Abstract

The development of materials engineering has facilitated the design of slender, light bridges replacing standard construction materials with others, which fulfil their purpose both in terms of structural behaviour and safety. This article focuses on the presentation of the problems related to the modelling of bridges and their loads modelling train passages, as well as an analysis of the influence of load parameters on the dynamic response of a structure. The problem has become essential with the development of materials engineering which enabled the design of slender and light bridges according to the assumptions of sustainable development. The article contains a number of numerical analyses which allowed the verification of the developed finite element bridge model (frame and plate-frame types) in terms of the possibility of using them at the design stage. The load was modelled as a system of concentrated forces, the so-called moving load (ML) model. The results obtained from theoretical analyses were compared with in situ measurements of the existing bridge subjected to the load variable in time (set of locomotives ST43 and ST45 and locomotive EP09). It has been found that in dynamic analysis, modelling of the load is essential. A simplified load model such as ML can be used when displacement values are the only results analysed in detail. ML and finite element plate and frame models give high accordance of the displacement results.

1 Introduction

An analysis of a structure under variable loading is a challenge to any designer. Due to the development of materials engineering and transport economy – which directly relates to increased vehicle speed and mass – with the use of lighter materials in construction of engineering structures, the problem of structural dynamics is becoming a key issue. With regard to sustainable development and environmental protection, every structure should be thoroughly analysed to use its behaviour optimally with a rational reduction in the materials required to construct it. The resources of any material used in construction of engineering structures may be exhausted over time and for this reason conducting advanced analyses enabling the reduction in construction costs and the quantity of materials, or the use of alternative materials is justified.

Theoretical analyses constitute an integral part of any study concerning the design documentation of engineering structures. The serviceability limit states and ultimate limit states are verified on their basis. Today, there are plenty of computer applications for performing complex theoretical analyses. In the case of bridges, the most often performed analyses are static, dynamic and modal ones. The results of the first two analyses are used to interpret the values of the displacements of certain structural members; the values of accelerations are obtained in a dynamic analysis, and natural frequencies and mode shapes are obtained in a modal analysis. The method used most often in numerical studies is the finite element method (FEM). The process of structural modelling is a key influence with regard to the obtained calculation results. The world literature contains a large number of publications on issues related to dynamics regarding bridge studies. They refer both to railway and road facilities. In the case of rail vehicle loads, high speed train passages are analysed. In the paper [1], the impact of track unevenness on the values of the accelerations and displacements of a bridge span are taken into consideration. It has been proved that the vertical component of acceleration is greater not only in the analysed structural elements but also in the rail vehicle. It has been established that using more precise models in analyses considering track roughness is recommended. The authors of ref. [2] verified various methods of modelling of foundation loaded with dynamic loads over time. A significant impact of the boundary conditions on the values of structural displacements was determined. The analysis with the use of ABAQUS software using non-standard procedures was described. Plenty of books and monographs on the issues of structural dynamics have been published, but refs [3,4] describing the problems related to the complex, coupled dynamic system structure – vehicle, which affect each other, are among the most important ones. The monograph [5] describes in detail the load-bridge interaction, for high speed trains. This is a key aspect bearing in mind the technology developing so rapidly to allow trains to move at very high speeds. Furthermore, the literature contains publications describing the studies of the impact of vehicle parameters on the dynamic response of a structure. The authors of refs [6,7] presented the study result on the basis of which it was verified that the defined speed of a vehicle and its wheelbase may cause excitation of a specific frequency, which may result in the dangerous phenomenon of resonance. In the case of bridges, the used type of surface also plays a key role. In the case of high-speed line bridges, the track ballast is used due to its good damping characteristics [8]. One should bear in mind that dynamic analyses are also performed to assess the possibility of adapting existing railway bridges in service to high-speed lines. The authors of ref. [9] performed a comprehensive dynamic analysis to verify the possibility of increasing the cruising speed on a selected bridge, using various numerical models, differing in terms of the mess density. Wind load also constitutes a very important factor in the case of dynamic analyses. The authors of refs [10,11] presented a method of wind load modelling with regard to a train travelling at high speed. In such cases, lateral wind pressure plays a key role. The authors of ref. [12] examined the influence of wind load on the footbridge structure of an untypical shape.

There are many factors that affect operation of a structure under dynamic load. It can be difficult and sometimes even impossible to include these factors in theoretical analyses. One of the key factors influencing the values obtained in a dynamic analysis is how load is modelled (transmission of a load to an object). In the literature, several load models can be found, three of them considered to be basic ones are described in ref. [13]. The first is the simplified model, the so-called moving load (ML) model describing a load as a set of concentrated forces moving at a constant speed. This model does not take into account the interaction between the load and the structure, thus results may be exaggerated. The main assumption is that the inertia of the moving train is small in relation to the inertia of the bridge structure. This is the main load model found in computer programs which enable dynamic analysis. The second, more accurate model is the so-called moving mass (MM) model, in which, when describing the load of the structure, mass distribution is considered as a function of time and space. Bridge inertia and bridge–train interaction can be taken into account this way. Additional elements consisting of vectors of shape functions and their derivatives, used in the FEM, are added to the mass matrix M, damping matrix C and stiffness matrix K. The global matrices M, C and K are expanded in this model. This model was first published in ref. [14]. The third model is a coupled system known as spring-mass-damper (SMD), which describes in detail the impact of train dynamics on bridge response. The vehicle model introduces its weight and suspension system. This model is more extensive than the MM model. In the literature, there are works related to dynamic analyses considering the passage of high-speed trains, where the load has been described by more complex models e.g. train-bridge dynamic interaction model [15]. This model is based on the multi-body system dynamics theory to simulate a train subsystem. This is a modern model; however, it does not take into account the interaction between the train-track and the bridge structure, which should be seen as an integrated dynamic system. For this purpose, a more advanced train-track-bridge dynamic interaction model has been created. This model takes into account the coupling between the train and the track as an interactive wheel-rail relationship, as well as between track and the bridge structure [16]. These models are used for advanced dynamic analyses of bridge structures, where trains run at speeds above 300 km/h. In the global literature, other author’s methods to model interaction of a vehicle with an object can be found. In the paper [17], there is presented an algorithm for nonlinear analysis of vertical interaction of a vehicle with the structure, by including for the vehicle and the structure in the equilibrium equations, values of vehicle movements and corresponding structure displacements. Authors in the paper [18] prove that not only bridge spans but also pillars and foundations should be taken into account in the dynamic analysis. This allows to obtain the real values of the natural frequencies of a bridge. In the paper [19], authors present results of their work in which they confirm that interaction between the maglev train and bridge is completely different than that for standard trains. These differences contributed to the creation of an individual model, describing the dynamic train-bridge system. Note that for standard bridge structures and not high cruising speeds of vehicles, the use of advanced load models may be disproportionate to the effect to be achieved. In Poland, most of the dynamic analyses carried out concern standard short bridge facilities, on which vehicles move at speeds below 200 km/h. In the case of railway facilities located within the lower classes of railway, or where the permissible speed of the vehicles is less than 100 km/h, it may be justified to use simpler load models, which, if a dynamic analysis is carried out, will be faster to perform and certainly economically more advantageous.

This article focuses on the presentation of the problems related to the modelling of bridges and their loads modelling train passages, as well as an analysis of the influence of load parameters on the dynamic response of a structure.

2 Research subject

The presented analyses use the results of the in situ study of the existing railway bridge located on railway line no. E30, at 127.475 km on the Ropczyce – Sędziszów Małopolski route, the Dębica – Sędziszów Małopolski section, in Poland. The structural elements of the bridge are made of the S355J2-N steel. Table 1 shows the parameters of the analysed structure.

