Abstract

Most of the sports underwear available is sewn using cutting and sewing techniques. During the exercise process, it is easy to cause discomfort to the skin due to repeated friction at the seam, and at the same time, it is also a waste of manpower and raw material costs. In order to address these issues present in existing sports underwear, during its design and development, combined with fully forming knitting technology, construction process model, so as to realize the integrated knitting of sports underwear. First of all, through the characteristics of the local style of sports underwear, the key points of its prototype were probed. Second, on this basis, its process model was established, including the forming methods and knitting rules of the body, shoulder collar, and bottom circumference. Finally, the feasibility of the technological model is proved by the braiding of a fully formed sports underwear. The change in the body size can be achieved by using the two-side braiding transfer method. The curve contour of the shoulder and neck can be obtained by using the triangular polyline segmentation method. The bottom part is divided into a cylinder part and a supporting part. The local braiding method is used to achieve the knitting. This study puts forward a process model and application method of fully formed sports underwear, which provides a certain method and reference for the design and production of fully formed sports underwear.

1 Introduction

Sports underwear, as the name suggests, refers to a kind of underwear especially suitable for women to wear during sports occasions. The original intention of its design is to avoid women’s chest injury in sports. Compared with ordinary underwear, it is more functional and can play a role in fixing and protecting the chest. In the existing sports underwear, most of them are stitched by cutting and sewing technology. Such products are easy to cause skin damage due to repeated friction at the seams in the process of movement, and also, it consumes a lot of labor and raw material costs in the production process. There are also some sports underwear with close-fitting and trackless function, such as weft knitted and warp knitted seamless underwear, which adopt one-molding knitting technology and obtain seamless underwear with high comfort. However, weft knitted seamless underwear is limited by the mechanical structure of circular machine and has problems such as small size change and poor shape conformal, while warp knitted seamless underwear has limitations such as high raw material requirements and few color changes. In addition, there are examples from Ubars®, which use traceless tailoring and gluing techniques, but cannot avoid the high cost and low efficiency of the cutting and gluing process. Horizontal braid full forming technology is widely used in the industry because it can make up for the problems encountered in the development of sports underwear.

Existing research on fully forming technology is common in the principle of fully forming knitting [1] and product development [2,3]. There are also some research works on the construction of full forming clothing process model [4,5], but there are only a few research works on the combination of full forming technology and sports underwear. Fully formed sports underwear is formed in one body without cutting and stitching, which can reduce the production cost caused by raw materials and labor in the production process. At the same time, the style is changeable, which can achieve true fit and beautiful. Combined with different organizational structures and raw materials, the overall sports underwear can be evenly stressed, stable, and tight, providing women with a better sportswear experience.

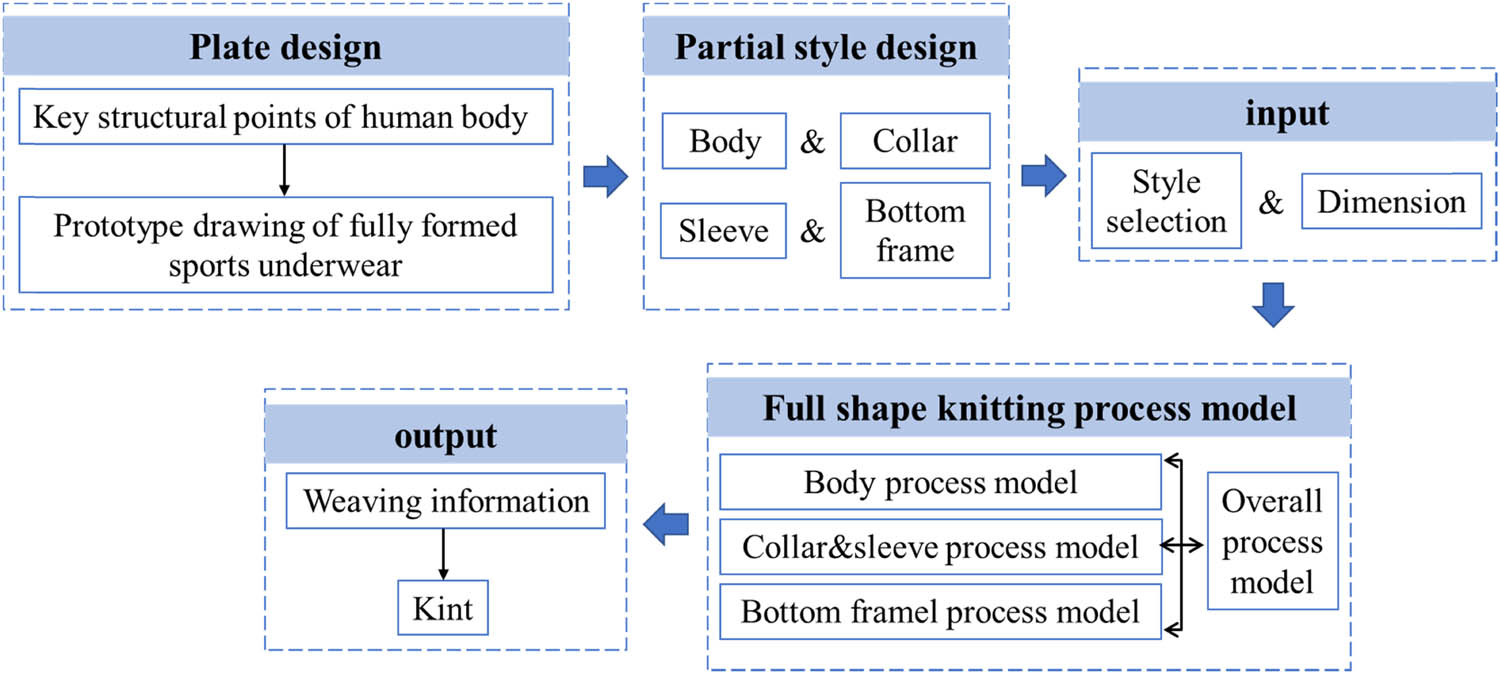

Therefore, based on key structural points of the female upper torso and the forming principle of four-needle bed computer flat knitting machine, this study obtains the prototype plate of fully formed sports underwear and constructs the process model of each part of fully formed sports underwear according to the style design of fully formed sports underwear. Finally, taking a typical fully formed sports underwear as an example, its forming process is analyzed. The feasibility of the process model is verified, in order to provide a certain theoretical reference for the process design and development practice of sports underwear under the fully formed technology. The overall design process is shown in Figure 1.

The overall design process of fully formed sports underwear.

2 Materials and method

2.1 Materials

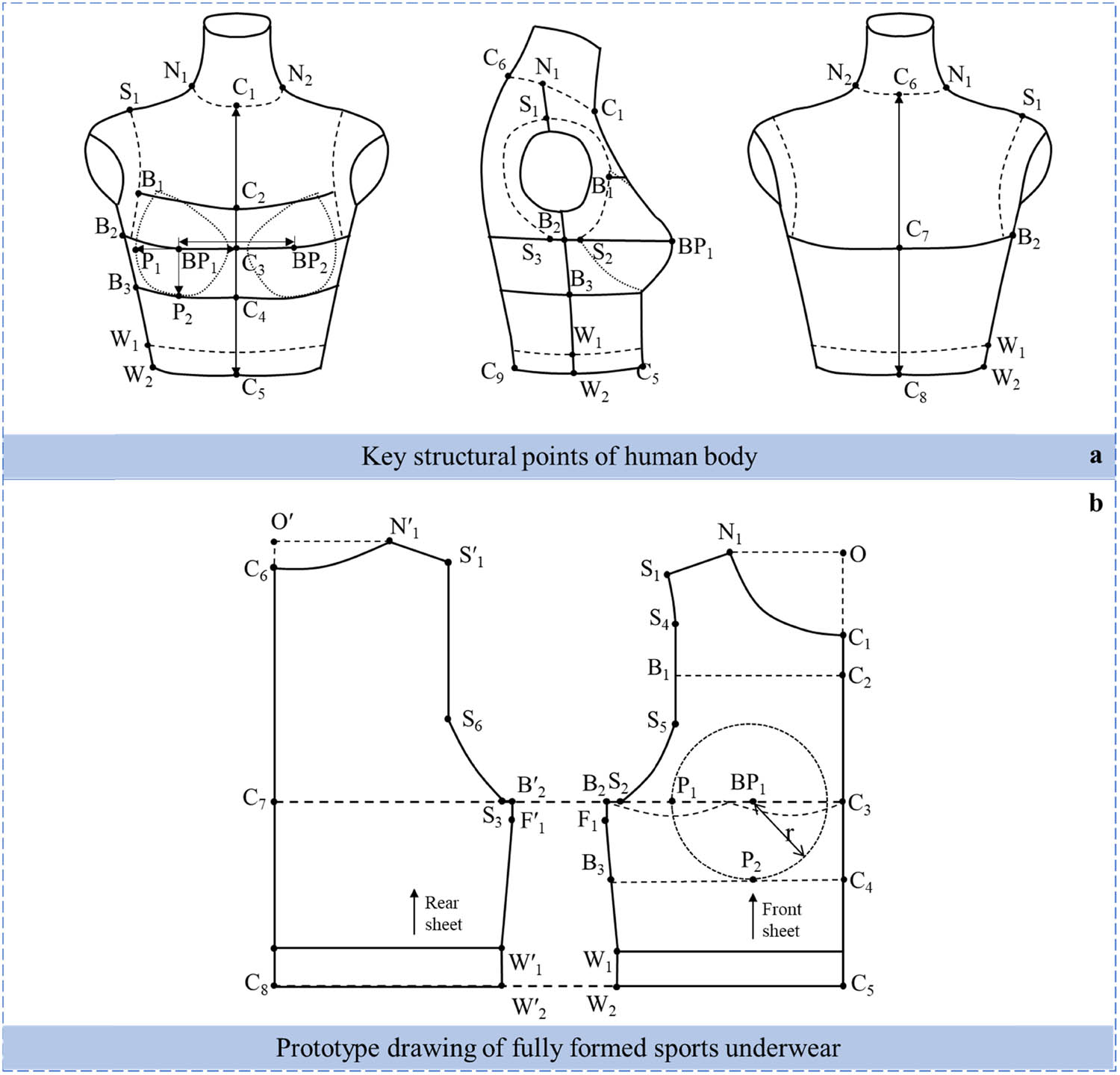

The key dimensions of female chest morphology include chest circumference, chest point spacing, chest point to heart position, chest point to comparison position, chest height to chest base position, etc. [6]. Therefore, in the design of fully formed sports underwear, the above sizes, front, middle length, back length, and waist circumference are taken as the key dimensions of human body [7]. Figure 2a shows the key structural points of human body. Among them, breast point interval (BP1BP2) refers to the horizontal distance between the two breast points; chest point to heart position (BP1C3) refers to the arc distance from the top of the chest to the front center line; breast point to comparison (BP1P1) refers to the arc distance from the breast peak to the side breast; high chest to base chest (BP1P2) refers to the arc distance from high chest to base chest [8]. On the basis of relevant key points, combined with the drawing method of knitted full-formed clothing [9] and supplemented relevant points, the complete full-formed sports underwear prototype plate is obtained, as shown in Figure 2b, and the corresponding key parts are shown in Table 1. In the actual product development process, if there are no special requirements, Chinese national standard sizes can be used, otherwise tailoring can be carried out.

Structure diagram of fully formed sports underwear. (a) Key structural points of human body and (b) prototype drawing of fully formed sports underwear.

Key parts of fully formed sports underwear prototype

| Key parts | Front sheet | Rear sheet |

|---|---|---|

| Length | C1C5 | C6C8 |

| Neck drop | OC1 | O′C6 |

| Neck width | ON1 | O′N′1 |

| Chest (back) width | B2C3 | B′2C7 |

| Upper chest width | 2B1C2 | / |

| Lower chest width | 2B3C4 | / |

| Hem length | W1W2 | W′1W′2 |

| Waist width/hem width | W2C5 | W′2C8 |

| Curved part of armhole | S1S4、S5S2 | S3S6 |

| Straight part of armhole | S4S5 | S′1S6 |

| Underarm flat width | B2S2 | B′2S3 |

In addition, in the process of drawing, the calculation relationship between the size of the output plate and the number of knitting needles and the number of knitting lines should be taken into account [10,11], according to the formula:

The conversion relationship between the size of the plate and the number of knitting stitches can be obtained. In the formula, A and B, respectively, represent the number of transverse knitting needles and the number of longitudinal knitting rows in the knitted plate; a and b, respectively, represent the transverse and longitudinal dimensions of the actual plate; and ρ a and ρ b , respectively, represent the transverse and longitudinal density of the knitted fabric. Before calculating the number of stitches, it is necessary to test knit fabric samples in advance to determine the transverse and longitudinal density of the fabric. Finally, according to the actual situation, the braided plate is fine-tuned to make it conform to the principle of flat knitting machine [12,13].

2.2 Method

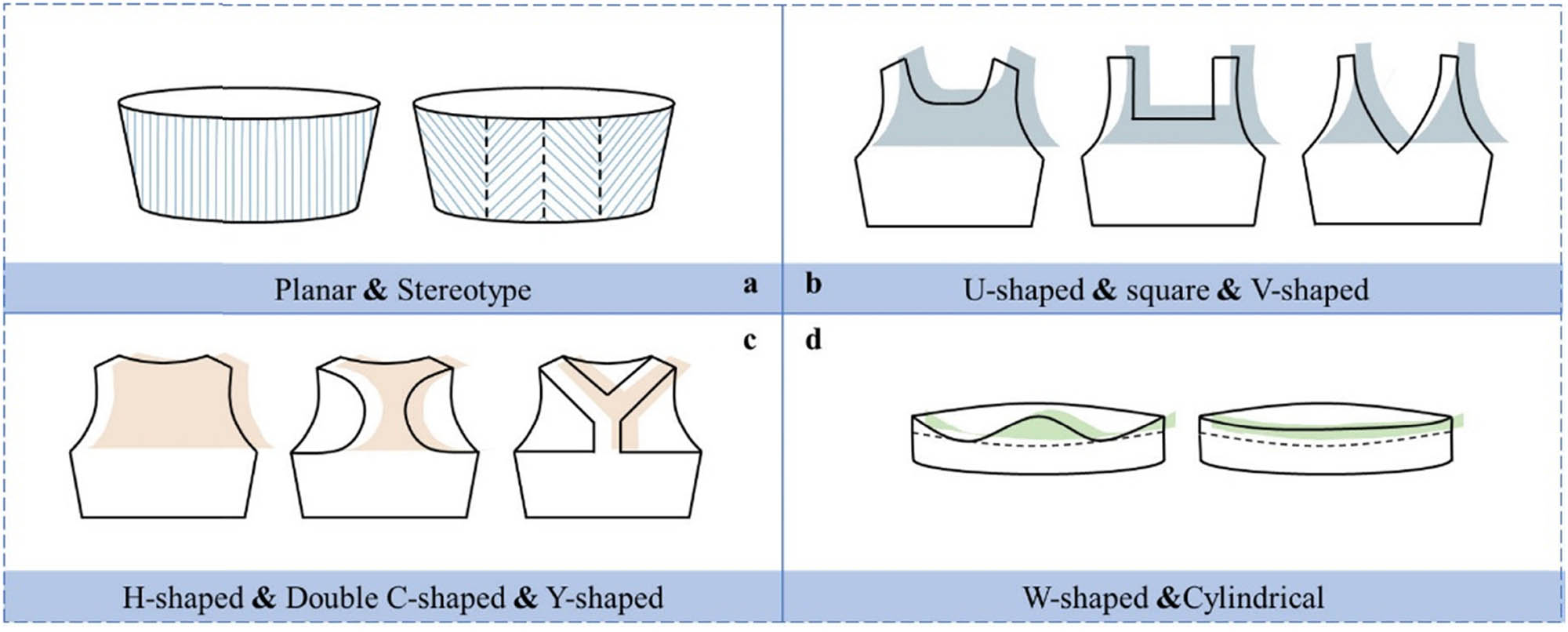

Fully formed sports underwear can be divided into three categories according to the corresponding exercise intensity: low intensity, medium intensity, and high intensity. Its style structure design [14] is divided into body part, collar part, sleeve part, and bottom circumference.

The body of sports underwear can be divided into flat type and vertical type according to whether it has darts, as shown in Figure 3a. The flat type has simple and elegant design, simple knitting process, but weak support for the chest, which is suitable for low intensity exercise. The vertical body shape design has a high fit with the human body and can provide better support for the chest, suitable for medium and high intensity exercise [15].

Fully formed sports underwear local style design. (a) Body, (b) neck, (c) sleeve, and (d) bottom circumference.

According to the wearing characteristics of sports underwear, the collar style should be a simple collar with only a linear collar socket but no collar seat or collar piece, as shown in Figure 3b, U-neck, square neck, and V-neck. The U-collar has the largest contact area with the skin and can provide greater support for the chest. It is generally used for high intensity exercise. Square and V-necks have better air permeability and more varied styles, which can be used for medium and low intensity exercise.

The cuff should be shaped with armhole arcs but no sleeves. As shown in Figure 3c, the rotator cuff can be divided into H, double C, and Y shapes according to the armhole arcs of the back piece [16]. Type H has the largest contact area with the back and has the best support and protection. It is suitable for high intensity exercise. The second is double C type, which is used for medium intensity exercise. The Y model is more breathable but not as supportive as the first two, so it is used in low intensity exercise.

As shown in Figure 3d, the bottom styles are divided into W type and cylinder type. W type adds a supporting part on the basis of cylinder type, which can provide better support for the chest. It is suitable for sports underwear of all strengths.

3 Process model of fully formed sports underwear

3.1 Body forming process model

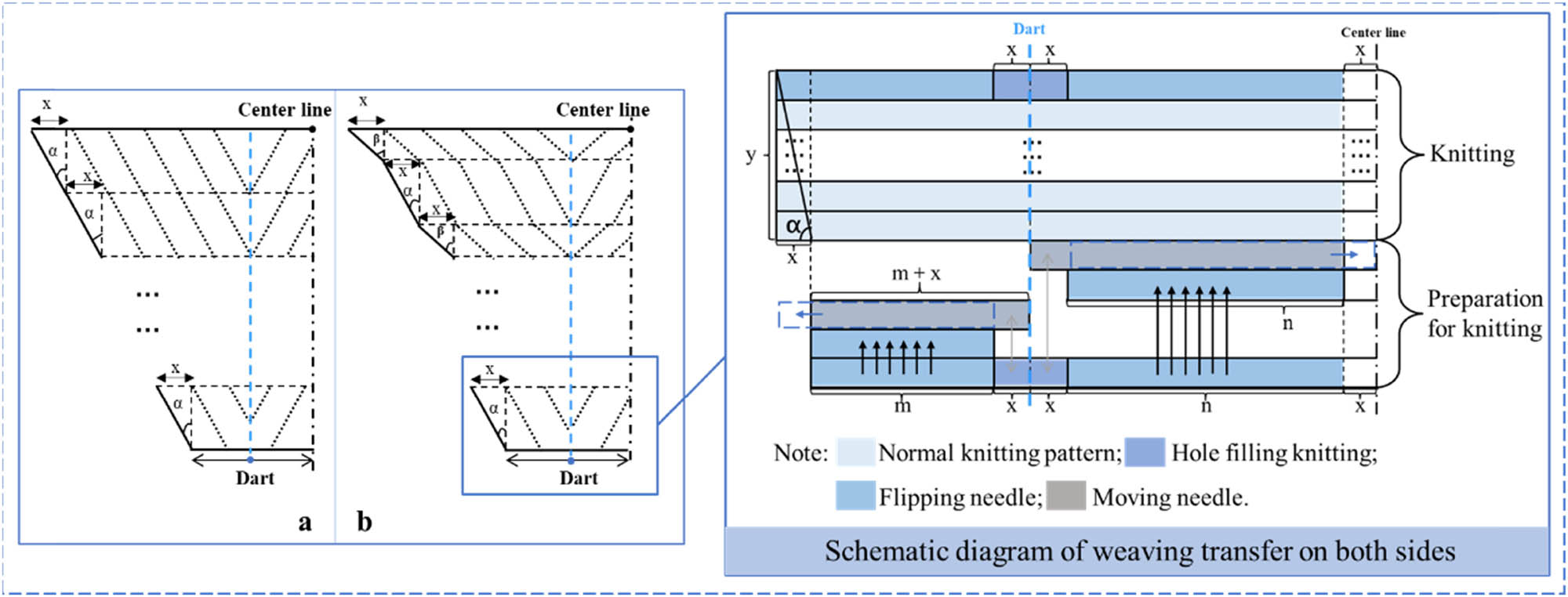

The knitting process of fully formed sports underwear body is based on tube knitting, among which the flat type refers to the formation of needles directly at the side seam; vertical form is designed by darting in the body, so that the body shape fits the human body better [17]. The specific method of vertical form knitting is called two-sided braiding transfer method. The basic principle of vertical form knitting is to transfer part of the needle amount to the waist by moving the needle evenly to the left and right, so as to realize the transverse size change between the waist line and the bust line. The other part is transferred to the front and back of the center to form a straight line, which is similar to the effect of the front and back of the center of the garment plate, helping to make the chest of the sports underwear more three-dimensional.

Figure 4 shows the process model of fully formed sports underwear body. Figure 4a shows the transfer of bilateral braid with fixed number of stitches and braid rows, and the actual braid shows the twill effect. Figure 4b shows that on the basis of Figure 4a, adding a different combination of the number of stitches and the number of rows of knitting on both sides of the braid transfer, the twill curve obtained is more variable, which can better enrich the modeling effect of sports underwear.

Fully formed sports underwear body process model. (a) Straight twill effect; (b) Curve twill effect.

The knitting principle of the dart on both sides of the needle placement method is shown in Figure 4. The dart is taken as the center line and needles are evenly distributed to both sides. This method is divided into two parts: the preparation part and the knitting part. In the preparation part, 2x stitches are made to fill holes at the m stitches on the outer side. The purpose of the filling is to fill holes formed after the needle is moved, and the rest of the knitting continues normal pattern knitting. Next is the knitting part, the coil from the outer side of the m needle is turned over, and the coil of the m + x needle is moved to the outside of the x needle and braided. At this time, the purpose of placing the x needle to the outside is realized. Then, the coil with the size of n needle, which is far from the front center line x needle, is turned over, and the coil of n + x needle is moved inward, namely, the direction of the center line, and the x needle is braided. At this time, the purpose of transferring the needle quantity to the front and back center lines is realized, and the preparation for braiding is completed. The variable of the braided part is the number of braided rows y, and the slope of the outer side α, i.e., the slope of the twill, is determined jointly by the number of needles x and the number of braided rows y.

Slope α, the number of needles x and the number of knitting rows y are combined in the following formula:

On this basis, if the number of body braiding rows is v, t times of needle placement are performed in the whole process of braiding, the number of needles each time is x, and if the angle of needle placement is α, then the following formula is satisfied:

If the needle setting angle is divided into α and β, the two angles cycle alternately according to the law of u:w, then the following formula is satisfied:

3.2 Collar and sleeve process model

Due to the changeable styles of the collar part and cuff in the fully formed motion, key points need to be added on the basis of the prototype. The process model is shown in Figure 5, and the corresponding supplementary key parts of the collar and cuff parts are shown in Table 2. Among them, arcs a, b, and c and arcs a', b', and c', respectively, correspond to the arcs of the front and rear collar sockets of the V-collar, U-collar, and square collar. Arcs i, ii, and iii correspond to H, double C, and Y rear armhole arcs, respectively.

Fully formed motion inner collar part and cuff process model.

Key parts of shoulder collar supplement of fully formed sports underwear

| Key parts | Front sheet | Rear sheet |

|---|---|---|

| Lead point connection | N1C1 | N′1C6 |

| Middle vertical line of leading point connection | N4N5 | N8N9 |

| Straight part of collar and bottom | N2C1、N3C1 | N6C6、N7C6 |

| Oblique shoulder | S7S1 | S′7S′1 |

| Armhole straightness measurement | S1B2 | / |

| Armhole | S1S10 | S′1S16 |

| Width of armhole edge | S5S9 | S6S13 |

| Straight part of armhole | S2B2 | S3B′2 |

| Depth of armhole curve | S8B2 | S6S16 |

On the basis of these points, the straight line part is called the flat roll section, such as the straight line part at the bottom of the collar, the straight line part of the armhole, etc., and the curve part is divided into four kinds according to the slope change: quick winding needle, quick releasing needle, slow winding needle, and slow releasing needle [18]. Among them, the slope of the snap-closing needle is in the interval (−1, 0), the slope of the snap-releasing needle is in the interval (0, 1), the slope of the slow-closing needle is in the interval (−∞, −1), and the slope of the slow-releasing needle is in the interval (1, +∞).

Figure 5 shows the schematic diagram of the triangular broken line segmenting method. Take a back armhole arc with a large slope change, i.e., the double C-shaped right back armhole arc, e.g., part A represents quick-closing pins. This part is divided into right triangles with different widths but the same height, whose height is the number of braided rows, and the fixed value of braided rows is generally 2–4 rows, and the width is the number of stitches. This part of the curve approximates the hypotenuse of a triangle. The curve of this part is divided into right triangles with different heights but the same width, whose width is the number of stitches each time, the fixed number of stitches is generally 1–3, and the height is the number of braided lines. Then, the curve of this part is similar to the hypotenuse of the triangle. Part C represents the buffer needle, similar to part B; Part D represents a quick release needle, similar to Part A.

If the length of the triangle is p pin, the height is q row, the angle between the horizontal direction and the curve is θ, and θ ∈ (0, Π/2), then the following formula is satisfied:

where ρ x2 and ρ y2 represent the transverse and longitudinal densities, respectively.

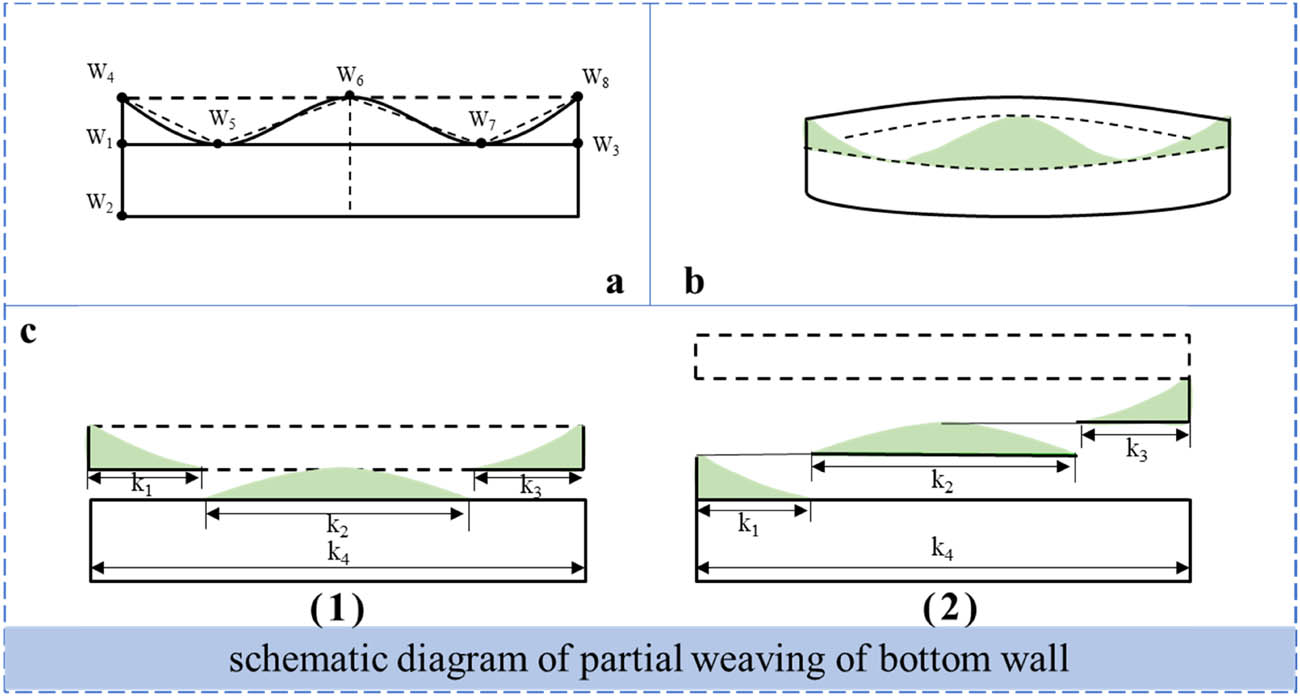

3.3 Bottom wall forming process model

In order to improve the support of the bottom circumference of fully formed sports underwear to the chest, a supporting part can be added on the basis of the cylinder part, that is, W3–W8 can be added on the basis of the prototype of the bottom circumference as its key point, as shown in Figure 6a. Figure 6b shows the structure of the bottom circumference of the fully formed sports underwear. The front and back pieces of the cylinder part have the same shape. The front pieces of the supporting part are W-shaped and the back pieces are rectangular.

Forming process model of bottom circumference. (a) Bottom wall key; (b) Structural drawing of bottom wall. (c1) Efficiency knitting, (c2) Structural knitting.

In the process of braiding the bottom of the fully formed sports underwear, the cylinder part is braided by the method of cylinder braiding first, i.e., the front and back pieces are braided alternately. The supporting part is applied to the process of local braiding, which can be realized by two braiding methods, as shown in Figure 6c. In Figure 6c(1), the method of stopping the middle braiding on both sides is first used to braid the protruding part of the front piece, and then the method of stopping the middle braiding on both sides is combined with the C-shape braiding process to braid the remaining part of the front piece and the rear part. This braiding method pays more attention to the braiding efficiency, while ignoring the braiding details. In Figure 6c(2), the cylinder part is braided in the same way as that in Figure 6c(1). Then, the front piece of the supporting part is divided into three parts in turn for lead back braiding [19].

In addition, in order to make the supporting part more stable in the process of knitting, it can play a better supporting role on the chest, at the same time make the organizational structure of the body not be pulled and deformed; by adjusting the braiding degree, the density of the supporting part is relatively larger than that of the cylinder part, and the supporting part is closer to the human body. Suppose the actual width of each part is k

1, k

2, k

3, and k

4, the transverse density of the cylinder part and the supporting part is ρ

x3 and ρ

x4, then the following formula is satisfied:

In particular, when the method of local knitting is used in different parts, if the upper and lower parts adopt different organizational structures or densities, then the following formula should be satisfied:

4 Process design and implementation of fully formed sports underwear

4.1 Full-form sports underwear design

4.1.1 Style design

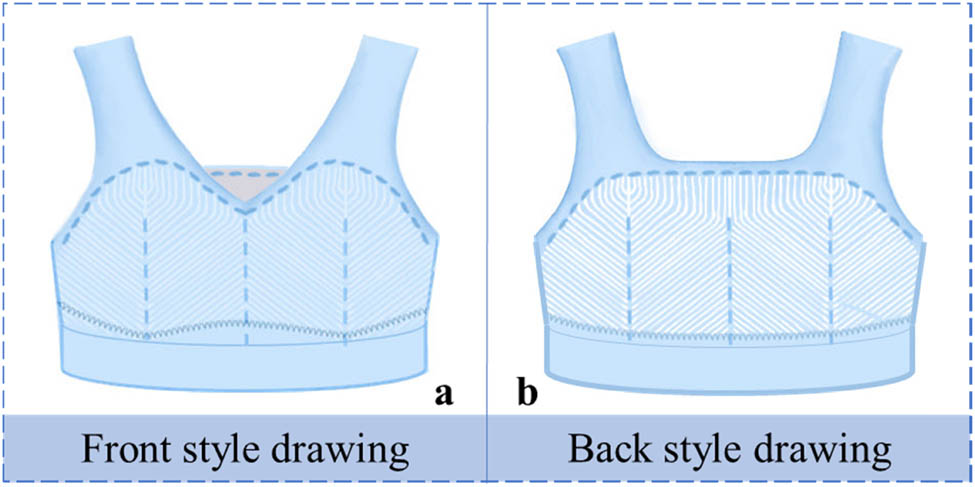

The style drawing of fully-formed sports underwear designed in this article is shown in Figure 7. Figure 7a is the front style drawing, and Figure 7b is the back style drawing. The body of the sports underwear adopts a three-dimensional design, which has a high fit to the human body and can provide better support for the chest; the front collar is a small V-neck shape, and the rear collar is a square collar shape, which has good breathability; the shoulder sleeve part is an H-shaped structure, which provides greater support for the chest; the bottom circumference is woven in a cylinder and increases the width of the bottom circumference, so that the sports underwear is not easy to shift during movement and is suitable for wearing in medium- and low-intensity movements [21].

Style diagram of fully formed sports underwear. (a) Front style drawing and (b) back style drawing.

4.1.2 Organization structure design

In order to ensure the overall wearing comfort of fully formed sports underwear, and that the parts have different functions, it is necessary to design the organizational structure of each part of the sports underwear [14,15,22,23].

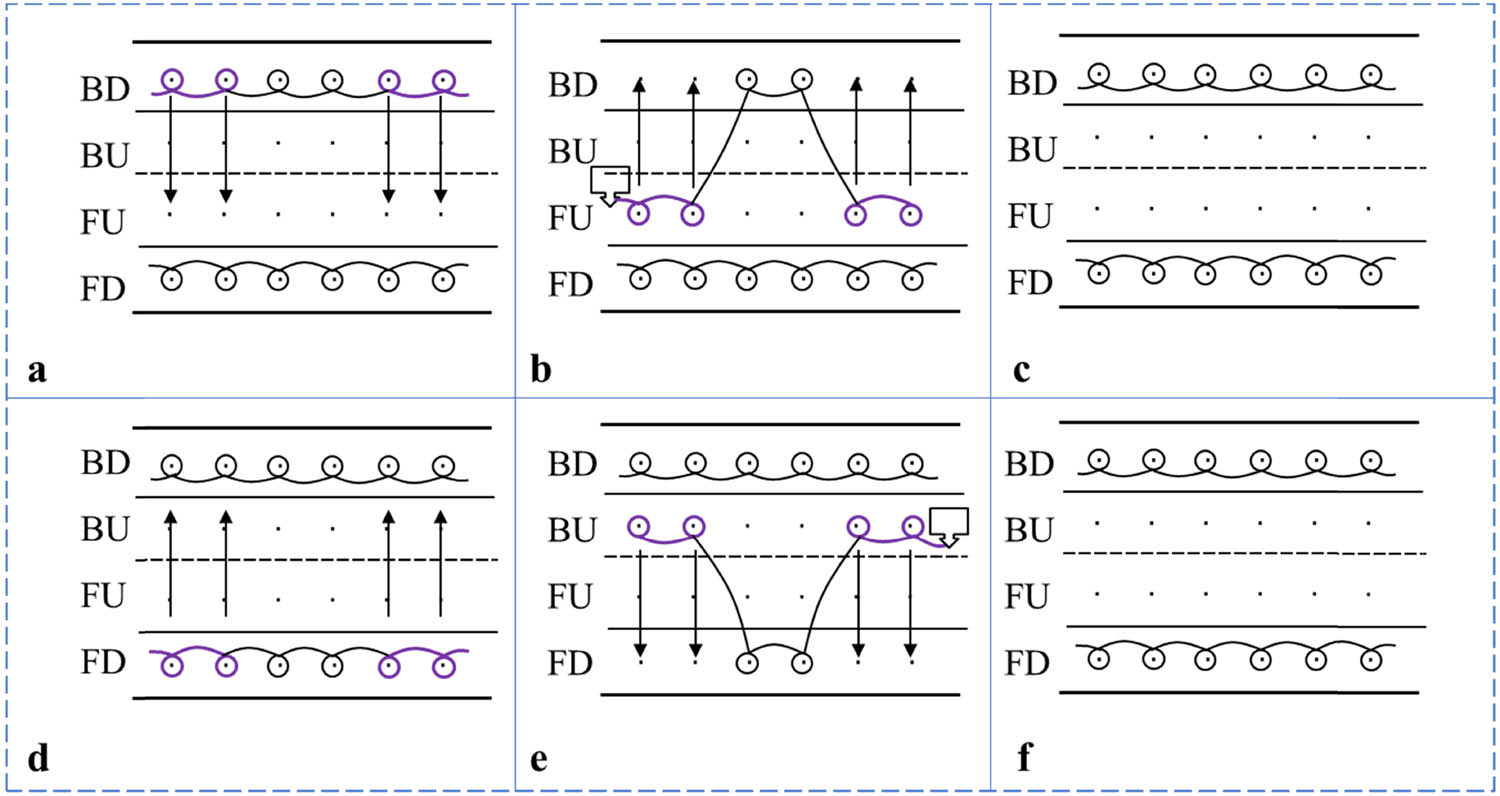

For the body part, in order to make use of its elasticity to achieve size changes, the 2 × 2 rib-knit structure with greater elasticity and better extensibility is adopted. The knitting diagram is shown in Figure 8. Figure 8a–c shows a row of ribbing for the back piece. First, turn the coils on the back lower needle bed to the front upper needle bed according to the rule of 2 by 2, and then knit a row of ribbing together on the front upper needle bed and the back lower needle bed. Finally, turn the coils on the front upper needle bed back to the back lower needle bed to return to the starting state. Figure 8d–f shows a row of ribbing for the front piece. First, the coils on the front lower bed and the corresponding ones on the back lower bed are turned over to the back upper bed, and then a row of ribbing is knitted together on the back upper and front lower beds. Finally, the coils on the back upper bed are turned back to the front lower bed to return to the starting state.

Schematic diagram of 2 × 2 rib knit. (a) Step 1; (b) Step 2; (c) Step 3; (d) Step 4; (e) Step 5; (f) Step 6.

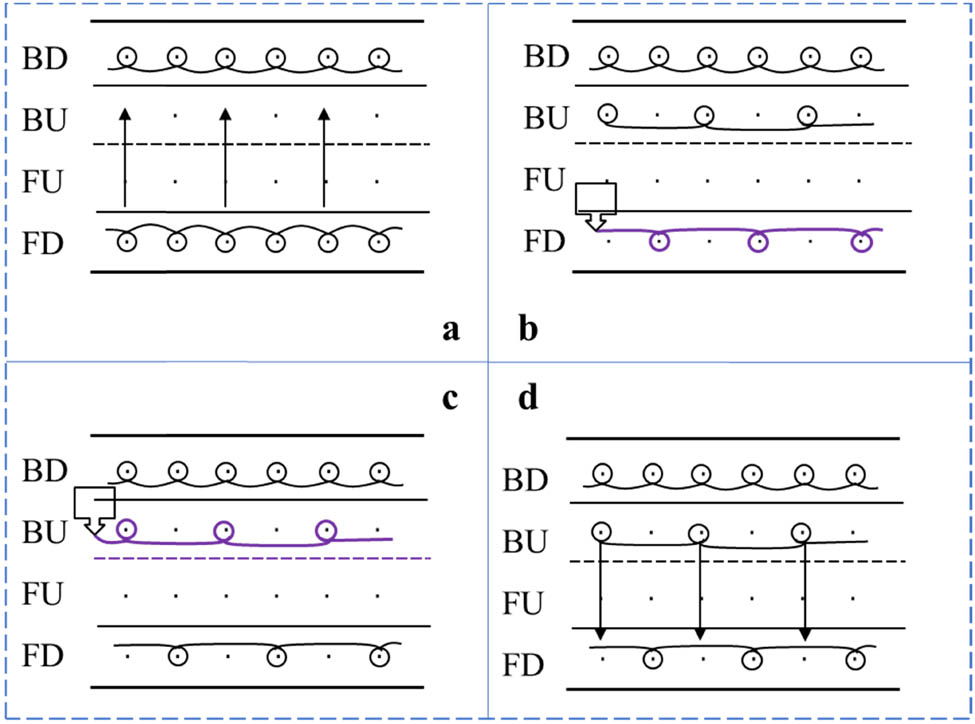

In order to provide stronger support to the chest, improve overall conformal, sports bra straps and bottom circumference choose double organization for woven [24], structure considering the limitation of four flat knitting machine needle bed, using every needle air layer organization, sectioned needle, for example, air layer organization before the knit diagram as shown in Figure 9 for the air layer outer layer of the knitting process. First, turn the coil 1 of the front lower needle bed from the front down to the back needle bed, and then knit a line of “floating thread~loop” cycle in the front lower needle bed; Figure 9c and d shows the process of knitting the inner layer of the air layer. First, knit a line of “floating thread~loop” that is misaligned with the front lower needle bed on the back upper needle bed, and then turn the coil on the back upper needle bed back to the front lower needle bed to return to the initial state. The above is to form a complete line of air layer tissue, forming a line of double-layer structure.

Schematic diagram of tissue knitting of air layer of septum needle. (a) Step 1; (b) Step 2; (c) Step 3; (d) Step 4.

In addition, when the chest is woven with double-layer structure, the air layer tissue of the needle is woven in the front piece, and the inner layer is copied in advance to facilitate the removal and cleaning of the chest pad.

4.2 Application of fully formed sports underwear process model

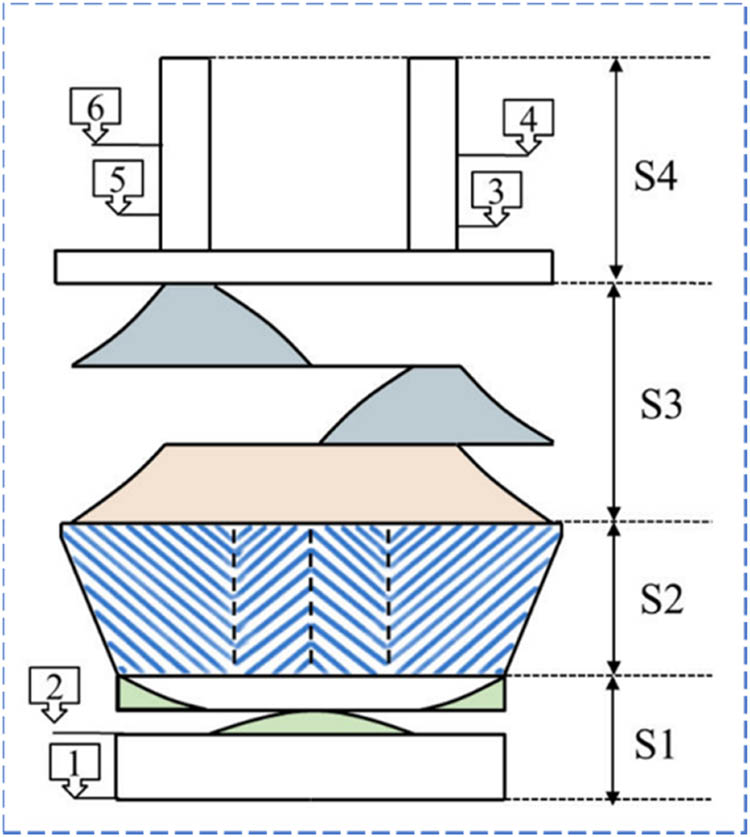

In this study, MACH2-153X four-needle bed computer flat machine with 18G needle number produced by Shima Seiki Company of Japan and its supporting SDS-ONE APPEX design system are adopted for knitting and design. Figure 10 shows the process model of a fully formed sports underwear, which is divided into four parts, S1–S4, and braided from bottom to top, sharing 7 nogs, among which nogs 1–6 are used for bulk braid, and nogs 7 are used for scrap braid.

Process model of fully formed sports underwear.

The S1 part represents the bottom circumference part of sports underwear, which is braided in a more efficient way in local braid. First, introduce the No. 1 yarn nozzle and weave the cylindrical part, and then, No. 2 nozzles are introduced, which braid the supporting part. In the S1 part, the actual width k

1 = k

3 = 8 cm, k

2 = 12 cm, k

4 = 30 cm, the transverse density ρ

x3 = 32 horizontal columns/5 cm of the cylinder part and the transverse density ρ

x4 = 30 horizontal columns/5 cm of the supporting part are substituted in equations

The S2 part represents the body of sports underwear, which adopts the No. 2 yarn tip and adopts the two-side braid transfer method to braid. The longitudinal straight lines at the position of BP point are, respectively, two reference lines, move one needle outward each time, the weaving rows are cycled in a 4:2 pattern, the transverse ρ

x1 = 35 transverse row/5 cm, longitudinal ρ

y1 = 35 longitudinal row/5 cm, substituted in the formulas

The S3 part is the shoulder and sleeve of sports underwear, still using No. 2 yarn mouth, the overall use of local braid method in turn on the back, right chest, left chest braid, and then according to the triangle line segment method in the back and left and right chest, respectively, triangle length p = 5 needles, high q = 3 lines, horizontal direction and curve angle θ = 30.1°, the transverse ρ

x2 = 35 transverse row/5 cm and longitudinal ρ

y2 = 35 longitudinal row/5 cm were substituted in equation

The S4 part is the edge and shoulder belt of the sports underwear. The 3–6 size yarn mouth is introduced, and the front and back pieces are woven alternately. Finally, the knitting is completed.

4.3 Realization of fully formed sports underwear

Since the fully formed sports underwear keeps the state of being closely worn in the sports environment, the raw materials used must have the characteristics of skin-friendly comfort, moisture absorption, and sweat removal [25,26]. The yarn wearing configuration of the underwear is shown in Table 3. The main yarn is made of blended viscose fiber and polyester fiber [27,28], in which the viscose fiber content accounts for about 70%, with good hygroscopic property, and the polyester fiber content accounts for about 30%, with good strength and elasticity, making it fit better. In addition, in order to further improve the overall stability of it, rubber yarn is added to the bottom circumference, which can not only prevent the bottom swing of sports underwear from deformation and laxity due to repeated washing, but also provide better support for the chest structure. This example of fully formed sports underwear design object is shown in Figure 11.

Spinning configuration of fully formed sports underwear

| Yarn mouth number | Weaving area | Yarn | Yarn specification |

|---|---|---|---|

| 1 (Left) | Bottom wall cylinder | Main yarn + rubber band yarn | 60 S/2, 52 S |

| 2 (Left) | Supporting part/large body | Main yarn | 60 S/2 |

| 3 (Right) | Right shoulder front piece | Main yarn | 60 S/2 |

| 4 (Right) | Rear right shoulder piece | Main yarn | 60 S/2 |

| 5 (Left) | Left shoulder front piece | Main yarn | 60 S/2 |

| 6 (Left) | Rear left shoulder piece | Main yarn | 60 S/2 |

| 7 (Right) | Waste yarn | polyester fiber | 50 S |

Design object of fully formed sports underwear.

5 Conclusion

This work studies the process model of full-formed sports underwear based on the fully forming knitting technology. The process model is divided into three parts: body part, leader part, and bottom circumference, and it was applied to the weaving of a fully formed sports bra, verifying the feasibility of the process model. Finally, the formation rules of full molding process conversion in the entire text were summarized, and the following conclusions were drawn:

The change in body contour is realized by using the needle placement method on both sides of the darts. That is, based on the position of the darts on the chest and waist, the needle shifting is carried out to the left and right of the darts, and part of the needle shifting is transferred to the waist side, and the other part is transferred to the front and back center to form a straight line, so as to realize the transverse size change from waist to chest and at the same time obtain the effect similar to the front and back of the darts in the garment plate, giving a more three-dimensional effect to the sports underwear. Using the formulas, the relationship between the number of knitting rows, the number of needle shifting, and the angle of needle placement can be calculated.

According to the curve contour of the collar and sleeve, triangle broken line segmentation method is used to realize it. According to the change in the slope of the curve, it is divided into different hypotenuses of right triangles. If the slope of the curve is between the interval (−1, 1), this part of the curve is evenly distributed vertically into appropriate lengths to form right triangles with different widths but with the same height. Think of this part of the curve as the hypotenuse of a triangle; on the contrary, the curves are evenly distributed horizontally into appropriate widths to form right triangles of different heights but with the same width, and finally the needles are rewound according to the hypotenuse slopes of different right triangles.

The bottom part of sports underwear can be divided into cylinder part and supporting part. The supporting part can be obtained by two different local braiding methods. Based on the relation between the actual braiding length and transverse density of the cylinder part and the supporting part, the relation between the actual braiding length and transverse density of the upper and lower parts in the process of local braiding is derived.

Acknowledgements

The authors acknowledge the foundation for basic research support from the National Science Foundation of China (61902150) and the Fundamental Research Funds for the Central Universities (JUSRP122003).

-

Funding information: The research was financially supported by: National Science Foundation of China (61902150) and the Fundamental Research Funds for the Central Universities (JUSRP122003).

-

Author contributions: All authors contributed to this study. Cong Honglian conceived and designed the experiments, analyzed and interpreted the data, and contributed to writing the manuscript. Wu Xiaowen conducted experiments, analyzed experimental results, and assisted in manuscript preparation and editing. Huang Xian contributed to data acquisition and analysis, reviewed literature, provided intellectual input, and approved the final version of the manuscript. Pan Qiudong provided logistical and administrative support, ensured compliance with ethical standards, and reviewed and approved the manuscript for submission.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Nakashima, T., Aida, S. (2017). Introduction to new industries by wholegarment. Japanese Journal of Complementary and Alternative Medicine, 14(2), 93–97.10.1625/jcam.14.93Search in Google Scholar

[2] Zhan, B., Huang, X., Cai, C, Cong H. (2022). Design and implementation of fake two-piece fully formed process for blouse. International Journal of Clothing Science and Technology, 34(3), 315–334.10.1108/IJCST-08-2020-0133Search in Google Scholar

[3] Peng, J., Jiang, G., Cong, H, Luo X., Zhao Y. (2018). Development of whole garment formed on four-bed computerized flat knitting machine. International Journal of Clothing Science and Technology, 30(3), 320–331.10.1108/IJCST-07-2017-0105Search in Google Scholar

[4] Liu, B., Cong, H. (2020). Research and implementation of flat-bed knitting process model of fully formed suit. Journal of Textile Research, 41(7), 53–58.Search in Google Scholar

[5] Sha, S., Wei, W., Xiao, B, Sha D., Gao Y., Cao R., et al. (2021). 3D dynamic simulation of knitwear based on the hybrid model. Journal of Engineered Fibers and Fabrics, 16, 1–9.10.1177/15589250211051589Search in Google Scholar

[6] Dong, Z., Jiang, G., Wu, Z, Cong H. (2015). 3D parametric human modeling for warp-knitted seamless garment. International Journal of Clothing Science and Technology, 27(4), 532–548.10.1108/IJCST-01-2014-0013Search in Google Scholar

[7] Wan, X, Dong, Z, Cong, H. (2023). Model design and jacquard stitches’ heat-moisture performance of warp-knitted fully formed head mas. The Journal of The Textile Institute, 114(11), 1658–1666.10.1080/00405000.2022.2145439Search in Google Scholar

[8] McRoberts, L. B., Black, C. M., Cloud, R. M. (2016). Evaluation of a prototype soft-structured thoracic posture support garment. Clothing and Textiles Research Journal, 34(2), 143–158.10.1177/0887302X15622571Search in Google Scholar

[9] Wang, D., Cong, H. (2013). Prototype design method of weft knitted seamless underwear. Journal of Textile Research, 34(5), 95–99.Search in Google Scholar

[10] Luo, X, Peng, J, Jiang, G, et al. (2018). Design and knitting shaping method of fully-fashioned knitwear. Journal of Textile Research, 39(7), 105–110.Search in Google Scholar

[11] Li, M. (2001). A study on the structure of close-fitting garment and its virtual design based on the analysis of women’s body. Shape, Master dissertation, Dong Hua University.Search in Google Scholar

[12] Luo, X., Jiang, G., Cong, H. (2021). Conversion from 3D to 2D pattern algorithm for the 3D-shaped knitwear. International Journal of Clothing Science and Technology, 33(1), 65–73.10.1108/IJCST-10-2017-0165Search in Google Scholar

[13] Zhao, B., Cong, H., Wu, G. (2021). Construction and system realization of the yarn tension model of fully fashioned flat knitting fabric. Textile Research Journal, 991(11–12), 1380–1388.10.1177/0040517520982386Search in Google Scholar

[14] Li, Y. M., Zhang, W. W, Liu Y. L. (2011). Research on dynamic heat and moisture comfort property of sports underwear in different style. Advanced Materials Research, 332, 894–897.10.4028/www.scientific.net/AMR.332-334.894Search in Google Scholar

[15] Lu L, Jiang G, Luo X. (2020). Research on knitting technique and wearability assessment of underarm stitching for complete garments. The Journal of The Textile Institute, 111(11), 1623–1631.10.1080/00405000.2020.1720157Search in Google Scholar

[16] Qiu, Z., Wu, Z. (2019). Armhole forming process of full fashioned garment. Wool Textile Journal, 47(4), 43–46.Search in Google Scholar

[17] Li, Y, Cong, H. (2023). Fast three-dimensional simulation based on data constraints and methods to improve the realism of knitted sweaters. Textile Research Journal, 93(21–22), 4983–4993.Search in Google Scholar

[18] Li, Y., Cong, H. (2023). Fast three-dimensional simulation based on data constraints and methods to improve the realism of knitted sweaters. Textile Research Journal, 993(21–22), 4983–4993.10.1177/00405175231189284Search in Google Scholar

[19] Liu, B, Cong, H. (2020). Process design and knitting principle of one-piece casual suits based on four-needle-bed flat knitting machine. Journal of Textile Research, 41(4), 129–134.Search in Google Scholar

[20] Wang, W. (2020). Realization method and application of partial knitting of transverse dart and pleat for fully formed knitwear. Journal of Silk, 57(10), 106–110.Search in Google Scholar

[21] Cheng, B, Jiang, G, Zhao, J, Li B. (2023), Design and modeling of partial knitting knitted fabric based on matrix transformation. International Journal of Clothing Science and Technology, 35(6), 918–937.10.1108/IJCST-06-2022-0085Search in Google Scholar

[22] Wang, J., Zhang, B., Yao, X, Shen J., Yuan L., Pan T., et al. (2023). Single-sided jacquard knit fabric development and seamless ski underwear zoning design based on body mapping sportswear. AUTEX Research Journal, 23(4), 483–494.10.2478/aut-2022-0033Search in Google Scholar

[23] Li, T., He, Y., Wang, C, Fu G., Wang Y., Gao H., et al. (2023). Designing three-dimensional changed spacer weft-knitted fabrics for efficient absorption and quick-drying partitioned garments. Textile Research Journal, 93(19–20), 4392–4405.10.1177/00405175231174644Search in Google Scholar

[24] Soundri, G. M., & Kumar B, S. (2022). Dimensional, moisture, and thermal properties of bi-layered knitted fabric for sportswear application. Research Journal of Textile and Apparel, 27(4), 543–559.10.1108/RJTA-05-2021-0074Search in Google Scholar

[25] Kowalski, K., Janicka, J., Massalska-Lipińska, T., et al. (2010). Impact of raw material combinations on the biophysical parameters and underwear microclimate of two-layer knitted materials. Fibres & Textiles in Eastern Europe, 18(5), 82.Search in Google Scholar

[26] Reljić, M., Lazić, B., Stepanović, J., et al. (2017). Thermophysiological properties of knitted fabrics for sports underwear. Structural Integrity and Life, 17(2), 145–149.Search in Google Scholar

[27] Cheng, P., Chen, D., Wang, J. (2021). Study on the influence of underwear on local thermal and moisture comfort of human body. Thermal Science, 25(4 Part A), 2589–2608.10.2298/TSCI190310229CSearch in Google Scholar

[28] Van Amber, R R., Wilson, C A., Laing, R M, Lowe B.J., Niven B.E. (2015). Thermal and moisture transfer properties of sock fabrics differing in fiber type, yarn, and fabric structure. Textile Research Journal, 85(12), 1269–1280.10.1177/0040517514561926Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry