiation shielding concrete and suggestions to solve: A case study

- Finite element analysis of train speed effect on dynamic response of steel bridge

- New approach to analysis of railway track dynamics – Rail head vibrations

- Special Issue: Trends in Logistics and Production for the 21st Century - Part I

- Design of production lines and logistic flows in production

- The planning process of transport tasks for autonomous vans

- Modeling of the two shuttle box system within the internal logistics system using simulation software

- Implementation of the logistics train in the intralogistics system: A case study

- Assessment of investment in electric buses: A case study of a public transport company

- Assessment of a robot base production using CAM programming for the FANUC control system

- Proposal for the flow of material and adjustments to the storage system of an external service provider

- The use of numerical analysis of the injection process to select the material for the injection molding

- Economic aspect of combined transport

- Solution of a production process with the application of simulation: A case study

- Speedometer reliability in regard to road traffic sustainability

- Design and construction of a scanning stand for the PU mini-acoustic sensor

- Utilization of intelligent vehicle units for train set dispatching

- Special Issue: ICRTEEC - 2021 - Part I

- LVRT enhancement of DFIG-driven wind system using feed-forward neuro-sliding mode control

- Special Issue: Automation in Finland 2021 - Part I

- Prediction of future paths of mobile objects using path library

- Model predictive control for a multiple injection combustion model

- Model-based on-board post-injection control development for marine diesel engine

- Intelligent temporal analysis of coronavirus statistical data