Abstract

To develop antibacterial durability and low yellowing of sports underwear fabric, silver ion polyurethane filaments (Ag+ PUFs) were used as base yarn, and polyamide filaments were used as face yarn. Nine fabric samples with different Ag+ PUF contents (7, 8, 9, 17, 18, and 19%) were prepared. The fabrics were dyed in light, medium, and dark pink. Ag+ PUF was characterized by scanning electron microscopes for the morphology. Antibacterial properties and mechanical properties of Ag+ PUF were measured. The antibacterial durability, yellowing, elastic recovery, air, and moisture permeability were tested, and fuzzy mathematics was used for comprehensive evaluation. The results demonstrated that Ag+ PUF has good antibacterial properties and mechanical properties. The inhibition rates of the fabric against Escherichia coli and Staphylococcus aureus were 100%. When Ag+ PUF content was 18 and 19%, the antibacterial rates of medium pink fabrics both E. coli and S. aureus were 100% after laundering 30 times. The yellowing of the fabric before dyeing was the lowest when Ag+ PUF content was 7%. Compared with before dyeing, the yellowing of the fabric decreased by 19.13 % after dyeing. The comprehensive performance of 3# fabric is the best, and it has antibacterial persistence and low yellowing.

1 Introduction

People’s demand for the antibacterial comfort of sports underwear is increasing not only because fabrics can provide an ideal microenvironment for the growth of microorganisms by providing sufficient moisture, nutrients, and oxygen, but also when sports produce high-temperature, wet, and closed conditions and promote bacterial reproduction [1,2]. Bacteria can attach to sports underwear, causing permanent changes to the fabric. These changes include a decrease in tensile strength and elasticity, and alterations in appearance [3]. Furthermore, sports underwear with bacteria and long-term contact with the body can be harmful to health [4]. In addition, some sports underwear fabrics are made from polyamide filament (PAF) and polyurethane filament (PUF), which is another serious problem as it causes yellowing in the finished fabric [5]. Therefore, it is urgent to develop sports underwear fabrics by PAF/PUF with excellent antibacterial durability and low yellowing.

To meet the antimicrobial requirements of sports underwear, antibacterial polyurethane filaments (APUFs) [6,7,8] are used. Sheikh et al. [9] synthesized APUF containing silver nanoparticles by electrospinning, and antimicrobial tests indicated that the prepared fibers had a high bactericidal effect against Escherichia coli. However, the preparation process of silver nanoparticles is complicated and the reaction device is expensive. The cost of electrospinning is high, and it is difficult to achieve large-scale production [10,11].

Silver ion polyurethane filaments (Ag+ PUFs) by dry spinning using silver ions and polyurethane solution can solve the aforementioned problems. Compared with nano-silver, the preparation of silver ion (Ag+) is more convenient, and the current factory production of PUF is still a dry method, the antimicrobial agent containing Ag+ and polyurethane solution mixed with dry spinning, easy to operate, and can be achieved in large-scale production and reduce costs. Moreover, Ag+ has dynamic inhibitory and bactericidal effects against a broad spectrum of Gram-positive and Gram-negative bacteria. The antibacterial mechanism is that the cell wall of the microorganism is infiltrated, the deoxyribonucleic acid is converted into a condensed form, and the sulfhydryl group of the protein is bound by silver ions, resulting in damage and death of the bacteria [12,13,14,15]. Hence, Ag+ is widely used in textiles. Ag+ is fixed on the fabric by coating [16], pad dry curing [17], chemical grafting [18], and other methods. Experimental experiments show that its antibacterial effect is very good but there is a problem of poor durability. Sun et al. [19] prepared polylactic acid porous fibers containing Ag+, and Wang et al. [20] coordinated Ag+ to polyacrylonitrile. Both fibers exhibited excellent antibacterial properties. However, there are very few reports on Ag+ PUF, and the only studies on silver-ion antimicrobial fibers are more focused on its preparation and properties, with very little research on the properties of their knitted fabric. Also, Ag+ PUF is knitted with other yarns, especially PAF, which easily produces fabric yellowing after storing for some time. In addition to being easily oxidized by reactive groups such as amino groups (–NH2) and amide groups (–CONH–) in the molecular chain of PAF and Ag+ PUF, Ag+ is highly susceptible to oxidation and yellowing when exposed to air. This is also a major reason for this [5]. Nevertheless, research on PAF/Ag+ PUF fabric in improving yellowing is less reported.

In this study, Ag+ PUF and PAF were designed to prepare various fabric samples with different parameters that affect the properties. According to the common form of knitted fabrics used for sports underwear, the different Ag+ PUF content of fabric was divided into three structures with 22.2 dtex and 44.4 dtex Ag+ PUF. The fabrics were dyed in three colors. Nine pieces of fabric were obtained by using the orthogonal design of experiments. The antibacterial effect as well as yellowing of the fabric was measured. Meanwhile, elastic recovery, air permeability, and moisture absorption of the fabric were characterized. Fuzzy mathematics was used for comprehensive evaluation.

2 Experimental

2.1 Materials

22.2 dtex and 44.4 dtex of Ag+ PUF and PUF were supplied from Lianyungang LDZ New Aoshen Spandex Co., Ltd., China. 77.8 dtex PAF was purchased from the market.

2.2 Experimental design

The main factors affecting the antibacterial and yellowing effect of fabrics include yarn thickness, fabric structure, and dyeing degree. The single-factor experiment was carried out on the fabric preparation process, the test factor levels are shown in Table 1, and the orthogonal test design table after transformation is shown in Table 2.

Test factor levels

| Level | Factor | ||

|---|---|---|---|

| Linear density of Ag+ PUF | Structure | Color | |

| 1 | 22.2 dtex | Plain weft | Light pink |

| 2 | 44.4 dtex | 3 + 1 mock rib | Medium pink |

| 3 | — | 2 + 2 mesh | Deep pink |

Orthogonal test design table after transformation

| Sample No. | Linear density of Ag+ PUF/dtex | Structure | Color |

|---|---|---|---|

| 1# | 22.2 | 3 + 1 mock rib | Light pink |

| 2# | 44.4 | 3 + 1 mock rib | Medium pink |

| 3# | 44.4 | 2 + 2 mesh | Light pink |

| 4# | 22.2 | 2 + 2 mesh | Medium pink |

| 5# | 22.2 | Plain weft | Deep pink |

| 6# | 44.4 | Plain weft | Light pink |

| 7# | 44.4 | 3 + 1 mock rib | Deep pink |

| 8# | 22.2 | 2 + 2 mesh | Deep pink |

| 9# | 44.4 | Plain weft | Medium pink |

2.3 Fabric preparation

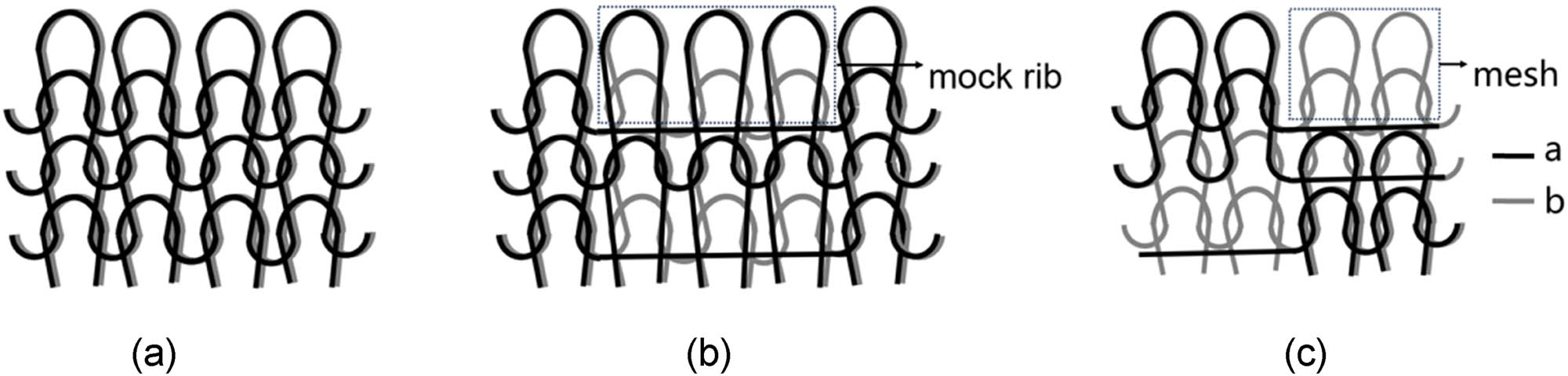

The fabric is made of PAF for the plating yarn and Ag+ PUF for the ground yarn. A seamless knitting machine (SM8-TOP2 MP2, Santoni, Italy) was used to produce all seamless fabrics. The cylinder diameter of the machine is 15 inches with 1,344 needles and a gauge of 28 (28 needles per inch). Two types of yarn feeders and eight yarn feeders each were anchored to the machine. The basic information on the fabric samples is given in tabular form in Table 3. Samples 1#–9# are plated stitches. The stitch structures of the fabric samples are shown in Figure 1 [21]. Figure 1(a) shows face yarn, in which PAF is used; Figure 1(b) shows base yarn, in which Ag+ PUF is used. As shown in Figure 1(b), as the partial yarn does not form a circle, the formation of floating line shrinkage leads to a mock rib effect. As shown in Figure 1(c), because the face yarn does not form a circle to form a floating line, the base yarn normally forms a circle, but the Ag+ PUF is too fine, so the mesh effect is formed. Figure 2 shows the notation of three stitch structures.

Basic information of fabric samples

| Sample no. | Courses per inch | Wales per inch | Areal density (g/m2) | Thickness (mm) | Porosity (%) | Ag+ PUF content (%) |

|---|---|---|---|---|---|---|

| 1# | 66 | 109 | 334 | 1.76 | 86.45 | 9.0 |

| 2# | 74 | 125 | 344 | 1.90 | 88.75 | 19.1 |

| 3# | 56 | 109 | 200 | 1.25 | 80.78 | 17.2 |

| 4# | 55 | 97 | 195 | 1.20 | 78.39 | 7.1 |

| 5# | 48 | 99 | 222 | 1.21 | 82.13 | 7.9 |

| 6# | 48 | 107 | 252 | 1.27 | 84.63 | 19.1 |

| 7# | 73 | 124 | 345 | 1.91 | 88.86 | 18.3 |

| 8# | 55 | 96 | 196 | 1.20 | 78.44 | 7.1 |

| 9# | 47 | 106 | 253 | 1.28 | 84.87 | 18.3 |

Stitch structures: (a) plain weft, (b) 3 + 1 mock rib, and (c) 2 + 2 mesh.

Notation of three stitch structures: (a) plain weft, (b) 3 + 1 mock rib, and (c) 2 + 2 mesh.

The grey fabrics are first washed in water at 98°C for 20 min for the first shaping, then placed in a tumble dryer at 50°C for 30 min for drying, and finally, ironed.

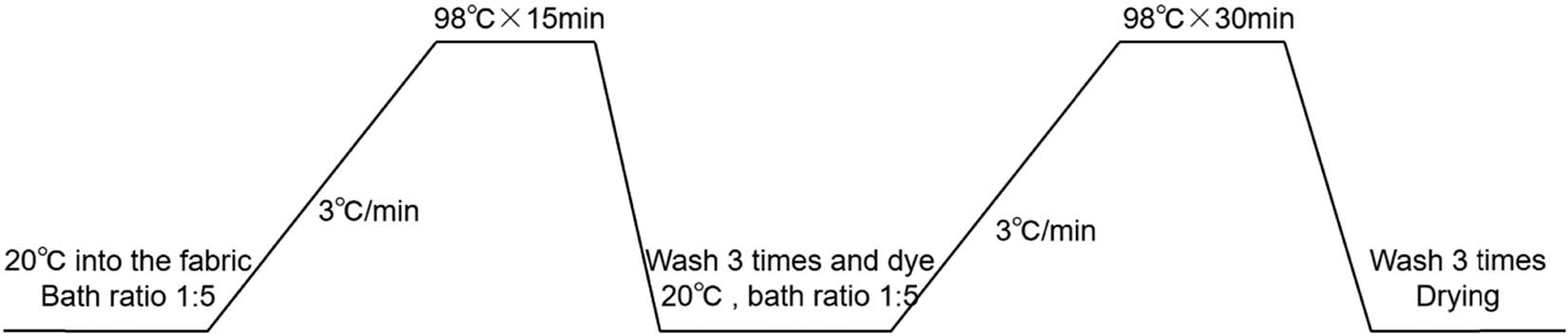

2.4 Fabric dyeing

The fabrics were dyed with acid dye, which was divided into two steps: cleaning and dyeing. The auxiliary agent required for cleaning is 2 g/L sodium carbonate and 1 mg/L high-efficiency refining agent; the dyeing formula is 10% acetic acid 10 mL/L and acid red dye. Light pink is 0.05 g. Medium pink is 0.15 g. Deep pink is 0.5 g. The dyeing flow chart is shown in Figure 3.

Fabric dyeing process flow chart.

2.5 Characterization tests

2.5.1 Yarn properties

2.5.1.1 Scanning electron microscope (SEM) of PUF and Ag+ PUF

PUF and Ag+ PUF 22.2 dtex and 44.4 dtex were cleaned by the ultrasonic wave and dried in the oven, then cut into small strips, and fixed on the sample table. After gold spraying, the surface morphology of them was observed by SEM (Hitachi High-Technologies Corp., Tokyo, Japan).

2.5.1.2 Mechanical properties of Ag+ PUF and PUF

The mechanical properties of Ag+ PUF and PUF were investigated according to the standard FZ/T 50006-2013 “Test method for the tenacity of spandex filament yarns” using a universal tensile tester (E43, MTS, China). The sample length was 50 mm. The tensile speed was 500 mm/min and the preload was 0.3 cN. Each sample was re-tested ten times and averaged.

2.5.1.3 Antibacterial properties of Ag+ PUF

The antibacterial methods in the study of Jiang et al. [22] were used to test the Ag+ PUF for E. coli and Staphylococcus aureus. For each sample, three blank, three control, and three experimental samples were set up in the experiment, and experimental results were averaged.

2.5.2 Fabric properties

2.5.2.1 Antibacterial properties of fabric with Ag+ PUF

The antibacterial effect of fabric was measured according to GB/T 20944.3-2008, and S. aureus was evaluated, respectively. For each sample, three blank, three control, and three experimental samples were included in the experiment. The experimental results were averaged.

2.5.2.2 Yellowing properties of fabric with Ag+ PUF

The degree of yellowing of the fabric was characterized by the whiteness value. The whiteness of the fabric was tested with a color measuring and matching instrument (Datacolor 650, Datacolor, America). A small aperture was selected, the fabric was folded twice (four layers), then, its whiteness was tested, and the E313 value was read. The smaller the value, the greater the yellowing degree. Each sample was re-tested five times and averaged.

2.5.2.3 Elastic recovery of fabric with Ag+ PUF

The elastic recovery of the fabric was tested according to FZ/T 70006-2004 “Stretch and recovery testing method for knitted fabrics” using the constant rate of extension method on an electronic tensile tester (YG028, Ningfang Instrument, China). Each sample was measured three times, and the results were averaged.

2.5.2.4 Air permeability of fabric with Ag+ PUF

The air permeability of the fabric was determined using a digital fabric permeability tester (YG461E-Ⅲ, Ningfang Instrument, China) in accordance with GB/T5453-1997 “Determination of the permeability of fabrics to air.” Each sample was measured three times, and the results were averaged.

2.5.2.5 Moisture penetrability of fabric with Ag+ PUF

The machine used to test moisture penetrability was the YG601H 46 by Ningfang Instrument in China. The test was conducted according to the GB/T 12704-1991 standard, which employs the Moisture Cup Method for measuring fabric moisture permeability. Each sample was measured three times and the results were averaged.

3 Results and discussion

3.1 Yarn properties

3.1.1 SEM analyses of PUF and Ag+ PUF

As can be seen from Figure 4(b) and (d), the surface of PUF is smooth, while the surface of Ag+ PUF has fine particles, and the surface of Ag+ PUF is smooth as a whole without separation phenomenon, indicating that the combination of silver ion antibacterial agent and Ag+ PUF is good, as shown in Figure 4(a) and (c).

Morphology of the Ag+ PUF and PU. (a) 22.2 dtex Ag+ PUF × 700; (b) 22.2 dtex PUF × 700; (c) 44.4 dtex Ag+ PUF × 500; and (d) 44.4 dtex PUF × 500.

3.1.2 Mechanical analyses of PUF and Ag+ PUF

The experimental results of PUF and Ag+ PUF are shown in Table 4. It can be seen that the breaking strength and elongation at the break of PUF and Ag+ PUF with the same liner density are very close, indicating that the antibacterial agent added has very little influence on the tensile property.

Breaking strength and elongation at break

| Liner density | Breaking strength (CN) | CV% | Breaking elongation (%) | CV% |

|---|---|---|---|---|

| PUF22.2 | 27.30 | 3.68 | 49.70 | 19.26 |

| Ag+ PUF 22.2 | 26.70 | 5.17 | 56.15 | 22.62 |

| PUF44.4 | 61.50 | 7.44 | 104.96 | 12.55 |

| Ag+ PUF 44.4 | 58.50 | 9.46 | 112.90 | 15.79 |

3.1.3 Antibacterial analyses of Ag+ PUF

A typical antibacterial picture is shown in Figure 5. PUF without the Ag+ antimicrobial agent has no effect on E. coli and S. aureus. However, as shown by the dramatic reduction in the number of surviving colonies after incubation, Ag+ PUF has excellent antimicrobial properties. This indicates that Ag+ is effective against E. coli and S. aureus [12,13,14,15].

Antibacterial properties of Ag+ PUF against E. coli and S. aureus: (a) E. coli: a0: control; a1: 22.2 dtex Ag+ PUF; and a2: 44.4 dtex Ag+ PUF. (b) S. aureus: b0: control sample; b1: 22.2 dtex Ag+ PUF; and b2: 44.4 dtex Ag+ PUF.

3.2 Fabric properties

3.2.1 Antibacterial analyses of fabric with Ag+ PUF

Figure 6 contains the antibacterial efficiency of nine kinds of fabrics against E. coli and S. aureus, which could reach 100%. No bacterial strain appeared in the test petri dish, indicating that the Ag+ PUF in the fabric contained sufficient antibacterial agents, showing excellent antibacterial properties. The effectiveness of silver ions against E. coli and S. aureus has been demonstrated [12,13,14,15].

Antibacterial properties of fabrics against E. coli and S. aureus: (a) E. coli:a0: control sample and a1–a9: sample 1#–9#. (b) S. aureus: b0: control sample and b1–b9: sample 1#–9#.

The antibacterial effects of the fabrics after washing 30 times are shown in Figure 7. It can be seen that the antibacterial effects of the fabrics with 44.4 dtex Ag+ PUF are better than those of the fabrics with 22.2 dtex Ag+ PUF.

Antibacterial effects of fabrics after washing: (a) E. coli: a0: control sample and a1–a9: sample 1#–9#. (b) S. aureus: b0: control sample and b1–b9: sample 1#–9#.

Table 5 is the orthogonal result of the antibacterial effect. The analysis shows that the linear density of Ag+ PUF has the greatest influence on the knitted fabric of the sample. The antibacterial rate of fabrics with 44.4 dtex Ag+ PUF is 18.8% higher than that of fabrics with 22.2 dtex Ag+ PUF. This is because 44.4 dtex Ag+ PUF is thicker than 22.2 dtex Ag+ PUF, which contains more Ag+ antibacterial agents. The second is the effect of color on the antibacterial permeability of the sample knitted fabric. The antibacterial permeability of sample 4# is 5.9% higher than that of sample 2#. The deepening of the dyeing degree made more dye molecules attached to the fabric surface, which may also be the reason for limiting the role of Ag+. The tissue structure was the least affected, and the antibacterial effect of the 3 + 1 mock rib tissue was better, followed by the plain weft tissue, and the 2 + 2 mesh tissue was the worst.

Antibacterial performance orthogonal results

| Sample number | Factors | ||

|---|---|---|---|

| A: linear density of Ag+ PUF | B: structure | C: color | |

| K1 | 347.90 | 283.60 | 295.90 |

| K2 | 497.10 | 296.70 | 285.20 |

| K3 | — | 264.70 | 263.90 |

| k1 | 115.97 | 94.53 | 98.63 |

| k2 | 165.70 | 98.90 | 95.07 |

| k3 | — | 88.23 | 87.97 |

| Optimal level | A2 | B2 | C1 |

| Range | 49.73 | 6.30 | 10.66 |

| Primary and secondary order | A>C>B | ||

3.2.2 Yellowing analyses of fabric with Ag+ PUF

Figure 8 displays the yellowing physical picture of fabric before dyeing. Compared with a0, the yellowing of a1–a9 fabrics is visible to the naked eye. The addition of Ag+ accelerates the yellowing of the fabric through an oxidation reaction. To be more objective, the yellowing performance of the fabric was tested. Figure 9 contains the yellowing permeability of nine fabric samples before and after dyeing. It can be seen that the whiteness value of fabric before dyeing is 71.45–79.33, while the whiteness value of fabric after dyeing is 85.59–92.59, and the average increase is 14.33.

The yellowing physical picture of fabric before dyeing: a0: control sample and a1–a9: sample 1#–9#.

Yellowing performance of fabrics before and after dyeing.

The range analysis of the yellowing performance of nine fabrics was carried out, and the influence of each factor on the yellowing performance of the fabric was obtained. As shown in Table 6, the linear density of Ag+ PUF has the greatest influence on the yellowing performance of the knitted fabric of the sample. The whiteness value of the 22.2 dtex Ag+ PUF sample is 7.88 higher than that of the 44.4 dtex Ag+ PUF fabric. Second, color has a great influence on the sample’s yellowing. Deep pink has the best whiteness value, 7.01 and 3.27 higher than light and medium pink. The main reason for this is that the fabric is washed to remove partial yellow stains before dyeing, and the more dye molecules are attached to the PAF, the more it discolors as the level of dyeing deepens [23]. Fabrics are prevented from turning yellow. The least influence on the yellowing performance of the fabric is the structure. Among them, the yellowing of the 2 + 2 mesh is the lowest, which may be due to the 2 + 2 mesh being loose, not as tight as the plain weft, and 3 + 1 mock rib, PAF, and Ag+ PUF contact is not close enough to cause.

Yellowing performance orthogonal results

| Sample number | Factors | ||

|---|---|---|---|

| A: linear density of Ag+ PUF | B: structure | C: color | |

| K1 | 447.24 | 267.52 | 261.11 |

| K2 | 355.16 | 264.17 | 268.56 |

| K3 | — | 270.71 | 272.73 |

| k1 | 149.08 | 89.17 | 87.04 |

| k2 | 118.39 | 88.06 | 89.52 |

| k3 | — | 90.24 | 90.91 |

| Optimal level | A1 | B3 | C3 |

| Range | 30.69 | 2.18 | 3.06 |

| Primary and secondary order | A>C>B | ||

3.2.3 Elastic recovery analyses of fabric with Ag+ PUF

The elastic recovery results of the fabric are shown in Table 7. It can be seen that the elastic recovery of the fabric is between 67.93 and 85.11%. Overall, the weft elastic recovery rate of the fabric is slightly greater than that of the wrap, which may be because the yarn feeding direction of the machine in the weaving process of the weft-knitted fabric is horizontal, and the fabric is easy to transfer during the weft stress process, so it is greater than the wrap [21].

Elastic recovery of fabric samples

| Sample | Elastic recovery (%) | |||

|---|---|---|---|---|

| Weft | Standard deviation | Wrap | Standard deviation | |

| 1# | 75.34 | 0.7 | 71.18 | 0.3 |

| 2# | 85.11 | 2.8 | 80.79 | 1.4 |

| 3# | 78.91 | 0.5 | 72.12 | 0.8 |

| 4# | 75.49 | 1.3 | 68.23 | 2.7 |

| 5# | 76.35 | 0.4 | 70.52 | 3.5 |

| 6# | 83.39 | 2.5 | 80.26 | 1.6 |

| 7# | 85.00 | 3.4 | 81.26 | 2.1 |

| 8# | 74.62 | 0.9 | 67.93 | 0.6 |

| 9# | 83.25 | 1.0 | 80.28 | 0.9 |

The orthogonal analysis results of the elastic recovery are shown in Table 8. The linear density of Ag+ PUF has the greatest influence on the elastic recovery of the sample. The elastic recovery of the 44.4 dtex Ag+ PUF sample is 10.49% higher than that of the 22.2 dtex Ag+ PUF fabric. Ag+ PUF belongs to elastic fiber and its elastic recovery increases with the increase of content. Second, the structure has a great influence on the elastic recovery of the sample. Among them, the elastic recovery of the 3 + 1 mock rib structure is the best, which is 8.65 and 12.04% higher than that of the plain weft structure and the 2 + 2 mesh structure. This is because 3 + 1 mock rib structure of the fabric makes the coil shrink due to the existence of floating wire, and the fabric is tight and thick. The least influence on the elastic recovery of the fabric is the color.

Elastic recovery orthogonal results

| Sample number | Factors | ||

|---|---|---|---|

| A: linear density of Ag+ PUF | B: structure | C: color | |

| K1 | 301.80 | 242.99 | 237.64 |

| K2 | 415.66 | 245.45 | 243.85 |

| K3 | — | 229.02 | 235.97 |

| k1 | 100.60 | 81.00 | 79.21 |

| k2 | 138.55 | 81.82 | 81.28 |

| k3 | — | 76.34 | 78.66 |

| Optimal level | A2 | B2 | C2 |

| Range | 38.55 | 5.48 | 2.62 |

| Primary and secondary order | A>B>C | ||

3.2.4 Air and moisture permeability analyses of fabric with Ag+ PUF

It can be seen from Figure 10 that the air and moisture permeability of fabrics 3#, 4#, and 8# is larger than other fabrics.

Air and moisture penetrability of fabrics: (a) air penetrability and (b) moisture penetrability.

To further analyze the influencing factors of the air and moisture permeability of the fabric, the range analysis of the air and moisture permeability is carried out. The orthogonal results are shown in Tables 9 and 10. The structure has the greatest influence on the air and moisture permeability of the sample fabric. Among them, the air and moisture permeability of the 2 + 2 mesh structure is the largest, which is 176.16 and 118.16 mm/s, 108.83 and 82.97 g/(m2 h) higher than that of the 3 + 1 mock rib and plain weft structure in air and moisture permeability, respectively. Because the 2 + 2 mesh structure is loose, it is relatively thin. Higher porosity is contained in the 2 + 2 mesh structure of the fabric. The linear density of Ag+ PUF has the greatest influence on the air and moisture permeability of the sample. The air and moisture permeability of the 22.2 dtex Ag+ PUF sample fabric is the best, and the 44.4 dtex Ag+ PUF sample fabric is relatively low. The influence of color on the air and moisture permeability of the sample fabric is the least significant.

Air penetrability orthogonal results

| Sample number | Factors | ||

|---|---|---|---|

| A: linear density of Ag+ PUF | B: structure | C: color | |

| K1 | 1018.41 | 629.31 | 678.46 |

| K2 | 1011.19 | 460.57 | 674.53 |

| K3 | — | 939.72 | 676.61 |

| k1 | 339.47 | 209.77 | 226.15 |

| k2 | 337.06 | 153.52 | 224.84 |

| k3 | — | 313.24 | 225.54 |

| Optimal level | A1 | B3 | C2 |

| Range | 2.41 | 159.72 | 1.31 |

| Primary and secondary order | B>A>C | ||

Moisture penetrability orthogonal results

| Sample number | Factors | ||

|---|---|---|---|

| A: linear density of Ag+ PUF | B: structure | C: color | |

| K1 | 1158.50 | 776.10 | 817.20 |

| K2 | 1267.02 | 655.41 | 811.63 |

| K3 | — | 994.02 | 796.69 |

| k1 | 386.17 | 258.70 | 272.40 |

| k2 | 422.34 | 218.47 | 270.54 |

| k3 | — | 322.34 | 265.56 |

| Optimal level | A2 | B2 | C2 |

| Range | 36.17 | 112.87 | 1.86 |

| Primary and secondary order | B>A>C | ||

3.3 Fuzzy mathematics comprehensive evaluation

Given the different linear densities of Ag+ PUF, structure, and color of nine sports underwear fabrics, the fuzzy mathematics comprehensive evaluation method can be used to evaluate the comprehensive performance of each fabric, select the optimal process parameters, and pave the way for the subsequent development of antibacterial durability and low yellowing seamless sports underwear. The fabric performance factor set is established U, U = { U1, U2, U3, U4, U5 }, where U1 is the antibacterial durability, U2 is the yellowing permeability, U3 is the elastic recovery rate, U4 is the air permeability, and U5 is the moisture permeability. The performance test values of the sample fabric are shown in Table 11.

Performance test results

| Sample number | Antibacterial durability | Yellowing permeability | Elastic recovery | Air permeability | Moisture permeability |

|---|---|---|---|---|---|

| 1# | 97.50 | 85.61 | 73.26 | 165.64 | 231.45 |

| 2# | 100.00 | 89.32 | 82.95 | 149.48 | 214.03 |

| 3# | 98.40 | 85.59 | 75.52 | 303.81 | 321.39 |

| 4# | 85.70 | 89.41 | 71.86 | 321.61 | 340.29 |

| 5# | 84.10 | 90.97 | 73.44 | 216.86 | 254.43 |

| 6# | 100.00 | 89.91 | 81.83 | 209.01 | 264.36 |

| 7# | 99.20 | 92.59 | 83.13 | 145.45 | 209.93 |

| 8# | 80.60 | 89.17 | 71.28 | 314.30 | 332.33 |

| 9# | 99.50 | 89.83 | 81.77 | 203.44 | 257.31 |

Standardize the different performance indicators of the fabric. For the above performance, the larger the test value, the better the performance, according to the following formula:

Calculate the fuzzy matrix R:

According to the previous research on the related aspects of antibacterial comfort fabrics and combined with the opinions of experts in this field, the subjective weighting method is adopted, and the weight distribution of each factor is as follows: A = {0.30, 0.30, 0.10, 0.15, 0.15}. According to formula (3), the evaluation vector B of this article is calculated, as shown in matrix (4).

According to the comprehensive evaluation results, the order of thermal-wet comfort and elastic recovery of nine seamless sports underwear fabrics is 3# > 4# > 8# > 6# > 9# > 1# > 5# > 2# > 7#. Among them, the evaluation value of 3# is the largest, indicating that the comprehensive performance of the light pink fabric with 2 + 2 mesh structure knitted with 44.4 dtex Ag+ PUF is the best.

4 Conclusion

In this work, Ag+ PUF was knitted with PAF into nine fabric samples prepared with different Ag+ PUF contents (7, 8, 9, 17, 18, and 19%) . After a series of tests and characterization, the conclusions are as follows: the antibacterial rates of Ag+ PUF against E. coli and S. aureus were 100%, both of which reached the antibacterial standard. The Ag+ PUF has good mechanical properties, which can be used to prepare underwear fabrics; the nine kinds of fabrics have excellent antibacterial properties before washing. When Ag+ PUF content was 18 and 19%, the antibacterial rates of medium pink fabrics of both E. coli and S. aureus were 100% after laundering 30 times. The antibacterial rate of the other six fabrics was the lowest at 80%, which met the antibacterial standard. The yellowing of the fabric before dyeing was the lowest when Ag+ PUF content was 7%. Compared with before dyeing, the yellowing of the fabric decreased by 19.13% after dyeing. Fabrics with 7 and 17% Ag+ PUF contents have the best air and moisture permeability, which has a lot to play with the high porosity of the 2 + 2 mesh. The comprehensive performance of 3# fabric is the best, and it has antibacterial persistence and low yellowing.

Ag+ PUF is a functional fiber based on antimicrobial silver ions. Most knitted products for sports underwear contain 5–20% PUF. Currently, there are few studies on the development of knitted products using APUF. In this study, Ag+ PUF was used to develop seamless sports underwear fabrics, which provides a reference for the development of antimicrobial functional products. However, the study of yellowing in this article was only to observe whether the severe yellowing caused by the addition of silver ions would affect the appearance of the dyed fabrics. To analyze the mechanism of yellowing of fabrics, further studies are expected to control whiteness degradation. Due to the instability of silver ions, research on PUF containing other antimicrobial agents without silver ions will be added to future research.

Acknowledgements

The authors acknowledge the financial support from the Fundamental Research Funds for the Central Universities (JUSRP122003) and the Natural Science Foundation of Jiangsu Province (BK20221094).

-

Conflict of interest: The author(s) declared no potential conflicts of interest concerning the research, authorship, and/or publication of this article.

-

Data availability statement: All relevant data are within the paper.

References

[1] Esam, S. A. (2022). Surface functionalization of polyester textiles for antibacterial and antioxidant properties. Polymers, 14(24), 5512.10.3390/polym14245512Search in Google Scholar PubMed PubMed Central

[2] Mariana, B., Viorica, M., Torsten, T., Boris, M. (2015). Synthesis and characterization of antimicrobial textile finishing based on Ag:ZnO nanoparticles/chitosan biocomposites. RSC Advances, 5, 21562–21571.10.1039/C4RA13918FSearch in Google Scholar

[3] Szostak-Kotowa, J. (2004) Biodeterioration of textiles. International Biodeterioration & Biodegradation, 53(3),165–170.10.1016/S0964-8305(03)00090-8Search in Google Scholar

[4] Bian, N. Y., Yang, X. L., Zhang, X. L., Zhang, F., Hou, Q., Pei, J. (2021). A complex of oxidised chitosan and silver ions grafted to cotton fibres with bacteriostatic properties. Carbohydrate Polymers, 262(1),117714.10.1016/j.carbpol.2021.117714Search in Google Scholar PubMed

[5] Luo, D. H. (2014). Anti-yellowing finishing of Brocade spandex fabric. Printing and Dyeing, 40(11), 25–28 in Chinese).Search in Google Scholar

[6] Qu, R. J., Gao, J. J., Tang, B., Ma, Q. L., Qu, B. H., Sun, C. M. (2014). Preparation and property of polyurethane/nanosilver complex fibers. Applied Surface Science, 294, 81–88.10.1016/j.apsusc.2013.11.116Search in Google Scholar

[7] Bihter, Z., Mehmet, H. M. (2015). Fabrication and Characterization of antibacterial polyurethane acrylate-based materials. Materials Research, 18(4), 867–87210.1590/1516-1439.026515Search in Google Scholar

[8] Shi, H. C., Liu, H. Y., Luan, S. F., Shi, D., Yan, S., Liu, C., et al. (2016). Antibacterial and biocompatible properties of polyurethane nanofiber composites with integrated antifouling and bactericidal components. Composites Science and Technology, 127, 28–35.10.1016/j.compscitech.2016.02.031Search in Google Scholar

[9] Sheikh, F. A., Barakat, N. A., Kanjwal, M. A., Chaudhari, A. A., Jung, I. H., Lee, J. H., et al. (2009). Electrospun antimicrobial polyurethane nanofibers containing silver nanoparticles for biotechnological applications, Macromolecular Research, 17, 688–696.10.1007/BF03218929Search in Google Scholar

[10] Abuskhuna, S., Briody, J., McCann, M., Devereux, M., Kavanagh, K., Fontecha, J. B., et al. (2004). Synthesis, structure and antifungal activity of dimeric Ag(I) complexes containing bis-imidazole ligands. Polyhedron, 23(7), 1249–1255.10.1016/j.poly.2004.02.006Search in Google Scholar

[11] Prabhu, S., Poulose, E. K. (2012). Silver nanoparticles: mechanism of antimicrobial action, synthesis, medical applications, and toxicity effects. International Nano Letters, 2(1), 1–10.10.1186/2228-5326-2-32Search in Google Scholar

[12] Li, H. Y., Gao, Y. C., Li, C. X., Ma, G., Shang, Y., Sun, Y. (2016). A comparative study of the antibacterial mechanisms of silver ion and silver nanoparticles by Fourier transform infrared spectroscopy. Vibrational Spectroscopy, 85, 112–121.10.1016/j.vibspec.2016.04.007Search in Google Scholar

[13] Lyutakov, O., Goncharova, I., Rimpelova, S., Kolarova, K., Svanda, J., Svorcik, V. (2015). Silver release and antimicrobial properties of PMMA films doped with silver ions, nano-particles and complexes. Biomaterials Advances, 49, 534–540.10.1016/j.msec.2015.01.022Search in Google Scholar PubMed

[14] Jung, W. K., Koo, H. C., Kim, K. W., Shin, S., Kim, S. H., Park, Y. H. (2008). Antibacterial activity and mechanism of action of the silver ion in Staphylococcus aureus and Escherichia coli. Applied and Environmental Microbiology, 74(8), 2171–2178.10.1128/AEM.02001-07Search in Google Scholar PubMed PubMed Central

[15] Feng, Q. L., Wu, J., Chen, G. Q., Cui, F. Z., Kim, J. O. (2015). A mechanistic study of the antibacterial effect of silver ions on Escherichia coli and Staphylococcus aureus. Journal of Biomedical Materials Research, 52(4), 662–668.10.1002/1097-4636(20001215)52:4<662::AID-JBM10>3.0.CO;2-3Search in Google Scholar

[16] Patil, K., Wang, X. G., Lin, T. (2013). Electrostatic coating of cashmere guard hair powder to fabrics: Silver ion loading and antibacterial properties. Powder Technology, 245, 40–47.10.1016/j.powtec.2013.04.015Search in Google Scholar

[17] Erdem, R., Rajendran, S. (2016). Influence of silver loaded antibacterial agent on knitted and nonwoven fabrics and some fabric properties. Journal of Engineered Fibers and Fabrics, 11(1), 38–46.10.1177/155892501601100107Search in Google Scholar

[18] Ou, J. F., Wu, B., Xue, M. S., Wang, F. (2019). Silver ions anchored to fabric via coordination: Evaluation on washing durability and antibacterial activity. Materials Letters, 237(15), 134–136.10.1016/j.matlet.2018.11.090Search in Google Scholar

[19] Sun, Z. Y., Fan, C. X., Tang, X. P., Zhao, J. H., Song, Y. H., Shao, Z. B., et al. (2016). Characterization and antibacterial properties of porous fibers containing silver ions. Applied Surface Science, 387, 828–838.10.1016/j.apsusc.2016.07.015Search in Google Scholar

[20] Wang, W. X., Wan, Y. X., Liu, Y., Jiang, L. L., Bai, L. J., Chen, H., et al. (2017). Microwave-assisted rapid fabrication of antibacterial polyacrylonitrile microfibers/nanofibers via nitrile click chemistry and electrospinning. Journal of Applied Polymer Science, 134(44), 45490.10.1002/app.45490Search in Google Scholar

[21] Wang, X. X., Wan, A. L., Zeng, D., Qi, Q. (2023). Design and properties of shape memory sports bras for comfortable pressure based on ergonomics. Textile Research Journal, 2023, 93, 5153–5167.10.1177/00405175231202036Search in Google Scholar

[22] Jiang, Y. C., Zheng, A. N., Guan, Y., Xu, X., Gong, W. L. (2020). Gene reconstruction spandex with intrinsic antimicrobial activity. Chemical Engineering Journal, 404, 125152.10.1016/j.cej.2020.125152Search in Google Scholar

[23] Wang, X. Y., Ma, Z. T., Xu, C. H. (2023). One-bath process for bleaching and dyeing of polyester-covered cotton fabric using disperse dye with high resistance to alkalis and peroxides. Journal of Textile Research, 44(5), 38–45.Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry