Abstract

The article concerns the study on multidirectional drape and bending rigidity of six wool (clothing) fabrics with two types of adhesive inserts. The aim of research was to investigate the effect of joining woolen fabrics with “Freudenberg Vilene” adhesive inserts on the bending rigidity and multidirectional drape. The adhesive inserts were differentiated according to mass per square meter, while the fabrics were differentiated according to thickness, weave, and mass per square meter. Based on the scientific literature, the issues related to the methods of testing the bending rigidity and multidirectional drape coefficient were discussed. All the conducted tests were aimed at the proper selection of adhesive inserts for the designed clothing products. The use of adhesive inserts affects the bending stiffness and multidirectional drapeability of clothing material. The fabric weave significantly affects the values of bending rigidity and drapeability. As the thickness of adhesive inserts increases, the overall bending rigidity increases. The greater the fabric mass per square meter, the stiffer the fabric. As the mass per square meter and thickness increase, the multidirectional rigidity of fabrics increases. The value of bending rigidity for the plain fabric is higher compared to twill fabric.

1 Introduction

The bonding of garment components with adhesive inserts has been indispensable in the practice of the apparel industry for many years. Over the years there has been noticed a development and specialization in all fields related to gluing (in the production of adhesive inserts, thermoplastic agents, and technical equipment). The technology of gluing requires knowledge of basic relationships between the parameters of gluing and the properties of glued parts. Manufacturers pay special attention to the selection of appropriate adhesive inserts for the type of assortment produced and the type of material used. The basic factors determining the quality of the adhesive joint, and consequently, the finished clothing product are the selection of the right type of adhesive insert for the surface material, the selection of optimal parameters of gluing process, and good technical condition of gluing presses [1].

Adhesive inserts are understood to be flat textile products, to which a thermoplastic agent has been permanently applied in one of the possible ways, making it possible, when heated to an appropriate temperature and under appropriate pressure, to adhere to the surface material [1]. The basic properties of adhesive inserts depend primarily on the properties of the outer material, the type of thermoplastic agent, the geometric distribution, and the shape of the glue dots on the adhesive insert surface.

Materials combined with adhesive inserts vary in terms of raw material composition, manufacturing technology, mass per square meter, construction, and surface finishing. Outerwear inserts are the most diverse group. They can be produced by weaving, knitting, or nonwoven techniques with different masses per square meter depending on its purpose. Synthetic adhesives of a thermoplastic nature are the most useful for clothing [2]. The ideal thermoplastic agent must be inexpensive, suitable for all application methods and all face materials, and provide good bonds resistant to maintenance treatments. Such a universal agent has not yet been invented. Fabrics made of natural silk or with the addition of silk yarns, materials with unstable shrinkage, materials that are not resistant to the pressures used in the bonding process, materials printed or dyed with dyes that are easily sublimated, and materials with a very loose structure are not suitable for backing [3].

Flexural stiffness is an important property of textile materials, especially regarding the comfort of the clothing wearer. In addition, it influences the aesthetic effect of the garment’s use and, most importantly, its fit to the wearer’s body [4]. In the case of clothing fabrics, their stiffness (rigidity) is strongly related to the fabric’s ability to make folds [5]. The bending properties of fabrics are determined by the bending yarn behavior, the fabric weave, and the finishing method [6].

Kim and Takatera [7] conducted research on the effect of adhesive means on the shear stiffness of laminated fabrics bonded with the adhesive fleece. They studied the shear rigidity of face fabrics with different weave densities and adhesive inserts. It was observed that the value of shear rigidity of adhesive inserts and the laminated fabric increases with the increase of adhesive insert mass per square meter.

Testing fabric bending rigidity is a complex issue due to the mechanical properties and the interaction between the component yarns [8,9]. The fabric bending rigidity is one of the very important parameters that influence comfort of wearing clothes. Starting with Peirce’s research [10] in 1930, the bending behavior of fabrics was studied very thoroughly. However, bending rigidity is one of the most important fabric properties and is an important factor influencing hand [11]. Moreover, it significantly affects the fabric deformability resistance to wrinkling and crushing [12]. Bending knowledge is very useful, when trying to automate out-of-plane manipulation processes. Abbott et al. [13] found that due to the pressures at the intersection points, the yarn is composed of alternating flexible and stiff sections. Therefore, they assumed that the yarn was arranged in straight lines [13,14,15]. Grosberg et al. [15,16] found that the behavior of fabric during bending is non-linear and that it is divided into two components: frictional resistance and bending rigidity.

Sadeghi et al. [11] also carried out a survey about the influence of fabric weave on bending rigidity. They studied the bending rigidity of woven fabric with different twill (1/2, 1/3, 1/4, 1/5) and plain structures using an energy method. The obtained results of bending rigidity show that the plain weave causes the higher values of bending rigidity compared to twill samples, because of very close yarn intersections.

Matusiak [4] studied and evaluated the bending rigidity of Seersucker fabrics. She tested nine variants of seersucker fabrics, which differed primarily in the type of weft yarn (different linear density of weft yarn). Flexural stiffness was measured using two measurement methods: the Peirce method (fabric stiffness tester) and the MOO3F digital pneumatic stiffness tester. Based on the results, an analysis of the effect of weft yarn linear density on stiffness parameters determined by the two methods was carried out. The obtained results confirmed that the linear density of weft yarn affects the bending rigidity of fabrics determined by both test methods used.

The purpose of the research carried out was to study the effect of combining wool fabrics with different adhesive inserts from “Freudenberg Vilene” on the bending rigidity and multidirectional drape (the properties important, when the clothing is designed). The adhesive inserts were differentiated by the mass per square meter only, while the wool fabrics were differentiated by the mass per square meter, thickness, and weave.

2 Materials

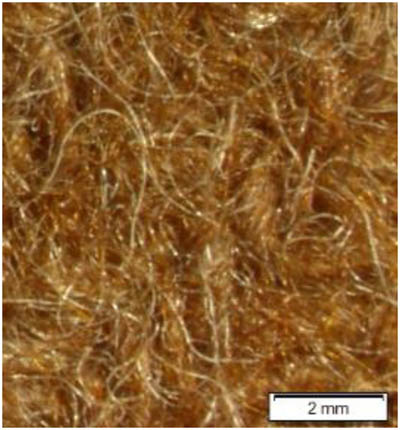

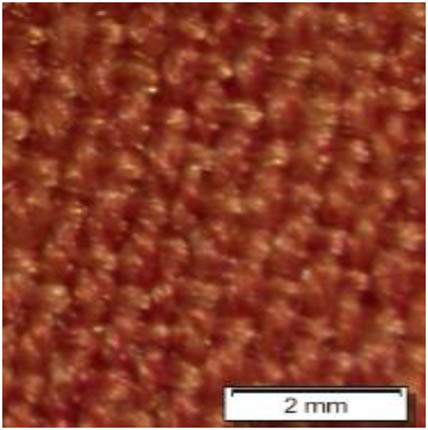

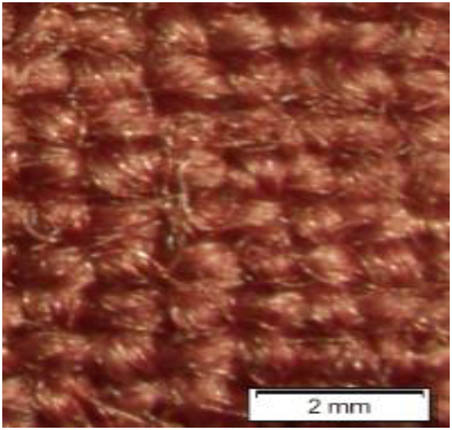

Six fabrics were selected for the study. All fabrics used in the tests were made of 100% wool. They differed in surface weight, thickness, and weave. Their parameters are given in Table 1.

Characteristics of selected fabrics

| Name | Fabric I | Fabric II | Fabric III |

|---|---|---|---|

| Photo |

|

|

|

| Mass per square meter (g/m2) | 345 | 316 | 316 |

| Thickness (mm) | 1.80 | 1.30 | 1.12 |

| Weave | Twill | Plain | Twill |

| Name | Fabric IV | Fabric V | Fabric VI |

|---|---|---|---|

| Photo |

|

|

|

| Mass per square meter (g/m2) | 261 | 236 | 221 |

| Thickness (mm) | 0.78 | 0.69 | 0.72 |

| Weave | Plain | Twill | Plain |

Two adhesive inserts were selected for testing. The first was designated BVM 60, while the second was BVM 80. The adhesive inserts for testing were provided by “Freudenberg Vilene Sp. z o. o.” (Lodz, Poland). The adhesive inserts used differed in mass per square meter and thickness. BVM 60 had a mass per square meter of 66.80 g/m2 and a thickness of 0.30 mm, while the BVM 80 adhesive insert showed a mass per square meter 84.00 g/m2 and a thickness of 0.32 mm. Both inserts were made with the plain weave from polyester yarns: they were characterized by a black color, the spread of adhesive points was 52 d/cm2 (dots/cm2), and the raw material of adhesive points was polyamide.

The parameters for fixing adhesive joints are: temperature − 124°C, time – 14.0 s, and pressure – 0.3 MPa.

3 Methods

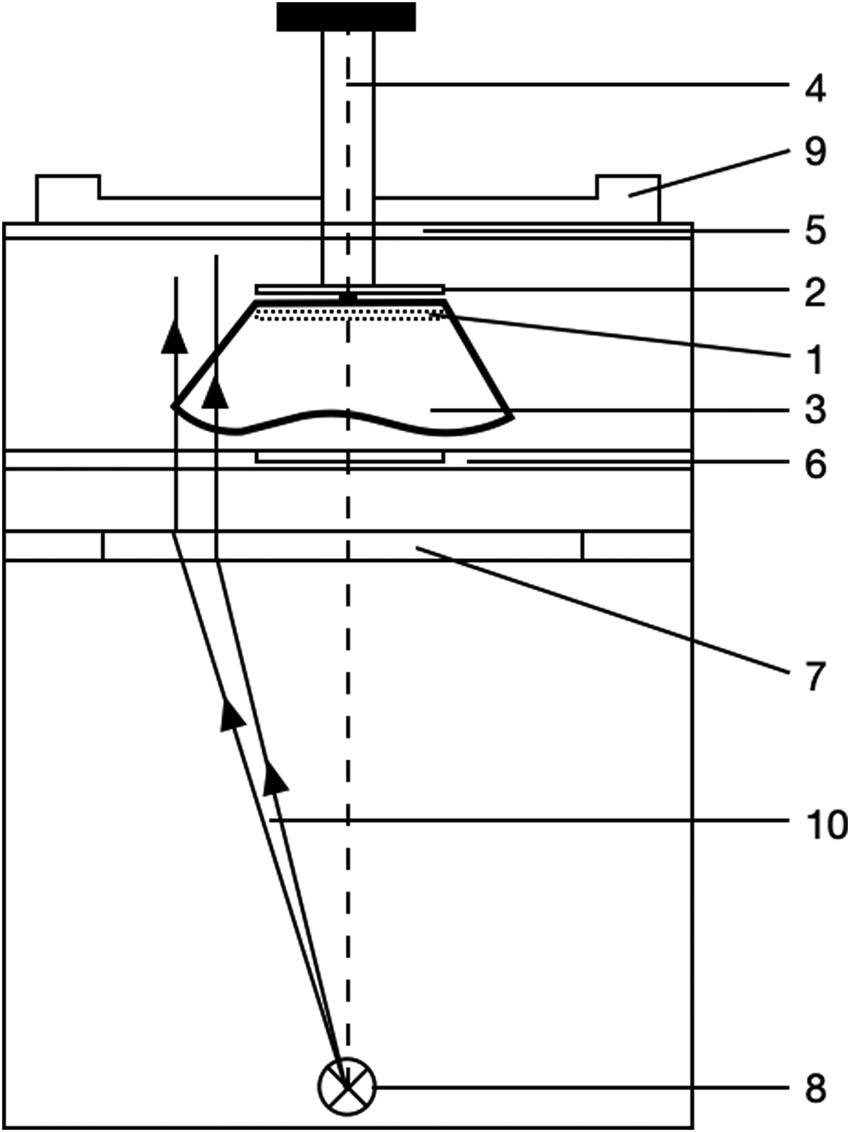

3.1 Determination of drape coefficient according to PN-ISO 9073-9:2008 [17]

The instrument shown in Figure 1 consists of movable plate 6, a support plate 1, pressure disc 2, movable pin 4, light source 8, lens 7, test specimen 3, screen 5, and frame 9. To carry out the test, three specimens with a diameter of 200 mm each are cut from the fabric at a distance from the edges of the fabric. A circle with a radius of 70 mm is marked on the right sides of the samples. The sample center and the circle center must coincide.

Device for the multidirectional drape measurement (own source).

A measure of multidirectional drape is the drape coefficient Ku. It is calculated as the quotient of the difference between the sample area and its projection area and the overhanging sample area. The Ku coefficient is expressed as a percentage and can range from 0 to 100%. For rigid products, it will be closer to 0%, while for flexible products, it will be close to 100%. After the measurements are taken, the following data are calculated:

where: S i is the planimetric projection area of the ith sample, m2 and n is the number of samples.

Mutidirectional drape coefficient K u:

where: r 1 is the radius of the support disc, m; r is the radius of the specimen, m; S is the mean value of the projection area of tested samples, m2.

3.2 Determination of the bending rigidity – Peirce’s method

The bending length was determined for each fabric by Peirce’s method (Figure 2) according to PN-ISO 9073-9:2008 [17]. Five samples were tested for each fabric. The samples were cut from the fabric in the longitudinal and transverse directions. The strips were (30 mm wide and 300 mm long) [18].

![Figure 2

Scheme of measurement by the Cantilever Stiffness Tester: L is the length of overhang; 1, gauge, 2, fabric sample [own source].](/document/doi/10.1515/aut-2024-0014/asset/graphic/j_aut-2024-0014_fig_002.jpg)

Scheme of measurement by the Cantilever Stiffness Tester: L is the length of overhang; 1, gauge, 2, fabric sample [own source].

Measurements were taken for the right and left sides of the sample in two directions – weft and warp. Then the bending rigidity B in the one direction was calculated according to formula (3); C bending length was determined according to formula (4), whereas the general bending stiffness B j was calculated according to formula (5). The test was conducted under normal climate conditions.

As a result, the final formula for determining bending rigidity took the form:

where: g is the earth acceleration, and W is the fabric mass per square meter.

where: C is the bending length, and L is the overhang length of sample, mm.

The general fabric bending rigidity (5) is calculated as follows:

where: B w is the bending rigidity in the weft direction and B o is the bending rigidity in the warp direction.

4 Results and discussion

Experimental tests were aimed at determining the bending rigidity and multidirectional drape for six fabrics. These parameters were determined for fabrics without and with two adhesive inserts. The fabrics were combined with adhesive inserts in such a way that the fabric warp was parallel to the adhesive insert warp.

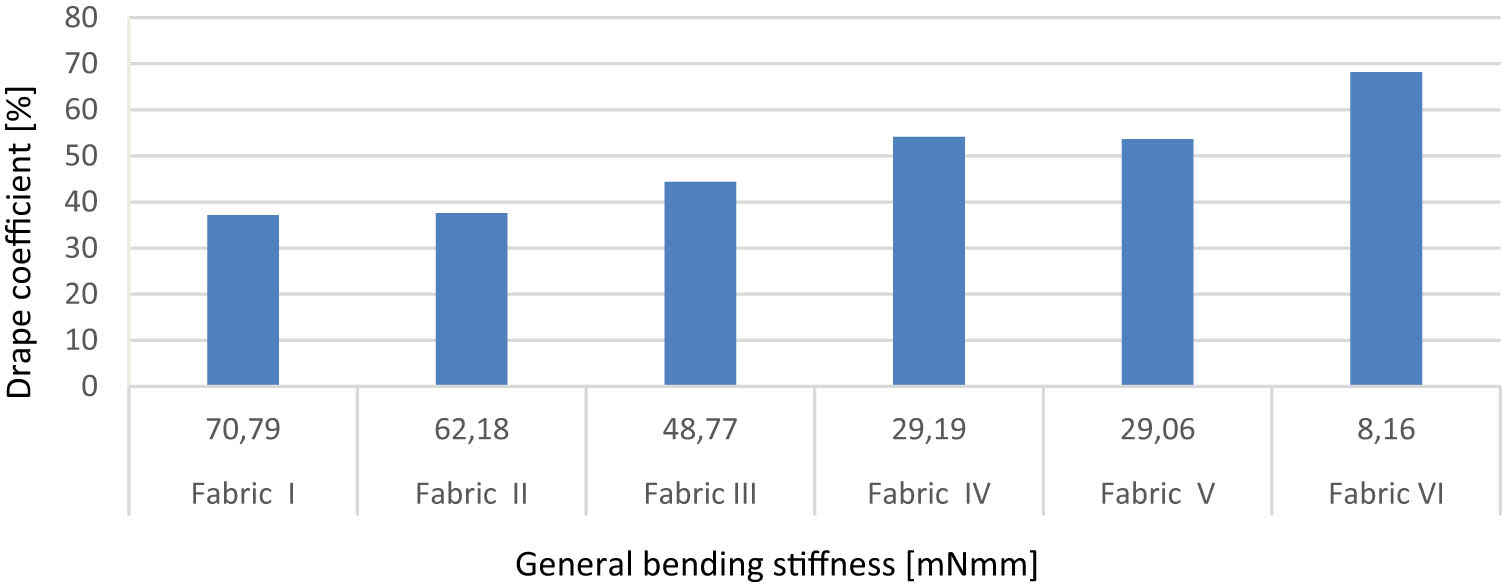

The obtained results of the drape coefficient for the six selected fabrics in the version without adhesive inserts and the use of adhesive inserts (designated BVM 60 and BVM 80) are shown in Figure 3.

The values of fabric drape parameter.

It can be seen from the above chart that among the fabrics without adhesive inserts, fabric VI has the highest value of drape coefficient, and fabric I – the lowest one. Among fabrics with BVM 60 and BVM 80 underlining, fabric VI has the highest value of drape coefficient, and fabric I also has the lowest. From the results, it can be concluded that the value of the drape coefficient decreases with the fabric thickness increase. The fabrics characterized by the greatest thickness obtain the lowest values of the drape coefficient. As the thickness increases, the value of the drape coefficient decreases, and the same relationship occurs for the fabric mass per square meter – the higher the value of mass per square meter, the lower the value of drape coefficient.

The obtained results of general bending rigidity for the six selected fabrics in the version without adhesive inserts and with the use of adhesive inserts (marked BVM 60 and BVM 80) are shown in Figure 4.

Comparison of all values of general bending rigidity.

The highest value of bending rigidity was shown by fabric I, and the lowest by fabric VI in all tested variants, i.e., without and with adhesive inserts in both variants. The use of an adhesive insert causes an increase in bending rigidity values. The greater the mass per square meter and thickness of the adhesive insert used, the higher the value of unit bending rigidity.

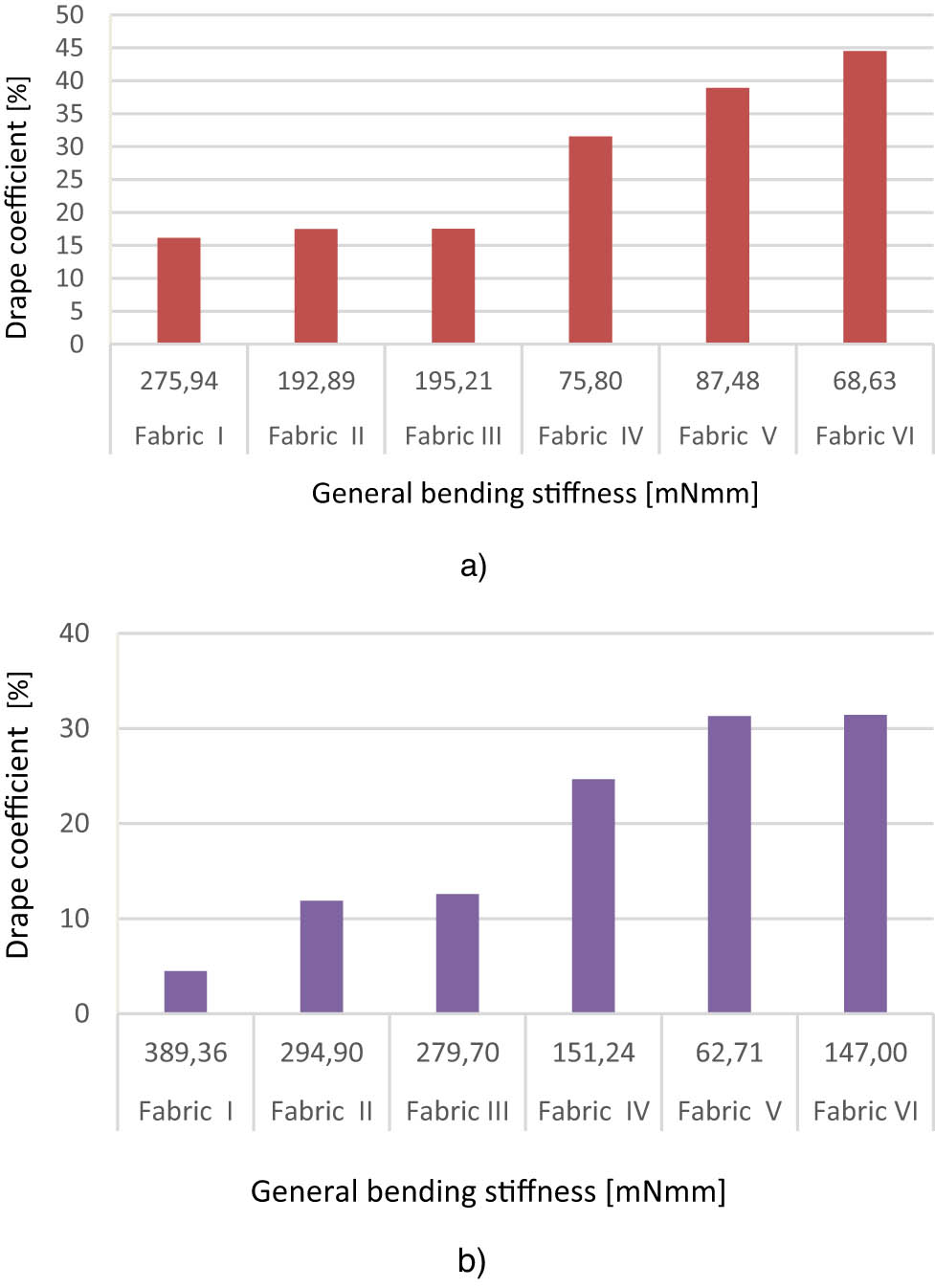

Figures 5 and 6 show the relationship between the general bending rigidity and the drape coefficient for fabrics without and with the use of BVM 60 and BVM 80 adhesive inserts.

Relationship between the general bending rigidity and a drape coefficient for fabrics without the adhesive inserts.

Relationship between the general bending rigidity and drape coefficient for the adhesive inserts: (a) BVM 60 and (b) BVM 80.

Figure 5 shows that as the general bending rigidity increases, the drape coefficient decreases. Only fabrics IV and V show slight differences in the value of the drape coefficient. Fabric V shows a lower value compared to fabric IV, although fabric V has a lower general bending rigidity value. This is due to the lower thickness and mass per square meter of fabric V (236 g/m2 and 0.69 mm) compared to fabric IV (261 g/m2 and 0.78 mm).

The presented results confirm that as the general bending rigidity increases, the drape coefficient decreases. This statement is true for all variants of adhesive inserts. As visible in the graph (Figure 6), the large difference in the drape coefficient occurring between fabrics III and IV is due to the significant difference in thickness and surface weight of the fabrics. It should also be considered that fabric III is characterized by a twill weave, while fabric IV has a plain weave.

5 Conclusions

Tests were carried out to determine the multidirectional drape coefficient and bending rigidity for six fabrics with and without the adhesive inserts BVM 60 and BVM 80. The following conclusions were drawn out:

With the use of thicker and thicker adhesive inserts, the general bending rigidity increases.

The value of general bending rigidity depends mainly on the fabric mass per square meter. The greater the fabric mass per square meter, the stiffer the fabric. The same relationship occurs for the thickness.

As the mass per square meter and thickness increases, the multidirectional drape of fabrics decreases.

Type of fabric weave affects the bending rigidity and drape coefficient. For plain fabrics, the drape coefficient is lower compared to the twill fabric with the same mass per square meter. The value of bending rigidity for the plain fabric is higher compared to the twill fabric.

The market offers a very wide range of fabrics. Parameters of multidirectional drape and bending rigidity are particularly important to determine the fabric behavior in each clothing product. Knowledge about these parameters is important in the phase of material designing of clothing.

Clothing production requires the use of adhesive inserts in places exposed to deformation or requiring stiffening, e.g., in cuffs and pockets. The adhesive insert should be selected appropriately to the material used, the intended use of the product, and the design assumption.

The purpose of combining material with adhesive inserts is to increase the bending rigidity in specific places of the clothing product. As a result, using such a product is more comfortable and it will look better, which is translated into overall human satisfaction with the use of such clothing.

-

Funding information: Authors state no funding involved.

-

Author contributions: IF and MS designed the experiments and MS carried them out. PM and IF prepared the manuscript with contributions from all co-authors. PM created the graphics for the article.

-

Conflict of interest: Authors state no conflict of interest.

References

[1] Zhang, Q., Kan, C. W. (2018). A review of fusible interlinings usage in garment manufacture. Polymers, 10, 1230.10.3390/polym10111230Search in Google Scholar PubMed PubMed Central

[2] Cagle C. V. (1977). Adhesives and bonding – an engineer’s and technician’s handbook, WNT, Warsaw. (in Polish).Search in Google Scholar

[3] Frydrych, I., Dziworska, G., Cieślińska, A. (1999). Influence of mechanical parameters of fabrics on their shapability. Part 2 Textile Review, 6, 11–15. (in Polish).Search in Google Scholar

[4] Matusiak, M. (2021). Evaluation of the bending stiffness of seersucker woven fabrics. Fibres & Textiles in Eastern Europe, 29(2(146)), 30–35.10.5604/01.3001.0014.6078Search in Google Scholar

[5] Matusiak, M. (2017). Influence of the structural parameters of woven fabrics on their drapeability. Fibres & Textiles in Eastern Europe, 25(1(121)), 56–64.10.5604/12303666.1227883Search in Google Scholar

[6] Özçelik Kayseri, G., Özdil, N., Süpüren Mengüç, G. (2012). Sensorial comfort of textile materials. In: Jeon, H. Y. (Ed.). Woven fabrics, InTech, Rijeka, pp. 235–265.Search in Google Scholar

[7] Kim, K. O., Takatera, M. (2012). Effects of adhesive agent on shear stiffness of fabrics bonded with adhesive interlining. Journal of Fiber Bioengineering & Informatics, 5(2), 151–162.10.3993/jfbi06201204Search in Google Scholar

[8] Fatahi, I., Yazdi, A. A. (2010). Assessment of the relationship between air permeability of woven fabrics and its mechanical properties. Surfaces, Fibres & Textiles in Eastern Europe, 83(6), 68–71.Search in Google Scholar

[9] Syerko, E., Comas-Cardona, S., Binetruy, C. (2012). Experimental characterization and modeling of bending properties of woven fibrous preforms. Key Engineering Materials, 504, 277–282.10.4028/www.scientific.net/KEM.504-506.277Search in Google Scholar

[10] Peirce, F. (1930). The handle of cloth as a measurable quantity. Journal of the Textile Institute, 21(9), 39.10.1080/19447023008661529Search in Google Scholar

[11] Sadeghi, M. R., Jeddi, A. A., Shaikhzadeh Najar, S. (2017). Theoretical and experimental analysis of bending rigidity of plain and twill woven fabrics. The Journal of The Textile Institute, 108(10), 1700–1706.10.1080/00405000.2017.1280760Search in Google Scholar

[12] Merati, A., Patir, H. (2011). Anisotropy in wrinkle properties of woven fabric. The Journal of The Textile Institute, 102(7), 639–646.10.1080/00405000.2010.507951Search in Google Scholar

[13] Abbott, N., Coplan, M., Platt, M. (1960). Theoretical considerations of bending and creasing in a fabric. Journal of the Textile Institute Transactions, 51(12), 13.10.1080/19447026008662571Search in Google Scholar

[14] Abbott, G. M., Gorsberg, P., Leaf, G. A. V. (1973). The elastic resistance to bending of plain-woven fabrics. Journal of Textile Institute, 64(6), 24.10.1080/00405007308630257Search in Google Scholar

[15] Grosberg, P., Swani, N. (1966). The mechanical properties of woven fabric – Part IV: The determination of the bending rigidity and frictional restraint in woven fabrics. Textile Research Journal, 36, 7.10.1177/004051756603600406Search in Google Scholar

[16] Grosberg, P., Kedia, S. (1966). The mechanical properties of woven fabrics: Part I: The initial load extension modulus of woven fabrics. Textile Research Journal, 36(8), 71–79.10.1177/004051756603600109Search in Google Scholar

[17] PN-ISO 9073-9 Textiles. (2008). Test methods for nonwovens. Determination of drape coefficient. ISO, Geneva, Switzerland.Search in Google Scholar

[18] Dziworska, G. (2004). Review of models, systems and methods of measuring bending stiffness of flat textile products. Textile Review, 8, 40–43.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry