Abstract

To enhance the intelligence of the ethnic clothing customization industry and provide online solutions for clothing ordering and fashion shows, this study analyses the latest developments in the fields of digital human models, 3D clothing models, and virtual clothing displays in recent years. This study focuses on analysing the categories and processes of three related technologies in clothing virtual display and compares the advantages and disadvantages of four human body modelling methods. Reshaping the facial features of a 3D body scan model and binding the bones of each part is key to providing a personalized body model. In addition, 3D clothing modelling technology is classified into three methods. The 3D fabric scan data are used to establish realistic seam information and process details simulation and use hybrid modelling methods to virtually sew 2D samples, which can enhance the realism of clothing models. The virtual display platform for ethnic clothing is constructed through layered design based on the Unity3D engine, matching versions and virtual display. The above research ideas can solve bottleneck problems in clothing customization. This has important guiding significance for opening up the ethnic clothing customization market, promoting the intelligence of the customization industry, and promoting ethnic clothing culture.

1 Introduction

The clothing customization market is booming in the era of the digital economy. The 3D virtual display technology is the key to realizing the smart customization consumer model, which covers more people and realizes more sales opportunities at the sales end. The main technical bottleneck of intelligent customization is to solve the problem of accurate measurement and achieve a Customer-to-Manufacturer (C2M) e-commerce model. The core of the C2M model is that consumers can choose fabrics online, participate in style design, and make personalized suggestions, and the key to achieving this personalized intelligent customization is to provide a realistic personalized virtual clothing effect display. Clothing personalized virtual displays can break the limitations of space and time, learn the function of interactive design, provide a highly efficient and low-cost online solution for intelligent customization of new releases, and obtain the body shape data of users and personalized needs in real-time for the manufacturing side.

Researchers have studied the workflow of the clothing design cycle system [1,2], integrating user operations into a workflow [1], establishing a 3D clothing library through coding [3], completing the whole process of clothing design and modelling, and providing standard patterns for clothing production. These studies of clothing modelling cannot meet the demand for high-volume personalized human digital models, and the research on the technology of large-volume personalized human digital models for the demand of intelligent customization is not enough. We found that there have been researchers who have developed a virtual clothing fitting system based on virtual reality (VR) technology [4]. However, this research needs to be further extended to observation systems with greater freedom to improve the problem of insufficient links between personalized human body modelling and clothing virtual display technology. The current virtual display technology is generally less mature and encounters several problems in which the fitting effect is not realistic enough, focusing on the human body model, fabric simulation effect, and the large gap between reality and other aspects. Personalized design, non-contact body measurement, and other consumer behaviour need to get fast positive feedback from the design and production ends.

This study divides the composition of clothing virtual displays into three parts: digital human body model, 3D clothing model, and platform-based virtual display. The corresponding digital technologies are 3D anthropometric technology, 3D body modelling technology, 3D clothing modelling technology, augmented reality (AR), and VR. Overall, 3D anthropometric technology provides an accurate data basis for 3D body modelling, generates accurate 3D human body models, and thus provides a digital virtual platform for the display of 3D clothing [5], realizing that 3D virtual clothing is “wearing” on the virtual human model. Then, building the display scene through the AR/VR technology, to realize the all-around virtual display of the human body, clothing, and other elements, as shown in Figure 1. The virtual display of ethnic clothing is the main content of building a digital resource base of ethnic clothing, actively creating intelligent customization of ethnic clothing relying on the Internet, accelerating online customization, B2M, C2M, and other e-commerce modes based on the real needs of users, which is of great significance for enhancing the level of design of ethnic clothing, expanding sales channels to improve the volume of orders as well as promoting the culture of ethnic clothing.

Content composition of virtual display of clothing.

2 Development process

2.1 Digital human body model

The digital human body model for the apparel field focuses on the human body shape and its parametric representation [6]. Personalization needs to quickly and conveniently construct the 3D human body models of different users at the sales end and the manufacturing end as effective physical support for virtual display [7], so there is an urgent need to build a method for personalized clothing customization, quickly obtaining human body parameters, and reconstructing the 3D human body model. Currently, the mainstream digital body modelling techniques include human body modelling based on 3D scanning technology, human body modelling based on parametric surface modelling, human body modelling based on specific software, and image-based human body modelling [8].

2.1.1 Human body modelling based on 3D scanning technology

3D body scanning combines information processing, electronics, computer graphics, computer vision, and other technologies to get single or multiple frames of data to reconstruct a static digital model. 3D body scanning is mainly completed to collect high-precision point cloud images of the human body, extract features, and other work [9].

The Cyberware WBX Full Body Colour 3D Scanner is capable of performing hundreds of thousands of scans of all parts of the human body. The system is equipped with four scanning heads, which rapidly scan each part of the human body from head to foot, generating a measurement data value every 2 mm to map out an accurate 3D dataset. The route for human body modelling based on 3D scanning technology is shown in Figure 2. The database of young male body shapes in Inner Mongolia has been established for the first time based on the principle of technical route and the advantages of human body shapes, to expand the boundaries of human body shape research, and to help the digital development of the clothing industry in Inner Mongolia.

A technical route for human modelling based on 3D scanning technology.

Yu and Kim [10] developed a dress form reflecting the body shape of middle-aged Korean women based on 3D human body data in Korean Size-6. Wen and Shih [11] developed a military body armour that protects and adapts using a K-means algorithm to create clusters of different body types for both sexes. Kolose et al. [12] developed a specific sizing system using anthropometric data from the New Zealand Defence Force Anthropometric Survey. All the above studies are built based on large-scale anthropometric data, taking advantage of 3D body scanning to establish a human body type database, which provides accurate data for clothing design, sizing systems, and smart prototypes, but cannot achieve the large number of personalized human digital model technologies required for smart customization. To be more accurately oriented to the development of specific clothing products, scholars have launched a study on the characteristics of the human body shape in local areas. Yoon et al. [13] broke through the use of traditional length data by defining six lateral shape directional vector angles based on three ground markers on the body shape, as well as a 3D surface created by standard landmarks. Then, the y-axis directional angle of the spatial vector was used to evaluate lateral body shape, and a logistic regression analysis was used to establish a classification and prediction model for upper lateral body shape. And established a classification and prediction model for upper body shape using logistic regression analysis. This method can be used to determine individual body shapes and can also interactively provide accurate sizing information to automated clothing pattern-making systems. Kim and Do [14] obtained foot shapes of elderly Korean men through a body scanner to help shoemakers produce multifunctional shoes. The 3D body scanning data are useful for studying obese body shapes [15], middle-aged and elderly people [16], and other special body shapes, accumulating accurate body shape data for people who need customized services and improving the quality of customized patterns. The idea is to summarize the original hundreds of individual data into dozens of characteristic parameters that can be highly correlated with customized clothing through mathematical and statistical methods [17], with a single parameter characterization [18] (length, angle) or a comprehensive mathematical relationship representation of several parts [19,20].

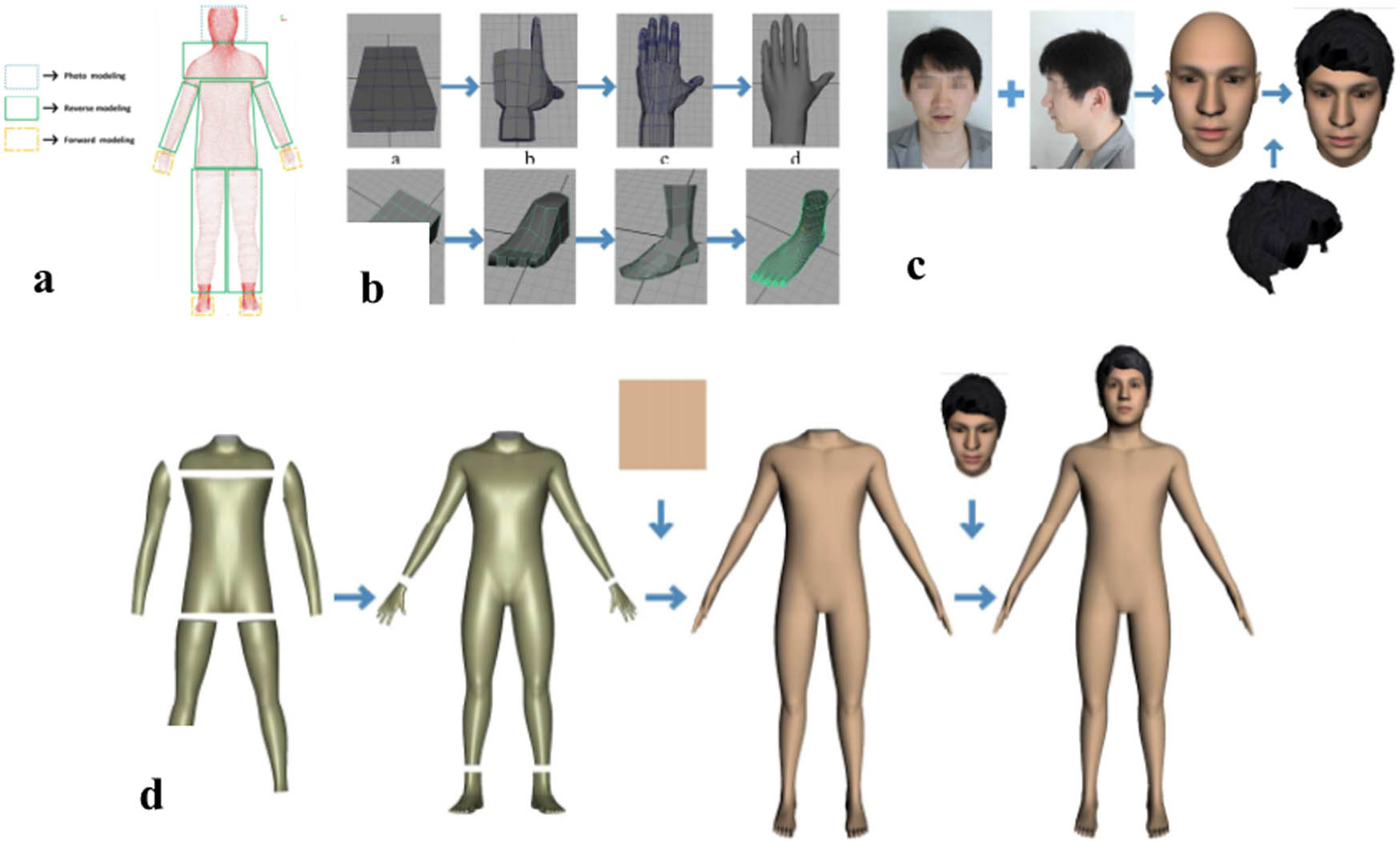

The focus of such digital human models (DHMs) is mainly on the measured body size data, ignoring the level of visualization of the specific model, which cannot satisfy or appeal to the visual experience of the customers at the sales end. Therefore, to build a personalized digital human body for e-commerce, Liu et al. [21] proposed a multiple modelling method (MMM) to create a realistic digital human body model. The TC2 is used to obtain the whole body point cloud data and then partition the human body module (Figure 3a). The forward modelling method is used to model the hand and foot (Figure 3b). The photo modelling method is used to model the head (Figure 3c) and the torso with the reverse modelling method (RMM) (Figure 3d). The hands, feet, head, and torso are integrated into a static model, and the virtual skeleton is bound to the avatar to create a DHM. In RMMs, the layout method is usually used to reconstruct various parts of the human body. First, extract the cross-section of the human body from the point cloud, and then fit the curve to obtain the human body slice. In general, the more curves, the more accurate it is to model the leg by this method. However, too many curves lead to rough surfaces of the model. It was found that a leg model which is fitted by lofting 20–25 curves can meet the needs of fashion design very well through trial and error. To construct human body parts such as arms, shoulders, and the middle of the torso with irregular point cloud data distribution as accurately as possible, it is first necessary to determine the boundary lines of each part based on the changes in human body curves. Then, the position of the cutting plane is determined based on the characteristic point coordinates of the human body curve and adopted spatial geometry and point clouds to fit surfaces. Finally, a human body part model can be established well. The hybrid modelling technology integrates the advantages of multiple modelling techniques to achieve personalized goals, which is a new approach to human body modelling.

MMM based on 3D body scanning including the process of a–d.

Human body modelling based on 3D body scanning technology mainly serves the manufacturing end of the clothing industry. The current problem is dealing with noise data and filling incomplete surfaces. Some details are still difficult to solve, including the shadow part of the armpit and crotch, the light absorption effect of hair and skin, data processing, etc. The follow-up should provide services for the industrial sales end from scanning technology and human body model reconstruction and establish a personalized digital human body.

2.1.2 Parametric-based human modelling

The parametric human modelling method combines ergonomic principles to establish a statistically obtained virtual human, which can change the body shape of the virtual human by inputting a set of low-dimensional feature parameters and outputting the corresponding 3D model of the human body. It is an essential human modelling tool due to its simple operation and easy popularization in commercial virtual fitting software, mainly including SCAPE, Skin Multi-Person Linear (SMPL), SMPL-X, and other high-accurate and high-speed parametric human body models [22].

Anguelov et al. [23] proposed a SCAPE parametric human model based on edge deformation (Figure 4) and achieved a high-quality animated surface model for moving sequences through motion capture. On this basis, Zhou et al. [24] proposed a simple and easy-to-use image modification technique to reconstruct 3D skeletons through 2D images for realistic image remodelling. Wang [25] synthesized a new parametric sample model of the human body by changing the feature wireframe. Parametric human modelling can achieve many modelling and flexible adjustments of inherent parameters. However, this method differs greatly from natural human surface deformation, and the base model in the existing software can hardly meet personalized customization. The human body reconstruction is affected by the parameter settings. If the parameters are not comprehensive, accurate human body reproduction cannot be achieved. Otherwise, too many parameters will reduce the modelling efficiency and cannot complete the desired effect.

The parametric human model of SCAPE.

2.1.3 Image-based human modelling

The image-based human modelling method refers to the use of real photos, drawn images, video images, depth images, etc., to obtain the two-dimensional information of human body images and the matching image processing algorithms to extract human body representation information, such as contours, feature dimensions, etc., and transform them into 3D spatial data to build a 3D human body model. The specific technical route is shown in Figure 5.

A technical route for image-based modelling.

The first problem of the image-based modelling method is to reconstruct parameters and size extraction of the 3D human body model. Gu et al. [26] used the method of “feature point - insertion point - feature curve - basal plane - human model” to establish 15 generation rules for feature section curves, achieving 3D virtual modelling of the female upper body and automatic generation of personalized panels. Cai et al. [27] classified the body shape of 178 female college students based on their waist, abdomen, and buttocks, achieving automatic recognition of body shape based on 2D photos. Both of the above two methods use “3D scanning + photos,” and the human body model built is more accurate. Li et al. [28] reconstructed a detailed 3D human body from multi-view images by combining voxel super-resolution with the learning of implicit representations. Zhang and Xiao [29] incorporated the topology of SMPL template mesh and flexible mesh deformation and first used a typical 2D CNN architecture ResNet-50 to extract perceptual features from the input image and fuse the image features into 3D space by perceptual feature transformation. This method can qualitatively generate 3D human body meshes with more details and can build more accurate dynamic pose models. Li et al. [30] effectively encoded the deformation by representing 3D human body shapes through vertex-based deformation. The aforementioned three studies focus on the visual communication of the human body’s dynamic poses and shapes, without involving the human body dimensions, and thus the models are not highly accurate. Lu et al. [31] improved the accuracy of image acquisition and constructed a fast and lightweight deep learning network called Fast Body Net to generate end-to-end human models. The consumer-grade RGBD camera proposed in this research can provide excellent applications in real-time display and interaction in VR.

Human body modelling based on image sequence has low equipment construction cost, convenient image acquisition, and is suitable for client input in the customization process. It has a certain value in the virtual fitting room on the sales side. However, the overall accuracy of the human body model could be higher. It should be combined with 3D human body scanning to obtain a more accurate model simultaneously. In addition, there is an increased requirement for human clothing, which still requires the human body to wear only underwear or no clothes. These methods need further research to reconstruct the natural human facial shape due to the complexity of facial structure.

2.1.4 Software-specific human modelling

Specific software can create or recreate human body parts and can render and interactively control them. Commonly used software includes Matlab, Geomagic, 3D Studio MAX, OpenGL, Poser, and Maya [8]. Matlab and Geomagic are reverse engineering software [32] that can reverse reconstruct the human body model, and that requires 3D human scanning models. 3D Studio MAX [33] and OpenGL [34] can build complex objects and carry out animation design and interactive control, which can be applied to virtual clothing design and virtual fitting systems. Poser can collect many vertex data of complex human surfaces and export them, then combine them with other software to build dynamic human models with diverse poses [35]. Maya has a powerful rendering function that can create lifelike characters [17] and environments, which is widely used in the field of film and television animation and graphic design. However, the human body model built by Maya has poor versatility, which is challenging to integrate into actual production and is rarely used in the clothing field.

Accurate human body data are the basis of clothing customization, and a realistic human shape model is the key for enhancing customer consumption experience. These two points are the bottleneck of digital human body modelling technology for smart customization. With the increasingly wide coverage of 5G networks, the demand for the digital human body for smart customization is not only limited to accurate data at the manufacturing end but has been expanded to areas such as personalized human body and interaction design at the sales end. With the rapid development of human body modelling technology, the subsequent research focuses on:

Large-scale personalized human modelling research.

Quickly generate realistic and personalized digital bodies.

Consider a detailed accurate model of the head and face.

Research on digital human body modelling technology is interfaced with industry applications and clients to be able to meet the needs of customized sales and production.

2.2 3D clothing model

Most consumers choose online customized clothing with the development of e-commerce, but they also give up buying because they cannot try on the real thing or judge whether the size is suitable [36]. In addition to solving the problem of direct measurement of human body data on the client side, the real wearing effect of the clothing model is also a challenging topic in the field of clothing digitization.

The 3D CAD system dedicated to clothing modelling aims to facilitate the visualization of changes to the clothing: the first method is that if changes to the clothing are required, the user will change the 2D patterns and re-run the visualization. Another more efficient method is to specify the desired 3D shape using advanced drawing tools in the 3D workspace. Currently, domestic and international research on the virtual modelling of clothing focuses on physical simulation methods, geometric simulation methods, and hybrid simulation methods. We summarize the technical route of 3D clothing modelling based on the above research in Figure 6.

3D clothing modelling technology route.

2.2.1 Physical simulation method for forward design

The idea of the physical simulation method is to study how to sew 2D patterns into 3D clothing and then import the 2D patterns into 3D software. Then, change the 3D shape by adjusting 2D patterns, and display the 3D dress effect in real-time [37]. This method matches the workflow of the manufacturing end of the clothing customization process, so it is called the forward design idea. To achieve realistic clothing draping effects and animation effects, realistic simulation of fabric is the prerequisite for the realization of 3D clothing modelling. Through the establishment of mechanical models, energy, and other physical quantities, the motion of each part of the fabric is transformed into the mass motion and particle model under the action of various forces [38] to simulate the constraint control of spatial motion deformation of 3D clothing patterns [39]. The spatial relationship between clothing and the human body is defined through the numerical solution, collision detection, and response [5].

Jin et al. [40] proposed two multi-precision fabric modelling methods based on machine learning to solve complex calculation problems and the long-time consumption of fabric physical simulation methods. Virtual sewing technology is another major difficulty of physical simulation methods, involving the conversion of 2D–3D clothing patterns, the boundary processing of sewing alignment, the constraint processing of the sewing process, etc. Zhang et al. [41] established a virtual clothing model with seams perfectly matching the sewing of the 2D patterns (Figure 7), which makes the clothing model of the virtual interface closer to the sewing state of the clothing in reality, and provides a more effective way for the intelligent customization client to achieve an interactive design with the manufacturing end. Chen et al. [42] proposed a novel Neural Sewing Machine, which can learn the representations of clothing with different shapes and topologies, and has been successfully applied to 3D clothing reconstruction and controllable manipulation.

Model of clothing with seam structure.

2.2.2 Geometric simulation method for the reverse design

The geometric simulation method aims to study how to design clothing directly on a 3D human model, confirm the clothing style by adjusting the 3D clothing display effect, and finally unfold it into a workable 2D pattern [37]. This method is based on the target results of the reverse generation of production elements, the opposite of the workflow of the clothing customization process, so it is called the reverse design idea. The basis of modelling is divided into human body models, clothing models, and pictures, using a data-driven approach to clothing modelling.

Kim and Vendrovsky [43] proposed a method to drive clothing deformation by human skeleton pose, adding collision detection to linear skin deformation to obtain a more ideal clothing model. Zakharkin et al. [44] proposed a new method to model clothing based on the human body point cloud, capturing the appearance of clothing from video and re-rendering. Geng et al. [45] proposed a data storage technique that allows users to draw 3D sketches on human surfaces and use contour lines as boundary lines by interpolation to obtain an interactive design of clothing models (Figure 8). Holte [46] scanned the real clothes using RGB-D sensors, then created the clothing model with the clothing modelling software MD, textured the surface, and approximated the colour of the obscured part by K-Nearest Neighbors, showing the results of digital clothing by scanning real clothes. Xu et al. [47] proposed a new method for constructing 3D virtual clothing models from photographs. The method only needs to input the front image and back image, to process various states of clothing: model, human body model, or plane. The predicted boundary is used to estimate the size information of clothing and deform the template clothing grid to generate the final 3D model. The method of geometric modelling is to generate a clothing model by changing the surface geometry of the 3D model, which is simple and efficient, but focuses on the appearance of the contour effect and gives less consideration to the physical properties of the clothing, which has poor draping and insufficiently realistic folds.

The clothing model was created by outlining the contour boundary lines on the human surface.

2.2.3 Hybrid modelling method

The hybrid modelling method combines the advantages of physical modelling and geometric modelling. Wang and Tang [48] added the calculation of clothing tension during the sewing process of 2D patterns to control the deformation effect of the clothing model under tension, to improve the realism of the clothing model (Figure 9). It takes into account the physical properties of the model while focusing on the realistic effect of the model, which also has a positive significance for the correction of 2D patterns. However, this method is based on fitted silhouette clothing, and the modelling effect for clothing with loose volume or pleats needs to be further verified.

Hybrid method clothing model.

At present, customized clothing is mostly produced by forward design, which has problems such as poor fit, the slow transmission of interactive information, a long design and production cycle, and high prices. The reverse design is often used for online sales and customer fitting in custom stores, which has poor interactivity and weak and untimely data support on the manufacturing end, such as personalized data, automatic correction, matching patterns, etc. It is also a key direction for future research.

In addition, there is an increasing interest in simulating the process of dressing [49] besides modelling single 3D clothing, and the overlapping function of multiple clothing is also worth exploring for research. Hu et al. [50] involved multi-layer animations of clothing taken by a 3D scanner in clothing modelling for the first time. The naked body of the object was scanned with an RGBD camera, and then the subjects wearing each layer of clothing were scanned again. The joint model formulated according to the previous step will be fitted to the newly scanned data. The new clothing was segmented semi-automatic and added as additional layers to the multi-layer clothing model. However, there are limitations to this method, as the segmentation of the clothing needs to be manually adjusted. The ability to scan the human body in any pose and fully automate clothing extraction is the key direction for future research of this technology.

2.3 Virtual interactive display

With the advantages of low cost and high efficiency, virtual apparel display provides a good service for brands, which cannot demonstrate their products offline [51]. Virtual clothing display technology has experienced a static simulation from 2D graphic design and 3D models to a 3D dynamic simulation process based on VR, AR, and other high realism [52]. Based on the digital human body model and clothing model, the main research content of the virtual display part is simulation optimization and display platform establishment. The technical route is shown in Figure 10.

Virtual clothing display technology route.

The application of virtual clothing display systems is commonly found in fashion shows, shopping malls virtual fitting rooms, virtual museums, etc. There are three mature display systems:

Based on the naked-eye 3D technology to display the dynamic effects of human models wearing clothing on a large screen, it cannot provide an immersive visualization experience [52].

Virtual fitting room based on VR technology [53,54], and AR technology [55], Niu established a 3D coordinate transformation model of the feature point and virtual clothing fitting system [4]. The core goal of virtual fitting is to create a sense of realism, which allows real-time viewing of the effect of clothing worn on the body, which is interesting, but is affected by the environment and has a weak sense of immersion.

The Unity 3D platform is used more often among VR platforms. Hong and Ge [56] constructed a VR clothing walkway based on the Unity 3D engine in the context of artificial intelligence (AI). Users rated the sensory evaluation and viewing fluency higher than the experience of traditional online clothing shows. In the future, online virtual clothing display is expected to become the mainstream way to display products in the clothing industry.

The virtual interactive display is an important part of the digital process in the clothing industry. The virtual display of ethnic clothing can assist the development of ethnic enterprises and build a virtual display platform for intelligent customization of ethnic clothing for personalized groups. The profits of ethnic clothing will be greatly increased when the combination of ethnic customized clothing and virtual technology can be done to interact with consumers. This can not only penetrate the precious ethnic culture into the lives of consumers but also drive the industrial economy of minority regions.

Digital simulation and virtual interactive display of ethnic custom clothing can not only provide a material basis for the study of minority cultures but also give virtual ethnic clothing an educational function through virtual interactive technology [57]. The virtual 3D scenes established by VR, and the establishment of a traditional ethnic clothing 3D model (Figure 11), achieve a 360-degree omnidirectional view. We provided technical support for the Huafu Xiaodangjia through the C-end products, for example, users can download the application software from their mobile phones to display 2D graffiti created by children in 3D form, achieving interactive functions between consumer graphic design and 3D display of virtual clothing. The model and virtual Mongolian robe-wearing state in the C-end product of Huafu Xiaodangjia shown in Figure 11 is the result of the research on digital models and 3D clothing, and the AR interactive experience with the user in the research field of virtual clothing display.

Interactive display of the 3D model of ethnic clothing and C-end product of Huafu Xiaodangjia.

Virtual clothing displays have been active in spreading ethnic clothing culture and displaying museum collections [58]. Ethnic clothing is an indispensable treasure of cultural resources for the national culture and creative industry [59]. Liang et al. [60] conducted a reflection on the current situation of the display of ethnic clothing museums and disseminated it to the public through physical displays. With the decay and disappearance of clothing or the death of handicraftsmen, intangible cultural heritage items also became extinct. More scholars have focused on the research of establishing a database of ethnic minority clothing. Qi and Shen [61] constructed a cultural database of Zhuang clothing, Liang et al. [62] studied a meta-database of traditional clothing preserved in Guangxi, and Yang et al. [63] created an improved neural network algorithm called DenseNet-BC to solve the problem of complicated details of ethnic clothing. The above research results have solved the problem of single feature scale, feature richness, and feature richness of the ordinary model extraction to a certain extent. For the research of interactive virtual display of ethnic clothing, Liu [64] put forward the virtual interactive display of ethnic clothing based on VR at an early stage, and Ba and Zhuang [65] believed that digitization is not only a simple collection of data and accumulation of information but also should focus on sorting, categorizing, processing, data systematization, and data reuse of existing physical information of ethnic clothing, and strive to restore the reality. It also provides accurate information for the inheritance and development of ethnic clothing culture, breaks through the limit of traditional culture protection, and gives new development space for national crafts. The virtual interactive display has been applied more in museum collection displays [66], optimizing the realism and accuracy of the virtual display model, and building a perfect application platform is the focus of this research.

3 Conclusion

With the development of human body digitization, modular clothing design, and the software and hardware of the fitting system, the clothing virtual display system is developing toward a more standardized, intelligent, networked, and highly simulated direction. It has fundamentally changed the fixed mode of the ethnic clothing manufacturing industry in designing and making sample clothes, repeated modification, and mass production, which can directly predict the shape and performance of future clothing products and make forward-looking strategies to improve the profitability of enterprises, to achieve a new upgrade of the production model.

In summary, the sales end and manufacturing end of the apparel industry have put forward higher requirements for the 3D human body, number, processing accuracy, modelling efficiency, complexity, and style changes.

Digital human body modelling: Accurate human body data are the basis of clothing customization, and a realistic human body shape model is the key to enhancing customer consumption experience. Human body modelling based on specific software can provide efficient solutions for clothing virtual design. But for the field of intelligent clothing customization, 3D scanning technology can provide more accurate human body data for human modelling than methods based on parameterization and image, providing a reliable foundation for better clothing customization services.

3D clothing modelling: Among the three clothing modelling methods, the material, transparency, gloss, elasticity, drape, and other characteristics of fabrics need to be reproduced by perfect digital technology. For the dynamic simulation of clothing, it is still necessary to strengthen the exploration of reasonable collision detection models, study the relative positional relationship between the human body surface and the clothing surface in the real world in response to external forces and time, and improve the phenomenon of wearing patterns during display is the key for reconstructing 3D clothing models.

Virtual interactive display: Whether equipped with any virtual interaction platform such as VR, AR, Unity 3D, etc., optimizing the realism and accuracy of display models has always been the focus of the virtual display. Design corresponding virtual display system functional modules based on the needs of the user and the manufacturing end. The current development goal of digital personalized customization of clothing is to build an application platform that combines cultural inheritance and industrial needs.

Acknowledgements

The authors would like to thank all the students who voluntarily participated in measuring the body shape of young men in Inner Mongolia for building the body shape database.

-

Funding information: This work was funded by the Inner Mongolia Autonomous Region Natural Science Foundation Project funding and was approved for public release (2023MS06019). This work was also funded by the Key Education Reform Project of Inner Mongolia University of Technology in 2022 (2022108).

-

Author contributions: Hui Shi: Writing – original draft. Jinjing Yu: Writing – review & editing. Ting Duan: Investigation.

-

Conflict of interest: Authors state no conflict of interest.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Li, J., Lu, G. (2014). Modelling 3D garments by examples. Computer-Aided Design, 49, 28–41. 10.1016/j.cad.2013.12.005.Search in Google Scholar

[2] McCartney, J., Hinds, B. K., Seow, B. L., Gong, D. (2000). Dedicated 3D CAD for garment modelling. Journal of Materials Processing Technology, 107(1–3), 31–36. 10.1016/S0924-0136(00)00695-6.Search in Google Scholar

[3] Zhang, D., Liu, Y., Wang, J., Li, J. (2018). An integrated method of 3D garment design. The Journal of The Textile Institute, 109(12), 1595–1605. 10.1080/00405000.2018.1436638.Search in Google Scholar

[4] Niu, M. (2020). Application of intelligent virtual reality technology in Clothing virtual wear and color saturation after COVID-19 epidemic situation. IFS, 39(6), 8943–8951. 10.3233/JIFS-189292.Search in Google Scholar

[5] Xue, X. Y., He, J. Z., Wang, M. (2022). Advances in the application of 3D virtual fitting technology in apparel design and performance evaluation. Modern Textile Technology, 31(2), 12–22. 10.19398/j.att.202207055.Search in Google Scholar

[6] Pishchulin, L., Wuhrer, S., Helten, T., Theobalt, C., Schiele, B. (2017). Building statistical shape spaces for 3D human modeling. Pattern Recognition, 67, 276–286. 10.1016/j.patcog.2017.02.018.Search in Google Scholar

[7] Zhang, S. Y., Fang, N. Y., Qiu, L. M., Liu, Y. S., Wang, Z. L. (2022). A multi-view profile 3D human body reconstruction method for garment personalization. Journal of Computer-Aided Design and Graphics, 34(11), 1753–1762.10.3724/SP.J.1089.2022.19206Search in Google Scholar

[8] Li, Y. Z., Li, X. R., Feng, W. Q., Jiang, L. (2022). Status of research on 3D reconstruction modeling of human body for apparel industry. Woolen Technology, 50(2), 116–123.Search in Google Scholar

[9] Li, Z. H. (2014) 3D body scanning system for apparel design. Journal Textile Research, 35(1), 144–150.Search in Google Scholar

[10] Yu, M., Kim, D. E. (2020). Body shape classification of Korean middle-aged women using 3D anthropometry. Fashion and Textile, 7(1), 35. 10.1186/s40691-020-00223-8.Search in Google Scholar

[11] Wen, C. H., Shih, Y. C. (2021). Designing new sizing bulletproof vests for Taiwanese soldiers. International Journal of Clothing Science and Technology, 33(3), 321–335. 10.1108/IJCST-09-2019-0150.Search in Google Scholar

[12] Kolose, S., Stewart, T., Hume, P., Tomkinson, G. R. (2021). Cluster size prediction for military clothing using 3D body scan data. Applied Ergonomics, 96, 103487. 10.1016/j.apergo.2021.103487.Search in Google Scholar PubMed

[13] Yoon, M. K., Nam, Y. J., Kim, W. (2016). Classifying male upper lateral somatotypes using space vectors. International Journal of Clothing Science and Technology, 28(1), 115–129. 10.1108/IJCST-03-2015-0043.Search in Google Scholar

[14] Kim, N., Do, W. (2019). Developing elderly men’s footwear sizing system based on their foot shapes. Fashion and Textile, 6(1), 28. 10.1186/s40691-019-0184-2.Search in Google Scholar

[15] Saeidi, E., Shin, E. (2020). Body shapes and fit analysis of ASTM size standards for overweight and obese men in the United States. Pivoting for the Pandemic, presented at the Pivoting for the Pandemic, Iowa State University Digital Press. 10.31274/itaa.12181.Search in Google Scholar

[16] Park, S., Choi, K. (2021). Analysis of segmented elderly women’s lower bodies using 3D-LOOK scan data and virtual representation. Textile Research Journal, 91(23–24), 2738–2756. 10.1177/00405175211019487.Search in Google Scholar

[17] Han, H., Kim, T., Jeon, E. (2020). 3D standard avatar creation of Korean women in their twenties and thirties by body types for apparel industry. International Journal of Industrial Ergonomics, 82, 103081. 10.1016/j.ergon.2020.103081.Search in Google Scholar

[18] Sun, J., Cai, Q., Li, T., Du, L., Zou, F. (2019). Body shape classification and block optimization based on space vector length. International Journal of Clothing Science and Technology, 31(1), 115–129. 10.1108/IJCST-07-2018-0089.Search in Google Scholar

[19] Cheng, P., Zeng, X., Bruniaux, P., Wang, J., Chen, D. (2022). Research on intelligent clustering of male upper body. Textile Research Journal, 92(13–14), 2174–2193. 10.1177/00405175211000125.Search in Google Scholar

[20] Lee, K. S., Song, H. K., Kim, S. (2020). Categorization of lower body shapes of abdominal obese men using a script-based 3D body measurement software. Fashion and Textile, 7(1), 3. 10.1186/s40691-019-0199-8.Search in Google Scholar

[21] Liu, K. X., Wang, J. P., Zhu, C., Kamalha, E., Hong, Y., Zhang, J. J., et al. (2017). A mixed human body modeling method based on 3D body scanning for clothing industry. International Journal of Clothing Science and Technology, 29(5), 673–685. 10.1108/IJCST-10-2016-0115.Search in Google Scholar

[22] Cheng, Z. Q., Chen, Y., Martin, R. R., Wu, T., Song, Z. (2018). Parametric modeling of 3D human body shape – A survey. Computers & Graphics, 71, 88–100. 10.1016/j.cag.2017.11.008.Search in Google Scholar

[23] Anguelov, D., Srinivasan, P., Koller, D., Thrun, S., Davis, J., Rodgers, J. (2005). SCAPE: Shape completion and animation of people. ACM Transactions on Graphics, 24(3), 408–416. 10.1145/1073204.1073207.Search in Google Scholar

[24] Zhou, S., Fu, H., Liu, L., Cohen-Or, D., Han, X. (2010). Parametric reshaping of human bodies in images. ACM Transactions on Graphics, 29(4), 1–10. 10.1145/1778765.1778863.Search in Google Scholar

[25] Wang, C. C. L. (2005). Parameterization and parametric design of mannequins. Computer-Aided Design, 37(1), 83–98. 10.1016/j.cad.2004.05.001.Search in Google Scholar

[26] Gu, B., Ahmed, M. K., Zhong, Z., Jin, J. (2020). 3D female upper body modelling based on 2D images. International Journal of Clothing Science and Technology, 32(4), 471–482. 10.1108/IJCST-03-2019-0042.Search in Google Scholar

[27] Cai, X., Gu, B., He, H. (2021). Classification analysis of young female students’ waist–abdomen–hip based on body photos. Textile Research Journal, 91(11–12), 1409–1418. 10.1177/0040517520979742.Search in Google Scholar

[28] Li, Z., Oskarsson, M., Heyden, A. (2022). Detailed 3D human body reconstruction from multi-view images combining voxel super-resolution and learned implicit representation. Applied Intelligence, 52(6), 6739–6759. 10.1007/s10489-021-02783-8.Search in Google Scholar

[29] Zhang, S., Xiao, N. (2021). Detailed 3D human body reconstruction from a single image based on mesh deformation. IEEE Access, 9, 8595–8603. 10.1109/ACCESS.2021.3049548.Search in Google Scholar

[30] Li, K., Wen, H., Feng, Q., Zhang, Y., Li, X., Huang, J., et al. (2021). Image-guided human reconstruction via multi-scale graph transformation networks. IEEE Transactions on Image Processing, 30, 5239–5251. 10.1109/TIP.2021.3080177.Search in Google Scholar PubMed

[31] Lu, Y., Yu, H., Ni, W., Song, L. (2022). 3D real-time human reconstruction with a single RGBD camera. Applied Intelligence, 2022, 1–11. 10.1007/s10489-022-03969-4.Search in Google Scholar PubMed PubMed Central

[32] Sreenivasa, M., Harant, M. (2018). ModelFactory: A Matlab/Octave based toolbox to create human body models. 10.5281/zenodo.1137656.Search in Google Scholar

[33] Michalski, R., Grobelny, J. (2014). Designing emergency-medical-service helicopter interiors using virtual manikins. IEEE Computer Graphics and Applications, 34(2), 16–23. 10.1109/MCG.2014.26.Search in Google Scholar PubMed

[34] Wang, X., Qian, X., Wang, L. (2020). Research on the reconstruction and parameterization of virtual costume draping mannequin in OpenGL environment. Journal of Physics: Conference Series, 1621(1), 012023. 10.1088/1742-6596/1621/1/012023.Search in Google Scholar

[35] Aoyagi, T., Kim, M., Takada, J., Hamaguchi, K., Kohno, R. (2011). Numerical simulations for wearable BAN propagation channel during various human movements. IEICE Transactions on Communications, E94.B(9), 2496–2500. 10.1587/transcom.E94.B.2496.Search in Google Scholar

[36] Cui, M., Chen, S. Y., Yin, W., Li, W. H. (2020). Garment design and development based on virtual fitting technology. Wool Textile Journal, 48(6), 58–61.Search in Google Scholar

[37] Jiang, Y., Wang, R. (2010). Design and implementation of virtual garment sewing system. Journal of Beijing Institute of Clothing Technology (Natural Science Edition), 30(1), 1–7.Search in Google Scholar

[38] Leong, I. F., Kuo, J. K., Fang, J. J. (2011). A clothing simulation system for realistic clothing and mannequin. Computer-Aided Design and Applications, 8(3), 335–344. 10.3722/cadaps.2011.335-344.Search in Google Scholar

[39] Umetani, N., Kaufman, D. M., Igarashi, T., Grinspun, E. (2011). Sensitive couture for interactive garment modeling and editing. ACM Transactions on Graphics, 30(4), 1–12. 10.1145/1964921.1964985.Search in Google Scholar

[40] Jin, Y. X., Chen, Z. X., Lu, Y., Yang, J., Liu, Y. B., Shi, Z. R. (2022). Research on multi-precision fabric modeling method based on machine learning. Scientific Programming, 2022, 1–13. 10.1155/2022/4339095.Search in Google Scholar

[41] Zhang, C. X., Chen, X. W., Wu, H. Y., Zhou, B. (2018). Modeling garment seam from a single image. Journal of Computer Science and Technology, 33(3), 463–474. 10.1007/s11390-018-1831-6.Search in Google Scholar

[42] Chen, X. P., Wang, G. R., Zhu, D. Z., Liang, X. D., Philip, H. S. T., Liang, L. (2023). Structure-preserving 3D garment modeling with neural sewing machines. arXiv, Nov. 12, 2022. Accessed: Jan. 13, 2023. [Online]. http://arxiv.org/abs/2211.06701.Search in Google Scholar

[43] Kim, T. Y., Vendrovsky, E. (2008). DrivenShape: A data-driven approach for shape deformation. In ACM SIGGRAPH 2008 talks (Aug. 2008, p. 1). ACM, Los Angeles California. 10.1145/1401032.1401121.Search in Google Scholar

[44] Zakharkin, I., Mazur, K., Grigorev, A., Lempitsky, V. (2021). Point-based modeling of human clothing. In 2021 IEEE/CVF International Conference on Computer Vision (ICCV) (Oct. 2021, pp. 14698–14707). IEEE, Montreal, QC, Canada. 10.1109/ICCV48922.2021.01445.Search in Google Scholar

[45] Geng, Y. L., Wang, J., Lu, G. D., Liu, Z., Chen, G. (2011). Sketch based garment modeling on an arbitrary view of a 3D virtual human model. Journal of Zhejiang University of Computer and Electronic Science, 12(3), 195–203. 10.1631/jzus.C1000049.Search in Google Scholar

[46] Holte, M. B. (2017). 3D scanning of clothing using a RGB-D sensor with application in a virtual dressing room. In Advances in applied digital human modeling and simulation, vol. 481, V. G. Duffy, Ed., In Advances in intelligent systems and computing (vol. 481, pp. 143–153). Springer International Publishing, Cham, 2017. 10.1007/978-3-319-41627-4_14.Search in Google Scholar

[47] Xu, Y., Yang, S., Sun, W., Tan, L., Li, K., Zhou, H. (2023). 3D virtual garment modeling from RGB images. arXiv, Jul. 31, 2019. Accessed: Jan. 13, 2023. [Online]. http://arxiv.org/abs/1908.00114.10.1109/ISMAR.2019.00-28Search in Google Scholar

[48] Wang, C. C. L., Tang, K. (2010). Pattern computation for compression garment by a physical/geometric approach. Computer-Aided Design, 42(2), 78–86. 10.1016/j.cad.2009.02.018.Search in Google Scholar

[49] Clegg, A., Tan, J., Turk, G., Liu, C. K. (2015). Animating human dressing. ACM Transactions on Graphics, 34(4), 1–9. 10.1145/2766986.Search in Google Scholar

[50] Hu, P., Komura, T., Holden, D., Zhong, Y. (2017). Scanning and animating characters dressed in multiple-layer garments. Visual Computer, 33(6–8), 961–969. 10.1007/s00371-017-1388-3.Search in Google Scholar

[51] Ghodhbani, H., Neji, M., Razzak, I., Alimi, A. M. (2022). You can try without visiting: A comprehensive survey on virtually try-on outfits. Multimedia Tools and Applications, 81(14), 19967–19998. 10.1007/s11042-022-12802-6.Search in Google Scholar PubMed PubMed Central

[52] Lin, J. C., Chen, M., Shi, Y. B., Lei, J., Guo, S. H., Gao, X., et al. (2021). A personalized virtual clothing display for haute couture. Journal of Zhejiang University (Science Edition), 48(4), 418–426 + 434.Search in Google Scholar

[53] Gan, W., Lin, L. (2022). Application of isomorphic block decoration based on VR and Internet of Things in fashion design. Mathematical Problems in Engineering, 2022, 1–10. 10.1155/2022/6115513.Search in Google Scholar

[54] Lai, H., Lee, S. (2020). The application of artificial intelligence and VR technology in clothing store display design. IEEE Access, 1. 10.1109/ACCESS.2020.3020551.Search in Google Scholar

[55] Tao, W. (2022). Application of garment customization system based on AR somatosensory interactive recognition imaging technology. Advances in Multimedia, 2022(1), 7174889. 10.1155/2022/7174889.Search in Google Scholar

[56] Hong, Y., Ge, Y. (2022). Design and analysis of clothing catwalks taking into account unity’s immersive virtual reality in an artificial intelligence environment. Computational Intelligence and Neuroscience, 2022, 1–12. 10.1155/2022/2861767.Search in Google Scholar PubMed PubMed Central

[57] Shi, H., Yu, F., Wei, C. L., Wang, L. P., Liu, J., Xue, Y. D. (2020). Exploring the teaching mode of Internet + Mongolian costume culture. Textile and Clothing Education, 35(4), 320–324 + 360.Search in Google Scholar

[58] Zou, Y. (2022). Computational technologies on modeling of museum interactive virtual display based on user experience. Security and Communication Networks, 2022, 1–8. 10.1155/2022/5659269.Search in Google Scholar

[59] Zhao, H. R., Zhao, J. F., Zhou, S. J. (2022). Research on digitization and dissemination of costume cultural heritage. Cotton Textile Technology, 50(11), 93.Search in Google Scholar

[60] Liang, H. E., Zhang, S. Y., Zhao, Y. (2014). A preliminary study on the art of digital display in ethnic costume museums: An investigation based on ethnic costume museums in Jiangsu, Zhejiang and Shanghai. Southeast Culture, (6), 100–106.Search in Google Scholar

[61] Qi, Y. L., Shen, Q. M. (2014). Exploring the digital protection and development of ethnic costume resources: An example of building a Zhuang costume culture database. Academic Forum, 37(10), 123–127.Search in Google Scholar

[62] Liang, J., Wang, Q., Zhao, Y. (2021). Construction of metadata for digitizing traditional costumes of Guangxi’s ethnic groups. Journal of Guangxi University for Nationalities (Philosophy and Social Science Edition), 43(5), 112–116.Search in Google Scholar

[63] Yang, B., Xu, D., Zhang, H. Y., Luo, H. N. (2021). Recognition of ethnic minority costumes based on improved DenseNet-BC. Journal of Zhejiang University (Science Edition), 48(6), 676–683.Search in Google Scholar

[64] Liu, J. L. (2015). Research on interactive virtual display of ethnic costumes. Shanghai Textile Science and Technology, 43(8), 27–29.Search in Google Scholar

[65] Ba, Y., Zhuang, L. F. (2015). Digital study of Chinese ethnic style virtual costumes. People’s Forum, 2015(33), 62–63.Search in Google Scholar

[66] Li, M. Q., Wang, G. H., Fu, X., Ren, L. L. (2022). Interactive design of museum display space based on virtual and reality technology. Wireless Communications and Mobile Computing, 2022, 1–14.10.1155/2022/8662037Search in Google Scholar

© 2024 by the authors, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry

Articles in the same Issue

- Characterization of viscoelastic properties of yarn materials: Dynamic mechanical analysis in the transversal direction

- Analysis of omni-channel implementations that are preferred by consumers in clothing sector

- Structural modeling and analysis of three-dimensional cross-linked braided preforms

- An experimental study of mechanical properties and comfortability of knitted imitation woven shirt fabrics

- Technology integration to promote circular economy transformation of the garment industry: a systematic literature review

- Research on T-shirt-style design based on Kansei image using back-propagation neural networks

- Research on She nationality clothing recognition based on color feature fusion with PSO-SVM

- Accuracy prediction of wearable flexible smart gloves

- Preparation and performance of stainless steel fiber/Lyocell fiber-blended weft-knitted fabric

- Development of an emotional response model for hospital gown design using structural equation modeling

- Preparation and properties of stainless steel filament/pure cotton woven fabric

- Facemask comfort enhancement with graphene oxide from recovered carbon waste tyres

- Use of enzymatic processes in the tanning of leather materials

- Optical-related properties and characterization of some textile fibers using near-infrared spectroscopy

- Network modeling of aesthetic effect for Chinese Yue Opera costume simulation images

- Predicting consumers’ garment fit satisfactions by using machine learning

- Non-destructive identification of wool and cashmere fibers based on improved LDA using NIR spectroscopy

- Study on the relationship between structure and moisturizing performance of seamless knitted fabrics of protein fibers for autumn and winter

- Antibacterial and yellowing performances of sports underwear fabric with polyamide/silver ion polyurethane filaments

- Numerical and experimental analysis of ballistic performance in hybrid soft armours composed of para-aramid triaxial and biaxial woven fabrics

- Phonetic smart clothing design based on gender awareness education for preschoolers

- Determination of anthropometric measurements and their application in the development of clothing sizing systems for women in the regions of the Republic of Croatia

- Research on optimal design of pleated cheongsam based on Kano–HOQ–Pugh model

- Numerical investigation of weaving machine heald shaft new design using composite material to improve its performance

- Corrigendum to “Use of enzymatic processes in the tanning of leather materials”

- Shaping of thermal protective properties of basalt fabric-based composites by direct surface modification using magnetron sputtering technique

- Numerical modeling of the heat flow component of the composite developed on the basis of basalt fabric

- Weft insertion guideway design based on high-temperature superconducting levitation

- Ultrasonic-assisted alkali hydrolysis of polyethylene terephthalate fabric and its effect on the microstructure and dyeing properties of fibers

- Comparative study on physical properties of bio-based PA56 fibers and wearability of their fabrics

- Investigation of the bias tape roll change time efficiency in garment factories

- Analysis of foot 3D scans of boys from Polish population

- Optimization of garment sewing operation standard minute value prediction using an IPSO-BP neural network

- Influence of repeated switching of current through contacts made of electroconductive fabrics on their resistance

- Numerical calculation of air permeability of warp-knitted jacquard spacer shoe-upper materials based on CFD

- Compact Spinning with Different Fibre Types: An Experimental Investigation on Yarn Properties in the Condensing Zone with 3D-Printed Guiding Device

- Modeling of virtual clothing and its contact with the human body

- Advances in personalized modelling and virtual display of ethnic clothing for intelligent customization

- Investigation of weave influence on flame retardancy of jute fabrics

- Balloonless spinning spindle head shape optimisation

- Research on 3D simulation design and dynamic virtual display of clothing flexible body

- Turkish textile and clothing SMEs: Importance of organizational learning, digitalization, and internationalization

- Corrigendum To: “Washing characterization of compression socks”

- Study on the promotion multiple of blood flow velocity on human epidermal microcirculation of volcanic rock polymer fiber seamless knitted fabric

- Bending properties and numerical analysis of nonorthogonal woven composites

- Bringing the queen mother of the west to life: Digital reconstruction and analysis of Taoist Celestial Beings Worshiping mural’s apparel

- Modeling process for full forming sports underwear

- Retraction of: Ionic crosslinking of cotton

- An observational study of female body shape characteristics in multiracial Malaysia

- Study on theoretical model and actual deformation of weft-knitted transfer loop based on particle constraint

- Design and 3D simulation of weft-knitted jacquard plush fabrics

- An overview of technological challenges in implementing the digital product passport in the textile and clothing industry

- Understanding and addressing the water footprint in the textile sector: A review

- Determinants of location changes in the clothing industry in Poland

- Influence of cam profile errors in a modulator on the dynamic response of the heald frame

- Quantitative analysis of wool and cashmere fiber mixtures using NIR spectroscopy

- 3D simulation of double-needle bar warp-knitted clustered pile fabrics on DFS

- Finite element analysis of heat transfer behavior in glass fiber/metal composite materials under constant heat load

- Price estimation and visual evaluation of actual white fabrics used for dress shirts and their photographic images

- Effect of gluing garment materials with adhesive inserts on their multidirectional drape and bending rigidity

- Optimization analysis of carrier-track collision in braiding process

- Numerical and experimental analysis of the ballistic performance of soft bulletproof vests for women

- The antimicrobial potential of plant-based natural dyes for textile dyeing: A systematic review using prisma

- Influence of sewing parameters on the skin–fabric friction

- Validation by experimental study the relationship between fabric tensile strength and weave structures

- Optimization of fabric’s tensile strength and bagging deformation using surface response and finite element in stenter machine

- Analysis of lean manufacturing waste in the process flow of ready-to-wear garment production in Nigeria

- An optimization study on the sol–gel process to obtain multifunctional denim fabrics

- Drape test of fully formed knitted flared skirts based on 3D-printed human body posture

- Supplier selection models using fuzzy hybrid methods in the clothing textile industry