Parameters of the analysed structure

| Parameter | Information about parameter |

|---|---|

| Static scheme | Simply supported beam; truss with a ride down |

| Theoretical span length | 51.44 m |

| Theoretical span width | 5.00 m |

| Bottom girder – steel beam | Height – 1500 mm; web thickness – 16 mm; bottom and top flanges 30 mm thick and 380 mm wide |

| Cross-braces of lower girder | Welded flat bars: height – 420 mm; variable width 240–460 mm |

| Cross-braces of upper girder | 10 mm × 100 mm × 100 mm angle bars |

| Bridge horizontal light | 45.37 m |

| Bearing spacing | 5.00 m |

| Vertical railway gauge | 7.00 m |

| Horizontal gauge of the ballast tray | 4.56 m |

| The thickness of the sheet metal of the ballast trough | 16 mm |

Information about the developed models

| Model | Number of nodes | Number of plate elements | Number of frame elements | Total weight (kN) |

|---|---|---|---|---|

| Plate-frame | 8,551 | 9,296 | 2,942 | 1533.7 |

| Frame | 3,630 | 2,048 | 3,868 | 1535.6 |

The analysed bridge is presented in Figure 1.

Bridge structure: (a) side view and (b) inside view. Source: The authors.

As part of the in situ study, measurements of the response of the structure to static and dynamic loads were conducted. For the measurements with a static load, the structure was loaded with a set of two locomotives, ST43 and ST45, positioned symmetrically to the centre of the span length. The total mass of both locomotives amounted to 218,600 kg, and the load of a single axle on the rail equalled 179 kN. The loading draft consisted of 12 loading axles, i.e. 24 wheels. The total length of the two connected locomotives was 35.10 m, which constituted 68% of the theoretical bridge length. As part of the study, the values of the vertical displacements of the bridge span were measured in one fourth (0.25L t ) and three eighths (0.375L t ) of the theoretical span length.

Dynamic studies were divided into two stages. In the first stage, the bridge was loaded with a draft of two locomotives, used in the static study before, travelling at a speed of 10, 30, 50, 70 and 80 km/h. In the second stage, a single locomotive EP-09, travelling at a speed of 10, 100, 120, 140 and 160 km/h, constituted the entire load. The locomotive EP-09 weighed 83,500 kg and the load of its single axle on the rail amounted to 210 kN. The loading draft consisted of four loading axles in total, i.e. eight wheels. The total length of the locomotive amounted to 16.74 m, which constituted 33% of the theoretical bridge length.

The process of the in situ studies and the analysis of their results are described in detail in ref. [20], the study results of which were used to verify models used in numerical analyses in this article and can be found in Tables 3 and 4.

Comparison of the vertical deflections of the bridge span resulting from its static loading obtained in the studies of the physical structure and numerical studies

| Model | Location of the point of measurement | |

|---|---|---|

| 0.250 L t | 0.375 L t | |

| Plate-frame u td | −7.80 | −11.67 |

| Frame u tu | −7.87 | −11.61 |

| In situ studies u is | −7.96 | −11.45 |

| u td /u is | 99.87% | 101.40% |

| u tu /u is | 97.99% | 101.92% |

Comparative analysis of the results of the bridge span natural frequencies obtained in the theoretical and physical studies

| In situ studies | Plate-frame model | Frame model | ||

|---|---|---|---|---|

| Amplitude value (m/s2) | Theoretical natural frequency f (Hz) | Mode of vibration | ||

| f 1EP09_V160 = 2.50 | a 1EP09_V160 = 7.85 × 10−4 | f 1 = 2.77 | f 1 = 2.55 | Horizontal torsion |

| f 1EP09_V120 = 2.50 | a 1EP09_V120 = 4.39 × 10−4 | |||

| f 1ST43-45_V80 = 2.45 | a 1ST43-45_V80 = 2.92 × 10−4 | |||

| f 1ST43-45_V50 = 2.46 | a 1ST43-45_V50 = 1.47 × 10−4 | |||

| f 2EP09_V160 = 4.30 | a 2EP09_V160 = 4.88 × 10−3 | f 2 = 4.17 | f 2 = 4.20 | Vertical bending |

| f 2EP09_V120 = 4.30 | a 2EP09_V120 = 3.44 × 10−3 | |||

| f 2ST43-45_V80 = 4.31 | a 2ST43-45_V80 = 5.51 × 10−5 | |||

| f 2ST43-45_V50 = 4.31 | a 2ST43-45_V50 = 5.21 × 10−5 | |||

| f 3EP09_V160 = 7.32 | a 3EP09_V160 = 4.45 × 10−3 | f 5 = 6.97 | f 5 = 7.82 | Horizontal torsion |

| f 3EP09_V120 = 7.31 | a 3EP09_V120 = 9.69 × 10−3 | |||

| f 3ST43-45_V80 = 7.40 | a 3ST43-45_V80 = 1.24 × 10−3 | |||

| f 3ST43-45_V50 = 7.39 | a 3ST43-45_V50 = 1.73 × 10−3 | |||

| f 4EP09_V160 = 9.58 | a 4EP09_V160 = 4.63 × 10−3 | f 23 = 8.60 | f 28 = 8.47 | Vertical bending |

| f 4EP09_V120 = 9.60 | a 4EP09_V120 = 1.46 × 10−3 | |||

| f 4ST43-45_V80 = 9.66 | a 4ST43-45_V80 = 2.38 × 10−3 | |||

| f 4ST43-45_V50 = 9.66 | a 4ST43-45_V50 = 1.34 × 10−3 | |||

| f 5EP09_V160 = 12.50 | a 5EP09_V160 = 3.39 × 10−4 | f 27 = 12.45 | f 32 = 12.51 | Vertical bending |

| f 5EP09_V120 = 12.49 | a 5EP09_V120 = 3.24 × 10−4 | |||

| f 5ST43-45_V80 = 12.47 | a 5ST43-45_V80 = 2.58 × 10−3 | |||

| f 5ST43-45_V50 = 12.47 | a 5ST43-45_V50 = 1.61 × 10−3 | |||

| f 6EP09_V160 = 12.84 | a 6EP09_V160 = 6.55 × 10−4 | f 28 = 12.48 | f 33 = 12.82 | Vertical bending |

| f 6EP09_V120 = 12.82 | a 6EP09_V120 = 8.22 × 10−4 | |||

| f 6ST43-45_V80 = 13.05 | a 6ST43-45_V80 = 5.68 × 10−4 | |||

| f 6ST43-45_V50 = 13.05 | a 6ST43-45_V50 = 2.12 × 10−3 | |||

To analyse the behaviour of a bridge subjected to dynamic loading over time, the damping ratio ζ (critical damping ratio) is required. To calculate this parameter, Discrete Fourier transform (DFT) analyses of the measured acceleration time series after the locomotive leaves the bridge were conducted. On such a basis, the natural frequencies of the structure were obtained, which is illustrated in Figure 2. Next a function passing through the extremes of the appropriately filtered time history of the accelerations of the following formula was determined:

where A – slope of the function, and ς-damping coefficient.

![Figure 2

Signal analysis based on acceleration measurements – DFT analysis of the signal after the locomotive leaves the bridge for 0.5 L

t

– in situ studies [20].](/document/doi/10.1515/eng-2021-0114/asset/graphic/j_eng-2021-0114_fig_002.jpg)

Signal analysis based on acceleration measurements – DFT analysis of the signal after the locomotive leaves the bridge for 0.5 L t – in situ studies [20].

Next steps consisted in the determination of the logarithmic decrement of damping using the formula:

where T – period of free vibrations.

Then the critical damping ratio can be calculated with the formula:

The experimental value of the damping ratio, calculated from the formula (3), amounted in this case to ζ = 0.32%.

3 Numerical analysis

The results obtained in the static and dynamic studies of the analysed bridge were used in the verification of the numerical finite element models of the bridge, developed and later calculated with the use of Autodesk Simulation Multiphysics. Two model types were developed: a simplified model using frame elements, referred to as “frame model,” and a more detailed model, referred as “plate-frame model” due to the use of frame and plate elements. The first part of the analyses regarded the verification of the models. In the second part, an analysis of the impact of the vehicle speed and mass on the values of displacements and accelerations was conducted. As in the case of the in situ studies, the static analysis was conducted as part of the theoretical analyses as a result of which the values of the vertical displacements of the selected structural elements of the bridge were obtained, and the modal analysis, on the basis of which the natural frequencies and mode shapes of the structure were verified, and the dynamic analysis from which the displacement and acceleration time series over time depending on the load speed modelling the movement of the locomotives, were obtained.

3.1 Finite element models

The development process of the finite element model of a structure has a significant influence on the quality of the obtained calculation results. At the stage of its development, it is necessary to check e.g. a finite element type used in the modelling of a certain structural element, the model mesh size, the shape of the geometric elements used to construct the mesh or its density at the points where the model will be loaded with e.g. concentrated forces applied in nodes. The problem is important as, in the development stage, a lot of simplifications are introduced, mainly in geometry, which results in the fact that the model may function improperly, i.e. the calculation results obtained as a result of using it may incorrectly describe the studied physical phenomena. The aforementioned simplification may result from limiting the number of the elements which may be used to develop the model, from the selection of an element type, or boundary conditions. Nevertheless, one should bear in mind that a greater number of finite elements in a model may significantly prolong the analysis performance period. The paper [21] presents a model of Most Solidarności (Solidarity Bridge) in Płock, consisting of over a million elements which contributed to the fact that the modal analysis took a few hours, while in the case of models consisting of fewer degrees of freedom, an analysis is performed within a few minutes. The level of the precision of a model also depends on its application. In the case of the common engineering problems, where the used structural solutions have already been tested multiple times, less precise models, requiring less time, can be used.

In the analysed case, the developed three-dimensional bridge models were qualified to the class (e 1 + e 2; p 3) (cf. [22]). Symbols e 1 and e 2 refer to the sizes of the used elements, while symbol p 3 refers to the space where the model was developed. The frame model was considered to be simplified as a lot of structural elements, such as bottom girders, were modelled as frame elements. It allowed the decrease in the number of its elements and nodes. In the case of the plate-frame model, more precise structural elements (except for cross-braces) were modelled by means of plate elements. This resulted in a more precise characteristics of the cross sections and more accurate stiffness as offsets between structural elements are directly modelled. The development process of such a model is much more labour intensive than in the case where frame elements are used, and the number of model elements and nodes is increased, and, what follows, the number of the degrees of freedom. Figure 3 presents the developed bridge models.

Numerical bridge models: (a) plate-frame model and (b) frame model. Source: The authors.

The principal assumption regarding the developed models was an attempt to map the bridge structure in such a way that its dead load and stiffness approached the characteristics of the actual structure and were similar in both models. A small difference in the weight of the models may have stemmed from the fact that when modelling a bridge element by means of e.g. a frame element, it obtains a cross section of known geometric parameters, but the computer application may not always be able to conduct accurate calculations and the weight of such an element may not equal the weight of the actual element. It principally regards elements of complex or untypical cross sections, i.e. different from standard cross sections, e.g. circular or rectangular ones. Autodesk Simulation Multiphysics does not allow a 3D preview of such an element in the case of untypical cross sections, therefore, it is very important to accurately calculate all the geometric features of a cross section and position in a global system correctly. The difference in weight between the plate-frame model and the frame model amounted to less than 0.1%. Table 2 contains a list of the differences between the simplified and precise models in terms of numbers. Within numerical analyses, the following material parameters assumptions for the steel elements of the bridge were adopted for modelling: modulus of elasticity (E = 205 GPa), mass density (7,850 kg/m3) and Poisson’s ratio (v = 0.3).

3.2 Verification of finite element models

The values of the displacements related only to the static loads (two locomotives) were obtained from calculations on the basis of a static analysis. The load reflected the positioning of the locomotive set, i.e. in the middle of the bridge span. The load constituted 2 × 12 concentrated forces, each corresponding to the single wheel load on a rail. The value of a single force was assumed as 89.5 kN. Figure 4a presents the manner of the application and the location of the forces, and Figure 4b shows a visualisation of the loaded plate-frame model including vertical displacements.

Static calculations of the plate-frame model: (a) the model with concentrated forces modelling the load of the wheels of locomotives ST43 and ST45 and (b) vertical displacements of the bridge caused by the weight of locomotives ST43 and ST45.

The obtained results, presented in Table 3, were compared with the values of the vertical displacements obtained in the in situ studies.

Having conducted the analysis of the displacements of the structural nodes of the bridge caused by static loading, one can conclude that both models correctly reflect the actual behaviour of the bridge. The consistency of the obtained results and the in situ measurements was around 98–101%. When comparing the frame model and the plate-frame model, very similar results were obtained. This confirmed the conclusions of ref. [23] according to which one can use simplified finite element model of a structure in the case of a static analysis due to the fact that the values of displacements are very close to the values obtained in the in situ studies.

The modal analysis enabled the verification of the natural frequencies and their modes obtained from both the models. Due to the numerous mode shapes not referring to the vibrations of the deck plate, the number mode shape is different from the one used in the in situ analysis. For plate and frame models, the second bending mode shape of the deck plate in the theoretical model can be found as the 23rd mode shape of the whole system (f 23). There is a similar situation in the case of the frame model. The results were then compared with the values obtained in the in situ studies and DFT analyses (cf. [20]) and listed in Table 4. Based on the in situ studies, it has been found that the speed at which the vehicle moves and its mass affect the operation of the structure under such dynamic load. These differences can be observed in the free vibration frequency values of the bridge plate. The wheelbase of the vehicle further affects the work of the structure. This can be seen in the spectrum values for the second frequency of free vibrations of the structure. Different wheelbase in the set of locomotives ST43 and ST45 resulted in damping of vibrations with frequency close to 4.30 Hz. Amplitudes in spectrum for this frequency range are 100 times lower than that in case of locomotive EP09 passage. It should be noted that the frequency of 4.30 Hz is the main, dominant vertical frequency of the bridge plate. The numerical studies conducted also confirmed the consistency of the models with the actual behaviour of the structure subjected to dynamic loading over time.

3.3 Dynamic analysis

The examination of the influence of the speed and weight of the locomotives on the dynamic response of the bridge was conducted by means of a dynamic analysis, consisting in the direct integration of motion equations. Calculations were performed for two sets of the locomotives, and for each set, analyses of all the speed values were obtained during the transit of the locomotives in the in situ studies, i.e. 10, 30, 50, 70, 80, 100, 120, 140 and 160 km/h.

In the conducted analyses, the mass-stiffness damping model (Rayleigh’s damping) was applied, described with the following formula:

where C – structural damping matrix, M – mass matrix, K – stiffness matrix, α = 0.109605 – mass damping parameter and β = 0.000089 – stiffness damping parameter.

Parameters α and β were determined from the formulas:

where ω i = 2πf 2 and ω j = 2πf 4 are the selected vertical values of natural frequencies.

The transit of the locomotives was modelled as a dynamic load over time using the so-called load curve, containing information on the values of loading forces and the values of time steps. The applied loading model was defined as so-called ML model. Unfortunately, the application does not include the change in the vehicle mass position – which may be of key significance with regard to the obtained values of displacements and accelerations – in the analysis. The ML model is, therefore, a simplification, because entire loading is defined by means of the concentrated forces applied to the nodes.

To model the load curve, information on the model mesh density (the dimension of an element along the bridge axis), the speed of the train during transit and the locomotive wheelbase were used. Furthermore, the time steps of the calculations, which had to be selected in such a way that the locomotive wheel load forces found the mesh nodes, were related to the aforementioned parameters. For the analysis to last longer than the transit of the train over the bridge, an appropriate number of time steps were assumed in the calculations. Table 5 lists information on the number of steps and the length of a time step. An example graphically describing the load curve for the draft of two trains (12 axles) traveling at the speed of 30 km/h is presented in Figure 5. The value of 1 on the vertical axis denotes the multiplier of the exact force when applied to the loaded node.

The number of values of time steps for specific speed values in the dynamic analysis

| Speed (km/h) | Time step (s) | Number of steps | Minimum calculation time (s) | ||

|---|---|---|---|---|---|

| Frame model | Plate-frame model | EP09 | ST43–ST45 | ||

| 10 | 0.0153120 | 8,000 | 5,000 | 22.42 | 29.44 |

| 30 | 0.0051010 | 7.47 | 9.81 | ||

| 50 | 0.0030624 | 4.48 | 5.89 | ||

| 70 | 0.0021874 | 3.20 | 4.21 | ||

| 80 | 0.0019140 | 2.80 | 3.68 | ||

| 100 | 0.0015312 | 2.24 | 2.94 | ||

| 120 | 0.0012760 | 1.87 | 2.45 | ||

| 140 | 0.0010937 | 1.60 | 2.10 | ||

| 160 | 0.0009570 | 1.40 | 1.84 | ||

The load curve of a single bridge node for two locomotives travelling at the speed of 30 km/h.

This part of the dynamic analysis also started with the verification of the model consisting in the comparison of the determined values of vertical displacements at three eighths of the theoretical span length (0.375L t ). Figure 6 shows the vertical displacement of the node located at the analysed span point during the entire transit over the bridge for the speed values of 10, 80 and 160 km/h for the purposes of the numerical and in situ studies. Figure 7 presents the accelerations obtained for the set of locomotives ST43–ST45 at the aforementioned velocities. As shown in the figures, the frame model is not stiff enough, and the plate-frame model – is a bit too stiff (in the case of the transit of locomotives ST43–ST45). Nevertheless, the displacement results for both models were similar to the measurements and form certain top and bottom limits. This would be used in the subsequent numerical studies in such a way that calculations would be conducted for both models, and their results would be regarded as the top and bottom limits with regard to the values determined for the actual structure.

Comparison of the displacement values at 0.375L t for selected combinations of dynamic locomotive transits.

Variances of the acceleration over time of the node at the middle of the span length during the transit of the set of locomotives ST43–ST45 at (a) v = 10 km/h, (b) v = 80 km/h and (c) v = 160 km/h. The vertical line denotes the moment the locomotive leaves from the bridge.

Figure 7 presents the increased values of accelerations with the increased speed. The figure also shows that after the locomotives leave the bridge, it is still subjected to the inertia forces resulting from the accelerations. The greater the speed of the locomotives, the greater the load, and the slower the process of acceleration damping.

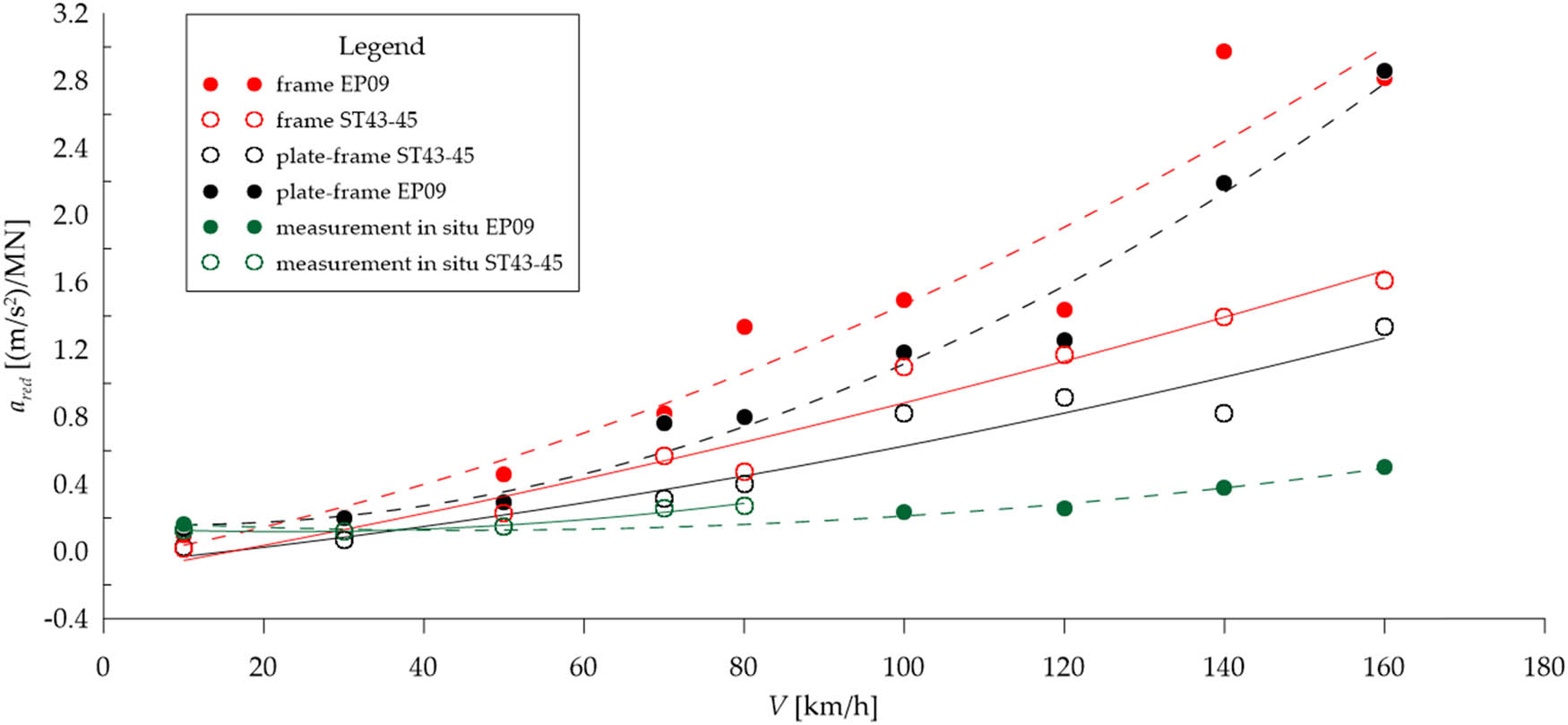

In the subsequent part of the analyses, the values of displacements and accelerations depending on the weight of vehicles as a function of speed were verified. For this purpose, reduced values were used, calculated from the formulas:

where u max and a max – extreme values of displacements and accelerations, and G – the weight of the locomotives.

Figures 8 and 9 present the cumulative graphs of reduced values. In the case of the maximum values of vertical displacements (Figure 8), an insignificant upward trend with an increase in speed is visible. This is confirmed by the results obtained from the in situ studies. In case of the locomotive EP09 passage, as the speed increases, the trend becomes steeper. With regard to the theoretical results, it can be concluded that in the speed range 60–80 km/h the load model adopted in the software may not take into account certain factors, or the range of this speed causes additional dynamic effects on the object. In the case of speeds of 70 and 80 km/h, you can see a significant increase in the values of displacement. They are higher than that for higher speeds. For speed of 160 km/h, displacement value is less than that for speed of 140 km/h. This has also been observed during the in situ tests. It should be noted that for the speed of 100, 120 and 140 km/h, values of theoretical and actual displacements show a similar trend (when analysing exactly this speed range). A detailed dynamic analysis should have to be performed for the speed range of 60–80 km/h for the passage of the locomotive EP09. Unfortunately, due to the inability to take measurements for the locomotive EP09 passage for speed in the range of 20–70 km/h, detailed comparative analysis of in situ studies with numerical studies was not possible. With regard to the values of displacement based on a set of locomotives ST43 and ST45 passage, the results of the theoretical tests for the plate-frame model are practically equivalent to those obtained from the in situ tests. Lower load cruising speeds, higher weight, different nature of the load (wheelbase and set length) certainly had an impact on the obtained results. Wheelbase and weight may cause damping of the structure within a range of certain frequencies which has been confirmed in Figure 2 and in Table 4.

Graph of the values of reduced vertical displacements u red depending on the locomotive speed v, continuous lines represent trend based on measurements or calculated values.

Graph of the reduced values of acceleration a red depending on the locomotive speed v, continuous lines represent trend based on measurements or calculated values.

For calculated theoretical acceleration values, there is a clear increasing trend in their maximum values as the speed increases. Based on the field studies carried out, there is also an upward trend, however, with much lower steepness. On the basis of the analyses carried out, it can be stated that the higher the speed of the vehicle, the greater the difference in the acceleration values between the theoretical values and the calculated ones. Change in the difference in acceleration values is nonlinear. These differences are very large, and the theoretical values of accelerations obtained cannot be considered correct. It is concluded that a simplified ML model should not be used to verify acceleration values in dynamic analyses. There are a number of factors that can influence the results, e.g. adopted damping model, damping values adopted at the analysis stage, how these values are calculated, filter type and its order (e.g. Butterworth or Bessel) and external factors, which may have influenced the measured values during field tests (e.g. damaged locomotive body and track roughness). It should be remembered that in theoretical dynamic analyses there are no external factors that may interfere with the measurement result. For locomotive EP09, both greater extreme vertical displacements and accelerations were obtained. It means that the distribution of the locomotive mass and its wheelbase also influence the dynamic response of a bridge.

In Figures 8 and 9, the trend lines are marked, but one can notice that the results are not arranged along the trend line. In the case of computer calculations, there is no external disruption which introduces measurement uncertainty, hence, one can assume that the trend line does not contain all the information on the described relationships. In future, numerical calculations shall be conducted with regard to a greater number of transit cases to establish whether there would occur any extremes indicating the resonance at certain velocities.

4 Conclusion

Bridge construction development allows less material to be used in the construction process or the replacement of the standard materials with new materials, so far not used in bridge construction. Today, designed structures are light and slim. These results in the alteration of the dynamic characteristics of a structure which, combined with changes in their operation e.g. increased speed of trains passing them, necessitate changes in the approach to the design of such structures, and, above all, call for precise dynamic analyses. As demonstrated in the article, when designing bridges, one can use both frame and plate-frame models, which describe the geometry and stiffness of a structure in a more precise manner. On the basis of the in situ studies and theoretical analyses it can be stated that the load model is crucial for the values obtained in dynamic analyses. ML model describing how the structure is loaded can be used when analysing the displacement values. The compatibility of theoretical results with the deflection values of the bridge plate was satisfactory for both the locomotive set ST43–ST45 as well as for the locomotive EP09. Finite element plate-frame model demonstrated higher accuracy in comparison to the ones obtained for the frame model. It is concluded that for dynamic analyses accurate finite element models should be used, which reflect to a higher extent the bridge object tested. However, it should be borne in mind that such a model has a higher number of degrees of freedom, thus the time needed to perform dynamic analysis will be longer than that for the frame model. It has been found out that the simplified ML model should not be applied to verify acceleration values in theoretical dynamic analyses. The differences between theoretical and actual values are greater with the higher speeds of the ML. For speed of 160 km/h, this difference was 470% of the value measured during the in situ studies. If you need to analyse acceleration values in dynamic analyses, consider using more detailed load models, e.g. MM or SMD models, which additionally take into account the impact of the change in the position of the mass or the impact of the elasticity of the vehicle suspension. DFT carried out confirmed that wheelbase, load weight, load length and the speed at which it moves, affect the dynamic operation of the structure. Passage of a set of locomotives ST43–ST45 did not excite the first vertical bending mode shape of the deck plate. Different wheelbase of the locomotives and their weight could affect this phenomenon, as these different parameters acted as vibration dampers. The calculated values of the free vibration frequency of the structure and the corresponding acceleration amplitudes are presented in Table 4. It has been noted that the higher the vibration frequency value, the greater the difference in acceleration values generated by the same type of excitation.

The analyses discussed in the article also confirm that the influence of vehicle speed and mass on the values of structural displacements and accelerations, and, in consequence, on the stress in bridge components, is of key significance. It has been noted – simultaneously confirming the conclusions of ref. [20] – that the influence of the parameters such as vehicle wheelbase and its length also has a significant impact on the dynamic response of the object.

-

Funding information: This research received no external funding.

-

Conflict of interest: The authors declare no conflict of interest.

References

[1] Salcher P, Adam Ch. Modeling of dynamic train–bridge interaction in high-speed railways. Acta Mech. 2015;226:2473–95. 10.1007/s00707-015-1314-6.Suche in Google Scholar

[2] Zbiciak A, Ataman M, Szcześniak W. Use of the finite element method in predicting vibrations of sandwich beams and plates resting on deformable foundations subjected to moving loads. Arch Civ Eng. 2017;63:51–69. 10.1515/ace-2017-0040.Suche in Google Scholar

[3] Frýba L. Dynamics of railway bridges. London: Thomas Telford; 1996.10.1680/dorb.34716Suche in Google Scholar

[4] Frýba L. Vibration of solids and structures under moving loads. London, UK: Thomas Telford; 1999.10.1680/vosasuml.35393Suche in Google Scholar

[5] Yang YB, Yau JD, Wu YS. Vehicle-bridge interaction dynamics with applications to high-speed railway. Singapore: World Scientific; 2004.10.1142/9789812567178Suche in Google Scholar

[6] Li J, Su M. The resonant vibration for a simply supported girder bridge under high-speed trains. J Sounds Vib. 1999;224(5):897–915.10.1006/jsvi.1999.2226Suche in Google Scholar

[7] Xia H, Zhang N, Guo WW. Analysis of resonance mechanism and conditions of train-bridge system. J Sounds Vib. 2006;297(3–5):810–22.10.1016/j.jsv.2006.04.022Suche in Google Scholar

[8] Szafrański M. Dynamic analysis of the railway bridge span under moving loads. Roads Bridges. 2018;17:299–316.10.7409/rabdim.018.019Suche in Google Scholar

[9] Zobel H, Zbiciak A, Oleszek R, Michalczyk R, Mossakowski P. Numerical identification of the dynamic characteristics of a steel-concrete railway bridge. Roads Bridges. 2014;13(3):189–215. 10.7409/rabdim.014.018.Suche in Google Scholar

[10] Deng E, Weichao Y, Deng L, Zhihui Z, Xuhui H, Ang W. Time-resolved aerodynamic loads on high-speed trains during running on a tunnel–bridge–tunel infrastructure under crosswind. Eng Appl Comput Fluid Mech. 2020;14(1):202–21. 10.1080/19942060.2019.1705396.Suche in Google Scholar

[11] Weichao Y, Deng E, Mingfeng L, Zhihui Z, Pingping Z. Transient aerodynamic performance of high-speed trains when passing through two windproof facilities under crosswinds. A comparative study. Eng Struct. 2019;188:729–44.10.1016/j.engstruct.2019.03.070Suche in Google Scholar

[12] Lipecki T, Bęc J, Bosak G, Flaga A. Aerodynamic analysis of a sinusoidal footbridge for pedestrian and bicycle traffic. Roads Bridges. 2013;12(3):297–316.10.7409/rabdim.013.021Suche in Google Scholar

[13] Caprani CC, Ahmadi E. Formulation of human–structure interaction system models for vertical vibration. J Sound Vib. 2016;377:346–67.10.1016/j.jsv.2016.05.015Suche in Google Scholar

[14] Biggs JM. Introduction to structural dynamics. New York: McGraw-Hill; 1964.Suche in Google Scholar

[15] Wanming Z, Zhaoling H, Zhaowei C, Liang L, Shengyang Z. Train–track–bridge dynamic interaction: a state-of- the-art review. Veh Syst Dyn. 2019;57:984–1027. 10.1080/00423114.2019.1605085.Suche in Google Scholar

[16] Zhai WM, Sun X. A detailed model for investigating vertical interaction between railway vehicle and track. Veh Syst Dyn. 1994;23:603–15.10.1201/9781003210900-45Suche in Google Scholar

[17] Nan Z, Yuan T, He X. A train-bridge dynamic interaction analysis method and its experimental validation. Engineering. 2016;2:528–36.10.1016/J.ENG.2016.04.012Suche in Google Scholar

[18] Diachenko L, Smirnov V. Dynamic interaction of the “bridge-train” system on high-speed railways. E3S Web Conf. 2020;157:06015.10.1051/e3sconf/202015706015Suche in Google Scholar

[19] Wang D, Li X, Liang L, Qiu X. Dynamic interaction analysis of bridges induced by a low-to-medium–speed maglev train. J Vib Control. 2020;26(21–22):2013–25.10.1177/1077546320910006Suche in Google Scholar

[20] Jukowski M, Zbiciak A, Skulski B. Influence of vehicle velocity and its parameters on the bridge structure response – case study. Archives Civil Eng. 2020;66(3):265–80. 10.24425/ace.2020.134397.Suche in Google Scholar

[21] Bęc J, Jukowski M. Static and modal analysis of Solidarity Bridge in Płock. Bud i Architektura. 2016;15:177–89.10.24358/Bud-Arch_16_151_19Suche in Google Scholar

[22] Jukowski M, Błazik-Borowa E, Bęc J. Dynamic structural parameters verification on the example of theoretical analysis and in situ tests of suspension footbridge. MATEC Web Conf. 2019;262:1–7. 10.1051/matecconf/201926210007.Suche in Google Scholar

[23] Jukowski M, Bęc J, Błazik-Borowa E. Identification of the numerical model of FEM in reference to measurements in situ. AIP Conf Proc. 2018;1922:150008–42. 10.1063/1.5019161.Suche in Google Scholar

© 2021 Michał Jukowski et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Electrochemical studies of the synergistic combination effect of thymus mastichina and illicium verum essential oil extracts on the corrosion inhibition of low carbon steel in dilute acid solution

- Adoption of Business Intelligence to Support Cost Accounting Based Financial Systems — Case Study of XYZ Company

- Techno-Economic Feasibility Analysis of a Hybrid Renewable Energy Supply Options for University Buildings in Saudi Arabia

- Optimized design of a semimetal gasket operating in flange-bolted joints

- Behavior of non-reinforced and reinforced green mortar with fibers

- Field measurement of contact forces on rollers for a large diameter pipe conveyor

- Development of Smartphone-Controlled Hand and Arm Exoskeleton for Persons with Disability

- Investigation of saturation flow rate using video camera at signalized intersections in Jordan

- The features of Ni2MnIn polycrystalline Heusler alloy thin films formation by pulsed laser deposition

- Selection of a workpiece clamping system for computer-aided subtractive manufacturing of geometrically complex medical models

- Development of Solar-Powered Water Pump with 3D Printed Impeller

- Identifying Innovative Reliable Criteria Governing the Selection of Infrastructures Construction Project Delivery Systems

- Kinetics of Carbothermal Reduction Process of Different Size Phosphate Rocks

- Plastic forming processes of transverse non-homogeneous composite metallic sheets

- Accelerated aging of WPCs Based on Polypropylene and Birch plywood Sanding Dust

- Effect of water flow and depth on fatigue crack growth rate of underwater wet welded low carbon steel SS400

- Non-invasive attempts to extinguish flames with the use of high-power acoustic extinguisher

- Filament wound composite fatigue mechanisms investigated with full field DIC strain monitoring

- Structural Timber In Compartment Fires – The Timber Charring and Heat Storage Model

- Technical and economic aspects of starting a selected power unit at low ambient temperatures

- Car braking effectiveness after adaptation for drivers with motor dysfunctions

- Adaptation to driver-assistance systems depending on experience

- A SIMULINK implementation of a vector shift relay with distributed synchronous generator for engineering classes

- Evaluation of measurement uncertainty in a static tensile test

- Errors in documenting the subsoil and their impact on the investment implementation: Case study

- Comparison between two calculation methods for designing a stand-alone PV system according to Mosul city basemap

- Reduction of transport-related air pollution. A case study based on the impact of the COVID-19 pandemic on the level of NOx emissions in the city of Krakow

- Driver intervention performance assessment as a key aspect of L3–L4 automated vehicles deployment

- A new method for solving quadratic fractional programming problem in neutrosophic environment

- Effect of fish scales on fabrication of polyester composite material reinforcements

- Impact of the operation of LNG trucks on the environment

- The effectiveness of the AEB system in the context of the safety of vulnerable road users

- Errors in controlling cars cause tragic accidents involving motorcyclists

- Deformation of designed steel plates: An optimisation of the side hull structure using the finite element approach

- Thermal-strength analysis of a cross-flow heat exchanger and its design improvement

- Effect of thermal collector configuration on the photovoltaic heat transfer performance with 3D CFD modeling

- Experimental identification of the subjective reception of external stimuli during wheelchair driving

- Failure analysis of motorcycle shock breakers

- Experimental analysis of nonlinear characteristics of absorbers with wire rope isolators

- Experimental tests of the antiresonance vibratory mill of a sectional movement trajectory

- Experimental and theoretical investigation of CVT rubber belt vibrations

- Is the cubic parabola really the best railway transition curve?

- Transport properties of the new vibratory conveyor at operations in the resonance zone

- Assessment of resistance to permanent deformations of asphalt mixes of low air void content

- COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Review Articles

- FMEA method in operational reliability of forest harvesters

- Examination of preferences in the field of mobility of the city of Pila in terms of services provided by the Municipal Transport Company in Pila

- Enhancement stability and color fastness of natural dye: A review

- Special Issue: ICE-SEAM 2019 - Part II

- Lane Departure Warning Estimation Using Yaw Acceleration

- Analysis of EMG Signals during Stance and Swing Phases for Controlling Magnetorheological Brake applications

- Sensor Number Optimization Using Neural Network for Ankle Foot Orthosis Equipped with Magnetorheological Brake

- Special Issue: Recent Advances in Civil Engineering - Part II

- Comparison of STM’s reliability system on the example of selected element

- Technical analysis of the renovation works of the wooden palace floors

- Special Issue: TRANSPORT 2020

- Simulation assessment of the half-power bandwidth method in testing shock absorbers

- Predictive analysis of the impact of the time of day on road accidents in Poland

- User’s determination of a proper method for quantifying fuel consumption of a passenger car with compression ignition engine in specific operation conditions

- Analysis and assessment of defectiveness of regulations for the yellow signal at the intersection

- Streamlining possibility of transport-supply logistics when using chosen Operations Research techniques

- Permissible distance – safety system of vehicles in use

- Study of the population in terms of knowledge about the distance between vehicles in motion

- UAVs in rail damage image diagnostics supported by deep-learning networks

- Exhaust emissions of buses LNG and Diesel in RDE tests

- Measurements of urban traffic parameters before and after road reconstruction

- The use of deep recurrent neural networks to predict performance of photovoltaic system for charging electric vehicles

- Analysis of dangers in the operation of city buses at the intersections

- Psychological factors of the transfer of control in an automated vehicle

- Testing and evaluation of cold-start emissions from a gasoline engine in RDE test at two different ambient temperatures

- Age and experience in driving a vehicle and psychomotor skills in the context of automation

- Consumption of gasoline in vehicles equipped with an LPG retrofit system in real driving conditions

- Laboratory studies of the influence of the working position of the passenger vehicle air suspension on the vibration comfort of children transported in the child restraint system

- Route optimization for city cleaning vehicle

- Efficiency of electric vehicle interior heating systems at low ambient temperatures

- Model-based imputation of sound level data at thoroughfare using computational intelligence

- Research on the combustion process in the Fiat 1.3 Multijet engine fueled with rapeseed methyl esters

- Overview of the method and state of hydrogenization of road transport in the world and the resulting development prospects in Poland

- Tribological characteristics of polymer materials used for slide bearings

- Car reliability analysis based on periodic technical tests

- Special Issue: Terotechnology 2019 - Part II

- DOE Application for Analysis of Tribological Properties of the Al2O3/IF-WS2 Surface Layers

- The effect of the impurities spaces on the quality of structural steel working at variable loads

- Prediction of the parameters and the hot open die elongation forging process on an 80 MN hydraulic press

- Special Issue: AEVEC 2020

- Vocational Student's Attitude and Response Towards Experiential Learning in Mechanical Engineering

- Virtual Laboratory to Support a Practical Learning of Micro Power Generation in Indonesian Vocational High Schools

- The impacts of mediating the work environment on the mode choice in work trips

- Utilization of K-nearest neighbor algorithm for classification of white blood cells in AML M4, M5, and M7

- Car braking effectiveness after adaptation for drivers with motor dysfunctions

- Case study: Vocational student’s knowledge and awareness level toward renewable energy in Indonesia

- Contribution of collaborative skill toward construction drawing skill for developing vocational course

- Special Issue: Annual Engineering and Vocational Education Conference - Part II

- Vocational teachers’ perspective toward Technological Pedagogical Vocational Knowledge

- Special Issue: ICIMECE 2020 - Part I

- Profile of system and product certification as quality infrastructure in Indonesia

- Prediction Model of Magnetorheological (MR) Fluid Damper Hysteresis Loop using Extreme Learning Machine Algorithm

- A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters

- Facile rheological route method for LiFePO4/C cathode material production

- Mosque design strategy for energy and water saving

- Epoxy resins thermosetting for mechanical engineering

- Estimating the potential of wind energy resources using Weibull parameters: A case study of the coastline region of Dar es Salaam, Tanzania

- Special Issue: CIRMARE 2020

- New trends in visual inspection of buildings and structures: Study for the use of drones

- Special Issue: ISERT 2021

- Alleviate the contending issues in network operating system courses: Psychomotor and troubleshooting skill development with Raspberry Pi

- Special Issue: Actual Trends in Logistics and Industrial Engineering - Part II

- The Physical Internet: A means towards achieving global logistics sustainability

- Special Issue: Modern Scientific Problems in Civil Engineering - Part I

- Construction work cost and duration analysis with the use of agent-based modelling and simulation

- Corrosion rate measurement for steel sheets of a fuel tank shell being in service

- The influence of external environment on workers on scaffolding illustrated by UTCI

- Allocation of risk factors for geodetic tasks in construction schedules

- Pedestrian fatality risk as a function of tram impact speed

- Technological and organizational problems in the construction of the radiation shielding concrete and suggestions to solve: A case study

- Finite element analysis of train speed effect on dynamic response of steel bridge

- New approach to analysis of railway track dynamics – Rail head vibrations

- Special Issue: Trends in Logistics and Production for the 21st Century - Part I

- Design of production lines and logistic flows in production

- The planning process of transport tasks for autonomous vans

- Modeling of the two shuttle box system within the internal logistics system using simulation software

- Implementation of the logistics train in the intralogistics system: A case study

- Assessment of investment in electric buses: A case study of a public transport company

- Assessment of a robot base production using CAM programming for the FANUC control system

- Proposal for the flow of material and adjustments to the storage system of an external service provider

- The use of numerical analysis of the injection process to select the material for the injection molding

- Economic aspect of combined transport

- Solution of a production process with the application of simulation: A case study

- Speedometer reliability in regard to road traffic sustainability

- Design and construction of a scanning stand for the PU mini-acoustic sensor

- Utilization of intelligent vehicle units for train set dispatching

- Special Issue: ICRTEEC - 2021 - Part I

- LVRT enhancement of DFIG-driven wind system using feed-forward neuro-sliding mode control

- Special Issue: Automation in Finland 2021 - Part I

- Prediction of future paths of mobile objects using path library

- Model predictive control for a multiple injection combustion model

- Model-based on-board post-injection control development for marine diesel engine

- Intelligent temporal analysis of coronavirus statistical data

Artikel in diesem Heft

- Regular Articles

- Electrochemical studies of the synergistic combination effect of thymus mastichina and illicium verum essential oil extracts on the corrosion inhibition of low carbon steel in dilute acid solution

- Adoption of Business Intelligence to Support Cost Accounting Based Financial Systems — Case Study of XYZ Company

- Techno-Economic Feasibility Analysis of a Hybrid Renewable Energy Supply Options for University Buildings in Saudi Arabia

- Optimized design of a semimetal gasket operating in flange-bolted joints

- Behavior of non-reinforced and reinforced green mortar with fibers

- Field measurement of contact forces on rollers for a large diameter pipe conveyor

- Development of Smartphone-Controlled Hand and Arm Exoskeleton for Persons with Disability

- Investigation of saturation flow rate using video camera at signalized intersections in Jordan

- The features of Ni2MnIn polycrystalline Heusler alloy thin films formation by pulsed laser deposition

- Selection of a workpiece clamping system for computer-aided subtractive manufacturing of geometrically complex medical models

- Development of Solar-Powered Water Pump with 3D Printed Impeller

- Identifying Innovative Reliable Criteria Governing the Selection of Infrastructures Construction Project Delivery Systems

- Kinetics of Carbothermal Reduction Process of Different Size Phosphate Rocks

- Plastic forming processes of transverse non-homogeneous composite metallic sheets

- Accelerated aging of WPCs Based on Polypropylene and Birch plywood Sanding Dust

- Effect of water flow and depth on fatigue crack growth rate of underwater wet welded low carbon steel SS400

- Non-invasive attempts to extinguish flames with the use of high-power acoustic extinguisher

- Filament wound composite fatigue mechanisms investigated with full field DIC strain monitoring

- Structural Timber In Compartment Fires – The Timber Charring and Heat Storage Model

- Technical and economic aspects of starting a selected power unit at low ambient temperatures

- Car braking effectiveness after adaptation for drivers with motor dysfunctions

- Adaptation to driver-assistance systems depending on experience

- A SIMULINK implementation of a vector shift relay with distributed synchronous generator for engineering classes

- Evaluation of measurement uncertainty in a static tensile test

- Errors in documenting the subsoil and their impact on the investment implementation: Case study

- Comparison between two calculation methods for designing a stand-alone PV system according to Mosul city basemap

- Reduction of transport-related air pollution. A case study based on the impact of the COVID-19 pandemic on the level of NOx emissions in the city of Krakow

- Driver intervention performance assessment as a key aspect of L3–L4 automated vehicles deployment

- A new method for solving quadratic fractional programming problem in neutrosophic environment

- Effect of fish scales on fabrication of polyester composite material reinforcements

- Impact of the operation of LNG trucks on the environment

- The effectiveness of the AEB system in the context of the safety of vulnerable road users

- Errors in controlling cars cause tragic accidents involving motorcyclists

- Deformation of designed steel plates: An optimisation of the side hull structure using the finite element approach

- Thermal-strength analysis of a cross-flow heat exchanger and its design improvement

- Effect of thermal collector configuration on the photovoltaic heat transfer performance with 3D CFD modeling

- Experimental identification of the subjective reception of external stimuli during wheelchair driving

- Failure analysis of motorcycle shock breakers

- Experimental analysis of nonlinear characteristics of absorbers with wire rope isolators

- Experimental tests of the antiresonance vibratory mill of a sectional movement trajectory

- Experimental and theoretical investigation of CVT rubber belt vibrations

- Is the cubic parabola really the best railway transition curve?

- Transport properties of the new vibratory conveyor at operations in the resonance zone

- Assessment of resistance to permanent deformations of asphalt mixes of low air void content

- COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Review Articles

- FMEA method in operational reliability of forest harvesters

- Examination of preferences in the field of mobility of the city of Pila in terms of services provided by the Municipal Transport Company in Pila

- Enhancement stability and color fastness of natural dye: A review

- Special Issue: ICE-SEAM 2019 - Part II

- Lane Departure Warning Estimation Using Yaw Acceleration

- Analysis of EMG Signals during Stance and Swing Phases for Controlling Magnetorheological Brake applications

- Sensor Number Optimization Using Neural Network for Ankle Foot Orthosis Equipped with Magnetorheological Brake

- Special Issue: Recent Advances in Civil Engineering - Part II

- Comparison of STM’s reliability system on the example of selected element

- Technical analysis of the renovation works of the wooden palace floors

- Special Issue: TRANSPORT 2020

- Simulation assessment of the half-power bandwidth method in testing shock absorbers

- Predictive analysis of the impact of the time of day on road accidents in Poland

- User’s determination of a proper method for quantifying fuel consumption of a passenger car with compression ignition engine in specific operation conditions

- Analysis and assessment of defectiveness of regulations for the yellow signal at the intersection

- Streamlining possibility of transport-supply logistics when using chosen Operations Research techniques

- Permissible distance – safety system of vehicles in use

- Study of the population in terms of knowledge about the distance between vehicles in motion

- UAVs in rail damage image diagnostics supported by deep-learning networks

- Exhaust emissions of buses LNG and Diesel in RDE tests

- Measurements of urban traffic parameters before and after road reconstruction

- The use of deep recurrent neural networks to predict performance of photovoltaic system for charging electric vehicles

- Analysis of dangers in the operation of city buses at the intersections

- Psychological factors of the transfer of control in an automated vehicle

- Testing and evaluation of cold-start emissions from a gasoline engine in RDE test at two different ambient temperatures

- Age and experience in driving a vehicle and psychomotor skills in the context of automation

- Consumption of gasoline in vehicles equipped with an LPG retrofit system in real driving conditions

- Laboratory studies of the influence of the working position of the passenger vehicle air suspension on the vibration comfort of children transported in the child restraint system

- Route optimization for city cleaning vehicle

- Efficiency of electric vehicle interior heating systems at low ambient temperatures

- Model-based imputation of sound level data at thoroughfare using computational intelligence

- Research on the combustion process in the Fiat 1.3 Multijet engine fueled with rapeseed methyl esters

- Overview of the method and state of hydrogenization of road transport in the world and the resulting development prospects in Poland

- Tribological characteristics of polymer materials used for slide bearings

- Car reliability analysis based on periodic technical tests

- Special Issue: Terotechnology 2019 - Part II

- DOE Application for Analysis of Tribological Properties of the Al2O3/IF-WS2 Surface Layers

- The effect of the impurities spaces on the quality of structural steel working at variable loads

- Prediction of the parameters and the hot open die elongation forging process on an 80 MN hydraulic press

- Special Issue: AEVEC 2020

- Vocational Student's Attitude and Response Towards Experiential Learning in Mechanical Engineering

- Virtual Laboratory to Support a Practical Learning of Micro Power Generation in Indonesian Vocational High Schools

- The impacts of mediating the work environment on the mode choice in work trips

- Utilization of K-nearest neighbor algorithm for classification of white blood cells in AML M4, M5, and M7

- Car braking effectiveness after adaptation for drivers with motor dysfunctions

- Case study: Vocational student’s knowledge and awareness level toward renewable energy in Indonesia

- Contribution of collaborative skill toward construction drawing skill for developing vocational course

- Special Issue: Annual Engineering and Vocational Education Conference - Part II

- Vocational teachers’ perspective toward Technological Pedagogical Vocational Knowledge

- Special Issue: ICIMECE 2020 - Part I

- Profile of system and product certification as quality infrastructure in Indonesia

- Prediction Model of Magnetorheological (MR) Fluid Damper Hysteresis Loop using Extreme Learning Machine Algorithm

- A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters

- Facile rheological route method for LiFePO4/C cathode material production

- Mosque design strategy for energy and water saving

- Epoxy resins thermosetting for mechanical engineering

- Estimating the potential of wind energy resources using Weibull parameters: A case study of the coastline region of Dar es Salaam, Tanzania

- Special Issue: CIRMARE 2020

- New trends in visual inspection of buildings and structures: Study for the use of drones

- Special Issue: ISERT 2021

- Alleviate the contending issues in network operating system courses: Psychomotor and troubleshooting skill development with Raspberry Pi

- Special Issue: Actual Trends in Logistics and Industrial Engineering - Part II

- The Physical Internet: A means towards achieving global logistics sustainability

- Special Issue: Modern Scientific Problems in Civil Engineering - Part I

- Construction work cost and duration analysis with the use of agent-based modelling and simulation

- Corrosion rate measurement for steel sheets of a fuel tank shell being in service

- The influence of external environment on workers on scaffolding illustrated by UTCI

- Allocation of risk factors for geodetic tasks in construction schedules

- Pedestrian fatality risk as a function of tram impact speed

- Technological and organizational problems in the construction of the radiation shielding concrete and suggestions to solve: A case study

- Finite element analysis of train speed effect on dynamic response of steel bridge

- New approach to analysis of railway track dynamics – Rail head vibrations

- Special Issue: Trends in Logistics and Production for the 21st Century - Part I

- Design of production lines and logistic flows in production

- The planning process of transport tasks for autonomous vans

- Modeling of the two shuttle box system within the internal logistics system using simulation software

- Implementation of the logistics train in the intralogistics system: A case study

- Assessment of investment in electric buses: A case study of a public transport company

- Assessment of a robot base production using CAM programming for the FANUC control system

- Proposal for the flow of material and adjustments to the storage system of an external service provider

- The use of numerical analysis of the injection process to select the material for the injection molding

- Economic aspect of combined transport

- Solution of a production process with the application of simulation: A case study

- Speedometer reliability in regard to road traffic sustainability

- Design and construction of a scanning stand for the PU mini-acoustic sensor

- Utilization of intelligent vehicle units for train set dispatching

- Special Issue: ICRTEEC - 2021 - Part I

- LVRT enhancement of DFIG-driven wind system using feed-forward neuro-sliding mode control

- Special Issue: Automation in Finland 2021 - Part I

- Prediction of future paths of mobile objects using path library

- Model predictive control for a multiple injection combustion model

- Model-based on-board post-injection control development for marine diesel engine

- Intelligent temporal analysis of coronavirus statistical data