Abstract

The mechanical properties of seaming stitch have been frequently reported. However, the frictional characteristics of seaming stitch have long been ignored. In this article, to reveal the influence of sewing process on the fabric’s friction, we measured the coefficient of friction (COF) of fabric with different seam patterns. These seam patterns were fabricated by using controllable sewing thread and sewing process. On the basis of our experiment, we found that the COF of fabric’s front was higher than that of fabric’s back. Another conclusion is that the COF in the weft direction was higher than that in the warp direction. Additionally, thin sewing thread, long stitch, and large seam space can cause low COF. On the contrary, relative high COF is generated by thick sewing thread, short stitch, and small seam space. According to our results, we expect to provide the matching suggestion between the fabric and seam pattern from the point view of trichology.

1 Introduction

The fabric–skin friction is a common situation in our daily life. Sometimes this friction may cause discomfort and even lead to the development of decubitus, blister, corns, calluses, and talon noir [1–6]. To elucidate the mechanism of fabric–skin friction, the correlation between fabric structure and frictional characteristics of fabrics has been extensively investigated. For instance, the yarn type, weave pattern, warp/weft orientation, finishing treatments, fabric areal density (AD), and even fiber shape all influenced the fabric friction characteristics according to some existing reports [7–14]. The floating length and stitch size of knitted fabric’s yarn reduced the coefficient of friction (COF) [7,14].

In addition, raw material of fabric also affects the frictional characteristics. For example, acrylic fabric exhibited relatively stronger friction than wool under the same conditions [15]. Van Amber et al. [11] found that fiber type did not affect dynamic frictional force or coefficient of dynamic friction of dry fabrics, it did affect these parameters when fabrics were damp. Due to complicated fabric structural parameters, Jeddi et al. [16–18] proposed a comprehensive index, fabric structural asperity index to explain the relations between the friction and structure of woven and knitted fabrics. Camillieri et al. [19] created a brush model to reveal the friction mechanism of hairy fabric.

The mentioned reports only studied the original structure of fabric such as yarn type, weave pattern, warp/weft density, floating length, and finishing treatments. However, the common textile products in everyday life including bedding bag, sofa cover, and cloth are stitched by multiple pieces of fabric. In the sewing process, thread for sewing plays a role in fixing fabric pieces and reinforce the products’ strength. Thus, many articles have reported the study of seam strength, type, and other properties [20–23].

However, to our best knowledge, the influence of seam on the friction characteristics of fabric is hardly reported even though seam can change the surface roughness [24]. In order to quantificationally investigate the influence of seam on the skin–fabric friction, we adjusted the sewing process, produced controllable seam pattern on the fabric, and performed sliding friction experiments. The whole work fills the blank of seam effects on the friction characteristics, and provides sewing process adjustment and sewing thread selection experience to the cloth manufacture process.

2 Experiment and methods

2.1 Fabric structure measurement

We randomly selected four types of fabrics from a same supplier (Kairui Sport Ltd, China). All fabrics were fully relaxed and placed under standard atmospheric conditions for 24 h to reach equilibrium prior to the measurements. We then measured its structural parameters, including the weft density, warp density, and fabric AD. The weft and warp density were defined as the number of yarns in 10 cm of fabric and measured by picking glass (Y115B, Qile Co. Ltd, China) according to the American Society for Testing and Materials (ASTM D8007-15). The fabric AD was expressed by

where M is the mass of the fabric sample which was weighed by an electronic balance (FA1004B, Hangzhou Jingjing Co. Ltd, China). S is the area of the fabric sample which was measured by straight steel ruler. Each measurement was performed four times. The final results are listed in Table 1.

Fabric structure

| Sample | Material | Weft density | Warp density | Fabric AD (kg/m2) | Type of weave | Structure |

|---|---|---|---|---|---|---|

| 1 | Terylene | 170 | 220 | 0.244 | Woven | Plain |

| 2 | Cotton | 310 | 320 | 0.159 | Knit | 1 + 1 rib |

| 3 | Linen | 210 | 230 | 0.171 | Woven | 3/2 right twill |

| 4 | Wool | 150 | 240 | 0.195 | Woven | Plain |

2.2 Sewing experiment

The orthogonal experiment was used to control the seam pattern. Each experimental condition is displayed in Table 2. The needle size is described by the US number and is shown in Figure 1, a larger number means a thicker needle, otherwise represents a thin needle. The sewing thread we used was terylene due to its high strength. The sewing thread size is expressed by “single yarn count/single yarn quantity.”

Orthogonal experiment

| Sample | Needle size (US) | Material | Sewing thread size | Stitch length (cm) | Seam space (cm) |

|---|---|---|---|---|---|

| 1 | 12# | Terylene | 60s/2 | 0.1 | 0.5 |

| 2 | 12# | Cotton | 50s/2 | 0.2 | 1 |

| 3 | 12# | Linen | 40s/2 | 0.3 | 2 |

| 4 | 12# | Wool | 40s/3 | 0.4 | 2.5 |

| 5 | 14# | Terylene | 50s/2 | 0.3 | 2.5 |

| 6 | 14# | Cotton | 60s/2 | 0.4 | 2 |

| 7 | 14# | Linen | 40s/3 | 0.1 | 1 |

| 8 | 14# | Wool | 40s/2 | 0.2 | 0.5 |

| 9 | 16# | Terylene | 40s/2 | 0.4 | 1 |

| 10 | 16# | Cotton | 60s/2 | 0.3 | 0.5 |

| 11 | 16# | Linen | 40s/3 | 0.2 | 2.5 |

| 12 | 16# | Wool | 50s/2 | 0.1 | 2 |

| 13 | 18# | Terylene | 40s/3 | 0.2 | 2 |

| 14 | 18# | Cotton | 40s/2 | 0.1 | 2.5 |

| 15 | 18# | Linen | 50s/2 | 0.4 | 0.5 |

| 16 | 18# | Wool | 60s/2 | 0.3 | 1 |

The needle employed in the sewing experiment.

The sketch of the experiment is shown in Figure 2. In order to control the seam space, we drew the lines on the fabric’s front before the sewing experiment. All of the samples were sewed along the drawn lines on the sewing machine (DDL-8700B, JUKI Co. Ltd, China). We could adjust the sewing speed and select suitable sewing thread and needle to complete appropriate stitch on the fabric. The fabricated samples are displayed in Figure 3. The sample order in Figure 3 is the same as that in Table 2.

Sewing process.

Samples style.

2.3 Sliding friction experiment

To mimic skin–fabric friction, we designed a sliding experiment, as shown in Figure 4. The slider is a cuboid of 200 g and its bottom size is 63 mm × 63 mm. The moveable platform has three different speed levels, namely slow, medium, and fast since previous studies found the effect of friction speed on the final results [25–28]. In order to eliminate this influence, each sample should be measured at the three different speed levels.

![Figure 4

Schematic of the sliding experiment [14].](/document/doi/10.1515/aut-2024-0020/asset/graphic/j_aut-2024-0020_fig_004.jpg)

Schematic of the sliding experiment [14].

Before the experiments, the sample was placed in the standard conditions for 24 h. And then a sample was glued onto the slider bottom. The glue should be strong in case of relative sliding between the sample and slider bottom. An artificial skin (C5-1, Sunshine 3DM Co. Ltd, China) was fixed on the top surface of the movable platform. Then the platform moved at a slow speed level (100 mm/min). The tension sensor provided a real-time output of the measured friction. We then changed the speed level of the platform to medium (150 mm/min) and fast (200 mm/min). After the sample was measured at all of the speed levels, we removed the sample and changed its direction to measure the friction along another orthometric direction. The sample was slightly torn off and replaced by the next sample after its measurements. Each sliding experiment was also performed four times for averaging purposes.

2.4 Original data processing method

Figure 5 shows a typical friction curve in a sliding experiment. The friction initially increases. When it reaches to the peak, the slider starts to move. The friction curve then gradually decreases until it stabilizes. In order to accurately obtain the dynamic friction, the stable friction values shown in Figure 5 were extracted and their average value was regarded as the dynamic friction. COF is calculated following Coulomb law of friction:

Typical curve of sliding friction.

3 Results and discussion

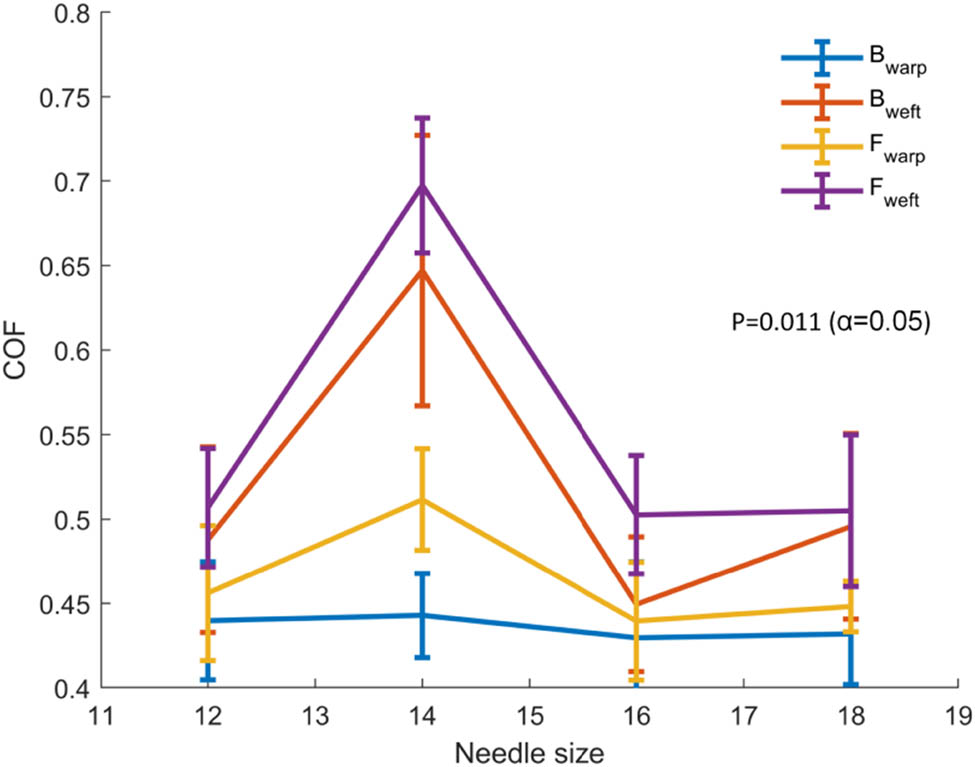

3.1 Influence of needle size

The results of friction experiment are shown in Figure 6. “F” and “B”, respectively, mean fabric’s front and back. Herein, front has been defined as the fabric surface which contacts the pressure foot and is signified in Figure 2. Subscript “warp” and “weft” mean the directions of yarn arrangement. The perpendicular line in the graphs is the error bar which represents the deviation of the average results. In Figure 6, the effect of needle size on the COF is ruleless. The needle size determines the needle hole on the fabric. Thick needle usually produces large hole. Originally, wide needle hole increases surface roughness and the COF. However, our experimental results do not find the rule. We suspected that the needle holes might be fully filled by sewing thread, thus the characteristics of sewing thread might directly affect the COF.

Influence of needle size.

Figure 6 demonstrates F warp > B warp and F weft > B weft. This means that the COF of fabric’s front is higher than that of fabric’s back in the same direction. This is a universal rule and will be reflected in each section. During sewing process, the sewing thread on the fabric’s back is pressed by the presser foot, sewing thread on most of the fabric’s back are evenly pressed inside the fabric. While, the sewing thread on the fabric’s front still floats on the surface of it. Therefore, the sewed fabric’s back is smoother than its front. Additionally, in Figure 6, B weft > B warp and F weft > F warp. This reflects that the COF in the weft direction is higher than that in the warp direction on the same side. This is another universal rule and will also be reflected in each section. Since the sewing direction is parallel to warp direction, when the slider moves in the warp direction, the stitch can hardly impede the slide. Otherwise, the stitch obstructs the slider movement in the weft direction.

3.2 Influence of sewing thread’s diameter

The effect of sewing thread’s fineness is shown in Figure 7. Thicker thread causes higher COF, conversely thinner thread contributes to lower COF. According to our observation, sewing thread floated on the sample’s surface and unevenly increased the thickness of the sample. The uneven thickness enhanced the roughness of sample’s surface and produced a higher COF. Additionally, we still found that the COF of fabric’s front is higher than that of fabric’s back in the same direction, and COF in the weft direction is higher than that in the warp direction on the same side.

Influence of sewing thread’s diameter.

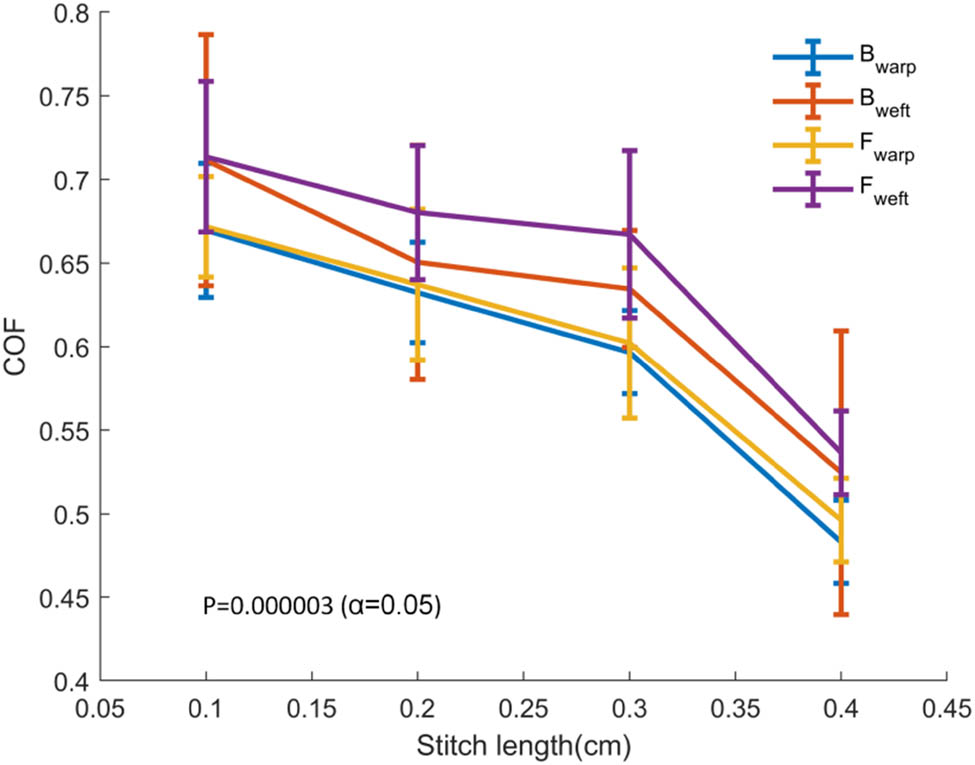

3.3 Influence of stitch length

The influence of stitch length is exhibited in Figure 8. It can be found that longer stitch reduces the COF. According to our observation, needle hole under the stitch is the main reason. Needle holes generate dents on the fabric’s surface and affect the roughness of the fabric. Compared with shorter stitch, the needle holes are scarcer under the longer stitch. In Section 3.1, we have proved that the size of needle holes are not directly related to the COF, but in this section, the quantity of needle holes do associate with the COF, since the latter can determine the stitch length while the former cannot affect other important parameters. From this, we can infer that the roughness caused by long stitch and resulting COF are relatively low. In addition, the above-mentioned two rules still exist in this section, namely, COF of fabric’s front is higher than that of fabric’s back in the same direction and COF in the weft direction is higher than COF in the warp direction on the same side.

Influence of stitch length.

3.4 Influence of seam space

In Figure 9, large seam space can reduce the COF. Large seam space reduces needle holes quantity on the fabric’s surface, while shorter seam space increases needle holes quantity. We have discussed the relationship between needle holes and roughness of fabric in the last section. Additionally, the slider tends to contact the original surface of fabric with large seam space. Thus, the seam cannot strongly affect the COF of the fabric with a large seam space. In addition, it is worth mentioning that the repeatedly mentioned two rules are applied to all our results. This proves that these two rules are universal in fabric’s friction experiment.

Influence of seam space.

3.5 Significance of influences

ANOVA method was used to verify the difference in the values. The results are displayed in the figures. The smaller the P value is, the more significant the influencing factors are. Three influences involving seam space, needle size, and stitch length are highly significant. Relatively, the influence of sewing thread’s diameter is significant. Therefore, the significance rank of the influences is stitch length > seam space > needle size > sewing thread’s diameter. This indicates that compared with needle and sewing thread, the seam pattern can provide relatively strong effects on the COF.

4 Conclusion

In this research work, we designed orthogonal experiments to find some general rules of seam pattern. According to our experimental results, all of the four influences proposed in this work significantly affect the COF of the fabric. Their effects range from strong to weak is stitch length, seam space, needle size, and diameter of sewing thread. Except for needle size, the remaining three regularly affect the COF. Thin sewing thread, long stitch, and large seam space can cause low COF. On the contrary, relative high COF is generated by thick sewing thread, short stitch, and small seam space. In addition, we also find that the COF of fabric’s front is higher than that of fabric’s back in the same direction. And the COF in the weft direction is higher than COF in the warp direction on the same side, because the sewing process was performed in the weft direction of front side on the fabric.

The skin of our body experiences thousands of frictions with garments daily, which can lead to discomfort. Therefore, a lower COF is essential. This study can offer recommendations for enhancing the comfort of apparel by considering aspects such as sewing processes and the choice of sewing thread.

-

Funding information: The authors disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: National Key R&D Program of China, Grant no. 2018YFC2000900, Hainan Provincial Natural Science Foundation of China (Grant no. 223MS054), and Class III Peak Discipline of Shanghai – Materials Science and Engineering (High-Energy Beam Intelligent Processing and Green Manufacturing).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results and approved the final version of the manuscript. Sun designed the experiments and carried them out. Guanzhi Li collected the experimental data and provided the analysis. Dong and Hu correted the whole manuscript. Chulin Li completed all of the pictures. Sun prepared the manuscript with contributions from all co-authors.

-

Conflict of interest: Authors state no conflict of interest.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Bansal, C., Scott, R., Stewart, D., Cockerell, C. J. (2005). Decubitus ulcers: a review of the literature. International Journal of Dermatology, 44, 805–810.10.1111/j.1365-4632.2005.02636.xSearch in Google Scholar PubMed

[2] Bass, M. J., Phillips, L. G. (2007). Pressure sores. Current Problems in Surgery, 44, 101–143.10.1067/j.cpsurg.2006.12.007Search in Google Scholar PubMed

[3] Grouios, G. (2004). Corns and calluses in athletes’ feet: a cause for concern. The Foot, 14, 175–184.10.1016/j.foot.2004.07.005Search in Google Scholar

[4] Heymann, W. R. (2005). Dermatologic problems of the endurance athlete. Journal of the American Academy of Dermatology, 52, 345–346.10.1016/j.jaad.2004.10.869Search in Google Scholar PubMed

[5] Mailler-Savage, E. A., Adams, B. B. (2006). Skin manifestations of running. Journal of the American Academy of Dermatology, 55(2), 290–301.10.1016/j.jaad.2006.02.011Search in Google Scholar PubMed

[6] Baussan, E., Bueno, M. A., Rossi, R. M., Derler, S. (2013). Analysis of current running sock structures with regard to blister prevention. Textile Research Journal, 83(8), 836–848.10.1177/0040517512461698Search in Google Scholar

[7] Thomdike, G. H., Varley, L. (1961). Measurement of the coefficient of friction between samples of the same cloth. Journal of the Textile Institute, 52, 255–271.10.1080/19447016108688509Search in Google Scholar

[8] Wilson, D. (1963). A study of fabric-on-fabric dynamic friction. Journal of the Textile Institute Transactions, 54, 143–155.10.1080/19447026308660165Search in Google Scholar

[9] Zurek, W., Jankowiak, D., Frydrych, I. (1985). The surface frictional resistance of fabrics woven from filament yarns. Textile Research Journal, 55, 113–121.10.1177/004051758505500207Search in Google Scholar

[10] Hosseini, R. S. A., Toriumi, K., Matsumoto, Y. (1994). Spectral analysis of the stick-slip motion of dynamic friction in the fabric surface. Textile Research Journal, 64, 224–229.10.1177/004051759406400406Search in Google Scholar

[11] Van Amber, R. R., Lowe, B. J., Niven, B. E., Laing, R. M., Wilson, C. A., Collie, S. (2015). The effect of fiber type, yarn structure and fabric structure on the frictional characteristics of sock fabrics. Textile Research Journal, 85(2), 115–127.10.1177/0040517514530029Search in Google Scholar

[12] Bertaux, E., Lewandowski, M. (2007). Relationship between friction and tactile properties for woven and knitted fabrics. Textile Research Journal, 77(6), 387–396.10.1177/0040517507074165Search in Google Scholar

[13] Bueno, M. A., Aneja, A. P., Renner, M. (2004). Influence of the shape of fiber cross section on fabric surface characteristics. Journal of Materials Science, 39, 557–564.10.1023/B:JMSC.0000011511.66614.48Search in Google Scholar

[14] Sun, G., Xie, H., Lake, M. J., Li, J., Chen, X., Li, Y. (2022). Walking-sliding experimental analysis of frictional characteristics socked feet. Journal of Industrial Textiles, 51(5S), 9031S–9046S.10.1177/1528083720988083Search in Google Scholar

[15] Herring, K. M., Richie, D. H. (1990). Friction blisters and sock fiber composition:a double-blind study. Journal of the American Podiatric Medical Association, 80, 63–71.10.7547/87507315-80-2-63Search in Google Scholar PubMed

[16] Jeddi, A. A., Shams, S., Nosraty, H., Sarsharzadeh, A. (2003). Relations between fabric structure and friction. Part I: woven fabrics. Journal of the Textile Institute, 94, 223–234.10.1080/00405000308630611Search in Google Scholar

[17] Jeddi, A. A., Khorram-Toussi, Z., Maleki, V., Yazdanifar, K. (2004). Relations between fabric structure and friction. Part II: weft knitted fabrics. Journal of the Textile Institute, 95, 359–367.10.1533/joti.2004.0007Search in Google Scholar

[18] Jeddi, A. A., Arshi, A, Maleki, V., Fakhr, V. (2006). Relations between fabric structure and friction. Part III: warp knitted fabrics. Journal of the Textile Institute, 97, 103–109.10.1533/joti.2005.0115Search in Google Scholar

[19] Camillieri, B., Bueno, M. A., Rossi, R. M., Derler, S. (2012). Brush model to predict the friction of hairy textile fabrics from indentation measurements. Wear, 296, 519–527.10.1016/j.wear.2012.07.027Search in Google Scholar

[20] Citoglu, F., Onur, N. (2010). The determination on the effects of the sewing parameters to the seam strength of the tencel fabric. Textile and Apparel, 20(4), 359–365.Search in Google Scholar

[21] Bansal, P., Sikka, M., Choudhary, A. K. (2021). Seam performance of knitted fabrics based on seam strength and seam efficiency. Indian Journal of Fibre & Textile Research (IJFTR), 46(1), 22–28.10.56042/ijftr.v46i1.32708Search in Google Scholar

[22] Shi, H., Zhang, L. X., Wang, J. P. (2017). Influence of seam types on seam quality of outdoor clothing. International Journal of Clothing Science and Technology, 29(4), 553–565.10.1108/IJCST-03-2016-0028Search in Google Scholar

[23] Unal, B. Z. (2012). The prediction of seam strength of denim fabrics with mathematical equations. Journal of the Textile Institute, 103(7), 744–751.10.1080/00405000.2011.603509Search in Google Scholar

[24] Mariolis, I. G., Dermatas, E. S. (2010). Automated assessment of textile seam quality based on surface roughness estimation. Journal of the Textile Institute, 101(7), 653–659.10.1080/00405000902732883Search in Google Scholar

[25] Hermann, D., Ramkumar, S. S., Seshaiyer, P., Parameswaran, S. (2004). Frictional study of woven fabrics: the relationship between the friction and velocity of testing. Journal of Applied Polymer Science, 92, 2420–2424.10.1002/app.20213Search in Google Scholar

[26] Ramkumar, S. S., Umrani, A. S., Shelly, D. C., Tock, R. W., Parameswaran, S., Smith, M. L. (2004). Study of the effect of sliding velocity on the frictional properties of nonwoven fabric substrates. Wear, 256, 221–225.10.1016/S0043-1648(03)00440-XSearch in Google Scholar

[27] Ajayi, J. O. (1992). Fabric smoothness, friction, and handle. Textile Research Journal, 62, 52–59.10.1177/004051759206200108Search in Google Scholar

[28] Virto, L., Naik, A. (1997). Frictional behavior of textile fabrics part I: sliding phenomena of fabrics on metallic and polymeric solid surfaces. Textile Research Journal, 67, 793–802.10.1177/004051759706701103Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry